Abstract

The cement industry accounts for 7% of global CO2 emissions, 90% of which is related to the clinkerization process, 50% of which corresponds to calcination and 40% to the burning of fossil fuels. Since the calcination process is inherent to the manufacturing of the product, the use of fuels with a lower environmental impact is an excellent alternative. This process of replacing traditional fuel with alternative fuels is known as co-processing. The objective of this article is to present the main alternative fuels used by the cement industry in Brazil and highlight their potential gains compared to fossil fuels. For this purpose, considering an energy replacement of 15% of petroleum coke by alternative fuel based on the lower heating value of the materials and carbon emission factor, the potential for reducing CO2 emissions was calculated. The analysis of the potential for reducing fuel costs was carried out based on market prices and the quantities required for each fuel. The estimates showed reductions of 13.4% in CO2 emissions/t of substituted coke and cost reductions of R$ 6.34 million/year.

Keywords

Portland cement; Greenhouse gases; Co-processing; Reduced fuel costs

A review of the co-processing process in the Brazilian cement industry

A review of the co-processing process in the Brazilian cement industry Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Fonte: adaptado de

Fonte: adaptado de  Fonte: adaptado de Mantegazza (2004).

Fonte: adaptado de Mantegazza (2004).

Fonte:

Fonte:  Fonte: adaptado de Rahman et al. (2017).

Fonte: adaptado de Rahman et al. (2017).

Fonte: adaptado de FLSmidth (2023).

Fonte: adaptado de FLSmidth (2023).

Fonte: adaptado de

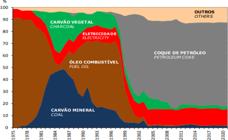

Fonte: adaptado de  Fonte: adaptado de “Panorama do Coprocessamento - Brasil 2022 (Ano base 2021) –

Fonte: adaptado de “Panorama do Coprocessamento - Brasil 2022 (Ano base 2021) –