Abstract

The potential benefits of engineer-to-order (ETO) prefabricated building systems include reductions in project cost and duration, and improvements in product quality. However, the scope of production planning and control systems in that context must be different from traditional projects, since it is necessary to coordinate different types of flows (design, manufacturing, logistics operations and site assembly). In this context, it is necessary to stabilise those flows and consequently reduce work in progress, which is strongly related to the effort of reducing production batch size. The aim of this research work is to propose a set of guidelines for the definition of assembly batches for ETO prefabricated concrete system, with the support of 4D BIM, based on concepts and principles of the lean production philosophy. Design Science Research was the methodological approach adopted in this investigation, which was based on an empirical study carried out in an airport expansion project. The main contributions of this study are a set of decision categories for the definition of assembly batches, and the development of tools for supporting decision-making in this context.

Keywords:

Engineer-to-order; Prefabricated concrete systems; Lean Production; 4D BIM; Line of balance

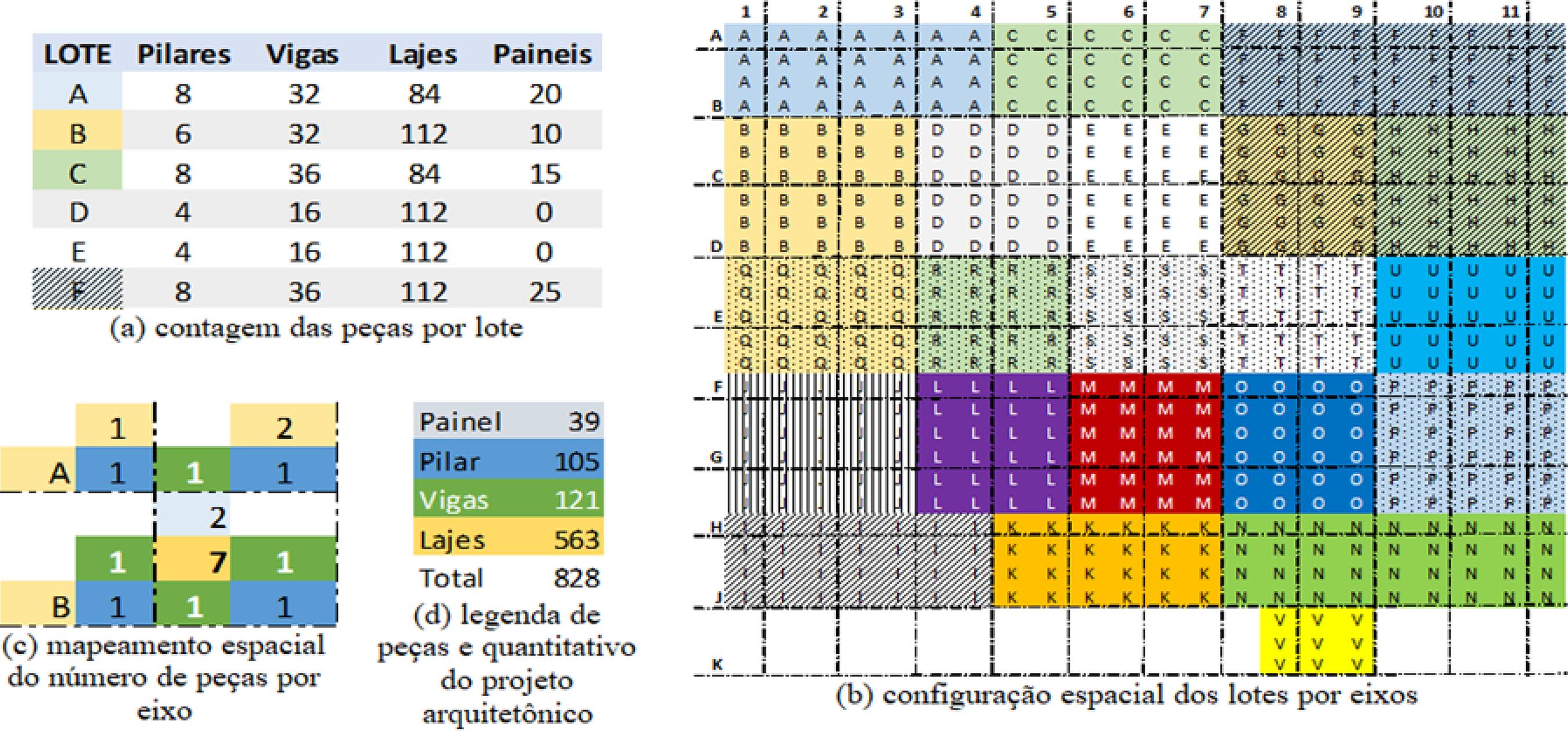

Fonte: empresa construtora.

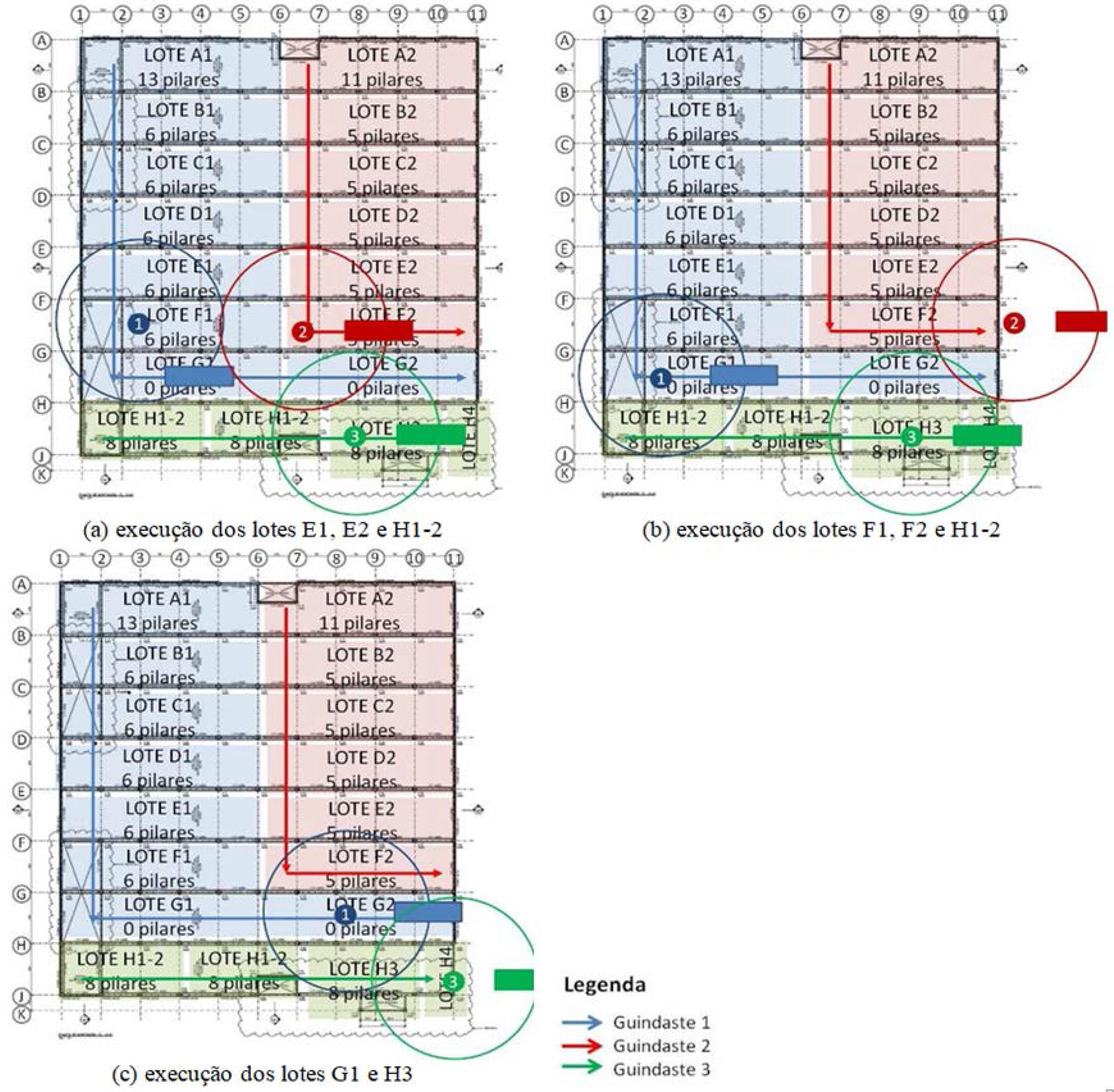

Fonte: empresa construtora.