Abstract

Sugarcane bagasse ash is a by-product produced by the energy cogeneration from biomass burning. Different processes can be applied to this material to adapt its chemical and physical characteristics to its use as pozzolan. This work aims to evaluate the effectiveness of the densimetric fractionation process in production of sugarcane bagasse ash with high pozzolanicity. Initially, a quartz-rich ash was collected in an industrial boiler and subjected to densimetric fractionation to remove the quartz particles through decantation. Then, the potentially pozzolanic ash portion was subjected to ultrafine grinding. The results showed high amorphous content (94.8%) in the ash after fractionation. Electrical conductivity and performance index tests confirmed the adequate pozzolanicity of the processed ashes. In addition, cement-based pastes with 20% cement replacement by bagasse ash (in mass) showed a reduction in the heat of hydration. Thus, the densimetric fractionation was efficient in producing a material with high reactivity compared to the original ash due to the reduction of contaminants and, consequently, the increase in the amorphous silica concentration.

Keywords:

Sugarcane bagasse ash; Pozzolan; Densimetric fractionation; Ultrafine grinding; Pozzolanic activity

Resumo

A cinza do bagaço da cana-de-açúcar é um resíduo produzido pela cogeração de energia a partir da queima de biomassa. Diferentes processos podem ser aplicados a esse material para adequar suas caracteríscitcas químicas e físicas ao emprego como pozolana. Este trabalho visa avaliar a efetividade do processo de fracionamento densimétrico na produção de uma cinza do bagaço da cana-de-açúcar de elevada pozolanicidade. Inicialmente, uma cinza rica em quartzo foi coletada em caldeira industrial e submetida ao fracionamento densimétrico para remoção das partículas de quartzo por meio de decantação. Em seguida, a parcela de cinza potencialmente pozolânica foi submetida à moagem ultrafina. Os resultados mostraram elevado teor de amorfos (94,8%) na cinza após fracionamento. Ensaios de condutividade elétrica e índice de desempenho confirmaram a adequada pozolanicidade das cinzas processadas. Além disso, pastas com 20% de substituição por cinzas do bagaço (em massa) mostraram redução do calor de hidratação. Portanto, o fracionamento densimétrico foi eficiente na produção de um material de elevada reatividade em comparação com a cinza original devido à redução de contaminantes e, consequentemente, pelo aumento da concentração de sílica amorfa.

Palavras-chave:

Cinza do bagaço da cana-de-açúcar; Pozolana; Fracionamento densimétrico; Moagem ultrafina; Atividade pozolânica

Introduction

Brazil is the world leader in sugarcane production, annually generating about 600 million tons of the product (COMPANHIA…, 2021COMPANHIA NACIONAL DE ABASTECIMENTO. Acompanhamento da safra brasileira de cana-de-açúcar. Disponível em: http://www.conab.gov.br. Acesso em: 15 maio 2021.

http://www.conab.gov.br...

). The importance of the sugarcane industry is due to the legacy left from the colonial era, when sugar was one of the main national products, followed by the investment made by the Federal Government by implementing programs to encourage the use of fuel alcohol from the 1970s (DE ANDRADE; DE CARVALHO; DE SOUZA, 2009DE ANDRADE, E. T.; DE CARVALHO, S. R. G.; DE SOUZA, L. F. Programa do Proálcool e o etanol no Brasil. Engevista, v. 11, p. 127-136, 2009.). On account of the large amount of sugarcane produced annually, residual bagasse is the main biomass used for bioelectricity generation, accounting for about 80% of the total clean energy generated in Brazil (UNIÃO…, 2021UNIÃO DA INDÚSTRIA DE CANA-DE-AÇÚCAR. Bioeletricidade em números. Disponível em: http://www.unica.com.br. Acesso em: 15 maio 2021.

http://www.unica.com.br...

). Burning bagasse is very positive from an environmental point of view. However, this procedure produces ash, which is commonly disposed of improperly.

Over the last decades, research has been developed on the use of sugarcane bagasse ash as a supplementary cementitious material aiming to reduce the clinker factor in cement production (GANESAN; RAJAGOPAL; THANGAVEL, 2007GANESAN, K.; RAJAGOPAL, K.; THANGAVEL, K. Evaluation of bagasse ash as cementitious material. Cement and Concrete Composites , v. 29, n. 6, p. 515-524, 2007.; CORDEIRO; TOLEDO FILHO; FAIRBAIRN, 2008CORDEIRO, G. C.; TOLEDO FILHO, R. D.; FAIRBAIRN, E. M. R. Use of ultra-fine sugar cane bagasse ash as mineral admixture for concrete. ACI Materials Journal, v. 105, n. 5, p. 487-493, 2008.; MINNU; BAHURUDEEN; ATHIRA, 2021MINNU, S. N.; BAHURUDEEN, A.; ATHIRA, G. Comparison of sugarcane bagasse ash with fly ash and slag: An approach towards industrial acceptance of sugar industry waste in cleaner production of cement. Journal of Cleaner Production, v. 285, 124836, 2021.). Thus, studies indicated improvements in mechanical (GANESAN; RAJAGOPAL; THANGAVEL, 2007GANESAN, K.; RAJAGOPAL, K.; THANGAVEL, K. Evaluation of bagasse ash as cementitious material. Cement and Concrete Composites , v. 29, n. 6, p. 515-524, 2007.; CORDEIRO; TOLEDO FILHO; FAIRBAIRN, 2008CORDEIRO, G. C.; TOLEDO FILHO, R. D.; FAIRBAIRN, E. M. R. Use of ultra-fine sugar cane bagasse ash as mineral admixture for concrete. ACI Materials Journal, v. 105, n. 5, p. 487-493, 2008.; CORDEIRO et al., 2018CORDEIRO, G. C. et al. Long-term compressive behavior of concretes with sugarcane bagasse ash as a supplementary cementitious material. Journal of Testing and Evaluation, v. 46, n. 2, p. 564-573, 2018.), rheological (CORDEIRO; TOLEDO FILHO; FAIRBAIRN, 2008CORDEIRO, G. C.; TOLEDO FILHO, R. D.; FAIRBAIRN, E. M. R. Use of ultra-fine sugar cane bagasse ash as mineral admixture for concrete. ACI Materials Journal, v. 105, n. 5, p. 487-493, 2008.) and durability (CORDEIRO; TOLEDO FILHO; FAIRBAIRN, 2008CORDEIRO, G. C.; TOLEDO FILHO, R. D.; FAIRBAIRN, E. M. R. Use of ultra-fine sugar cane bagasse ash as mineral admixture for concrete. ACI Materials Journal, v. 105, n. 5, p. 487-493, 2008.; CHUSILP; JATURAPITAKKUL; KIATTIKOMOL, 2009CHUSILP, N.; JATURAPITAKKUL, C.; KIATTIKOMOL, K. Utilization of bagasse ash as a pozzolanic material in concrete. Construction and Building Materials , v. 23, n. 11, p. 3352-3358, 2009.) properties of concretes due to the pozzolanic activity and the filler effect of ash (CORDEIRO; KURTIS, 2017CORDEIRO, G. C.; KURTIS, K, E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cement and Concrete Research, v. 97, p. 41-49, 2017.). In addition, the use of ash as a cement replacement combines two important environmental benefits, which are a correct destination for the siliceous ash and the reduction in greenhouse gas emissions (FAIRBAIRN et al., 2012FAIRBAIRN, E. M. R. et al. Evaluation of partial clinker replacement by sugar cane bagasse ash: CO2 emission reductions and potential for carbon credits. Ibracon Structures and Materials Journal, v. 5, n. 2, p. 229-251, 2012.) generated during the production of Portland cement.

Despite the benefits provided by ash and its wide availability in the world, estimated at 12.6 million tons in 2018 (ANDRADE NETO et al. 2021ANDRADE NETO, J. D. S. et al. Effects of adding sugarcane bagasse ash on the properties and durability of concrete. Construction and Building Materials, v. 266, p. 120959, 2021.), some factors need to be verified for its large-scale use as supplementary cementitious material. As bagasse burning occurs in an uncontrolled manner in boilers, the ash may present varied chemical composition and particle size (BARBOSA; CORDEIRO, 2021BARBOSA, F. L.; CORDEIRO, G. C. Partial replacement by different sugar cane bagasse ashes: hydration-related, compressive strength and autogenous shrinkage. Construction and Building Materials , v. 272, p. 121625, 2021.). In addition, the presence of contaminants, usually from soil or fertilisers, is recurrent, and quartz is the most common for this type of material (CORDEIRO; TAVARES; TOLEDO FILHO, 2016CORDEIRO, G. C.; TAVARES, L. M.; TOLEDO FILHO, R. D. Improved pozzolanic activity of sugar cane bagasse ash by selective grinding and classification. Cement and Concrete Research , v. 89, p. 269-275, 2016.). Therefore, procedures such as grinding, controlled burning and acid leaching have been used to increase the uniformity and concentration of amorphous silica in ash (BAHURUDEEN; SANTHANAM, 2015BAHURUDEEN, A.; SANTHANAM, M. Influence of different processing methods on the pozzolanic performance of sugarcane bagasse ash. Cement and Concrete Composites, v. 56, p. 32-45, 2015.; CORDEIRO et al., 2020CORDEIRO, G. C. et al. Production of agroindustrial ashes with pozzolanic activity via acid leaching, conjugated burning and ultrafine grinding. Ambiente Construído, Porto Alegre, v. 20, n. 4, p. 189-203, out./dez. 2020.).

Although these procedures improve the ash pozzolanic properties, they are still insufficient to significantly reduce the quartz content of the sample. From this perspective, densimetric fractionation aims to separate the amorphous fraction and crystalline phase of the ash through the difference in density between them (ANDREÃO et al., 2019ANDREÃO, P. V. et al. Sustainable use of sugarcane bagasse ash in cement-based materials. Green Materials, v. 7, p. 61-70, 2019.). Besides, ultrafine grinding can be mentioned for its consolidation as a beneficiation method (CHUSILP; JATURAPITAKKUL; KIATTIKOMOL, 2009CHUSILP, N.; JATURAPITAKKUL, C.; KIATTIKOMOL, K. Utilization of bagasse ash as a pozzolanic material in concrete. Construction and Building Materials , v. 23, n. 11, p. 3352-3358, 2009.; CORDEIRO; TAVARES; TOLEDO FILHO, 2016CORDEIRO, G. C.; TAVARES, L. M.; TOLEDO FILHO, R. D. Improved pozzolanic activity of sugar cane bagasse ash by selective grinding and classification. Cement and Concrete Research , v. 89, p. 269-275, 2016.; YADAV et al., 2020YADAV, A. L. et al. An overview of the influences of mechanical and chemical processing on sugarcane bagasse ash characterisation as a supplementary cementitious material. Journal of Cleaner Production , v. 245, p. 118854, 2020.). Particle size reduction ensures enhancement of the filler effect and an increase of the ash specific surface area, which are directly associated with improvements in mechanical properties and durability of cementitious systems (CORDEIRO; KURTIS, 2017CORDEIRO, G. C.; KURTIS, K, E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cement and Concrete Research, v. 97, p. 41-49, 2017.). In this respect, the present work aims to assess the influence of densimetric fractionation and ultrafine grinding on the pozzolanic activity of sugarcane bagasse ash. The ash used in the study was selected due to the predominant presence of silica in its chemical composition.

Methodology

The sugarcane bagasse ash was collected from an industrial boiler of a sugar mill located in Campos do Goytacazes, RJ. The original ash (in natura) was submitted to a densimetric fractionation process to separate the potentially pozzolanic ash fraction from the quartz, through the density difference. This method was adapted from the process initially proposed by Andreão et al. (2019)ANDREÃO, P. V. et al. Sustainable use of sugarcane bagasse ash in cement-based materials. Green Materials, v. 7, p. 61-70, 2019.. The first fractionation step consisted of immersing 2 L of ash in 15 L of water, followed by manual stirring of the dispersion for 1 min. After 3 min of standing, 10 L of the dispersion were removed and placed to stand for 72 h in order to promote the decantation of the solid portion. Afterwards, the excess water volume was removed by siphoning and the decanted ash was dried in an oven at 100 °C for 24 h. The dispersed ash sample generated by densimetric fractionation was called SCBA-D and the yield of the process was about 8% of the mass. The residual quartz-rich material from the fractionation, equivalent to 72% by mass of the original ash, was washed, dried, and stored to study its use as fine aggregate.

Next, the original ash and a portion of the dispersed ash were comminuted in an attritor mill (Union Process) for 2 h and 1 h, respectively. Grinding times were adjusted to obtain similar particle size curves, with a characteristic size D 50 around 10 µm (BARBOSA; CORDEIRO, 2021BARBOSA, F. L.; CORDEIRO, G. C. Partial replacement by different sugar cane bagasse ashes: hydration-related, compressive strength and autogenous shrinkage. Construction and Building Materials , v. 272, p. 121625, 2021.). After grinding, the original and dispersed ground ashes were called SCBA-GO and SCBA-GD, respectively.

The oxide composition of the ashes was obtained by semi-quantitative analysis in an X-ray fluorescence spectrometer (Shimadzu EDX-720). Loss on ignition and density were obtained according to NBR NM 18 (ABNT, 2012aASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR NM 18: Portland cement: chemical analysis: determination of loss on ignition. Rio de Janeiro, 2012a.) and NBR 16605 (ABNT, 2017ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 16605:Portland cement and other powdered material: determination of the specific gravity. Rio de Janeiro, 2017.), respectively. The particle size distribution of the samples was determined by laser granulometry (Malvern Mastersizer 2000). The nitrogen adsorption technique at 77 K was used to obtain the BET specific surface area values (BRUNAUER; EMMETT; TELLER, 1938BRUNAUER, S.; EMMETT, P. H.; TELLER, E. Adsorption of gases in multimolecular layers. Journal of the American Chemical Society, v, 60, p. 309-319, 1938.) in Quantachrome Nova 1200 equipment. In this test, samples were degassed at 150 °C for 4 h.

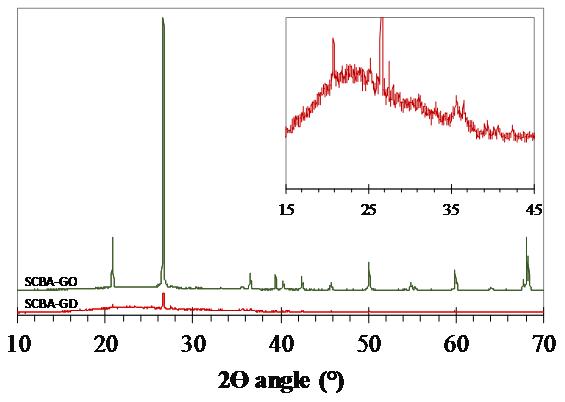

X-ray diffractometry analyses (RigakuMiniflex 600) were performed with Cu-kα radiation in the range of 2θ between 8 and 70°, a voltage of 40 kV, a current of 15 mA, an angular step of 0.02°, and a scanning speed of 10°/min to determine the ash mineralogy. Quantitative analyses were performed by Rietveld refinement (LIU; KUO, 1996LIU, H.; KUO, C. Quantitative multiphase determination using the Rietveld method with high accuracy. Materials Letters, v. 26, p. 171-175, 1996.) to quantify the constituent phases. The analysis conditions were the same as those adopted in the qualitative analysis, except for the scanning speed that was equal to 5°/min, the addition of a sample spinner, and the use of ultrafine lithium fluoride (LiF, 99.99%) as an internal standard for amorphous quantification. The mass ratio between ash and LiF was 4:1. The phases were identified and quantified using the PDXL v. 2.0 software (Rigaku).

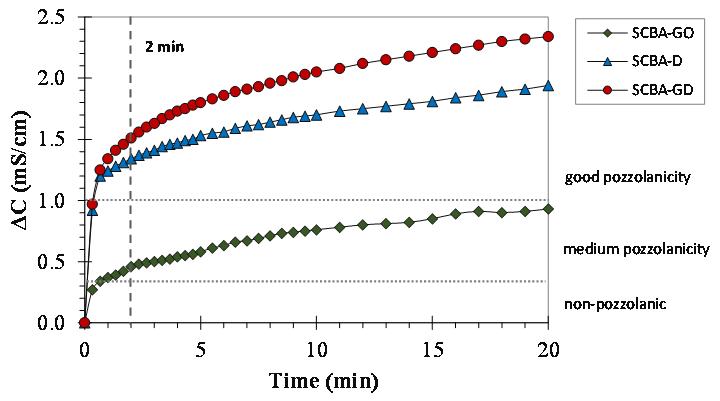

The pozzolanic activity of the ashes was initially assessed by the electrical conductivity method proposed by Luxán, Madruga and Saavedra (1989)LUXÁN, M. P.; MADRUGA, F.; SAAVEDRA, J. Rapid evaluation of pozzolanic activity of natural products by conductivity measurement. Cement and Concrete Research , v. 19, n. 1, p. 63-68, 1989., which consists of monitoring the variation of the electrical conductivity of the sample in an alkaline solution over time. For this purpose, a solution maintained at 40 ± 1° C was prepared with 98.7 mg of calcium hydroxide Ca(OH)2 and 70 g of deionized water, which remained in a water bath and under agitation for 20 min. Then, 1.75 g of the sample to be evaluated was added, and the conductivity variation was monitored for 20 min using an Alfakit AT 230 conductivity metre. The pozzolanicity was also analysed using the mechanical performance index (PI)(ABNT, 2014ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 5752: pozzolanic materials: determination of the performance index with Portland cement at 28 days. Rio de Janeiro, 2014.), which consists of a ratio between the compressive strength at 28 days of a mortar with 25% mass replacement of Portland cement by a mineral addition and the strength of a reference mortar. In this test, class G CPP cement (ABNT, 2020ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 9831: oil well Portland cements: requirements and test methods. Rio de Janeiro, 2020.), which does not contain mineral additions or limestone, and Brazilian standard sand (ABNT, 2015aASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7214: standard sand for cement tests: specification. Rio de Janeiro, 2015a.) were used. The main characteristics of Brazilian sand are shown in Table 1. The dosage of mortars was established for water-binder and sand-binder ratios (cement and ash) equal to 0.48 and 3.0, respectively. Table 2 shows the superplasticiser (modified carboxylic ether with specific mass of 1.12 g/cm³ and solids content of 28.9%) contents used to maintain the consistency of the mortars in the range of 200 ± 10 mm. This parameter was confirmed in all mortars, according to the consistency test on the spreading table (ABNT, 2019ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7215: Portland cement: determination of compressive strength of cylindrical test specimens. Rio de Janeiro, 2019.). Three cubic specimens that have a 5 cm edge were moulded for each mix and kept in the moulds for 24 hours in a humid environment. Once this period was concluded, the specimens were demoulded and kept immersed in a saturated lime solution for 28 days. The axial compression test was performed on a Shimadzu UHI-500kNI universal testing machine with a loading rate of 0.5 mm/min.

The hydration of cementitious pastes containing produced ashes was assessed by isothermal calorimetry testing (Calmetrix I-CAL 2000 calorimeter) for 72 h at 25 ± 0.1°C. In this case, pastes with 20% mass replacement of Portland cement by each type of addition (P-X, where X is the type of ash) were made, in addition to a reference paste (P-REF), which was produced without using mineral addition. This replacement content was used in previous studies on cementitious pastes with different types of sugarcane bagasse ashes (CORDEIRO; KURTIS, 2017CORDEIRO, G. C.; KURTIS, K, E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cement and Concrete Research, v. 97, p. 41-49, 2017.; ANDREÃO et al., 2019ANDREÃO, P. V. et al. Sustainable use of sugarcane bagasse ash in cement-based materials. Green Materials, v. 7, p. 61-70, 2019.; BARBOSA; CORDEIRO, 2021BARBOSA, F. L.; CORDEIRO, G. C. Partial replacement by different sugar cane bagasse ashes: hydration-related, compressive strength and autogenous shrinkage. Construction and Building Materials , v. 272, p. 121625, 2021.). The same cement previously used was applied to produce the pastes, with a water-cement material ratio equal to 0.4 and superplasticiser content (modified carboxylic ether) equal to 0.03%. The mixing procedure was standardised for all pastes and consisted of two steps. First, the deionised water and superplasticiser were homogenised, followed by manual mixing with a spatula, for 30 seconds, of the liquid part with the cementitious material. Then, the mixing was finished in a Hamilton Beach mixer for 30 s at 260 rpm and for 60 s at 600 rpm.

Results and discussion

Characterisation of sugarcane bagasse ashes

Table 3 shows the oxide composition and the values of loss on ignition for the three produced ashes. The samples, as expected, presented silica (SiO2) contents above 50%. Densimetric fractionation promoted changes in ash composition, especially in the reduction of SiO2 content by removing much of the quartz present on the original ash. Furthermore, SCBA-D also showed an increase in the Al2O3, K2O, CaO and P2O5 contents due to the concentration of all oxides by quartz removal. Regarding loss on ignition, the ashes presented values lower than the maximum content of 6% established in NBR 12653 (ABNT, 2015bASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 12653: pozzolanic materials: requirements. Rio de Janeiro, 2015b.). The high concentration of organic matter is not advisable in pozzolanic ash as it decreases the concentration of amorphous silica and, consequently, the pozzolanic activity of ash (MALI; NANTHAGOPALAN, 2021MALI, A. K.; NANTHAGOPALAN, P. Thermo-mechanical treatment of sugarcane bagasse ash with very high LOI: a pozzolanic paradigm. Construction and Building Materials , v. 288, p. 122988, 2021.). Moreover, ash with a high loss on ignition promotes an increase in the water demand and setting times of cementitious systems (CORDEIRO; BARROSO; TOLEDO FILHO, 2018CORDEIRO, G. C.; BARROSO, T. R.; TOLEDO FILHO, R. D. Enhancement the properties of sugar cane bagasse ash with high carbon content by a controlled re-calcination process. KSCEJournal of Civil Engineering, v. 22, p. 1250-1257, 2018.). The K2O content in the ashes (3 and 5% for SCBA-GO and SCBA-D, respectively) may limit the amount of cement to be replaced as a result of the increase in the alkaline equivalent. This may increase the amount of alkali in the cement, causing changes in properties in the fresh and hardened states of pastes, mortars and concretes (DE SIQUEIRA; CORDEIRO, 2022DE SIQUEIRA, A. A.; CORDEIRO, G. C. Properties of binary and ternary mixes of cement, sugarcane bagasse ash and limestone. Construction and Building Materials , v. 317, p. 126150, 2022.). A positive aspect was the presence of expressive levels of Al2O3 both in the original ash and in the sample after densimetric fractionation.

The X-ray diffractograms of the ashes are shown in Figure 1 and indicate the presence of quartz in both SCBA-GO and SCBA-D. The SCBA-D diffractogram showed an amorphism halo between angles 2θ of 20 and 30° (detail in Figure 1), which indicated the presence of amorphous silica. Table 4 shows the quantification of crystalline phases of the ashes obtained by Rietveld refinement and confirmed the predominant presence of quartz in SCBA-GO. On the other hand, SCBA-D presented a higher concentration of the amorphous phase (94.8%) compared to the original ash (40.3%). There was also a significant reduction in the quartz content, which was 59.7% for SCBA-GO and only 5.2% for SCBA-D. These results are positive and confirm the effectiveness of the densimetric fractionation process to concentrate the amorphous portion of the ash and substantially reduce its quartz contamination. Similar results were obtained by Andreão et al. (2019)ANDREÃO, P. V. et al. Sustainable use of sugarcane bagasse ash in cement-based materials. Green Materials, v. 7, p. 61-70, 2019., who developed a densimetric separation process with the removal of the most reactive portion by sieving.

Figure 2 shows the granulometric distribution of the three different types of ash and the comparison between the curves indicates that the ground ashes (SCBA-GO and SCBA-GD) presented similar particle size distributions, with values of D 50 approximately equal to 4 µm (Table 4). The unground ash (SCBA-D) presented, as expected, coarse granulometry, with a D 50 of 28.20 μm. Homogenisation and reduction of particles is an important procedure to ensure ash reactivity since the pozzolanic activity is maximised by increasing the specific surface area associated with the reduction of particle size (BARBOSA; CORDEIRO, 2021BARBOSA, F. L.; CORDEIRO, G. C. Partial replacement by different sugar cane bagasse ashes: hydration-related, compressive strength and autogenous shrinkage. Construction and Building Materials , v. 272, p. 121625, 2021.; CORDEIRO; KURTIS, 2017CORDEIRO, G. C.; KURTIS, K, E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cement and Concrete Research, v. 97, p. 41-49, 2017.). Table 4 shows the BET specific surface area values for the different samples, which reveal important information. Initially, it was observed that densimetric fractionation made it possible to obtain ash with a specific surface area value 400% higher than that observed for the original ash with a similar particle size. This specific surface area increase was caused by the higher concentration of amorphous phases in SCBA-D. In this respect, it is interesting to note that the dispersed ash presented a high specific surface area even with a coarser particle size. Despite this, the results confirmed the importance of ultrafine grinding in terms of increasing the specific surface area of agro-industrial ash, as noted in previous studies (CORDEIRO; TAVARES; TOLEDO FILHO, 2016CORDEIRO, G. C.; TAVARES, L. M.; TOLEDO FILHO, R. D. Improved pozzolanic activity of sugar cane bagasse ash by selective grinding and classification. Cement and Concrete Research , v. 89, p. 269-275, 2016.; CORDEIRO; KURTIS, 2017CORDEIRO, G. C.; KURTIS, K, E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cement and Concrete Research, v. 97, p. 41-49, 2017.; MORAES et al., 2021MORAES, J. C. B. et al. Improving the reactivity of a former ground sugarcane bagasse ash produced by autogenous combustion through employment of two different additional grinding procedures. Construction and Building Materials , v. 270, p. 121471, 2021.). It should be noted that the enhancement in the ash specific surface area increased the demand of the superplasticiser, as seen in Table 2.

X-ray diffraction patterns of ashes. Peaks in the SCBA-GO (green) and SCBA-GD (red) diffractograms refer to quartz (ICDD code #01-083-0539)

The density values are indicated in Table 4 and are equal to 2.32 g/cm3 for SCBA-D and SCBA-GD samples, and 2.56 g/cm3 for SCBA-GO. In general, ashes containing iron and quartz tend to have higher values of density, while materials predominantly formed by amorphous silica and with few impurities have lower values (BARBOSA; CORDEIRO, 2021BARBOSA, F. L.; CORDEIRO, G. C. Partial replacement by different sugar cane bagasse ashes: hydration-related, compressive strength and autogenous shrinkage. Construction and Building Materials , v. 272, p. 121625, 2021.). Indeed, the result found for SCBA-GO was close to the density of 2.65 g/cm3 of quartz sand (SALES; LIMA, 2010SALES, A.; LIMA, S. A. Use of Brazilian sugarcane bagasse ash in concrete as sand replacement. Waste Management, v. 30, p. 1114-1122, 2010.). Thus, the values found were consistent with the chemical and mineralogical composition of the ashes, as the lower density value of the dispersed ash can be attributed to the concentration of amorphous silica and quartz reduction. The difference between the ash densities explained the effectiveness of the densimetric separation process for quartz removal.

Evaluation of pozzolanic activity of sugarcane bagasse ashes

The electrical conductivity results are shown in Figure 3. The curves clearly showed the different behaviors of the three types of investigated ashes. The variation in electrical conductivity, in this case, is attributed to the dissolution of calcium hydroxide by amorphous silica present in the pozzolans. However, Payá et al. (2001PAYÁ, J. et al. Enhanced conductivity measurement techniques for evaluation of fly ash pozzolanic activity. Cement and Concrete Research , v. 31, p. 41-49, 2001.) discussed the importance of considering other elements, such as salts and carbon, which can react with Ca(OH)2 and cause conductivity reduction. Considering the high concentrations of amorphous silica and the low presence of the contaminants mentioned in the studied ashes, the conductivity test was an appropriate method for assessing its pozzolanicity, mainly due to its simple execution and rapid result. According to the classification proposed by Luxán, Madruga and Saavedra (1989)LUXÁN, M. P.; MADRUGA, F.; SAAVEDRA, J. Rapid evaluation of pozzolanic activity of natural products by conductivity measurement. Cement and Concrete Research , v. 19, n. 1, p. 63-68, 1989., based on the conductivity variation at 2 min, the SCBA-GD and SCBA-D samples were classified as materials of good pozzolanicity, with variations of 1.51 mS/cm and 1.34 mS/cm, respectively. The best result of SCBA-GD, in relation to SCBA-D, is due to ultrafine grinding, given the smaller particle size of the dispersed and ground sample, which led to an increase in the specific surface area of the material and, consequently, higher solubility of the amorphous silica (CORDEIRO; KURTIS, 2017CORDEIRO, G. C.; KURTIS, K, E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cement and Concrete Research, v. 97, p. 41-49, 2017.). The SCBA-GO presented a variation of 0.46 mS/cm, and is classified as ash of medium pozzolanicity. Since SCBA-GO and SCBA-GD had similar particle sizes, the most significant variation in conductivity of SCBA-GD can be attributed to the lower presence of quartz in its composition, high specific surface area, and high amorphous content. The obtained results showed the influence of densimetric fractionation on the pozzolanic activity of the samples, considering the higher reactivity of ashes from pre-treatment compared to the ash that was subjected only to grinding.

The results from the consistency index (ABNT, 2019ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7215: Portland cement: determination of compressive strength of cylindrical test specimens. Rio de Janeiro, 2019.) and compressive strength of the mortars used to calculate the performance indices are presented in Table 5. The performance index values are shown in Table 4. The pozzolanic character of the samples was confirmed by the results exceeding the minimum 90% established by NBR 12653 (ABNT, 2015bASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 12653: pozzolanic materials: requirements. Rio de Janeiro, 2015b.). SCBA-GD obtained the best performance among the studied ashes, followed by SCBA-D, with indexes of 132% and 126%, respectively. SCBA-GO showed a lower result, with a PI of 110%, which can be attributed to quartz contamination. It is important to emphasise that the PI is influenced by the physical and chemical effects of ash (CORDEIRO; KURTIS, 2017CORDEIRO, G. C.; KURTIS, K, E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cement and Concrete Research, v. 97, p. 41-49, 2017.). Thus, the prominence of SCBA-GD can be associated with the filler effect caused by its small particle size, high specific surface area, high amorphous content, and low quartz contamination. The results corroborated the electrical conductivity results, which confirmed the specific pozzolanic effects developed by each ash.

Main (standard deviation in parentheses) values of consistency and compressive strength of the mortars

In this regard, Figure 4 presents a correlation between the values of electrical conductivity variation at 2 minutes and the performance index results for the data of this research and other recent studies (CORDEIRO; TAVARES; TOLEDO FILHO, 2016CORDEIRO, G. C.; TAVARES, L. M.; TOLEDO FILHO, R. D. Improved pozzolanic activity of sugar cane bagasse ash by selective grinding and classification. Cement and Concrete Research , v. 89, p. 269-275, 2016.; CORDEIRO et al., 2020CORDEIRO, G. C. et al. Production of agroindustrial ashes with pozzolanic activity via acid leaching, conjugated burning and ultrafine grinding. Ambiente Construído, Porto Alegre, v. 20, n. 4, p. 189-203, out./dez. 2020.). In both works, different beneficiation methods were applied to the sugarcane bagasse ashes. Cordeiro, Tavares and Toledo Filho (2016)CORDEIRO, G. C.; TAVARES, L. M.; TOLEDO FILHO, R. D. Improved pozzolanic activity of sugar cane bagasse ash by selective grinding and classification. Cement and Concrete Research , v. 89, p. 269-275, 2016. subjected the collected ashes to a series of grindings to reduce the amount of contaminating quartz. Cordeiro et al. (2020)CORDEIRO, G. C. et al. Production of agroindustrial ashes with pozzolanic activity via acid leaching, conjugated burning and ultrafine grinding. Ambiente Construído, Porto Alegre, v. 20, n. 4, p. 189-203, out./dez. 2020. used the methods of densimetric fractionation, controlled burning, acid leaching and grinding to enhance the reactivity of the material. In this case, the fractionation followed the procedure presented by Andreão et al. (2019)ANDREÃO, P. V. et al. Sustainable use of sugarcane bagasse ash in cement-based materials. Green Materials, v. 7, p. 61-70, 2019., in which the supernatant portion of the ash is collected. Figure 4 shows that there was a good linear fit (R2 = 88%) among the results of the two pozzolanic activity methods for sugarcane bagasse ashes with a low loss on ignition (values less than 5%), which is especially interesting due to the operational simplicity and speed of the conductivity test.

Heat of hydration of cement-based pastes

Figure 5a shows the heat flow curves of hydration of the pastes. The P-SCBA-GO mix showed no significant difference compared to the P-REF in the initial 6 h of hydration. The low reactivity of SCBA-GO maintained the initial time of the acceleration period. This behavior is typical of bagasse ashes with high quartz contamination (BARBOSA; CORDEIRO, 2021BARBOSA, F. L.; CORDEIRO, G. C. Partial replacement by different sugar cane bagasse ashes: hydration-related, compressive strength and autogenous shrinkage. Construction and Building Materials , v. 272, p. 121625, 2021.; CORDEIRO; KURTIS, 2017CORDEIRO, G. C.; KURTIS, K, E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cement and Concrete Research, v. 97, p. 41-49, 2017.). For pastes with dispersed ashes, there was a sensitive acceleration of hydration, which can be attributed to the recurring dilution and heterogeneous nucleation effects of mineral additions. The first effect is associated with the lower amount of cement in the paste, while the nucleation is due to the small particle size and high specific surface area of the ashes (KADRI et al., 2010KADRI, E. H. et al. Combined effect of chemical nature and fineness of mineral powders on Portland cement hydration. Materials and Structures, v. 43, p. 665-673, 2010.). The peak associated with the hydration of C3A is more significant in the pastes with the ashes due to the considerable presence of Al2O3 in the samples (BARBOSA; CORDEIRO, 2021BARBOSA, F. L.; CORDEIRO, G. C. Partial replacement by different sugar cane bagasse ashes: hydration-related, compressive strength and autogenous shrinkage. Construction and Building Materials , v. 272, p. 121625, 2021.). The curves referring to the released heat by the pastes are shown in Figure 5b. During the first hours of hydration, it was observed that the P-SCBA-GD and P-SCBA-D mixes released more heat than the P-REF. This increase is a consequence of pozzolanic activity and heterogeneous nucleation caused by the ashes. In addition, the high content of Al2O3 present in the composition of the different types of ash also contributed to the increased hydration heat of the two pastes (BARBOSA; CORDEIRO, 2021BARBOSA, F. L.; CORDEIRO, G. C. Partial replacement by different sugar cane bagasse ashes: hydration-related, compressive strength and autogenous shrinkage. Construction and Building Materials , v. 272, p. 121625, 2021.; BRAZ et al., 2019BRAZ, I. G. et al. Effect of the addition of aluminum recycling waste on the pozzolanic activity of sugarcane bagasse ash and zeolite. Waste and Biomass Valorization, v. 10, p. 3493-3513, 2019.). At the end of 72 h, all the pastes with ash presented maximum values of released energy lower than the P-REF. Considering that SCBA-GO is the least reactive among the studied ashes, it is consistent that its hydration process developed less accumulated heat, as observed.

Conclusions

Based on the results obtained in the present research, it can be concluded that the original and dispersed ashes showed chemical characteristics indicative of pozzolanic activity, such as high silica content and reduced loss on ignition. Mineralogical analysis revealed that densimetric fractionation was effective in separating quartz from the reactive ash fraction. This was observed by the silica concentration in the amorphous state in the dispersed ash.

From the pozzolanic assessment tests, it was observed that SCBA-GD presented higher reactivity due to its smaller particle size distribution, high specific surface area, high amorphous content and reduced quartz contamination. It is crucial to conclude that SCBA-D and SCBA-GO also presented a pozzolanic character.

Adding different ashes in the cement pastes caused a reduction in the hydration heat released. P-SCBA-GO showed more significant reduction due to the low pozzolanicity and reduced specific surface area of the ash compared to the others. The high reactivity of the samples SCBA-GD and SCBA-D was verified by accelerating the initial hydration period due to the dilution and heterogeneous nucleation effects.

Correlation between electrical conductivity (ΔC) and performance index (PI) values for sugarcane bagasse ash samples

(a) Specific heat flow and (b) released heat curves for the cementitious pastes, calculated by cementitious material mass

The densimetricfractionation allowed an increase in pozzolanic activity with a significant reduction in grinding time when SCBA-GO and SCBA-GD were compared. Finally, by comparing SCBA-D and SCBA-GD, it can be concluded that densimetric fractionation was more relevant to the reactivity of the ashes than ultrafine grinding since the significant reduction in particle size did not lead to a proportional increase in pozzolanic activity. This behavior is economically interesting for large-scale production of SBCA as grinding requires higher electricity consumption. Besides, the ash is commonly removed from boilers using water, which facilitates the use of fractionation in the plants. In this particular one, grinding could be performed in a milder way to ensure homogeneity to the pozzolan or, in specific cases, to produce highly reactive ashes.

Acknowlegdments

The present work was accomplished with the support of the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) and the Fundação Carlos Chagas Filho de Amparo à Pesquisa do Estado do Rio de Janeiro (FAPERJ).

References

- ANDRADE NETO, J. D. S. et al Effects of adding sugarcane bagasse ash on the properties and durability of concrete. Construction and Building Materials, v. 266, p. 120959, 2021.

- ANDREÃO, P. V. et al Sustainable use of sugarcane bagasse ash in cement-based materials. Green Materials, v. 7, p. 61-70, 2019.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 12653: pozzolanic materials: requirements. Rio de Janeiro, 2015b.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 13956-02: Silica fume for use with Portland cement in concrete, mortar and paste: part 2: chemical test methods. Rio de Janeiro, 2012b.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 16605:Portland cement and other powdered material: determination of the specific gravity. Rio de Janeiro, 2017.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 5752: pozzolanic materials: determination of the performance index with Portland cement at 28 days. Rio de Janeiro, 2014.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7214: standard sand for cement tests: specification. Rio de Janeiro, 2015a.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7215: Portland cement: determination of compressive strength of cylindrical test specimens. Rio de Janeiro, 2019.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 9831: oil well Portland cements: requirements and test methods. Rio de Janeiro, 2020.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR NM 18: Portland cement: chemical analysis: determination of loss on ignition. Rio de Janeiro, 2012a.

- BAHURUDEEN, A.; SANTHANAM, M. Influence of different processing methods on the pozzolanic performance of sugarcane bagasse ash. Cement and Concrete Composites, v. 56, p. 32-45, 2015.

- BARBOSA, F. L.; CORDEIRO, G. C. Partial replacement by different sugar cane bagasse ashes: hydration-related, compressive strength and autogenous shrinkage. Construction and Building Materials , v. 272, p. 121625, 2021.

- BRAZ, I. G. et al Effect of the addition of aluminum recycling waste on the pozzolanic activity of sugarcane bagasse ash and zeolite. Waste and Biomass Valorization, v. 10, p. 3493-3513, 2019.

- BRUNAUER, S.; EMMETT, P. H.; TELLER, E. Adsorption of gases in multimolecular layers. Journal of the American Chemical Society, v, 60, p. 309-319, 1938.

- CHUSILP, N.; JATURAPITAKKUL, C.; KIATTIKOMOL, K. Utilization of bagasse ash as a pozzolanic material in concrete. Construction and Building Materials , v. 23, n. 11, p. 3352-3358, 2009.

- COMPANHIA NACIONAL DE ABASTECIMENTO. Acompanhamento da safra brasileira de cana-de-açúcar. Disponível em: http://www.conab.gov.br Acesso em: 15 maio 2021.

» http://www.conab.gov.br - CORDEIRO, G. C. et al Long-term compressive behavior of concretes with sugarcane bagasse ash as a supplementary cementitious material. Journal of Testing and Evaluation, v. 46, n. 2, p. 564-573, 2018.

- CORDEIRO, G. C. et al Production of agroindustrial ashes with pozzolanic activity via acid leaching, conjugated burning and ultrafine grinding. Ambiente Construído, Porto Alegre, v. 20, n. 4, p. 189-203, out./dez. 2020.

- CORDEIRO, G. C.; BARROSO, T. R.; TOLEDO FILHO, R. D. Enhancement the properties of sugar cane bagasse ash with high carbon content by a controlled re-calcination process. KSCEJournal of Civil Engineering, v. 22, p. 1250-1257, 2018.

- CORDEIRO, G. C.; KURTIS, K, E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cement and Concrete Research, v. 97, p. 41-49, 2017.

- CORDEIRO, G. C.; TAVARES, L. M.; TOLEDO FILHO, R. D. Improved pozzolanic activity of sugar cane bagasse ash by selective grinding and classification. Cement and Concrete Research , v. 89, p. 269-275, 2016.

- CORDEIRO, G. C.; TOLEDO FILHO, R. D.; FAIRBAIRN, E. M. R. Use of ultra-fine sugar cane bagasse ash as mineral admixture for concrete. ACI Materials Journal, v. 105, n. 5, p. 487-493, 2008.

- DE ANDRADE, E. T.; DE CARVALHO, S. R. G.; DE SOUZA, L. F. Programa do Proálcool e o etanol no Brasil. Engevista, v. 11, p. 127-136, 2009.

- DE SIQUEIRA, A. A.; CORDEIRO, G. C. Properties of binary and ternary mixes of cement, sugarcane bagasse ash and limestone. Construction and Building Materials , v. 317, p. 126150, 2022.

- FAIRBAIRN, E. M. R. et al Evaluation of partial clinker replacement by sugar cane bagasse ash: CO2 emission reductions and potential for carbon credits. Ibracon Structures and Materials Journal, v. 5, n. 2, p. 229-251, 2012.

- GANESAN, K.; RAJAGOPAL, K.; THANGAVEL, K. Evaluation of bagasse ash as cementitious material. Cement and Concrete Composites , v. 29, n. 6, p. 515-524, 2007.

- KADRI, E. H. et al Combined effect of chemical nature and fineness of mineral powders on Portland cement hydration. Materials and Structures, v. 43, p. 665-673, 2010.

- LIU, H.; KUO, C. Quantitative multiphase determination using the Rietveld method with high accuracy. Materials Letters, v. 26, p. 171-175, 1996.

- LUXÁN, M. P.; MADRUGA, F.; SAAVEDRA, J. Rapid evaluation of pozzolanic activity of natural products by conductivity measurement. Cement and Concrete Research , v. 19, n. 1, p. 63-68, 1989.

- MALI, A. K.; NANTHAGOPALAN, P. Thermo-mechanical treatment of sugarcane bagasse ash with very high LOI: a pozzolanic paradigm. Construction and Building Materials , v. 288, p. 122988, 2021.

- MINNU, S. N.; BAHURUDEEN, A.; ATHIRA, G. Comparison of sugarcane bagasse ash with fly ash and slag: An approach towards industrial acceptance of sugar industry waste in cleaner production of cement. Journal of Cleaner Production, v. 285, 124836, 2021.

- MORAES, J. C. B. et al Improving the reactivity of a former ground sugarcane bagasse ash produced by autogenous combustion through employment of two different additional grinding procedures. Construction and Building Materials , v. 270, p. 121471, 2021.

- PAYÁ, J. et al Enhanced conductivity measurement techniques for evaluation of fly ash pozzolanic activity. Cement and Concrete Research , v. 31, p. 41-49, 2001.

- SALES, A.; LIMA, S. A. Use of Brazilian sugarcane bagasse ash in concrete as sand replacement. Waste Management, v. 30, p. 1114-1122, 2010.

- UNIÃO DA INDÚSTRIA DE CANA-DE-AÇÚCAR. Bioeletricidade em números. Disponível em: http://www.unica.com.br Acesso em: 15 maio 2021.

» http://www.unica.com.br - YADAV, A. L. et al An overview of the influences of mechanical and chemical processing on sugarcane bagasse ash characterisation as a supplementary cementitious material. Journal of Cleaner Production , v. 245, p. 118854, 2020.

Publication Dates

-

Publication in this collection

09 Sept 2022 -

Date of issue

Oct-Dec 2022

History

-

Received

15 Nov 2021 -

Accepted

19 Apr 2022