| Process |

Implementation and operation |

Labor-intensive process: too many crews to allocate |

● |

● |

● |

|

Integrate MTP into the safety and quality systems, incorporating prerequisites and safety conditions into the QMS procedures (empirical research). Automate MTP (Chua; Jun; Hwee, 1999; Chua; Shen, 2001; Chua; Shen; Bok, 2003; Dong et al., 2012; Dong, 2012, 2013) and use 4D BIM to systematically share information (Toledo ., 2014; Alves; Britt, 2011). Adopt spreadsheets for analysis of constraints (Tommelein; Ballard, 1997; Ballard, 2000; Kemmer , 2007; Hamzeh, 2009; Hamzeh ., 2012). |

| Lack of a planning routine |

● |

● |

● |

|

Get support from senior management, standardize the PPC in the company and integrate it into the QMS, train teams, carry out periodic audits and automate the MTP to facilitate its routine. |

| Partial crew allocation to jobs (not all crews are assigned to the whole set of activities under way) |

● |

● |

● |

Ballard (1997), Hamzeh, Ballard and Tommelein (2008, 2012), Hamzeh et al. (2012, 2015), Khanh and Kim (2016) and Perez and Ghosh (2018). |

Standardize the PP&C, integrate it into the QMS with team training, conduct periodic audits (empirical research) and implement phase planning (Ribeiro; Costa; Magalhães, 2017). |

| Short-term planning including activities not yet made ready |

● |

|

|

Kemmer et al. (2007), Hamzeh, Ballard and Tommelein (2008), Hamzeh (2012), Wesz, Formoso and Tzortzopoulos (2013) and Khanh and Kim (2016). |

Analyze activities listed in the constraint spreadsheet and ensure they are made ready and complete (Tommelein; Ballard, 1997; Ballard, 2000; Kemmer et al., 2007; Hamzeh, 2009). |

| Planning error |

● |

|

|

Kemmer et al. (2007), Hamzeh, Ballard and Tommelein (2008) and Khanh and Kim (2016). |

Prepare budget for standardized work packages, with allocation of resources approved by the planning or coordination managers. |

| Process |

Prototyping |

Model apartment used only to leverage sales |

|

|

● |

|

Build a prototype apartment and include it in the long-term schedule. |

| Not having a detailed design of critical processes |

|

|

● |

|

Use BIM to understand the work and detail specific operations (Hamzeh et al., 2012) |

| Insufficient integration of various planning levels |

Disregarding short-term control data |

● |

|

● |

Hamzeh, Ballard and Tommelein (2008), Hamzeh and Langerud (2011), Wesz, Formoso and Tzortzopoulos (2013) and Toledo, Olivares and Gónzalez (2016). |

Analyze short-term data in MTP meetings and determine a failure indicator (% of activities not completed due to MTP inaccuracy) (Hamzeh et al., 2012). |

| Using LBMS with no consideration of tacted decisions and contract duration |

● |

|

|

|

Utilize the LBMS to analyze the medium-term strategy by comparing planned and actual durations to evaluate deadlines and define corrective actions (Kemmer et al., 2007; Seppänen; Modrich; Ballard, 2015; Dave; Seppänen; Modrich, 2016; Seppänen; Ballard; Pesonen, 2010). |

| Method |

Unproductive meetings |

Main stakeholders do not participate in MTP meetings |

● |

● |

● |

- |

Involve external sectors and secure support from top management by assigning constraints to all hierarchical levels. Ensure removal dates are recorded in an online system, and relevant indicators are generated. |

| Long meetings with many agendas |

● |

|

● |

- |

Train engineers on meeting objectives and leadership. |

| Lack of understanding of the purpose of the meetings |

● |

|

● |

- |

Communicate the agenda and purpose of the meeting in advance, ensuring adequate preparation for all involved. |

| No prior preparation for meetings |

● |

|

● |

Britt et al. (2014), Toledo, Olivares and Gónzalez (2016). |

Automate the communication of actions and hold those responsible for remaining constraints accountable, with the support of senior management. |

| Lack of leadership |

● |

|

● |

- |

Set agenda for MTP meetings. |

| Method |

Constraint analysis |

Incomplete identification of constraints |

|

● |

● |

Bortolazza and Formoso (2006), Kemmer et al. (2007), Hamzeh, Ballard and Tommelein (2008), Wesz, Formoso and Tzortzopoulos (2013), Salvatierra (2015), Khanh and Kim (2016) and Perez and Ghosh (2018). |

Record lessons learned from constraints by service (Kemmer et al., 2007). |

| Lack of method and experience for constraints identification |

● |

|

● |

- |

Distribute the agenda before the meeting, ensuring the participation of key production employees. |

| Resistance to acknowledging the potential effects of constraints |

|

● |

|

- |

Encourage prior identification of constraints by stakeholders before the MTP meeting. |

| Delay of materials |

● |

● |

|

- |

Secure support from top management, track purchases through to delivery, train the supply team, and monitor indicators of urgent requests and delays. |

| Lack of analysis of process interference |

|

|

● |

- |

Involve external sectors in meetings by setting a prior basic agenda. |

| Inadequate constraints identification for subcontracted activities |

● |

● |

|

|

Discuss contractor constraints, include subcontractors in meetings, and record lessons learned (Kemmer et al., 2007). |

| Management |

Organizational structure |

Lack of support from company departments |

|

● |

● |

Hamzeh, Ballard and Tommelein (2008) and Britt et al. (2014). |

Implement an automatic communication system, ensure feedback from those responsible for removal of constraints with the support of senior management and generate indicators. |

| Control |

Process and product variability |

|

|

● |

- |

Involve the supply and commercial functions, include contractual clauses with deadlines for changes, and adopt a change control system. |

| Change of specification by purchasing / senior management sector |

|

● |

|

- |

Adopt a change control system and include the supply sector in MTP meetings. |

| Management |

Subcontractors’ awareness and induction |

Material stock locations are not clearly identified |

● |

|

|

- |

Include physical flows in the MTP meeting agenda, designate the person responsible for logistics and ensure the participation of subcontracted workers in the meetings (Kemmer et al., 2007; Britt et al., 2014). |

| Delay in work front release |

● |

|

|

- |

Integrate terminality and quality inspection into short-term planning and include staff responsible for quality in meetings. |

| Overly lengthy work assignments |

● |

|

|

- |

Manage subcontracted goals and ensure the participation of workers in meetings (Kemmer et al., 2007; Britt et al., 2014). |

| Over production |

● |

|

|

- |

Ensure the participation of subcontracted workers in phase and MTP meetings (Kemmer et al., 2007; Britt et al., 2014). |

| Human Resources |

Culture |

Fire-fighting on constraints removal |

|

● |

● |

- |

Constraints management automation, make sure staff, responsible for constraints removed to maintain the system use a Percentage of Constraint Removal (PCR). |

| Arguments for non-acceptance of MTP rationale |

|

● |

|

- |

Use indicator of removal of constraints by sector and person responsible (Kim; Jang, 2006). |

| Suppliers’ avoidance of MTP meetings |

|

● |

|

- |

Ensure subcontracted participation in phase and MTP meetings (Kemmer et al., 2007; Britt et al., 2014). |

| Include a contractual clause for participation of subcontracted workers in meetings. |

| Knowledge |

Lack of training on MTP and its rationale |

|

|

● |

- |

Conduct LPS training and record lessons learned from constraints removal (Kemmer et al., 2007) |

| Lack of mastery of the construction process |

● |

|

|

- |

Integrate the MTP into the executive procedures of the QMS. |

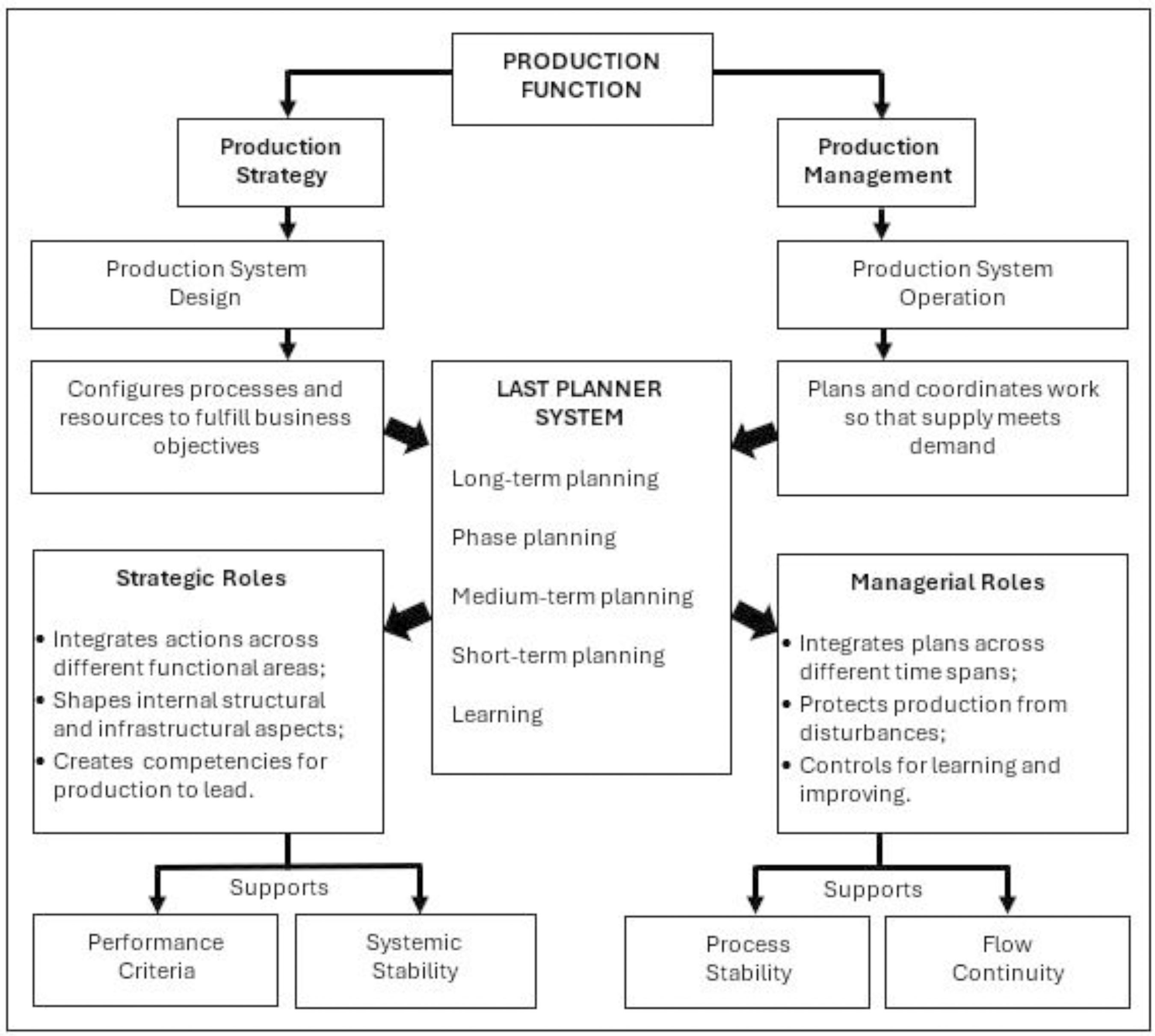

Medium-term planning considering the roles of the Last Planner System in production strategy and management

Medium-term planning considering the roles of the Last Planner System in production strategy and management Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail