Abstract

Drying is a fundamental process in the food industry, especially for highly perishable foods, such as fruits and vegetables, because they tend to have short durability post-harvest, resulting in economic and environmental losses. The Refractance Window (RW) is a suitable technique for fruits and vegetables as it maintains the nutritional quality of the raw material in the dry product. Although RW is more energy-efficient than hot air-based techniques, the equipment traditionally consumes electricity, largely obtained from fossil fuels, emitting polluting gases. As a solution to this problem, hybridization of the heating system can be adopted in the drying process. Hybridization is when two or more heat transfer techniques are used in food dehydration. Renewable alternatives, such as solar energy, represents a clean and abundant energy source. The integration of these technologies (RW with solar energy) represents a technological improvement for the food industry, especially regarding environmental concerns. The present study analyzed the current progress in the integration of renewable energies into traditional RW for the drying of fruits and vegetables, as well as highlighted the existing knowledge gaps.

Keywords:

Cast-tape drying; Food quality; Hybrid drying; Conventional drying; Renewable energy; Non-renewable energy

HIGHLIGHTS

The RW is a suitable technique for drying fruits and vegetables

The use of solar energy in a hybrid form with electricity reduces costs and possible environmental impacts

Compared to conventional techniques, the RW is more energy efficient

Bioactive retention is more effective compared to freeze-dried material

1 Introduction

Fresh foods, such as fruits and vegetables, have between 80 and 95% of moisture content; a factor that contributes to their rapid degradation, generating a high volume of losses and food waste (Prosapio & Norton, 2018Prosapio, V., & Norton, I. (2018). Simultaneous application of ultrasounds and firming agents to improve the quality properties of osmotic + freeze-dried foods. LWT, 96, 402-410. http://dx.doi.org/10.1016/j.lwt.2018.05.068

http://dx.doi.org/10.1016/j.lwt.2018.05....

; Waghmare, 2021Waghmare, R. (2021). Refractance window drying: A cohort review on quality characteristics. Trends in Food Science & Technology, 110, 652-662. http://dx.doi.org/10.1016/j.tifs.2021.02.030

http://dx.doi.org/10.1016/j.tifs.2021.02...

). To avoid this issue an alternative solution is the use of drying, which is the oldest conservation method developed by mankind (Acar et al., 2020Acar, C., Dincer, I., & Mujumdar, A. (2020). A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Drying Technology, 1-27. http://dx.doi.org/10.1080/07373937.2020.1848858

http://dx.doi.org/10.1080/07373937.2020....

). Water removal from the food achieved through the drying process limits microbial growth and decreases chemical reaction rates meanwhile still maintaining the food’s nutritional quality (Onwude et al., 2022Onwude, D. I., Iranshahi, K., Rubinetti, D., Schudel, S., Schemminger, J., Martynenko, A., & Defraeye, T. (2022). How much do process parameters affect the residual quality attributes of dried fruits and vegetables for convective drying? Food and Bioproducts Processing, 131, 176-190. http://dx.doi.org/10.1016/j.fbp.2021.11.005

http://dx.doi.org/10.1016/j.fbp.2021.11....

; Qiu et al., 2019Qiu, J., Acharya, P., Jacobs, D. M., Boom, R. M., & Schutyser, M. A. I. (2019). A systematic analysis on tomato powder quality prepared by four conductive drying technologies. Innovative Food Science & Emerging Technologies, 54, 103-112. http://dx.doi.org/10.1016/j.ifset.2019.03.013

http://dx.doi.org/10.1016/j.ifset.2019.0...

). Currently, a large variety of drying technologies are available such as sun drying with direct exposure to outdoor solar radiation (Deng et al., 2021Deng, Z., Li, M., Xing, T., Zhang, J., Wang, Y., & Zhang, Y. (2021). A literature research on the drying quality of agricultural products with using solar drying technologies. Solar Energy, 229, 69-83. http://dx.doi.org/10.1016/j.solener.2021.07.041

http://dx.doi.org/10.1016/j.solener.2021...

), hot air drying (convection), high-tech drying equipment (Zhang et al., 2017Zhang, M., Chen, H., Mujumdar, A. S., Tang, J., Miao, S., & Wang, Y. (2017). Recent developments in high-quality drying of vegetables, fruits, and aquatic products. Critical Reviews in Food Science and Nutrition, 57(6), 1239-1255. PMid:26055086. http://dx.doi.org/10.1080/10408398.2014.979280

http://dx.doi.org/10.1080/10408398.2014....

), hybrid dryers and alternative technologies that are more environmentally friendly (Acar et al., 2020Acar, C., Dincer, I., & Mujumdar, A. (2020). A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Drying Technology, 1-27. http://dx.doi.org/10.1080/07373937.2020.1848858

http://dx.doi.org/10.1080/07373937.2020....

).

Now, the intensive focus has been directed on developing energy-efficient technologies that leverage environmental capabilities. Industrial drying equipment is responsible for up to 25% of energy consumption in the food processing industries. Traditionally, the energy required in these systems is obtained directly and indirectly from fossil fuels, which are the major responsibility for greenhouse gas (GHG) emissions (Mourshed et al., 2017Mourshed, M., Masud, M. H., Rashid, F., & Joardder, M. U. H. (2017). Towards the effective plastic waste management in Bangladesh: A review. Environmental Science and Pollution Research International, 24(35), 27021-27046. PMid:29079979. http://dx.doi.org/10.1007/s11356-017-0429-9

http://dx.doi.org/10.1007/s11356-017-042...

). On the other hand, countries like Brazil have been investing in renewable energy sources, relying on its potential to explore alternative sources (such as solar and wind power) in combination with drying techniques to help reduce the carbon footprint of their operations (Empresa de Pesquisa Energética, 2021Empresa de Pesquisa Energética – EPE. (2021). Balanço Nacional Energético (BEN) 2021: Ano Base 2020. Retrieved in 2021, October 4, from https://www.epe.gov.br/pt/publicacoes-dados-abertos/publicacoes/balanco-energetico-nacional-2021

https://www.epe.gov.br/pt/publicacoes-da...

).

In this sense, among the available technologies, Refractance Window (RW) is a relatively new technique and presents some advantages such as a short drying period, conservation of bioactive, thermal and energy efficiency, and mechanical simplicity (Raghavi et al., 2018Raghavi, L. M., Moses, J. A., & Anandharamakrishnan, C. (2018). Refractance window drying of foods: A review. Journal of Food Engineering, 222, 267-275. http://dx.doi.org/10.1016/j.jfoodeng.2017.11.032

http://dx.doi.org/10.1016/j.jfoodeng.201...

). In a previous study carried out analyzing asparagus dehydration, plant moisture reduction from 90% to 4% was obtained in only 5 minutes (Nindo & Tang, 2007Nindo, C. I., & Tang, J. (2007). Refractance Window dehydration technology: A novel contact drying method. Drying Technology, 25(1), 37-48. http://dx.doi.org/10.1080/07373930601152673

http://dx.doi.org/10.1080/07373930601152...

). This short processing period contributes to the maintenance of quality parameters such as color and aroma (Nindo et al., 2003Nindo, C. I., Feng, H., Shen, G. Q., Tang, J., & Kang, D. H. (2003). Energy utilization and microbial reduction in a new film drying system. Journal of Food Processing and Preservation, 27(2), 117-136. http://dx.doi.org/10.1111/j.1745-4549.2003.tb00506.x

http://dx.doi.org/10.1111/j.1745-4549.20...

; Raghavi et al., 2018Raghavi, L. M., Moses, J. A., & Anandharamakrishnan, C. (2018). Refractance window drying of foods: A review. Journal of Food Engineering, 222, 267-275. http://dx.doi.org/10.1016/j.jfoodeng.2017.11.032

http://dx.doi.org/10.1016/j.jfoodeng.201...

). Researchers have also shown that considering milk dehydration, a 61% reduction in processing time was obtained when compared to a traditional concentrator (Al‐Hilphy et al., 2020Al‐Hilphy, A. R., Ali, H. I., Al‐IEssa, S. A., Lorenzo, J. M., Barba, F. J., & Gavahian, M. (2020). Optimization of process variables on physicochemical properties of milk during an innovative refractance window concentration. Journal of Food Processing and Preservation, 44(10), http://dx.doi.org/10.1111/jfpp.14782

http://dx.doi.org/10.1111/jfpp.14782...

). In addition, the RW dryer has been proven to present good energy efficiency when compared to conventional dryers (between 28% and 38%) (Acar et al., 2020Acar, C., Dincer, I., & Mujumdar, A. (2020). A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Drying Technology, 1-27. http://dx.doi.org/10.1080/07373937.2020.1848858

http://dx.doi.org/10.1080/07373937.2020....

; Nindo & Tang, 2007Nindo, C. I., & Tang, J. (2007). Refractance Window dehydration technology: A novel contact drying method. Drying Technology, 25(1), 37-48. http://dx.doi.org/10.1080/07373930601152673

http://dx.doi.org/10.1080/07373930601152...

; Ortiz-Jerez et al., 2015Ortiz-Jerez, M. J., Gulati, T., Datta, A. K., & Ochoa-Martínez, C. I. (2015). Quantitative understanding of Refractance WindowTM drying. Food and Bioproducts Processing, 95, 237-253. http://dx.doi.org/10.1016/j.fbp.2015.05.010

http://dx.doi.org/10.1016/j.fbp.2015.05....

). Finally, when focusing on the preservation of bioactive compounds such as vitamin C, antioxidants, and phenolic compounds, RW has proven to yield higher final concentrations when compared to traditional techniques such as freeze-drying (Celli et al., 2016Celli, G. B., Khattab, R., Ghanem, A., & Brooks, M. S. (2016). Refractance WindowTM drying of haskap berry: Preliminary results on anthocyanin retention and physicochemical properties. Food Chemistry, 194, 218-221. PMid:26471547. http://dx.doi.org/10.1016/j.foodchem.2015.08.012

http://dx.doi.org/10.1016/j.foodchem.201...

).

Overall, the RW technique has a promising future as a drying solution. However, there are still potential areas of improvement which would ease its ample industrial application such as reducing the use of conventional energies sources for operation. The main objective of this work is to present a compilation of some potential improvements for the RW technique bringing to light the current state of the art, the potential for hybridization with renewable technologies, or other more recently developed solutions (e.g. ultrasound and infrared). Finally, a brief discussion on the future trends regarding the use of renewable energy in drying models will be presented.

2 Drying process of fruits and vegetables

The consumption of fruits and vegetables, especially fruits in nature is highly encouraged due to the several health benefits associated with adding regular portions of them to your daily diet (Silva & Claro, 2019Silva, L. E. S., & Claro, R. M. (2019). Tendências temporais do consumo de frutas e hortaliças entre adultos nas capitais brasileiras e Distrito Federal, 2008-2016. Cadernos de Saude Publica, 35(5), e00023618. http://dx.doi.org/10.1590/0102-311x00023618

http://dx.doi.org/10.1590/0102-311x00023...

). However, because they are highly perishable (moisture content > 80%) they are commonly the reason for product losses in the food industry. Thus, the dehydration of foods with high water content is applied as a practical solution to the problem presented (Mat Desa et al., 2019Mat Desa, W. N., Mohammad, M., & Fudholi, A. (2019). Review of drying technology of fig. Trends in Food Science & Technology, 88, 93-103. http://dx.doi.org/10.1016/j.tifs.2019.03.018

http://dx.doi.org/10.1016/j.tifs.2019.03...

). Consumptions of dried fruits present several health benefits including control of satiety and improvements in lipid profile (Chang et al., 2016Chang, S. K., Alasalvar, C., & Shahidi, F. (2016). Review of dried fruits: Phytochemicals, antioxidant efficacies, and health benefits. Journal of Functional Foods, 21, 113-132. http://dx.doi.org/10.1016/j.jff.2015.11.034

http://dx.doi.org/10.1016/j.jff.2015.11....

). Improvements in bone health (Wallace, 2017Wallace, T. (2017). Dried plums, prunes and bone health: A comprehensive review. Nutrients, 9(4), 401. PMid:28422064. http://dx.doi.org/10.3390/nu9040401

http://dx.doi.org/10.3390/nu9040401...

) have also been reported, since many phytochemicals remain in the product even after dehydration (Alasalvar et al., 2020Alasalvar, C., Salvadó, J. S., & Ros, E. (2020). Bioactives and health benefits of nuts and dried fruits. Food Chemistry, 314, 126192. PMid:31958750. http://dx.doi.org/10.1016/j.foodchem.2020.126192

http://dx.doi.org/10.1016/j.foodchem.202...

; Hernández-Alonso et al., 2017Hernández-Alonso, P., Camacho-Barcia, L., Bulló, M., & Salas-Salvadó, J. (2017). Nuts and dried fruits: An update of their beneficial effects on type 2 diabetes. Nutrients, 9(7), 673. PMid:28657613. http://dx.doi.org/10.3390/nu9070673

http://dx.doi.org/10.3390/nu9070673...

; Onwude et al., 2022Onwude, D. I., Iranshahi, K., Rubinetti, D., Schudel, S., Schemminger, J., Martynenko, A., & Defraeye, T. (2022). How much do process parameters affect the residual quality attributes of dried fruits and vegetables for convective drying? Food and Bioproducts Processing, 131, 176-190. http://dx.doi.org/10.1016/j.fbp.2021.11.005

http://dx.doi.org/10.1016/j.fbp.2021.11....

; Senadeera et al., 2020Senadeera, A., Adiletta, G., Önal, B., Di Matteo, M., & Russo, P. (2020). Influence of different hot air drying temperatures on drying kinetics, shrinkage, and colour of persimmon slices. Foods, 9(1), 101. PMid:31963701. http://dx.doi.org/10.3390/foods9010101

http://dx.doi.org/10.3390/foods9010101...

). Table 1 shows previous research analyzing the dehydration of fruits and vegetables.

Fruits and vegetables found in the literature are dehydrated by different drying methodologies.

Fruits and vegetables are potentially suited for dehydration; however, it is important to note that the quality of the final material varies according to the drying technology applied. Fruits and vegetables are thermally sensitive, and the inadequate choice of drying technology can induce nutritional value loss, product oxidation, color change, and the development of unpleasant texture and flavors (Zhang et al., 2017Zhang, M., Chen, H., Mujumdar, A. S., Tang, J., Miao, S., & Wang, Y. (2017). Recent developments in high-quality drying of vegetables, fruits, and aquatic products. Critical Reviews in Food Science and Nutrition, 57(6), 1239-1255. PMid:26055086. http://dx.doi.org/10.1080/10408398.2014.979280

http://dx.doi.org/10.1080/10408398.2014....

). Factors such as physiological properties, characteristics of the materials to be dried, desired initial and final moisture content, temperature, and drying time are important characteristics to be considered when determining drying procedures (Sehrawat et al., 2018Sehrawat, R., Babar, O. A., Kumar, A., & Nema, P. K. (2018). Recent trends in fruits and vegetables. In R. Sehrawat, K. A. Khan, M. R. Goyal & P. K. Paul (Eds.), Technological interventions in the processing of fruits and vegetables. Boca Raton: Apple Academic Press. http://dx.doi.org/10.1201/9781315205762-6

http://dx.doi.org/10.1201/9781315205762-...

). Additionally, minimal repair and maintenance, low energy consumption, material versatility, ease of operation, and reduced cost are some of the relevant operational criteria considered for drying equipment selection (Chua & Chou, 2003Chua, K. J., & Chou, S. K. (2003). Low-cost drying methods for developing countries. Trends in Food Science & Technology, 14(12), 519-528. http://dx.doi.org/10.1016/j.tifs.2003.07.003

http://dx.doi.org/10.1016/j.tifs.2003.07...

).

3 Drying technologies

The food industry relies on high-performance equipment to reach drying processes that yield high-quality dried foods. This equipment requires a high implementation cost which is only found in companies that present large investment capacity (Chua & Chou, 2003Chua, K. J., & Chou, S. K. (2003). Low-cost drying methods for developing countries. Trends in Food Science & Technology, 14(12), 519-528. http://dx.doi.org/10.1016/j.tifs.2003.07.003

http://dx.doi.org/10.1016/j.tifs.2003.07...

). Among the technologies applied, 85% of dryers used in the industry are conventional dryers that use hot air as a drying medium (Kluczek & Olszewski, 2017Kluczek, A., & Olszewski, P. (2017). Energy audits in industrial processes. Journal of Cleaner Production, 142, 3437-3453. http://dx.doi.org/10.1016/j.jclepro.2016.10.123

http://dx.doi.org/10.1016/j.jclepro.2016...

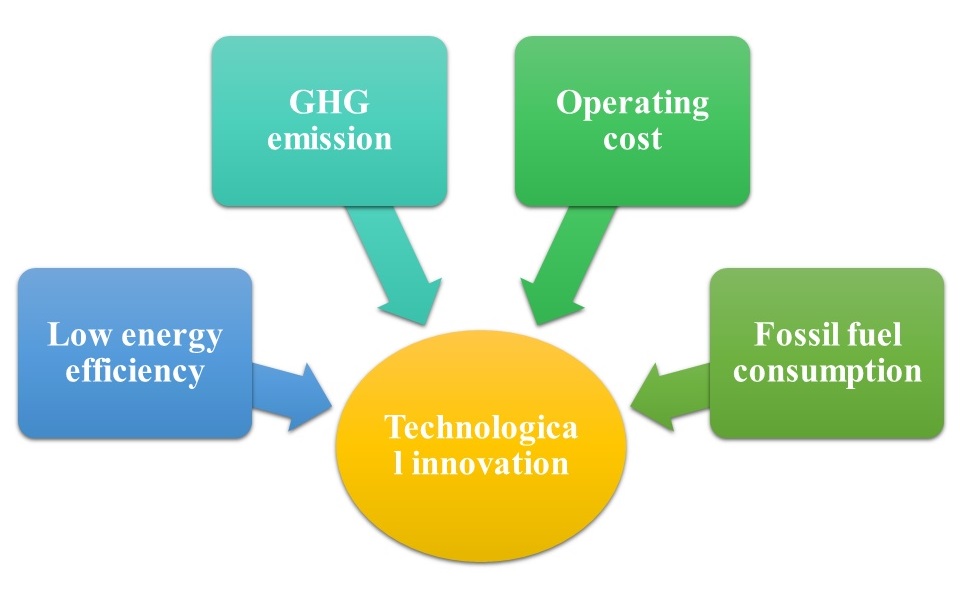

). These dryers account for 20% of energy consumption in the food production process, have low energy efficiency (about 30%) and contribute to 90% of the total costs in the production process. Figure 1 highlights some of the major issues that can be addressed with new drying technologies.

Consequently, new techniques are currently under development to improve drying efficiency, reduce costs and curb the use of fossil fuels in the process. Acar et al. (2020Acar, C., Dincer, I., & Mujumdar, A. (2020). A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Drying Technology, 1-27. http://dx.doi.org/10.1080/07373937.2020.1848858

http://dx.doi.org/10.1080/07373937.2020....

), conducted a broad study on the advances made in drying technologies. Among the techniques studied are adsorption-mediated drying, agitated thin film, electrotechnology, heat pump, microwave, ohmic-heating, RW, hybrid systems, impingement, rotating drum, superheated steam, and vacuum. With this analysis, the authors concluded that the selection of the best drying method was not a straightforward process with electricity consumption and cost varying immensely between processes. Moreover, inclinations to lower electricity consumption were found for processes that did not necessarily present the lower operational cost, bringing to light the need for the development of more efficient solutions that can combine advantageous conditions for all the operational requirements necessary.

Additionally, previous studies analyzing the RW, have demonstrated that the technique is a good alternative to more conventional technologies since it is overall cheaper, can be combined with renewable energy, and is energy efficient (Acar et al., 2020Acar, C., Dincer, I., & Mujumdar, A. (2020). A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Drying Technology, 1-27. http://dx.doi.org/10.1080/07373937.2020.1848858

http://dx.doi.org/10.1080/07373937.2020....

; Shende & Datta, 2019Shende, D., & Datta, A. K. (2019). Refractance window drying of fruits and vegetables: A review. Journal of the Science of Food and Agriculture, 99(4), 1449-1456. PMid:30207393. http://dx.doi.org/10.1002/jsfa.9356

http://dx.doi.org/10.1002/jsfa.9356...

).

3.1 Refractance Window (RW)

The RW is a relatively new process, considered a 4th generation technique (Vega-Mercado et al., 2001Vega-Mercado, H., Góngora-Nieto, M., & Barbosa-Cánovas, G. V. (2001). Advances in dehydration of foods. Journal of Food Engineering, 49(4), 271-289. http://dx.doi.org/10.1016/S0260-8774(00)00224-7

http://dx.doi.org/10.1016/S0260-8774(00)...

) which has been gaining relevance in the latest years (Acar et al., 2020Acar, C., Dincer, I., & Mujumdar, A. (2020). A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Drying Technology, 1-27. http://dx.doi.org/10.1080/07373937.2020.1848858

http://dx.doi.org/10.1080/07373937.2020....

; Calderón-Chiu et al., 2020Calderón-Chiu, C., Martínez-Sánchez, C. E., Rodríguez-Miranda, J., Juárez-Barrientos, J. M., Carmona-García, R., & Herman-Lara, E. (2020). Evaluation of the combined effect of osmotic and Refractance Window drying on the drying kinetics, physical, and phytochemical properties of beet. Drying Technology, 38(12), 1663-1675. http://dx.doi.org/10.1080/07373937.2019.1655439

http://dx.doi.org/10.1080/07373937.2019....

; Shende & Datta, 2020Shende, D., & Datta, A. K. (2020). Optimization study for refractance window drying process of Langra variety mango. Journal of Food Science and Technology, 57(2), 683-692. PMid:32116377. http://dx.doi.org/10.1007/s13197-019-04101-0

http://dx.doi.org/10.1007/s13197-019-041...

). RW is also referred to as conductive hydro-drying and is considered a form of Cast-Tape Dryer (CTD). CTD is applied to suspensions or viscous materials to transform them into flakes, films, or powders (Baeghbali et al., 2019Baeghbali, V., Niakousari, M., Ngadi, M. O., & Hadi Eskandari, M. (2019). Combined ultrasound and infrared assisted conductive hydro-drying of apple slices. Drying Technology, 37(14), 1793-1805. http://dx.doi.org/10.1080/07373937.2018.1539745

http://dx.doi.org/10.1080/07373937.2018....

; Frabetti et al., 2018Frabetti, A. C. C., Durigon, A., & Laurindo, J. B. (2018). Effect of process variables on the drying of guava pulp by cast-tape drying. LWT, 96, 620-626. http://dx.doi.org/10.1016/j.lwt.2018.06.021

http://dx.doi.org/10.1016/j.lwt.2018.06....

; Ortiz-Jerez & Ochoa-Martínez, 2015Ortiz-Jerez, M. J., & Ochoa-Martínez, C. I. (2015). Heat transfer mechanisms in conductive hydro-drying of pumpkin (Cucurbita maxima) pieces. Drying Technology, 33(8), 965-972. http://dx.doi.org/10.1080/07373937.2015.1009538

http://dx.doi.org/10.1080/07373937.2015....

). For the process, the material to be dried is arranged in thin layers on a transparent infrared conveyor belt (polyester film or fiberglass coated with TeflonTM) floating in overheated water or steam (heated to 98 °C) (Raghavi et al., 2018Raghavi, L. M., Moses, J. A., & Anandharamakrishnan, C. (2018). Refractance window drying of foods: A review. Journal of Food Engineering, 222, 267-275. http://dx.doi.org/10.1016/j.jfoodeng.2017.11.032

http://dx.doi.org/10.1016/j.jfoodeng.201...

). RW dryers keep the water in circulation being reheated so that the temperature is maintained throughout the process.

The thermal energy of the water is transferred through the plastic film (or fiberglass coated with TeflonTM) and radiated through the film to the material arranged on the conveyor. The vaporized water of the product is removed by an extractor present in the dryer. In this technique, there are three processes of heat transfer occurring simultaneously: conduction (between the plastic sheet and material), radiation (through the material), and convection (between material and air; and between the treadmill and water) (Bernaert et al., 2019Bernaert, N., van Droogenbroeck, B., van Pamel, E., & de Ruyck, H. (2019). Innovative refractance window drying technology to keep nutrient value during processing. Trends in Food Science & Technology, 84, 22-24. http://dx.doi.org/10.1016/j.tifs.2018.07.029

http://dx.doi.org/10.1016/j.tifs.2018.07...

; Durigon et al., 2016Durigon, A., de Souza, P. G., Carciofi, B. A. M., & Laurindo, J. B. (2016). Cast-tape drying of tomato juice for the production of powdered tomato. Food and Bioproducts Processing, 100, 145-155. http://dx.doi.org/10.1016/j.fbp.2016.06.019

http://dx.doi.org/10.1016/j.fbp.2016.06....

). Although three heat transfer mechanisms are occurring simultaneously, the thermal radiation emitted by the heating medium (hot water or water vapor) is responsible for only 5% of the amount of energy supplied to the material and can be neglected (Frabetti et al., 2018Frabetti, A. C. C., Durigon, A., & Laurindo, J. B. (2018). Effect of process variables on the drying of guava pulp by cast-tape drying. LWT, 96, 620-626. http://dx.doi.org/10.1016/j.lwt.2018.06.021

http://dx.doi.org/10.1016/j.lwt.2018.06....

; Zotarelli et al., 2015Zotarelli, M. F., Carciofi, B. A. M., & Laurindo, J. B. (2015). Effect of process variables on the drying rate of mango pulp by Refractance Window. Food Research International, 69, 410-417. http://dx.doi.org/10.1016/j.foodres.2015.01.013

http://dx.doi.org/10.1016/j.foodres.2015...

). Figure 2 shows an industrial RW dryer scheme.

Literature shows variations of the industrial equipment, that work under the same principle. The drying of pumpkin puree was investigated by commercial equipment and pilot equipment aiming to reduce microbial activity and energy efficiency of the process. In both, MylarTM plastic film was used with 0.2 mm thickness and water temperature of around 95 °C. In the pilot-scale equipment, the film was placed on hot water with dimensions 3 m × 0.6 m × 0.2 mm. On the industrial scale, the film had 12.9 m × 1.41 m × 0.2 mm in size. It was possible to reduce the moisture content from 80% to about 5% in less than 5 min. The energy efficiency of the commercial equipment varied between 50% and 70%. The analysis of the microbiological activity in the product obtained in pilot-scale equipment was satisfactory, with a reduction in detectable levels of coliforms, Escherichia coli, and Listeria innocua (Nindo et al., 2003Nindo, C. I., Feng, H., Shen, G. Q., Tang, J., & Kang, D. H. (2003). Energy utilization and microbial reduction in a new film drying system. Journal of Food Processing and Preservation, 27(2), 117-136. http://dx.doi.org/10.1111/j.1745-4549.2003.tb00506.x

http://dx.doi.org/10.1111/j.1745-4549.20...

).

Studies on the energy efficiency of different dryer technologies have already been carried out. Baeghbali et al. (2016)Baeghbali, V., Niakousari, M., & Farahnaky, A. (2016). Refractance Window drying of pomegranate juice: Quality retention and energy efficiency. Lebensmittel-Wissenschaft + Technologie, 66, 34-40. http://dx.doi.org/10.1016/j.lwt.2015.10.017

http://dx.doi.org/10.1016/j.lwt.2015.10....

studied quality and energy efficiency in the dehydration of pomegranate juice by different techniques (RW, freeze-dryer, and spray dryer). For the RW drying, the following configurations were followed: the water temperature was 91 °C; track speed 3.9 mm/s; and material thickness on the mat was 0.5 mm. For spray-drying: dryer with an internal diameter of 115 cm and height of 165 cm; and the pressure of 1 bar. The feed rate was 0.75 L/h and the feed temperature was 40 °C. The air inlet and outlet temperatures were around 140 °C and 75 °C, respectively. In the freeze-dryer, the operational conditions were the pressure of 3.0 kPa, the temperature of the heating plate at 20 °C, and the condenser temperature of -40 °C. The drying experiments were performed until moisture content in a wet base (wb) of 5.3%, 2.9%, and 8.5% was reached, for RW, spray dryer, and freeze-dryer, respectively. RW drying presented better results in energy consumption, energy efficiency, and lower CO2 emissions. Although the freeze-dryer is usually used as a standard technique for high-quality dry products, its energy efficiency is low, besides being an expensive process (Nindo & Tang, 2007Nindo, C. I., & Tang, J. (2007). Refractance Window dehydration technology: A novel contact drying method. Drying Technology, 25(1), 37-48. http://dx.doi.org/10.1080/07373930601152673

http://dx.doi.org/10.1080/07373930601152...

). While the drying by RW obtained 31.56% efficiency, for the freeze-dryer it was only 1.12%.

Leiton-Ramírez et al. (2020a)Leiton-Ramírez, Y. M., Ayala-Aponte, A., & Ochoa-Martínez, C. I. (2020a). Drying, is widely used in food industry. However, the high consumption of energy and use of electricity from non-renewable sources makes the process costly and environmentally aggravating. The refractance window (RW) technique uses heated water as a heat. Processes, 8(1), http://dx.doi.org/10.3390/pr8010106

http://dx.doi.org/10.3390/pr8010106...

evaluated moisture content, color, porosity, volume variation, water activity, carotenoids content, and vitamin C content after drying guava pulp by three different methods (freeze-drying, convection, and RW). As a result, RW required the shortest drying time (from 80% db to 4% db in 76 min) to reduce moisture contributing to greater overall color retention of the final product obtained. The freeze-drying and RW methods showed the highest retention of physical and nutritional characteristics compared to convection. Based on these results, the authors conclude that RW is a suitable technique for the development of guava snacks.

Regarding the drying of fruits and vegetables with RW, only 26 studies were found by the Web of Science tool in the last 10 years, studying: apple (Hernández et al., 2020Hernández, Y., Ramírez, C., Moreno, J., Núñez, H., Vega, O., Almonacid, S., Pinto, M., Fuentes, L., & Simpson, R. (2020). Effect of Refractance Window on dehydration of osmotically pretreated apple slices: Color and texture evaluation. Journal of Food Process Engineering, 43(2), http://dx.doi.org/10.1111/jfpe.13304

http://dx.doi.org/10.1111/jfpe.13304...

; Nascimento et al, 2020Nascimento, C. S., Rodrigues, A. M. da C., & da Silva, L. H. M. (2020). Development of a dehydrated product with edible film characteristics from mammee apple (Mammea americana L.) using Refractance Window drying. Food Science and Technology (Campinas), 40(1), 245-249. http://dx.doi.org/10.1590/fst.36218

http://dx.doi.org/10.1590/fst.36218...

; Rajoriya et al., 2019Rajoriya, D., Shewale, S. R., & Hebbar, H. U. (2019). Refractance Window drying of apple slices: Mass transfer phenomena and quality parameters. Food and Bioprocess Technology, 12(10), 1646-1658. http://dx.doi.org/10.1007/s11947-019-02334-7

http://dx.doi.org/10.1007/s11947-019-023...

, 2020Rajoriya, D., Shewale, S. R., Bhavya, M. L., & Hebbar, H. U. (2020). Far infrared assisted refractance window drying of apple slices: Comparative study on flavour, nutrient retention and drying characteristics. Innovative Food Science & Emerging Technologies, 66, 102530. http://dx.doi.org/10.1016/j.ifset.2020.102530

http://dx.doi.org/10.1016/j.ifset.2020.1...

); mango (Shende & Datta, 2020Shende, D., & Datta, A. K. (2020). Optimization study for refractance window drying process of Langra variety mango. Journal of Food Science and Technology, 57(2), 683-692. PMid:32116377. http://dx.doi.org/10.1007/s13197-019-04101-0

http://dx.doi.org/10.1007/s13197-019-041...

; Zotarelli et al., 2015Zotarelli, M. F., Carciofi, B. A. M., & Laurindo, J. B. (2015). Effect of process variables on the drying rate of mango pulp by Refractance Window. Food Research International, 69, 410-417. http://dx.doi.org/10.1016/j.foodres.2015.01.013

http://dx.doi.org/10.1016/j.foodres.2015...

); papaya (Minuye et al., 2021Minuye, M., Getachew, P., Laillou, A., Chitekwe, S., & Baye, K. (2021). Effects of different drying methods and ascorbic acid pretreatment on carotenoids and polyphenols of papaya fruit in Ethiopia. Food Science & Nutrition, 9(6), 3346-3353. PMid:34136199. http://dx.doi.org/10.1002/fsn3.2324

http://dx.doi.org/10.1002/fsn3.2324...

); yam (Santos et al., 2020Santos, S. J. L., Canto, H. K. F., Silva, L. H. M., & Rodrigues, A. M. C. (2020). Characterization and properties of purple yam (Dioscorea trifida) powder obtained by refractance window drying. Drying Technology, 1-11. http://dx.doi.org/10.1080/07373937.2020.1847140

http://dx.doi.org/10.1080/07373937.2020....

); beetroot (Preethi et al., 2020Preethi, R., Deotale, S. M., Moses, J. A., & Anandharamakrishnan, C. (2020). Conductive hydro drying of beetroot (Beta vulgaris L) pulp: Insights for natural food colorant applications. Journal of Food Process Engineering, 43(12), http://dx.doi.org/10.1111/jfpe.13557

http://dx.doi.org/10.1111/jfpe.13557...

); physalis (Puente-Díaz et al., 2020Puente-Díaz, L., Spolmann, O., Nocetti, D., Zura-Bravo, L., & Lemus-Mondaca, R. (2020). Effects of infrared-assisted refractance WindowTM drying on the drying kinetics, microstructure, and color of physalis fruit purée. Foods, 9(3), 343. PMid:32188035. http://dx.doi.org/10.3390/foods9030343

http://dx.doi.org/10.3390/foods9030343...

); sapota (Jalgaonkar et al., 2020Jalgaonkar, K., Mahawar, M. K., Vishwakarma, R. K., Shivhare, U. S., & Nambi, V. E. (2020). Optimization of process condition for preparation of sapota bar using Refractance window drying method. Drying Technology, 38(3), 269-278. http://dx.doi.org/10.1080/07373937.2018.1482314

http://dx.doi.org/10.1080/07373937.2018....

); pomegranate (Baeghbali et al., 2016Baeghbali, V., Niakousari, M., & Farahnaky, A. (2016). Refractance Window drying of pomegranate juice: Quality retention and energy efficiency. Lebensmittel-Wissenschaft + Technologie, 66, 34-40. http://dx.doi.org/10.1016/j.lwt.2015.10.017

http://dx.doi.org/10.1016/j.lwt.2015.10....

; Tontul & Topuz, 2019Tontul, I., & Topuz, A. (2019). Storage stability of bioactive compounds of pomegranate leather (pestil) produced by refractance window drying. Journal of Food Process Engineering, 42(2), e12973. http://dx.doi.org/10.1111/jfpe.12973

http://dx.doi.org/10.1111/jfpe.12973...

); pupunha, tucupi and mango (Costa et al., 2019Costa, R. D. S., de Cruz Rodrigues, A. M., Borges, J. L., & da Silva, L. H. M. (2019). Development of dehydrated products from peach palm-tucupi blends with edible film characteristics using refractive window. Journal of Food Science and Technology, 56(2), 560-570. PMid:30906013. http://dx.doi.org/10.1007/s13197-018-3454-x

http://dx.doi.org/10.1007/s13197-018-345...

); cherry, blueberry and strawberry (Nemzer et al., 2018Nemzer, B., Vargas, L., Xia, X., Sintara, M., & Feng, H. (2018). Phytochemical and physical properties of blueberries, tart cherries, strawberries, and cranberries as affected by different drying methods. Food Chemistry, 262, 242-250. PMid:29751916. http://dx.doi.org/10.1016/j.foodchem.2018.04.047

http://dx.doi.org/10.1016/j.foodchem.201...

; Tontul et al., 2018Tontul, I., Eroğlu, E., & Topuz, A. (2018). Convective and refractance window drying of cornelian cherry pulp: Effect on physicochemical properties. Journal of Food Process Engineering, 41(8), e12917. http://dx.doi.org/10.1111/jfpe.12917

http://dx.doi.org/10.1111/jfpe.12917...

); guava (Frabetti et al., 2018Frabetti, A. C. C., Durigon, A., & Laurindo, J. B. (2018). Effect of process variables on the drying of guava pulp by cast-tape drying. LWT, 96, 620-626. http://dx.doi.org/10.1016/j.lwt.2018.06.021

http://dx.doi.org/10.1016/j.lwt.2018.06....

; Leiton-Ramírez et al., 2020bLeiton-Ramírez, Y. M., Ayala-Aponte, A., & Ochoa-Martínez, C. I. (2020b). Physicochemical properties of guava snacks as affected by drying technology. Processes, 8(1), 106. http://dx.doi.org/10.3390/pr8010106

http://dx.doi.org/10.3390/pr8010106...

), and pumpkin (Ortiz & Ochoa-Martínez, 2018).

The application of RW in fruits and vegetable drying has several advantages such as low or zero cross-contamination, lower operating cost, lower temperatures requirements and energy consumption, conservation of bioactive contents (color, vitamins, and antioxidants), faster process, thermal efficiency, and mechanical simplicity (Acar et al., 2020Acar, C., Dincer, I., & Mujumdar, A. (2020). A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Drying Technology, 1-27. http://dx.doi.org/10.1080/07373937.2020.1848858

http://dx.doi.org/10.1080/07373937.2020....

; Baeghbali et al., 2016Baeghbali, V., Niakousari, M., & Farahnaky, A. (2016). Refractance Window drying of pomegranate juice: Quality retention and energy efficiency. Lebensmittel-Wissenschaft + Technologie, 66, 34-40. http://dx.doi.org/10.1016/j.lwt.2015.10.017

http://dx.doi.org/10.1016/j.lwt.2015.10....

; Moses et al., 2014Moses, J. A., Norton, T., Alagusundaram, K., & Tiwari, B. K. (2014). Novel drying techniques for the food industry. Food Engineering Reviews, 6(3), 43-55. http://dx.doi.org/10.1007/s12393-014-9078-7

http://dx.doi.org/10.1007/s12393-014-907...

; Nindo & Tang, 2007Nindo, C. I., & Tang, J. (2007). Refractance Window dehydration technology: A novel contact drying method. Drying Technology, 25(1), 37-48. http://dx.doi.org/10.1080/07373930601152673

http://dx.doi.org/10.1080/07373930601152...

).

Nevertheless, some disadvantages of RW are worthwhile noting among which are: low production capacity; and required cleaning of the treadmill before or after a new process. Also, when compared to drum drying and spray dryer the RW is more expensive, however, when compared to freeze-drying the cost reduction is significant (Acar et al., 2020Acar, C., Dincer, I., & Mujumdar, A. (2020). A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Drying Technology, 1-27. http://dx.doi.org/10.1080/07373937.2020.1848858

http://dx.doi.org/10.1080/07373937.2020....

). In addition, drying cannot be performed at higher temperatures (above 98 °C) and is not recommended for materials with a high sugar content (fructose and glucose) due to the adhesive behavior of the pulp resulting from the material's low glass transition temperature. In this case, it is necessary to choose the appropriate material to be dried or change the MylarTM film (usually used in RW) for another material with a low glass transition (Tg) temperature (such as fiberglass coated with TeflonTM) to ease the removal of the material from the belt. (Durigon et al., 2018Durigon, A., Parisotto, E. I. B., Carciofi, B. A. M., & Laurindo, J. B. (2018). Heat transfer and drying kinetics of tomato pulp processed by cast-tape drying. Drying Technology, 36(2), 160-168. http://dx.doi.org/10.1080/07373937.2017.1304411

http://dx.doi.org/10.1080/07373937.2017....

; Waghmare, 2021Waghmare, R. (2021). Refractance window drying: A cohort review on quality characteristics. Trends in Food Science & Technology, 110, 652-662. http://dx.doi.org/10.1016/j.tifs.2021.02.030

http://dx.doi.org/10.1016/j.tifs.2021.02...

).

3.1.1 Product quality obtained by RW

Fruits and vegetables are heat-sensitive foods and their quality properties (e.g. color, antioxidants content, and microbiological activity) are affected by dryers. Although the RW operates at temperatures above 90 °C, the heating is not applied directly to the food, in this case, the temperature reached by the food is lower than the temperature of the bath (70-85 °C) preventing the product from becoming brittle or losing the quality of the product. (Mat Desa et al., 2019Mat Desa, W. N., Mohammad, M., & Fudholi, A. (2019). Review of drying technology of fig. Trends in Food Science & Technology, 88, 93-103. http://dx.doi.org/10.1016/j.tifs.2019.03.018

http://dx.doi.org/10.1016/j.tifs.2019.03...

; Sehrawat et al., 2018Sehrawat, R., Babar, O. A., Kumar, A., & Nema, P. K. (2018). Recent trends in fruits and vegetables. In R. Sehrawat, K. A. Khan, M. R. Goyal & P. K. Paul (Eds.), Technological interventions in the processing of fruits and vegetables. Boca Raton: Apple Academic Press. http://dx.doi.org/10.1201/9781315205762-6

http://dx.doi.org/10.1201/9781315205762-...

; Waghmare, 2021Waghmare, R. (2021). Refractance window drying: A cohort review on quality characteristics. Trends in Food Science & Technology, 110, 652-662. http://dx.doi.org/10.1016/j.tifs.2021.02.030

http://dx.doi.org/10.1016/j.tifs.2021.02...

).

Regarding quality determining parameters (e.g. bioactive content and physicochemical properties) of the material dried by RW (Waghmare, 2021Waghmare, R. (2021). Refractance window drying: A cohort review on quality characteristics. Trends in Food Science & Technology, 110, 652-662. http://dx.doi.org/10.1016/j.tifs.2021.02.030

http://dx.doi.org/10.1016/j.tifs.2021.02...

), concluded that although there are studies on these impacts, there is still much to be explored. According to Celli et al. (2016)Celli, G. B., Khattab, R., Ghanem, A., & Brooks, M. S. (2016). Refractance WindowTM drying of haskap berry: Preliminary results on anthocyanin retention and physicochemical properties. Food Chemistry, 194, 218-221. PMid:26471547. http://dx.doi.org/10.1016/j.foodchem.2015.08.012

http://dx.doi.org/10.1016/j.foodchem.201...

, products dried by RW showed good retention of bioactive content, with above 90% of anthocyanins and vitamin C preserved. The ascorbic acid (vitamin C) is especially relevant because it is an unstable compound and it indicates the degradation of the remaining vitamins in the food, thus being directly correlated with the high quality of the dry product (Rajoriya et al., 2021Rajoriya, D., Bhavya, M. L., & Hebbar, H. U. (2021). Impact of process parameters on drying behaviour, mass transfer and quality profile of refractance window dried banana puree. LWT, 145, 111330. http://dx.doi.org/10.1016/j.lwt.2021.111330

http://dx.doi.org/10.1016/j.lwt.2021.111...

). In the study carried out by Tontul et al. (2018)Tontul, I., Eroğlu, E., & Topuz, A. (2018). Convective and refractance window drying of cornelian cherry pulp: Effect on physicochemical properties. Journal of Food Process Engineering, 41(8), e12917. http://dx.doi.org/10.1111/jfpe.12917

http://dx.doi.org/10.1111/jfpe.12917...

, it was possible to observe a higher concentration of vitamin C in the cherry pulp when drying by RW compared to convective drying (90% and 80%, respectively), thus confirming the positive effect on the conservation of the bioactive of the RW technique.

Literature has also presented a detailed analysis of the physicochemical properties obtained from RW drying. Particle size distribution, bulk density, particle density, porosity, moisture, morphology, color, total carotenoids content, glass transition temperature, and water sorption were analyzed by Zotarelli et al. (2017)Zotarelli, M. F., Silva, V. M., Durigon, A., Hubinger, M. D., & Laurindo, J. B. (2017). Production of mango powder by spray drying and cast-tape drying. Powder Technology, 305, 447-454. http://dx.doi.org/10.1016/j.powtec.2016.10.027

http://dx.doi.org/10.1016/j.powtec.2016....

in the production of mango powder with and without the addition of maltodextrin (viscosity reducing agent) by spray-drying and RW drying. According to the authors, due to the sticky characteristics of the mango pulp, it is important to add maltodextrin in the spray-dryer process, which was not required for RW. However, to produce the final powder it is necessary to adopt a grinding after the RW process when an irregular structure is obtained. The RW drying process resulted in powders with an apparent density of 0.8 g cm-3 and 0.7 g cm-3 (with and without maltodextrin, respectively) higher than those presented by the spray dryer (0.45 g cm-3, 0.5 g cm-3). The concentration of carotenoids was higher in the powder produced by spray-drying (113 μm of carotenoid g- 1 of dry mass). As for stability, the powder obtained by RW presented better conditions than the powder obtained by spray-drying. After all the analyzes the authors considered RW or CTD a suitable process in the production of mango powder. Table 2 summarizes the conditions and main quality results.

3.2 Hybrid technologies

The term “hybrid technology” is relatively new and is used in processes that use two or more drying methods or multiple heat transfer modes, to improve the efficiency of the system and ensure product quality, minimizing costs and possible environmental impacts (Menon et al., 2020Menon, A., Stojceska, V., & Tassou, S. A. (2020). A systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends in Food Science & Technology, 100, 67-76. http://dx.doi.org/10.1016/j.tifs.2020.03.014

http://dx.doi.org/10.1016/j.tifs.2020.03...

). The ideal concept of this combination of technologies is to minimize the negative effects of an isolated method. For example, although widely studied, convective dryers present several problems, such as prolonged process time, high energy consumption, and reduction in product quality (Politowicz et al., 2018Politowicz, J., Lech, K., Sánchez-Rodríguez, L., Figiel, A., Szumny, A., Grubor, M., & Carbonell-Barrachina, A. A. (2018). Volatile composition and sensory profile of oyster mushroom as affected by drying method. Drying Technology, 36(6), 685-696. http://dx.doi.org/10.1080/07373937.2016.1274903

http://dx.doi.org/10.1080/07373937.2016....

). Often, infrared is used to minimize such negative aspects in convective methods, to reverse the problems presented (Taghinezhad et al., 2021Taghinezhad, E., Kaveh, M., & Szumny, A. (2021). Optimization and prediction of the drying and quality of turnip slices by convective-infrared dryer under various pretreatments by RSM and ANFIS methods. Foods, 10(2), 284. PMid:33572543. http://dx.doi.org/10.3390/foods10020284

http://dx.doi.org/10.3390/foods10020284...

).

Andrade et al. (2019)Andrade, K. S., Prado, M. M., & Marques, L. G. (2019). Estudo da transferência de calor e massa na secagem infravermelho combinada com convecção forçada do resíduo da laranja. Brazilian Journal of Development, 5(10), 20199-20206. https://doi.org/10.34117/bjdv5n10-216.

https://doi.org/10.34117/bjdv5n10-216...

studied the effects of the combination of infrared and convective drying on the drying kinetics of orange residue. Tests were performed with and without air heating. With heating, an incandescent lamp (60 W) at full power was used. In the experiments, the heated air reached 49 and 42 °C, for velocities of 0.4 and 1.0 m/s, respectively. The infrared source temperatures were 80 and 100 °C. The authors showed that at 80 °C and 4 m/s it was possible to reduce the time needed to reach equilibrium moisture from 140 to 100 min. With the increase in speed to 1 m/s, there was a reduction in the drying time of 100 and 80 min without heated air and with heated air, respectively. The authors show that the heated air contributed to a higher temperature in the material during drying, increasing the rate of dehydration, and thus reducing the drying time. Additional studies developed by Taghinezhad et al. (2021)Taghinezhad, E., Kaveh, M., & Szumny, A. (2021). Optimization and prediction of the drying and quality of turnip slices by convective-infrared dryer under various pretreatments by RSM and ANFIS methods. Foods, 10(2), 284. PMid:33572543. http://dx.doi.org/10.3390/foods10020284

http://dx.doi.org/10.3390/foods10020284...

, used the combination of infrared convective drying for turnip dehydration. The authors concluded that adding the infrared drying to the process brought some improvements to the results obtained, mainly, in energy efficiency where an increase from 0.9 to 15.23% was noted.

Hybrid dryers allow you to increase efficiency and overcome disadvantages related to conventional hot air systems, such as lower product quality, low thermal/energy efficiency, and slow drying kinetics. (Fan et al., 2017Fan, K., Zhang, M., & Mujumdar, A. S. (2017). Application of airborne ultrasound in the convective drying of fruits and vegetables: A review. Ultrasonics Sonochemistry, 39, 47-57. PMid:28732971. http://dx.doi.org/10.1016/j.ultsonch.2017.04.001

http://dx.doi.org/10.1016/j.ultsonch.201...

; Menon et al., 2020Menon, A., Stojceska, V., & Tassou, S. A. (2020). A systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends in Food Science & Technology, 100, 67-76. http://dx.doi.org/10.1016/j.tifs.2020.03.014

http://dx.doi.org/10.1016/j.tifs.2020.03...

; Mohammed et al., 2020Mohammed, S., Fatumah, N., & Shadia, N. (2020). Drying performance and economic analysis of novel hybrid passive-mode and active-mode solar dryers for drying fruits in East Africa. Journal of Stored Products Research, 88, 101634. http://dx.doi.org/10.1016/j.jspr.2020.101634

http://dx.doi.org/10.1016/j.jspr.2020.10...

). A compilation of studies on hybrid methodologies can be seen in Table 3.

Calderón-Chiu et al. (2020)Calderón-Chiu, C., Martínez-Sánchez, C. E., Rodríguez-Miranda, J., Juárez-Barrientos, J. M., Carmona-García, R., & Herman-Lara, E. (2020). Evaluation of the combined effect of osmotic and Refractance Window drying on the drying kinetics, physical, and phytochemical properties of beet. Drying Technology, 38(12), 1663-1675. http://dx.doi.org/10.1080/07373937.2019.1655439

http://dx.doi.org/10.1080/07373937.2019....

analyzed the color, texture, total polyphenol content, total flavonoid content, and antioxidant capacity of beet dried by RW and Osmotic Dehydration (OD). OD was performed with 35, 50, and 65% of sucrose concentrations and temperatures of 30, 40, and 60 °C. The polyester film temperatures were maintained between 60 and 85 °C and beetroot was sliced into chips of 1 and 5 mm. RW-DO hybridization partially reduced moisture, reducing drying time for RW at 85 °C (100 and 40 min at 60 and 85 °C, respectively). According to the authors, hybridization provided a stable product while maintaining chemical and physical properties.

Another widely studied technique is the hybridization of solar dryers. Solar drying reduces operating costs and reduces greenhouse gas emissions (Roratto et al., 2021Roratto, T. B., Monteiro, R. L., Carciofi, B. A. M., & Laurindo, J. B. (2021). An innovative hybrid-solar-vacuum dryer to produce high-quality dried fruits and vegetables. LWT, 140, 110777. http://dx.doi.org/10.1016/j.lwt.2020.110777

http://dx.doi.org/10.1016/j.lwt.2020.110...

). Hybrid solar dryers use sun-radiated thermal energy, along with energy sources such as electricity, fossil fuels, or biomass to complete the supply of energy during periods where there is no solar incidence (Amjad et al., 2021Amjad, W., Waseem, M., Munir, A., Ghafoor, A., Asghar, F., & Gilani, G. A. (2021). Solar assisted dehydrator for decentralized controlled and homogeneous multi-product drying. Journal of Solar Energy Engineering, 143(1), 011011. http://dx.doi.org/10.1115/1.4047671

http://dx.doi.org/10.1115/1.4047671...

; Lakshmi et al., 2018Lakshmi, D. V. N., Muthukumar, P., Layek, A., & Nayak, P. K. (2018). Drying kinetics and quality analysis of black turmeric (Curcuma caesia) drying in a mixed mode forced convection solar dryer integrated with thermal energy storage. Renewable Energy, 120, 23-34. http://dx.doi.org/10.1016/j.renene.2017.12.053

http://dx.doi.org/10.1016/j.renene.2017....

).

Roratto et al. (2021)Roratto, T. B., Monteiro, R. L., Carciofi, B. A. M., & Laurindo, J. B. (2021). An innovative hybrid-solar-vacuum dryer to produce high-quality dried fruits and vegetables. LWT, 140, 110777. http://dx.doi.org/10.1016/j.lwt.2020.110777

http://dx.doi.org/10.1016/j.lwt.2020.110...

developed equipment that uses solar energy and operates under a vacuum. Vacuum drying reduces the temperature of the food and increases the drying rate, contributing to higher quality products compared to hot air drying. With this equipment, it is possible to dry 4 kg of food in 3-4 h. Slices of banana, persimmon, and carrot were dried as test samples for this study. The solar hybrid system contributed to supplying the necessary thermal energy for the drying process, as long as drying conditions are similar to those presented in this study are followed.

An Ultrasound and Infrared Assisted Conducted Hydro-Drying (UIACHD) was developed by Baeghbali et al. (2019)Baeghbali, V., Niakousari, M., Ngadi, M. O., & Hadi Eskandari, M. (2019). Combined ultrasound and infrared assisted conductive hydro-drying of apple slices. Drying Technology, 37(14), 1793-1805. http://dx.doi.org/10.1080/07373937.2018.1539745

http://dx.doi.org/10.1080/07373937.2018....

aiming to increase the drying rate, reduce the hot water temperature and increase the thickness of the drying material. The quality of the product (flavonoid content, total phenolic compounds, antioxidant activity, vitamin C content, and color), energy consumption, and energy efficiency were compared to freeze-dryer and cabinet dryers in the drying of apple slices (1, 2, and 3 mm). An ultrasound unit (1680 W) and two incandescent infrared lamps (250 W) were installed in the UIACHD on a pilot scale (2.65 m in length). The circulating water temperature was set at 85 °C. Studies carried out in these conditions show the positive effects of drying by UIACHD. In addition to physical-chemical parameters similar to the freeze-dryer and superior to the cabinet dryer. In this way, UIACHD proves to be good equipment to maintain product quality, in addition to reducing the use of energy in the drying process.

4 Future perspectives in RW drying

New technologies are currently being developed and they are expected to be cost-efficient, energy-efficient, and environmentally effective. Considering these expectations, renewable energies are seen as a viable solution to help reach such requirements. In this sense, alternatives for technological development in the drying field using processes integrated with renewable energies are still scarce. For example, there is only one paper in the literature that explores this integration. Seyfi et al. (2021)Seyfi, A., Rezaei Asl, A., & Motevali, A. (2021). Comparison of the energy and pollution parameters in solar refractance window (photovoltaic-thermal), conventional refractance window, and hot air dryer. Solar Energy, 229, 162-173. http://dx.doi.org/10.1016/j.solener.2021.05.094

http://dx.doi.org/10.1016/j.solener.2021...

showed that it was possible to combine a photovoltaic-thermal system that allows drying process improvements, such as zero GHG emissions. In the study, three methods were compared: Conventional RW (CRW); Solar RW (SRW); and a Hot Air dryer (HA). Four temperatures (60, 70, 80, and 90°C) and three thicknesses (1, 2, and 3 mm) were used for the dehydration of Aloe Vera pulp. According to the authors, there were no social costs due to the non-emission of pollutants in the SRW system. The results showed that the content of phenols in SRW/CRW dryers increased from 1.30 to 2.73 folds when compared to HA. Similar behavior was also noted for glucose (1.07 to 1.37 folds increase). In the SRW and CRW methods, energy efficiency and Drying Efficiency (DE) were increased with higher temperatures and lower thickness (the DE and EE in the SRW/CRW dryer increased by 1.50 to 2.54 and 1.59 to 2.65 folds compared to the HA dryer).

From this analysis, it was possible to conclude that there is a knowledge gap that needs to be addressed for studies of RW drying with the use of solar thermal energy as the heat source for the water heating in the RW process, or even hybrid, solar-electric heating. Waghmare (2021)Waghmare, R. (2021). Refractance window drying: A cohort review on quality characteristics. Trends in Food Science & Technology, 110, 652-662. http://dx.doi.org/10.1016/j.tifs.2021.02.030

http://dx.doi.org/10.1016/j.tifs.2021.02...

could explain that more research is required for further understanding of RW drying, for example, a hybrid solar-RW dryer can be analyzed, to produce an even more efficient dryer, with better quality parameters and that is more environmentally friendly. The use of renewable energies in hybrid systems is considered beneficial due to their continuous supply. Moreover, solar energy can be used in various ways and has significant participation in moisture removal when used in combination with other technologies (Anum et al., 2017Anum, R., Ghafoor, A., & Munir, A. (2017). Study of the drying behavior and performance evaluation of gas fired hybrid solar dryer. Journal of Food Process Engineering, 40(2), e12351. http://dx.doi.org/10.1111/jfpe.12351

http://dx.doi.org/10.1111/jfpe.12351...

; Roratto et al., 2021Roratto, T. B., Monteiro, R. L., Carciofi, B. A. M., & Laurindo, J. B. (2021). An innovative hybrid-solar-vacuum dryer to produce high-quality dried fruits and vegetables. LWT, 140, 110777. http://dx.doi.org/10.1016/j.lwt.2020.110777

http://dx.doi.org/10.1016/j.lwt.2020.110...

).

5 Final considerations

Drying is an extremely important unit operation of the food industry. Through it, it is possible to keep quality products out of the harvest season, especially in the case of fruits, vegetables, and greens, as they are highly perishable and cause great waste. However, unfortunately, the consumption of electricity by dryers in the food industry is excessive, making the process expensive, energy inefficient, and environmentally damaging. New technologies are being developed and/or improved to overcome the presented problems. In this sense, RW has proven to be an important part of the possible solutions being analyzed. It is a cheap technique compared to traditional techniques such as spray-drying, hot air, and freeze-drying (Acar et al., 2020Acar, C., Dincer, I., & Mujumdar, A. (2020). A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Drying Technology, 1-27. http://dx.doi.org/10.1080/07373937.2020.1848858

http://dx.doi.org/10.1080/07373937.2020....

; Celli et al., 2016Celli, G. B., Khattab, R., Ghanem, A., & Brooks, M. S. (2016). Refractance WindowTM drying of haskap berry: Preliminary results on anthocyanin retention and physicochemical properties. Food Chemistry, 194, 218-221. PMid:26471547. http://dx.doi.org/10.1016/j.foodchem.2015.08.012

http://dx.doi.org/10.1016/j.foodchem.201...

), which is used as a quality standard in dehydrated products. Moreover, it is energy efficient and, if combined with renewable energy, such as solar, can be environmentally friendly. In short, the exchange of fossil fuels for renewable sources in industries still needs to be more thoroughly studied and this important knowledge gap should be addressed to improve drying processes and enable a net-zero transition in this industrial sector.

Acknowledgments

This work was carried out with the support of the Coordination for the Improvement of Higher Education Personnel - Brazil (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES)) - Financing Code 001.

-

Cite as: Santos, V. C. S., Souza, R. L., Figueiredo, R. T., & Alsina, O. L. S. (2022). A review on refractance window drying process of fruits and vegetables: its integration with renewable energies. Brazilian Journal of Food Technology, 25, e2021153.

-

Funding: Coordination for the Improvement of Higher Education Personnel - Brazil (CAPES) - Financing Code 001.

References

- Acar, C., Dincer, I., & Mujumdar, A. (2020). A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Drying Technology, 1-27. http://dx.doi.org/10.1080/07373937.2020.1848858

» http://dx.doi.org/10.1080/07373937.2020.1848858 - Alasalvar, C., Salvadó, J. S., & Ros, E. (2020). Bioactives and health benefits of nuts and dried fruits. Food Chemistry, 314, 126192. PMid:31958750. http://dx.doi.org/10.1016/j.foodchem.2020.126192

» http://dx.doi.org/10.1016/j.foodchem.2020.126192 - Al‐Hilphy, A. R., Ali, H. I., Al‐IEssa, S. A., Lorenzo, J. M., Barba, F. J., & Gavahian, M. (2020). Optimization of process variables on physicochemical properties of milk during an innovative refractance window concentration. Journal of Food Processing and Preservation, 44(10), http://dx.doi.org/10.1111/jfpp.14782

» http://dx.doi.org/10.1111/jfpp.14782 - Amjad, W., Waseem, M., Munir, A., Ghafoor, A., Asghar, F., & Gilani, G. A. (2021). Solar assisted dehydrator for decentralized controlled and homogeneous multi-product drying. Journal of Solar Energy Engineering, 143(1), 011011. http://dx.doi.org/10.1115/1.4047671

» http://dx.doi.org/10.1115/1.4047671 - Andrade, K. S., Prado, M. M., & Marques, L. G. (2019). Estudo da transferência de calor e massa na secagem infravermelho combinada com convecção forçada do resíduo da laranja. Brazilian Journal of Development, 5(10), 20199-20206. https://doi.org/10.34117/bjdv5n10-216

» https://doi.org/10.34117/bjdv5n10-216 - Anum, R., Ghafoor, A., & Munir, A. (2017). Study of the drying behavior and performance evaluation of gas fired hybrid solar dryer. Journal of Food Process Engineering, 40(2), e12351. http://dx.doi.org/10.1111/jfpe.12351

» http://dx.doi.org/10.1111/jfpe.12351 - Azam, R. S. M., Zhang, M., Law, C. L., & Mujumdar, A. S. (2019). Effects of drying methods on quality attributes of peach (Prunus persica) leather. Drying Technology, 37(3), 341-351. http://dx.doi.org/10.1080/07373937.2018.1454942

» http://dx.doi.org/10.1080/07373937.2018.1454942 - Azizi, D., Jafari, S. M., Mirzaei, H., & Dehnad, D. (2017). The influence of refractance window drying on qualitative properties of kiwifruit slices. International Journal of Food Engineering, 13(2), http://dx.doi.org/10.1515/ijfe-2016-0201

» http://dx.doi.org/10.1515/ijfe-2016-0201 - Baeghbali, V., Niakousari, M., & Farahnaky, A. (2016). Refractance Window drying of pomegranate juice: Quality retention and energy efficiency. Lebensmittel-Wissenschaft + Technologie, 66, 34-40. http://dx.doi.org/10.1016/j.lwt.2015.10.017

» http://dx.doi.org/10.1016/j.lwt.2015.10.017 - Baeghbali, V., Niakousari, M., Ngadi, M. O., & Hadi Eskandari, M. (2019). Combined ultrasound and infrared assisted conductive hydro-drying of apple slices. Drying Technology, 37(14), 1793-1805. http://dx.doi.org/10.1080/07373937.2018.1539745

» http://dx.doi.org/10.1080/07373937.2018.1539745 - Bernaert, N., van Droogenbroeck, B., van Pamel, E., & de Ruyck, H. (2019). Innovative refractance window drying technology to keep nutrient value during processing. Trends in Food Science & Technology, 84, 22-24. http://dx.doi.org/10.1016/j.tifs.2018.07.029

» http://dx.doi.org/10.1016/j.tifs.2018.07.029 - Calderón-Chiu, C., Martínez-Sánchez, C. E., Rodríguez-Miranda, J., Juárez-Barrientos, J. M., Carmona-García, R., & Herman-Lara, E. (2020). Evaluation of the combined effect of osmotic and Refractance Window drying on the drying kinetics, physical, and phytochemical properties of beet. Drying Technology, 38(12), 1663-1675. http://dx.doi.org/10.1080/07373937.2019.1655439

» http://dx.doi.org/10.1080/07373937.2019.1655439 - Celli, G. B., Khattab, R., Ghanem, A., & Brooks, M. S. (2016). Refractance WindowTM drying of haskap berry: Preliminary results on anthocyanin retention and physicochemical properties. Food Chemistry, 194, 218-221. PMid:26471547. http://dx.doi.org/10.1016/j.foodchem.2015.08.012

» http://dx.doi.org/10.1016/j.foodchem.2015.08.012 - Chang, S. K., Alasalvar, C., & Shahidi, F. (2016). Review of dried fruits: Phytochemicals, antioxidant efficacies, and health benefits. Journal of Functional Foods, 21, 113-132. http://dx.doi.org/10.1016/j.jff.2015.11.034

» http://dx.doi.org/10.1016/j.jff.2015.11.034 - Chen, J., Zhang, M., Xu, B., Sun, J., & Mujumdar, A. S. (2020). Artificial intelligence assisted technologies for controlling the drying of fruits and vegetables using physical fields: A review. Trends in Food Science & Technology, 105, 251-260. http://dx.doi.org/10.1016/j.tifs.2020.08.015

» http://dx.doi.org/10.1016/j.tifs.2020.08.015 - Chua, K. J., & Chou, S. K. (2003). Low-cost drying methods for developing countries. Trends in Food Science & Technology, 14(12), 519-528. http://dx.doi.org/10.1016/j.tifs.2003.07.003

» http://dx.doi.org/10.1016/j.tifs.2003.07.003 - Costa, R. D. S., de Cruz Rodrigues, A. M., Borges, J. L., & da Silva, L. H. M. (2019). Development of dehydrated products from peach palm-tucupi blends with edible film characteristics using refractive window. Journal of Food Science and Technology, 56(2), 560-570. PMid:30906013. http://dx.doi.org/10.1007/s13197-018-3454-x

» http://dx.doi.org/10.1007/s13197-018-3454-x - Deng, Z., Li, M., Xing, T., Zhang, J., Wang, Y., & Zhang, Y. (2021). A literature research on the drying quality of agricultural products with using solar drying technologies. Solar Energy, 229, 69-83. http://dx.doi.org/10.1016/j.solener.2021.07.041

» http://dx.doi.org/10.1016/j.solener.2021.07.041 - Durigon, A., de Souza, P. G., Carciofi, B. A. M., & Laurindo, J. B. (2016). Cast-tape drying of tomato juice for the production of powdered tomato. Food and Bioproducts Processing, 100, 145-155. http://dx.doi.org/10.1016/j.fbp.2016.06.019

» http://dx.doi.org/10.1016/j.fbp.2016.06.019 - Durigon, A., Parisotto, E. I. B., Carciofi, B. A. M., & Laurindo, J. B. (2018). Heat transfer and drying kinetics of tomato pulp processed by cast-tape drying. Drying Technology, 36(2), 160-168. http://dx.doi.org/10.1080/07373937.2017.1304411

» http://dx.doi.org/10.1080/07373937.2017.1304411 - Eltawil, M. A., Azam, M. M., & Alghannam, A. O. (2018). Energy analysis of hybrid solar tunnel dryer with PV system and solar collector for drying mint (MenthaViridis). Journal of Cleaner Production, 181, 352-364. http://dx.doi.org/10.1016/j.jclepro.2018.01.229

» http://dx.doi.org/10.1016/j.jclepro.2018.01.229 - Empresa de Pesquisa Energética – EPE. (2021). Balanço Nacional Energético (BEN) 2021: Ano Base 2020. Retrieved in 2021, October 4, from https://www.epe.gov.br/pt/publicacoes-dados-abertos/publicacoes/balanco-energetico-nacional-2021

» https://www.epe.gov.br/pt/publicacoes-dados-abertos/publicacoes/balanco-energetico-nacional-2021 - Fan, K., Zhang, M., & Mujumdar, A. S. (2017). Application of airborne ultrasound in the convective drying of fruits and vegetables: A review. Ultrasonics Sonochemistry, 39, 47-57. PMid:28732971. http://dx.doi.org/10.1016/j.ultsonch.2017.04.001

» http://dx.doi.org/10.1016/j.ultsonch.2017.04.001 - Frabetti, A. C. C., Durigon, A., & Laurindo, J. B. (2018). Effect of process variables on the drying of guava pulp by cast-tape drying. LWT, 96, 620-626. http://dx.doi.org/10.1016/j.lwt.2018.06.021

» http://dx.doi.org/10.1016/j.lwt.2018.06.021 - Franco, S., Jaques, A., Pinto, M., Fardella, M., Valencia, P., Núñez, H., Ramírez, C., & Simpson, R. (2019). Dehydration of salmon (Atlantic salmon), beef, and apple (Granny Smith) using Refractance windowTM: Effect on diffusion behavior, texture, and color changes. Innovative Food Science & Emerging Technologies, 52, 8-16. http://dx.doi.org/10.1016/j.ifset.2018.12.001

» http://dx.doi.org/10.1016/j.ifset.2018.12.001 - Hernández, Y., Ramírez, C., Moreno, J., Núñez, H., Vega, O., Almonacid, S., Pinto, M., Fuentes, L., & Simpson, R. (2020). Effect of Refractance Window on dehydration of osmotically pretreated apple slices: Color and texture evaluation. Journal of Food Process Engineering, 43(2), http://dx.doi.org/10.1111/jfpe.13304

» http://dx.doi.org/10.1111/jfpe.13304 - Hernández-Alonso, P., Camacho-Barcia, L., Bulló, M., & Salas-Salvadó, J. (2017). Nuts and dried fruits: An update of their beneficial effects on type 2 diabetes. Nutrients, 9(7), 673. PMid:28657613. http://dx.doi.org/10.3390/nu9070673

» http://dx.doi.org/10.3390/nu9070673 - Horuz, E., Bozkurt, H., Karataş, H., & Maskan, M. (2017). Effects of hybrid (microwave-convectional) and convectional drying on drying kinetics, total phenolics, antioxidant capacity, vitamin C, color and rehydration capacity of sour cherries. Food Chemistry, 230, 295-305. PMid:28407914. http://dx.doi.org/10.1016/j.foodchem.2017.03.046

» http://dx.doi.org/10.1016/j.foodchem.2017.03.046 - Jalgaonkar, K., Mahawar, M. K., Vishwakarma, R. K., Shivhare, U. S., & Nambi, V. E. (2020). Optimization of process condition for preparation of sapota bar using Refractance window drying method. Drying Technology, 38(3), 269-278. http://dx.doi.org/10.1080/07373937.2018.1482314

» http://dx.doi.org/10.1080/07373937.2018.1482314 - Kluczek, A., & Olszewski, P. (2017). Energy audits in industrial processes. Journal of Cleaner Production, 142, 3437-3453. http://dx.doi.org/10.1016/j.jclepro.2016.10.123

» http://dx.doi.org/10.1016/j.jclepro.2016.10.123 - Lakshmi, D. V. N., Muthukumar, P., Layek, A., & Nayak, P. K. (2018). Drying kinetics and quality analysis of black turmeric (Curcuma caesia) drying in a mixed mode forced convection solar dryer integrated with thermal energy storage. Renewable Energy, 120, 23-34. http://dx.doi.org/10.1016/j.renene.2017.12.053

» http://dx.doi.org/10.1016/j.renene.2017.12.053 - Leiton-Ramírez, Y. M., Ayala-Aponte, A., & Ochoa-Martínez, C. I. (2020a). Drying, is widely used in food industry. However, the high consumption of energy and use of electricity from non-renewable sources makes the process costly and environmentally aggravating. The refractance window (RW) technique uses heated water as a heat. Processes, 8(1), http://dx.doi.org/10.3390/pr8010106

» http://dx.doi.org/10.3390/pr8010106 - Leiton-Ramírez, Y. M., Ayala-Aponte, A., & Ochoa-Martínez, C. I. (2020b). Physicochemical properties of guava snacks as affected by drying technology. Processes, 8(1), 106. http://dx.doi.org/10.3390/pr8010106

» http://dx.doi.org/10.3390/pr8010106 - Managa, M. G., Sultanbawa, Y., & Sivakumar, D. (2020). Effects of different drying methods on untargeted phenolic metabolites, and antioxidant activity in Chinese cabbage (Brassica rapa L. subsp. chinensis) and Nightshade (Solanum retroflexum Dun.). Molecules, 25(6), 1326. PMid:32183223. http://dx.doi.org/10.3390/molecules25061326

» http://dx.doi.org/10.3390/molecules25061326 - Mat Desa, W. N., Mohammad, M., & Fudholi, A. (2019). Review of drying technology of fig. Trends in Food Science & Technology, 88, 93-103. http://dx.doi.org/10.1016/j.tifs.2019.03.018

» http://dx.doi.org/10.1016/j.tifs.2019.03.018 - Menon, A., Stojceska, V., & Tassou, S. A. (2020). A systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends in Food Science & Technology, 100, 67-76. http://dx.doi.org/10.1016/j.tifs.2020.03.014

» http://dx.doi.org/10.1016/j.tifs.2020.03.014 - Minuye, M., Getachew, P., Laillou, A., Chitekwe, S., & Baye, K. (2021). Effects of different drying methods and ascorbic acid pretreatment on carotenoids and polyphenols of papaya fruit in Ethiopia. Food Science & Nutrition, 9(6), 3346-3353. PMid:34136199. http://dx.doi.org/10.1002/fsn3.2324

» http://dx.doi.org/10.1002/fsn3.2324 - Mohammed, S., Fatumah, N., & Shadia, N. (2020). Drying performance and economic analysis of novel hybrid passive-mode and active-mode solar dryers for drying fruits in East Africa. Journal of Stored Products Research, 88, 101634. http://dx.doi.org/10.1016/j.jspr.2020.101634

» http://dx.doi.org/10.1016/j.jspr.2020.101634 - Monteiro, R. L., Link, J. V., Tribuzi, G., Carciofi, B. A. M., & Laurindo, J. B. (2018). Microwave vacuum drying and multi-flash drying of pumpkin slices. Journal of Food Engineering, 232, 1-10. http://dx.doi.org/10.1016/j.jfoodeng.2018.03.015

» http://dx.doi.org/10.1016/j.jfoodeng.2018.03.015 - Moses, J. A., Norton, T., Alagusundaram, K., & Tiwari, B. K. (2014). Novel drying techniques for the food industry. Food Engineering Reviews, 6(3), 43-55. http://dx.doi.org/10.1007/s12393-014-9078-7

» http://dx.doi.org/10.1007/s12393-014-9078-7 - Mourshed, M., Masud, M. H., Rashid, F., & Joardder, M. U. H. (2017). Towards the effective plastic waste management in Bangladesh: A review. Environmental Science and Pollution Research International, 24(35), 27021-27046. PMid:29079979. http://dx.doi.org/10.1007/s11356-017-0429-9

» http://dx.doi.org/10.1007/s11356-017-0429-9 - Nascimento, C. S., Rodrigues, A. M. da C., & da Silva, L. H. M. (2020). Development of a dehydrated product with edible film characteristics from mammee apple (Mammea americana L.) using Refractance Window drying. Food Science and Technology (Campinas), 40(1), 245-249. http://dx.doi.org/10.1590/fst.36218

» http://dx.doi.org/10.1590/fst.36218 - Nayak, B., Berrios, J. D. J., Powers, J. R., Tang, J., & Ji, Y. (2011). Colored potatoes (Solanum tuberosum L.) dried for antioxidant-rich value-added foods. Journal of Food Processing and Preservation, 35(5), 571-580. http://dx.doi.org/10.1111/j.1745-4549.2010.00502.x

» http://dx.doi.org/10.1111/j.1745-4549.2010.00502.x - Nemzer, B., Vargas, L., Xia, X., Sintara, M., & Feng, H. (2018). Phytochemical and physical properties of blueberries, tart cherries, strawberries, and cranberries as affected by different drying methods. Food Chemistry, 262, 242-250. PMid:29751916. http://dx.doi.org/10.1016/j.foodchem.2018.04.047

» http://dx.doi.org/10.1016/j.foodchem.2018.04.047 - Nindo, C. I., & Tang, J. (2007). Refractance Window dehydration technology: A novel contact drying method. Drying Technology, 25(1), 37-48. http://dx.doi.org/10.1080/07373930601152673

» http://dx.doi.org/10.1080/07373930601152673 - Nindo, C. I., Feng, H., Shen, G. Q., Tang, J., & Kang, D. H. (2003). Energy utilization and microbial reduction in a new film drying system. Journal of Food Processing and Preservation, 27(2), 117-136. http://dx.doi.org/10.1111/j.1745-4549.2003.tb00506.x

» http://dx.doi.org/10.1111/j.1745-4549.2003.tb00506.x - Ochoa-Martínez, C. I., Quintero, P. T., Ayala, A. A., & Ortiz, M. J. (2012). Drying characteristics of mango slices using the Refractance WindowTM technique. Journal of Food Engineering, 109(1), 69-75. https://doi.org/10.1016/j.jfoodeng.2011.09.032

» https://doi.org/10.1016/j.jfoodeng.2011.09.032 - Onwude, D. I., Iranshahi, K., Rubinetti, D., Schudel, S., Schemminger, J., Martynenko, A., & Defraeye, T. (2022). How much do process parameters affect the residual quality attributes of dried fruits and vegetables for convective drying? Food and Bioproducts Processing, 131, 176-190. http://dx.doi.org/10.1016/j.fbp.2021.11.005

» http://dx.doi.org/10.1016/j.fbp.2021.11.005 - Ortiz, M. J., & Ochoa Martínez, C. I. (2018). Efecto de las condiciones del hidrosecado sobre el encogimiento de trozos de zapallo (Cucurbita maxima). Ingenieria y Competitividad, 20(2), 37. http://dx.doi.org/10.25100/iyc.v20i2.5809

» http://dx.doi.org/10.25100/iyc.v20i2.5809 - Ortiz-Jerez, M. J., & Ochoa-Martínez, C. I. (2015). Heat transfer mechanisms in conductive hydro-drying of pumpkin (Cucurbita maxima) pieces. Drying Technology, 33(8), 965-972. http://dx.doi.org/10.1080/07373937.2015.1009538

» http://dx.doi.org/10.1080/07373937.2015.1009538 - Ortiz-Jerez, M. J., Gulati, T., Datta, A. K., & Ochoa-Martínez, C. I. (2015). Quantitative understanding of Refractance WindowTM drying. Food and Bioproducts Processing, 95, 237-253. http://dx.doi.org/10.1016/j.fbp.2015.05.010

» http://dx.doi.org/10.1016/j.fbp.2015.05.010 - Politowicz, J., Lech, K., Sánchez-Rodríguez, L., Figiel, A., Szumny, A., Grubor, M., & Carbonell-Barrachina, A. A. (2018). Volatile composition and sensory profile of oyster mushroom as affected by drying method. Drying Technology, 36(6), 685-696. http://dx.doi.org/10.1080/07373937.2016.1274903

» http://dx.doi.org/10.1080/07373937.2016.1274903 - Preethi, R., Deotale, S. M., Moses, J. A., & Anandharamakrishnan, C. (2020). Conductive hydro drying of beetroot (Beta vulgaris L) pulp: Insights for natural food colorant applications. Journal of Food Process Engineering, 43(12), http://dx.doi.org/10.1111/jfpe.13557

» http://dx.doi.org/10.1111/jfpe.13557 - Prosapio, V., & Norton, I. (2018). Simultaneous application of ultrasounds and firming agents to improve the quality properties of osmotic + freeze-dried foods. LWT, 96, 402-410. http://dx.doi.org/10.1016/j.lwt.2018.05.068

» http://dx.doi.org/10.1016/j.lwt.2018.05.068 - Puente-Díaz, L., Spolmann, O., Nocetti, D., Zura-Bravo, L., & Lemus-Mondaca, R. (2020). Effects of infrared-assisted refractance WindowTM drying on the drying kinetics, microstructure, and color of physalis fruit purée. Foods, 9(3), 343. PMid:32188035. http://dx.doi.org/10.3390/foods9030343

» http://dx.doi.org/10.3390/foods9030343 - Qiu, J., Acharya, P., Jacobs, D. M., Boom, R. M., & Schutyser, M. A. I. (2019). A systematic analysis on tomato powder quality prepared by four conductive drying technologies. Innovative Food Science & Emerging Technologies, 54, 103-112. http://dx.doi.org/10.1016/j.ifset.2019.03.013

» http://dx.doi.org/10.1016/j.ifset.2019.03.013 - Raghavi, L. M., Moses, J. A., & Anandharamakrishnan, C. (2018). Refractance window drying of foods: A review. Journal of Food Engineering, 222, 267-275. http://dx.doi.org/10.1016/j.jfoodeng.2017.11.032

» http://dx.doi.org/10.1016/j.jfoodeng.2017.11.032 - Rajoriya, D., Bhavya, M. L., & Hebbar, H. U. (2021). Impact of process parameters on drying behaviour, mass transfer and quality profile of refractance window dried banana puree. LWT, 145, 111330. http://dx.doi.org/10.1016/j.lwt.2021.111330

» http://dx.doi.org/10.1016/j.lwt.2021.111330 - Rajoriya, D., Shewale, S. R., & Hebbar, H. U. (2019). Refractance Window drying of apple slices: Mass transfer phenomena and quality parameters. Food and Bioprocess Technology, 12(10), 1646-1658. http://dx.doi.org/10.1007/s11947-019-02334-7

» http://dx.doi.org/10.1007/s11947-019-02334-7 - Rajoriya, D., Shewale, S. R., Bhavya, M. L., & Hebbar, H. U. (2020). Far infrared assisted refractance window drying of apple slices: Comparative study on flavour, nutrient retention and drying characteristics. Innovative Food Science & Emerging Technologies, 66, 102530. http://dx.doi.org/10.1016/j.ifset.2020.102530

» http://dx.doi.org/10.1016/j.ifset.2020.102530 - Rodrigues, J. J., Lima, M. E. P., Alves, K. A., Pacheco, T. H., Cunha, G. L. N., Jovelino, J. R., & Silva, A. S. (2021). Análise cinética de secagem solar em amostras de batata doce. Brazilian Journal of Development, 7(4), 43122-43130. http://dx.doi.org/10.34117/bjdv7n4-668

» http://dx.doi.org/10.34117/bjdv7n4-668 - Roratto, T. B., Monteiro, R. L., Carciofi, B. A. M., & Laurindo, J. B. (2021). An innovative hybrid-solar-vacuum dryer to produce high-quality dried fruits and vegetables. LWT, 140, 110777. http://dx.doi.org/10.1016/j.lwt.2020.110777

» http://dx.doi.org/10.1016/j.lwt.2020.110777 - Santos, S. J. L., Canto, H. K. F., Silva, L. H. M., & Rodrigues, A. M. C. (2020). Characterization and properties of purple yam (Dioscorea trifida) powder obtained by refractance window drying. Drying Technology, 1-11. http://dx.doi.org/10.1080/07373937.2020.1847140

» http://dx.doi.org/10.1080/07373937.2020.1847140 - Sehrawat, R., Babar, O. A., Kumar, A., & Nema, P. K. (2018). Recent trends in fruits and vegetables. In R. Sehrawat, K. A. Khan, M. R. Goyal & P. K. Paul (Eds.), Technological interventions in the processing of fruits and vegetables Boca Raton: Apple Academic Press. http://dx.doi.org/10.1201/9781315205762-6