ABSTRACT

Due to the complex distribution of greenhouse seedbeds and the limited area of greenhouses, the accuracy of the positioning of modular planting of crops is required to be high. Moreover, modern greenhouses are mostly vertical planting structures. Most of the existing positioning modes only support plane positioning, and cannot determine the specific position of the seedbed in space through three-dimensional space positioning. In order to spray pesticides on various crops planted vertically in a modern greenhouse, a greenhouse fixed-point spraying system based on Ultra-Wideband (UWB) indoor positioning was designed. The system uses UWB indoor positioning technology to cope with the complex environments in modern greenhouses. Four base stations and one label are used to obtain the position coordinates of vertically planted crops. This information is processed through an embedded kernel, and then the upper computer sends instructions remotely. The motor drives a screw to rotate and move the nozzle to the location of the crop to complete the pesticide spraying. Experiments show that the real-time accuracy in the coordinates collected by this system is below 10 cm, which makes fixed-point spraying feasible in a modern greenhouse.

UWB; indoor positioning; location awareness; greenhouse spraying; wireless communication

INTRIDUCTION

With the rapid development of facility agriculture, the number and area of greenhouses have soared, and the demand for intelligent and automated greenhouse machinery has increased rapidly. Unmanned operation has become the direction for the future development of greenhouse machinery.

At present, a global positioning system (GPS) and the beidou navigation satellite system (BDS) can provide accurate and real-time positioning information such as longitude and latitude for ground users, and are widely used for positioning agricultural machinery (Hegarty, 2017; Farahsari et al., 2022). However, in greenhouses, traditional positioning systems such as GPS do not work well:they have low accuracy and are unable to fulfill the positioning requirements. As a popular indoor positioning technology in recent years, ultra-wideband technology has become ideal for indoor positioning due to its centimeter-level accuracy and convenience of configuration (You et al., 2020).

Different positioning algorithms are needed for different indoor scenarios. At present, the UWB positioning algorithm is often used in indoor positioning systems (Wang et al., 2021). The UWB positioning system can provide high-precision positioning for multiple points at the same time and achieve long-term, high-precision indoor positioning, which can be applied in many real-world scenarios (Tian & Xiang, 2020; Long et al., 2021; Elsanhoury et al., 2022; Sung et al., 2023). At present, most of the research on UWB positioning seeks to improve its accuracy by correcting the measurement error due to the influence of NLOS, and some of them incorporate machine learning and deep learning to improve its performance (Cheng et al., 2020; Yang et al., 2021; Yang et al., 2022; Peng et al., 2022; Wang et al., 2023).

In order to economize on planting area and improve the efficiency and quality of production, modern greenhouses mostly adopt vertical planting. In vertical planting systems, the plants are densely planted in vertical structures, which makes spraying relatively difficult. Therefore, this paper designs a greenhouse fixed-point spraying system which can effectively resolve the difficulties of spraying in a greenhouse. The system is simple to operate, controllable and will not occupy the effective planting space of the greenhouse, so it maximizes the economic benefits of greenhouse and realizes an automatic operation of greenhouse fixed-point spraying.

MATERIALS AND METHODS

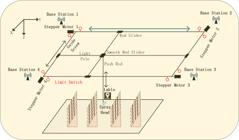

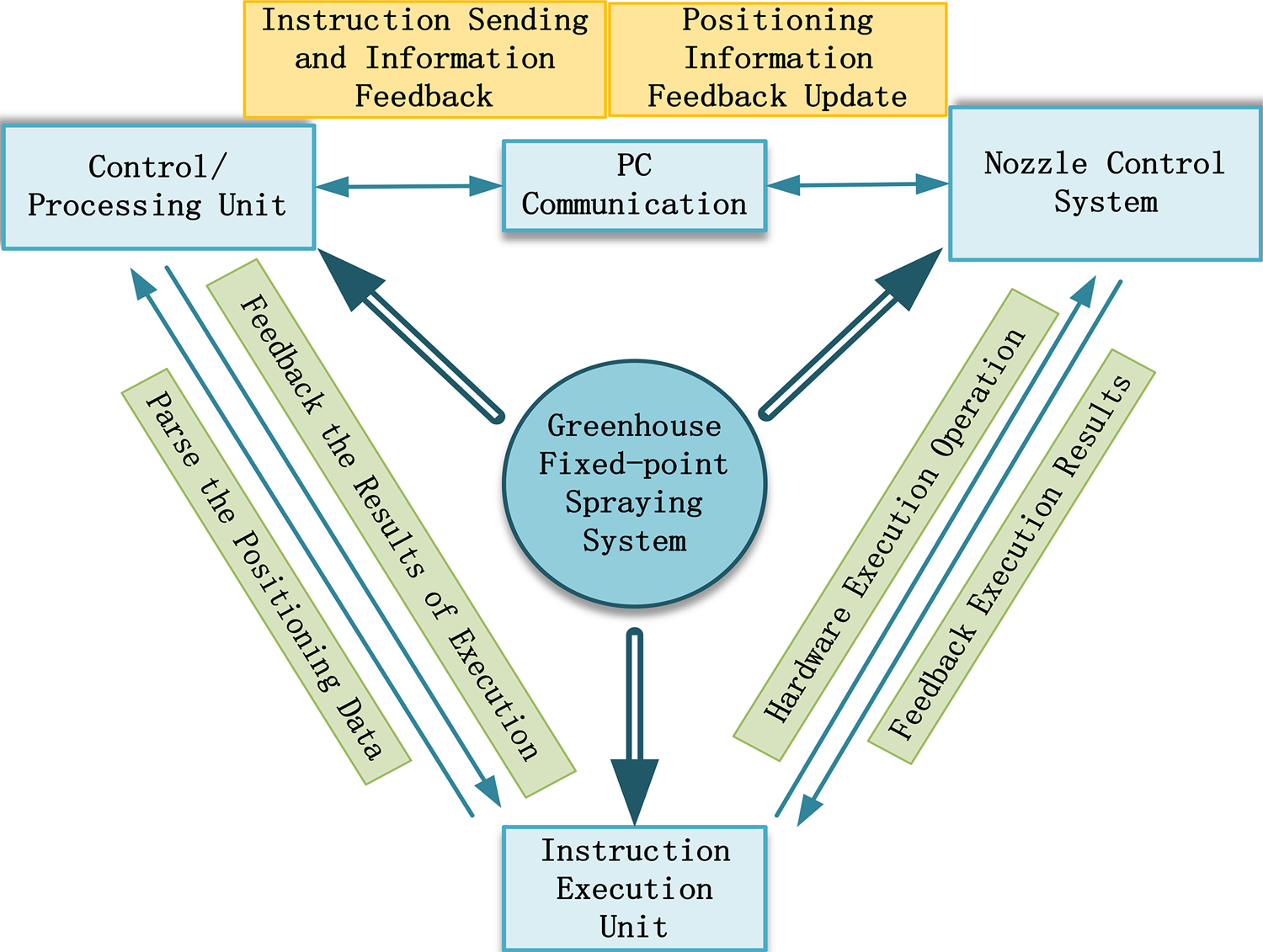

The overall design of the system

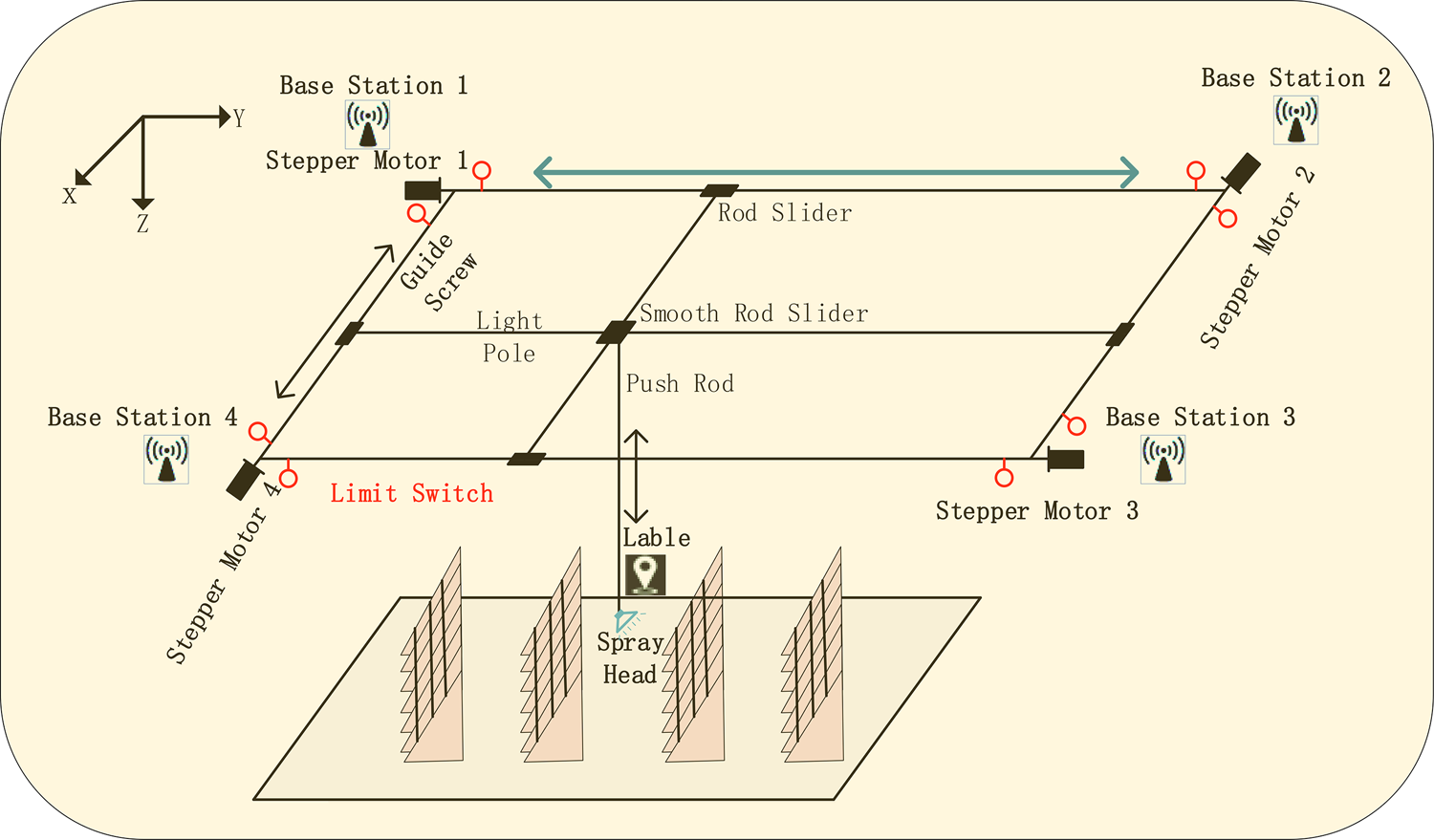

This system consists of a CPU module, a UWB indoor positioning module, a spraying action control module, a power supply module, a wireless communications module, a human-computer interaction interface, and other modules. The overall structure of the system is shown in photos and a schematic of its system designin Figure 1. The main controller adopts an STM32H743 series microprocessor; the power supply module uses a switching power supply to convert AC 220 V into a low-voltage DC power supply for the system; the UWB indoor positioning module employs four base stations and one label (Zhang et al., 2021). An STM32F103 is used as the CPU, and a DWM1000 chip is used as the communication module. The base station sends a UWB signal, and the label returns a response signal after receiving the signal. The position of the label is obtained by the trilateral positioning algorithm, and the information about the position is transmitted to the main controller to be unpacked so as to obtain the position of the nozzle (Zeng et al., 2024). The spray action control module can realize a 24V / 12V relay switch action control; the upper computer software has been developed by QT creator to realize the remote control of the lower computer’s execution system.

UWB positioning principle

Ultra Wide Band (UWB) is an ultra-wideband communication technology (Rahman et al., 2020). This positioning system uses the TWR bidirectional ranging method to realize one-to-many TWR bidirectional ranging. After obtaining multiple distances, the trilateral positioning algorithm is used to realize the position settlement of the label to complete the positioning.

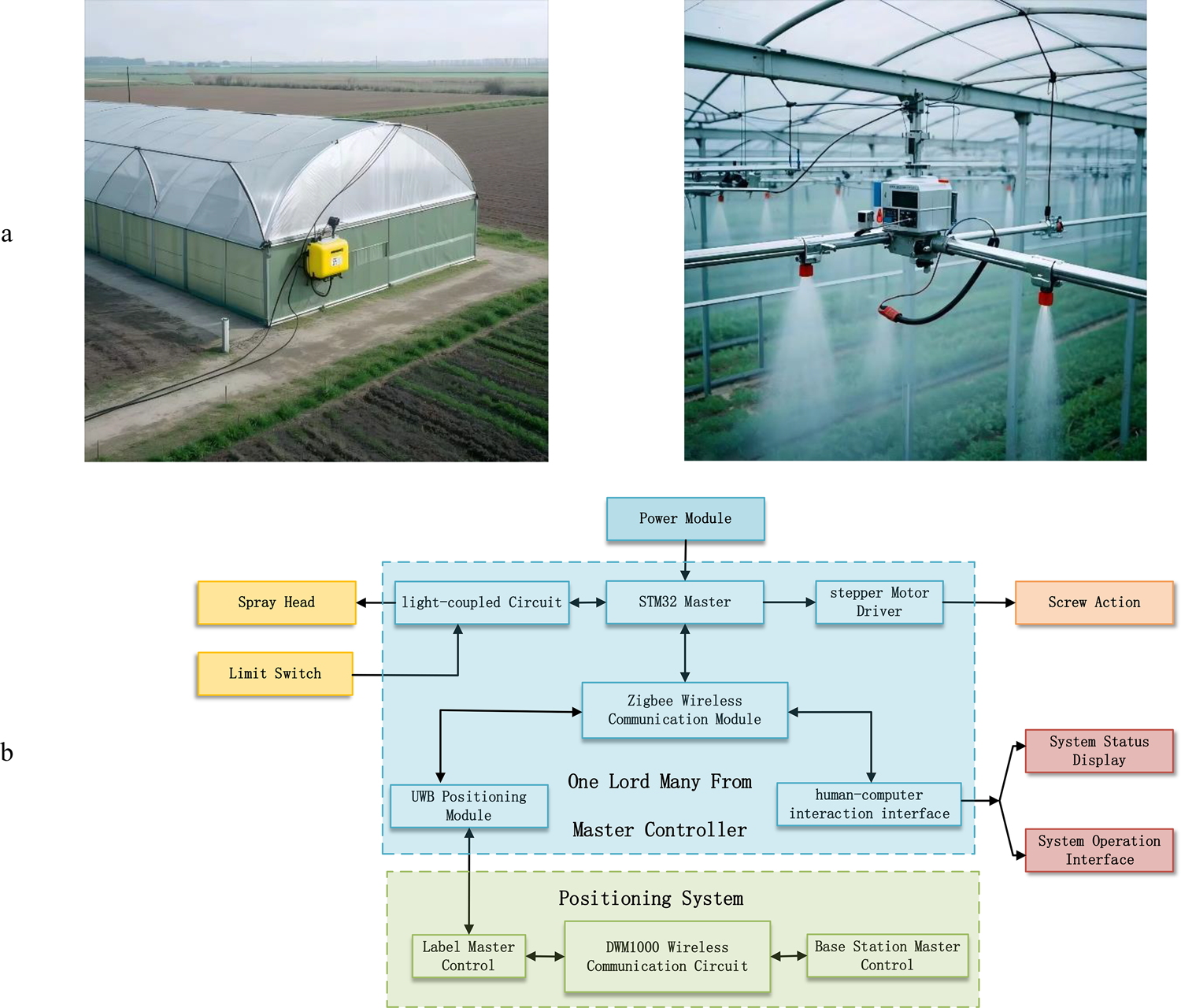

TWR two-way ranging

The measurement of the distance between the two devices mainly depends on the time difference of the signals between the two devices. The base station and the label generate independent time stamps. The base station sends a pulse signal to the label at the time stamp Ta1. The label generates a time stamp Tb1 after receiving the signal, and returns a pulse signal to the base station at the Tb2 time stamp. The base station receives the signal sent by the label when the time is Ta2. The TWR ranging principle is shown in Figure 2:

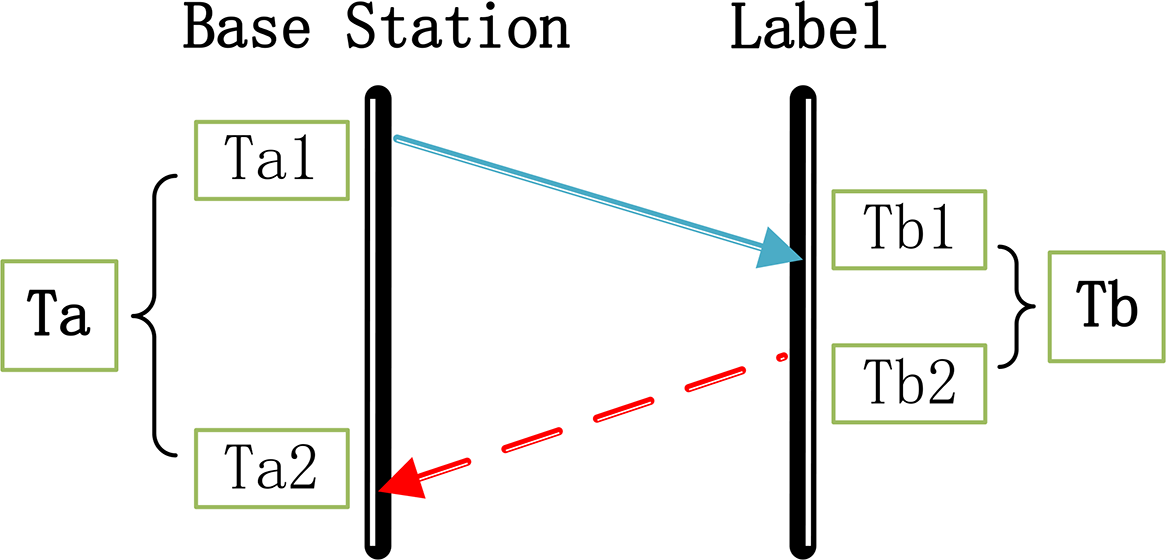

Taking the positioning mode of four base stations and one label in this system as an example, the solution is to let the label send a Poll signal outward. Four base stations will return a Response signal to the label after receiving the signal. The label sends a Final signal outward after receiving it. All base stations complete the ranging after receiving the Final signal and complete a ranging cycle. The principle of multi-base station ranging is shown in Figure 3:

The ranging process of the base station and the label designed by this system is bilateral ranging, and the specific implementation is shown in Figure 4. The algorithm can reduce the positioning error caused by the clock drift of the positioning device and minimize the error of the calculated flight time.

Each device records the timestamp of signal reception and transmission. The distance between each base station and the label can be obtained by calculation. The specific formula for this calculation formula is

In this formula, is the time when each base station sends a signal, ms; is the time required for each base station to perform a two-way ranging, ms; is the delay time of each base station for speed measurement, ms.

Positioning method

UWB positioning methods are based on time of flight (TOF ), angle of arrival (AOA), time of arrival (TOA), time difference of arrival (TDOA), as well as other methods (Zhang et al., 2022). Because the indoor environment has a great influence on the propagation of the signal, the signal arrival time difference method can reduce the positioning error caused by environmental factors.

The TDOA method calculates the distance between the label and the base station by the propagation time of the signal in the air. It is known that the propagation speed of an electromagnetic wave is the same as that of light, so the distance between the label and the base station can be obtained by the propagation time of the signal.

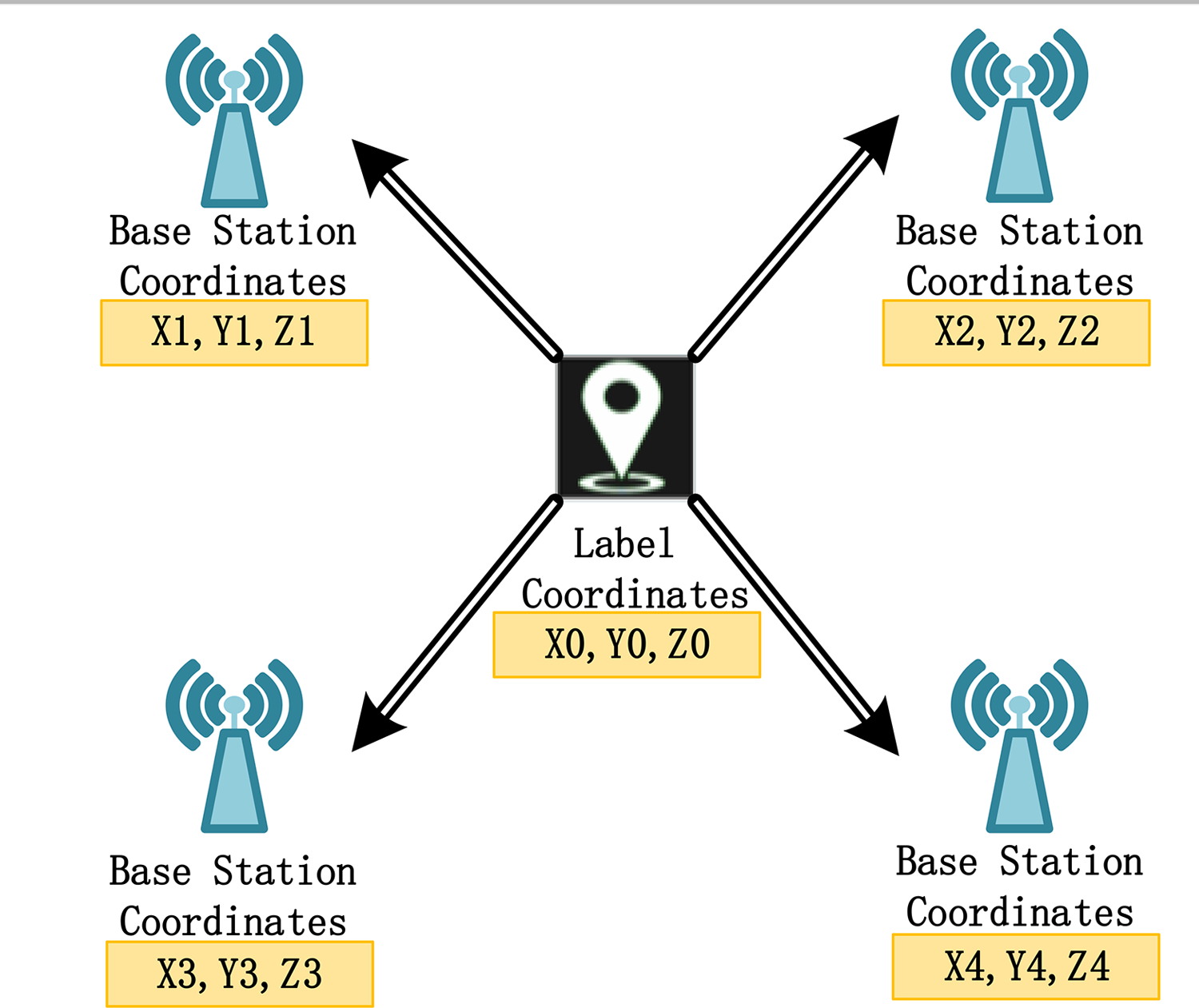

TDOA three-dimensional space

For the determination of the location of the label, the method used is to make the four base stations have the same horizontal height in space, that is, the Z coordinates of the four base stations are the same, and then select the Z coordinates smaller than the Z coordinate of the base station as the positioning label in the two intersection points. The three-dimensional geometric principle is shown in Figure 5.

The formulas for calculating the three-dimensional space coordinates are

In these formulas: is the distance between each base station and the label, cm; are the x-coordinates of the label and each base station in the coordinate system, cm, and the are their y-coordinates, cm.

Taylor series algorithm

The Taylor series algorithm is a recursive algorithm for determining the weighted least-squares estimate of the position. By constantly correcting the estimated value of the position coordinates of the label, the true position of the label is gradually approached. The formula for the distance is

After some algebra, formula (3) can be rewritten as

According to the Time Difference of Arrival (TDOA) positioning method, the deviation between the actual distance from the label to each base station and the distance from the label to the selected reference base station can be expressed as

The iteration’s initial point is selected and the Taylor series expansion is performed on the above formula. After removing the high-order components, it can be transformed into the following expression:

CH20

Here, is the distance between the base station and the label in the iterative process. The weighted least squares solution of the above equation can be obtained:

Here, Q is the covariance of TDOA, so the initial value of the next iteration is obtained. Then a new round of Taylor series expansion is carried out, and the initial value of the next iteration is obtained as follows:

Repeat the above steps recursively until

Where is some chosen threshold. The resulting gives the coordinates of the position of the label.

Hardware design

The main hardware includes: a microprocessor, a power supply module, a UWB positioning module, an execution module, a ZigBee wireless communication module, and a display module. The power supply module supplies power to all the hardware circuits in the system. The microprocessor is the core of the entire system, and the remaining modules communicate with each other through the ZigBee wireless communication module.

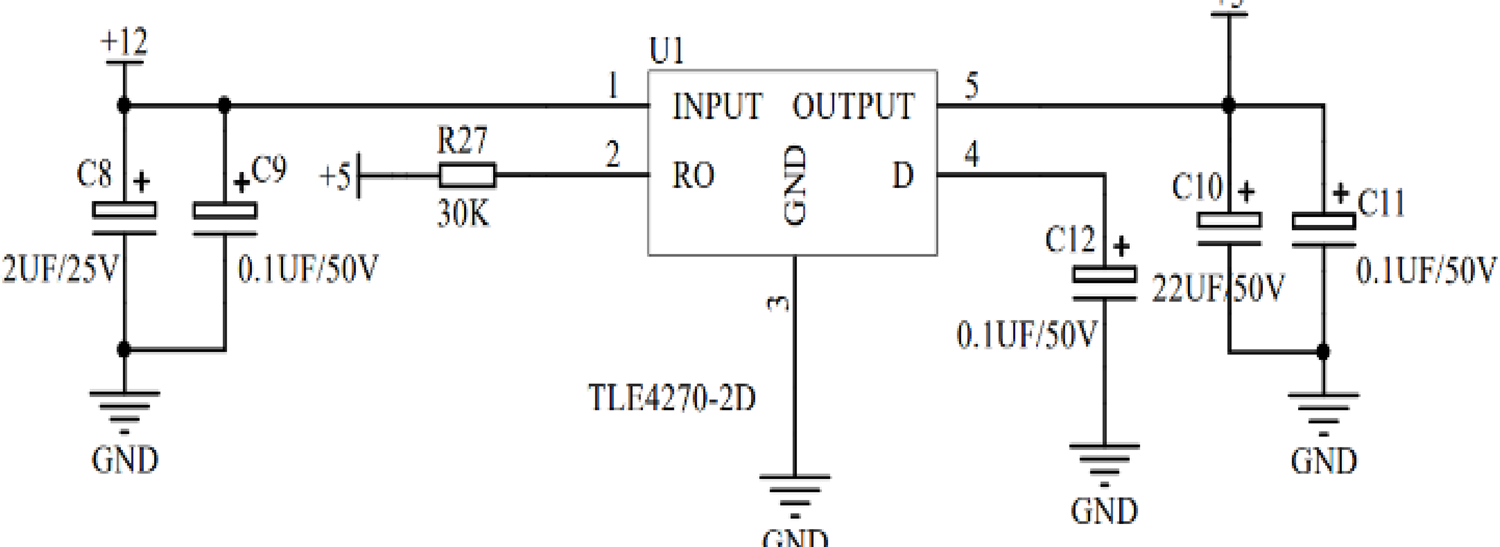

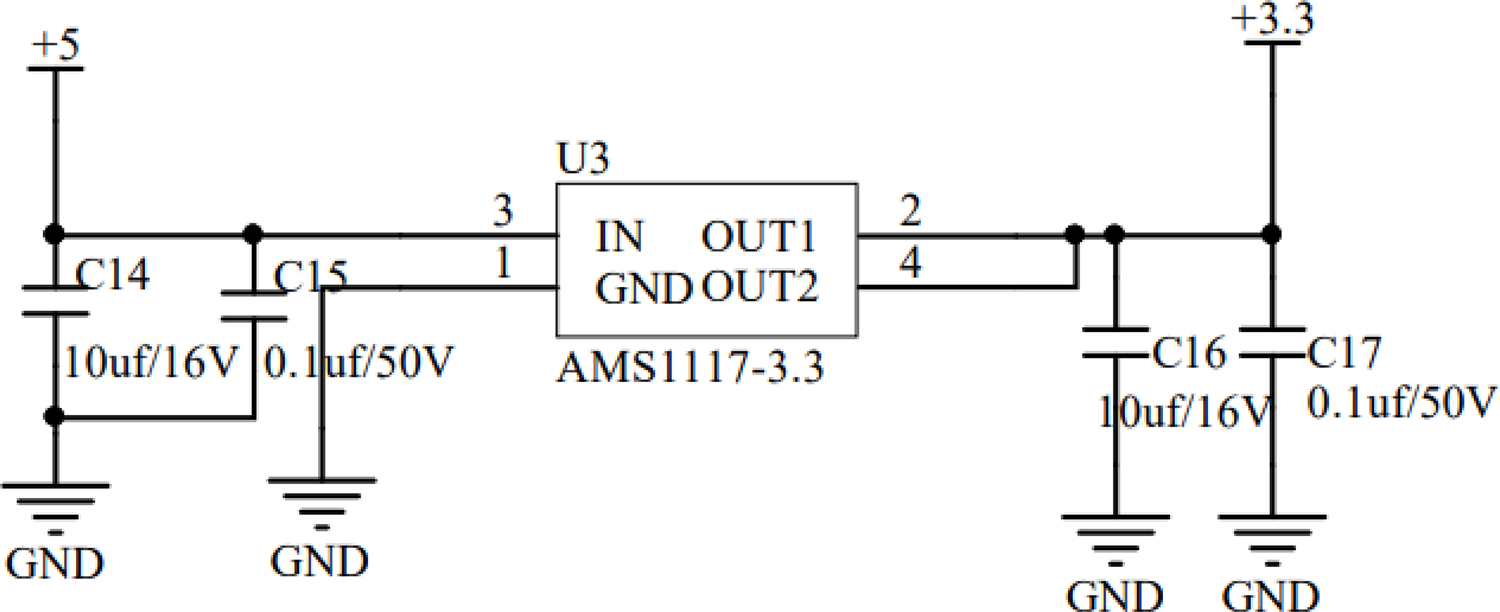

Power supply module

The power supply module needs to meet the power demand of the system. The power supply voltage of the system motor is 12 V, the power supply voltage of the microprocessor is 3.3 V, and the power supply voltage of the other modules such as the UWB positioning module is 5 V. This design uses an AC220 V-DC12 V switching power supply, a 3.3 V step-down circuit and a 5 V step-down circuit to meet the power supply.

The 5 V voltage regulator chip selected os TLE4270-2D. This chip is a monolithic integrated low-voltage drop 5V voltage regulation integrated circuit with short-circuit protection, temperature overheating protection and other functions, and has stable performance. The 3.3 V voltage regulator chip selected os an AMS1117-3.3, which is a forward low voltage drop regulator with an output voltage of 3.3 V, limited current, and automatic switching. A schematic diagram of the 5 V step-down circuit is shown in Fig. 6, and a schematic diagram of the 3.3 V step-down circuit is shown in Fig. 7.

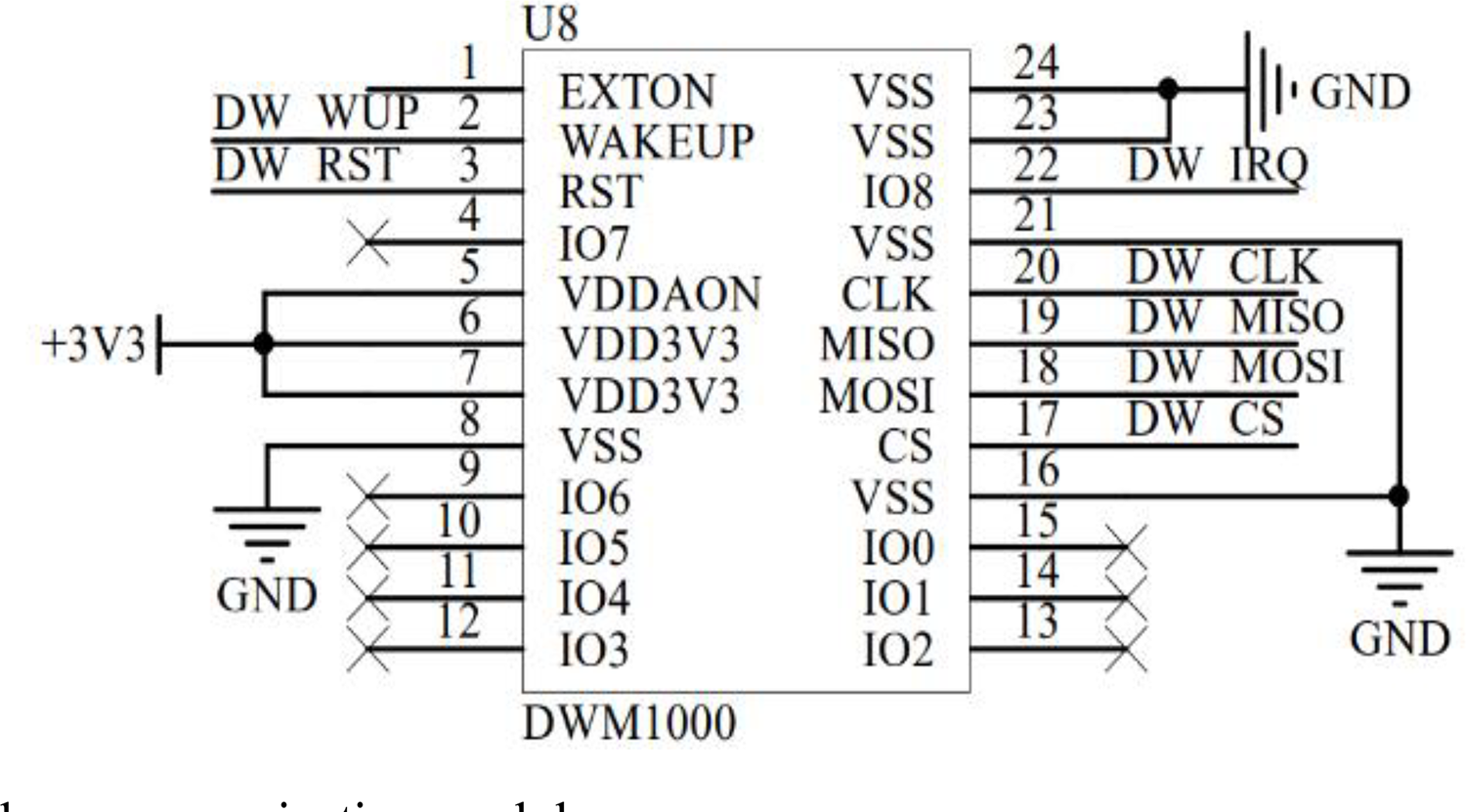

UWB positioning module

The UWB positioning module is the core module of the system. It uses an STM32F103 as the main controller, and uses four base stations and one label. The distance between the four base stations is obtained from the time difference of the label signal, and the real-time three-dimensional coordinates of the label can be obtained by the trilateral positioning algorithm and the TWR algorithm. The positioning accuracy is within 10 cm, which can fulfill the system requirements.

The UWB positioning system uses the DWM1000 chip provided by Decawava company. The DWM1000 module is a wireless network receiving module that follows the IEEE802.15.4-2011 ultra-wideband specification. Its main function is to communicate with the label, by generating a timestamp to calculate the distance. A circuit schematic is shown in Fig. 8.

Zigbee wireless communication module

Zigbee wireless communication technology is a short-range, low-power two-way wireless communication technology (Ding et al., 2021). It works in the ISM band, the frequency band is 2.4 GHz, and the transmission rate is 10 kb/s ~ 250 kb/s. It has the advantages of high security performance, short response time, and zero point-to-point packet loss rate. The system uses its Zigbee wireless communication module to transmit the real-time coordinates of the label to the main controller, so as to carry out the positioning.

Executing module

The frame is made of an aluminum alloy, and a screw is driven so as to move the position of the nozzle through the synchronous rotation of the four stepper motors, so that the nozzle reaches the position of the crop.

Motor driver

The system uses four stepper motors. Due to the synchronous rotation of the two, two stepper drivers are needed. The motor driver is shown in Figure 9. This design uses an SH-8611A stepper motor driver, which is controlled by pulse width modulation (PWM) (Peng et al., 2021). It has a small size, has automatic overheating protection, automatic locked rotor protection, Hall error protection and brake protection. The design is easy to use and simple to control.

The connection methods of a stepper motor driver include common anode connection, common cathode connection and differential connection. This system uses a common anode wiring method (Hammoodi et al., 2020), as shown in Figure 9:

Photoelectronic coupling circuit

The photoelectric coupling circuit is used for limit switch and control nozzle. In order to prevent the coordinate position from being inaccurate due to the failure of the UWB positioning module, a limit switch is used to limit the movement of the screw and prevent the system from being disordered. There are a total of eight limit switches around the

frame. When the screw hits the limit switch, the nozzle has moved to the edge of the frame, and the system stops running immediately. The photoelectric coupling circuit of the limit switch is shown in Figure 10. When the nozzle reaches the specified spraying point, the nozzle needs to be opened by switching control. The spraying control photoelectric coupling circuit is shown in Fig.11.

Software design

The overall idea of the design of the software

In the software control, the DMA (Direct Memory Access) mode of STM32H7 is used to transmit data with the serial port to ensure the real-time information, prevent data packet loss, improve the stability of the whole system, and achieve accurate positioning. At the same time, the host computer is designed to display the position information and moving trajectory of the nozzle in real time to achieve a better monitoring. The specific process is shown in Figure 12:

Human-computer interaction interface

The man-machine interface is an important platform for the interaction between modern greenhouses and external personnel. The main contents of its realization include: Show the current situation of crops, such as the growth area of crops, the specific distribution location of each species and other information; according to the signal of the spraying control system, the corresponding instructions are sent to the screw and the nozzle, and the control system completes the corresponding operation.

In order to realize an intelligent human-computer interaction interface, the program uses Python scripts to expand the application, and runs redundant scripts and algorithms through PYCHARM software. Through the configuration interface of the GUI host computer, the key parameters of the script algorithm program are set as the key parameters of the program operation: The real-time data and

information of the actuator can be uploaded to the GUI human-computer interaction display interface in time (He & Li, 2020). The greenhouse positioning software undertakes the function of human-computer interactions in the system. It is important to stres the convenience and relative freedom of the system compared with other products on the market. The host computer software was developed based on the serial port assistant. The various instructions are displayed in the form of the host computer button or interface, and the functions of the system are displayed in a more intuitive form.

RESULTS AND DISCUSSION

Results of tests of the performance of the system and an analysis of these results

A diagram given the operation of the whole system is shown in Figure 13. In order to verify the practicability of the system, a field simulation test was carried out.

Accuracy test

The error of the UWB positioning module is less than 10 cm in theory, but the output coordinate jitter is serious due to the movements of indoor personnel or machines (Long et al., 2022). To ensure real-time updating of the label coordinates,

the Kalman filter is used to improve the positioning accuracy to 5 cm (Qinghe & Quanqing, 2022). The system error mainly comes from the system positioning error, so in the system performance test, the positioning accuracy is measured and analyzed. The measurement results are shown in Table 1.

From the positioning data, it can be seen that the positioning accuracy is relatively stable, and the average error is less than 5 cm.

Spray head trajectory test

The trajectory test experiment successively inputs the position coordinates of the four corners of the test site, so that the spraying and the trajectory is roughly a rectangle. The motion data is processed by MATLAB and drawn into a two-dimensional trajectory map. The specific trajectory path is shown in Figure 14.

In the figure, the red dotted line is the standard trajectory, and the blue solid line is the nozzle moving trajectory. From the figure, it can be seen that the movement trajectory of the spraying head is relatively stable and close to the real trajectory, but there will be fluctuations in some sections. The first reason for this is that the deployment of the positioning base station position will affect the final positioning accuracy of the system positioning algorithm, and the coordinates of the base station cannot be accurately positioned due to the limitations of the measurement tools and the environment when building the system. The second reason is that there are many obstacles in the experimental site, which has a great influence on the positioning system and makes the positioning poor.

ZigBee transmission distance test

All the data transmission in this system is by ZigBee wireless transmission, so the transmission distance of ZigBee is particularly important. The packet loss rate of ZigBee was tested under different distances and different numbers of walls. The test data are shown in Table 2:

It can be seen from the experimental data that ZigBee wireless communication is a short-distance communication technology, and blocking by the wall has a great influence on ZigBee. When the ZigBee data transmission distance is far and there are many walls to be penetrated, the packet loss rate of the data is very high, and the normal operation of the system cannot be maintained. Therefore, when the system is applied to a larger greenhouse, it is necessary to consider using other wireless transmission modules or enhancing the power of the ZigBee wireless transmission module.

Motor working state test

In order to test whether the stepper motor runs stably in the process of the nozzle not performing the spraying task and performing the task, it is necessary to compare whether the set time is consistent with the running time of the motor during the normal execution of the task. Before the test, the motor is stopped to prevent interference caused by voltage, current and other problems. By setting multiple sets of time, the experimental results are obtained as shown in Table 3 and Table 4:

According to the data of Table 3, the motor running time of the nozzle in the process of finding the target crop is the same as the set time, and the motor runs stably. According to the data of Table 4, the motor running time is the same as the set time during the spraying task of the nozzle, and the motor also runs stably.

System overall test

After the system is completed, the host computer software is used to send the target crop coordinates for spraying operation test. When the nozzle reaches the predetermined position, the host computer prompts that the spraying operation can be carried out, and the spraying button is clicked to test the spraying function. The experimental data are shown in Table 5:

Comparison with existing indoor positioning methods

We now present a comparison of this method with some other methods in the literature in Table 6.

(Assayag et al., 2020) proposed PoDME (Positioning using Dynamic Model Estimation) and a novel method for choosing the three best anchor nodes, achieving a position estimation error of 3 m in a large-scale experimental environment. However, the positioning algorithm is too dependent on anchors and was not embedded in the real world for application. (Long et al., 2021) proposed a UWB ranging calibration and positioning system based on a CNN regression model to achieve high-precision indoor positioning. The system can reduce the impact of environmental changes on positioning results. However, it is easily limited by the size of CNN model and fingerprint image. (Sung et al., 2023) proposed a novel UWB-based indoor positioning approach that significantly improves localization accuracy under dynamic personal device environments, the distance measurement errors by NLoS are minimized by applying weights determined by deep learning to the Kalman filter. However, it continually needs additional learning data and improvements in the deep learning models.

In this study, the positioning method is on an indoor test platform. Through the Kalman filter, the positioning accuracy is improved to within 5 cm, which is within the allowable range of error. The advantage of this study is that based on the UWB indoor positioning technology, the use of four base stations and one label provides high-precision, real-time and reliable positioning services for vertically planted crops, and the nozzle fixed-point spraying test is preliminarily completed. The disadvantage of this study is that it is easily affected by the position of the installation of the base station and by obstacles.

CONCLUSIONS

This greenhouse fixed-point spraying system is a terminal control equipment based on UWB indoor positioning technology. The goal is to realize the intelligent and efficient management of modern greenhouses, optimize the problems of low agricultural modernization and poor greenhouse planting environment in China, and realize rapid retrieval, accurate positioning and convenient operation.

Proved by many experiments, it has the advantages of simple operation, relatively low cost, and strong controllability. It reduces the use of human resources and does not occupy the effective planting space of the greenhouse, so it maximizes the economic benefits of greenhouses and meets the needs of modern greenhouse planting.

REFERENCES

-

Hegarty, C. J. (2017). The global positioning system (GPS). In: The Springer Handbook of Global Navigation Satellite Systems, pp. 197-218. https://doi.org/10.1007/978-3-319-42928-1_7

» https://doi.org/10.1007/978-3-319-42928-1_7 -

Assayag, Y., Oliveira, H., Souto, E., Barreto, R., & Pazzi, R. (2020). Indoor positioning system using dynamic model estimation. Sensors, 20(24), 7003. https://doi.org/10.3390/s20247003

» https://doi.org/10.3390/s20247003 -

Cheng, L., Zhao, A., Wang, K., Li, H., Wang, Y., & Chang, R. (2020). Activity recognition and localization based on UWB indoor positioning system and machine learning. In: 2020 11th IEEE Annual Information Technology, Electronics and Mobile Communication Conference (IEMCON) (pp. 0528 - 0533). IEEE. https://doi.org/10.1109/IEMCON51383.2020.9284937

» https://doi.org/10.1109/IEMCON51383.2020.9284937 -

Ding, S., Liu, J., Yue, M. (2021). The use of ZigBee wireless communication technology in industrial automation control. Wireless Communications and Mobile Computing, 2021(1), 8317862. https://doi.org/10.1155/2021/8317862

» https://doi.org/10.1155/2021/8317862 -

Elsanhoury, M., Mäkelä, P., Koljonen, J., Välisuo, P., Shamsuzzoha, A., Mantere, T., & Kuusniemi, H. (2022). Precision positioning for smart logistics using ultra-wideband technology-based indoor navigation: A review. IEEE Access, 10, 44413 - 44445. https://doi.org/10.1109/ACCESS.2022.3169267

» https://doi.org/10.1109/ACCESS.2022.3169267 -

Farahsari, P. S., Farahzadi, A., Rezazadeh, J., Bagheri, A. (2022). A survey on indoor positioning systems for IoT-based applications. IEEE Internet of Things Journal, 9(10), 7680 - 7699. https://doi.org/10.1109/JIOT.2022.3149048

» https://doi.org/10.1109/JIOT.2022.3149048 -

Hammoodi, S. J., Flayyih, K. S., Hamad, A. R. (2020). Design and implementation speed control system of DC motor based on PID control and Matlab Simulink. International Journal of Power Electronics and Drive Systems, 11(1), 127 - 134. http://dx.doi.org/10.11591/ijpeds.v11.i1.pp127-134

» http://dx.doi.org/10.11591/ijpeds.v11.i1.pp127-134 -

He, S., Li, P. (2020). A MATLAB based graphical user interface (GUI) for quickly producing widely used hydrogeochemical diagrams. Geochemistry, 80(4), 125550. https://doi.org/10.1016/j.chemer.2019.125550

» https://doi.org/10.1016/j.chemer.2019.125550 -

Long, K., Nsalo Kong, D. F., Zhang, K., Tian, C., & Shen, C. (2021). A CSI-based indoor positioning system using single UWB ranging correction. Sensors, 21(19), 6447. https://doi.org/10.3390/s21196447

» https://doi.org/10.3390/s21196447 -

Long, Z., Xiang, Y., Lei, X., Li, Y., Hu, Z., & Dai, X. (2022). Integrated indoor positioning system of greenhouse robot based on UWB/IMU/Odom/LiDAR. Sensors, 22(13), 4819. https://doi.org/10.3390/s22134819

» https://doi.org/10.3390/s22134819 -

Peng, P., Yu, C., Xia, Q., Zheng, Z., Zhao, K., & Chen, W. (2022). An indoor positioning method based on UWB and visual fusion. Sensors, 22(4), 1394. https://doi.org/10.3390/s22041394

» https://doi.org/10.3390/s22041394 -

Peng, Z., Meng, C., Liu, L., Wang, D., Li, T. (2021). PWM-driven model predictive speed control for an unmanned surface vehicle with unknown propeller dynamics based on parameter identification and neural prediction. Neurocomputing, 432, 1 - 9. https://doi.org/10.1016/j.neucom.2020.12.036

» https://doi.org/10.1016/j.neucom.2020.12.036 -

Qinghe, L. I. U., Quanqing, Y. U. (2022). The lithium battery SOC estimation on square root unscented Kalman filter. Energy Reports, 8, 286 - 294. https://doi.org/10.1016/j.egyr.2022.05.079

» https://doi.org/10.1016/j.egyr.2022.05.079 -

Rahman, M. L., Zhang, J. A., Huang, X., Guo, Y. J., & Lu, Z. (2020). Joint communication and radar sensing in 5G mobile network by compressive sensing. IET Communications, 14(22), 3977 - 3988. https://doi.org/10.1049/iet-com.2020.0384

» https://doi.org/10.1049/iet-com.2020.0384 -

Sung, S., Kim, H., & Jung, J. I. (2023). Accurate indoor positioning for UWB-based personal devices using deep learning. IEEE Access, 11, 20095 - 20113. https://doi.org/10.1109/ACCESS.2023.3250180

» https://doi.org/10.1109/ACCESS.2023.3250180 -

Tian, D., & Xiang, Q. (2020). Research on indoor positioning system based on UWB technology. In 2020 IEEE 5th Information Technology and Mechatronics Engineering Conference (ITOEC) (pp. 662 - 665). IEEE. https://doi.org/10.1109/ITOEC49072.2020.9141707

» https://doi.org/10.1109/ITOEC49072.2020.9141707 -

Wang, F., Tang, H., Chen, J. (2023). Survey on NLOS identification and error mitigation for UWB indoor positioning. Electronics, 12(7), 1678. https://doi.org/10.3390/electronics12071678

» https://doi.org/10.3390/electronics12071678 -

Wang, J., Wang, M., Yang, D., Liu, F., & Wen, Z. (2021). UWB positioning algorithm and accuracy evaluation for different indoor scenes. International Journal of Image and Data Fusion, 12(3), 203 - 225. https://doi.org/10.1080/19479832.2020.1864788

» https://doi.org/10.1080/19479832.2020.1864788 -

Yang, B., Li, J., Shao, Z., & Zhang, H. (2022). Robust UWB indoor localization for NLOS scenes via learning spatial-temporal features. IEEE Sensors Journal, 22(8), 7990 - 8000. https://doi.org/10.1109/JSEN.2022.3156971

» https://doi.org/10.1109/JSEN.2022.3156971 -

Yang, X., Wang, J., Song, D., Feng, B., & Ye, H. (2021). A novel NLOS error compensation method based IMU for UWB indoor positioning system. IEEE Sensors Journal, 21(9), 11203 - 11212. https://doi.org/10.1109/JSEN.2021.3061468

» https://doi.org/10.1109/JSEN.2021.3061468 -

You, W., Li, F., Liao, L., & Huang, M. (2020). Data fusion of UWB and IMU based on unscented Kalman filter for indoor localization of quadrotor UAV. IEEE Access, 8, 64971- 64981. https://doi.org/10.1109/ACCESS.2020.2985053

» https://doi.org/10.1109/ACCESS.2020.2985053 -

Zeng, L., Guo, S., Zhu, M., Duan, H., Bai, J. (2024). An Improved Trilateral Localization Technique Fusing Extended Kalman Filter for Mobile Construction Robot. Buildings, 14(4), 1026. https://doi.org/10.3390/buildings14041026

» https://doi.org/10.3390/buildings14041026 -

Zhang, H., Zhang, Z., Zhao, R., Lu, J., Wang, Y., & Jia, P. (2021). Review on UWB-based and multi-sensor fusion positioning algorithms in indoor environment. In: 2021 IEEE 5th Advanced Information Technology, Electronic and Automation Control Conference (IAEAC) (Vol. 5, pp. 1594 - 1598). IEEE. https://doi.org/10.1109/IAEAC50856.2021.9390630

» https://doi.org/10.1109/IAEAC50856.2021.9390630 -

Zhang, Y., Chu, Y., Fu, Y., Li, Z., & Song, Y. (2022). UWB positioning analysis and algorithm research. Procedia Computer Science, 198, 466 - 471. https://doi.org/10.1016/j.procs.2021.12.271

» https://doi.org/10.1016/j.procs.2021.12.271

-

FUNDING:

The author was supported by the Natural Science Foundation of Shandong Province (ZR2022MF306), the National Modern Agricultural Industrial Technology System (CARS-09-P32) and the Taishan Industry Leading Talents Project in Shandong Province (LJNY201804), and would like to thank the editors and reviewers for their valuable comments and constructive suggestions.

Edited by

-

Area Editor:

Héliton Pandorfi

-

Edited by

SBEA

Publication Dates

-

Publication in this collection

17 Feb 2025 -

Date of issue

2025

History

-

Received

13 Aug 2024 -

Accepted

13 Dec 2024

DESIGN OF GREENHOUSE FIXED-POINT SPRAYING SYSTEM BASED ON ULTRA-WIDEBAND INDOOR POSITIONING TECHNOLOGY

DESIGN OF GREENHOUSE FIXED-POINT SPRAYING SYSTEM BASED ON ULTRA-WIDEBAND INDOOR POSITIONING TECHNOLOGY