ABSTRACT

Babassu (Orbignya speciosa Mart.) is an oil palm that can be used as an alternative in biodiesel production. However, few studies have compared the babassu and soybean biodiesel production. Therefore, the objective of this study was to compare the performance and emissions of babassu and soybean biodiesels under different engine loads. Four babassu and soybean blends (B10, B15, B20, and B100) were used in a 3-kVA generator engine at resistive loads ranging between 500 and 2500 W. The measured parameters were the specific fuel consumption (SFC), exhaust gas temperature (EGT), nitrogen oxides (NOx), hydrocarbon (HC), and carbon monoxide (CO). The results showed that the SFC of the babassu biodiesel was 9% lower than that of soybean B20 at a 2500-W load. Interestingly, the NOx emissions and EGT decreased for B100 at all tested loads for babassu biodiesel compared with those for soybean biodiesel. Conversely, the soybean biodiesel exhibited lower HC emissions than babassu biodiesel at all loads. The B20 babassu biodiesel blend exhibited better performance in terms of HC and CO emissions. Therefore, babassu biodiesel can be used as an alternative in biodiesel production.

KEYWORDS

Orbignya speciosa; Mart; biodiesel; performance; gas emissions

INTRODUCTION

Researchers are actively investigating renewable fuels to reduce oil dependence and commodity price fluctuations. Biodiesel is a good alternative that can be obtained from resources such as algal oils, microbial oils, animal fats, vegetable oils, and waste oils (Talapatra et al., 2023). Biodiesel is environmentally safe, non-toxic, and reduces carbon dioxide emissions (Ranjan et al., 2016; Outili et al., 2020). However, biodiesel may present some disadvantages such as high cost and high viscosity (Mathew et al., 2021; Aguilar-Aguilar et al., 2025).

Soybeans constitute most of the raw materials that feed the Brazilian biodiesel production chain, with approximately 70% of the Brazilian biodiesel being produced from soybeans. Currently, soybeans have the advantage of meeting the domestic demand for biodiesel and have the most competitive price compared with other raw materials (César et al., 2019; Bassegio & Zanotto, 2020). However, in terms of oil production per hectare, soybean is not the most attractive option for biodiesel production, considering its seed oil content (18%–21%) compared to other oilseeds (Gongora et al., 2022).

In this context, diversifying biodiesel feedstocks with other oilseeds can strengthen both the biofuel sector and related production chains. Among the unconventional oilseeds, babassu (Orbignya speciosa Mart.) represents a promising alternative for expanding the raw materials available for biodiesel production.

Babassu is a palm tree widely distributed in northeastern and northern Brazil. Its exploitation generates income for local families, contributing to social stability and reducing rural-to-urban migration (Girardi et al., 2021). On average, its fruits contain about 7% almonds, of which nearly 65% can be extracted (Paiva et al., 2013). Babassu oil has emerged as a more sustainable alternative, with a lower environmental impact than soybean oil. Its extraction production contributes to environmental conservation and the development of traditional communities (Afonso & Ângelo, 2009).

Chemically, babassu oil is rich in lauric acid (40–55%), which facilitates transesterification reactions and results in biodiesel with favorable properties, such as resistance to non-enzymatic oxidation and a low melting point (Machado et al., 2006).

The composition of biodiesel varies depending on the feedstock and can affect emissions and engine performance. Differences in the chemical nature of biodiesel and saturated and unsaturated long-chain fatty acids can result in differences in the basic properties of biodiesel, thereby affecting engine performance and pollutant emissions (Benjumea et al., 2008). In general, biodiesel with higher saturated fatty acid content, such as babassu biodiesel, exhibits a higher cetane number than soybean biodiesel, which can influence engine performance by reducing ignition delay and improving fuel efficiency (Palash et al., 2013)

Rashed et al. (2016) observed that babassu biodiesel performed better than jatropha and moringa biodiesels in a four-cylinder diesel engine. Sanjid et al. (2014) verified that a combination of babassu and jatropha biodiesel increases the specific fuel consumption (SFC) and reduces hydrocarbon (HC) and carbon monoxide (CO) emissions in a single-cylinder diesel engine. To date, no study has comprehensively evaluated and compared the performance of babassu biodiesel with conventional soybean biodiesel in generator engines, particularly in the context of decentralized energy applications for remote communities in regions where babassu palm is abundantly available.

Therefore, the objective of this study was to evaluate a generator engine operating with different resistive loads, biodiesel blends (B10, B15, B20, and B100) and two feedstocks soybean and babassu.

MATERIAL AND METHODS

Experiments were conducted at the Chemistry and Electricity Microgeneration Laboratory of the State University of Western Paraná (UNIOESTE, Cascavel and Toledo, Paraná, Brazil).

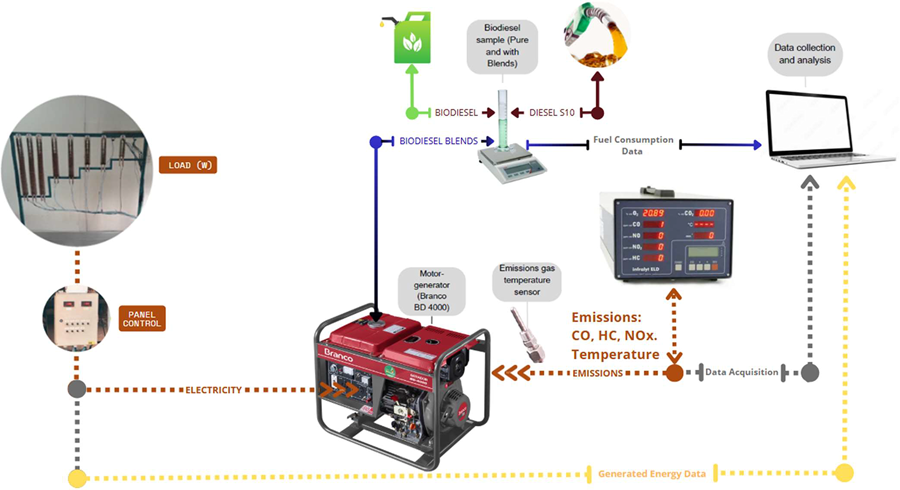

A diesel generator set manufactured by Branco (model BD 4000; 7 HP; 3600 rpm) was used in this study (Figure 1). The engine was coupled to a 110/220-V Kohlbach normal-phase generator with a maximum continuous power of 3 kVA and current of 20 A. The generator was connected to a resistance bank with a resistance ranging between 0 and 8 kVA. A resistance bank was used to simulate different loads in the motor-generator set, with variations in the motor capacity ranging between 0% and 100%. The engine was evaluated within a range of 500–2500 W with a variation of 500 W. No changes to the engine were necessary.

Schematic diagram of the system used with a diesel/generator cycle engine, resistive loads and biofuel.

Babassu biodiesel was obtained via a transesterification reaction using sodium hydroxide (NaOH) as the catalyst (1% of the oil weight) and methanol as the alcohol (25% of the oil volume). First, methanol and sodium were mixed vigorously for 10–25 min. Next, the formed odium methoxide was mixed with oil in a round-bottom flask, stirred continuously via shaking, and maintained at a temperature of 60 °C (Figure 2A). Once the reaction time had passed, the contents were transferred to a separating funnel and allowed to separate into two layers for 12 h (Figure 1B). After separation, the biodiesel was washed with distilled water. Finally, the biodiesel was placed in an incubator to remove excess water (Figures 2C and D) (Gongora et al., 2022).

Mixing process of babassu oil and methyl alcohol (A), collapse of glycerol in the mixture (B), washing process of babassu biodiesel (C) and biodiesel produced for blending with diesel (D).

The desired biodiesel density was obtained at 20 °C using a pycnometer and a four-decimal precision balance (Marte, Ay220). Kinematic viscosity was measured using a Canon–Fenske capillary viscometer in a thermostatic bath at 40 °C (Table 1). The higher calorific values of the fuels were determined using an isothermal calorimeter (DDS Calorimeter, E2K). The acidity index was determined using the method established by the Association of Official Analytical Chemists for B100 biodiesels (Table 1). The cetane number was analyzed according to the American Society for Testing and Materials (ASTM D613) standard methods.

In this study, volumetric blends of babassu biodiesel and soybean biodiesel with diesel were prepared at 10%, 15%, 20%, and 100% biodiesel (B10, B15, B20, and B100, respectively) were used. These blends were chosen because the Brazilian mandatory biodiesel-diesel blend is B10. However, in 2022, the blend ratio was changed to B12, and the target for 2026 is a B15 blend with a future target of 20%. A commonly available diesel oil type (A S10) was used, denoted as D100, which is pure without biodiesel.

The mass flow rates of the biodiesel, blends, and pure diesel were measured using a graduated burette and stopwatch (Sarvestani et al., 2016).

The SFC was calculated using [eq. (1)].

Where:

SFC is the specific fuel consumption (g kW -1 h-1);

mi and mf are the fuel weight (g) at the start and end of testing, respectively;

Pe is the engine power (kW), and

t is the consumption time in hours of generator engine operation.

The exhaust gas emissions were quantified using an environmental combustion analyzer (Saxon, Junkalor GmbH, model ELD Infralite D-06846), with the sampling probe inserted 20 cm inside the engine-generator exhaust pipe. The analyzed gases were CO, HC, and nitrogen oxides (NOx), as well as the exhaust gas temperature (EGT).

To evaluate the values obtained from the tests, uncertainty analyses of the variables were conducted using [eq. (2)] (Bharti et al., 2023).

Where:

𝓊𝓍 is the uncertainty;

Ѕis the standard deviation, and

𝓃 is the number of experiments.

The uncertainty results for each measured parameter are in Table 2. Uncertainty was evaluated assuming a Gaussian distribution with confidence limits of ±2σ, corresponding to a 95% confidence interval. The uncertainties of engine power, SFC, CO, NOx, HC, and exhaust gas temperature (EGT) were ±1.10%, ±2.01%, ±2.05%, ±1.97%, ±1.83%, and ±2.84%, respectively.

The overall combined uncertainty of the experimental system was calculated using [eq. (3)].

The overall uncertainty was calculated as follows:

yielding the following values:

In engine performance testing, uncertainties below ±5% are generally considered acceptable. In this study, the overall uncertainty was 4.97%, indicating that all evaluated parameters were within the recommended range and confirming the reliability of the results. Uncertainty analysis is essential to ensure the accuracy of experimental data, as potential deviations may arise from nonlinear device operation or calibration errors (Duan et al., 2019; Çakmak & Özcan, 2022).

RESULTS AND DISCUSSION

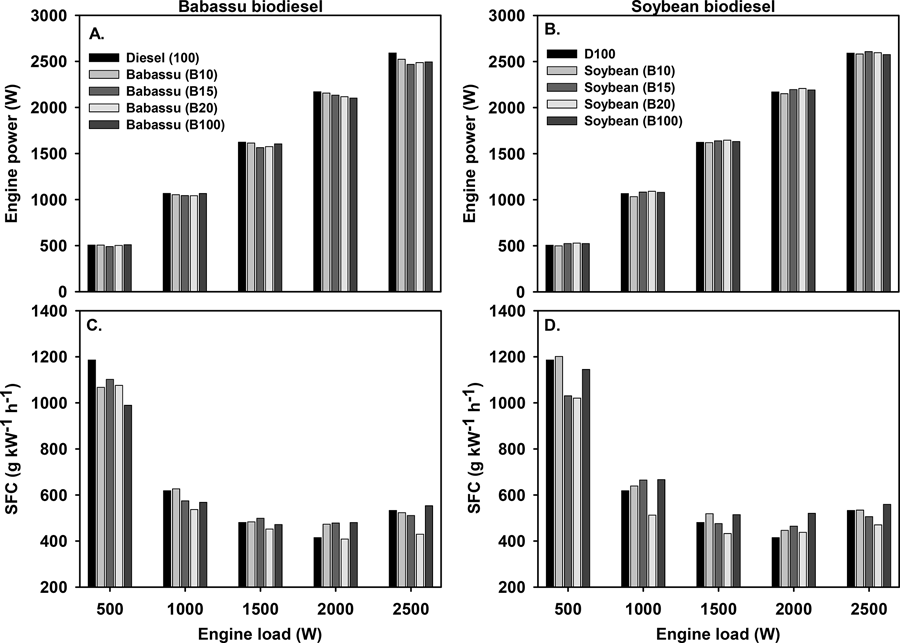

For all babassu biodiesel blends, an engine load of 2500 W produced less electrical power than for diesel and soybean biodiesel (Figures 3A and B). Owing to their lower calorific value and higher density and viscosity, biodiesels generate less power when a higher load is required (Thiyagarajan et al., 2020; Yesilyurt et al., 2020).

Engine power of babassu biodiesel (A) and soybean biodiesel (B), and specific fuel consumption of babassu (SFC) (C) and soybean biodiesel (D) according to engine load and biodiesel blends.

The SFC of the B20 soybean biodiesel blend was lower than that of the B20 babassu biodiesel blend, particularly at low loads (Figures 3C and D). However, the B20 babassu biodiesel blend exhibited a better SFC at 2500 W than the other babassu and soybean biodiesel blends. This may be due to the higher pressure and compression support required for better fuel atomization (Shete et al., 2022).

The higher SFC of the babassu and soybean biodiesel blends can be attributed to the lower calorific value of biodiesel compared to that of diesel. Therefore, it is expected that the biodiesel in the blend would have a higher SFC than diesel (Figures 3C and D).

According to Ilkılıç et al. (2011), the SFC of biodiesel increases as the biodiesel content increases. As the calorific value of biodiesel is lower than that of diesel fuel, more fuel is injected from the fuel pump to reach a power equal to that generated by diesel fuel, leading to an increase in SFC (Simsek, 2020). Neat babassu and soybean biodiesel have high viscosity and density, which affect the spray atomization, leading to slower heat release and an increase in energy consumption because more fuel is required to produce the same power (Thiyagarajan et al., 2020).

The SFC decreased as the load increased for all fuels (Figures 3C and D). This may have been due to an increase in energy production and a subsequent increase in the temperature inside the cylinder (Yesilyurt et al., 2020).

The CO emissions increased for pure diesel (B0) compared to those of the babassu and soybean biodiesels (Figures 4A and B). Oxygen presence in biodiesels improves the burning of carbon molecules, leading to a more complete combustion process (Aydın et al., 2020). At higher engine loads and the resulting higher combustion temperatures, the use of biodiesel results in a more efficient performance while generating less CO emissions (Kivevele et al., 2011). CO emissions from the exhaust represent a loss of chemical energy during combustion owing to incomplete diesel fuel burning (Deheri et al., 2020). Additionally, a higher cetane number promotes a reduction in ignition delay and a more complete combustion (Erman et al., 2020).

Carbon monoxide (CO) of babassu biodiesel (A) and soybean biodiesel (B), and nitrogen oxides (NOx) of babassu (C) and soybean biodiesel (D) according to engine load and biodiesel blends.

In this study, the babassu (B100) and soybean (B100) biodiesels exhibited differences in NOx emissions (Figures 4C and D). As expected, soybean biodiesel (B100) produced higher emissions than the other soybean biodiesel and diesel blends. According to Mofijur et al. (2014), the use of biodiesel derived from different oilseeds generally increases NOx emissions. Interestingly, babassu biodiesel (B100) produced lower emissions than the other babassu biodiesel and diesel blends. Soybean biodiesel (B100) produced 18% more NOx emissions than babassu biodiesel (B100). Related research has shown that NOx formation depends on the biodiesel saturation degree (Samuelsen et al., 2013).

In general, biodiesel saturated without a double bond produces a lower NOx amount than unsaturated fuels (Bakeas et al., 2011; Palash et al., 2013), which may help explain our results. By contrast, the effect of increasing the double bonds on NOx emissions, such as soybeans, is that NOx emissions increase as the unsaturation degree increases. A correlation between an increase in the unsaturation degree and an increase in the ignition delay has been previously reported (Schönborn et al., 2009).

As the load increases, the NOx emissions increase (Figures 4C and D). This means that both babassu and soybean biodiesels exhibit more NOx emissions at higher loads, as well as combustion and more fuel-produced heat (Shete et al., 2022).

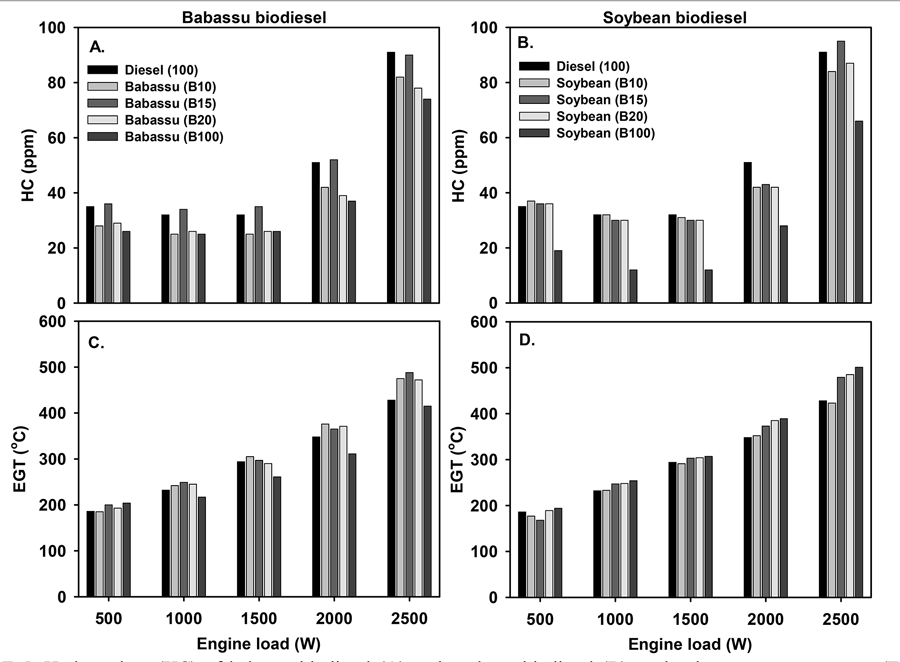

HC emissions from diesel fuel were higher than those from the other evaluated fuels (Figures 5A and B). This difference in HC emissions can be attributed to the fact that diesel is a mineral-based fuel that does not contain dissolved oxygen (Samraj et al., 2023). Consequently, partial diesel fuel combustion occurs throughout the combustion process, resulting in higher HC emissions.

The biodiesel cetane amount affects the HC emissions. Combustion improves as the blend ratio increases, resulting in lower HC emissions. The results showed that the B100 soybean biodiesel produces less HC (66 ppm) than the B100 babassu biodiesel (74 ppm) at a 2500-W load (Figures 5A and B). The HC emissions decreased with the soybean biodiesel percentage in the diesel, and reductions in the HC and CO emissions were observed.

The EGT increased as the load increased owing to the improved quality of the combustion process, and the amount of injected fuel also increased (Figures 5C and D). Furthermore, the EGT was lower for the B100 babassu biodiesel than that for diesel fuel because of the saturated oil, higher oxygen content, and lower heating value of the biodiesel (Saridemir et al., 2020).

Hydrocarbon (HC) of babassu biodiesel (A) and soybean biodiesel (B), and exhaust gas temperature (EGT) of babassu (C) and soybean biodiesel (D) according to engine load and biodiesel blends.

The utilization of babassu biodiesel in power generators can provides traditional and remote communities with access to a locally available and renewable energy source, fostering greater energy autonomy. This strategy has the potential to reduce dependence on imported diesel, decrease energy costs, and establish a value-added chain for babassu harvesters, thereby contributing to local economic development and strengthening energy resilience.

Despite the positive results obtained for babassu biodiesel, comprehensive research on babassu biodiesel engine durability is still required to understand its wear mechanisms. Engine component durability depends on deterioration over time and usage (Gupta & Agarwal, 2021). Additional tests should be conducted with different engine types and operational conditions.

CONCLUSIONS

-

The results showed that the SFC of the babassu and soybean biodiesels were similar, although babassu B20 reduced the SFC by 9% compared to soybean B20 at a 2500-W load.

-

The babassu B100 blend exhibited lower CO and NOx emissions and EGT than soybean biodiesel at all engine loads.

-

The babassu biodiesel B20 bland exhibited lower CO, NOx, and HC emissions than the soybean and diesel fuels at low loads.

-

The babassu biodiesel B20 blend exhibited better performance in terms of HC and CO emissions than the soybean biodiesel.

ACKNOWLEDGEMENTS

The authors would like to thank the National Council for Scientific and Technological Development (CNPq) and the Coordination for the Improvement of Higher Education Personnel - Brazil (CAPES).

REFERENCES

-

Afonso, S. R., & Ângelo, H. (2009). Mercado dos produtos florestais não-madeireiros do cerrado brasileiro. Ciência Florestal, 19 (3), 315-326. https://doi.org/10.5902/19805098887

» https://doi.org/10.5902/19805098887 -

Aguilar-Aguilar, F. A., Mena-Cervantes, V. Y., & Hernandez-Altamirano, R. (2025). Analysis of public policies and resources for biodiesel production in México. Biomass and Bioenergy, 196, 107762. https://doi.org/10.1016/j.biombioe.2025.107762

» https://doi.org/10.1016/j.biombioe.2025.107762 -

Aydin, M., Uslu, S., & Çelik, M. B. (2020). Performance and emission prediction of a compression ignition engine fueled with biodiesel-diesel blends: A combined application of ANN and RSM based optimization. Fuel, 269, 117472. https://doi.org/10.1016/j.fuel.2020.117472

» https://doi.org/10.1016/j.fuel.2020.117472 -

Bakeas, E., Karavalakis, G., & Stournas, S. (2011). Biodiesel emissions profile in modern diesel vehicles. Part 1: Effect of biodiesel origin on the criteria emissions. Science of The Total Environment, 409(9), 1670-1676. https://doi.org/10.1016/j.scitotenv.2011.01.024

» https://doi.org/10.1016/j.scitotenv.2011.01.024 -

Bassegio, D., & Zanotto, M. D. (2020). Growth, yield, and oil content of Brassica species under Brazilian tropical conditions. Bragantia, 79, 203 - 212. https://doi.org/10.1590/1678-4499.20190411

» https://doi.org/10.1590/1678-4499.20190411 -

Benjumea, P., Agudelo, J., & Agudelo, A. (2008). Basic properties of palm oil biodiesel-diesel blends. Fuel, 87 (10 - 11), 2069 - 2075. https://doi.org/10.1016/j.fuel.2007.11.004

» https://doi.org/10.1016/j.fuel.2007.11.004 -

Bharti, A., Debbarma, S., & Das, B. (2023). Effect of hydrogen enrichment and TiO2 nanoparticles on waste cooking palm biodiesel run CRDI engine. International Journal of Hydrogen Energy, 48 (75), 29391 - 29402. https://doi.org/10.1016/j.ijhydene.2023.04.081

» https://doi.org/10.1016/j.ijhydene.2023.04.081 -

Çakmak, A., Özcan, H. (2022). Analysis of combustion and emissions characteristics of a DI diesel engine fuelled with diesel/biodiesel/glycerol tert-butyl ethers mixture by altering compression ratio and injection timing. Fuel, 315, 123200. https://doi.org/10.1016/j.fuel.2022.123200

» https://doi.org/10.1016/j.fuel.2022.123200 -

César, A.S, Conejero, M. A., Ribeiro, E. C. B., & Batalha, M. O. (2019). Competitiveness analysis of "social soybeans" in biodiesel production in Brazil. Renewable Energy, 133, 1147-1157. https://doi.org/10.1016/j.renene.2018.08.108

» https://doi.org/10.1016/j.renene.2018.08.108 -

Deheri, C., Acharya, S. K., Thatoi, D. N., & Mohanty, A. P. (2020). A review on performance of biogas and hydrogen on diesel engine in dual fuel mode. Fuel, 260, 116337. https://doi.org/10.1016/j.fuel.2019.116337

» https://doi.org/10.1016/j.fuel.2019.116337 -

Duan, X., Li, Y., Liu, J., Guo, G., Fu, J., Zhang, Q., Zhang S., & Liu, W. (2019). Experimental study the effects of various compression ratios and spark timing on performance and emission of a lean-burn heavy-duty spark ignition engine fueled with methane gas and hydrogen blends. Energy, 169, 558-571. https://doi.org/10.1016/j.energy.2018.12.029

» https://doi.org/10.1016/j.energy.2018.12.029 -

Erman, A. G., Hellier, P., & Ladommatos, N. (2020). The impact of ignition delay and further fuel properties on combustion and emissions in a compression ignition engine. Fuel, 262, 116155. https://doi.org/10.1016/j.fuel.2019.116155

» https://doi.org/10.1016/j.fuel.2019.116155 -

Girardi, J. C., Bariccatti, R. A., de Souza, S. N. M., do Amaral, C. Z., & Guedes, C. L. B. (2021). Natural compounds as antifreeze additives to improve babassu biodiesel. Fuel, 289, 119746. https://doi.org/10.1016/j.fuel.2020.119746

» https://doi.org/10.1016/j.fuel.2020.119746 -

Gongora, B., Souza, S. N. M., Bassegio, D., Santos, R. F., Siqueira, J. A. C., Bariccatti, R. A., Gurgacz F., Secco D., Tokura L. K., & Sequinel, R. (2022). Comparison of emissions and engine performance of safflower and commercial biodiesels. Industrial Crops and Products, 179, 114680. https://doi.org/10.1016/j.indcrop.2022.114680

» https://doi.org/10.1016/j.indcrop.2022.114680 -

Gupta, J. G., & Agarwal, A. K. (2021). Engine durability and lubricating oil tribology study of a biodiesel fuelled common rail direct injection medium-duty transportation diesel engine. Wear, 486, 204104. https://doi.org/10.1016/j.wear.2021.204104

» https://doi.org/10.1016/j.wear.2021.204104 -

Ilkiliç, C., Aydin, S., Behcet, R., & Aydin, H. (2011). Biodiesel from safflower oil and its application in a diesel engine. Fuel Processing Technology, 92 (3), 356-362. https://doi.org/10.1016/j.fuproc.2010.09.028

» https://doi.org/10.1016/j.fuproc.2010.09.028 -

Kivevele, T. T., Mbarawa, M. M., Bereczky, A., Laza, T., & Madarasz, J. (2011). Impact of antioxidant additives on the oxidation stability of biodiesel produced from Croton Megalocarpus oil. Fuel Processing Technology, 92 (6), 1244 - 1248. https://doi.org/10.1016/j.fuproc.2011.02.009

» https://doi.org/10.1016/j.fuproc.2011.02.009 -

Machado, G. C., Chaves, J. B. P., & Antoniassi, R. (2006). Composição em ácidos graxos e caracterização física e química de óleos hidrogenados de coco babaçu/physical and chemical characterization and fatty acid composition of babassu oil. Ceres, 53 (308). https://ojs.ceres.ufv.br/ceres/article/view/3169

» https://ojs.ceres.ufv.br/ceres/article/view/3169 -

Mathew, G. M., Raina, D., Narisetty, V., Kumar, V., Saran, S., Pugazhendi, A., Sindhu, R., Pandey, A., & Binod, P. (2021). Recent advances in biodiesel production: Challenges and solutions. Science of the Total Environment, 794, 148751. https://doi.org/10.1016/j.scitotenv.2021.148751

» https://doi.org/10.1016/j.scitotenv.2021.148751 -

Mofijur, M., Masjuki, H. H., Kalam, M. A., Atabani, A. E., Fattah, I. R., & Mobarak, H. M. (2014). Comparative evaluation of performance and emission characteristics of Moringa oleifera and Palm oil based biodiesel in a diesel engine. Industrial Crops and Products, 53, 78-84. https://doi.org/10.1016/j.indcrop.2013.12.011

» https://doi.org/10.1016/j.indcrop.2013.12.011 -

Outili, N., Kerras, H., Nekkab, C., Merouani, R., & Meniai, A. H. (2020). Biodiesel production optimization from waste cooking oil using green chemistry metrics. Renewable Energy, 145, 2575-2586. https://doi.org/10.1016/j.renene.2019.07.152

» https://doi.org/10.1016/j.renene.2019.07.152 -

Paiva, E. J., da Silva, M. L. C., Barboza, J. C., de Oliveira, P. C., de Castro, H. F., & Giordani, D. S. (2013). Non-edible babassu oil as a new source for energy production-a feasibility transesterification survey assisted by ultrasound. Ultrasonics sonochemistry, 20 (3), 833 - 838. https://doi.org/10.1016/j.ultsonch.2012.11.003

» https://doi.org/10.1016/j.ultsonch.2012.11.003 -

Palash, S. M., Kalam, M. A., Masjuki, H. H., Masum, B. M., Fattah, I. R., & Mofijur, M. (2013). Impacts of biodiesel combustion on NOx emissions and their reduction approaches. Renewable and Sustainable Energy Reviews, 23, 473-490. https://doi.org/10.1016/j.rser.2013.03.003

» https://doi.org/10.1016/j.rser.2013.03.003 -

Ranjan, A., Singh, S., Malani, R. S., & Moholkar, V. S. (2016). Ultrasound-assisted bioalcohol synthesis: review and analysis. RSC advances, 6 (70), 65541-65562. https://doi.org/10.1039/c6ra11580b

» https://doi.org/10.1039/c6ra11580b -

Rashed, M. M., Kalam, M. A., Masjuki, H. H., Mofijur, M., Rasul, M. G., & Zulkifli, N. W. M. (2016). Performance and emission characteristics of a diesel engine fueled with palm, jatropha, and moringa oil methyl ester. Industrial Crops and Products, 79, 70-76. https://doi.org/10.1016/j.indcrop.2015.10.046

» https://doi.org/10.1016/j.indcrop.2015.10.046 -

Samraj, A., Barik, D., Bhatlu, M. L. D., Rout, S. K., Ayadi, B., Aich, W., ... & Kolsi, L. (2023). Effect of diethyl ether on the performance and emission characteristics of a diesel engine fueled with a light fraction of waste cooking oil. Processes, 11 (9), 2613. https://doi.org/10.3390/pr11092613

» https://doi.org/10.3390/pr11092613 -

Samuelsen, G. S., Brouwer, J., Vardakas, M. A., & Holdeman, J. D. (2013). Experimental and modeling investigation of the effect of air preheat on the formation of NO x in an RQL combustor. Heat and Mass Transfer, 49, 219 - 231. https://doi.org/10.1007/s00231-012-1080-0

» https://doi.org/10.1007/s00231-012-1080-0 -

Sanjid, A., Masjuki, H. H., Kalam, M. A., Rahman, S. A., Abedin, M. J., & Palash, S. M. (2014). Production of palm and jatropha based biodiesel and investigation of palm-jatropha combined blend properties, performance, exhaust emission and noise in an unmodified diesel engine. Journal of Cleaner Production, 65, 295 - 303. https://doi.org/10.1016/j.jclepro.2013.09.026

» https://doi.org/10.1016/j.jclepro.2013.09.026 -

Saridemir, S., Gürel, A. E., Agbulut, Ü., & Bakan, F. (2020). Investigating the role of fuel injection pressure change on performance characteristics of a DI-CI engine fuelled with methyl ester. Fuel, 271, 117634. https://doi.org/10.1016/j.fuel.2020.117634

» https://doi.org/10.1016/j.fuel.2020.117634 -

Sarvestani, N. S., Rohani, A., Farzad, A., & Aghkhani, M. H. (2016). Modeling of specific fuel consumption and emission parameters of compression ignition engine using nanofluid combustion experimental data. Fuel Processing Technology, 154, 37-43. https://doi.org/10.1016/j.fuproc.2016.08.013

» https://doi.org/10.1016/j.fuproc.2016.08.013 -

Schönborn, A., Ladommatos, N., Williams, J., Allan, R., & Rogerson, J. (2009). The influence of molecular structure of fatty acid monoalkyl esters on diesel combustion. Combustion and flame, 156 (7), 1396-1412. https://doi.org/10.1016/j.combustflame.2009.03.011

» https://doi.org/10.1016/j.combustflame.2009.03.011 -

Shete, M., Deshpande, H., & Bhosale, S. (2022). Experimental evaluation of performance and emission characteristics of different blends of ecofriendly Hibiscus and Coconut oil mixture on CRDI engine. Sustainable Energy Technologies and Assessments, 54, 102853. https://doi.org/10.1016/j.seta.2022.102853

» https://doi.org/10.1016/j.seta.2022.102853 -

Simsek, S. (2020). Effects of biodiesel obtained from Canola, sefflower oils and waste oils on the engine performance and exhaust emissions. Fuel, 265, 117026. https://doi.org/10.1016/j.fuel.2020.117026

» https://doi.org/10.1016/j.fuel.2020.117026 -

Talapatra, N., Gautam, R., Mittal, V., & Ghosh, U. K. (2023). A comparative study of the growth of microalgae-bacteria symbiotic consortium with the axenic culture of microalgae in dairy wastewater through extraction and quantification of chlorophyll. Materials Today: Proceedings, 80, 2268-2273. https://doi.org/10.1016/j.matpr.2021.06.227

» https://doi.org/10.1016/j.matpr.2021.06.227 -

Thiyagarajan, S., Sonthalia, A., Geo, V. E., Prakash, T., Karthickeyan, V., Ashok, B., Nanthagopal, K., & Dhinesh, B. (2020). Effect of manifold injection of methanol/n-pentanol in safflower biodiesel fuelled CI engine. Fuel, 261, 116378. https://doi.org/10.1016/j.fuel.2019.116378

» https://doi.org/10.1016/j.fuel.2019.116378 -

Yesilyurt, M. K., Cesur, C., Aslan, V., & Yilbasi, Z. (2020). The production of biodiesel from safflower (Carthamus tinctorius L.) oil as a potential feedstock and its usage in compression ignition engine: A comprehensive review. Renewable and Sustainable Energy Reviews, 119, 109574. https://doi.org/10.1016/j.rser.2019.109574

» https://doi.org/10.1016/j.rser.2019.109574

-

DATA AVAILABILITY STATEMENT:

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Edited by

-

Area Editor:

Juliana Lobo Paes

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Publication Dates

-

Publication in this collection

21 Nov 2025 -

Date of issue

2025

History

-

Received

28 Nov 2023 -

Accepted

17 Sept 2025

PERFORMANCE AND EMISSION CHARACTERISTICS OF A DIESEL ENGINE FUELED BY BABASSU AND SOYBEAN BIODIESELS

PERFORMANCE AND EMISSION CHARACTERISTICS OF A DIESEL ENGINE FUELED BY BABASSU AND SOYBEAN BIODIESELS