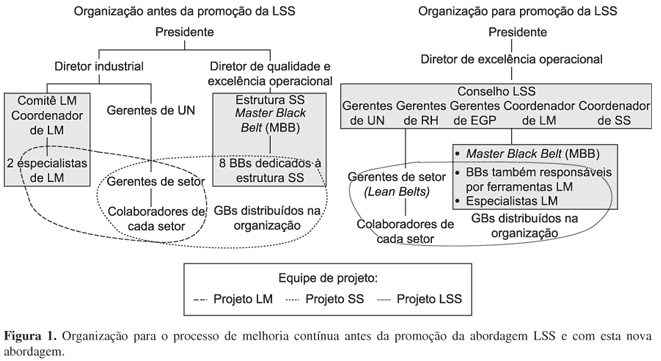

Among the diverse critical success factors that the firms must consider, the pursuit of increasingly higher standards of productivity and quality stands out. In this context, the purpose of this article is to present an initiative to integrate the promotion of the Lean Manufacturing and Six Sigma methodologies in seeking enhanced operational performance. This integration combines the application of Lean Manufacturing elements that aim at the streamlining of value streams by the elimination of wastes with Six Sigma elements which aim at the systematization of the analysis and control of process variation for accomplishing superior quality. This work is based on a case study on the changes undertaken for the implementation of this approach in an auto parts manufacturer. The organizational structure which was established for the promotion of this approach as well as the mode how projects for the improvement of operational performance are tackled by means of it are examined. The results accomplished reveal that the initiative of conciliating the application of these two methodologies may bring about a more wide-ranging and effective continuous improvement process.

Lean Manufacturing; Six Sigma; Lean Six Sigma; Productivity; Quality