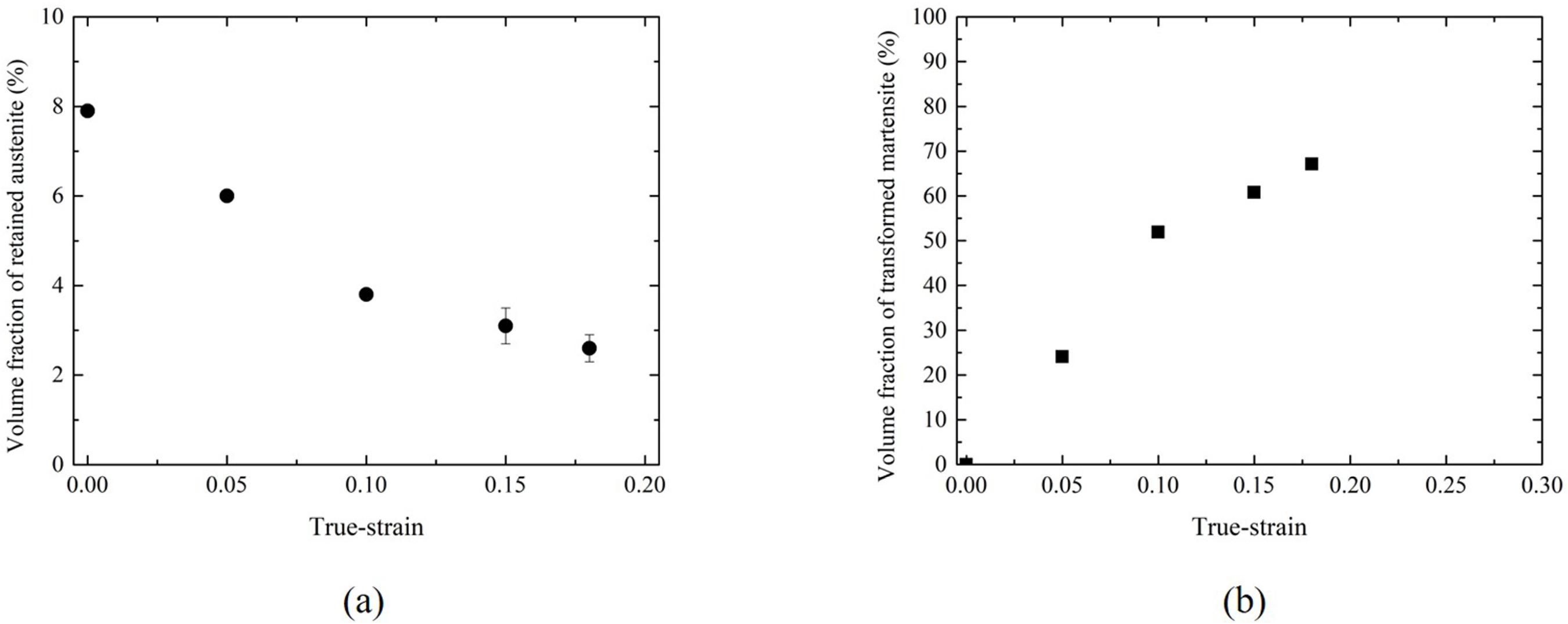

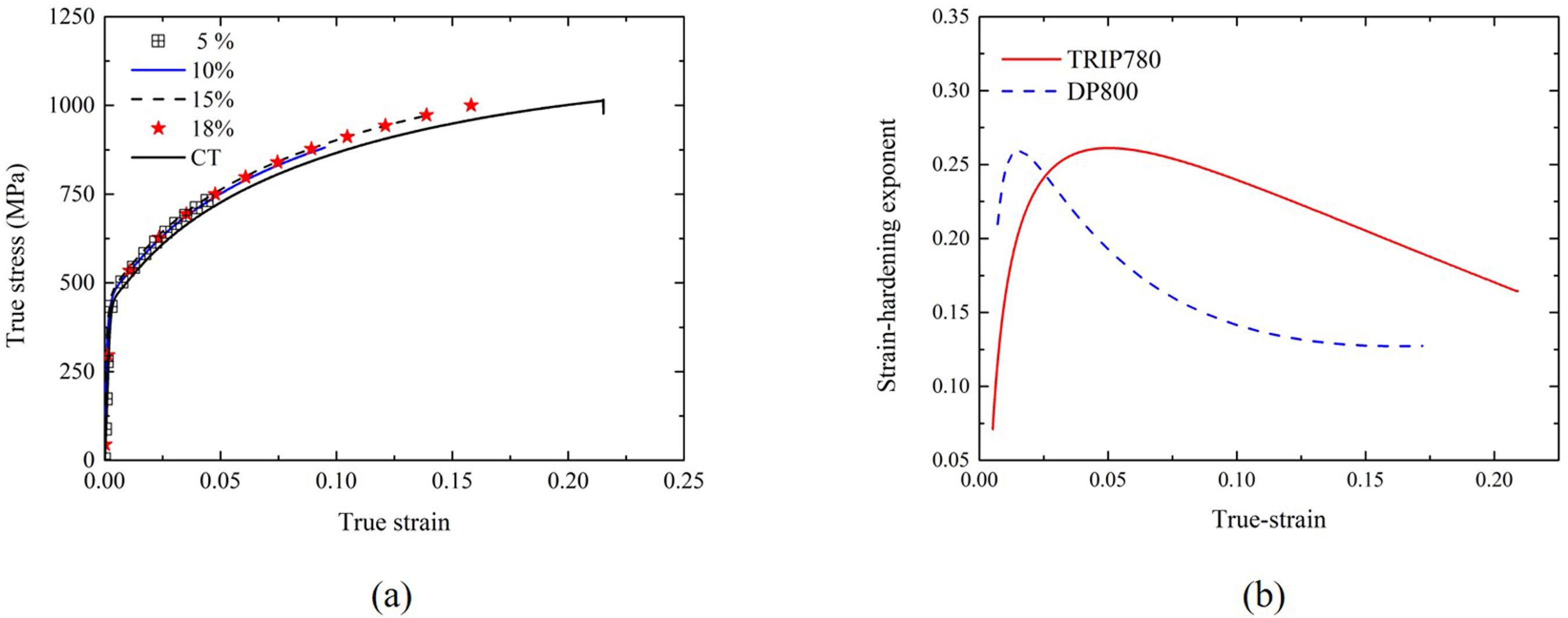

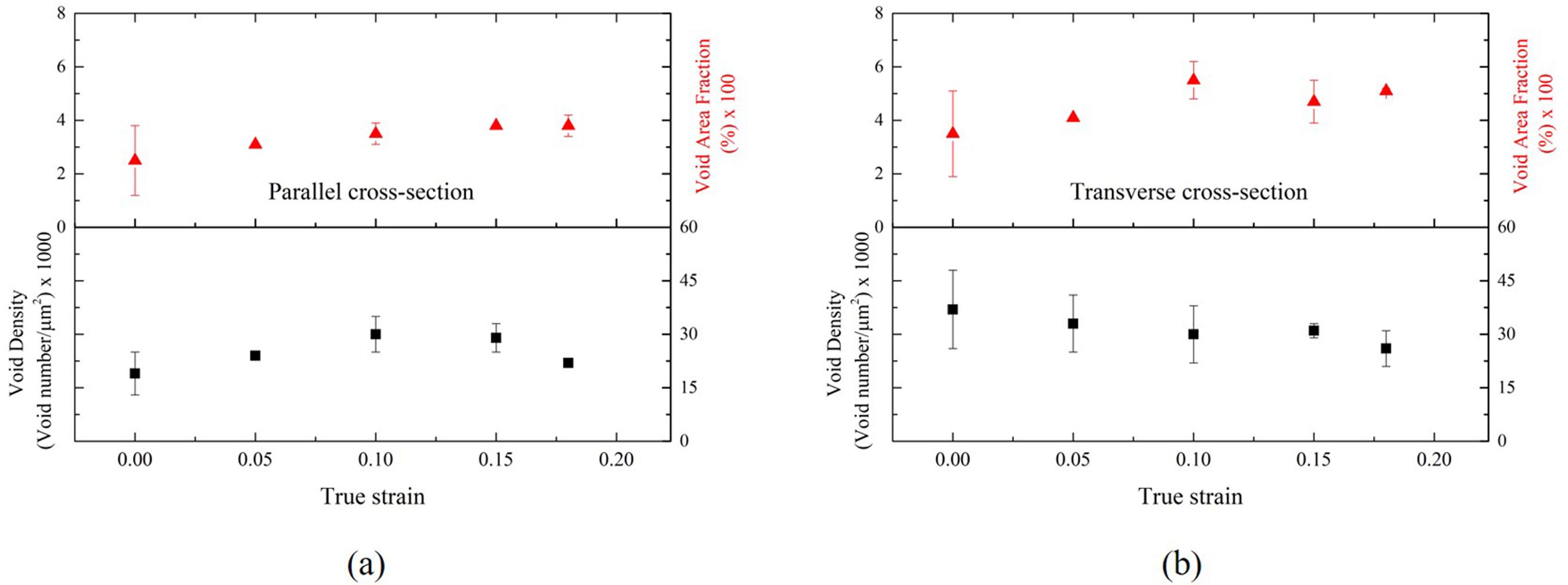

This work aimed to analyze the damage behavior of cold rolled TRIP780 steel sheet submitted to interrupted uniaxial tensile tests performed along the rolling direction. The formation of voids is investigated as a function of the straining level using digital image analysis of scanning electron micrographs to obtain the measures of void density, void area fraction, void aspect ratio and mean void size. The volume fractions of both ferrite/martensite and retained austenite constituents were obtained from X-ray diffraction measurements. An abruptly decrease of retained austenite was observed at early stages of deformation followed by a slow saturation. The resulting strain-induced martensite is responsible for improving the formability of the TRIP780 as observed by instantaneous strain-hardening exponent. In the lower strain range, growth and coalescence of existing microvoids prevailed at both in-plane directions whereas nucleation of microvoids was also observed along the loading direction. Conversely, nucleation prevailed at the transverse direction in the intermediate strain range whereas growth and coalescence were predominant aligned to the loading direction. At larger strain levels, growth and coalescence of microvoids prevailed at both directions. The microvoids were initially found around inclusions and at the interface of ferrite-martensite phases and lastly also at the ferrite matrix.

Keywords:

Strain-induced martensite; retained austenite; void formation; uniaxial tensile; TRIP780 steel