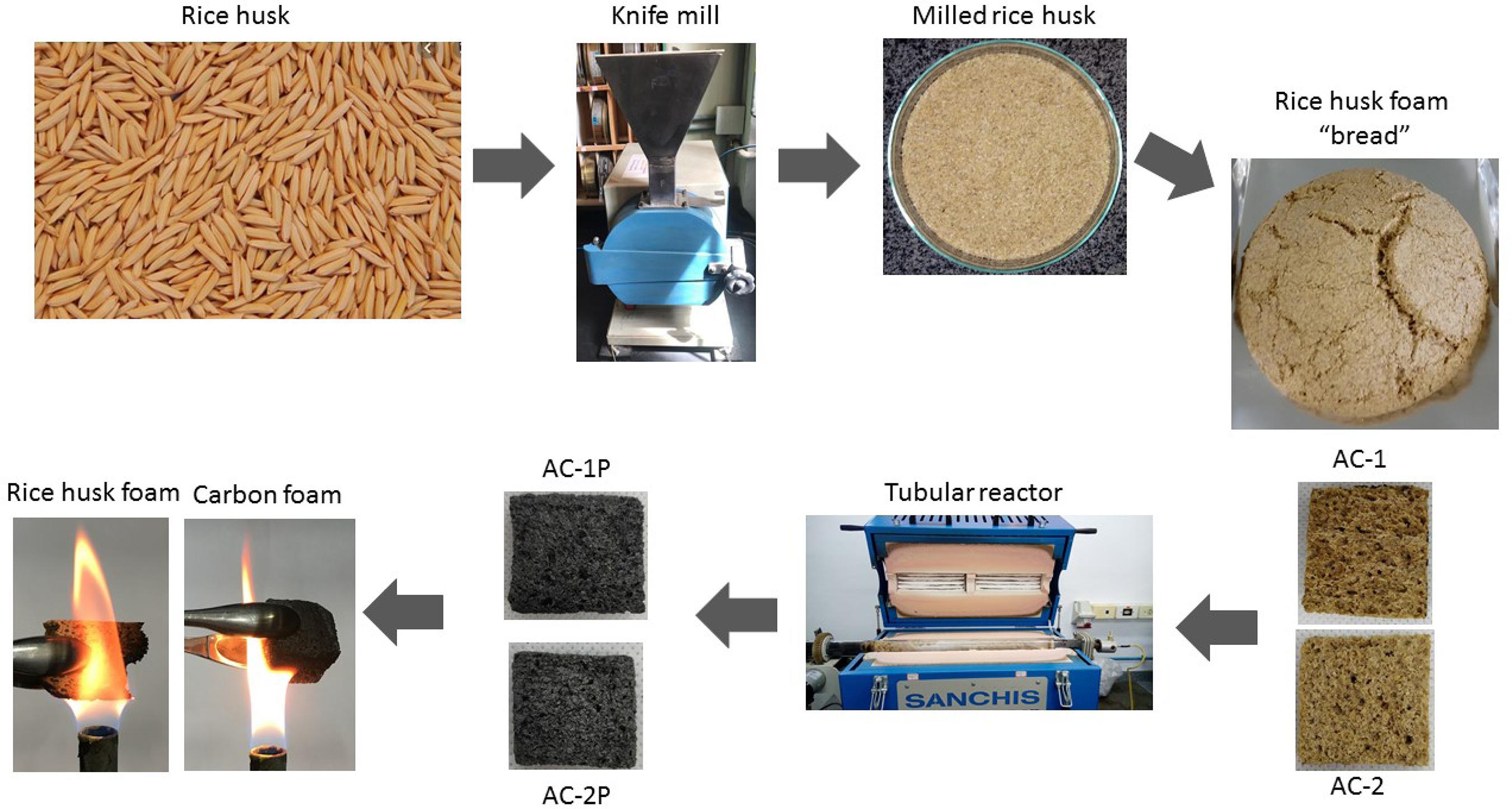

The production of a material with rigid, multifunctional three-dimensional porous structure at a low cost is still challenging to date. In this work, a light and rigid carbon foam was prepared using rice husk as the basic element through a simple fermentation process followed by carbonization. For the fermentation process, the amount of biological yeast (7.5 g for the carbon foam CA-1P and 5 g for the carbon foam CA-2P) was used to evaluate its influence on the morphology of the foams. In order to prove that the heat treatment made in the foam alters the hydrophilic character of the rice husk foam, a chemical treatment with steam deposition was carried out. The foams were characterized by the following analyzes: apparent density, micrograph, thermogravimetry, contact angle, water sorption capacity and thermal conductivity. Visually, the CA-1P foams presented a structure with larger pores due to the greater amount of yeast used in its formulation. The heat treatment of rice potato foams proved to be as efficient as the chemical treatment for water contact angle above 90º, proving the ability of the foams to repel water/moisture. The thermal conductivity of the foams (0.029 and 0.026 W m-1 K-1 for CA-1P and CA-2P, respectively) was close to the conductivity of polyurethane foams (0.032 W m-1 K-1). Thus, the method used in the production of the carbon foams produced from the rice husk proved to be effective. In addition, the foams produced have the potential to be used for thermal insulation.

Keywords:

Carbon foams; rice husk; thermal insulation