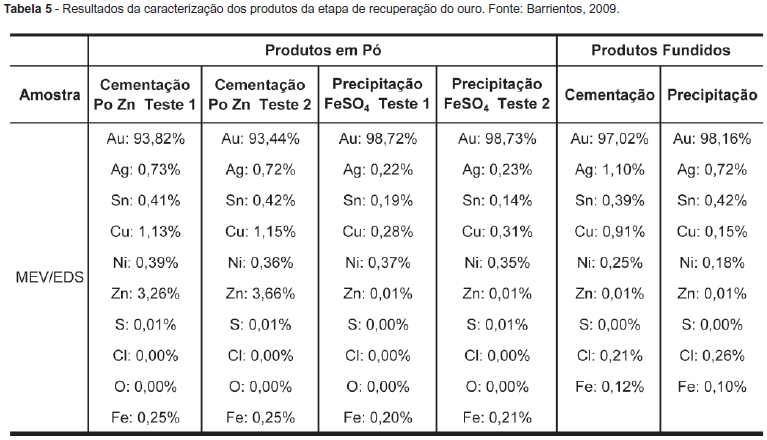

A great amount of scrap metal waste is lost in the manufacturing of gold jewelry due the lack of available knowledge for precious metal recovery in small jewelery shops. This study presents the experimental results on a bench laboratory scale of a hydrometallurgical route to treat gold jewelry scrap using samples with proportions that are higher and lower than 10% Ag. The adopted route consisted of preliminary sampling, leaching with HNO3 to extract the silver, followed by aqua regia leaching of a gold solid residue from the previous leaching stage to dissolve the contained gold. Some typical parameters of the leaching stage were evaluated with the use of a statistical planning of experiments by "The complete Factorial Method" with two experimental levels. The optimum experimental conditions for the maximum metallic extraction were determined by "the ascending path method for statistical optimization". The leaching liquors were treated, aiming for the gold and silver recovery. The silver recovery (94%) occurred by the AgCl calcination obtained with the NaCl added to the HNO3 liquor, and the gold recovery (98.7%) was obtained by the precipitation with the FeSO4 added to the aqua regia liquor.

Gold; silver; precious metals; scrap jewelry treatment; leaching; hydrometallurgy