Abstract

The rheological behavior of poly (butylene adipate-co-terephthalate) (PBAT) and its composites prepared with three different organoclays was investigated. Composites containing up to 7.5%, w/w organoclay, were prepared by two routes: (a) direct melt blending in an internal laboratory mixer with high intensity rotors and (b) concentrates (prepared in the internal mixer) with 50 %, by weight, of the organoclays diluted in a co-rotating twin screw extruder equipped with a high intensity mixing thread operating at a nominal speed of 480 rpm. The samples were characterized by both torque and parallel plate rheometry. Results indicate that nanodispersions in the clay layers were obtained during processing and that, like the pure matrix, at high shear rates, the organoclay compounds follow the power law, although with higher viscosity. It is believed that the interaction of the polymer with the organoclay is responsible for the increase in melt viscosity (observed by increases in torque and relaxation time) of the hybrid systems.

Keywords:

PBAT; organoclay; nanocomposites; rheometry

1. Introduction

Nowadays there is a growing interest in moving towards the production of polymer materials and/or blends that are more environmentally friendly than most commercial polymers, such as polyethylene, polypropylene and polystyrene are not biodegradable and their disposal leads to severe environmental problems (Kashi et al., 2016KASHI, S., GUPTA, R. K., KAO, N., BHATTACHARYA, S. N. Viscoelastic properties and physical gelation of poly (butylene adipate-co-terephthalate)/graphene nanoplatelet nanocomposites at elevated temperatures. Polymer, v. 101, p. 347-357, 2016.). Whenever possible, the substitution of conventional by biodegradable polymers is a means to achieve this goal. PBAT is a highly flexible aliphatic/aromatic copolyester derived from petroleum with high wear and fracture strengths. Moreover, it is deemed to be completely biodegradable with the aliphatic part being responsible for its biodegradability, and the aromatic part providing good mechanical properties compared to other polymers (Bittmann et al., 2012BITTMANN, B., SOUZA, R., BARRAL, L., GONZÁLEZ-RODRÍGUEZ, M. V., ABAD, M. J. Nanoclay-reinforced poly(butylene adipate-co-terephthalate) biocomposites for packaging applications. Polymer Composites, v. 33, p. 2022-2028, 2012., Shalari and Lee, 2012SHAHLARI, M., LEE, S. Mechanical and morphological properties of poly(butylene adipate-co-terephthalate) and poly(lactic acid) blended with organically modified silicate layers. Polymer Engineer Science, v. 52, n. 7, p. 1420-1428, 2012.). In addition, it displays good adhesion and compatibility with many other polymers (Yeh et al., 2010YEH, J.-T, TSOU, C.-H., HUANG, C.-Y., CHEN, K.-N., WU, C.-S., CHAI, W.-L. Compatible and crystallization properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends. Journal Applied Polymer Science, v. 116, n. 2, p. 680-687, 2010.). While exhibiting some excellent properties, such as greater elongation at break and thermal stability at elevated temperatures than most biodegradable polyesters, PBAT has low tensile strength and thus is often used as a second phase in polymer blends. Some researchers, however, have shown that the addition of inorganic fillers, such as clays, to PBAT can improve this low resistance, generating systems with improved mechanical, thermal and electrical properties (Fukushima et al., 2013FUKUSHIMA, K., RASYIDA, A., YANG, M.-C. Characterization, degradation and biocompatibility of PBAT based nanocomposites. Applied Clay Science, v. 80-81, p. 291-298, 2013., Wu, 2009WU, C.-S. Antibacterial and static dissipating composites of poly(butylene adipate-co-terephthalate) and multi-walled carbon nanotubes. Carbon, v. 47, n. 13, p. 3091-3098, 2009.).

Generally, organically modified clays are used to enhance the properties of PBAT. Organophilization reduces clay polarity and increases its basal spacing, which promotes greater chemical and structural affinity with the polymer matrix, as well as favoring clay dispersion and exfoliation. When the intercalation of polymer chains between the clay lamellae increases, the clay layer separates and weakens its stacking bond strength, leading to well dispersed and occasionally exfoliated structures (Singla, 2012SINGLA, P., MEHTA, R., UPADHYAY, S. N. Clay modification by the use of organic cátions. Green and Sustainable Chemistry, v. 2, p. 21-25, 2012.).

The rheological characterization of the composites after mixing may determine the level of dispersion and distribution of the clay in these materials, although there is still controversy regarding the type of structure formed. The viscoelastic response of the composites depends, among other factors, on the degree of compatibility between the biopolymer and the clay (Beatrice et al., 2011BEATRICE, C. A. G., MARINI, J., FAVARO, M. M., BRANCIFORTI, M. C., BRETAS, R. E. S. Processamento e caracterização reológica de nanocompósitos de poli(butileno adipato-co-tereftalato)/montmorilonita (Processing and rheological characterization of poly(butylene adipate-co-terephthalate)/montmorillonite nanocomposites). In: CONGRESSO BRASILEIRO DE POLÍMEROS, 10. Anais... 2011.).

In the present study, up to 7.5% by weight of three types of organoclays were incorporated into PBAT by two different melt mixing routes: a) direct mixing in a torque rheometer and b) by preparing a masterbatch in a torque rheometer followed by dilution to the desired organoclay content in a twin screw extruder. The rheological behavior of the PBAT/organoclay composites was investigated. Torque rheometry was applied to study the effect of filler type and load level on the increase or reduction of viscosity and the degradation rate of each system was compared to that of the matrix. Parallel plate rheometry, performed to analyze the rheological properties of the systems under low shear rates, allows to determine, among other properties, the loss and storage modulus of the systems and to verify if polymer/clay interaction in the molten state in each of the polymer systems investigated exists or not (Bretas et al., 2008BRETAS, R. E. S., ZANIN, M., FARAH, M., CRUZ, S. A. Avaliação das propriedades reológicas de PEAD Virgem/PEAD reciclado (Evaluation of rheological properties of HDPE Virgin/HDPE recycled). Polímeros Ciência e Tecnologia, v. 18, p. 144-151, 2008., Memon and Muller, 1998MEMON, N. A., MULLER, R. Interface, morphology, and rheological properties of polymethylmethacrylate/impact modifier blends. Journal of Polymer Science Part B: Polymer Physics, v. 36, p. 2623-2634, 1998.).

2. Materials and methods

Poly(butylene adipate-co-terephthalate) (PBAT) pellets, supplied by BASF (Ludwigshafen, Germany) as Ecoflex® F Blend 1200, was used as the matrix for the compounds. This aliphatic-aromatic, semicrystalline copolyester has a density of 1.26 g/cm3, melting point below 140ºC, and melt flow rate between 2.7 to 4.9 dg/min (ASTM D1238, 190ºC/2.16Kg) (Yamamoto et al., 2002YAMAMOTO, M., WITT, U., SKUPIN, G., BEIMBORN, D., MÜLLER, R. J. Biodegradable aliphatic-aromatic polyesters: Ecoflex, In: STEINBÜCHEL, A., DOI, Y. (Eds.). Biopolymers - polyesters iii - applications and commercial products. New York & Wenheim: Wiley, 2002. p. 299.).

Three different organoclays were used in the present study; all organically modified sodium montmorillonites employed in this study were supplied by BYL Southern Clay Products (Gonzalez TX, USA). The difference between them is the quaternary ammonium cation used to substitute the inorganic cation in the interlayer gap:

-

Cloisite 10A (C10A): dimethyl benzyl alkyl ammonium cation

-

Cloisite 20A (C20A): dimethyl dialkyl ammonium cation

-

Cloisite 30b (C30B): methyl bis-2-hydroxyethyl alkyl ammonium cation

The alkyl residues are linear saturated chains with 14 to 18 carbon atoms. The clays are supplied as fine whitish powders (90% mass with particle size ≤ 13 µm) and less than 2% moisture content (BYK Additives, 2018BYK ADDITIVES. Cloisite® 10A Nanoclay - Technical Data Sheet, 2018. BYK Additives, Cloisite® 20A Nanoclay - Technical Data Sheet, 2018. BYK Additives, Cloisite® 30B Nanoclay - Technical Data Sheet, 2018.). Some of their properties are listed in Table 1.

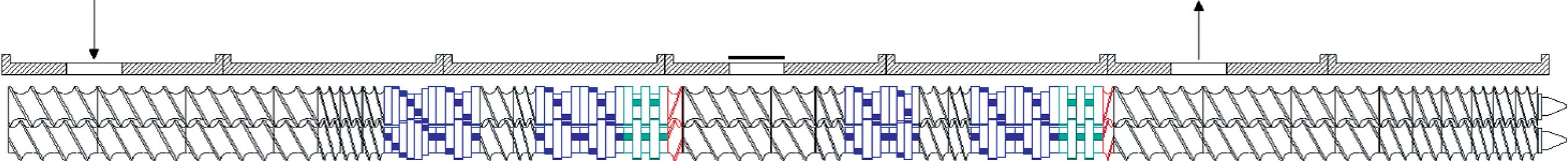

Samples for the rheological characterization were prepared by a three-step procedure. First, masterbatches with 50% (by mass) organoclay content were produced in a Haake Rheomix 3000 laboratory internal mixer fitted with high intensity "roller" rotors, operated at a nominal speed of 120 rpm for 15 min, with the mixing chamber wall kept at 170ºC and a fill factor of approximately 70% estimated at feed conditions. The masterbatches, prepared with the three organoclays, were then grounded and let down to 5% w/w organoclay content in a 22 mm, 38 L/D co-rotating twin-screw extruder NZ, model SJ-20, operated at 480 rpm, flow rate of 10.0 Kg/h and the barrel temperature maintained at 160ºC. The screw configuration is shown in Figure 1.

Finally, type I tensile test (ASTM D638) specimens were injection molded in an Arburg Allrounder equipment. The neat polymer matrix was processed in the same way for comparison purposes.

Although flow patterns in mixers and twin-screw extruders involve extensional as well as shear components and the viscoelastic nature of molten polymers makes its mathematical description extremely complex (Tadmor & Gogos, 2006TADMOR, Z., GOGOS, C. G. Principles of polymer processing. (2. ed.). Hoboken NJ: Wiley-Interscience, 2006.; Agassant et al, 2017AGASSANT, J.-F., AVENAS, P., CARREAU, P. J., VERGNES, B., VINCENT, M. Polymer processing. Principles and modeling, (2. ed.) Munich & Cincinnati: Hanser, 2017.), it may be analyzed, in first approximation, as a simple shear flow characterized by a shear rate and temperature dependent viscosity.

The rheological characteristics of matrix and compounds were investigated with a parallel plate rheometer Physica MCR 301 from Anton Parr (Graz, Austria), with 25- mm diameter plates and a gap of 1 mm, operated in oscillatory mode and small amplitudes. Samples were cut from the central part of the specimens. Tests were conducted at 170ºC, 180ºC, and 190ºC, at frequencies between 0.01 a 600 s-1.

In addition, compounds of PBAT with 2.5%, 5.0% and 7.5% w/w of Cloisite 20A were prepared by direct mixing in the laboratory internal mixer, operated at two different nominal rotor speeds (60 and 180 rpm) and the same chamber wall temperature, fill factor, and processing time employed for the preparation of the masterbatch. The rheological characteristics and incipient degradation were determined from the torque and temperature reported by the instrument as functions of time during the last stage of processing (melt processing).

Torque rheometry and parallel plate rheometry were independent studies. Torque rheometry was performed to investigate nanocomposites stability during processing, was done at a single shear rate and is not a sensitive technique compared to parallel plate rheometry.

3. Results and discussion

Parallel plate rheometry

Samples of PBAT (as received), as well as processed PBAT and PBAT/5%C10A, PBAT/5%C20A, and PBAT/5%C30B compounds prepared as described in the Experimental section, were tested by parallel plate rheometry at three temperatures (170ºC, 180ºC and 190ºC) and frequencies in the range 0.012 to 600 s-1. The magnitude of the complex viscosity η* was computed from the shear storage and loss modulus, G' and G", for each frequency of oscillation ω:

Cox-Merz rule (Cox and Merz, 1958COX, W., MERZ, E. Correlation of dynamic and steady-flow viscosities. Journal of Polymer Science, Part A-2: Polymer Physics, v. 28, p. 619, 1958.) allows the identification of |η*|as a function of ω with the shear (ordinary) viscosity η as a function of the shear rate :

Figure 2 shows a log-log plot of η = η () for T = 180ºC; similar plots were obtained for other temperatures tested.

The shear rate dependence of the viscosity of the neat matrix follows the usual pattern, with a Newtonian plateau at low shear rates ( <1 s-1) and power-law dependence at high shear rates ( >100 s-1), and a broad transition between the two regimes (1s-1 < < 100 s-1). The effect of processing is shown as a 45% decrease of the (Newtonian) viscosity compared with the pristine, unprocessed resin.

At high shear rates, the organoclay compounds follow a power-law just like the neat polymer, albeit at a high viscosity level, increasing according to the load C30B < C20A < C10A. No Newtonian plateau is observed at low shear rates. Instead, viscosity becomes directly proportional to the rate of shear, indicating the existence of a yield stress, as shown in Figure 3, where the same data are plotted as a function of shear stress, τ = η. .

The viscosities of the neat polymers (as received and processed) may be correlated as a function of shear rate over the whole interval of measured values by the well-known Cross model (Cross, 1965CROSS, M. M. Rheology of non-Newtonian fluids: a new flow equation for pseudoplastic systems. Journal of Colloid Science, v. 20, n. 5, p. 417, 1965.):

where η0 is the Newtonian viscosity, n is power law (or pseudoplasticity) index, and λ0 is a characteristic time ( γ0 = λ0 -1is the characteristic shear rate at which the rheological behavior of the melt changes from that of a Newtonian - purely viscous - liquid to a power-law - viscoelastic - fluid). Parameters obtained by nonlinear regression of the experimental data (r2 > 0.998) are presented in Table 2.

The Newtonian viscosity and characteristic time show a significant dependence on temperature. Within the limited temperature range tested in this work, their dependence is well represented by a simple exponential expression:

where T0 is an arbitrary reference temperature (e.g. T0 = 180ºC). Linear regression of ln 0 is the Newtonian viscosity, n is power law (or pseud0 versus T - T0 (r2 > 0.995) lead to β0 = 0.035ºC−1 for the unprocessed PBAT and to β0 = 0.038ºC−1 for the processed PBAT. The power-law index is practically independent on temperature; values of n = 0.44 for the unprocessed PBAT and n = 0.40 for the processed PBAT may be used.

The viscosities of the PBAT/organoclay compounds may be correlated as a function of shear rate by the expression obtained adding a yield stress term to the Cross model (Shenoy, 1999SHENOY, A. V. Rheology of filled polymer systems. Dordrecht: Springer Science & Business Media, 1999.):

where τ0 is an apparent yield stress. Parameters obtained by nonlinear regression of the experimental data (r2 > 0.995) are displayed in Table 3.

It is known that the existence of an apparent yield stress in layered silicate compounds suggests an exfoliated morphology (Wagener and Reisinger, 2003WAGENER, R., REISINGER, T. J. G. A rheological method to compare the degree of exfoliation of nanocomposites. Polymer, v. 44, p. 7513-7518, 2003., Zhao et al., 2005ZHAO, J., MORGAN, A. B., HARRIS, J. D. Rheological characterization of polystyrene-clay nanocomposites to compare the degree of exfoliation and dispersion. Polymer, v. 46, p. 8641-8660, 2005., Costa et al., 2006COSTA, F. R., WAGENKNECHT, U., JEHNICHEN, D., GOAD, M. A., HEINRICH, G. Nanocomposites based on polyethylene and Mg-Al layered double hydroxide. Rheological characterization. Polymer, v. 47, p. 1649-1660, 2006., Durmus et al., 2007DURMUS, A., KASGOZ, A., MACOSKO, C. W. Linear low density polyethylene (LLDPE)/clay nanocomposites. Structural characterization and quantifying clay dispersion by melt rheology. Polymer, n. 48, p. 4492-4502, 2007., Bhattacharya et al., 2008BHATTACHARYA, S. N., KAMAL, M. R., GUPTA, R. K. Polymeric nano-composites - theory and practice. Munich & Cincinnati: Hanser, 2008., Cassagnau, 2008CASSAGNAU, P. Melt rheology of organoclay and fumed silica nanocomposites. Polymer, v. 49, p. 2183-2196, 2008., Vergnes, 2011VERGNES, B. The use of apparent yield stress to characterize exfoliation in polymer nanocomposites. International Polymer Processing, v.26, p. 229-232, 2011.). Thus, the results obtained in this investigation suggest the dispersion of all organoclays tested in the PBAT matrix at a nanometric level, with a significant degree of exfoliation of the clay layers, when the compounds were processed as described in the Experimental section. Nanodispersion was probably achieved in the co-rotating twin-screw extrusion step, although the contribution of the masterbatch preparation in the internal mixer cannot be discarded.

Comparison of the Newtonian viscosity η0 of the nanocompounds and the neat matrix shows that the organoclays enhanced the degradation of the polymer during processing. However, the viscosity of the compounds is higher than that of the matrix at high shear rates, due to the 200-fold increase of the characteristic time (a parameter associated to the relaxation time) of the nanocompounds compared with the neat matrix. Figure 4 graphically shows two important rheological parameters of the nanocompounds.

Figure 4a reveals the C20A organoclay, with non-polar substituents on the organic cation, is two times more efficient at promoting exfoliation than the C30B organoclay, the only clay tested which has a polar substituent in its structure. Considering the polar nature of the PBAT matrix, this finding seems paradoxical. The efficiency of the C20A in comparison with the C30B may be explained by the greater bulkiness of the organic modifier - reflected in the lower density and higher interlayer spacing of the organoclay, as shown in Table 1, which may facilitate the intercalation of the polymer chains and eventual exfoliation of the clay.

Figure 4b shows a peculiarity of the nanocompounds tested: the temperature dependence of the power-law index, a parameter which is virtually independent of temperature in neat matrix.

Although the normal stresses were not measured directly, an estimate of the relative importance of the elastic characteristics of the viscoelastic molten matrix and compounds may be obtained (Bird et al., 1987BIRD, R. B., ARMSTRONG, R. C., HASSAGER, O. Dynamics of polymeric liquids. Fluids Mechanics. (2. ed.). New York: John Wiley & Sons, 1987. v. 1.):

where N1 is the first difference of normal stresses and τ is the shear stress. Eq. (6) was derived from the equivalent of the Cox-Merz rule for the elastic components of the viscoelastic response reported by Laun (Laun, 1986LAUN, H. M. Prediction of elastic strains of polymer melts in shear an elongation. Journal Rheology, v. 30, n. 3, p. 459, 1986., Winter, 2009WINTER, H. H. Three views of viscoelasticity for Cox-Merz materials. Rheological Acta, v. 48, n.3, p.24, 2009., Sharma and McKinley, 2012SHARMA, V., MCKINLEY, G. H. An intriguing empirical rule for computing the first normal stress difference from steady shear viscosity data for concentrated polymer solutions and melts. Rheological Acta, v. 51, n. 6, p. 487, 2012.). The stress ratio S is shown in Figure 5 as a function of shear rate for T = 180ºC; similar plots were obtained for other temperatures tested.

At low shear rates, the neat matrices behave as viscous liquids, their viscoelastic character increasing with the shear rate. On the other hand, elastic components dominate the rheological behavior of the nanocompounds at all rates of deformation tested.

Torque rheometry

During melt processing in an internal mixer at constant rotor speed, torque - which is a measure of the rate of energy dissipation in the mixing chamber - is proportional to the viscosity. If the temperature dependence of the viscosity is eliminated defining a temperature-adjusted torque Z*:

where Z and T are the time-dependent torque and melt temperature in the processing chamber, β is a temperature coefficient of the viscosity at processing conditions, and T* is an arbitrary reference temperature. Changes in adjusted torque with time reflect changes in the molar mass of the polymer matrix, and have been used to estimate the incipient polymer degradation or recovery during processing (Almeida et al., 2016ALMEIDA, T. G., SILVA NETO, J. E., COSTA, A. R. M., SILVA, A. S., CARVALHO, L. H., CANEDO, E. L. Degradation during processing in poly(butylene adipate-co-terephthalate)/vegetable fiber compounds estimated by torque rheometry. Polymer Testing, v. 55, p. 204-211, 2016., Alves et al., 2016ALVES, T. S., SILVA NETO, J. E. S, SILVA, S. M. L., CARVALHO, L. H., CANEDO, E. L. Process simulation of laboratory internal mixers. Polymer Testing, v. 50, p. 94-100, 2016., Duarte et al., 2016DUARTE, I. S., TAVARES, A. A., LIMA, P. S., ANDRADE, D. L. A. C. S., CARVALHO, L. H., CANEDO, E. L., SILVA, S. M. L. Chain extension of virgin and recycled poly(ethylene terephthalate): Effect of processing conditions and reprocessing. Polymer Degradation and Stability, v. 124, p. 26-34, 2016., Tavares et al., 2016TAVARES, A. A., SILVA, D. F. A., LIMA, P. S., ANDRADE, D. L. A. C. S., SILVA, S. M. L., CANEDO, E. L. Chain extension of virgin and recycled polyethylene terephthalate. Polymer Testing, v. 50, p. 26-32, 2016.). The relative decrease rate of the adjusted torque in the last stage of processing in the internal mixer is given by:

and it may be considered a valid measure of the polymer stability during processing. Rz is approximately proportional to the rate of change of the mass-average molar mass (Marinho et al., 2017MARINHO, V. A. D., PEREIRA, C. A. B., VITORINO, M. B. C., SILVA, A. S., CARVALHO, L. H., CANEDO, E. L. Degradation and recovery in poly(butylene adipate-co-terephthalate)/thermoplastic starch blends. Polymer Testing, v. 58, p. 166-172, 2017.):

Figure 6 graphically shows the effect of the clay content and rotor speed (proportional to the rate of deformation) on adjusted torque (proportional to melt viscosity) and rate of adjusted torque decrease (proportional to the rate of degradation), evaluated as described in the Experimental section, during the last third (10-15 min) processing time.

Results (Figure 6a) show that organoclay incorporation did not affect melt viscosity, not even at high rotor speed, a finding consistent with the behavior of low loading level isometric microcomposites, suggesting that nanodispersion was nor achieved during processing in the internal mixer. They confirm the suspicion that twin-screw extruder processing was responsible for the excellent results previously reported herein. Incipient degradation of PBAT, minimal in the neat resin sample, increased to moderate levels upon incorporation of the clay (Figure 6b).

4. Conclusions

Nanocomposites were obtained by melt intercalation in an internal laboratory mixer followed in a double-screw extruder, with a significant degree of exfoliation of the clay layers during the extrusion stage. The rheological behavior of the matrix and the prepared nanocomposites were investigated by torque rheometry and a parallel plate rheometry to understand the effects of the interaction between matrix and organoclays on the rheological behavior of these materials. The results indicate that just as the pure matrix, at high shear rates, the organoclays compounds follow the power law, albeit with higher viscosity. It is believed that the interaction of the polymer with the organoclays is responsible for the increase in melt viscosity (observed by increases in torque and relaxation time) of the hybrid systems. Incorporation of the organoclays into the PBAT increases degradation of the polymer during processing. The molten materials behave as pseudoplastics in the range studied.

Acknowledgements

The authors grateful to the Conselho Nacional de Pesquisa (CNPQ-Brazil), Grant #463622/2013-0, and the Coordenação de Aperfeiçoamento do Ensino Superior (CAPES-Brazil), for financial support.

References

- AGASSANT, J.-F., AVENAS, P., CARREAU, P. J., VERGNES, B., VINCENT, M. Polymer processing. Principles and modeling, (2. ed.) Munich & Cincinnati: Hanser, 2017.

- ALMEIDA, T. G., SILVA NETO, J. E., COSTA, A. R. M., SILVA, A. S., CARVALHO, L. H., CANEDO, E. L. Degradation during processing in poly(butylene adipate-co-terephthalate)/vegetable fiber compounds estimated by torque rheometry. Polymer Testing, v. 55, p. 204-211, 2016.

- ALVES, T. S., SILVA NETO, J. E. S, SILVA, S. M. L., CARVALHO, L. H., CANEDO, E. L. Process simulation of laboratory internal mixers. Polymer Testing, v. 50, p. 94-100, 2016.

- BEATRICE, C. A. G., MARINI, J., FAVARO, M. M., BRANCIFORTI, M. C., BRETAS, R. E. S. Processamento e caracterização reológica de nanocompósitos de poli(butileno adipato-co-tereftalato)/montmorilonita (Processing and rheological characterization of poly(butylene adipate-co-terephthalate)/montmorillonite nanocomposites). In: CONGRESSO BRASILEIRO DE POLÍMEROS, 10. Anais... 2011.

- BHATTACHARYA, S. N., KAMAL, M. R., GUPTA, R. K. Polymeric nano-composites - theory and practice Munich & Cincinnati: Hanser, 2008.

- BIRD, R. B., ARMSTRONG, R. C., HASSAGER, O. Dynamics of polymeric liquids. Fluids Mechanics (2. ed.). New York: John Wiley & Sons, 1987. v. 1.

- BITTMANN, B., SOUZA, R., BARRAL, L., GONZÁLEZ-RODRÍGUEZ, M. V., ABAD, M. J. Nanoclay-reinforced poly(butylene adipate-co-terephthalate) biocomposites for packaging applications. Polymer Composites, v. 33, p. 2022-2028, 2012.

- BRETAS, R. E. S., ZANIN, M., FARAH, M., CRUZ, S. A. Avaliação das propriedades reológicas de PEAD Virgem/PEAD reciclado (Evaluation of rheological properties of HDPE Virgin/HDPE recycled). Polímeros Ciência e Tecnologia, v. 18, p. 144-151, 2008.

- BYK ADDITIVES. Cloisite® 10A Nanoclay - Technical Data Sheet, 2018. BYK Additives, Cloisite® 20A Nanoclay - Technical Data Sheet, 2018. BYK Additives, Cloisite® 30B Nanoclay - Technical Data Sheet, 2018.

- CASSAGNAU, P. Melt rheology of organoclay and fumed silica nanocomposites. Polymer, v. 49, p. 2183-2196, 2008.

- COSTA, F. R., WAGENKNECHT, U., JEHNICHEN, D., GOAD, M. A., HEINRICH, G. Nanocomposites based on polyethylene and Mg-Al layered double hydroxide. Rheological characterization. Polymer, v. 47, p. 1649-1660, 2006.

- COX, W., MERZ, E. Correlation of dynamic and steady-flow viscosities. Journal of Polymer Science, Part A-2: Polymer Physics, v. 28, p. 619, 1958.

- CROSS, M. M. Rheology of non-Newtonian fluids: a new flow equation for pseudoplastic systems. Journal of Colloid Science, v. 20, n. 5, p. 417, 1965.

- DUARTE, I. S., TAVARES, A. A., LIMA, P. S., ANDRADE, D. L. A. C. S., CARVALHO, L. H., CANEDO, E. L., SILVA, S. M. L. Chain extension of virgin and recycled poly(ethylene terephthalate): Effect of processing conditions and reprocessing. Polymer Degradation and Stability, v. 124, p. 26-34, 2016.

- DURMUS, A., KASGOZ, A., MACOSKO, C. W. Linear low density polyethylene (LLDPE)/clay nanocomposites. Structural characterization and quantifying clay dispersion by melt rheology. Polymer, n. 48, p. 4492-4502, 2007.

- FUKUSHIMA, K., RASYIDA, A., YANG, M.-C. Characterization, degradation and biocompatibility of PBAT based nanocomposites. Applied Clay Science, v. 80-81, p. 291-298, 2013.

- KASHI, S., GUPTA, R. K., KAO, N., BHATTACHARYA, S. N. Viscoelastic properties and physical gelation of poly (butylene adipate-co-terephthalate)/graphene nanoplatelet nanocomposites at elevated temperatures. Polymer, v. 101, p. 347-357, 2016.

- LAUN, H. M. Prediction of elastic strains of polymer melts in shear an elongation. Journal Rheology, v. 30, n. 3, p. 459, 1986.

- MARINHO, V. A. D., PEREIRA, C. A. B., VITORINO, M. B. C., SILVA, A. S., CARVALHO, L. H., CANEDO, E. L. Degradation and recovery in poly(butylene adipate-co-terephthalate)/thermoplastic starch blends. Polymer Testing, v. 58, p. 166-172, 2017.

- MEMON, N. A., MULLER, R. Interface, morphology, and rheological properties of polymethylmethacrylate/impact modifier blends. Journal of Polymer Science Part B: Polymer Physics, v. 36, p. 2623-2634, 1998.

- SHAHLARI, M., LEE, S. Mechanical and morphological properties of poly(butylene adipate-co-terephthalate) and poly(lactic acid) blended with organically modified silicate layers. Polymer Engineer Science, v. 52, n. 7, p. 1420-1428, 2012.

- SHARMA, V., MCKINLEY, G. H. An intriguing empirical rule for computing the first normal stress difference from steady shear viscosity data for concentrated polymer solutions and melts. Rheological Acta, v. 51, n. 6, p. 487, 2012.

- SHENOY, A. V. Rheology of filled polymer systems Dordrecht: Springer Science & Business Media, 1999.

- SINGLA, P., MEHTA, R., UPADHYAY, S. N. Clay modification by the use of organic cátions. Green and Sustainable Chemistry, v. 2, p. 21-25, 2012.

- TADMOR, Z., GOGOS, C. G. Principles of polymer processing (2. ed.). Hoboken NJ: Wiley-Interscience, 2006.

- TAVARES, A. A., SILVA, D. F. A., LIMA, P. S., ANDRADE, D. L. A. C. S., SILVA, S. M. L., CANEDO, E. L. Chain extension of virgin and recycled polyethylene terephthalate. Polymer Testing, v. 50, p. 26-32, 2016.

- VERGNES, B. The use of apparent yield stress to characterize exfoliation in polymer nanocomposites. International Polymer Processing, v.26, p. 229-232, 2011.

- WAGENER, R., REISINGER, T. J. G. A rheological method to compare the degree of exfoliation of nanocomposites. Polymer, v. 44, p. 7513-7518, 2003.

- WINTER, H. H. Three views of viscoelasticity for Cox-Merz materials. Rheological Acta, v. 48, n.3, p.24, 2009.

- WU, C.-S. Antibacterial and static dissipating composites of poly(butylene adipate-co-terephthalate) and multi-walled carbon nanotubes. Carbon, v. 47, n. 13, p. 3091-3098, 2009.

- YAMAMOTO, M., WITT, U., SKUPIN, G., BEIMBORN, D., MÜLLER, R. J. Biodegradable aliphatic-aromatic polyesters: Ecoflex, In: STEINBÜCHEL, A., DOI, Y. (Eds.). Biopolymers - polyesters iii - applications and commercial products New York & Wenheim: Wiley, 2002. p. 299.

- YEH, J.-T, TSOU, C.-H., HUANG, C.-Y., CHEN, K.-N., WU, C.-S., CHAI, W.-L. Compatible and crystallization properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends. Journal Applied Polymer Science, v. 116, n. 2, p. 680-687, 2010.

- ZHAO, J., MORGAN, A. B., HARRIS, J. D. Rheological characterization of polystyrene-clay nanocomposites to compare the degree of exfoliation and dispersion. Polymer, v. 46, p. 8641-8660, 2005.

Publication Dates

-

Publication in this collection

Apr-Jun 2019

History

-

Received

22 May 2018 -

Accepted

27 Nov 2018