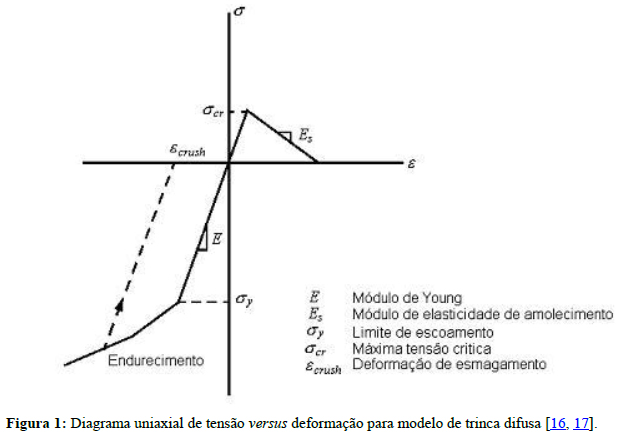

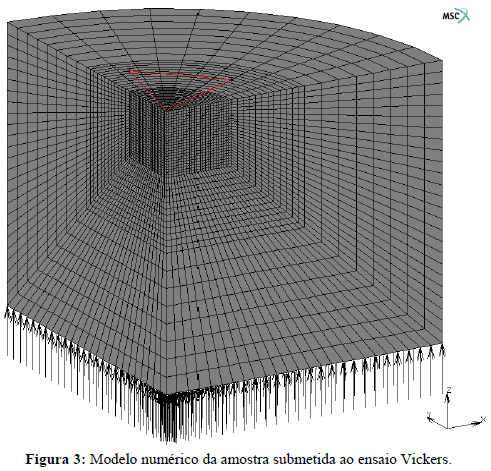

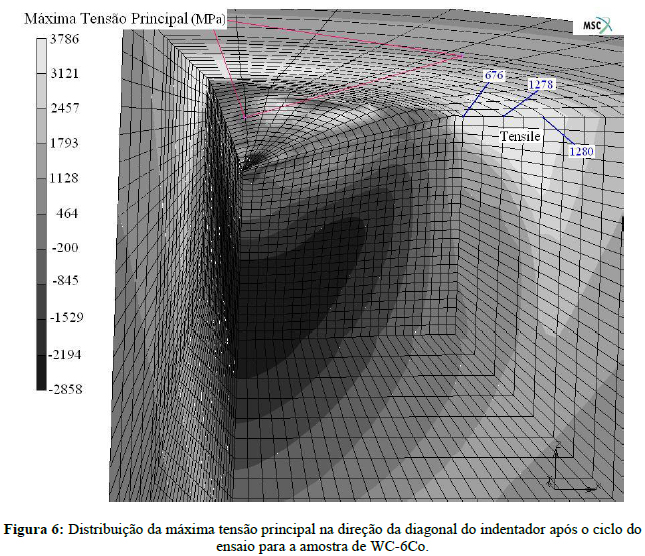

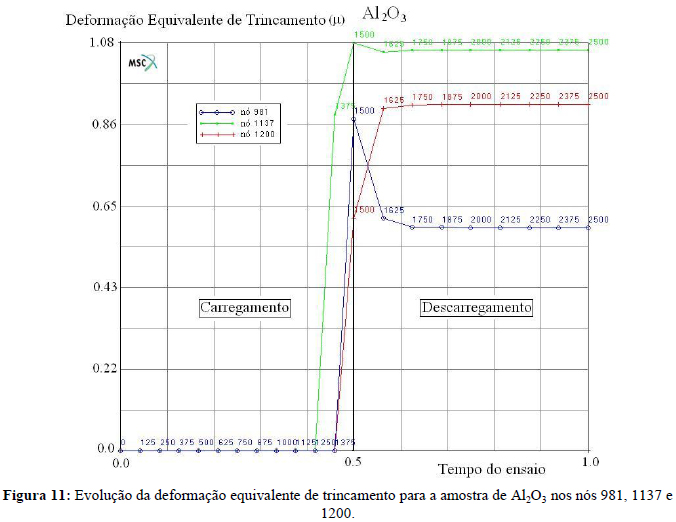

The experimental indentation testing is a methodology used during decades to obtain the surface hardness of different kinds of materials. Nowadays, these tests have been reported in the literature as a reliable tool for mechanical properties determination, such as hardness, Young modulus, yielding stress and fracture toughness. However, the implementation of this indentation technique to evaluate the mechanical properties and also the results therefrom obtained has still brought doubts on research areas. These doubts are really intense when they involve problems which aim to analyse the mechanical behaviour of brittle materials. Because of those testing analysis limitations, the use of a numerical technique, able to evaluate the stress and strain fields during the indentation cycle, may help on a more accurate interpretation of the testing. In this study, the numerical simulation of Vickers hardness testing is modelled with three-dimensional elements making use of commercial explicit finite element code. Two different brittle materials were analyzed, tungsten carbide with cobalt and alumina. The numerical analysis indicated that the model represents well the strain and stress fields during the loading and unloading phases of the Vickers indentation cycle. Those results were found to agree well with the experimental trends presented in the literature. Finally, a diffuse crack constitutive model was used to identify the most probable crack nucleation sites that usually occur during real indentation testing.

Vickers testing; finite element; fracture; brittle materials; cracking model