ABSTRACT

In this paper, we report the characterization of NdTi0.8M0.2O3.4 (M = Ga, Al) ceramics prepared via mixed oxide solid state sintering route. X-ray diffraction analysis of the samples revealed the formation of single phase for NdTi0.8Ga0.2O3.4 sample while secondary phase was formed in the case of NdTi0.8Al0.2O3.4. Microstructural analysis of the sample showed dense packed grains. NdTi0.8M0.2O3.4 with M = Ga and Al exhibited a dielectric constant (er) = 34, quality factor (Q×f) = 9,776 and 10,867 GHz and temperature coefficient of resonance frequency (τf) = -113 and -90 ppm/oC, respectively. Further work is required on tuning the low τf of the samples for possible applications in the GHz frequency range.

Keywords

Ceramics; ABO3.4; Perovskites; Microwave dielectric properties

Keywords

cobalt ferrite; organic pollutant decomposition; photo-Fenton; solar energy propagation

1. INTRODUCTION

The explosive development in the modern wireless communication industry such as cellular phones, base stations, wireless LAN, intelligent transport system (ITS) and microwave integrated circuits (MIC) has increased the demand for investigating new dielectric materials [11 SEBASTIAN, M., UBIC, R., JANTUNEN, H., “Low-loss dielectric ceramic materials and their properties”, Int. Mater. Rev., v. 60, n. 7, pp. 392-412, 2015.]. These applications require appropriate dielectric constant (εr), low dielectric loss or high quality factor (Q×f), and near zero temperature coefficient of resonant frequency (τf) for devices such as resonators, filters, duplexers, and oscillators[22 REANEY, I.M., IDDLES, D., “Microwave dielectric ceramics for resonators and filters in mobile phone networks”, J. Am. Ceram. Soc.; v. 89, pp. 2063-2072, 2006.]. These parameters show the usage of material in different applications. Numerous compounds have been studied for their potential applications in the microwave region but still work is underway to explore new materials.

Dielectric materials show unique dielectric properties and are potential candidate materials for microwave devices. It is well known that among the three important characteristics (εr,Q×f and τf) of dielectric materials, dielectric losses are of prime importance. Dielectric losses depend on various factors including composition, processing and crystal structure [33 HU, L., ZHOU, H., SUN, Q., et al., “Effects of ZrO2–ZnO on the sintering behavior and microwave dielectric properties of 0.65CaTiO3–0.35SmAlO3 ceramics”, J. Mater. Sci.: Mater. Electron.; v. 27, pp. 12834-12839, 2016., 44 HUANG, J., ZHOU, H., WANG, N., et al., “Preparation, structure and microwave dielectric properties of 3MgO–Al2O3–3TiO2 ceramics”, J. Mater. Sci.: Mater. Electron., v. 28, n. 6, pp. 4565–4569, 2016.]. Non-centrosymmetric materials exhibit high dielectric losses due to lack of inversion symmetry while centrosymmetric materials exhibit low dielectric losses. Dielectric losses fall into two categories (intrinsic and extrinsic losses). Intrinsic losses depend on the crystal structure and the interaction of phonons with the electric field while extrinsic losses depends on defects, crystal imperfections, cations ordering, microcracks, porosity, inner stresses and oxygen vacancies etc. [55 LI, L., LI, S., TIAN, T., et al., “Microwave dielectric properties of (1-x)MgTiO3-x(Ca0.6Na0.2Sm0.2)TiO3 ceramic system”, J. Mater. Sci.: Mater. Electron., v. 27, pp. 1286-1292, 2016.

6 ZHANG, H., WANG, X., CHENG, Q., et al., “Preparation of Li2MoO4 using aqueous solution method and microwave dielectric properties after sintering”, J. Mater. Sci.: Mater. Electron., v. 27, pp. 5422-5426, 2016.-77 W. LEI, W.Z. LU, X.H. WANG, et al., “Phase Composition and Microwave Dielectric Properties of ZnAl2O4–Co2TiO4 Low-Permittivity Ceramics with High Quality Factor”, J. Am. Ceram. Soc.; v. 94, pp. 20-23, 2011.]. The major contributor towards dielectric losses is extrinsic. On the hand, K is almost directly proportional to τf (in the absence of any phase transition) and can be controlled by dopants either at A- or B-site of the lattice while τf depends on the tilting schemes [88 REANEY, I.M., COLLA, E.L., SETTER, N., “Dielectric and structural characteristics of Ba-and Sr-based complex perovskites as a function of tolerance factor”, Jap. J. Appl. Phys.; v. 33, pp. 3984-3990, 1994.].

AnBnO3n+2 (n = 5) type layered perovskite structure are attractive materials for the production of passive microwave components in wireless communication systems [99 JAWAHAR, I.N., SANTHA, N.I, SEBASTIAN, M.T, et al., “Microwave Dielectric Properties of MO–La2O3–TiO2 (M= Ca, Sr, Ba) Ceramics”, J. Mater. Res.; v. 17, pp. 3084-3089, 2002.

10 CHEN, Y.C., TSAI, J.M., “Influence of CuO addition and sintering temperature on microwave dielectric properties of Ca0.99Zn0.01La4Ti5O17 ceramics for application in stacked patch antenna”, Jap. J. Appl. Phys.; v. 47, pp. 7959–7962, 2008.

11 DEMŠAR, K., ŠKAPIN, S.D., MEDEN, A., et al., “Rietveld Refinement and Dielectric Properties of CaLa4Ti5O17 and SrLa4Ti5O17 Ceramics”, Acta Chim. Sloven.; v. 55, pp. 966–972, 2008.-1212 MUHAMMAD, R., IQBAL, Y., “Preparation and characterization of K-substituted NaCa4Nb5O17 microwave dielectric ceramics”, J. Mater. Sci.: Mater. Electron.; v. 24, pp. 2322-2326, 2013.]. These compounds consist of five corner shared octahedral slabs connected with each other. The crystal structure and dielectric properties of layered perovskites has received great attention in the last few years [1313 LI, C., WEI, X., FANG, L., “Dielectric and complex impedance analysis of Sr5Nb4TiO17 ceramic with perovskite-like structure”, J. Mater. Sci.: Mater. Electron.; v. 26, pp. 8714-8719, 2015.]. For example, Zinc-substituted Ca0.2La0.8TiO3.4 possesses εr= 57.6,Q×f= 17,100 GHz, τf= -4.9 ppm/°C [1414 ZHAO, F., YUE, Z., GUI, Z., et al., “Effects of zinc substitution on crystal structure and microwave dielectric properties of CaLa4Ti5O17 ceramics”, J. Am. Ceram. Soc.; v. 89, pp. 3421-3425, 2006.]. LaMg0.2Ti0.8O3.4 has been reported to exhibit εr= 29,Q×f= 13,000 GHz, τf= -22 ppm/°C [1515 VANDERAH, T.A., MILLER, V., LEVIN, I., et al., “Phase relations, crystal chemistry, and dielectric properties in sections of the La2O3–CaO–MgO–TiO2 system”, J. Solid State Chem.; v. 177, pp. 2023-2038, 2004.]. Manan and Qazi [1616 MANAN, A., QAZI, I., “Synthesis and microwave dielectric properties of Ca substituted SrLa4Ti4•93Zr0•07O17 ceramics”, Bull. Mater. Sci.; v. 37, pp. 679-683, 2014.] reported Sr0.2La0.8Ti0.986Zr0⋅014O3.4 which exhibited εr= 55,Q×f= 11,960 GHz and τf= 5.2 ppm/°C. Similarly, NaCa4Ta5O17 has been reported to exhibit εr= 41,Q×f= 11,595 GHz and τf= −14 ppm/°C [1717 MUHAMMAD, R., IQBAL, Y., RAMBO, C.R., “Structure–property relationship in NaCa4B5O17 (B = Nb, Ta) perovskites”, J. Mater. Sci.: Mater. Electron.; v. 26, pp. 2161-2166, 2015.]. The microwave dielectric properties of NdTi0.8M0.2O3.4 (M = Al, Ga) phases have not been studied previously, therefore, in the present study, we have characterized NdTi0.8M0.2O3.4 (M = Al, Ga) ceramics and investigated their microwave dielectric properties.

2. MATERIALS AND METHODS

NdTi0.8M0.2O3.4 (M = Al, Ga) ceramics were prepared through solid state route using Nd2O3, TiO2, Al2O3 and Ga2O3 as starting raw materials. In the first step, Nd2O3, TiO2, and Al2O3 were dried at 800 °C for 6 h while Ga2O3 was dried at 500 °C for 6 h, to remove hydroxyl ions and moisture for accurate weighing of 20 g batches. The dried powders were weighted according to the molar ratios of the compositions and then mixed / milled in polyethylene jars, using yttrium stabilized zirconia balls as a grinding media and isopropanol as a liquid medium. The slurries were dried at 85 °C and then sieved through mesh (size 300 mm). The sieved powders were calcined in crucibles at 1250 °C for 6 h, at a heating / cooling rate of 5 °C/min. The calcined powders were re-milled to dissociate agglomerates (if any). The re-milled powders were pressed into pellets in a 10 mm steel die using a uniaxial pellet presser at 100 MPa. These pellets were sintered in the temperature range 1475-1650 °C for 4 h, at a heating / cooling rate of 5 °C/min.

Densities of the pellets were measured using an MD-300s electronic densitometer, based on Archimedes principle. Phase analysis of the samples was carried out using a D-5000 Siemens X-ray diffractometer (with Cu Kα radiation). Raman spectra of the samples were collected using Renishaw microscope system (New Mills, Wotton-Under-Eagle, UK) with a diode 514 nm excitation laser. Microstructure of the samples was examined using FEI Inspect-F Scanning Electron Microscope with built-in EDS system. For microstructural analysis, samples were mechanically polished, thermally etched and coated with carbon. Microwave dielectric properties of the samples were measured using resonant cavity method [1818 LONG, S., MCALLISTER, M., SHEN, L., “The resonant cylindrical dielectric cavity antenna”, IEEE T. Antenn. Propag.; v. 31, pp. 406-412, 1983.]. τf was calculated in temperature range ~20 to 70°C using the formula

where f1 and f2 are the resonance frequency at room temperature and 70°C.

3. RESULTS and discussion

Figure 1 illustrates the room temperature XRD patterns of NdTi0.8Ga0.2O3.4 and NdTi0.8Al0.2O3.4 samples sintered at 1500 and 1600 °C for 4 h. The XRD pattern for NdTi0.8Ga0.2O3.4 (Fig. 1a) matched JCPDS#04-009-0684, for orthorhombic structure (Pnn2 symmetry). The refined lattice parameters were a = 5.4522(17) Å, b = 31.166(8) Å, c = 3.8441(12) Å and V = 653.2(3) Å3. The XRD pattern for NdTi0.8Al0.2O3.4 (Fig. 1b) matched JCPDS#04-009-0684; however, a secondary phase was also formed which matched JCPDS#04-017-8183 for CaLa8Ti9O31 i.e. the major phase belongs to n = 5 and the secondary phase belongs to n = 4.5 series of AnBnO3n+2 type layered perovskite structure.

XRD patterns of sintered a) NdTi0.8Ga0.2O3.4 and b) NdTi0.8Al0.2O3.4 ceramics, showing the formation of single phase for NdTi0.8Ga0.2O3.4 and a secondary phase for NdTi0.8Al0.2O3.4 ceramics.

The room temperature Raman spectra for NdTi0.8Ga0.2O3.4 and NdTi0.8Al0.2O3.4 samples are shown in Fig. 2. Within the studied range, a total of 11 active bands are observed for the sample LaTi0.8Ga0.2O3.4. Amongst them the bands between 270-350 cm-1 may be associated with B-site ordering and rotation of the octahedral cage. The broad bands near 475-550 cm-1 may be due to symmetric breathing of BO6 octahedra, while the strongest band near 768 cm-1 (referred to A1g mode) along with a clear shoulder on lower frequency side can be ascribed to asymmetric breathing of the same octahedra. The band appearing near 603 cm-1 arises due to B-O stretching vibration. Based on the modes observed NdTi0.8Ga0.2O3.4 is concluded to be iso-structural to CaLa4Ti5O17 [1414 ZHAO, F., YUE, Z., GUI, Z., et al., “Effects of zinc substitution on crystal structure and microwave dielectric properties of CaLa4Ti5O17 ceramics”, J. Am. Ceram. Soc.; v. 89, pp. 3421-3425, 2006.], La5Ti4GaO17 [1919 MUHAMMAD, R., IQBAL, Y., REANEY, I.M., “Structure and microwave dielectric properties of La5-xSrxTi4+xGa1-xO17 ceramics”, J. Mater. Res.; v. 50, pp. 3510-3516, 2015.] and La5Ti4ScO17 [2020 MUHAMMAD, R., KHESRO, A., NICHOLLS, S.J., “Layered perovskitestructured La5-xSrxTi4+xSc1-xO17 microwave ceramics for dielectricallyloadedantennas”, Ceram. Int.; v. 42, pp. 6422–6427, 2015.] which is also consistent with the present XRD result (Fig. 1a). However, for NdTi0.8Al0.2O3.4 several additional modes appeared. The identification of these modes need further investigations but based on XRD results we suggest that extra modes may be due to the presence of secondary phases evident from XRD (Fig. 1b).

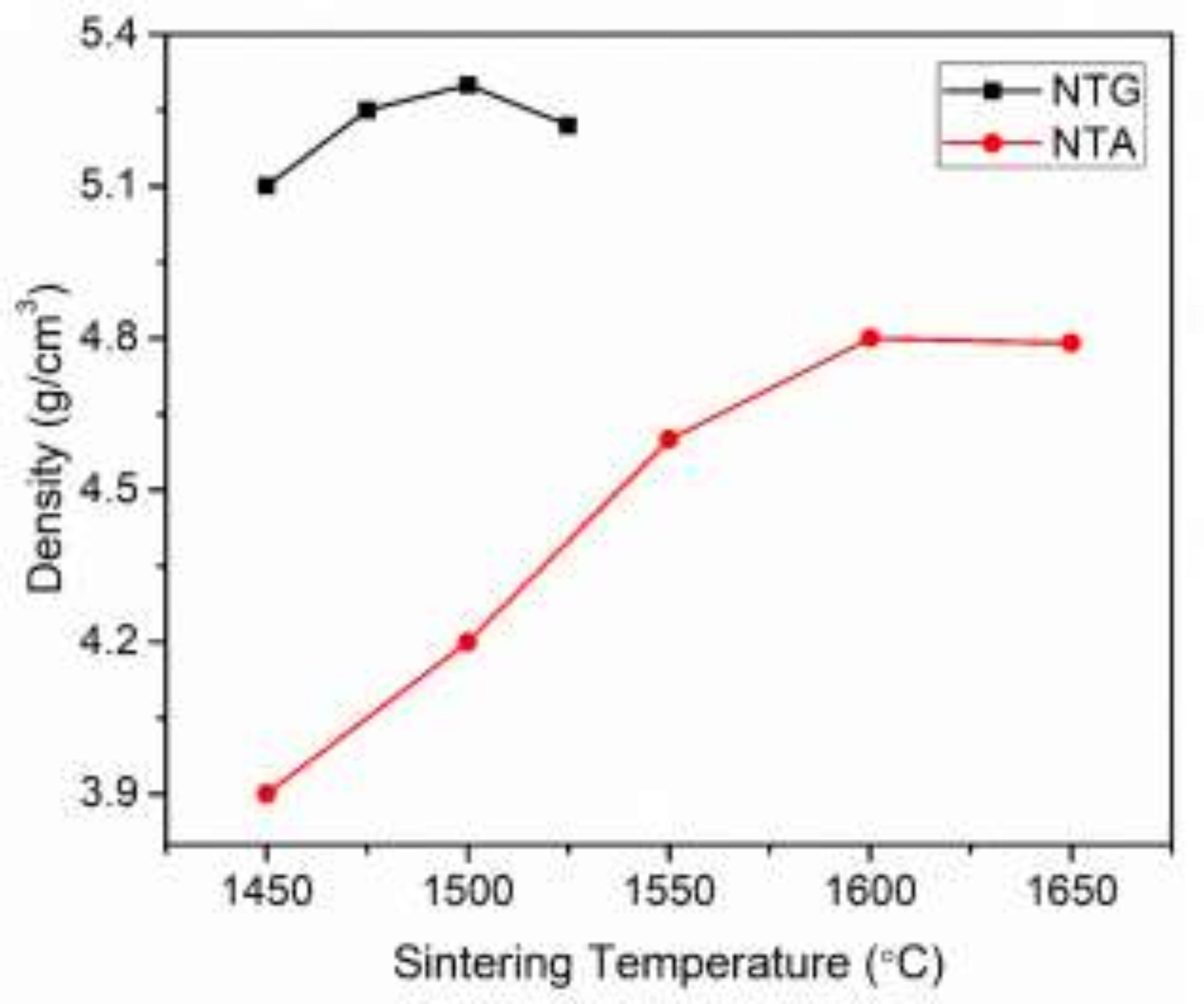

Plot of sintering temperature versus density is shown in Fig. 3. The density of the sample NdTi0.8Ga0.2O3.4 increased with increasing sintering temperature from 1450 to 1500°C; however, no improvement in the density was observed upon further increase in temperature. Similarly, the optimum sintering temperature of the sample NdTi0.8Al0.2O3.4 was found to be 1600°C. The SEM micrographs of the fractured surfaces of NdTi0.8M0.2O3.4 (B = Ga, Al) ceramics sintered at their optimum sintering temperature are shown in Fig. 4. The sample NdTi0.8Ga0.2O3.4 showed rod like grain morphology with size ranging from 1-9.3 mm. Fig. 4b illustrates the SEM micrograph for NdTi0.8Al0.2O3.4 which shows two different types of grains (marked as A and B) which was further confirmed using EDS. The EDS spectra for both grain A and B are shown in Fig. 5. The grain ‘A’ shows smaller concentration of Al while grain ‘B’ shows higher concentration of Al. Therefore, the EDS results showed that grain ‘A’ and ‘B’ belongs to NdTi0.8Al0.2O3.4 and Nd9Ti8AlO31 phases, consistent with the XRD and Raman data.

Plot of apparent density versus sintering temperature for NdTi0.8M0.2O3.4 (B = Ga, Al) ceramics.

SEM images for a) NdTi0.8Ga0.2O3.4 and b) NdTi0.8Al0.2O3.4 ceramics sintered at 1500 and 1600°C for 4 h, respectively.

EDS spectra for the grain ‘A’ and ‘B’ for sample NdTi0.8Al0.2O3.4, showing different concentration of Al in both grains

At optimum sintering temperatures, both NdTi0.8Ga0.2O3.4 and NdTi0.8Al0.2O3.4 samples exhibited similar values of K. Generally, it has been reported that low polarizable cation may decrease K and the NdTi0.8Al0.2O3.4 sample should have lower K than NdTi0.8Ga0.2O3.4 because of lower ionic polarizability of Al (a = 0.79 Å3) than Ga (a = 1.5 Å3) [2121 SHANNON, R.D., “Dielectric polarizabilities of ions in oxides and fluorides”, J. Appl. Phys.; v. 73, pp. 348-366, 1993.]. This statement may be true for single phase ceramics because the two different phases may have different contributions. However, Q×f of the sample NdTi0.8Al0.2O3.4 was larger than NdTi0.8Ga0.2O3.4 which may be possibly related to smaller ionic radii of the Al3+ (0.535 Å) than Ga3+ (0.62 Å) which decrease the an-harmonic lattice vibrations, resulting into low dielectric losses [2222 SEBASTIAN, M., SANTHA, N., BIJUMON, P., et al., “Microwave dielectric properties of (1-x)CeO2–xCaTiO3 and (1-x)CeO2–xSm2O3 ceramics”, J. Eur. Ceram. Soc.; v. 24, pp. 2583-2589, 2004.]. τf for NdTi0.8Ga0.2O3.4 and NdTi0.8Al0.2O3.4 samples were observed to be -113 and -90 ppm/°C. The τf values are quite low but to move it towards the ideal value of zero, further investigations needs to be done.

4. CONCLUSIONS

NdTi0.8M0.2O3.4 (B = Ga, Al) samples were prepared via mixed oxide route and characterized using XRD, Raman, SEM, EDS and Vector Network Analyzer. The NdTi0.8Ga0.2O3.4 sample was single phase while in the case of NdTi0.8Al0.2O3.4, the two different phases were observed i.e. NdTi0.8Al0.2O3.4 and Nd9Ti8AlO31, which were further confirmed using Raman, SEM and EDS techniques. NdTi0.8Ga0.2O3.4 exhibited a K = 34, Q×f = 9,776 GHz and τf = -113 ppm/oC, while sample NdTi0.8Al0.2O3.4 exhibited 34, Q×f = 10,867 GHz and τf = -90 ppm/oC. Further modification in the compositions is required for tuning the low τf through zero.

ACKNOWLEDGMENTS

The authors acknowledge the laboratory support provided by Functional Materials and Devices Group, Department of Materials Science and Engineering, University of Sheffield, UK.

BIBLIOGRAPHY

-

1SEBASTIAN, M., UBIC, R., JANTUNEN, H., “Low-loss dielectric ceramic materials and their properties”, Int. Mater. Rev, v. 60, n. 7, pp. 392-412, 2015.

-

2REANEY, I.M., IDDLES, D., “Microwave dielectric ceramics for resonators and filters in mobile phone networks”, J. Am. Ceram. Soc; v. 89, pp. 2063-2072, 2006.

-

3HU, L., ZHOU, H., SUN, Q., et al, “Effects of ZrO2–ZnO on the sintering behavior and microwave dielectric properties of 0.65CaTiO3–0.35SmAlO3 ceramics”, J. Mater. Sci.: Mater. Electron.; v. 27, pp. 12834-12839, 2016.

-

4HUANG, J., ZHOU, H., WANG, N., et al, “Preparation, structure and microwave dielectric properties of 3MgO–Al2O3–3TiO2 ceramics”, J. Mater. Sci.: Mater. Electron, v. 28, n. 6, pp. 4565–4569, 2016.

-

5LI, L., LI, S., TIAN, T., et al, “Microwave dielectric properties of (1-x)MgTiO3-x(Ca0.6Na0.2Sm0.2)TiO3 ceramic system”, J. Mater. Sci.: Mater. Electron, v. 27, pp. 1286-1292, 2016.

-

6ZHANG, H., WANG, X., CHENG, Q., et al, “Preparation of Li2MoO4 using aqueous solution method and microwave dielectric properties after sintering”, J. Mater. Sci.: Mater. Electron, v. 27, pp. 5422-5426, 2016.

-

7W. LEI, W.Z. LU, X.H. WANG, et al, “Phase Composition and Microwave Dielectric Properties of ZnAl2O4–Co2TiO4 Low-Permittivity Ceramics with High Quality Factor”, J. Am. Ceram. Soc; v. 94, pp. 20-23, 2011.

-

8REANEY, I.M., COLLA, E.L., SETTER, N., “Dielectric and structural characteristics of Ba-and Sr-based complex perovskites as a function of tolerance factor”, Jap. J. Appl. Phys; v. 33, pp. 3984-3990, 1994.

-

9JAWAHAR, I.N., SANTHA, N.I, SEBASTIAN, M.T, et al, “Microwave Dielectric Properties of MO–La2O3–TiO2 (M= Ca, Sr, Ba) Ceramics”, J. Mater. Res; v. 17, pp. 3084-3089, 2002.

-

10CHEN, Y.C., TSAI, J.M., “Influence of CuO addition and sintering temperature on microwave dielectric properties of Ca0.99Zn0.01La4Ti5O17 ceramics for application in stacked patch antenna”, Jap. J. Appl. Phys; v. 47, pp. 7959–7962, 2008.

-

11DEMŠAR, K., ŠKAPIN, S.D., MEDEN, A., et al, “Rietveld Refinement and Dielectric Properties of CaLa4Ti5O17 and SrLa4Ti5O17 Ceramics”, Acta Chim. Sloven; v. 55, pp. 966–972, 2008.

-

12MUHAMMAD, R., IQBAL, Y., “Preparation and characterization of K-substituted NaCa4Nb5O17 microwave dielectric ceramics”, J. Mater. Sci.: Mater. Electron; v. 24, pp. 2322-2326, 2013.

-

13LI, C., WEI, X., FANG, L., “Dielectric and complex impedance analysis of Sr5Nb4TiO17 ceramic with perovskite-like structure”, J. Mater. Sci.: Mater. Electron; v. 26, pp. 8714-8719, 2015.

-

14ZHAO, F., YUE, Z., GUI, Z., et al, “Effects of zinc substitution on crystal structure and microwave dielectric properties of CaLa4Ti5O17 ceramics”, J. Am. Ceram. Soc; v. 89, pp. 3421-3425, 2006.

-

15VANDERAH, T.A., MILLER, V., LEVIN, I., et al, “Phase relations, crystal chemistry, and dielectric properties in sections of the La2O3–CaO–MgO–TiO2 system”, J. Solid State Chem; v. 177, pp. 2023-2038, 2004.

-

16MANAN, A., QAZI, I., “Synthesis and microwave dielectric properties of Ca substituted SrLa4Ti4•93Zr0•07O17 ceramics”, Bull. Mater. Sci; v. 37, pp. 679-683, 2014.

-

17MUHAMMAD, R., IQBAL, Y., RAMBO, C.R., “Structure–property relationship in NaCa4B5O17 (B = Nb, Ta) perovskites”, J. Mater. Sci.: Mater. Electron; v. 26, pp. 2161-2166, 2015.

-

18LONG, S., MCALLISTER, M., SHEN, L., “The resonant cylindrical dielectric cavity antenna”, IEEE T. Antenn. Propag; v. 31, pp. 406-412, 1983.

-

19MUHAMMAD, R., IQBAL, Y., REANEY, I.M., “Structure and microwave dielectric properties of La5-xSrxTi4+xGa1-xO17 ceramics”, J. Mater. Res; v. 50, pp. 3510-3516, 2015.

-

20MUHAMMAD, R., KHESRO, A., NICHOLLS, S.J., “Layered perovskitestructured La5-xSrxTi4+xSc1-xO17 microwave ceramics for dielectricallyloadedantennas”, Ceram. Int; v. 42, pp. 6422–6427, 2015.

-

21SHANNON, R.D., “Dielectric polarizabilities of ions in oxides and fluorides”, J. Appl. Phys; v. 73, pp. 348-366, 1993.

-

22SEBASTIAN, M., SANTHA, N., BIJUMON, P., et al, “Microwave dielectric properties of (1-x)CeO2–xCaTiO3 and (1-x)CeO2–xSm2O3 ceramics”, J. Eur. Ceram. Soc; v. 24, pp. 2583-2589, 2004.

Publication Dates

-

Publication in this collection

25 Nov 2019 -

Date of issue

2019

History

-

Received

26 Jan 2018 -

Accepted

04 Feb 2019