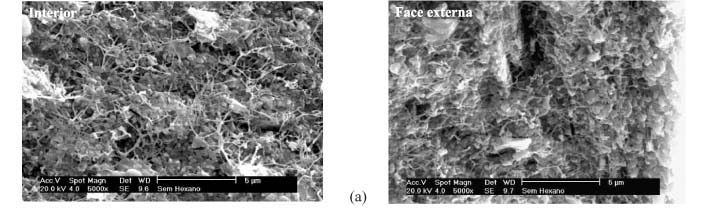

A moldagem por injeção de pós cerâmicos tem se tornado um processo altamente atrativo por aliar a versatilidade e a produtividade da moldagem por injeção convencional às propriedades inerentes aos materiais cerâmicos. A remoção do ligante, usado como veículo orgânico nesse processo, é uma das etapas críticas para a produção de peças cerâmicas sem defeitos. Neste trabalho avaliou-se a influência da geometria das peças injetadas na remoção do ligante, tanto por imersão em solvente como por decomposição térmica. Alumina em pó foi misturada fisicamente a um ligante composto por polipropileno [PP], parafina [PW] e ácido esteárico [AE]. As peças com diferentes geometrias foram mantidas imersas em hexano, secas sob vácuo e acompanhada a variação de massa devido à solubilização do PW e AE. A determinação da porosidade das peças, realizada por meio das isotermas de adsorção/desorção de nitrogênio, mostrou um aumento de porosidade de 0,5% volume para aproximadamente 20% volume após a imersão em solvente. A remoção térmica do PP remanescente produziu hidrocarbonetos alifáticos e compostos insaturados, determinados e quantificados por espectroscopia de infravermelho, que permearam a estrutura porosa da peça. A geometria das peças tem grande influência na remoção do ligante, podendo afetar não só a qualidade do produto final, mas também as etapas subseqüentes do processo.

Moldagem por injeção; alumina; polipropileno; decomposição térmica