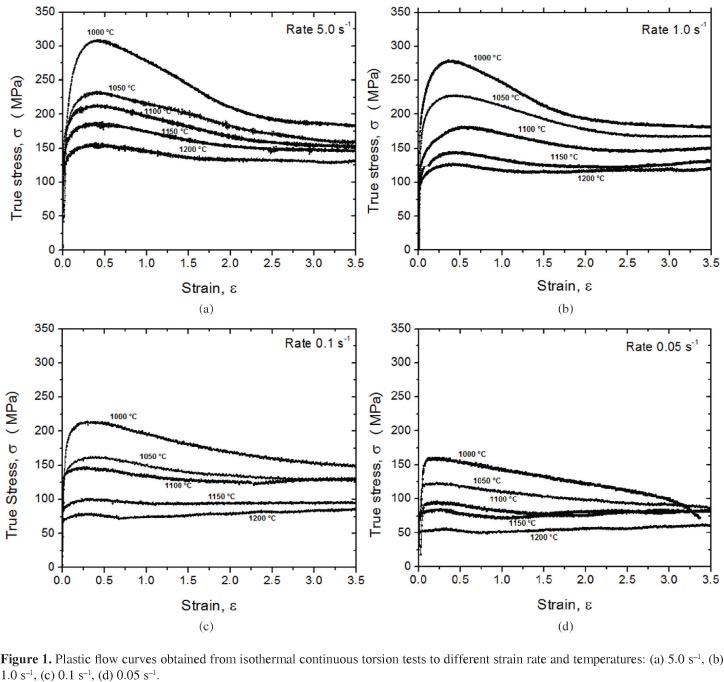

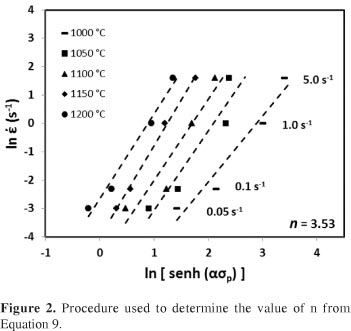

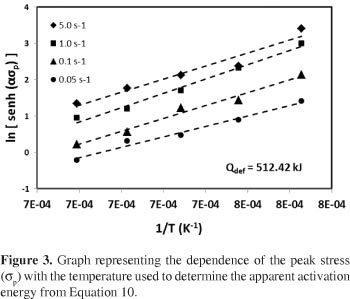

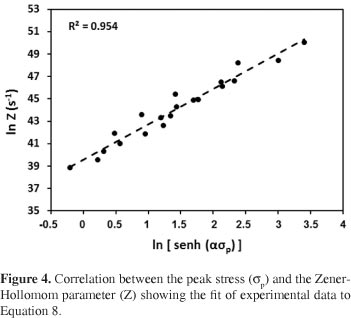

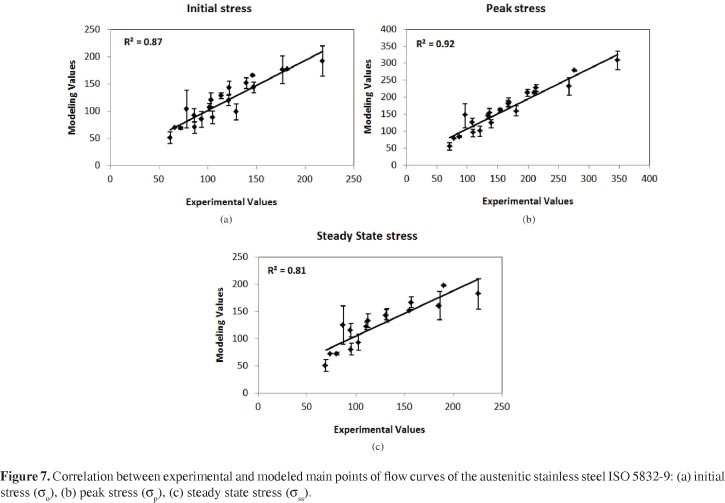

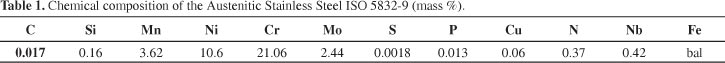

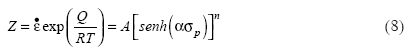

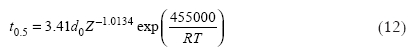

An austenitic stainless steel ISO 5832-9 used as a biomaterial was torsion-deformed over the temperature range of 1000-1200 °C and strain rates of 0.05, 0.1, 1.0 and 5.0 s- 1. The flow stress curves obtained showed two regions where firstly there is a rising on stress characterized as work hardening mechanism acting and secondly a decreasing in work-softening after a peak stress. The flow curves were modeled by adjusting the experimental data with Zener-Hollomom parameter to construct the constitutive equations that describe the plastic behavior in both regions. The first region was described until the peak stress, taking into consideration the competition between work hardening and recovery while the second one was described applying the softening time of 50% and the Avrami equation. In some hot deformation conditions the simulated curves showed good agreement with the experimental ones while in others conditions the simulated showed differences to experimental curves that was discussed and associated with other mechanisms that acted during hot deformation.

flow stress curves; modeling of hot deformation; dynamic recristalization