Abstract

Introduction

Solution blow spinning (SBS) and airbrushing are two techniques that can be used as alternatives to electrospinning in the production of fibrous scaffolds for tissue engineering (TE). SBS seems particularly interesting due to its versatility, however, it has not been much explored and no automated SBS systems were found in the literature. Therefore, the present work aimed to develop such equipment and compare the results to those found for airbrushing, considering the same set of parameters.

Methods

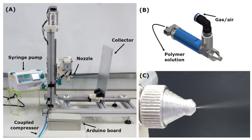

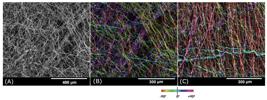

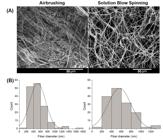

A new SBS set up, composed of a specially designed nozzle with automated movement, a syringe pump and a compressor, was used to produce fibrous poly (ε-caprolactone) (PCL) mats. The airbrushed fibers were produced under the same conditions, and samples of both types of mats were imaged using scanning electron microscopy (SEM) to compare them in terms of microstructure and fiber diameter.

Results

The SBS system was robust and performed well, in terms of movement and fiber deposition. In comparison to airbrushing’s, SBS mats presented different microstructural characteristics (considering the parameters used).

Conclusion

The biggest advantage over airbrushing may be its versatility and simple automation, which may improve sample reproducibility, especially considering scaled up processes. To further improve this apparatus, a better understanding of how process variables interfere in the microstructure is needed, as well as more sophisticated interface and operation.

Keywords

Fibrous scaffolds; Solution blow spinning; Airbrushing

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail