Abstract

There are few methods to obtain uniform and well dispersed cuprous oxide nanoparticles, which limits its application widely. In this research, an improved method to prepare nanoparticles was introduced. Cuprous oxides were prepared by the reduction of cupric nitrate, with hydrazine hydrate as a reductant in the presence of glucose. The nanoparticles formed have the characteristics of small particle size and uniform distribution. The crystalline structure and morphological characteristics were analyzed by XRD and TEM respectively. The result showed they were pure sphere polycrystal. The particle size is about 9nm. Subsequently, the antifouling activity was tested in detail through comparative experiments. The results indicated that the effective concentration of nanoparticles was obviously lower than ordinary cuprous oxide.

Keywords:

marine biological fouling; nanoparticles; antifouling activity

INTRODUCTION

Ocean accounts for 71% of the Earth's surface area, and it is essential for human to survive and utilize. Any unprotected ship hulls solid surfaces immersed in the sea water will be fouled with numerous marine organisms (there are more than 4000 species) after a relatively short immersion time. The fouling of immersed surfaces takes place in various stages, in the first stage (first minutes of immersion), organic molecules of proteins, polysaccharides, glycoproteins and others become physically adhered to the surface, conditioning it for a second stage, corresponding approximately to the first 24 h of immersion, in which bacteria and unicellular algae are adsorbed. in a third stage, spores of microalgae that will constitute a biofilm which, in turn, will allow the increased capture of more particles and organisms, such as larvae of marine macroorganisms (fourth stage), in 2 or 3 weeks of immersion. The conditions are then set for the fixing and growth of either macroalgae or marine invertebrates.11 Almeida, E.; Diamantino, T. C.; Sousa, O. D.; Prog. Org. Coat. 2007, 59, 2.,22 Yebra, D. M.; Kiil, S.; Dam-Johansen, K.; Prog. Org. Coat. 2004, 50, 75. Hence, the ships' speed will be reduced, and fuel consumption significantly increased.33 Anderson, C.; Atlar, M.; Callow, M.; Candries, M.; Milne, A.; Townsin, R. L.; Journal of Marine Design and Operations 2003, 4, 11. For economic reasons, underwater ship parts must be kept relatively smooth in order to reduce drag resistance and thus minimise fuel consumption.44 Ruffolo, S. A.; Russa, M. F. L.; Malagodi, M.; Rossi, C. O.; Palermo, A. M.; Crisci, G. M.; Appl. Phys. A: Mater. Sci. Process. 2010, 100, 829.,55 Ruffolo, S. A.; Macchia, A.; Russa, M. F. L.; Mazza, L.; Urzì, C.; Leo, F. D.; Barberio, M.; Crisci. G. M.; Int. J. Photoenergy 2013, 2013, 1.

Therefore, development of antifouling methods to prevent attachment of marine organisms is urgently required. The common and efficient method was brushing antifouling coatings on the surface of immersed material. The mixtures of oil, resin, brimstone, and simply brimstone used to protect the hulls prior to the eighteenth century. The most successful antifouling coatings emerged in the mid 19th century and were based on the idea of dispersing a powerful toxicant in a polymeric binder. The International Maritime Organization (IMO) adopted the Convention on the International Control of Harmful Antifouling Bottom Systems of Ships on October 1, 2001, which is a global mandatory legal document. According to the Convention, since January I, 2003, ships of all countries should prohibit the use of anti-fouling paints, which are more toxic to marine organisms. In view of this situation, countries are actively studying and developing low toxicity or non-toxic antifouling coatings.66 Chambers, L. D.; Stokes, K. R.; Walsh, F. C.; Wood, R. J. K.; Surf. Coat. Technol. 2006, 201, 3642.,77 Maréchal, J. P.; Hellio, C.; Int. J. Mol. Sci. 2009, 10, 4623. From then on, major research efforts have been initiated to develop an ideal antifouling to be environmentally acceptable, economical, no-poisonous to marine species, and efficient both in port and at sea.88 Ralston, E.; Swain, G.; Mar. Technol. Soc. J. 2011, 45, 216.

The copper sheathing was proposed as an antifouling protection in 1708.99 Cock, R.; The Mariner’s Mirror 2001, 4, 446. Afterwards, the oxides of copper have widespread use. At present, cuprous oxide is known for excellent antifouling effect, which commonly used for antifouling coating. With the development of shipbuilding industry and navigation industry, the demand for cuprous oxide antifouling coatings is increasing year by year.1010 Thomas, K.; Raymond, K.; Chadwick, J.; Waldock, M.; Appl. Organometal. Chem. 1999, 13, 453. Compared with common cuprous oxide, Cu2O nanoparticles have strong chemical activity, so they have more advantages in catalytic adsorption, and superior anti-fouling performance. So far, there are numerous preparation methods of Cu2O nanoparticles, and every method has its own merits and demerits. In this research, an improved method to prepare Cu2O nanoparticles was introduced. The effect of antifouling activity of prepared nanoparticles was also evaluated through comparative experiments

EXPERIMENTAL

The preparation procedure of Cu2O nanoparticles is introduced as follows (Figure 1):

In this research, cuprous oxides (Cu2O) were prepared by the reduction of cupric nitrate, with hydrazine hydrate as a reductant in the presence of glucose, at room temperature. The specific reaction equations are as follows:

0.07 mol L-1 cupric nitrate solution was prepared, then 7 g L-1 glucose was added into the solution and completely dissolved, which called the A solution. Subsequently, hydrazine hydrate solution was prepared, which called the B solution. Afterwards the A and B solution were added into a self-made special precipitate reactor together. In addition, the pH value of the reaction solution was adjustedto be between 7.0 and 8.0, and the solution was rapidly stirred with a magnetic stirrer at 387 r min-1. The prepared precipitate was laid up for about ten minutes. Next, the deionized water was used to wash the precipitate until the nitrate ions were completely removed (detected by nitron). Eventually, the precipitate was freeze-dried to obtain orange-yellow Cu2O nanoparticles.

X-ray diffraction (XRD) experiment of prepared Cu2O nanoparticles was carried out on a D8-Advance diffraction instrument (Bruker, Germany), and the patterns were recorded at a scan speed of 8º per minute with Cu Kα radiation (λ =0.154 nm) operating at 40 kV and 40 mA. Transmission electron microscopic (TEM) observation was carried out using an EM-420 electron microscope (Philips, Amsterdam, the Netherlands), and the particles average size was calculated.

The antifouling activity of prepared Cu2O nanoparticles at different concentration levels was evaluated with the selected microorganisms (diatoms). The same volume of diatom water and prepared culture medium after autoclaving at high temperature were put in the conical flasks. Subsequently, different concentrations (0.025 g L-1, 0.1 g L-1, 1.0 g L-1 and 10.0 g L-1 ) of prepared Cu2O nanoparticles were added separately in the conical flasks, compared with the same concentration gradient of ordinary cuprous oxide, moreover, the blank sample without cuprous oxide was used as a reference. Each conical flask placed a glass slide and sealed with cotton gauze was put in a manual incubator for culturing at room temperature. Afterwards, the glass slides would be taken out regularly to wash off the diatoms and impurities that didn’t attach to the surface with the culture solution after culturing for a period of time, as well as observed and photographed under a three-dimensional video stereo microscope. The number of the diatoms attached on the glass slide was recorded by self-compiled software to calculate the density of the diatom cells.

Furthermore, the fresh mussels’ byssuses were cut off and selected for the experiment. A certain amount of prepared Cu2O nanoparticles powder was weighed to uniformly disperse in acrylic resin. The glass slides were modified with prepared Cu2O nanoparticles at different percentage concentration (1%, 10%, 20%, 40%), and every concentration was made three parallel samples; likewise, the same percentage concentration of ordinary cuprous oxide purchased from the market was utilized to make a comparison. Additionally, the glass slides were modified with 1 mL of pure acrylic resin for the blank sample. Afterwards, each glass slide fixed two well-treated mussels was placed in a petri dish, and a free mussel was also put in the same petri dish. Subsequently 30 mL of seawater was added into each petri dish, as well as 1 mL of diatoms was also added to feed the mussels, moreover, the water was changed once a day. Meanwhile, the daily tendency of the free mussel was observed, and the number of the mussels’ byssuses attached to the glass slide was recorded as well.

RESULTS AND DISCUSSION

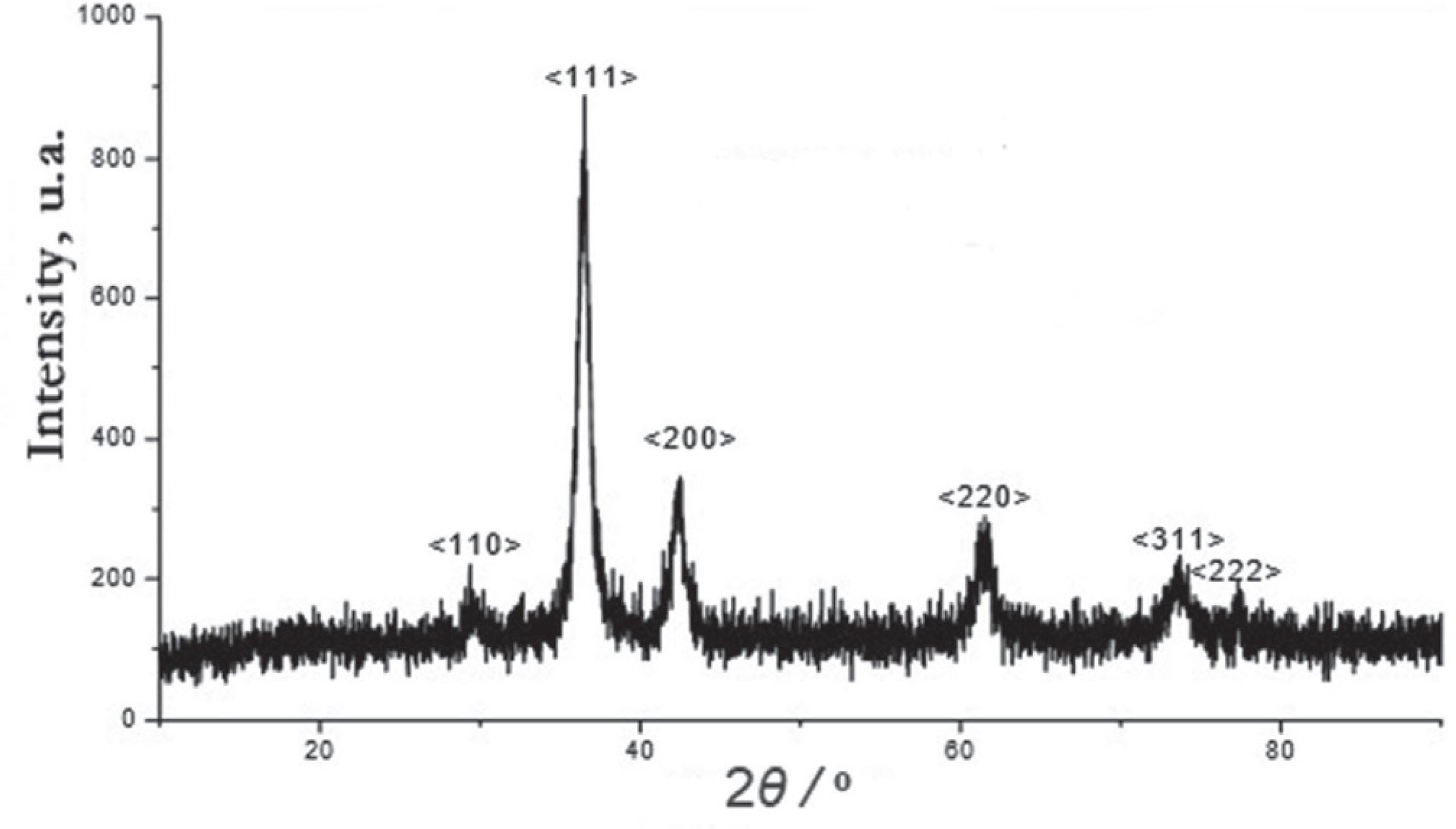

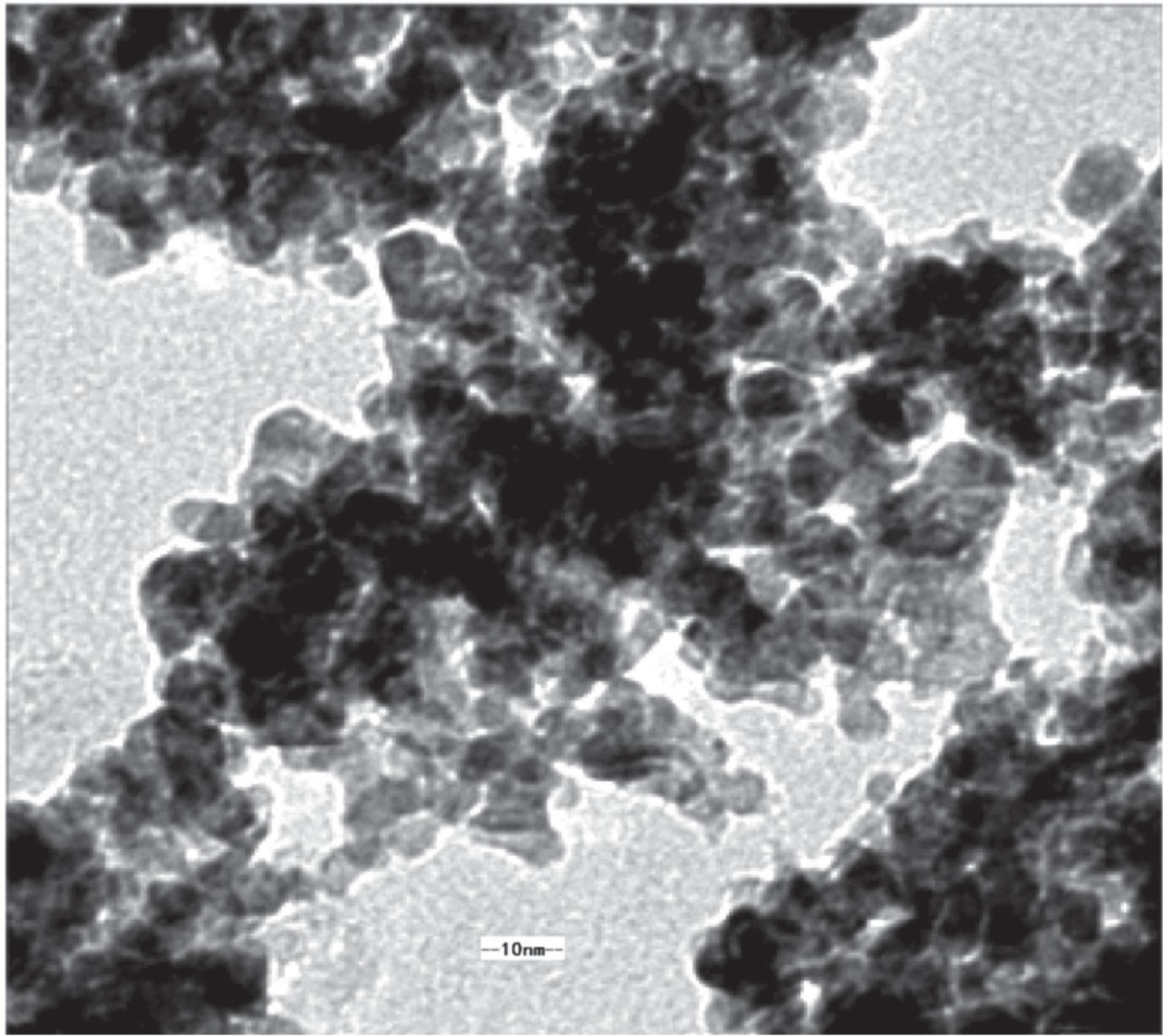

Under the conditions of adding 7 g L-1 glucose as dispersant and rotating speed at 387 r min-1, the best disperse ability of prepared Cu2O nanoparticles was obtained. The crystalline structure of prepared Cu2O nanoparticles was characterized by XRD pattern, shown in Figure 2. In addition, the morphological characteristics of prepared nanoparticles were analyzed by TEM, and the TEM image magnified 50000 times was shown in Figure 3.

Apparently, no characteristic peaks related to the impurities were detected in the XRD patterns shown in Figure 2, the XRD reflections of cuprous oxide matched that of JCPDS no. 78-2067 indicating that the improved method of preparation of prepared Cu2O nanoparticles was performed successfully. The characteristic peaks as observed at 2θ values of 29.53, 36.37, 42.31, 62.25, 74.43 and 77.52º belong to the crystal planes of (110), (111), (200), (220), (311), and (222) of crystalline cuprous oxide, respectively. The results obtained exactly consistent with the cuprous oxide standard diffraction peak data (JCPDS no. 78-2067). The average crystallite size of prepared Cu2O nanoparticles was 9 nm estimated by Scherrer formula: . Where Dis the average crystallite size, λ is 0.154 nm (wavelength of the radiation source), k is a constant (0.9), θ is the angle of diffraction, and β/2 is the width of peak at half height. It is considerably significant to directly visualize nanoparticle morphology through the transmission electron microscope (TEM) image. The TEM image of prepared Cu2O nanoparticles showed that the cubic crystalline particles had a uniform distribution, and the average crystalline diameter is about 8 to 12 nm. Despite there was some small reunion, the boundaries among nanoparticles were clear.

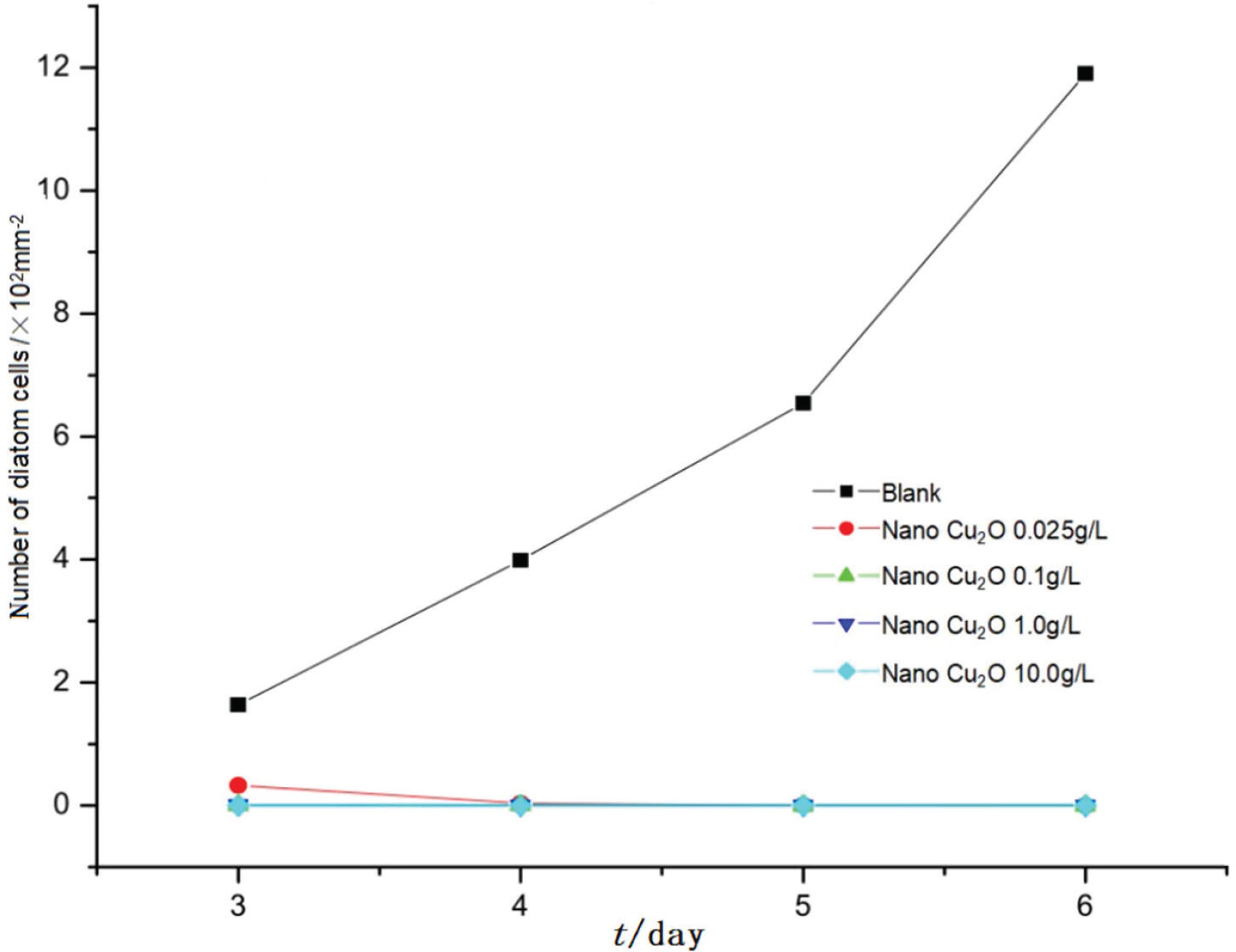

The inhibitory effect of prepared Cu2O nanoparticles on the adhesion of the diatoms (the blank sample severed as reference) was shown in Figure 4. The diatom cells were not counted in the first three days because of the lower density, in order to avoid influencing the results of the adhesion of the diatom. Furthermore, the inhibitory effects of prepared Cu2O nanoparticles on the growth of the diatom cells compared with ordinary cuprous oxide at the same concentration (0.025 g L-1, 0.1 g L-1, 1.0 g L-1 and 10.0 g L-1) were shown in Figure 5.

The obtained results clearly indicate that, prepared Cu2O nanoparticles significantly inhibited the growth of the diatom cells in comparison with the blank sample at all concentration levels. In addition, the inhibitory effects of prepared Cu2O nanoparticles on the growth of the diatom cells were obviously higher than ordinary cuprous oxide at the same concentration. The growth of the diatom cells was completely inhibited by prepared Cu2O nanoparticles at the concentration of 1.0 g L-1, whereas the highest inhibitory effect of ordinary cuprous on the growth of the diatom cells at the concentration of 10.0 g L-1, which approached to the inhibitory effects of prepared Cu2O nanoparticles at the concentration of 1.0 g L-1. It can be easily observed that the antifouling activity of prepared Cu2O nanoparticles is increasingly superior to ordinary cuprous oxide against the adhesion of the diatom with the increase of concentration.

Different percentage concentration of prepared Cu2O nanoparticles and ordinary cuprous oxide were divided into four groups to study the antifouling activity against the attachment of the mussel, the blank samples without cuprous oxide were prepared for comparison as well. Furthermore, each group was designed nine parallel samples. The mean number of secreted byssuses per group was shown in Figure 6.

Figure 6 suggests that the mean number of the secreted byssuses on ordinary cuprous oxide (1%) modified glass slide was very high, and the growth rate of the mussels’ byssuses approached to the blank sample. But the inhibitory effect of prepared Cu2O nanoparticles (1%) was higher than ordinary cuprous oxide (10%), which was almost the same as ordinary cuprous oxide (20%). The results demonstrate that the inhibitory effect of prepared Cu2O nanoparticles is considerably superior to ordinary cuprous oxide on the attachment of the mussels. Furthermore, the inhibition rate of prepared Cu2O nanoparticles (1%) was approximately the same as ordinary cuprous oxide (20%) against the attachment of the mussels which nearly reached 74%. When the percentage concentration of prepared Cu2O nanoparticles was increased to 10%, the inhibition rate was higher than 97%. In addition, the attachment of the mussels was completely inhibited by prepared Cu2O nanoparticles at the percentage concentration of 40%, however, the inhibition rate of ordinary cuprous oxide (40%) was lower than prepared Cu2O nanoparticles (10%). Apparently, prepared Cu2O nanoparticles has remarkable advantages over ordinary cuprous oxide in inhibiting the growth of the mussel’ byssuses. (Table 1 summarizes the results of the inhibition rate with varying percentage concentration of prepared Cu2O nanoparticles and ordinary oxide.

Inhibition rate of different cuprous oxide percentage concentration against the attachment of the mussel

Materials in the form of nanoparticles attain unique properties, present a wide range of activity, including optical, electrical, magnetic, and biological activity, and can be suitably manipulated for the desired applications.1111 Usman, M. S.; Zowalaty, M. E.; Shameli, K.; Zainuddin, N.; Salama, M.; Ibrahim, N. A.; Int. J. Nanomed. 2013, 8,4467.,1212 Gyawali, R.; Ibrahim, S. A.; Abu Hasfa, S. H.; Smqadri, S. Q.; Haik, Y.; J. Pathog. 2011, 2011, 1. In addition, metal nanoparticles are effective for antifouling activity due to their high surface-to-volume ratio and high ability to release the metal ions.1313 Ramyadevi, J.; Jeyasubramanian, K.; Marikani, A.; Rajakumar, G.; Rahuman, A. A.; Mater. Lett. 2012, 71, 114.,1414 Hashemipour, H.; Zadeh, M. E.; Pourakbari, R.; Rahimi, P.; Int. J. Phys. Sci. 2011, 6, 4331. Previous work has demonstrated that Cu+ and metallic Cu possess higher antimicrobial activity than the Cu2+ state.1515 Nietojuarez, J. I.; Pierzchła, K.; Sienkiewicz, A.; Kohn, T.; Environ. Sci. Technol. 2010, 44, 3351. Furthermore, the antifouling activity of the nanoparticles are closely related to their size and shape. It is not easy for larger nanoparticles to penetrate through the cell walls of microorganisms and result in cell destruction, in addition, the antifouling activity of cubic Cu2O is superior to octahedral Cu2O.1616 Lee, Y. J.; Kim, S.; Park, S. H.; Park, H.; Huh, Y. D.; Mater. Lett. 2011, 65, 818. The influence of solution pH on the size and shape of copper nanoparticles was also studied in detail, the results demonstrated that the size, shape, chemical composition and structure of Cu nanoparticles strongly depended on the synthesis pH, and the prepared particles at pH 7 or above present smaller particle sizes which explicates their higher antifouling efficiency.1717 Motlatle, A. M.; Pillai, S. K.; Scriba, M. R.; Ray, S. S.; J. Nanopart. Res. 2016, 18, 312. In this research, 7 g L-1 glucose as dispersant and stirring speed at 387 r min-1, provided the optimum reaction conditions. With the increase of glucose, the dispersion of nanocuprous oxide was greatly improved, but after a certain value, the dispersion becomes worse. The optimum addition of glucose was 7 g L-1 by TEM characterization. With the increase of rotational speed, the number of explosive nucleation increases, and the size of nanoparticles decreases, but the density of spherical polycrystals increases. TEM showed that 387 r min-1 was the best speed. Through high strength mechanical stirring, a large number of fresh interfaces of reaction solution were formed in a short time, which resulted in the explosive nucleation of precipitated components at the fresh interface. Because the reaction time is very short and the number density of nuclei is huge, the newly formed nanoparticles can not grow up. The formed nanoparticles have the characteristics of small particle size and uniform distribution. The number of the surface atoms rapidly increased, contributing to enhancing the chemical activity of Cu2O nanoparticles, as a consequence, a large number of copper ions would be released in a flash to attack the attached marine organisms.

CONCLUSIONS

In this research, cupric nitrate was reduced by hydrazine hydrate under alkaline conditions adding glucose as dispersant to prepare Cu2O nanoparticles. XRD characteristic peaks of the prepared Cu2O nanoparticles exactly consistent with the standard diffraction peak data. The TEM image demonstrated that the prepared Cu2O nanoparticles were cubic crystalline particles as well as the average diameter of the particles was about 9nm. The effect of antifouling activity was evaluated in detail through the comparative experiments. The results suggest that the effect of antifouling activity of prepared Cu2O nanoparticles was obviously superior to ordinary cuprous oxide.

ACKNOWLEDGMENTS

This work was financially supported by the National Nature Science Foundation of China (No.11805089), and Key Project of University of Science and Technology Liaoning, China (XJGZD201709).

REFERENCES

-

1Almeida, E.; Diamantino, T. C.; Sousa, O. D.; Prog. Org. Coat. 2007, 59, 2.

-

2Yebra, D. M.; Kiil, S.; Dam-Johansen, K.; Prog. Org. Coat. 2004, 50, 75.

-

3Anderson, C.; Atlar, M.; Callow, M.; Candries, M.; Milne, A.; Townsin, R. L.; Journal of Marine Design and Operations 2003, 4, 11.

-

4Ruffolo, S. A.; Russa, M. F. L.; Malagodi, M.; Rossi, C. O.; Palermo, A. M.; Crisci, G. M.; Appl. Phys. A: Mater. Sci. Process. 2010, 100, 829.

-

5Ruffolo, S. A.; Macchia, A.; Russa, M. F. L.; Mazza, L.; Urzì, C.; Leo, F. D.; Barberio, M.; Crisci. G. M.; Int. J. Photoenergy 2013, 2013, 1.

-

6Chambers, L. D.; Stokes, K. R.; Walsh, F. C.; Wood, R. J. K.; Surf. Coat. Technol. 2006, 201, 3642.

-

7Maréchal, J. P.; Hellio, C.; Int. J. Mol. Sci. 2009, 10, 4623.

-

8Ralston, E.; Swain, G.; Mar. Technol. Soc. J. 2011, 45, 216.

-

9Cock, R.; The Mariner’s Mirror 2001, 4, 446.

-

10Thomas, K.; Raymond, K.; Chadwick, J.; Waldock, M.; Appl. Organometal. Chem. 1999, 13, 453.

-

11Usman, M. S.; Zowalaty, M. E.; Shameli, K.; Zainuddin, N.; Salama, M.; Ibrahim, N. A.; Int. J. Nanomed 2013, 8,4467.

-

12Gyawali, R.; Ibrahim, S. A.; Abu Hasfa, S. H.; Smqadri, S. Q.; Haik, Y.; J. Pathog 2011, 2011, 1.

-

13Ramyadevi, J.; Jeyasubramanian, K.; Marikani, A.; Rajakumar, G.; Rahuman, A. A.; Mater. Lett. 2012, 71, 114.

-

14Hashemipour, H.; Zadeh, M. E.; Pourakbari, R.; Rahimi, P.; Int. J. Phys. Sci. 2011, 6, 4331.

-

15Nietojuarez, J. I.; Pierzchła, K.; Sienkiewicz, A.; Kohn, T.; Environ. Sci. Technol. 2010, 44, 3351.

-

16Lee, Y. J.; Kim, S.; Park, S. H.; Park, H.; Huh, Y. D.; Mater. Lett. 2011, 65, 818.

-

17Motlatle, A. M.; Pillai, S. K.; Scriba, M. R.; Ray, S. S.; J. Nanopart. Res. 2016, 18, 312.

Publication Dates

-

Publication in this collection

15 Aug 2019 -

Date of issue

June 2019

History

-

Received

01 Mar 2019 -

Accepted

31 May 2019 -

Published

26 June 2019