Abstracts

In this study, water uptake by poultry carcasses during cooling by water immersion was modeled using artificial neural networks. Data from twenty-five independent variables and the final mass of the carcass were collected in an industrial plant to train and validate the model. Different network structures with one hidden layer were tested, and the Downhill Simplex method was used to optimize the synaptic weights. In order to accelerate the optimization calculus, Principal Component Analysis (PCA) was used to preprocess the input data. The obtained results were: i) PCA reduced the number of input variables from twenty-five to ten; ii) the neural network structure 4-6-1 was the one with the best result; iii) PCA gave the following order of importance: parameters of mass transfer, heat transfer, and initial characteristics of the carcass. The main contributions of this work were to provide an accurate model for predicting the final content of water in the carcasses and a better understanding of the variables involved.

chillers; artificial neural networks; water retention

Neste trabalho, foi realizada a modelagem da absorção de água que ocorre no processo de resfriamento de carcaças de frango por imersão utilizando Redes Neurais Artificiais. Dados de vinte e cinco variáveis independentes e da massa final da carcaça foram coletados em uma planta industrial para ajustar o modelo. Foram testadas diferentes estruturas de redes com uma camada oculta e o método Downhill Simplex foi empregado para otimizar os pesos sinápticos. No intuito de acelerar os cálculos de otimização, a Análise de Componentes Principais (ACP) foi utilizada para pré-processar os dados de entrada. Os resultados obtidos foram: i) com a ACP reduziu-se o número de varáveis de entrada das redes para dez; ii) a modelagem com a rede neural de estrutura 4-6-1 foi a que apresentou os melhores resultados; iii) a ACP indicou a seguinte ordem de relevância: parâmetros de transferência de massa, transferência de calor e características iniciais da carcaça. As principais contribuições deste trabalho foram fornecer um modelo preciso para predizer o teor final de água nas carcaças, bem como uma melhor compreensão acerca das variáveis envolvidas.

chillers; redes neurais artificiais; retenção de água

ORIGINAL PAPERS

Modeling the water uptake by chicken carcasses during cooling by immersion

Modelagem da absorção de água por carcassas de frango durante o resfriamento por imersão

Tiago Dias MartinsI, * * Corresponding author ; Túlio KlassenI; Rafael Luan Sehn CanevesiI; Rodrigo Augusto BarellaI; Lucio Cardozo FilhoII; Edson Antonio da SilvaI

INúcleo de Biotecnologia e Desenvolvimento de Processos Químicos, Universidade Estadual do Oeste do Paraná - UNIOESTE, Rua da Faculdade, 645, CEP 85903-000, Jardim La Salle, Toledo, PR, Brasil, e-mail: tiagodmartins.eq@gmail.com

IIDepartamento de Engenharia Química, Universidade Estadual de Maringá - UEM, Maringá, PR, Brasil

ABSTRACT

In this study, water uptake by poultry carcasses during cooling by water immersion was modeled using artificial neural networks. Data from twenty-five independent variables and the final mass of the carcass were collected in an industrial plant to train and validate the model. Different network structures with one hidden layer were tested, and the Downhill Simplex method was used to optimize the synaptic weights. In order to accelerate the optimization calculus, Principal Component Analysis (PCA) was used to preprocess the input data. The obtained results were: i) PCA reduced the number of input variables from twenty-five to ten; ii) the neural network structure 4-6-1 was the one with the best result; iii) PCA gave the following order of importance: parameters of mass transfer, heat transfer, and initial characteristics of the carcass. The main contributions of this work were to provide an accurate model for predicting the final content of water in the carcasses and a better understanding of the variables involved.

Keywords: chillers; artificial neural networks; water retention.

RESUMO

Neste trabalho, foi realizada a modelagem da absorção de água que ocorre no processo de resfriamento de carcaças de frango por imersão utilizando Redes Neurais Artificiais. Dados de vinte e cinco variáveis independentes e da massa final da carcaça foram coletados em uma planta industrial para ajustar o modelo. Foram testadas diferentes estruturas de redes com uma camada oculta e o método Downhill Simplex foi empregado para otimizar os pesos sinápticos. No intuito de acelerar os cálculos de otimização, a Análise de Componentes Principais (ACP) foi utilizada para pré-processar os dados de entrada. Os resultados obtidos foram: i) com a ACP reduziu-se o número de varáveis de entrada das redes para dez; ii) a modelagem com a rede neural de estrutura 4-6-1 foi a que apresentou os melhores resultados; iii) a ACP indicou a seguinte ordem de relevância: parâmetros de transferência de massa, transferência de calor e características iniciais da carcaça. As principais contribuições deste trabalho foram fornecer um modelo preciso para predizer o teor final de água nas carcaças, bem como uma melhor compreensão acerca das variáveis envolvidas.

Palavras-chave:chillers; redes neurais artificiais; retenção de água.

1 Introduction

Among all stages of the industrial processing of poultry carcasses - such as awareness, evisceration, scalding, and others -meat cooling has got special importance, mainly because it to assures product quality and health (KLASSEN, 2004; CARCIOFI; LAURINDO, 2007). In this stage, microorganism contamination can be minimized (RODRIGUES et al., 2008; von RÜCKERT et al., 2009). This process can be done by immersion of carcasses in iced water to ensure rapid cooling, known as immersion chilling, or it can be done using cooling tunnels with chilled air, known as air-chilling (CARROLL; ALVARADO, 2008). In Brazil the immersion chilling method is commonly applied in the poultry industry (KLASSEN et al., 2009).

In chiller cooling process, the carcasses are placed in contact with water in horizontal tanks, with cylindrical geometry, endowed with an inner helical coil that slowly moves the carcasses along its axial direction (KLASSEN et al., 2009). Water renovation in the chillers, air bubbling, and cooling jackets containing propylene glycol are often used to improve heat transfer. Some of the advantages of the chiller cooling are the cooling speed, low cost, and high quality of the final product. However, the main disadvantage that limits the usage of chillers is the lack of absorption control of the cooling fluid solution (in this case, water) by the products (CARROLL; ALVARADO, 2008).

For the industry, it is important to identify the main variables that affect the water absorption by the carcasses during the chilling. This can improve significantly the process control. In addition, each country has a specific legislation that establishes operating limits which must be accomplished. In Brazil, these variable limits are regulated by the governmental decree 210 (BRASIL, 1998) which defines the maximum entrance and exit temperature of the water at the chillers, minimum stream flow, number of tanks, and other operational characteristics. The legislation also establishes that: in the chillers, the minimum necessary water renewal rate is 1 L/carcass, the water temperature in the exit must be less than 4 °C, and that the maximum allowed gain in mass due water absorption is 8%.

There are few studies in the literature that investigate and model poultry carcass chilling (JAMES et al., 2006; CARCIOFI; LAURINDO, 2007; KLASSEN et al., 2009). Analytical solution of rigorous models is hardly found due its non-linearity and the influence of several variables and parameters, besides energy and mass transfer in transient condition. On the other hand, simple mathematical models discard some important aspects that influence the process, making them too simplified (KLASSEN, 2004; CARCIOFI; LAURINDO, 2007).

Artificial Neural Networks (ANNs) modeling can be an alternative to obtain the information needed from the industrial plant with high efficiency (ALVES; NASCIMENTO, 2002). ANNs are mathematical algorithms that have the capacity to relate input (independent variables) and output parameters (dependent variables) learning from given examples, without requesting any knowledge about the variables relation that interfere on the studied process. They are known as universal function approximators (HORNIK; STINCHCOMBE; WHITE, 1989; BRAGA; CARVALHO; LUDERMIR, 2000). An ANN is a set of computational units (or artificial neurons) that are interconnected and organized into layers. The information process in an ANN begins relating the input (xi) of each neuron to a synaptic weight (wij) that assesses this entry influence on the output of this neuron (activation coefficients). The sum of all activation coefficients makes the neuron activation. The answer of the input stimulus is obtained applying an activation function to the neuron activation, generally the sigmoid or the hyperbolic tangent function. This procedure extends to the output layer of the network, where the neuron answer is the dependent variable of the problem.

Modeling with ANNs consists of finding suitable weights and biases that minimize the deviation among observed and calculated data (ASSIDJO et al., 2008). This step is called network training, in which the learning in ANN is evaluated. ANNs have been successfully used to solve problems concerning food processing, process control, biotechnological processes, heavy metal biosorption etc. (MITTAL; ZHANG, 2000, 2001; SOUZA; TEIXEIRA; PENACINNO, 2003; FERREIRA et al., 2004; MEDEIROS, 2006; FAGUNDES-KLEN et al., 2007; RIVERA et al., 2007; ASSIDJO et al., 2008; DA CRUZ et al., 2009).

The main objective of this work was to apply artificial neural networks in an attempt to model the water uptake that by poultry carcasses during the cooling process in chillers and determine the process main variables through Principal Component Analysis.

2 Materials and methods

2.1 Data set

All the experimental data used in this study were obtained from a poultry processing unit. The system constituted of three chillers disposed in series, over which the carcasses were cooled due to the contact with a mix of water and ice. The second and third chillers had thermal jackets with circulation of propylene glycol and addition of ice; all modules were air bubbled. The flow rate and the temperature of feed water were different in each tank.

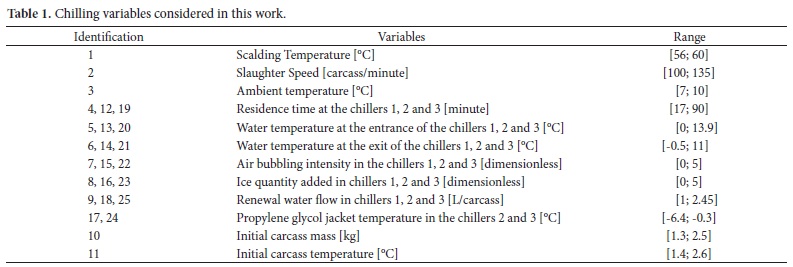

Poultry chilling process includes several variables (operational conditions of chiller and characteristic and properties of poultry carcass). The variables considered in this study are shown in Table 1. The temperature of scalding (the prior process) was also considered.The scald process can modify the properties of poultry carcass and consequently the level of water uptake (DYER, 2007).

The carcasses were removed from the hooks before dropping into the chillers and packed in plastic boxes. The initial mass was then measured, and a plastic tag containing an identification number was affixed to the carcass. After all the measurements had been made, the carcasses were then dropped into the first module of the cooling system. Simultaneously, time, water temperature at the beginning of the module, flow rate of water, intensity of the bubbling, and amount of ice added were also recorded. This procedure was repeated for each chiller. To evaluate the water absorption by the poultry carcasses, several samples of 13 carcasses was taken, resulting in a total of 350 vector data. The determination of the carcasses mass was performed using a digital scale (Mettler Toledo, 1 g).

2.2 ANN input preprocessing

Data compression is a technique that reduces the dimensionality of a set of variables without losing relevant information, eliminating extraneous information, noise, and correlations that exist in the original sets of variables. Principal Component Analysis (PCA) is a technique widely used for preprocessing ANN inputs.

PCA is a technique of multivariate analysis that aims to reduce the dimensionality of data sets without losing significant information. As a final result, PCA generates the principal components (PCs) that are linear combinations of the original values of the variables.

This methodology was developed mathematically by Hotelling (1933a, b) and thereafter used in many areas of science in data analysis and pre-treatment (ABEYWARDENA, 1972; GONTARSKI et al., 2000; FERREIRA et al., 2003; SILVA et al., 2006; YU; QIN, 2008; HASHIM et al., 2010). Geometrically, PCA consists of a rotation of axes to select the new coordinate axes representing the direction of maximum variance (HOTELLING, 1933a, b).

Before applying the PCA, it is necessary to eliminate the data heterogeneity, which can influence the final result. In this study, Equation (1) was used for this purpose. Computational routines in Fortran77 language was developed for the calculation of PCs following the algorithm described in Härdle and Simar (2007):

2.3 Artificial neural network modeling

The proper selection of a network topology is not an easy task. There is no rule or a theorem that determines the optimal topology for a given data set. However, this can be done through the performance analysis of the network.

In the present study, water retention by the poultry carcasses in the chilling process was modeled using several ANN structures with one hidden layer, besides the input and output layers. The structures tested had between 2 and 15 neurons at the input and the hidden layer. One neuron was in the output layer corresponding to the output variable: the final carcass mass.

The convergence criterion used was 1.10-10, and the initial estimates of the synaptic weights were established between 0 and 0.1. The hyperbolic tangent function was used as the activation function for all simulations, except for the output layer, which was a linear function. The objective function to be minimized was the quadratic error defined by Equation 2:

where: is the experimental normalized value of the final poultry carcass mass, corresponds to the normalized final poultry mass calculated by the ANN, and n is the number of experimental points.

The initial synaptic weight values were attributed randomly. In all cases, the Downhill Simplex (NELDER; MEAD, 1965) and a set of 300 vectors were used in the ANNs' training step. The 50 other vectors were used in the model validation.

The input variables were composed of the output data obtained by the PCA analysis. This topic will be discussed in section 3.

3 Results and discussion

3.1 Principal component analysis

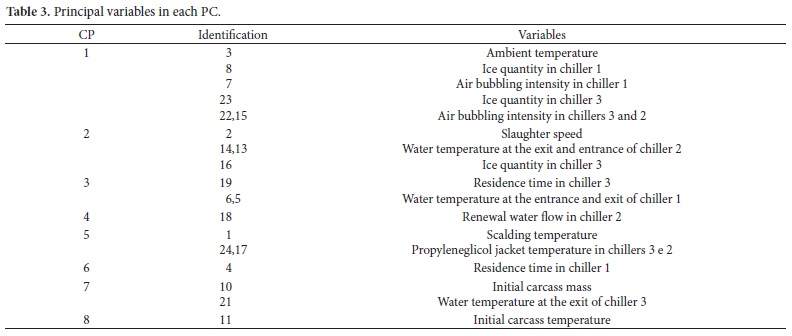

The results of the PCA applied in the set of data obtained in this study resulted in a significant reduction of the number of independent variables that describe the process of absorption. Mardia, Kent and Bibby (1979) reported that the number of PCs that presents 90% of cumulated variance should be sufficient to describe the process.

According to Figures 1a, b , from the 25 PCs generated, the first ten components can be used for the representation of the process without significant loss of information. This set covers a total of 89.5% of the variance of all components. Thus, all results of the next section correspond to those in which the ANNs were composed of 10 new input variables (generated from the result of PCA).

3.2 Artificial neural networks modeling

Table 2 shows the best results (objective function - fOBJ,ANN , absolute average deviation - AAD (Equation 3), and correlation coefficient - r2) for the tested ANN structures, where the symbols T and V correspond to training and validation, respectively:

From these results, it can be seen that the network structure has a strong influence on the training step performance: the objective functions calculated were more than 200% apart from each other. Also, the AAD obtained in this stage were very different for each test.

The predictive capacity of neural network requires the comparison of the results with data that were excluded from the training data set. Table 2 shows that the AADs of the validation step are not well correlated with the objective function.

Therefore, the choice criteria of the best ANN structure were a mixed analysis of objective function, AAD, and correlation coefficient values for validation step. Accordingly, it can be seen in Table 2 that the best results were obtained using networks which had four neurons at the input layer, six neurons at the hidden layer, and one at the output layer (4-6-1). Figures 2a, b show the relationship among the experimental and the calculated values for the ANN with structure 4-6-1 for the training and validation steps, respectively.

The present study is one of a few papers which studies modeling of water retention in poultry carcass. Only Carciofi and Laurindo (2007), who investigated water retention in poultry carcasses using a pilot plant with dimensions 1 × 0.915 × 0.540 m, proposed a phenomenological model to describe this process and their predicted results presented AAD in a range of 5-8%. Their model took into account material characteristics and immersion time; however, the authors discarded other important variables such as water renewal, ice quantity in the tank, ambient temperature etc., which were considered here.

3.3 Determination of the main variables

The analysis of the variables influence on each PC can be obtained directly from the calculated values of the eigenvectors of the variance-covariance matrix - since these values correspond to a weighting on the original variables. However, the components of eigenvectors are dependent on the scale of the variables, thus it is more appropriated to use a measure of association that is independent on that scale. The correlation coefficient can be used for this task and is given by (HÄRDLE; SIMAR, 2007) Equation 4:

There are variables (or group of variables) that influence each PC significantly. In this study, significant variables are those with correlation above 0.50. In Table 3, which presents the results of this analysis, it can be seen that the variables are divided into three main groups. The parameters of mass transfer have greater influence (PC1), followed by the parameters of heat transfer (PC1 to PC6) and initial properties of the carcass (PC7 and PC8).

These results are consistent with those obtained by Carciofi and Laurindo (2007), which is an indication that the significance of process variables remains the same after the scale- up. The experimental results obtained by those authors showed that water retention is strongly influenced by the intensity of agitation of the water, water temperature in the tank, and hydrostatic pressure (not reviewed here).

James et al. (2006) related the immersion time influence, water temperature, and ice quantity with the final temperature and water quantity absorbed by the carcasses. They also made comparisons between cooling by immersion and air-chiller considering the microbial load and the cross-contamination of the carcasses, aspect, taste, texture and operation costs. According to the authors, the residence time and degree of agitation are the most influencing factors for water uptake. In addition, the ice percentage added to the water affects both the final temperature of the carcass and the water absorption during the cooling.

According to Dyer (2007), the temperature and the scalding time are important factors influencing the capacity of water retention by the carcasses. Since the scalding tanks have fixed size, time becomes just a line velocity function. Moreover, air bubbling is an important parameter in the process because it influences the heat transfer coefficient from the poultry to the water and the water retention. The influence of the temperature on the scalding step is an important outcome. The temperature of scalding favors the opening of follicles where the feathers are fixed, which influences the uptake of water (DYER, 2007).

The results obtained in this study have great importance when modeling such a complex process such as chilling. In addition to giving information about the process, PCA favors the simplification of the model since the number of adjustable parameters is reduced when training a new ANN structure using only the most important independent components. Modeling with ANNs has the advantage of not requiring phenomenological knowledge of the process. Together, the two techniques can be a powerful tool that helps to control the chilling process with accuracy, less efforts, and low costs.

4 Conclusions

In this study, artificial neural networks were applied to model the water uptake by poultry carcasses during the cooling process in a chiller system. An artificial neural network with 4 neurons at the input layer and six at the hidden layer was able to describe the phenomenon with accuracy. The Principal Component Analysis provided information about the major parameters of the process and reduced drastically the number of ANN input data (from 25 to 10). The combination of the two techniques provided a promising way of predicting water uptake by poultry carcass in the chilling immersion process, as well information to apply a suitable control and reduce production costs in industrial plants.

Received 14/12/2008

Accepted 5/6/2010 (003982)

- ABEYWARDENA, V. An application of principal component analysis in genetics. Journal of Genetics, v. 61, n. 1, p. 27-51, 1972. http://dx.doi.org/10.1007/BF02984099

- ALVES, R. M. B.; NASCIMENTO, C. A. O. Gross errors detection of industrial data by neural network and cluster techniques. Brazilian Journal of Chemical Engineering, v. 19, p. 483-489, 2002. http://dx.doi.org/10.1590/S0104-66322002000400018

- ASSIDJO, E. et al. Modeling of an industrial drying process by artificial neural networks. Brazilian Journal of Chemical Engineering, v. 25, p. 515-522, 2008. http://dx.doi.org/10.1590/S0104-66322008000300009

- BRAGA, A. P.; CARVALHO, A. P. L.; LUDERMIR, T. B. Redes Neurais Artificiais: Teoria e Aplicações. Rio de Janeiro: LTC - Livros Técnicos e Científicos, 2000.

- BRASIL. Ministério da Agricultura, Pecuária e Abastecimento - MAPA. Portaria nº 210, de 10 de novembro de 1998. Regulamento técnico da inspeção tecnológica e higiênico-sanitária de carne de aves. Diário Oficial da República Federativa do Brasil, Brasília, DF, 26 nov. 1998. Seção 1, p. 226.

- CARCIOFI, B. A. M.; LAURINDO, J. B. Water uptake by poultry carcasses during cooling by water immersion. Chemical Engineering and Processing, v. 46, n. 5, p. 444-450, 2007. http://dx.doi.org/10.1016/j.cep.2006.05.020

- CARROLL, C. D.; ALVARADO, C. Z. Comparison of Air and Immersion Chilling on Meat Quality and Shelf Life of Marinated Broiler Breast Fillets. Poultry Science, v. 87, n. 2, p. 368-372, 2008. PMid:18212383. http://dx.doi.org/10.3382/ps.2007-00213

- DA CRUZ, A. G. et al. Monitoring the authenticity of low-fat yogurts by an artificial neural network. Journal of Dairy Science, v. 92, n. 10, p. 4797-4804, 2009. PMid:19762794. http://dx.doi.org/10.3168/jds.2009-2227

- DYER, J. Personal Communication, 2007.

- FAGUNDES-KLEN, M. R. et al. Equilibrium study of the binary mixture of cadmium-zinc ions biosorption by the Sargassum filipendula species using adsorption isotherms models and neural network. Biochemical Engineering Journal, v. 34, n. 2, p. 136-146, 2007. http://dx.doi.org/10.1016/j.bej.2006.11.023

- FERREIRA, L. S. et al. Analysis of experimental biosensor/FIA lactose measurements. Brazilian Journal of Chemical Engineering, v. 20, n. 1, p. 7-13, 2003. http://dx.doi.org/10.1590/S0104-66322003000100003

- FERREIRA, L. S. et al. A lactose fia-biosensor system for monitoring and process control. Brazilian Journal of Chemical Engineering, v. 21, p. 307-315, 2004. http://dx.doi.org/10.1590/S0104-66322004000200021

- GONTARSKI, C. A. et al. Simulation of an industrial wastewater treatment plant using artificial neural networks. Computers & Chemical Engineering, v. 24, n. 2-7, p. 1719-1723, 2000.

- HÄRDLE, W.; SIMAR, L. Applied multivariate statistical analysis Berlin: Springer Berlin Heidelberg, 2007.

- HASHIM, D. M. et al. Potential use of Fourier transform infrared spectroscopy for differentiation of bovine and porcine gelatins. Food Chemistry, v. 118, n. 3, p. 856-860, 2010. http://dx.doi.org/10.1016/j.foodchem.2009.05.049

- HORNIK, K.; STINCHCOMBE, M.; WHITE, H. Multilayer feedforward networks are universal approximators. Neural Networks, v. 2, n. 5, p. 359-366, 1989. http://dx.doi.org/10.1016/0893-6080(89)90020-8

- HOTELLING, H. Analysis of a complex of statistical variables into principal components. Journal of Educational Psychology, v. 24, n. 7, p. 498-520, 1933a. http://dx.doi.org/10.1037/h0070888

- HOTELLING, H. Analysis of a complex of statistical variables into principal components. Journal of Educational Psychology, v. 24, n. 6, p. 417-441, 1933b. http://dx.doi.org/10.1037/h0071325

- JAMES, C. et al. The primary chilling of poultry carcasses--a review. International Journal of Refrigeration, v. 29, n. 6, p. 847-862, 2006. http://dx.doi.org/10.1016/j.ijrefrig.2005.08.003

- KLASSEN, T. Modelagem do sistema de resfriamento de carcaças de frangos com redes neurais artificiais 2004. 29 f. Monografia (Especialização em Engenharia de Alimentos)-Universidade Estadual do Oeste do Paraná, Toledo, 2004.

- KLASSEN, T. et al. Modelagem do sistema de resfriamento por imersão de carcaças de frangos utilizando redes neurais artificiais. Acta Scientiarum Technology, v. 31, n. 2, p. 201-205, 2009.

- MARDIA, K. V.; KENT, J. T.; BIBBY, J. M. Multivariate analysis London: Academic Press, 1979.

- MEDEIROS, F. T. P. Desenvolvimento de um modelo de predição de condições operacionais de altos-fornos siderúrgicos com base em redes neurais artificiais 2006. 134 f. Tese (Doutorado em Engenharia Química)-Universidade Estadual de Campinas, Campinas, 2006.

- MITTAL, G. S.; ZHANG, J. Prediction of freezing time for food products using a neural network. Food Research International, v. 33, n. 7, p. 557-562, 2000. http://dx.doi.org/10.1016/S0963-9969(00)00091-0

- MITTAL, G. S.; ZHANG, J. Artificial neural network for the prediction of temperature, moisture and fat contents in meatballs during deep-fat frying. International Journal of Food Science & Technology, v. 36, n. 5, p. 489-497, 2001. http://dx.doi.org/10.1046/j.1365-2621.2001.00490.x

- NELDER, J. A.; MEAD, R. A Simplex Method for Function Minimization. The Computer Journal, v. 7, n. 4, p. 308-313, 1965.

- RIVERA, E. C. et al. Development of adaptive modeling techniques to describe the temperature-dependent kinetics of biotechnological processes. Biochemical Engineering Journal, v. 36, n. 2, p. 157-166, 2007. http://dx.doi.org/10.1016/j.bej.2007.02.011

- RODRIGUES, A. C. A. et al. A. Análise e monitoramento de pontos críticos no abate de frangos utilizando indicadores microbiológicos. Ciencia Rural, v. 38, p. 1948-1953, 2008. http://dx.doi.org/10.1590/S0103-84782008000700023

- SILVA, B. M. et al. Principal component analysis as tool of characterization of quince (Cydonia oblonga Miller) jam. Food Chemistry, v. 94, n. 4, p. 504-512, 2006. http://dx.doi.org/10.1016/j.foodchem.2004.11.045

- SOUZA, E. A.; TEIXEIRA, L. C. V.; PENACINNO, M. R. Aplicação de Redes Neurais para Avaliação do Teor de Carne Mecanicamente Separada em Salsicha de Frango. Ciência de Tecnologia de Alimentos, v. 23, n. 3, p. 307-311, 2003. http://dx.doi.org/10.1590/S0101-20612003000300002

- Von RÜCKERT, D. A. S. et al. Pontos críticos de controle de Salmonella spp. no abate de frangos. Arquivo Brasileiro de Medicina Veterinaria e Zootecnia, v. 61, p. 326-330, 2009. http://dx.doi.org/10.1590/S0102-09352009000200007

- YU, J.; QIN, S. J. Multimode process monitoring with bayesian inference-based finite Gaussian mixture models. AIChE Journal, v. 54, n. 7, p. 1811-1829, 2008. http://dx.doi.org/10.1002/aic.11515

Publication Dates

-

Publication in this collection

21 Oct 2011 -

Date of issue

Sept 2011

History

-

Received

14 Dec 2008 -

Accepted

05 June 2010