Abstract

The quality of the construction production process may be improved using several different methods such as Lean Construction, ISO 9001, ISO 14001 or ISO 18001. Construction companies need a preliminary study and systematic implementation of changes to become more competitive and efficient. This paper presents a multicriteria decision model for the selection and ranking of such alternatives for improvement approaches regarding the aspects of quality, sustainability and safety, based on the PROMETHEE II method. The adoption of this model provides more confidence and visibility for decision makers. One of the differentiators of this model is the use of a fragmented set of improvement alternatives. These alternatives were combined with some restrictions to create a global set of alternatives. An application to three scenarios, considering realistic data, was developed. The results of the application show that the model should be incorporated into the strategic planning process of organizations.

Quality management; Multicriteria decision analysis; Civil construction

1. Introduction

Continuous improvement of enterprise processes may be a key issue in contributing for its business excellence. Therefore, improving processes quality is a powerful choice for advancing in competition, with market and cost advantages.

Civil construction, the focus of this study, is composed of a series of activities

with different degrees of complexity. These activities are interconnected by a wide

product diversification with various technological processes and different types of

demand (MELLO; AM0RIM, 2009MELLO, L. C. B. B.; AMORIM, S. R. L. The subsector of buildings of

the civil construction in Brazil: a x-ray of the sector compared to the European

Union and the United States Produção, v. 19, n. 2, p. 388-399,

2009.). To select some

of the improvement alternatives (programs, methods or standards), the decision maker

of the construction company has several axes of evaluation (criteria). These

criteria of evaluation are elements that drive the analysis, and they should be

established based on modeling of consequences, so that they represent relevant

dimensions of the problem as it has been shown in many studies in the literature

(VINCKE, 1992VINCKE, P. Multicriteria decision-aid. Chichester:

John Wiley, 1992.; TSAI; HSU; CHOU, 2011TSAI, W.; HSU, W.; CHOU, W. A gap analysis model for improving

airport service quality. Total Quality Management &

Business Excellence, v. 22, n. 10, p. 1025-1040, 2011.

http://dx.doi.org/10.1080/147833 63.2011.611326

http://dx.doi.org/10.1080/14783363.2011....

; BRIT0;

ALMEIDA, MOTA, 2010BRITO, A. J.; ALMEIDA, A. T.; MOTA, C. M. A multicriteria model for

risk sorting of natural gas pipelines based on electre tri integrating utility

theory. European Journal of Operational Research, v. 200, p.

812-821, 2010. http://dx.doi.org/10.1016/j.ejor.2009.01.016

http://dx.doi.org/10.1016/j.ejor.2009.01...

; P0LITIS; SISK0S,

2010POLITIS, Y.; SISKOS, Y. Self-assessment for measuring business

excellence: The MUSABE method. Total Quality Management &

Business Excellence, v. 21, n. 11, p. 1063-1083, 2010.

http://dx.doi. org/10.1080/14783360902924283

http://dx.doi.org/10.1080/14783360902924...

; MORAIS; ALMEIDA, 2006MORAIS, D. C; ALMEIDA, A. T. Water supply system decision-making

using multicriteria analysis. Water SA, v. 32, n. 2, p.

229-235, 2006.; MOTA; ALMEIDA; ALENCAR, 2009MOTA, C. M. M.; ALMEIDA, A. T.; ALENCAR, L. H. A multiple criteria

decision model for assigning priorities to activities in project management.

International Journal of Project Management, v. 27, n. 2,

p. 175-181, 2009.

http://dx.doi.Org/10.1016/j.ijproman.2008.08.005

http://dx.doi.Org/10.1016/j.ijproman.200...

; VAL0IS; ALMEIDA, 2009VAL0IS, U.; ALMEIDA, A. T. Support model for multicriteria decision

to outsource productive activities based on SMARTS method.

Produção, v. 19, n. 2, p. 249-260, 2009.

http://dx.doi.org/10.1590/S0103-65132009000200003

http://dx.doi.org/10.1590/S0103-65132009...

; ALMEIDA; DUARTE, 2011ALMEIDA, A. T.; DIJARTE, M. D. 0. A multi-criteria decision model

for selecting project portfolio with consideration being given to a new concept

for synergies. Pesquisa Operational, v. 32, p. 1-18,

2011.; M0RAIS;

CAVALCANTE; ALMEIDA, 2010MORAIS, D. C; CAVALCANTE, C. A. V.; ALMEIDA, A. T. Priorização de

areas de controle de perdas em redes de distribuição de água. Pesquisa

Operacional, v. 30, n. 1, p. 15–32, 2010.).

The need for multi-criteria evaluation in order to establish a support structure for decision-making is then set. The objective of this research work is to develop a model that facilitates the selection and sequencing of implementation of improvement alternatives directed to Quality, Safety, Sustainability and Rationalization in construction companies. A data survey of four construction companies established in the metropolitan area of Recife in Brazil was performed. The interview was partially used, and the points of interest discussed were: identification of improvement practices undertaken in the sector, criteria for selection of improvement alternatives, importance and understanding of them.

Therefore, a modeling approach was performed using the Multicriteria Decision method: PROMETHEE II. The application of this method was conducted based on interviews conducted in construction companies and three scenarios were developed to analyze the problem. The application required the use of a fragmented set of improvement alternatives, which have been combined with some restrictions to become a global set of alternatives. Following criteria are considered: impact of the benefits on the production process, positive impact on the company's image, average cost of implementation and average length of implementation.

2. Multi-criteria decision aid

Multi-criteria decision methods address specific situations in which a decision maker

has to solve one problem dealing with several objectives to be achieved

simultaneously (TSAI; HSU; CHOU, 2011TSAI, W.; HSU, W.; CHOU, W. A gap analysis model for improving

airport service quality. Total Quality Management &

Business Excellence, v. 22, n. 10, p. 1025-1040, 2011.

http://dx.doi.org/10.1080/147833 63.2011.611326

http://dx.doi.org/10.1080/14783363.2011....

; BRIT0; ALMEIDA; MOTA, 2010BRITO, A. J.; ALMEIDA, A. T.; MOTA, C. M. A multicriteria model for

risk sorting of natural gas pipelines based on electre tri integrating utility

theory. European Journal of Operational Research, v. 200, p.

812-821, 2010. http://dx.doi.org/10.1016/j.ejor.2009.01.016

http://dx.doi.org/10.1016/j.ejor.2009.01...

; P0LITIS; SISK0S, 2010POLITIS, Y.; SISKOS, Y. Self-assessment for measuring business

excellence: The MUSABE method. Total Quality Management &

Business Excellence, v. 21, n. 11, p. 1063-1083, 2010.

http://dx.doi. org/10.1080/14783360902924283

http://dx.doi.org/10.1080/14783360902924...

; M0RAIS; ALMEIDA, 2006MORAIS, D. C; ALMEIDA, A. T. Water supply system decision-making

using multicriteria analysis. Water SA, v. 32, n. 2, p.

229-235, 2006.; MOTA;

ALMEIDA; ALENCAR, 2009MOTA, C. M. M.; ALMEIDA, A. T.; ALENCAR, L. H. A multiple criteria

decision model for assigning priorities to activities in project management.

International Journal of Project Management, v. 27, n. 2,

p. 175-181, 2009.

http://dx.doi.Org/10.1016/j.ijproman.2008.08.005

http://dx.doi.Org/10.1016/j.ijproman.200...

; VAL0IS; ALMEIDA,

2009VAL0IS, U.; ALMEIDA, A. T. Support model for multicriteria decision

to outsource productive activities based on SMARTS method.

Produção, v. 19, n. 2, p. 249-260, 2009.

http://dx.doi.org/10.1590/S0103-65132009000200003

http://dx.doi.org/10.1590/S0103-65132009...

; ALMEIDA; DUARTE, 2011ALMEIDA, A. T.; DIJARTE, M. D. 0. A multi-criteria decision model

for selecting project portfolio with consideration being given to a new concept

for synergies. Pesquisa Operational, v. 32, p. 1-18,

2011.; MORAIS; CAVALCANTE; ALMEIDA, 2010MORAIS, D. C; CAVALCANTE, C. A. V.; ALMEIDA, A. T. Priorização de

areas de controle de perdas em redes de distribuição de água. Pesquisa

Operacional, v. 30, n. 1, p. 15–32, 2010.).

Synthesis Function or Multiple Attribute Utility Theory (MAUT). which brings together different points of view in a single function that should be subsequently optimized (the American School). Examples of models thus considered are: MAUT, AHP, SMART;

Outranking Methods (the French School), which include the construction of outranking relations, which represent the decision makers's set of preferences. These methods seek to explore relations in a way that helps the decision maker to solve the problem. They differ from the American School mainly by allowing for the possibility of incomparability between alternatives. Examples of such models are: FLFCTRF; PROMETHEE; QUALIFLFX; OROFST; MELCHI0R;

Interactive methods are, in general, a sequence of dialog steps and calculations, through which a systematic exploration of space making is made. Examples of such models are: STEM; TRIMAP. Note that interactive methods are not addressed in this article. PROMETHEE II, focus of the work, took the non-compensatory hypothesis, which tends to favour more balanced alternatives (alternatives that have reasonably good ratings in all criteria) and provides a cardinal score for each alternative that can be used to develop a pre - complete order.

It is worth to point out that MCDM methods have been supported for many tools,

according to patents records, associated with a variety of themes such as: Business

Process Management (CAMPOS; DAHER; ALMEIDA,

2011CAMPOS, A. C. S. M.; DAHER, S. F. D.; ALMEIDA, A. T.; New Patents on

Business Process Management Information Systems and Decision Support.

Recent Patents on Computer Science, v. 4, p. 91-97, 2011.

http://dx.doi.org/10.2174/2213275911104020091

http://dx.doi.org/10.2174/22132759111040...

) and Group Decision Support (DAHER;

ALMEIDA, 2010DAHER, S. F. D.; ALMEIDA, A. T. Recent Patents Using Group Decision

Support Systems: A Short Review. Recent Patents on Computer

Science, v. 3, p. 81-90, 2010.

http://dx.doi.org/10.2174/2213275911003020081

http://dx.doi.org/10.2174/22132759110030...

).

There are few applications of Multiple-criteria decision-making (MCDM) in total

quality management (TQM) context problems in the literature, for instance: a

multi-criteria evaluation model to evaluate the expected service quality is proposed

within the airport passenger service context (TSAI;

HSU; CHOU, 2011TSAI, W.; HSU, W.; CHOU, W. A gap analysis model for improving

airport service quality. Total Quality Management &

Business Excellence, v. 22, n. 10, p. 1025-1040, 2011.

http://dx.doi.org/10.1080/147833 63.2011.611326

http://dx.doi.org/10.1080/14783363.2011....

), selecting technologies that will support the aims of

strategic total quality management (MADU et al.,

1996MADU, C. N. et al. Adoption of strategic total quality management

philosophies - Multi-criteria decision analysis model. International

Journal of Quality & Reliability Management, v. 13, n. 3, p.

57-72, 1996. http://dx.doi.org/10.1108/02656719610116081

http://dx.doi.org/10.1108/02656719610116...

); ranking of critical factors for TQM implementation in Shanghai

manufacturing industry (CHIN, 2002CHIN, K. S. et al. An AMP based study of critical factors for TQM

implementation in Shanghai manufacturing industries.

Technovation, p. 707-715, 2002.

http://dx.doi.org/10.1016/S0166-4972(01)00065-7

http://dx.doi.org/10.1016/S0166-4972(01)...

); a

systematic decision process for selecting external consultant in TQM program

(SAREMI; MOUSAVI; SANAYEI, 2008); Selection of lean manufacturing systems (GURUMURTHY; KODALI, 2008GURUMURTHY, A.; KODALI, R. A multi-criteria decision-making model

for justification of lean manufacturing systems. International Journal

of Management Science and Engineering Management, v. 3, n. 2, p.

100-118, 2008.), Selecting

improvement initiatives and quality management (QM) approaches in three companies in

Thailand (THAWESAENGSKULTHAI, 2010THAWESAENGSKULTHAI, N. An empirical framework for selecting quality

management and improvement initiatives. International Journal of Quality

& Reliability Management, v. 27, n. 2, p. 156-172, 2010.

http://dx.doi.org/10.1108/02656711011014285

http://dx.doi.org/10.1108/02656711011014...

) and

Quality Function Deployment (QED) combined with decision support system (ANDRONIKIDIS et al., 2009ANDRONIKIDIS, A. et al. The application of quality function

deployment in service quality management. The TQM Journal, v.

21, n. 4, p. 319–333, 2009.

http://dx.doi.org/10.1108/17542730910965047

http://dx.doi.org/10.1108/17542730910965...

; BEHZADIAN et al., 2013BEHZADIAN, M. et al. PROMETHEE Group Decision Support System and the

House of Quality. Group Decision and Negotiation, v. 22, n. 2,

p. 189-205, 2013. http://dx.doi.org/10.1007/sl0726-011-9257-3

http://dx.doi.org/10.1007/sl0726-011-925...

; KAVOSI; MOZAEEARI; MAVI, 2011KAVOSI, M.; MOZAFFARI, M. M.; MAVI, R. K. Incorporating cost and

environmental factors in quality function deployment using TOPSIS method.

International Journal of Quality Engineering and

Technology, v. 2, n. 1, p. 63-74, 2011.

http://dx.doi.org/10.1504/UQET.2011.038723

http://dx.doi.org/10.1504/UQET.2011.0387...

).

It is important to mention that this study is aimed at aligning MCDM and quality management based on civil construction, concerning which publications are scarce.

2.1. Preference method for enrichment evaluation (Promethee)

The family of PROMETHEE methods aims to build a relationship of Outranking, This family adds information between the alternatives and the criteria, and uses this relationship to support the decision. In PROMETHEE, the decision maker's preference in favor of one alternative a over another option b increases with a greater difference [fj (a) - fj (b)] between the performance of the alternatives for each criterion j and fj (a) and fj (b), respectively, are the values of the performance of the alternatives a and b in criterion j.

Brans and Vincke (1985)BRANS, J. P.; VINCKE, P. H. A preference ranking organization

method, the PROMETHEE method for MCDM. Management Science, v.

31, p. 647-656, 1985. http://dx.doi.Org/10.1287/mnsc.31.6.647

http://dx.doi.Org/10.1287/mnsc.31.6.647...

presented six

different ways to determine such a preference, which have values between 0 and 1

from the definition of the general functions, or preferably according to Table 1.

- –

Indifference Threshold (q j): this represents the biggest difference between fj (a) and fj (b) below which the decision maker considers that a and b are indifferent;

- –

Preference Threshold (p j): this is the smallest value of this difference over which the decision maker expresses a strict preference in favor of a stock;

- –

Threshold (s j): this corresponds to an average degree of preference and is between a threshold of preference q and a threshold of strict preference p.

Comparing the alternatives a and b, the degree of outranking ϖ (a, b) is, according Vincke (1992)VINCKE, P. Multicriteria decision-aid. Chichester: John Wiley, 1992.:

as:

- –

Descending order of (ϕ)+(a), where (ϕ+ (a) = ϖΣ(a,b), called the outflow, represents the intensity of preference for a on all alternatives. The higher (ϕ)+(a), the better the alternative;

- –

Ascending order of (ϕ)–(a), where: (ϕ)–(a) = ϖΣ(b,a), called the inflow. It represents the intensity of preference for all other alternatives on a. The smaller (ϕ)–(a), the better the alternative.

http://dx.doi.Org/10.1287/mnsc.31.6.647... ; BRANS; MARESCHAL, 1992BRANS, J. P.; MARESCHAL, B. Promethee V: MCDM problems with segmentation constraints. INFOR, v. 30, n. 2, p. 85-86, 1992.; TALEB; MARESCHAL, 1995TALEB, M. F. A.; MARESCHAL, B. Water resources planning in the Middle East: application of the PROMETHEE V multicriteria method. European Journal of Operational Research, v. 81, p. 500-511, 1995. http://dx.doi.org/10.1016/0377-2217(94)00007-Y

http://dx.doi.org/10.1016/0377-2217(94)0... ):

- –

PROMETHEE I - the intersection between previous flows establishes an Outranking relationship between alternatives, taking incomparability into account, establishing a incomplete pre-order among the alternatives;

- –

PROMETHEE II - ranks the alternatives, establishing an order of (ϕ)(a) = <ϕ)+(a) - (ϕ)-(a) (liquid flow); establishes a complete pre-order among the alternatives;

- –

PROMETHEE III and IV - were developed for the treatment of more sophisticated decision problems, particularly with a stochastic component;

- –

PROMETHEE V - with this implementation, a complete order among the alternatives is established (PROMETHEE II), restrictions are introduced, and the problem identified for the options selected. This method incorporates a philosophy of integer optimization;

- –

PROMETHEE VI - when the decision maker is unable or unwilling to define precisely the weights for the criteria, ranges of possible values can be identified rather than a fixed amount for each weight. In these cases, the implementation of PROMETHEE VI is recommended.

Each of these methods is appropriate for a particular decision situation. Eor the study conduct in this paper the PROMETHEE II has been found to be the most suitable. That is, the situation requires a ranking, with a complete pre-order among these alternatives.

A comprehensive literature review, including methodologies and applications

issues, is given by Behzadian et al.

(2010)BEHZADIAN, M. et al. PROMETHEE: A comprehensive literature review on

methodologies and applications. European Journal of Operational

Research, v. 200, p. 198–215, 2010.

http://dx.doi.Org/l0.l0l6/j.ejor.2009.0l.021

http://dx.doi.Org/l0.l0l6/j.ejor.2009.0l...

on PROMETHEE methods. They analyze 217 papers from 100 journal

contributions related to PROMETHEE methods, which are categorized into

application areas and non-application papers. However, according to their study

only seven papers are related to PROMETHEE methods applications considering

quality. Most of these papers deal with general problems, including quality

criteria, such as: selecting residential houses based on air quality criteria,

and determining water quality behavior.

3. Construction of the model

The definition of alternatives (solutions, decisions) is sometimes one of the most difficult steps in the process of supporting decision-making (VINCKE, 1992VINCKE, P. Multicriteria decision-aid. Chichester: John Wiley, 1992.). Eor this author, the group of A alternatives can be stable or progressive or globalized and fragmented.

Stable - when the set of A alternatives is defined a priori as finite and not open to changes during the process.

Progressive - can be modified in the process, either because of results that appear during the process, or because the decision problem is, naturally, in a changing environment.

Globalized - each element of the A set excludes some other one.

Fragmented - the results of the decision-making process involve various combinations of elements of A.

For construction of the model, a framework of three steps is required: (1) Development of the fragmented set of alternatives. (2) Conversion of the fragmented set into a globalized set and (3) Application of Decision-Making.

Then, to better understand the model, some concepts are developed that will support the construction process. For situations where the set of A alternatives A is stable and fragmented, there is a need to convert this set to a Globalized one from simple arrangements and simple arrangements without permutation (simple combinations) as per the second stage of the framework. After this conversion, the conditions have been met that enable the decision-making process to be applied appropriately, as shown in the third stage.

3.1. Drawing up the fragmented set of alternatives

The research is aimed at medium and large companies in the sector of residential,

commercial and institutional building and which also work with public works

(tenders), in order to encompass a larger number of alternatives for improving

processes in the aspects of Quality, Environment and Safety at Work. The model

can be used easily by small businesses, including a more simplified set of

alternatives for improvements. To Claver and

Tarí (2008)CLAVER, E.; TARI, J. J. The Individual Effects of Total Quality

Management on Customers, People and Society Results and Quality Performance in

SMEs. Quality and Reliability engineering International, v. 24,

p. 199-211, 2008. http://dx.doi.org/10.1002/qre.885

http://dx.doi.org/10.1002/qre.885...

, several empirical studies have shown the link between

quality management practices and improved performance, while others do not find

such a link. In general, although studies have focused mainly on large firms,

the literature shows that the implementation of quality management may impact on

performance in medium-sized enterprises and in large firms.

As a result, eight alternatives were considered for improving the process, that is, improvement alternatives for the production process in the Civil Construction Sector in Brazil.

-

Alternative 1 (A1 - Implementation of ISO Standard 9001:2008 and/or Brazilian Program of Quality and Productivity in the Habitat (PBQP-H) / System of Evaluation of the Compliance of Service Companies and Works (SiAC) - Level A.

Standard with guidelines for improving and controlling the process, with a view to certification and initial level for an efficient Quality Management System. It is worth stressing that Level A of SiAC covers 100% of ISO 9001:2008.

Knowledge and application of some activities / methodologies are important for implementing this series of standards, such as 5S, PDCA Cycle and the Traditional Seven Quality Management Tools. According to Sampaio, Saraiva and Rodrigues (2010)SAMPAI0, P.; SARAIVA, P.; RODRIGUES, A. G. A classification model for prediction of certification motivations. Total Quality Management & Business Excellence, v. 21, n. 12, p. 1279-1298, 2010. http://dx.doi.org/10.1080/14783363.2010.529367

http://dx.doi.org/10.1080/14783363.2010.... , it is important to emphasize that some companies that have become certified based mostly upon external motivations, defined their main goal as 'obtaining registration', and thus are of a very limited nature in terms of quality management systems implementation and certification. -

Alternative 2 (A2) - Implementation of the PBQP-H System of Evaluation of the Compliance of Service Companies and Works (SiAC)- Level B;

Standard with guidelines for improving and controlling the process, with a view to certification, and which cover 73.58% of ISO 9001:2008;

-

Alternative 3 (A3) - Implementation of the PBQP-H System of Evaluation of the Compliance of Service Companies and Works (SiAC)- Level C;

Standard with guidelines for improving and controlling the process, with a view to certification, and which cover 62.26% of ISO 9001:2008;

-

Alternative 4(A4)- Implementation of the PBQP-H System of Evaluation of the Compliance of Service Companies and Works (SiAC)- Level D;

Standard with guidelines for improving and controlling the process, with a view to certification, and which cover 26.42% of ISO 9001:2008;

-

Alternative 5 (A5)- Implementation of the Seven Management Tools for Quality.

These Seven Tools are: Relations Diagram, Affinity Diagram, Tree Diagram, Matrix Diagram, Matrix data analysis, Arrow Diagram, Process Decision Program Chart. These tools give support to planning and to help understand and solve problems.

-

Alternative 6 (A6)- Implementation of Standard ISO 14001:2004

Standard with guidelines for improving the process in the aspects related to the environment.

-

Alternative 7(A7) - Implementation of Standard OHSAS 18001:2007;

Standard with guidelines for improving the process in the aspects related to Health and Hygiene at Work;

Alternative 8(A8) - Implementation of Lean Construction.

Principles of Lean Production targeted on the Civil Construction segment, which encompass stabilizing the flow of material and information (flow kaizen), improving the construction processes (process Kaizen) and just-in-time production.

In this work, the A group of alternatives is considered stable and fragmented, since combinations of the eight alternatives presented will be used.

According to Mast and Bergman (2006)MAST, J.; BERGMAN, M. Hypothesis Generation in Quality Improvement

Projects: Approaches for Exploratory Studies. Quality and Reliability

engineering International, v. 22, p. 839-850, 2006.

http://dx.doi.org/10.1002/qre.767

http://dx.doi.org/10.1002/qre.767...

,

improvement programs teach people a scientific attitude towards problem solving

and quality and efficiency improvement. In the study by Oliveira et al. (2011)OLIVEIRA, J. A. et al. A study on the use of quality systems,

programs and tools in companies of interior of São Paulo State.

Produção, v. 21, n. 4, p. 708-723, 2011.

http://dx.doi.org/10.1 590/S0103-65132011005000044

http://dx.doi.org/10.1590/S0103-65132011...

, the authors ratify the importance

of the use of quality tools and programs because these options, when adopted,

generate considerable competitive advantages. The eight alternatives presented

aim at improving the production process, the work environment and satisfying the

end customer, collaborators and society. However, simultaneous implementation of

some alternatives is considered more difficult in this context because there is

some resistance to changes at all levels of the hierarchy, due to a strongly

ingrained organizational culture. The construction sector is a very traditional

one, in which innovations occur somewhat more slowly.

The initial implementations of the same ISO 9000, ISO 14000 and OHSAS 18000 are more complex and are utilized less in the construction industry in Brazil. Thus, in the case of this work, the implementations of these standards will be considered in isolation.

A construction company can also choose to implement a Quality Management System based on the ISO 9001:2008 (ASSOCIAÇÃO..., 2008ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS - ABNT. NBR ISO 9001:2008: Sistemas de gestão da qualidade-Requisitos. ABNT, 2008.) standard between levels A (100% of the standard), B (73.58«/o), C (62.260/o) or D (26,420/o) of the SiAC in accordance with the Brazilian Program for Quality and Productivity (2012) in the Habitat (PBQP-H in Portuguese). This program has fostered raising the quality and productivity of the various agents of construction. As for the seven new tools of quality planning that characterize alternative 7, they can be implemented, whether simultaneously or not, with the other alternatives.

Programs such as Rationalization in Civil Construction, a product of the COMPET1R project, resulting from the Technical Cooperation Agreement between the governments of Brazil and Germany, may be slotted into Alternative 8 (A8).

3.2. Conversion of the fragmented set into a globalized one

The new alternatives for the implementation of choice will be obtained through simple combinations of the 8 alternatives presented.

- –

The alternatives A, A, A3 and A4 are considered mutually exclusive, i.e. they cannot be combined with each other;

- –

The macro alternative that might contain A (ISO 9001:2008/SiAC level A), for example, may not contain A2 (SiAC level B), A3 (SiAC level C) or A4 (SiAC level D), since A1 already includes all D, C and B levels.

It is worth noting that the permutation (P n= n!) will not be brought about, since the groupings are chosen from elements / alternatives that differ from each other only by the nature of their elements and not by their ranking. The simple combinations were obtained as per equation (3).

C = simple Combination

A = simple Arrangement

- 1)

When the improvement alternative A is considered, there is the group A1 A5, A6, A7 A8 which can be grouped 2 by 2, 3 by 3, 4 by 4 and 5 by 5 to form the macro alternatives;

- 2)

When the improvement alternative A2 is considered, there is the group A2 A5, A6, A7 A8 which can be grouped 2 by 2, 3 by 3, 4 by 4 and 5 by 5 to form the macro alternatives;

- 3)

When the improvement alternative A3 is considered, there is the qroup A3 A5, A6, A7 A8 which can be grouped 2 by 2, 3 by3, 4 by 4 and 5 by 5 to form the macro alternatives;

- 4)

When the improvement alternative A4is considered, there is the group A4 A5, A6, A7 A8 which can be grouped 2 by2, 3 by 3, 4 by 4 and 5 by 5 to form the macro alternatives.

The improvement alternatives were combined to dimension the macro alternatives. Thus it was considered that the construction company established a globalized set of 79 macro alternatives.

3.3. Framework for the decision making process

Among the global set of alternatives drawn up based on the combinations, the construction company will select a macro alternative for improvement in order to achieve its strategic objectives in the medium and long term. In order to structure the sequencing of implementation, a ranking will be performed to identify, for example, if OHSAS 18000 will be applied before or after the series of ISO 14000 standards, and by doing so, the problematic of ranking is identified.

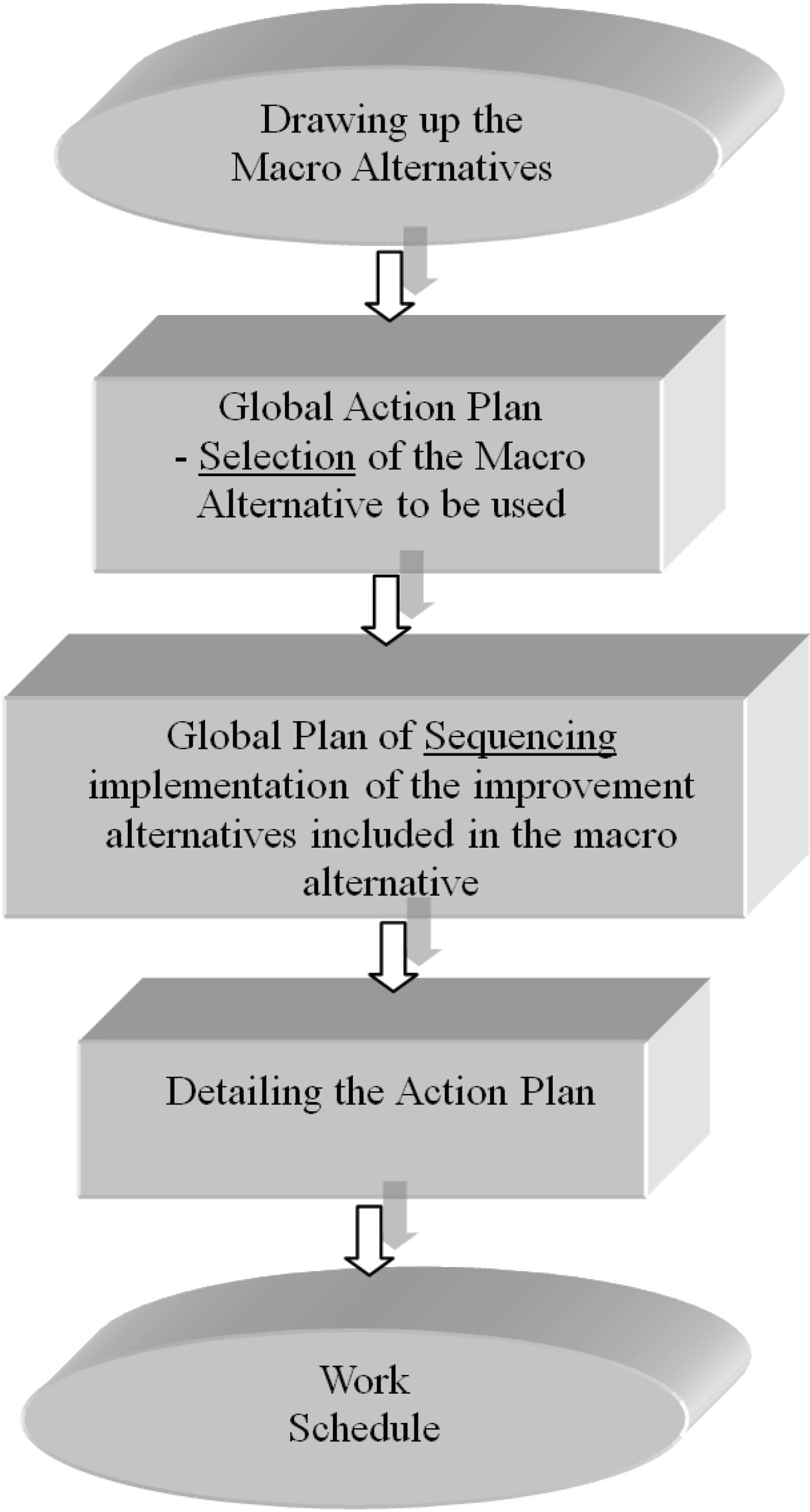

The purpose of the Global Plan of Action is to select the macro alternative for improvement to be adopted. Thereafter, if the macro alternative includes more than one improvement alternative, they will be ranked with a view to sequencing the activities and drawing up a detailed work plan with its schedule, in an effective way according to Figure 1.

Description of the Systematics of Selection

The procedure for selecting the macro alternative of the process comprises the steps presented below.

Identification of Strategic Objectives

First of all, the construction company's long-and medium-term strategic objectives are identified in the strategic plan already drawn up by the company, or through brainstorming sessions with senior management and key people in the organization, should the company not have a formalized plan.

According to Schwarber (2005)SCHWARBER, P. D. Leaders and the decision-making process.

Management Decision, v. 43, n. 7-8, p. 1086-1092, 2005.

http://dx.doi.Org/10.1108/00251740510610099

http://dx.doi.Org/10.1108/00251740510610...

,

this starts with objectives, with the group asking itself: What are we

trying to accomplish? What are the results we are trying to achieve?

This paves the way for honest, open discussion and eliminates jumping to

alternatives.

A Meeting to establish the criteria

Thereafter, a meeting is held with the stakeholders to define the criteria to be used, such as, for example: cost of implementation; length of implementation; time of adoption as culture and ease of implementation. The actors involved in this meeting include decision-makers (directors, shareholders or key people in the organization), the facilitator and analyst.

Presentation of the Macro Alternative

In this step, the presentation and subsequent clarification by the analyst with regard to the 79 macro alternatives for improvement of the process applied in the civil construction industry are made to the decision maker.

Choice of Multicriteria Method

The multicriteria method is chosen by the analyst based on an analysis of various factors such as: type of problem, scenario under study, understanding of the decision-making process by the decision maker, the actors, the preference structure, and so on.

Choice of the macro alternative to be implemented

In this stage, the application of the multicriteria model for the selection of the macro alternative is conducted. As a result, the construction company will have a macro alternative which comprises between one and five improvement alternatives.

Description of the Systematics of Ranking

The procedure for ranking the improvement alternatives included in the macro alternative for improvement of the process comprises the steps presented below:

Presentation of the macro alternative chosen

The macro alternative chosen will be presented to the construction company. If it includes more than one improvement alternative, ranking will be required.

Choice of Method

If the method chosen earlier in the systematics of selecting the alternative includes ranking the macro alternative, this step of choosing a new multicriteria method is unnecessary, since there is ranking of all the macro alternatives.

In some selection/choice methods such as Electre 1, for example, the Pα problematic is clarified by way of choosing a subset that is restricted as much as possible and contains the best alternatives, i.e. a subset K (minimum dominant set). Thus, there will be a need to use another method for the systematics of ranking the improvement alternatives contained in the macro alternative.

Sequencing of Implementation

In this step, the aim is to sequence the improvement alternatives presented in the macro alternative. It is worth stressing that one should not be forced to use a method that supplies the ranking of macro alternatives in the systematics of choice / selection in order to take advantage of the results obtained.

When there is no need to use a new method to rank the improvement alternatives contained in the macro alternative, this is because the results from the selection model already applied will be used.

In this case, the result from the model selecting the macro alternative displays a ranking of all the macro alternatives contained in this model, including those containing only one improvement alternative.

Thus, there is a need to know the ranking of the improvement alternatives contained in the macro alternative, as per the illustrative example below.

illustrative example

Macro Alternative 36 results from the systematics of selection, as shown below.

There will be a need to conduct the sequencing of the alternatives A2, A5 and A7 Therefore, the ranking of the macro alternatives 2, 5 and 7 is verified in the result from the selection model. Respectively, they include only the improvement alternatives A2 A5 and A7, as shown below.

If the company has the result which is the sequencing of the improvement alternatives, it will be able to target its resources more efficiently and effectively, thus reducing costs and increasing its competitive advantage in the market.

Detailing the Action Plan

This step takes time and effort, and it is where many points which cause the greatest difficulties when implementing a management system, program or methodology in a construction company are thought through in advance. They are: organizational culture and resistance to change; excessive bureaucracy; lack of staff involvement; lack of commitment from top management; and so forth.

Many research results have shown that one of the main reasons for failure

in implementing quality management or other advantageous managerial

frameworks is insufficient understanding and involvement of employees,

and insufficient involvement and leadership of top management (DAHLGAARD PARK; DAHLGAARD, 2010DAHLGAARD PARK, S.; DAHLGAARD, J. J. Organizational leamability and

lnnovability: a system for assessing, diagnosing and Improving Innovations.

International Journal of Quality and Service Sciences, v.

2, n. 2, p. 153-174, 2010. http://dx.doi.

org/10.1108/17566691011057339

http://dx.doi.org/10.1108/17566691011057...

;

LAOHAVICHIEN; FREDENDALL; CANTRELL,

2010LAOHAVICHIEN, T.; FREDENDALL, L. D.; CANTRELL, R. S. Leadership and

qualitymanagement practices in Thailand. International Journal of

Operations & Production Management, v. 31, n. 10, p. 1048-1070,

2010. http://dx.doi.org/10.1108/01443571111172426

http://dx.doi.org/10.1108/01443571111172...

; VALMOHAMMADI,

2011VALMOHAMMADI, C. The impact of TQM implementation on the

organizational performance of Iranian manufacturing SMEs. The TQM

Journal, v. 23, n. 5, p. 496-509, 2011.

http://dx.doi.org/10.1108/17542731111157608

http://dx.doi.org/10.1108/17542731111157...

; CORREDOR; G0ISII,

2011CORREDOR, P.; GONI, S. TQM and performance: Is the relationship so

obvious? Journal of Business Research, v. 64, p. 830-838, 2011.

http://dx.doi.Org/10.1016/j.jbusres.2010.10.002

http://dx.doi.Org/10.1016/j.jbusres.2010...

; HERAS-SAIZARBITORIA,

2011HERAS-SAIZARBITORIA, 1. Intemalization of ISO 9000: an exploratory

study. Industrial Management & Data Systems, v. 111, n. 8,

p. 1214-1237, 2011. http://dx.doi.org/10.1108/02635571111170776

http://dx.doi.org/10.1108/02635571111170...

).

3.4. Criteria

Vincke (1992)VINCKE, P. Multicriteria decision-aid. Chichester: John Wiley, 1992. defines a criterion as a function g, defined on A, taking its values in a totally ordered set, and representing the decision-maker's preferences according to some point of view.

An overall analysis was performed in 4 construction companies in the Metropolitan Region of Recife in Brazil in order to obtain a preliminary view and better understanding of the criteria. Using partially structured interviews, a convergence to 4 important criteria was verified: implementation cost, length of implementation, positive impact on the corporate image and impact of the benefits on the production process.

It is noteworthy that measurements of the importance of criteria such as weights or other parameters should be determined within the axiomatic structure of each method and can vary in meaning from one method to another. Another point to stress is that the criteria used may change in accordance with the company or even for the same company after a certain period of time.

4. Application of the PROMETHEE II Method

The applications shown below are not a real specific case, but they consider realistic data, based on a given context and structure of relationship between the variables considered.

Three scenarios were developed to analyze the problem, and each scenario corresponds to a specific vector of weight that meets the applied research according to Table 2.

- –

Impact of the benefits on the production process (C1): it is also a qualitative criterion and the preference function Type I (Usual Criterion - no Threshold) was adopted;

- –

Positive impact on the company's image (C2): it is also a qualitative criterion and the preference function Type I (Usual Criterion - no Threshold] was adopted;

- –

Average cost of implementation (C3): preference function Type II (Shape Criterion- q threshold] was considered more appropriate, as it uses the Indifference Threshold. The construction company will remain indifferent to certain differences between the costs. It is a criterion for minimization;

- –

Average length of implementation (C4): the preference function Type II (Shape Criterion - q threshold) was also proposed and it is a criterion for minimization.

The data and parameters were estimated through a literature review and consultation with specialists. Once all parameters have been defined and the array of performance achieved, the process of multicriteria aggregation of preferences begins. In this process, the degree of over-classification of the alternatives, the inflow, outflow, and finally, the liquid flow are determined. At the end, the alternatives are sorted according to their liquid flow.

Table 4 shows the ranking of alternatives according to the liquid flow for the three scenarios.

- –

For scenario 1, the recommendation was the macro alternative MA 9. It consists of the improvement alternatives A1 and A5

This macro alternative is preferable to other options because it results in a greater liquid flow. It is important to mention that the results differ from that of Scenarios 2 and 3. For Scenario 1, MA 9 obtained good performance in the criteria C3 and C4 with weights of 0.245 and 0.2 respectively.

- –

For scenarios 2 and 3, the recommendation was the alternative MA 76. It consists of the improvement alternatives A1, A5, A6, A7, and A8 This macro alternative is preferable to other options because it has a greater liquid flow result in these two scenarios and it performed well on criteria Cl and C2, whose weights are higher when compared to the weights in scenario 1.

4.1. Systematic of ranking of improvement alternatives

Prioritization of improvement alternatives contained in the Macro Alternative 9 (Scenario 1);

After the choice of macro alternative, there is the need to rank the improvement alternatives. In this they are: A1 and A5. For this ordering, the results of this method are also used. Thus, for this scenario, the options for improvement contained in the MA 9 will be the order of implementation: A5 and A1, according to Table 5.

Prioritization of improvement alternatives contained in the Macro Alternative 76 (Scenarios 2 and 3).

For scenarios 2 and 3, the improvement alternatives contained in the MA 76 have this order of implementation: A5, A6, A8, A1, A7, as shown on Table 6 below.

5. Discussion of the results

Three scenarios were considered. For scenario 1, MA 9 was chosen, consisting of the improvement alternatives A1 and A5. In this scenario, the criteria C3 and C4 have weights higher than the same criteria in the other two scenarios. As for scenarios 2 and 3, the same alternative was chosen, MA 76. It consists of the improvement alternatives A5, A6, A8, A1 A7. These two scenarios have only minor differences in the weights of the criteria C1 and C4.

In relation to ordering / prioritizing, the improvement alternative A5 (Implementation of the Seven Quality Management Tools) came in 1st place in MA 9 (scenario 1) and in MA 76 (scenario 2 and scenario 3). The ordering of the alternatives contained in the improvement of MA 76 was the same for both scenarios 2 and 3.

It can be verified that the process of selection and ranking of improvement alternatives for construction companies has an important role in organizational success. The well-planned choice of improvement alternatives with the support of the new method provides several benefits, such as the implementation of improvement changes taking into consideration important dimensions: growth in the production process, corporate image, cost and implementation time.

6. Final considerations

When an organization shows concern for Quality Management, Environment and Safety, the production process is benefited in some way, such as reduction of defects, rework or waste, as well as the reduction / elimination of occupational accidents and increased organization and comfort in the environment of these workers. The improvement possibilities (alternatives) of the production process involve these three areas.

One of the differentials of this model is the use of a fragmented set of improvement alternatives. These alternatives were combined with some restrictions so that they became a new global set of alternatives (macro alternatives). The model of this study is particularly aimed at medium and large construction companies. It may be noted that, in the modeling, there were no financial constraints regarding the maximum number of improvement alternatives, but these restrictions can be taken into consideration, especially for smaller companies. Thus, this model can also be adapted for small businesses, with different alternatives or a further reduced fragmented set.

The measurement of each criterion worked on in the model demands detailed analysis. Another point to be made carefully is the correct measurement of each criterion for each macro alternative, this being an alternative that often works with combinations of improvement alternatives, and these combinations are not always linear functions. Therefore, the proposed model helps the selection and ranking of improvement alternatives of the process and it has an important role in organizational strategy. It should be inserted in the strategic planning process.

References

- ALMEIDA, A. T.; DIJARTE, M. D. 0. A multi-criteria decision model for selecting project portfolio with consideration being given to a new concept for synergies. Pesquisa Operational, v. 32, p. 1-18, 2011.

- ANDRONIKIDIS, A. et al. The application of quality function deployment in service quality management. The TQM Journal, v. 21, n. 4, p. 319–333, 2009. http://dx.doi.org/10.1108/17542730910965047

» http://dx.doi.org/10.1108/17542730910965047 - ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS - ABNT. NBR ISO 9001:2008: Sistemas de gestão da qualidade-Requisitos. ABNT, 2008.

- BEHZADIAN, M. et al. PROMETHEE: A comprehensive literature review on methodologies and applications. European Journal of Operational Research, v. 200, p. 198–215, 2010. http://dx.doi.Org/l0.l0l6/j.ejor.2009.0l.021

» http://dx.doi.Org/l0.l0l6/j.ejor.2009.0l.021 - BEHZADIAN, M. et al. PROMETHEE Group Decision Support System and the House of Quality. Group Decision and Negotiation, v. 22, n. 2, p. 189-205, 2013. http://dx.doi.org/10.1007/sl0726-011-9257-3

» http://dx.doi.org/10.1007/sl0726-011-9257-3 - BRANS, J. P.; VINCKE, P. H. A preference ranking organization method, the PROMETHEE method for MCDM. Management Science, v. 31, p. 647-656, 1985. http://dx.doi.Org/10.1287/mnsc.31.6.647

» http://dx.doi.Org/10.1287/mnsc.31.6.647 - BRANS, J. P.; MARESCHAL, B. Promethee V: MCDM problems with segmentation constraints. INFOR, v. 30, n. 2, p. 85-86, 1992.

- BRAZILIAN PROGRAM FOR QUALITY AND PRODUCTIVITY IN THE HABITAT - PBQP-H. Disponivel em: <http://www2.cidades.gov.br/pbqp-h/projetos_siac.php>. Acesso em: 02 fev. 2012.

» http://www2.cidades.gov.br/pbqp-h/projetos_siac.php - BRITO, A. J.; ALMEIDA, A. T.; MOTA, C. M. A multicriteria model for risk sorting of natural gas pipelines based on electre tri integrating utility theory. European Journal of Operational Research, v. 200, p. 812-821, 2010. http://dx.doi.org/10.1016/j.ejor.2009.01.016

» http://dx.doi.org/10.1016/j.ejor.2009.01.016 - CAMPOS, A. C. S. M.; DAHER, S. F. D.; ALMEIDA, A. T.; New Patents on Business Process Management Information Systems and Decision Support. Recent Patents on Computer Science, v. 4, p. 91-97, 2011. http://dx.doi.org/10.2174/2213275911104020091

» http://dx.doi.org/10.2174/2213275911104020091 - CHIN, K. S. et al. An AMP based study of critical factors for TQM implementation in Shanghai manufacturing industries. Technovation, p. 707-715, 2002. http://dx.doi.org/10.1016/S0166-4972(01)00065-7

» http://dx.doi.org/10.1016/S0166-4972(01)00065-7 - CLAVER, E.; TARI, J. J. The Individual Effects of Total Quality Management on Customers, People and Society Results and Quality Performance in SMEs. Quality and Reliability engineering International, v. 24, p. 199-211, 2008. http://dx.doi.org/10.1002/qre.885

» http://dx.doi.org/10.1002/qre.885 - CORREDOR, P.; GONI, S. TQM and performance: Is the relationship so obvious? Journal of Business Research, v. 64, p. 830-838, 2011. http://dx.doi.Org/10.1016/j.jbusres.2010.10.002

» http://dx.doi.Org/10.1016/j.jbusres.2010.10.002 - DAHER, S. F. D.; ALMEIDA, A. T. Recent Patents Using Group Decision Support Systems: A Short Review. Recent Patents on Computer Science, v. 3, p. 81-90, 2010. http://dx.doi.org/10.2174/2213275911003020081

» http://dx.doi.org/10.2174/2213275911003020081 - DAHLGAARD PARK, S.; DAHLGAARD, J. J. Organizational leamability and lnnovability: a system for assessing, diagnosing and Improving Innovations. International Journal of Quality and Service Sciences, v. 2, n. 2, p. 153-174, 2010. http://dx.doi. org/10.1108/17566691011057339

» http://dx.doi.org/10.1108/17566691011057339 - GURUMURTHY, A.; KODALI, R. A multi-criteria decision-making model for justification of lean manufacturing systems. International Journal of Management Science and Engineering Management, v. 3, n. 2, p. 100-118, 2008.

- HERAS-SAIZARBITORIA, 1. Intemalization of ISO 9000: an exploratory study. Industrial Management & Data Systems, v. 111, n. 8, p. 1214-1237, 2011. http://dx.doi.org/10.1108/02635571111170776

» http://dx.doi.org/10.1108/02635571111170776 - KAVOSI, M.; MOZAFFARI, M. M.; MAVI, R. K. Incorporating cost and environmental factors in quality function deployment using TOPSIS method. International Journal of Quality Engineering and Technology, v. 2, n. 1, p. 63-74, 2011. http://dx.doi.org/10.1504/UQET.2011.038723

» http://dx.doi.org/10.1504/UQET.2011.038723 - LAOHAVICHIEN, T.; FREDENDALL, L. D.; CANTRELL, R. S. Leadership and qualitymanagement practices in Thailand. International Journal of Operations & Production Management, v. 31, n. 10, p. 1048-1070, 2010. http://dx.doi.org/10.1108/01443571111172426

» http://dx.doi.org/10.1108/01443571111172426 - MAST, J.; BERGMAN, M. Hypothesis Generation in Quality Improvement Projects: Approaches for Exploratory Studies. Quality and Reliability engineering International, v. 22, p. 839-850, 2006. http://dx.doi.org/10.1002/qre.767

» http://dx.doi.org/10.1002/qre.767 - MELLO, L. C. B. B.; AMORIM, S. R. L. The subsector of buildings of the civil construction in Brazil: a x-ray of the sector compared to the European Union and the United States Produção, v. 19, n. 2, p. 388-399, 2009.

- MORAIS, D. C; ALMEIDA, A. T. Water supply system decision-making using multicriteria analysis. Water SA, v. 32, n. 2, p. 229-235, 2006.

- MORAIS, D. C; CAVALCANTE, C. A. V.; ALMEIDA, A. T. Priorização de areas de controle de perdas em redes de distribuição de água. Pesquisa Operacional, v. 30, n. 1, p. 15–32, 2010.

- MOTA, C. M. M.; ALMEIDA, A. T.; ALENCAR, L. H. A multiple criteria decision model for assigning priorities to activities in project management. International Journal of Project Management, v. 27, n. 2, p. 175-181, 2009. http://dx.doi.Org/10.1016/j.ijproman.2008.08.005

» http://dx.doi.Org/10.1016/j.ijproman.2008.08.005 - MADU, C. N. et al. Adoption of strategic total quality management philosophies - Multi-criteria decision analysis model. International Journal of Quality & Reliability Management, v. 13, n. 3, p. 57-72, 1996. http://dx.doi.org/10.1108/02656719610116081

» http://dx.doi.org/10.1108/02656719610116081 - OLIVEIRA, J. A. et al. A study on the use of quality systems, programs and tools in companies of interior of São Paulo State. Produção, v. 21, n. 4, p. 708-723, 2011. http://dx.doi.org/10.1 590/S0103-65132011005000044

» http://dx.doi.org/10.1590/S0103-65132011005000044 - POLITIS, Y.; SISKOS, Y. Self-assessment for measuring business excellence: The MUSABE method. Total Quality Management & Business Excellence, v. 21, n. 11, p. 1063-1083, 2010. http://dx.doi. org/10.1080/14783360902924283

» http://dx.doi.org/10.1080/14783360902924283 - SAMPAI0, P.; SARAIVA, P.; RODRIGUES, A. G. A classification model for prediction of certification motivations. Total Quality Management & Business Excellence, v. 21, n. 12, p. 1279-1298, 2010. http://dx.doi.org/10.1080/14783363.2010.529367

» http://dx.doi.org/10.1080/14783363.2010.529367 - SAREMI, M.; MOUSAVI, F.; SANAYEI, A. TQM consultant selection in SMEs with TOPSIS under fuzzy environment. Expert Systems with Applications, v. 36, n. 2, p. 2742-2749, 2009. http://dx.doi.Org/10.1016/j.eswa.2008.01.034

» http://dx.doi.Org/10.1016/j.eswa.2008.01.034 - SCHWARBER, P. D. Leaders and the decision-making process. Management Decision, v. 43, n. 7-8, p. 1086-1092, 2005. http://dx.doi.Org/10.1108/00251740510610099

» http://dx.doi.Org/10.1108/00251740510610099 - TALEB, M. F. A.; MARESCHAL, B. Water resources planning in the Middle East: application of the PROMETHEE V multicriteria method. European Journal of Operational Research, v. 81, p. 500-511, 1995. http://dx.doi.org/10.1016/0377-2217(94)00007-Y

» http://dx.doi.org/10.1016/0377-2217(94)00007-Y - THAWESAENGSKULTHAI, N. An empirical framework for selecting quality management and improvement initiatives. International Journal of Quality & Reliability Management, v. 27, n. 2, p. 156-172, 2010. http://dx.doi.org/10.1108/02656711011014285

» http://dx.doi.org/10.1108/02656711011014285 - TSAI, W.; HSU, W.; CHOU, W. A gap analysis model for improving airport service quality. Total Quality Management & Business Excellence, v. 22, n. 10, p. 1025-1040, 2011. http://dx.doi.org/10.1080/147833 63.2011.611326

» http://dx.doi.org/10.1080/14783363.2011.611326 - VINCKE, P. Multicriteria decision-aid Chichester: John Wiley, 1992.

- VALMOHAMMADI, C. The impact of TQM implementation on the organizational performance of Iranian manufacturing SMEs. The TQM Journal, v. 23, n. 5, p. 496-509, 2011. http://dx.doi.org/10.1108/17542731111157608

» http://dx.doi.org/10.1108/17542731111157608 - VAL0IS, U.; ALMEIDA, A. T. Support model for multicriteria decision to outsource productive activities based on SMARTS method. Produção, v. 19, n. 2, p. 249-260, 2009. http://dx.doi.org/10.1590/S0103-65132009000200003

» http://dx.doi.org/10.1590/S0103-65132009000200003

Publication Dates

-

Publication in this collection

17 Sept 2013 -

Date of issue

Jan-Mar 2015

History

-

Received

24 Sept 2012 -

Accepted

21 Dec 2012