Abstract

Paper aims

The present study aims to identify the limitations of the artifacts used in the decision-making process in the adoption of energy efficiency measures in productive systems, using non-intensive energy companies as a delimitation.

Originality

Identifies authors and connections, the relationships between them and how these interactions contribute to the advancement of knowledge on the subject. Regarding energy efficiency, studies show that the real investment in initiatives in the industrial sector is below the full potential and that the artifacts used in the decision-making process have severe limitations when used in a complex and dynamic context.

Research method

In this paper a systematic literature review was conducted from the Literature-Grounded Theory. Additionally, social network analysis was used.

Main findings

It concludes that the approaches are limited to technical and financial factors and does not consider a systemic and dynamic understanding of different internal and external variables to the organization.

Implications for theory and practice

The contribution of this study is that it identifies the initiatives that help in the process of decision-making for the adoption of energy efficiency measures in productive systems. Specifically, the focus of this study is on non-intensive energy companies. Scientific articles published in the main databases of management were selected.

Keywords

Energy efficiency; Energy management; Decision support systems; Manufacturing industries

1. Introduction

Until the economic crisis of the 1970s, energy costs were reduced compared to other production expenses, which led to an uncontrolled increase in energy consumption (Aplak & Sogut, 2013Aplak, H. S., & Sogut, M. Z. (2013). Game theory approach in decisional process of energy management for industrial sector. Energy Conversion and Management, 74, 70-80.). The oil crisis challenged the industrialized world, forcing decision makers and researchers to think about a future in which it would be necessary to turn to alternative energy sources and reduce consumption (Olanrewaju & Jimoh, 2014Olanrewaju, O. A., & Jimoh, A. A. (2014). Review of energy models to the development of an efficient industrial energy model. Renewable & Sustainable Energy Reviews, 30, 661-671.).

Energy development is a barometer of economic development. Countries seeking economic growth will necessarily consume more energy. However, increasing the levels of energy production and use through existing initiatives can be difficult, costly and environmentally unsustainable (Reddy, 2013Reddy, B. S. (2013). Barriers and drivers to energy efficiency: a new taxonomical approach. Energy Conversion and Management, 74, 403-416.). One of the methods found to solve this given problem is energy efficiency.

Energy efficiency (EE) refers to the decreasing use of energy in producing a “useful output”. In industrial environments, this useful output is the number of services or products generated from a production process (Aplak & Sogut, 2013Aplak, H. S., & Sogut, M. Z. (2013). Game theory approach in decisional process of energy management for industrial sector. Energy Conversion and Management, 74, 70-80.). In this sense, increased energy efficiency can be achieved with the use of more efficient initiatives, energy recovery in the same process or greater use of energy waste in different processes and greater energy conversion efficiency or optimized operating practices (Bunse et al., 2011Bunse, K., Vodicka, M., Schönsleben, P., Brülhart, M., & Ernst, F. O. (2011). Integrating energy efficiency performance in production management: gap analysis between industrial needs and scientific literature. Journal of Cleaner Production, 19(6-7), 667-679.; Perroni et al., 2016Perroni, M. G., Gouvea, S. E. C., Pinheiro, E. de L., & Silva, W. V. (2016). The relationship between enterprize efficiency in resource use and energy efficiency practices adoption. International Journal of Production Economics, 190, 108-119.).

Considering the implementation of energy efficiency, there are different approaches to classifying companies in terms of energy consumption. In Brazil, the terms electro-intensive or energy-intensive are used to classify organizations operating in the cement, copper, aluminum, chemical and petrochemical, ferroalloys, steel, mining, paper and cellulose, air gases, among others commonly classified as heavy industry. For other companies, the most used term is non-energy intensive industries. Therefore, the term “non-energy intensive” is generally used to refer to companies classified as a non-energy intensive industry, or light industry.

In this scenario, energy management can play an important role in contributing to increase profitability and productivity of companies (Aplak & Sogut, 2013Aplak, H. S., & Sogut, M. Z. (2013). Game theory approach in decisional process of energy management for industrial sector. Energy Conversion and Management, 74, 70-80.). At the same time, neglecting energy management and energy efficiency can constrain organizations' performance. In companies classified as non-intensive, energy consumption is not the largest share of production costs (Finnerty et al., 2017Finnerty, N., Sterling, R., Coakley, D., Contreras, S., Coffey, R., & Keane, M. M. (2017). Development of a Global Energy Management System for non-energy intensive multi-site industrial organisations: a methodology. Energy, 136, 16-31. http://dx.doi.org/10.1016/j.energy.2016.10.049.

http://dx.doi.org/10.1016/j.energy.2016....

). This leads to a lack of studies and research agendas related to energy efficiency in these industrial environments (Fenerich et al., 2017Fenerich, F. C., Costa, S. G., & Lima, E. P. (2017). Energy efficiency in industrial environments: overview and research agenda. IEEE Latin America Transactions, 15(3), 415-422.; Hasan et al., 2019Hasan, A. S. M. M., Hossain, R., Tuhin, R. A., Sakib, T. H., & Thollander, P. (2019). Empirical investigation of barriers and driving forces for efficient energy management practices in non-energy-intensive manufacturing industries of Bangladesh. Sustainability, 11(9), 2671. http://dx.doi.org/10.3390/su11092671.

http://dx.doi.org/10.3390/su11092671...

) that guides to non-intensive industries not entirely aware of the concepts of energy management and energy efficiency (Hasan et al., 2019Hasan, A. S. M. M., Hossain, R., Tuhin, R. A., Sakib, T. H., & Thollander, P. (2019). Empirical investigation of barriers and driving forces for efficient energy management practices in non-energy-intensive manufacturing industries of Bangladesh. Sustainability, 11(9), 2671. http://dx.doi.org/10.3390/su11092671.

http://dx.doi.org/10.3390/su11092671...

).

However, when contextualizing energy efficiency in a segmented manner with emphasis on the industrial sector, Thollander And Palm (2015) present important information about the potential and actual use of initiatives to increase energy efficiency. In the electro-intensive industry, there is a smaller disparity between the potential and the real possibility of energy efficiency, considering the available initiatives. In non-intensive industry, however, this disparity is greater.

Small and medium-sized enterprises (SMEs), which can be classified as non-intensive energy use, consume more than 13% of the total global energy demand (International Energy Agency, 2016International Energy Agency – IEA. (2016). Energy efficiency market report. Paris: IEA.). The energy efficiency measures in these companies have the potential to save up to 6.1 x 1012 terawatt-hour (TWh), representing more energy than the sum of the annual consumption in Japan and South Korea (International Energy Agency, 2016International Energy Agency – IEA. (2016). Energy efficiency market report. Paris: IEA.). Studies have shown that there is a significant disparity between the potential and the actual implementation of energy efficiency initiatives between intensive and non-intensive industries (Bunse et al., 2011Bunse, K., Vodicka, M., Schönsleben, P., Brülhart, M., & Ernst, F. O. (2011). Integrating energy efficiency performance in production management: gap analysis between industrial needs and scientific literature. Journal of Cleaner Production, 19(6-7), 667-679.; Cassettari et al., 2017Cassettari, L., Bendato, I., Mosca, M., & Mosca, R. (2017). Energy Resources Intelligent Management using online real-time simulation: a decision support tool for sustainable manufacturing. Applied Energy, 190, 841-851.; Perroni et al., 2016Perroni, M. G., Gouvea, S. E. C., Pinheiro, E. de L., & Silva, W. V. (2016). The relationship between enterprize efficiency in resource use and energy efficiency practices adoption. International Journal of Production Economics, 190, 108-119.; Pusnik et al., 2016Pusnik, M., Al-Mansour, F., Sucic, B., & Gubina, A. F. (2016). Gap analysis of industrial energy management systems in Slovenia. Energy, 108, 41-49.; Schulze et al., 2016Schulze, M., Nehler, H., Ottosson, M., & Thollander, P. (2016). Energy management in industry: a systematic review of previous findings and an integrative conceptual framework. Journal of Cleaner Production, 112, 3692-3708.; Nehler & Rasmussen, 2016Nehler, T., & Rasmussen, J. (2016). How do firms consider non-energy benefits? Empirical findings on energy-efficiency investments in Swedish industry. Journal of Cleaner Production, 113, 472-482.; Cooremans, 2012Cooremans, C. (2012). Investment in energy efficiency: Do the characteristics of investments matter? Energy Efficiency, 5(4), 497-518.; Knobloch & Mercure, 2016Knobloch, F., & Mercure, J. F. (2016). The behavioural aspect of green technology investments: a general positive model in the context of heterogeneous agents. Environmental Innovation and Societal Transitions, 21, 39-55.; Lung et al., 2005Lung, R. B., Mckane, A., Leach, R. & Marsh, D. (2005). Ancillary savings and production benefits in the evaluation of industrial energy efficiency measures. In ACEEE Summer Study on Energy Efficiency in Industry (pp. 103-114). Washington: ACEEE.; May et al., 2015May, G., Barletta, I., Stahl, B., & Taisch, M. (2015). Energy management in production: a novel method to develop key performance indicators for improving energy efficiency. Applied Energy, 149, 46-61., 2017May, G., Stahl, B., Taisch, M., & Kiritsis, D. (2017). Energy management in manufacturing: from literature review to a conceptual framework. Journal of Cleaner Production, 167, 1464-1489. http://dx.doi.org/10.1016/j.jclepro.2016.10.191.

http://dx.doi.org/10.1016/j.jclepro.2016...

; Never, 2016Never, B. (2016). Behave and save? Behaviour, energy efficiency and performance of micro and small enterprises in Uganda. Energy Research & Social Science, 15, 34-44.; Palm & Thollander, 2010Palm, J., & Thollander, P. (2010). An interdisciplinary perspective on industrial energy efficiency. Applied Energy, 87(10), 3255-3261.; Paramonova & Thollander, 2016Paramonova, S., & Thollander, P. (2016). Energy-efficiency networks for SMEs: learning from the Swedish experience. Renewable & Sustainable Energy Reviews, 65, 295-307.). Therefore, there is potential to use energy efficiency initiatives in non-intensive industries, and it is termed as a gap in power management (Thollander & Palm, 2015Thollander, P., & Palm, J. (2015). Industrial energy management decision making for improved energy efficiency: strategic system perspectives and situated action in combination. Energies, 8(6), 5694-5703.). Regarding that, the aim of this study is to identify the limitations of the artifacts used in the decision-making process in the adoption of energy efficiency measures in productive systems.

An artifact, models, techniques and tools, can be defined as the organization of elements of the internal environment to achieve goals in each external environment (Dresch et al., 2015Dresch, A., Lacerda, D., & Antunes Junior, J. (2015). Design science research: a method for science and technology advancement. Cham: Springer.; Lacerda et al., 2013Lacerda, D. P., Dresch, A., Proença, A., Antunes Júnior, J., & Valle, J. A. (2013). Design Science Research: método de pesquisa para a engenharia de produção. Gestão & Produção, 20(4), 741-761. http://dx.doi.org/10.1590/S0104-530X2013005000014.

http://dx.doi.org/10.1590/S0104-530X2013...

). This study contributes with the identification of the artifacts that assist in the process of decision-making when adopting energy efficiency measures in productive systems, specifically focusing on non-intensive energy companies. Structure of this paper: first, the methodology is discussed, followed by a section focused on the results and discussion, and the final considerations are presented in the last section.

2. Methodology

It is essential to be sufficiently informed about what was researched, how it was researched, and the results found in the research (Morandi & Camargo, 2015Morandi, M. I. W. M., & Camargo, L. F. (2015). Revisão sistemática da literatura. In A. Dresch, D. P. Lacerda & J. A. V. Júnior Antunes (Eds.), Design Science Research: método de pesquisa para a engenharia de produção (pp. 141-175). Porto Alegre: Bookman.), in order to discover what is not known or not understood (Ermel et al., 2021Ermel, A. P. C., Lacerda, D. P., Morandi, M. I. W. M., & Gauss, L. (2021). Literature reviews: modern methods for investigating scientific and technological knowledge. Cham: Springer.). Literature-Grouded Theory consists of a systematic set of steps that seek to review, analyze, and synthesize the literature (Ermel et al., 2021Ermel, A. P. C., Lacerda, D. P., Morandi, M. I. W. M., & Gauss, L. (2021). Literature reviews: modern methods for investigating scientific and technological knowledge. Cham: Springer.). In this sense, a systematic literature review was performed (SLR) to conduct the study (Ermel et al., 2021Ermel, A. P. C., Lacerda, D. P., Morandi, M. I. W. M., & Gauss, L. (2021). Literature reviews: modern methods for investigating scientific and technological knowledge. Cham: Springer.; Veit et al., 2017Veit, D. R., Lacerda, D. P., Camargo, L. F. R., Kipper, L. M., & Dresch, A. (2017). Towards Mode 2 knowledge production. Business Process Management Journal, 23, 293-328.). Initially, the problem of revision and the conceptual framework was defined to understand how the impacts of decisions and initiatives to increase energy efficiency are evaluated in industrial environments. Decision support tools have been identified, including any structured and systematized models, methods, techniques and/or approaches, that are used by companies in the industrial segment, manufacturing companies, production systems, and manufacturing systems within the context of efficiency energy.

Terms were defined to search for studies related to the decision process on energy efficiency in production systems. The strings used are the combination of the terms and are shown in Table 1.

The databases used were ProQuest-Technology Collection, Scopus-Elsevier, Science Direct-Elsevier, and Web of Science - Main Collection, as they are among the main databases for research in the field of management (Dresch et al., 2015Dresch, A., Lacerda, D., & Antunes Junior, J. (2015). Design science research: a method for science and technology advancement. Cham: Springer.), and the IEEE Xplore Digital Library, that is known for making available quality technical literature in the field of engineering and technology. The search of documents was made regarding the fields Title, Abstract and Keywords aiming to ensure a wide coverage. The time horizon was articles published since 1973, a milestone year due to the oil crisis. The research protocol used in the RSL can be found in Appendix A Appendix A LSR Protocol RESEARCHERS: Jonatas Campos Martins, Maria Isabel Wolf Motta Morandi, Daniel Pacheco Lacerda, Barbara Pisoni Bender Andrade DATE: Aug/2021 CONCEPTUAL FRAMEWORK Research Topic: Energy Efficiency in Operations Research object: Decision support tools for Energy Efficiency in industrial environments. Summary of the problem situation: Uncertainty in energy supply has awakened the field of energy efficiency research, as the efficient use of energy, as well as the current context (which involves market, economic, political and technological changes) indicate the need for approaches that can help assess the impact of decisions and initiatives used to increase energy efficiency. This need is even more pressing in industrial environments, as the manufacturing industry requires approximately 1/3 of primary energy, being one of the main energy consumers. In other words, in addition to raw material values and changes in demand, energy can also affect businesses and companies' competitiveness. CONTEXT Energy efficiency will be considered in the context of Strategies to Meet Future Electric Energy Demand, assuming that this can be achieved through: (i) Demand-side management; (ii) Offer Expansion: Distributed Generation and Self-Production. Decision support tools include any structured and systematized models, methods, techniques, and/or approaches that can be used to support decision-making. Companies in the industrial segment, manufacturing companies, production systems, manufacturing system. Non-energy intensive companies. HORIZON Studies published since 1973 (Oil Crisis). THEORETICAL CURRENTS Approaches used to “evaluate the impacts of decisions and initiatives to increase energy efficiency in industrial environments”. Strategies, Indicators and Practices related to EE. LANGUAGES English; Portuguese. REVIEW QUESTION How to assess the impacts of decisions and initiatives to increase energy efficiency in industrial environments? REVIEW STRATEGY () Aggregative (X) Configurative SEARCH CRITERIA Inclusion criteria: Exclusion criteria: Application in industrial environments; Do not contain artifact related to evaluation and/or decision making; Modeling use; EE of engines, turbines and the like; I use structured and systematized methods, techniques, and/or approaches; EE building; Contain strategies, indicators and/or practices related to EE; EE related to the use of electric vehicles; Complete text. EE chips, memories, etc; Energy intensive industries only. SEARCH TERMS # P01: “Energy efficiency” AND “Decision support” AND (Manufacturing OR Industri*) P02: “Energy efficiency” AND “Decision-making” AND (Manufacturing OR Industri*) P03: “Energy efficiency” AND “Economic evaluation” AND (Manufacturing OR Industr*) P04: “Energy efficiency” AND “Impact assessment” AND (Manufacturing OR Industr*) P05: “Energy efficiency” AND “Strategic decision” AND (Manufacturing OR Industri*) P06: “Energy Management” AND “Decision support” AND (Manufacturing OR Industr*) P07: “Energy Management” AND “Decision-making” AND (Manufacturing OR Industr*) P08: “Energy Management” AND “Economic evaluation” AND (Manufacturing OR Industr*) P09: “Energy Management” AND “Impact assessment” AND (Manufacturing OR Industr*) P10: “Energy Management” AND “Strategic decision” AND (Manufacturing OR Industr*) # P11: “Industrial energy efficiency” AND “Decision support” P12: “Industrial energy efficiency” AND “Decision-making” P13: “Industrial energy efficiency” AND Evaluation P14: “Industrial energy efficiency” AND Assessment P15: “Industrial energy efficiency” AND Strateg* P16: “Industrial energy management” AND “Decision support” P17: “Industrial energy management” AND “Decision-making” P18: “Industrial energy management” AND Evaluation P19: “Industrial energy management” AND Assessment P20: “Industrial energy management” AND Strateg* SEARCH SOURCES Data base: Internet: (1) ProQuest|Technology Collection () Google Scholar (2) Scopus | Elsevier (3) Science Direct | Elsevier Others (Grey Literature): (4) Web of Science | Main Collection () National Electric Energy Agency - ANEEL (5) IEEE Xplore Digital Library () Center for Management and Strategic Studies - CGEE () Compendex | Engineering Village () Energy Research Company - EPE () Emerald Insight () International Energy Agency - IEA () Capes Periodicals () International Renewable Energy Agency – IRENA This material is available as part of the online article from https://www.scielo.br/j/prod . The total numbers of records found from each string search in the cited databases are presented in Table 2.

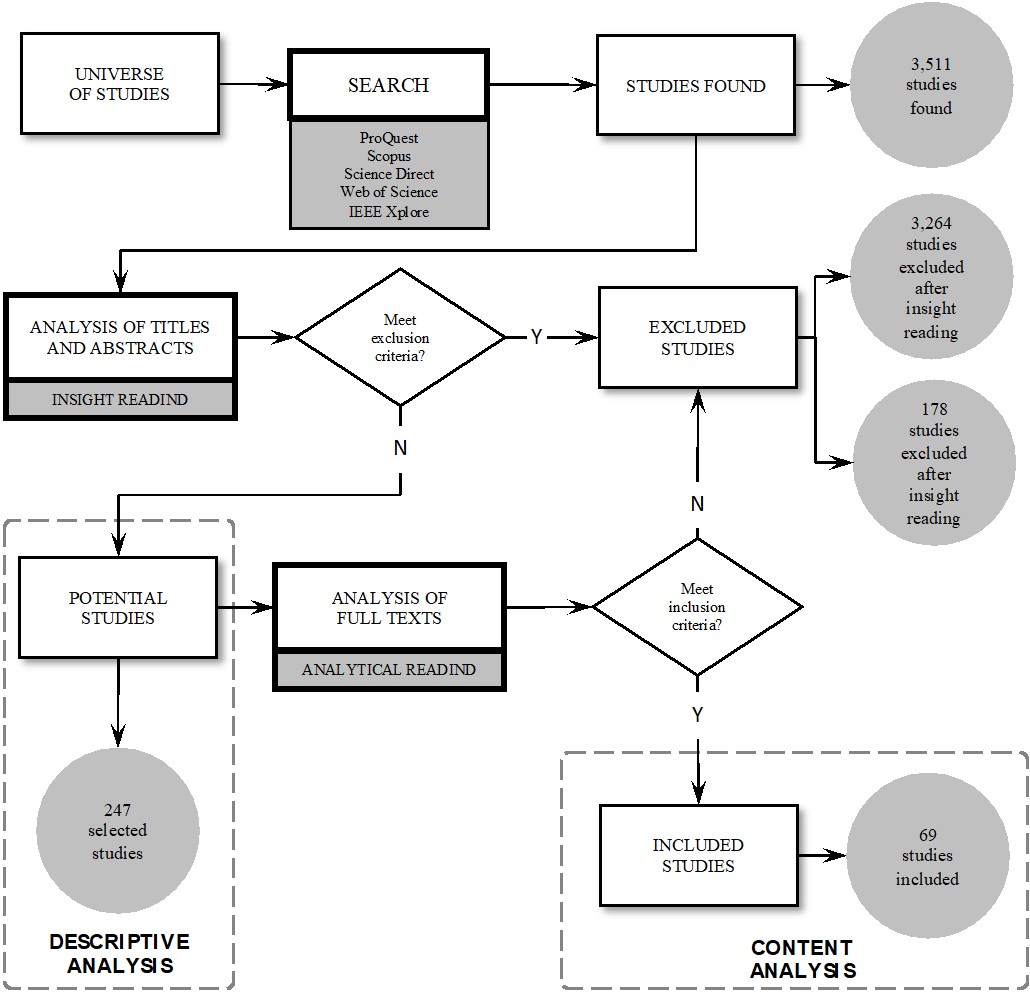

The total number of records found was 4,573 in all the cited databases. To finish this step, the duplicate records were removed, resulting in 3,509 articles, which comprised the eligibility step. Figure 1 shows the overview of the search process, eligibility and coding used in the SLR.

The titles and abstracts of the studies were evaluated by insight reading (Adler & van Doren, 2010Adler, M. J., & van Doren, C. (2010). Como ler livros: o guia clássico para a leitura inteligente. É Realizações.). The exclusion criteria considered at this stage were: (i) papers that do not present artifacts related to evaluation and/or decision making; (ii) research on energy efficiency of motors, turbines and the like and building energy efficiency; (iii) studies on energy efficiency related to the use of electric vehicles; (iv) papers on chip energy efficiency, memories and the like; (vi) research on mechanical and thermodynamic energy efficiency; (vii) studies specific to the electro-intensive industry only. The last exclusion criterion keeps electro-intensive industry papers, if they are in conjunction with non-intensive industry ones.

Overall, 3,511 studies were found, from the first analyses, 3,264 studies were eliminated based on the exclusion criteria, resulting in 247 studies with analytical reading (Adler & van Doren, 2010Adler, M. J., & van Doren, C. (2010). Como ler livros: o guia clássico para a leitura inteligente. É Realizações.) and descriptive analysis potential. In this stage of eligibility, the inclusion criteria were considered to be studies that contemplated: (i) application in industrial settings; (ii) use of modeling; (iii) use, methods, techniques and/or structured and systematized approaches; (iv) strategies, indicators and/or practices related to energy efficiency. At the end of the analytical reading of the full texts, 69 articles were included in the study for content analysis. The descriptive and content analyses are detailed and explored.

3. Results and discussion

From the RSL, 247 studies were pre-selected for analytical reading that make up the set of works considered in the descriptive analysis. From this set, 69 studies were selected based on the inclusion criteria, which were used to carry out the content analysis. The result of both analyzes will be described below.

3.1. Descriptive analysis

To analyze the temporal evolution, we considered the period between 1995 and the first eight months of 2021, time of the oldest and of the most recent study. The behavior of the volume of publications can be observed in Figure 2. It is possible to highlight two distinct periods in relation to the quantity of publications. The first, between 1995 and 2007, presents a small and stable volume of publications. During this period, the amount of annual publications ranged from zero to four. Although it is not possible to say that there is any relationship, from 2007-2008, when it triggered one of the biggest economic crises of international scope, the number of annual publications began to grow significantly, ranging from 3 to 34 annual publications in 2017. In the first 8 months of 2021, the quantity of publications reached 8, allowing a total of 12 to be projected in the year if the frequency of publications on the subject is maintained.

Two important events in the energy scenario occurred during this period. On January 2nd, 2008, the price of a barrel of oil reached US$100 for the first time in history. On the 29 of March 2008, there was the “Earth Hour” in more than 400 cities on the planet, a global movement to mobilize society against global warming. On that date, governments, businesses and people around the world turned off the lights for an hour to express concern about global warming.

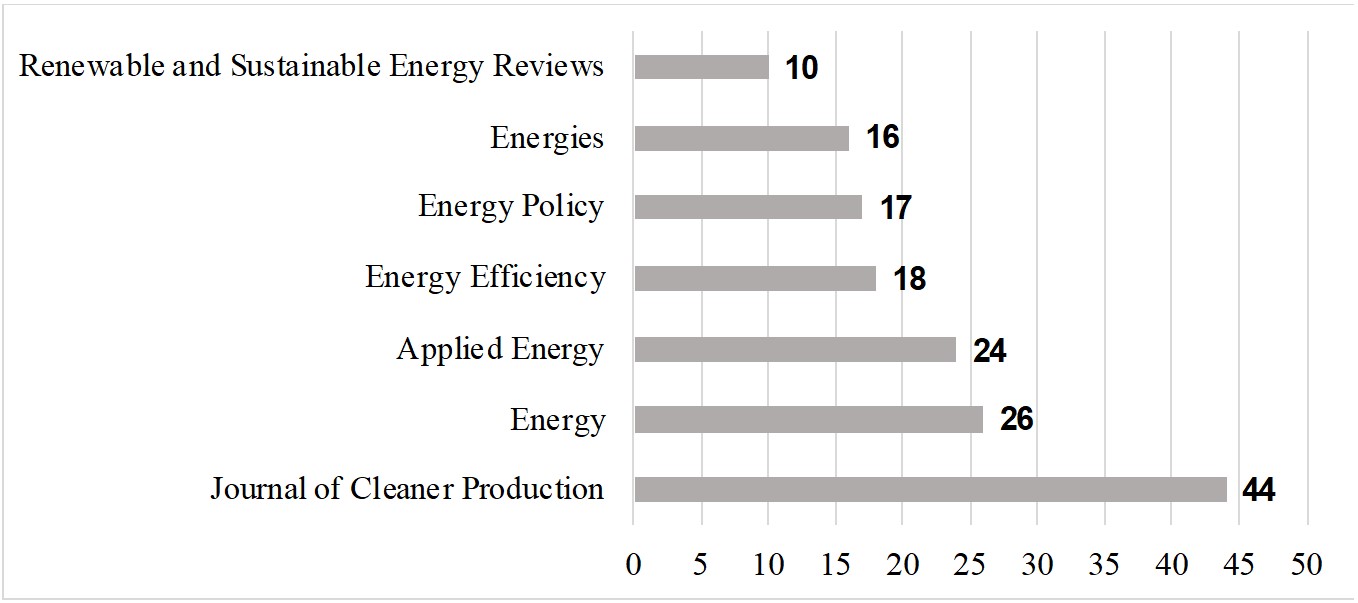

Of the 245 selected studies, seven journals concentrate 155 publications, which is equivalent to 63% of publications. The other 90 publications are distributed among other 73 journals. That is, a restricted quantity of journals concentrates most of the publications in the area. Figure 3 presents the quantity of publications per journal, highlighting the most relevant ones.

A detailed analysis of the data presented in Table 3 shows that, between 2013 and 2021, the journals “Journal of Cleaner Production (JCL) IF-JCR 9.297, Applied Energy (AEN) IF-JCR 9.746 and Energy (ENY) IF-JCR 7.147 published 82 studies. The volume of publications increased in three journals. The remaining publications have been distributed in the journals Energy Policy (EPL) IF-JCR 6.142, Energy Efficiency (EFF) IF-JCR 2.574, Renewable and Sustainable Energy Reviews (RNW) IF-JCR 14.98 and Energies (ENS) IF-JCR 3.004. This allows us to infer that the evolution of the publications was mainly concentrated in 3 journals.

3.2. Social Network Analysis (SNA)

Social Network Analysis (SNA) emphasizes network actors and their relationships by mapping the connections established in each community (Piovezan & Fujita, 2015Piovezan, L. B., & Fujita, M. S. L. (2015). Análise de cocitação de autores: uma aplicação em estudos de indexação. Em Questão, 21(1), 110-129.). The parameters for SNA are as follows:

-

a

density: it is an indicator for the general level of connectivity of the graph, and it is defined as the ratio between the number of connections and the number of vertices in a complete graph with the same number of nodes (Otte & Rousseau, 2002Otte, E., & Rousseau, R. (2002). Social network analysis: a powerful strategy, also for the information sciences. Journal of Information Science, 28(6), 441-453.);

-

b

centrality of degree: in a co-authoring graph, the degree of centrality of an actor is the number of authors in the graph with collaboration in at least one article (Otte & Rousseau, 2002Otte, E., & Rousseau, R. (2002). Social network analysis: a powerful strategy, also for the information sciences. Journal of Information Science, 28(6), 441-453.);

-

c

distance: it is also an indicator of centrality, but with a more general characteristic than the previous one. The proximity of a node is equal to the total distance of this node to the other nodes in the graph (Otte & Rousseau, 2002Otte, E., & Rousseau, R. (2002). Social network analysis: a powerful strategy, also for the information sciences. Journal of Information Science, 28(6), 441-453.).

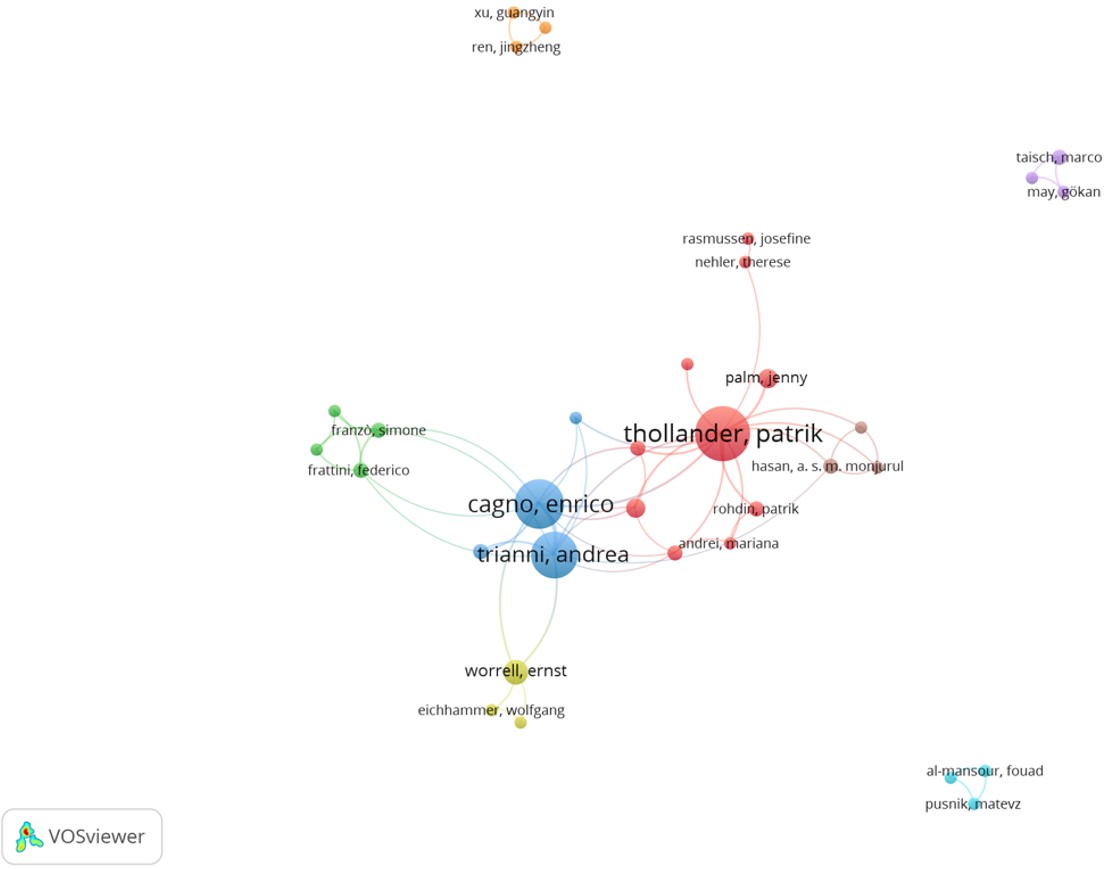

A total of 664 authors were involved in the 245 studies. The coauthoring analysis allows establishing if there is a relation or proximity to the authors. From VOSviewerÒ software, was considered as a parameter for coauthoring analysis authors who published at least two documents, as well as each cluster with least three authors. In all, eight clusters were found, formed by 33 authors, according to Table 4.

The clusters 1 and 3 are representative of the three authors (Cagno, Trianni, and Thollander). Studies were carried out mainly in Italy and Sweden. Figure 4 allows for a complementary analysis of the co-authorship network, as it represents density (size of circles), centrality (position of circles) and proximity (distance between circles).

In addition to the coauthoring analysis, the term network is another element of SNA that allows the visualization of connections between the main terms used in the studies, complementing the characteristics of density, centrality and proximity used in the coauthoring analysis, with the addition of a temporal factor. Figure 5 shows the temporal evolution of each term using the blue color for the most used terms, going through the colors of the Kelvin scale, until reaching the terms most recently used, which are represented by red. For the joint elaboration of terms, a minimum incidence of 5 was considered.

Even though the term “energy efficiency” is in the Cluster B, all the clusters interconnect with this term, what was expected since it is the main term of the work. Cluster A, together with Cluster B, are the ones with the highest number of terms, eight and six, respectively. A is focused on the management and industrial terms, formed by “barriers”, “decision-making”, “drivers”, “energy efficiency measures”, “energy management practices”, “industrial energy efficiency”, “non-energy benefits”, “small and medium-sized enterprises” (SME). B, in the other hand, have its terms linked to the energy and efficiency area, those are “data envelopment analysis”, “efficiency”, “energy”, “energy efficiency”, “renewable energy”, “sustainable energy”. Regarding time distribution, there is a recent network of studies formed by the terms “energy efficiency measures”, “decision-making”, “renewable energy” and “iso 50001”, which may indicate a new field of research, still at an early stage. There is therefore room for further research and consolidation of concepts. Another important point is that after 2018 there are no new terms added.

Based on descriptive analysis, it is possible to observe research trends (Figure 5), central authors (Figure 4), and the main research lines (Table 4) regarding the decision-making process for adopting measures of energy efficiency in production systems. The next section deepens the analysis to achieve the research objective.

3.3. Content analysis

In order to carry out the content analysis (Bardin, 2015Bardin, L. (2015). Análise de conteúdo. São Paulo: Edições 70.; Mozzato & Grzybovski, 2011Mozzato, A. R., & Grzybovski, D. (2011). Análise de conteúdo como técnica de análise de dados qualitativos no campo da administração: potencial e desafios. Revista de Administração Contemporânea, 15(4), 731-747.) of the 69 studies included, the main concepts used in the studies related to energy efficiency in industrial environments were initially identified inductively. The analysis sequence was built from a set of codes elaborated and grouped into families, as shown in Table 5. During the content analysis, the studies were initially classified according to such categories to assist in the evaluation of the works and to identify gaps in the literature.

Most empirical studies are related exclusively to indicators (Table 6), totaling twelve publications, followed by strategy with eight and practices with seven. Two empirical studies contemplated more than one theme, strategy and practice.

Among the theoretical studies (Finnerty et al., 2017Finnerty, N., Sterling, R., Coakley, D., Contreras, S., Coffey, R., & Keane, M. M. (2017). Development of a Global Energy Management System for non-energy intensive multi-site industrial organisations: a methodology. Energy, 136, 16-31. http://dx.doi.org/10.1016/j.energy.2016.10.049.

http://dx.doi.org/10.1016/j.energy.2016....

; Palm & Thollander, 2010Palm, J., & Thollander, P. (2010). An interdisciplinary perspective on industrial energy efficiency. Applied Energy, 87(10), 3255-3261.; Thollander & Palm, 2015Thollander, P., & Palm, J. (2015). Industrial energy management decision making for improved energy efficiency: strategic system perspectives and situated action in combination. Energies, 8(6), 5694-5703.; Bhanot et al., 2017Bhanot, N., Rao, P. V., & Deshmukh, S. G. (2017). An integrated approach for analysing the enablers and barriers of sustainable manufacturing. Journal of Cleaner Production, 142(4), 4412-4439. http://dx.doi.org/10.1016/j.jclepro.2016.11.123.

http://dx.doi.org/10.1016/j.jclepro.2016...

; Cooremans, 2011Cooremans, C. (2011). Make it strategic! Financial investment logic is not enough. Energy Efficiency, 4(4), 473-492., 2012Cooremans, C. (2012). Investment in energy efficiency: Do the characteristics of investments matter? Energy Efficiency, 5(4), 497-518.; Henriques & Catarino, 2016Henriques, J., & Catarino, J. (2016). Motivating towards energy efficiency in small and medium enterprises. Journal of Cleaner Production, 139, 42-50.; Reddy, 2013Reddy, B. S. (2013). Barriers and drivers to energy efficiency: a new taxonomical approach. Energy Conversion and Management, 74, 403-416.; Trianni et al., 2017Trianni, A., Cagno, E., & Neri, A. (2017). Modelling barriers to the adoption of industrial sustainability measures. Journal of Cleaner Production, 168, 1482-1504. http://dx.doi.org/10.1016/j.jclepro.2017.07.244.

http://dx.doi.org/10.1016/j.jclepro.2017...

; Cagno et al., 2018Cagno, E., Neri, A., & Trianni, A. (2018). Broadening to sustainability the perspective of industrial decision-makers on the energy efficiency measures adoption: some empirical evidence. Energy Efficiency, 11, 1193-1210. http://dx.doi.org/10.1007/s12053-018-9621-0.

http://dx.doi.org/10.1007/s12053-018-962...

; Neri et al., 2018Neri, A., Cagno, E., di Sebastiano, G., & Trianni, A. (2018). Industrial sustainability: modelling drivers and mechanisms with barriers. Journal of Cleaner Production, 194, 452-472. http://dx.doi.org/10.1016/j.jclepro.2018.05.140.

http://dx.doi.org/10.1016/j.jclepro.2018...

; Rotzek et al., 2018Rotzek, J. N., Scope, C., & Günther, E. (2018). What energy management practice can learn from research on energy culture? Sustainability accounting. Management and Policy Journal, 9(4), 515-551. http://dx.doi.org/10.1108/SAMPJ-07-2017-0067.

http://dx.doi.org/10.1108/SAMPJ-07-2017-...

; Mawson & Hughes, 2019Mawson, V. J., & Hughes, B. R. (2019). The development of modelling tools to improve energy efficiency in manufacturing processes and systems. Journal of Manufacturing Systems, 51, 95-105. http://dx.doi.org/10.1016/j.jmsy.2019.04.008.

http://dx.doi.org/10.1016/j.jmsy.2019.04...

; Çoban et al., 2020Çoban, V., Onar, E., Oztaysi, B., & Kahraman, C. (2020). Energy management maturity model based on fuzzy probabilistic linguistic term sets. Journal of Multiple-Valued Logic & Soft Computing, 35(1-2), 217-237.; Simeonovski et al., 2021Simeonovski, K., Kaftandzieva, T., & Brock, G. (2021). Energy efficiency management across EU countries: a DEA approach. Energies, 4(9), 2619. http://dx.doi.org/10.3390/en14092619.

http://dx.doi.org/10.3390/en14092619...

), there are publications focusing on strategic character. The topic indicators are treated theoretically in twelve publications, practices are the object of theoretical study in eight publications. Two theoretical studies approach strategy, indicators and practices at the same time one mention strategies and indicators, two strategies and practices and four approach indicators and practices, all this information can be seen in Table 6.

3.3.1. Strategy studies

Energy is generally not an issue when relevant decisions are made about it (Cooremans, 2011Cooremans, C. (2011). Make it strategic! Financial investment logic is not enough. Energy Efficiency, 4(4), 473-492.). Decision makers are generally unwilling to invest in energy efficiency, even if the investment is profitable, due to the lack of connection to the core business. This means that there is a tendency to concentrate efforts on what is strategic for the company, that is, on known domains, and consider investment in energy efficiency as something secondary (Cooremans, 2011Cooremans, C. (2011). Make it strategic! Financial investment logic is not enough. Energy Efficiency, 4(4), 473-492.).

However, the study by Cooremans (2011)Cooremans, C. (2011). Make it strategic! Financial investment logic is not enough. Energy Efficiency, 4(4), 473-492. questions the attitude of neglecting energy efficiency initiatives by stating that an investment can be considered strategic if it contributes to creating, maintaining or developing a sustainable competitive advantage. Thus, if initiatives to increase the company's energy efficiency contribute to expanding an organization's competitive advantage, they are strategic and, therefore, must be considered by decision makers.

From the study by Cooremans (2011)Cooremans, C. (2011). Make it strategic! Financial investment logic is not enough. Energy Efficiency, 4(4), 473-492., other theoretical studies have come to consider the strategic nature of investments in energy efficiency (Finnerty et al., 2017Finnerty, N., Sterling, R., Coakley, D., Contreras, S., Coffey, R., & Keane, M. M. (2017). Development of a Global Energy Management System for non-energy intensive multi-site industrial organisations: a methodology. Energy, 136, 16-31. http://dx.doi.org/10.1016/j.energy.2016.10.049.

http://dx.doi.org/10.1016/j.energy.2016....

; Cooremans, 2012Cooremans, C. (2012). Investment in energy efficiency: Do the characteristics of investments matter? Energy Efficiency, 5(4), 497-518.; May et al., 2017May, G., Stahl, B., Taisch, M., & Kiritsis, D. (2017). Energy management in manufacturing: from literature review to a conceptual framework. Journal of Cleaner Production, 167, 1464-1489. http://dx.doi.org/10.1016/j.jclepro.2016.10.191.

http://dx.doi.org/10.1016/j.jclepro.2016...

; Thollander & Palm, 2015Thollander, P., & Palm, J. (2015). Industrial energy management decision making for improved energy efficiency: strategic system perspectives and situated action in combination. Energies, 8(6), 5694-5703.; Bhanot et al., 2017Bhanot, N., Rao, P. V., & Deshmukh, S. G. (2017). An integrated approach for analysing the enablers and barriers of sustainable manufacturing. Journal of Cleaner Production, 142(4), 4412-4439. http://dx.doi.org/10.1016/j.jclepro.2016.11.123.

http://dx.doi.org/10.1016/j.jclepro.2016...

; Henriques & Catarino, 2016Henriques, J., & Catarino, J. (2016). Motivating towards energy efficiency in small and medium enterprises. Journal of Cleaner Production, 139, 42-50.; Reddy, 2013Reddy, B. S. (2013). Barriers and drivers to energy efficiency: a new taxonomical approach. Energy Conversion and Management, 74, 403-416.; König, 2020König, W. (2020). Energy efficiency in industrial organizations: a cultural-institutional framework of decision making. Energy Research & Social Science, 60, 101314. http://dx.doi.org/10.1016/j.erss.2019.101314.

http://dx.doi.org/10.1016/j.erss.2019.10...

), but without delving into the subject. An advance was made by Cooremans (2012)Cooremans, C. (2012). Investment in energy efficiency: Do the characteristics of investments matter? Energy Efficiency, 5(4), 497-518., which stated that in order to measure the strategic character of an investment, it is necessary to measure its contribution to competitive advantage in each dimension: value, costs, and risk (Cooremans, 2012Cooremans, C. (2012). Investment in energy efficiency: Do the characteristics of investments matter? Energy Efficiency, 5(4), 497-518.). The more an investment decision contributes to competitive advantage, the more strategic it is (Cooremans, 2011Cooremans, C. (2011). Make it strategic! Financial investment logic is not enough. Energy Efficiency, 4(4), 473-492.). In this sense, the way an organization strategically works the energy issue, as well as the procedures chosen for it, is the core elements of the concept of energy management (Thollander & Palm, 2015Thollander, P., & Palm, J. (2015). Industrial energy management decision making for improved energy efficiency: strategic system perspectives and situated action in combination. Energies, 8(6), 5694-5703.).

Two recent studies (Bhanot et al., 2017Bhanot, N., Rao, P. V., & Deshmukh, S. G. (2017). An integrated approach for analysing the enablers and barriers of sustainable manufacturing. Journal of Cleaner Production, 142(4), 4412-4439. http://dx.doi.org/10.1016/j.jclepro.2016.11.123.

http://dx.doi.org/10.1016/j.jclepro.2016...

; Trianni et al., 2017Trianni, A., Cagno, E., & Neri, A. (2017). Modelling barriers to the adoption of industrial sustainability measures. Journal of Cleaner Production, 168, 1482-1504. http://dx.doi.org/10.1016/j.jclepro.2017.07.244.

http://dx.doi.org/10.1016/j.jclepro.2017...

), presented aspects about the lack of metrics to evaluate energy efficiency projects, as well as the absence of models that allow a systemic understanding of internal and external factors to be considered in the strategic evaluation of investments in energy efficiency.

The scarcity of metrics was addressed by two empirical studies (Aplak & Sogut, 2013Aplak, H. S., & Sogut, M. Z. (2013). Game theory approach in decisional process of energy management for industrial sector. Energy Conversion and Management, 74, 70-80.; Alcorta et al., 2014Alcorta, L., Bazilian, M., De Simone, G., & Pedersen, A. (2014). Return on investment from industrial energy efficiency: evidence from developing countries. Energy Efficiency, 7(1), 43-53.), but only considered financial indicators as part of the evaluation in decision-making. The study of Paramonova & Thollander (2016)Paramonova, S., & Thollander, P. (2016). Energy-efficiency networks for SMEs: learning from the Swedish experience. Renewable & Sustainable Energy Reviews, 65, 295-307. advanced in the theme as it presented the learning of SMEs in the Swedish industry. The relevance of Sweden in the field of energy efficiency research for non-intensive energy companies was highlighted in the co-authoring analysis, as shown in Table 3.

3.3.2. Indicator studies

There is no consensus on the energy efficiency indicator that can be widely applied. Appropriate indicators should be defined according to the decision to be made or the decision tool to be applied (Bunse et al., 2011Bunse, K., Vodicka, M., Schönsleben, P., Brülhart, M., & Ernst, F. O. (2011). Integrating energy efficiency performance in production management: gap analysis between industrial needs and scientific literature. Journal of Cleaner Production, 19(6-7), 667-679.). The study by Bunse et al. (2011)Bunse, K., Vodicka, M., Schönsleben, P., Brülhart, M., & Ernst, F. O. (2011). Integrating energy efficiency performance in production management: gap analysis between industrial needs and scientific literature. Journal of Cleaner Production, 19(6-7), 667-679. provided an overview of different energy efficiency indicators. Although studies have been conducted on energy efficiency indicators at a national or sector level, there are a limited number of studies in companies, plants, or production processes (Bunse et al., 2011Bunse, K., Vodicka, M., Schönsleben, P., Brülhart, M., & Ernst, F. O. (2011). Integrating energy efficiency performance in production management: gap analysis between industrial needs and scientific literature. Journal of Cleaner Production, 19(6-7), 667-679.).

Most theoretical studies (Olanrewaju & Jimoh, 2014Olanrewaju, O. A., & Jimoh, A. A. (2014). Review of energy models to the development of an efficient industrial energy model. Renewable & Sustainable Energy Reviews, 30, 661-671.; Perroni et al., 2016Perroni, M. G., Gouvea, S. E. C., Pinheiro, E. de L., & Silva, W. V. (2016). The relationship between enterprize efficiency in resource use and energy efficiency practices adoption. International Journal of Production Economics, 190, 108-119.; Pusnik et al., 2016Pusnik, M., Al-Mansour, F., Sucic, B., & Gubina, A. F. (2016). Gap analysis of industrial energy management systems in Slovenia. Energy, 108, 41-49.; Nehler & Rasmussen, 2016Nehler, T., & Rasmussen, J. (2016). How do firms consider non-energy benefits? Empirical findings on energy-efficiency investments in Swedish industry. Journal of Cleaner Production, 113, 472-482.; May et al., 2015May, G., Barletta, I., Stahl, B., & Taisch, M. (2015). Energy management in production: a novel method to develop key performance indicators for improving energy efficiency. Applied Energy, 149, 46-61.; Horschig & Thrän, 2017Horschig, T., & Thrän, D. (2017). Are decisions well supported for the energy transition? A review on modeling approaches for renewable energy policy evaluation. Energy, Sustainability and Society, 7(1), 5.; Rasmussen, 2017Rasmussen, J. (2017). The additional benefits of energy efficiency investments: a systematic literature review and a framework for categorisation. Energy Efficiency, 10(6), 1401-1418. http://dx.doi.org/10.1007/s12053-017-9528-1.

http://dx.doi.org/10.1007/s12053-017-952...

; Trianni et al., 2014Trianni, A., Cagno, E., & De Donatis, A. (2014). A framework to characterize energy efficiency measures. Applied Energy, 118, 207-220.) present conceptual proposals for integrating indicators with energy management systems. These integration proposals aim to evaluate energy efficiency by considering physical, thermodynamic, and economic characteristics. However, the indicator Energy Intensity stands out when it comes to energy efficiency mainly in broad assessments to measure the competitiveness of industry in different countries (Bunse et al., 2011Bunse, K., Vodicka, M., Schönsleben, P., Brülhart, M., & Ernst, F. O. (2011). Integrating energy efficiency performance in production management: gap analysis between industrial needs and scientific literature. Journal of Cleaner Production, 19(6-7), 667-679.).

The other studies address the theme of indicators and measurements of performance in energy efficiency as complementary elements for the development of models to assist in the evaluation and the decision-making using different approaches, such as linear programming (Karlsson, 2011Karlsson, M. (2011). The MIND method: a decision support for optimization of industrial energy systems: principles and case studies. Applied Energy, 88(3), 577-589.), dynamics modeling systems (Adane et al., 2014Adane, T. F., Nafisi, M., Asif, F. M. A., Semere, D. T., & Nicolescu, M. (2014). System dynamics analysis of energy usage: case studies in automotive manufacturing. International Journal of Manufacturing Research, 9(2), 131-156.), multicriteria decision (Boehner, 2015Boehner, J. (2015). Multi criteria decision making enhancing sustainable energy management. Applied Mechanics and Materials, 805, 32-37. http://dx.doi.org/10.4028/www.scientific.net/AMM.805.32.

http://dx.doi.org/10.4028/www.scientific...

; Li et al., 2020Li, T., Li, A., & Guo, X. (2020). The sustainable development-oriented development and utilization of renewable energy industry: a comprehensive analysis of MCDM methods. Energy, 212, 118694. http://dx.doi.org/10.1016/j.energy.2020.118694.

http://dx.doi.org/10.1016/j.energy.2020....

), DEA (Kim et al., 2015Kim, K. T., Lee, D. J., Park, S. J., Zhang, Y., & Sultanov, A. (2015). Measuring the efficiency of the investment for renewable energy in Korea using data envelopment analysis. Renewable & Sustainable Energy Reviews, 47, 694-702.; Simeonovski et al., 2021Simeonovski, K., Kaftandzieva, T., & Brock, G. (2021). Energy efficiency management across EU countries: a DEA approach. Energies, 4(9), 2619. http://dx.doi.org/10.3390/en14092619.

http://dx.doi.org/10.3390/en14092619...

), computational simulation (Cassettari et al., 2017Cassettari, L., Bendato, I., Mosca, M., & Mosca, R. (2017). Energy Resources Intelligent Management using online real-time simulation: a decision support tool for sustainable manufacturing. Applied Energy, 190, 841-851.; Ionescu & Darie, 2020Ionescu, C. V., & Darie, G. 2020. Energy Effectiveness-New Energy Performance Indicator to optimize the Industrial Energy Consumptions. In EPE 2020 - Proceedings of the 2020 11th International Conference and Exposition on Electrical And Power Engineering (pp. 462-465). Piscataway: Institute of Electrical and Electronics Engineers Inc. https://doi.org/10.1109/EPE50722.2020.9305663.

https://doi.org/10.1109/EPE50722.2020.93...

), mathematical model (Sarkar et al., 2019Sarkar, M., Kim, S., Jemai, J., Ganguly, B., & Sarkar, B. (2019). An application of time-dependent holding costs and system reliability in a multi-item sustainable economic energy efficient reliable manufacturing system. Energies, 12(15), 2857. http://dx.doi.org/10.3390/en12152857.

http://dx.doi.org/10.3390/en12152857...

) and fuzzy logic (Dong & Huo, 2017Dong, J., & Huo, H. (2017). Identification of financing barriers to energy efficiency in small and medium-sized enterprises by integrating the fuzzy delphi and fuzzy DEMATEL approaches. Energies, 10(8), 1172.; Çoban et al., 2020Çoban, V., Onar, E., Oztaysi, B., & Kahraman, C. (2020). Energy management maturity model based on fuzzy probabilistic linguistic term sets. Journal of Multiple-Valued Logic & Soft Computing, 35(1-2), 217-237.).

3.3.3. Practices studies

Five of the total studies only approach non-electro intensive industries (Zeng et al., 2015Zeng, M., Wang, G., Wang, H., Gao, Y., Guo, L., Zhang, J., & Zhang, H. (2015). Industrial system energy efficiency assessment using system dynamics. In Proceedings of the 2015 3rd International Conference on Machinery, Materials and Information Technology Applications (Vol. 35, pp. 1299-1302). Dordrecht: Atlantis Press.; Zhu et al., 2017Zhu, S., Jiang, Z., Zhang, H., Tian, G., & Wang, Y. (2017). A carbon efficiency evaluation method for manufacturing process chain decision-making. Journal of Cleaner Production, 148, 665-680.; Lopes et al., 2018Lopes, J. R., Ávila, S., Kalid, R., & Rodríguez, J. L. M. (2018). Energy efficiency improvement in non-intensive energy enterprises: a framework proposal. Energies, 11(5), 1271. http://dx.doi.org/10.3390/en11051271.

http://dx.doi.org/10.3390/en11051271...

; Hasan et al., 2019Hasan, A. S. M. M., Hossain, R., Tuhin, R. A., Sakib, T. H., & Thollander, P. (2019). Empirical investigation of barriers and driving forces for efficient energy management practices in non-energy-intensive manufacturing industries of Bangladesh. Sustainability, 11(9), 2671. http://dx.doi.org/10.3390/su11092671.

http://dx.doi.org/10.3390/su11092671...

; Martins et al., 2019Martins, J. C., Morandi, M. I. W. M., & Lacerda, D. P. (2019). Estimating the long-term financial impact of solar microgeneration and energy efficiency for a brazilian medium-sized enterprise. IEEE Latin America Transactions, 17(10), 1607-1615. http://dx.doi.org/10.1109/TLA.2019.8986438.

http://dx.doi.org/10.1109/TLA.2019.89864...

, 2020Martins, J. C., Lacerda, D. P., Wolf Motta Morandi, M. I., Goldmeyer, D., & Piran, F. S. (2020). Systems dynamic modeling to analyze the systemic viability of the combined use of regenerative converters and energy storage in a UPS manufacturer. Journal of Cleaner Production, 246, 118950. http://dx.doi.org/10.1016/j.jclepro.2019.118950.

http://dx.doi.org/10.1016/j.jclepro.2019...

). Two empirical studies stand out for evaluating the minimum requirements proposed by (Schulze et al., 2016Schulze, M., Nehler, H., Ottosson, M., & Thollander, P. (2016). Energy management in industry: a systematic review of previous findings and an integrative conceptual framework. Journal of Cleaner Production, 112, 3692-3708.) in real environments. The first (Zeng et al., 2015Zeng, M., Wang, G., Wang, H., Gao, Y., Guo, L., Zhang, J., & Zhang, H. (2015). Industrial system energy efficiency assessment using system dynamics. In Proceedings of the 2015 3rd International Conference on Machinery, Materials and Information Technology Applications (Vol. 35, pp. 1299-1302). Dordrecht: Atlantis Press.) used system dynamics modeling (SDM) to regularly measure and monitor the energy consumption of the main production processes, and the second (Fresner et al., 2017Fresner, J., Morea, F., Krenn, C., Aranda Uson, J., & Tomasi, F. (2017). Energy efficiency in small and medium enterprises: lessons learned from 280 energy audits across Europe. Journal of Cleaner Production, 142, 1650-1660.) evaluated the initial energy audit to identify potential energy savings in 280 SMEs in Europe. Although energy audits are one of the most widely used and widespread tools to overcome barriers to energy efficiency, comprehensive and effective tools are still needed to conduct an effective energy auditing (Fresner et al., 2017Fresner, J., Morea, F., Krenn, C., Aranda Uson, J., & Tomasi, F. (2017). Energy efficiency in small and medium enterprises: lessons learned from 280 energy audits across Europe. Journal of Cleaner Production, 142, 1650-1660.).

The practices most found in the studies analyzed are related to what is defined as the energy management system (EnMS) (Antunes et al., 2014Antunes, P., Carreira, P., & Silva, M. M. (2014). Towards an energy management maturity model. Energy Policy, 73, 803-814. http://dx.doi.org/10.1016/j.enpol.2014.06.011.

http://dx.doi.org/10.1016/j.enpol.2014.0...

). The EnMS is a set of interrelated elements used to establish an energy policy and energy goals, as well as processes and practices to achieve such goals (Schulze et al., 2016Schulze, M., Nehler, H., Ottosson, M., & Thollander, P. (2016). Energy management in industry: a systematic review of previous findings and an integrative conceptual framework. Journal of Cleaner Production, 112, 3692-3708.). Thus, the selected theoretical studies that address the elements and characteristics of EnMS in industrial environments constitute the majority among the energy efficiency practices (Finnerty et al., 2017Finnerty, N., Sterling, R., Coakley, D., Contreras, S., Coffey, R., & Keane, M. M. (2017). Development of a Global Energy Management System for non-energy intensive multi-site industrial organisations: a methodology. Energy, 136, 16-31. http://dx.doi.org/10.1016/j.energy.2016.10.049.

http://dx.doi.org/10.1016/j.energy.2016....

; Bunse et al., 2011Bunse, K., Vodicka, M., Schönsleben, P., Brülhart, M., & Ernst, F. O. (2011). Integrating energy efficiency performance in production management: gap analysis between industrial needs and scientific literature. Journal of Cleaner Production, 19(6-7), 667-679.; Schulze et al., 2016Schulze, M., Nehler, H., Ottosson, M., & Thollander, P. (2016). Energy management in industry: a systematic review of previous findings and an integrative conceptual framework. Journal of Cleaner Production, 112, 3692-3708.; May et al., 2017May, G., Stahl, B., Taisch, M., & Kiritsis, D. (2017). Energy management in manufacturing: from literature review to a conceptual framework. Journal of Cleaner Production, 167, 1464-1489. http://dx.doi.org/10.1016/j.jclepro.2016.10.191.

http://dx.doi.org/10.1016/j.jclepro.2016...

; Bhanot et al., 2017Bhanot, N., Rao, P. V., & Deshmukh, S. G. (2017). An integrated approach for analysing the enablers and barriers of sustainable manufacturing. Journal of Cleaner Production, 142(4), 4412-4439. http://dx.doi.org/10.1016/j.jclepro.2016.11.123.

http://dx.doi.org/10.1016/j.jclepro.2016...

; Antunes et al., 2014Antunes, P., Carreira, P., & Silva, M. M. (2014). Towards an energy management maturity model. Energy Policy, 73, 803-814. http://dx.doi.org/10.1016/j.enpol.2014.06.011.

http://dx.doi.org/10.1016/j.enpol.2014.0...

; Palm & Thollander, 2019Palm, J., & Thollander, P. 2019. Reframing energy efficiency in industry: a discussion of definitions, rationales, and management practices. In M. Lopes, C. H. Antunes & K. B. Janda (Eds.), Energy and behaviour: towards a low carbon future (pp. 153-175). London: Elsevier. https://doi.org/10.1016/B978-0-12-818567-4.00007-7.

https://doi.org/10.1016/B978-0-12-818567...

; Schützenhofer, 2021Schützenhofer, C. (2021). Overcoming the efficiency gap: energy management as a means for overcoming barriers to energy efficiency, empirical support in the case of Austrian large firms. Energy Efficiency, 14, 45. http://dx.doi.org/10.1007/s12053-021-09954-z.

http://dx.doi.org/10.1007/s12053-021-099...

).

3.3.4. Artifacts, limitations, and gaps

Among the artifacts identified in the RSL, PB (Payback), NPV (Net Present Value) and IRR (Internal Rate of Return) are those that represent most of the applications, totaling 31 incidences. This means that these 3 investment analysis tools are the most widely used to assess the feasibility of adopting energy efficiency initiatives in industrial settings. However, as highlighted in the literature, the approaches using PB, NPV and IRR have important limitations, causing initiatives not to be adopted even when these methods present attractive results. Among the limitations of financial techniques, there is the absence of non-economic factors or non-financial benefits. A summary of these limitations is presented in Table 7.

The limitations found by financial techniques include the absence of non-economic factors, also called non-financial benefits. Given the fact that financial characteristics alone are not sufficient to drive the choice of an energy efficient technology, the absence of non-financial factors implies an even greater misalignment of these approaches. In this sense, other studies have begun to evaluate the use of non-financial tools to complement financial tools.

In artifacts that have non-financial characteristics present techniques related to multi-criteria decision methods (MCDM) consumption (Olanrewaju & Jimoh, 2014Olanrewaju, O. A., & Jimoh, A. A. (2014). Review of energy models to the development of an efficient industrial energy model. Renewable & Sustainable Energy Reviews, 30, 661-671.; Finnerty et al., 2017Finnerty, N., Sterling, R., Coakley, D., Contreras, S., Coffey, R., & Keane, M. M. (2017). Development of a Global Energy Management System for non-energy intensive multi-site industrial organisations: a methodology. Energy, 136, 16-31. http://dx.doi.org/10.1016/j.energy.2016.10.049.

http://dx.doi.org/10.1016/j.energy.2016....

; Boehner, 2015Boehner, J. (2015). Multi criteria decision making enhancing sustainable energy management. Applied Mechanics and Materials, 805, 32-37. http://dx.doi.org/10.4028/www.scientific.net/AMM.805.32.

http://dx.doi.org/10.4028/www.scientific...

; Dong & Huo, 2017Dong, J., & Huo, H. (2017). Identification of financing barriers to energy efficiency in small and medium-sized enterprises by integrating the fuzzy delphi and fuzzy DEMATEL approaches. Energies, 10(8), 1172.; Aplak & Sogut, 2013Aplak, H. S., & Sogut, M. Z. (2013). Game theory approach in decisional process of energy management for industrial sector. Energy Conversion and Management, 74, 70-80.; Bhanot et al., 2017Bhanot, N., Rao, P. V., & Deshmukh, S. G. (2017). An integrated approach for analysing the enablers and barriers of sustainable manufacturing. Journal of Cleaner Production, 142(4), 4412-4439. http://dx.doi.org/10.1016/j.jclepro.2016.11.123.

http://dx.doi.org/10.1016/j.jclepro.2016...

; Horschig & Thrän, 2017Horschig, T., & Thrän, D. (2017). Are decisions well supported for the energy transition? A review on modeling approaches for renewable energy policy evaluation. Energy, Sustainability and Society, 7(1), 5.; Li et al., 2020Li, T., Li, A., & Guo, X. (2020). The sustainable development-oriented development and utilization of renewable energy industry: a comprehensive analysis of MCDM methods. Energy, 212, 118694. http://dx.doi.org/10.1016/j.energy.2020.118694.

http://dx.doi.org/10.1016/j.energy.2020....

), such as the analytic hierarchy process (AHP) (Lyubchenko et al., 2020Lyubchenko, V. Y., Iskhakov, A. F., & Pavlyuchenko, D. A. (2020). Rating of organization’s energy efficiency based on Harrington’s desirability function. In 2020 International Multi-Conference on Industrial Engineering and Modern Technologies, FarEastCon 2020. Piscataway: Institute of Electrical and Electronics Engineers Inc. https://doi.org/10.1109/FarEastCon50210.2020.9271239.

https://doi.org/10.1109/FarEastCon50210....

; Li et al., 2020Li, T., Li, A., & Guo, X. (2020). The sustainable development-oriented development and utilization of renewable energy industry: a comprehensive analysis of MCDM methods. Energy, 212, 118694. http://dx.doi.org/10.1016/j.energy.2020.118694.

http://dx.doi.org/10.1016/j.energy.2020....

) and fuzzy logic (Ho & Ma, 2018Ho, W., & Ma, X. (2018). The state-of-the-art integrations and applications of the analytic hierarchy process. European Journal of Operational Research, 267(2), 399-414. http://dx.doi.org/10.1016/j.ejor.2017.09.007.

http://dx.doi.org/10.1016/j.ejor.2017.09...

; Çoban et al., 2020Çoban, V., Onar, E., Oztaysi, B., & Kahraman, C. (2020). Energy management maturity model based on fuzzy probabilistic linguistic term sets. Journal of Multiple-Valued Logic & Soft Computing, 35(1-2), 217-237.; Li et al., 2020Li, T., Li, A., & Guo, X. (2020). The sustainable development-oriented development and utilization of renewable energy industry: a comprehensive analysis of MCDM methods. Energy, 212, 118694. http://dx.doi.org/10.1016/j.energy.2020.118694.

http://dx.doi.org/10.1016/j.energy.2020....

) were found in the SLR. The study of Aplak & Sogut (2013)Aplak, H. S., & Sogut, M. Z. (2013). Game theory approach in decisional process of energy management for industrial sector. Energy Conversion and Management, 74, 70-80., proposed an approach combining elements of AHP, Fuzzy and Game Theory to deploy industrial strategies and prioritize the choices related to energy management. Despite being comprehensive, this approach presents a linear process, without considering the possible interrelationships between internal and external variables. Other studies have used techniques such as Monte Carlo (Cassettari et al., 2017Cassettari, L., Bendato, I., Mosca, M., & Mosca, R. (2017). Energy Resources Intelligent Management using online real-time simulation: a decision support tool for sustainable manufacturing. Applied Energy, 190, 841-851.; Knobloch & Mercure, 2016Knobloch, F., & Mercure, J. F. (2016). The behavioural aspect of green technology investments: a general positive model in the context of heterogeneous agents. Environmental Innovation and Societal Transitions, 21, 39-55.), simulation of discrete events (Cassettari et al., 2017Cassettari, L., Bendato, I., Mosca, M., & Mosca, R. (2017). Energy Resources Intelligent Management using online real-time simulation: a decision support tool for sustainable manufacturing. Applied Energy, 190, 841-851.; Sáenz et al., 2012Sáenz, J. P., Celik, N., Asfour, S., & Son, Y. J. (2012). Electric utility resource planning using Continuous-Discrete Modular Simulation and Optimization (CoDiMoSO). Computers & Industrial Engineering, 63(3), 671-694.; Horschig & Thrän, 2017Horschig, T., & Thrän, D. (2017). Are decisions well supported for the energy transition? A review on modeling approaches for renewable energy policy evaluation. Energy, Sustainability and Society, 7(1), 5.), optimization (Karlsson, 2011Karlsson, M. (2011). The MIND method: a decision support for optimization of industrial energy systems: principles and case studies. Applied Energy, 88(3), 577-589.; Sáenz et al., 2012Sáenz, J. P., Celik, N., Asfour, S., & Son, Y. J. (2012). Electric utility resource planning using Continuous-Discrete Modular Simulation and Optimization (CoDiMoSO). Computers & Industrial Engineering, 63(3), 671-694.; Hasan & Trianni, 2020Hasan, A. S. M. M., & Trianni, A. (2020). A review of energy management assessment models for industrial energy efficiency. Energies, 13(21), 5713. http://dx.doi.org/10.3390/en13215713.

http://dx.doi.org/10.3390/en13215713...

; Sarkar et al., 2019Sarkar, M., Kim, S., Jemai, J., Ganguly, B., & Sarkar, B. (2019). An application of time-dependent holding costs and system reliability in a multi-item sustainable economic energy efficient reliable manufacturing system. Energies, 12(15), 2857. http://dx.doi.org/10.3390/en12152857.

http://dx.doi.org/10.3390/en12152857...

; Ionescu & Darie, 2020Ionescu, C. V., & Darie, G. 2020. Energy Effectiveness-New Energy Performance Indicator to optimize the Industrial Energy Consumptions. In EPE 2020 - Proceedings of the 2020 11th International Conference and Exposition on Electrical And Power Engineering (pp. 462-465). Piscataway: Institute of Electrical and Electronics Engineers Inc. https://doi.org/10.1109/EPE50722.2020.9305663.

https://doi.org/10.1109/EPE50722.2020.93...

; Simeonovski et al., 2021Simeonovski, K., Kaftandzieva, T., & Brock, G. (2021). Energy efficiency management across EU countries: a DEA approach. Energies, 4(9), 2619. http://dx.doi.org/10.3390/en14092619.

http://dx.doi.org/10.3390/en14092619...

; Roemer & Strassburger, 2019Roemer, A. C., & Strassburger, S. (2019). Hybrid system modeling approach for the depiction of the energy consumption in production simulations. In Proceedings of the 2019 Winter Simulation Conference. New York: IEEE.) and system dynamic modeling (Adane et al., 2014Adane, T. F., Nafisi, M., Asif, F. M. A., Semere, D. T., & Nicolescu, M. (2014). System dynamics analysis of energy usage: case studies in automotive manufacturing. International Journal of Manufacturing Research, 9(2), 131-156.; Zeng et al., 2015Zeng, M., Wang, G., Wang, H., Gao, Y., Guo, L., Zhang, J., & Zhang, H. (2015). Industrial system energy efficiency assessment using system dynamics. In Proceedings of the 2015 3rd International Conference on Machinery, Materials and Information Technology Applications (Vol. 35, pp. 1299-1302). Dordrecht: Atlantis Press.; Horschig & Thrän, 2017Horschig, T., & Thrän, D. (2017). Are decisions well supported for the energy transition? A review on modeling approaches for renewable energy policy evaluation. Energy, Sustainability and Society, 7(1), 5.; Martins et al., 2020Martins, J. C., Lacerda, D. P., Wolf Motta Morandi, M. I., Goldmeyer, D., & Piran, F. S. (2020). Systems dynamic modeling to analyze the systemic viability of the combined use of regenerative converters and energy storage in a UPS manufacturer. Journal of Cleaner Production, 246, 118950. http://dx.doi.org/10.1016/j.jclepro.2019.118950.

http://dx.doi.org/10.1016/j.jclepro.2019...

).

The theoretical model identified in the literature presents a set of gaps and limitations, focusing on the use of artifacts that, in summary, do not consider the possible inter-relationship between external and internal variables and adopting a static linear decision process, with a local focus. In the current model, evaluations of the decision to adopt an Energy Efficiency Action are made based on traditional approaches such as NPV, ROI and Payback, which has not contributed to the adoption of energy efficiency practices by small industrial consumers, increasing the energy efficiency gap.

3.3.5. Energy efficiency initiatives

There is a so-called energy efficiency gap related to the non-implementation of energy efficiency and energy management initiatives despite their cost-effectiveness (Finnerty et al., 2017Finnerty, N., Sterling, R., Coakley, D., Contreras, S., Coffey, R., & Keane, M. M. (2017). Development of a Global Energy Management System for non-energy intensive multi-site industrial organisations: a methodology. Energy, 136, 16-31. http://dx.doi.org/10.1016/j.energy.2016.10.049.

http://dx.doi.org/10.1016/j.energy.2016....

; Fenerich et al., 2017Fenerich, F. C., Costa, S. G., & Lima, E. P. (2017). Energy efficiency in industrial environments: overview and research agenda. IEEE Latin America Transactions, 15(3), 415-422.; Bunse et al., 2011Bunse, K., Vodicka, M., Schönsleben, P., Brülhart, M., & Ernst, F. O. (2011). Integrating energy efficiency performance in production management: gap analysis between industrial needs and scientific literature. Journal of Cleaner Production, 19(6-7), 667-679.; Thollander & Palm, 2015Thollander, P., & Palm, J. (2015). Industrial energy management decision making for improved energy efficiency: strategic system perspectives and situated action in combination. Energies, 8(6), 5694-5703.; Alcorta et al., 2014Alcorta, L., Bazilian, M., De Simone, G., & Pedersen, A. (2014). Return on investment from industrial energy efficiency: evidence from developing countries. Energy Efficiency, 7(1), 43-53.; Henriques & Catarino, 2016Henriques, J., & Catarino, J. (2016). Motivating towards energy efficiency in small and medium enterprises. Journal of Cleaner Production, 139, 42-50.; Reddy, 2013Reddy, B. S. (2013). Barriers and drivers to energy efficiency: a new taxonomical approach. Energy Conversion and Management, 74, 403-416.; Wen et al., 2021Wen, X., Cao, H., Hon, B., Chen, E., & Li, H. (2021). Energy value mapping: a novel lean method to integrate energy efficiency into production management. Energy, 217, 119353. http://dx.doi.org/10.1016/j.energy.2020.119353.

http://dx.doi.org/10.1016/j.energy.2020....

; Palm & Thollander, 2019Palm, J., & Thollander, P. 2019. Reframing energy efficiency in industry: a discussion of definitions, rationales, and management practices. In M. Lopes, C. H. Antunes & K. B. Janda (Eds.), Energy and behaviour: towards a low carbon future (pp. 153-175). London: Elsevier. https://doi.org/10.1016/B978-0-12-818567-4.00007-7.

https://doi.org/10.1016/B978-0-12-818567...

). That is, practical evidence and theoretical studies suggest that while the industrial sector records a continuous improvement in energy efficiency, there is ample potential to be explored (Bunse et al., 2011Bunse, K., Vodicka, M., Schönsleben, P., Brülhart, M., & Ernst, F. O. (2011). Integrating energy efficiency performance in production management: gap analysis between industrial needs and scientific literature. Journal of Cleaner Production, 19(6-7), 667-679.).

The debate on the energy efficiency gap should focus on the reasons why companies do not make investments considered profitable to increase energy efficiency. Understanding the disparity between the potential and the implementation of energy efficiency initiatives, as well as the scarcity of specific artifacts, is the main limitation found in the literature.

Despite the existence of studies that call for an integrated and strategic approach to consider energy efficiency (Cooremans, 2011Cooremans, C. (2011). Make it strategic! Financial investment logic is not enough. Energy Efficiency, 4(4), 473-492., 2012Cooremans, C. (2012). Investment in energy efficiency: Do the characteristics of investments matter? Energy Efficiency, 5(4), 497-518.; Patterson, 1996Patterson, M. G. (1996). What is energy efficiency? Concepts, indicators and methodological issues. Energy Policy, 24(5), 377-390.), there are few studies in the researched literature that detail ways to make this integration feasible. In other words, the literature has advanced in relation to “what to do”, but practically ignores the “how to”.

The first gap is related to how the potential of energy efficiency measures are evaluated by companies, especially non-energy intensive companies. It means the industry's need to establish a set of metrics to assess the impacts of energy efficiency initiatives. However, the approaches found in the literature indicate that most companies use only financial indicators. Even if the results of these indicators are financially attractive, the level of adoption of energy efficiency initiatives are low.

Thus, the question of how to reduce the gap in the implementation of measures to increase energy efficiency has been a recurrent issue in recent studies. The main model used to explain this discrepancy is barriers, according to which different barriers to energy efficiency inhibit the adoption of economically attractive measures (Thollander & Palm, 2015Thollander, P., & Palm, J. (2015). Industrial energy management decision making for improved energy efficiency: strategic system perspectives and situated action in combination. Energies, 8(6), 5694-5703.). Barriers are mechanisms that inhibit a decision or a behavior that seems to be energy efficient and economical. Several studies have examined barriers to the implementation of measures to improve energy efficiency in enterprises in different contexts (Perroni et al., 2016Perroni, M. G., Gouvea, S. E. C., Pinheiro, E. de L., & Silva, W. V. (2016). The relationship between enterprize efficiency in resource use and energy efficiency practices adoption. International Journal of Production Economics, 190, 108-119.; Knobloch & Mercure, 2016Knobloch, F., & Mercure, J. F. (2016). The behavioural aspect of green technology investments: a general positive model in the context of heterogeneous agents. Environmental Innovation and Societal Transitions, 21, 39-55.; Palm & Thollander, 2010Palm, J., & Thollander, P. (2010). An interdisciplinary perspective on industrial energy efficiency. Applied Energy, 87(10), 3255-3261.; Paramonova & Thollander, 2016Paramonova, S., & Thollander, P. (2016). Energy-efficiency networks for SMEs: learning from the Swedish experience. Renewable & Sustainable Energy Reviews, 65, 295-307.; Thollander & Palm, 2015Thollander, P., & Palm, J. (2015). Industrial energy management decision making for improved energy efficiency: strategic system perspectives and situated action in combination. Energies, 8(6), 5694-5703.; Henriques & Catarino, 2016Henriques, J., & Catarino, J. (2016). Motivating towards energy efficiency in small and medium enterprises. Journal of Cleaner Production, 139, 42-50.; Reddy, 2013Reddy, B. S. (2013). Barriers and drivers to energy efficiency: a new taxonomical approach. Energy Conversion and Management, 74, 403-416.; Trianni et al., 2014Trianni, A., Cagno, E., & De Donatis, A. (2014). A framework to characterize energy efficiency measures. Applied Energy, 118, 207-220., 2017Trianni, A., Cagno, E., & Neri, A. (2017). Modelling barriers to the adoption of industrial sustainability measures. Journal of Cleaner Production, 168, 1482-1504. http://dx.doi.org/10.1016/j.jclepro.2017.07.244.

http://dx.doi.org/10.1016/j.jclepro.2017...

; Rasmussen, 2017Rasmussen, J. (2017). The additional benefits of energy efficiency investments: a systematic literature review and a framework for categorisation. Energy Efficiency, 10(6), 1401-1418. http://dx.doi.org/10.1007/s12053-017-9528-1.

http://dx.doi.org/10.1007/s12053-017-952...

; König, 2020König, W. (2020). Energy efficiency in industrial organizations: a cultural-institutional framework of decision making. Energy Research & Social Science, 60, 101314. http://dx.doi.org/10.1016/j.erss.2019.101314.

http://dx.doi.org/10.1016/j.erss.2019.10...

; Hasan & Trianni, 2020Hasan, A. S. M. M., & Trianni, A. (2020). A review of energy management assessment models for industrial energy efficiency. Energies, 13(21), 5713. http://dx.doi.org/10.3390/en13215713.

http://dx.doi.org/10.3390/en13215713...

; Li et al., 2020Li, T., Li, A., & Guo, X. (2020). The sustainable development-oriented development and utilization of renewable energy industry: a comprehensive analysis of MCDM methods. Energy, 212, 118694. http://dx.doi.org/10.1016/j.energy.2020.118694.

http://dx.doi.org/10.1016/j.energy.2020....

; Schützenhofer, 2021Schützenhofer, C. (2021). Overcoming the efficiency gap: energy management as a means for overcoming barriers to energy efficiency, empirical support in the case of Austrian large firms. Energy Efficiency, 14, 45. http://dx.doi.org/10.1007/s12053-021-09954-z.

http://dx.doi.org/10.1007/s12053-021-099...

).

The factors pointed out in the literature that can contribute to the adoption of practices to increase energy efficiency in production systems are called drivers. Drivers may influence part of the organization and the decision-making process to overcome barriers (Perroni et al., 2016Perroni, M. G., Gouvea, S. E. C., Pinheiro, E. de L., & Silva, W. V. (2016). The relationship between enterprize efficiency in resource use and energy efficiency practices adoption. International Journal of Production Economics, 190, 108-119.; Reddy, 2013Reddy, B. S. (2013). Barriers and drivers to energy efficiency: a new taxonomical approach. Energy Conversion and Management, 74, 403-416.; Trianni et al., 2017Trianni, A., Cagno, E., & Neri, A. (2017). Modelling barriers to the adoption of industrial sustainability measures. Journal of Cleaner Production, 168, 1482-1504. http://dx.doi.org/10.1016/j.jclepro.2017.07.244.

http://dx.doi.org/10.1016/j.jclepro.2017...

; Hasan et al., 2019Hasan, A. S. M. M., Hossain, R., Tuhin, R. A., Sakib, T. H., & Thollander, P. (2019). Empirical investigation of barriers and driving forces for efficient energy management practices in non-energy-intensive manufacturing industries of Bangladesh. Sustainability, 11(9), 2671. http://dx.doi.org/10.3390/su11092671.

http://dx.doi.org/10.3390/su11092671...

).

Some studies have similar positions with regard to the change in the form of evaluation of energy efficiency investments (Cooremans, 2011Cooremans, C. (2011). Make it strategic! Financial investment logic is not enough. Energy Efficiency, 4(4), 473-492., 2012Cooremans, C. (2012). Investment in energy efficiency: Do the characteristics of investments matter? Energy Efficiency, 5(4), 497-518.; Thollander & Palm, 2015Thollander, P., & Palm, J. (2015). Industrial energy management decision making for improved energy efficiency: strategic system perspectives and situated action in combination. Energies, 8(6), 5694-5703.; Aplak & Sogut, 2013Aplak, H. S., & Sogut, M. Z. (2013). Game theory approach in decisional process of energy management for industrial sector. Energy Conversion and Management, 74, 70-80.; Bhanot et al., 2017Bhanot, N., Rao, P. V., & Deshmukh, S. G. (2017). An integrated approach for analysing the enablers and barriers of sustainable manufacturing. Journal of Cleaner Production, 142(4), 4412-4439. http://dx.doi.org/10.1016/j.jclepro.2016.11.123.

http://dx.doi.org/10.1016/j.jclepro.2016...

), proposing a strategic analysis inserted in a sociotechnical paradigm. However, most studies reinforce that the most used techniques to evaluate energy efficiency investments are based on traditional investment analysis approaches such as Net Present Value (NPV), Internal Rate of Return (IRR) and Payback (PB) (Finnerty et al., 2017Finnerty, N., Sterling, R., Coakley, D., Contreras, S., Coffey, R., & Keane, M. M. (2017). Development of a Global Energy Management System for non-energy intensive multi-site industrial organisations: a methodology. Energy, 136, 16-31. http://dx.doi.org/10.1016/j.energy.2016.10.049.

http://dx.doi.org/10.1016/j.energy.2016....