Abstracts

Determination of animal profile from production scenarios by modeling is essential to improve production. The objective of this study was to model and evaluate the performance, the supply and nutrients requirements for pigs, during the growing and finishing phases, in real production scenarios. Six scenarios with 2,200 animals, which consumed six ad libitum diets, were selected. The collected data from the production scenarios were modeled based on the average animal. Animals were housed at 65±7 days old and weighing 22.11±1.41kg and were slaughtered at 159±10 days old and weighing 121.18±7kg. Average of the scenarios was greater than 0.27kg for consumption and 0.12kg for weight gain; feed conversion was equivalent to the standard animal profile (SAP). Scenarios were 1.60g higher for the requirement and 2.67g higher for daily digestible lysine per animal when compared to the SAP. Production scenarios showed differences between performance, supply and nutrient requirements for pigs during the growing and finishing phases. Modeling is a tool that can be used to describe and compare the characteristics of each production scenario.

animal production; animal profile; InraPorc(r); lysine.

A determinação do perfil animal de cenários de produção, por modelagem, é imprescindível para melhorar a produção. O objetivo deste estudo foi modelar e avaliar o desempenho zootécnico, o fornecimento e as exigências de nutrientes para suínos nas fases de crescimento e terminação em cenários de produção reais. Foram selecionados seis cenários com total de 2.200 animais que consumiram seis dietas ad libitum. Os dados coletados nos cenários de produção foram modelados com base na média animal. Os animais foram alojados com 65±7 dias de idade e 22,11±1,41kg de peso e foram abatidos com 159±10 dias e 121,18±7kg. A média dos cenários foi superior a 0,27kg em consumo e 0,12kg em ganho de peso, a conversão alimentar foi equivalente ao perfil animal padrão (PAP). Os cenários foram superiores em 1,60g para exigência e 2,67g para fornecimento de lisina digestível diária por animal em relação ao PAP. Os cenários de produção apresentam diferenças para desempenho zootécnico, fornecimento e exigências de nutrientes para suínos nas fases de crescimento e terminação. A modelagem é uma ferramenta que pode ser utilizada para descrever e comparar as especificidades em cada cenário de produção.

produção animal; perfil animal; InraPorc(r); lisina.

INTRODUCTION:

Industrial pig production is stimulated by the demand for quality animal protein conditioned to maximum animal performance based on diets with high nutrition concentrations and high costs. Food represents about two thirds of swine production costs, therefore reduce the value derived from this fraction is interesting from the economic point of view.

The methods used to estimate nutritional requirements are based on the response of the population (empirical) or individual (factorial) (HAUSCHILD et al., 2010HAUSCHILD, L. et al. Systematic comparison of the empirical and factorial methods used to estimate the nutrient requirements of growing pigs. Animal, v.4, p.714-723, 2010. Available from: <http://www.ncbi.nlm.nih.gov/pubmed/22444124>. Accessed: Feb. 10, 2014. doi: 10.1017/S1751731109991546.

http://www.ncbi.nlm.nih.gov/pubmed/22444...

). Results compilation provides tables with static data about nutritional recommendations for general animal profile, such as those published by ARC (1981ARC. The nutrients requirements of pigs: technical review. London, England: Commonwealth Agricultural Bureaux, 1981. 307p.), NRC (1998NRC. National Research Council, nutrient requirements of swine. Washington: NRC, National Academy of Science, 1998. 189p.) and ROSTAGNO et al. (2011ROSTAGNO, H.S. et al. Tabelas brasileiras para aves e suínos: composição de alimentos e exigências nutricionais. 3.ed. Viçosa: UFV, 2011. 252p.). These tables are conventionally used in industrial production systems to develop empirical diets and food programs. Although functional, this procedure applies generalizations to specific scenarios and results in inaccuracies. These inaccuracies can have effects on performance, digestive and metabolic processes regarding protein and lipid deposition (FABIAN et al., 2003FABIAN, J. et al. Growth performance, dry matter and nitrogen digestibilities, serum profile, and carcass and meat quality of pigs with distinct genotypes. Journal of Animal Science, v.81, p.1142-1149, 2003. Available from: <http://www.journalofanimalscience.org/content/81/5/1142.full.pdf+html>. Accessed: Jan. 15, 2014.

http://www.journalofanimalscience.org/co...

), and/or production costs.

Growth phenomena should be evaluated dynamically, depending on the response of the animal to ingested nutrients (SAUVANT et al., 1995SAUVANT, D. et al. Systèmes d'unités d'alimentation et lois de réponse du porc aux régimes alimentaires. Journées Recherche Porcine, v.27, p.237-244, 1995. Available from: <http://www.journees-recherche-porcine.com/texte/1995/95txtAlim/A9507.pdf>. Accessed: Jan. 3, 2014.

http://www.journees-recherche-porcine.co...

), which requires the development of new concepts. The InraPorc(r) model uses the principles of swine nutrition, such as digestible amino acids, net energy (NOBLET et al., 2001NOBLET, J.; QUINIOU, N. Principaux facteurs de variation du besoin en acides aminés du porc en croissance. Techni Porc, v.22, p.9-16, 1999. Available from: <http://www.ifip.asso.fr/sites/default/files/pdf-documentations/tp1999n4noblet.pdf>. Accessed: Feb. 5, 2014.

http://www.ifip.asso.fr/sites/default/fi...

) and the ideal protein, using a dynamic methodology that is both mechanistic and deterministic to represent the phenomena related to nutrition, feed, and genetics (VAN MILGEN et al., 2008VAN MILGEN, J. et al. InraPorc: a model and decision support tool for the nutrition of growing pigs. Animal Feed Science and Technology, v.143, p.387-405, 2008. Available from: <http://www.sciencedirect.com/science/article/pii/S0377840107001782>. Accessed: Feb. 5, 2014. doi: 10.1016/j.anifeedsci.2007.05.020.

http://www.sciencedirect.com/science/art...

). Determination of nutritional requirements is elementary in terms of production efficiency (POMAR et al., 2009POMAR, C. et al. Applying precision feeding techniques in growing-finishing pig operations. Revista Brasileira de Zootecnia, v.38, p.226-237, 2009. Available from: <http://www.scielo.br/pdf/rbz/v38nspe/v38nspea23.pdf>. Accessed: Jan. 23, 2014. doi: 10.1590/S1516-35982009001300023.

http://www.scielo.br/pdf/rbz/v38nspe/v38...

), due to diets with higher nutritional precision according to animal profile.

Determining the animal profile of each production scenario (a result of interactions between food consumption, dynamics growth, nutrients use, and the influence of environment) is essential to improve feed efficiency and reduce diets cost and excretion of polluting elements. Studies to identify the specific nutritional requirements of animal profiles in a mechanical and dynamic way are important for balancing diets. In this context, the aim of this study was to model and evaluate the growth performance, supply, and nutrient demands of pigs during the growing and finishing phases in production scenarios.

MATERIALS AND METHODS:

Data collection was carried out in an industrial pig production system in the northwest of Rio Grande do Sul, between August and November 2012. The criterion for sampling was an interval of three days, to delimit the number of farms and minimize climatic effects. Data were collected from six farms or production scenarios (PS), i.e. 1PS, 2PS, 3PS, 4PS, 5PS and 6PS, with equivalent management protocols. The scenarios presented variations in terms of facilities, equipment, location and orientation, capacity, and total number of animals. These factors (environment) were implicit in the performance of the PS, as other studies have reported in the literature (DE LANGE et al., 2001DE LANGE, C.F.M. et al. Application of pig growth models in commercial pork production. Canadian Journal of Animal Science, v.81, p.1-8, 2001. Available from: <http://pubs.aic.ca/doi/pdf/10.4141/A00-006>. Accessed: Feb. 11, 2014.

http://pubs.aic.ca/doi/pdf/10.4141/A00-0...

; VAN MILGEN et al., 2008VAN MILGEN, J. et al. InraPorc: a model and decision support tool for the nutrition of growing pigs. Animal Feed Science and Technology, v.143, p.387-405, 2008. Available from: <http://www.sciencedirect.com/science/article/pii/S0377840107001782>. Accessed: Feb. 5, 2014. doi: 10.1016/j.anifeedsci.2007.05.020.

http://www.sciencedirect.com/science/art...

).

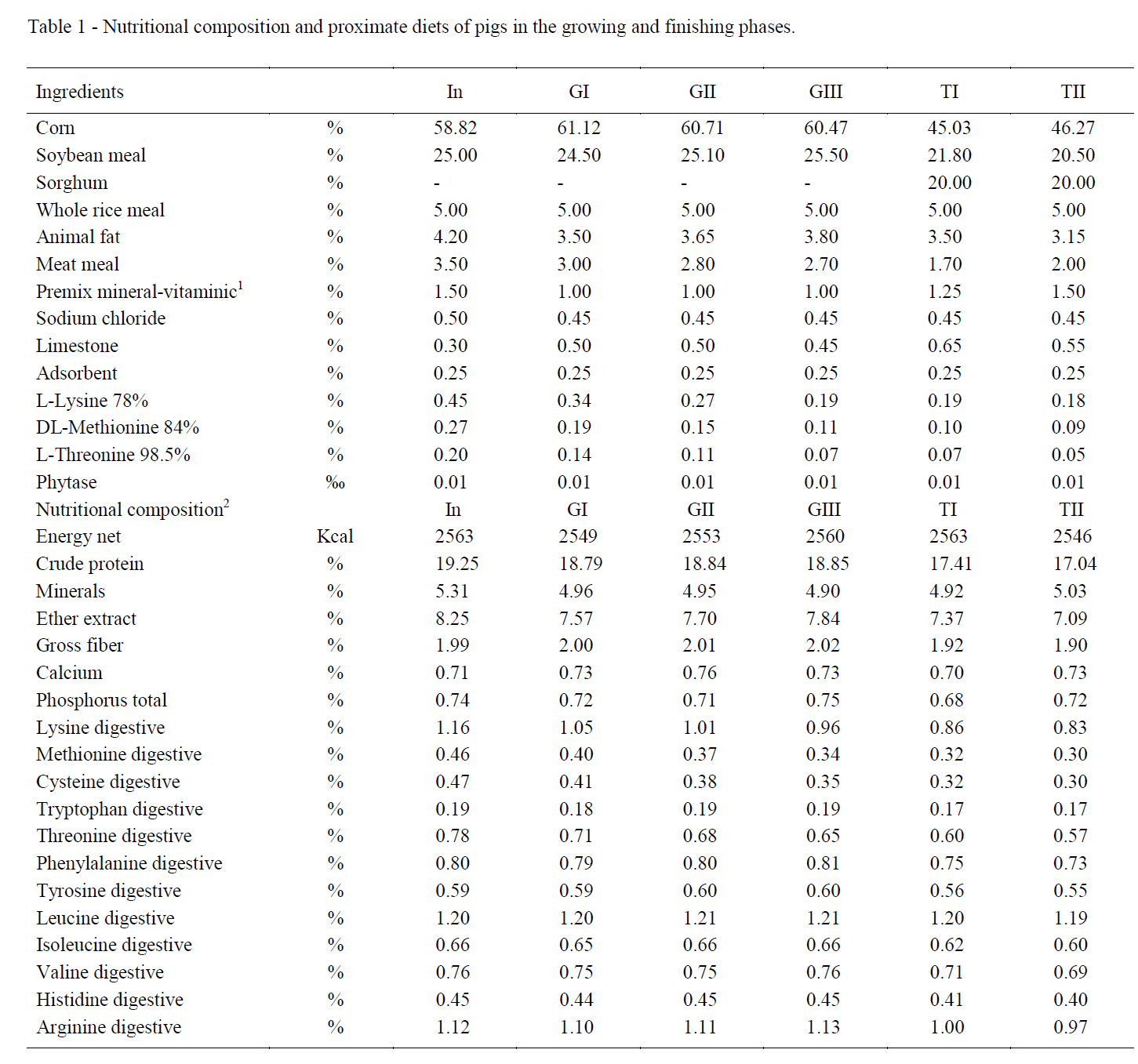

The scenarios showed an average of 367±186 animals, with a minimum population of 200 (5PS) and maximum of 724 animals (6PS). In total, 2,200 animals were used in six mixed batches (females and castrated males). Recommendations for housing the animals were 64 days old and 22.00kg. The diet program followed a pre-established period, sequence and quantities of each diet for animals in each stage. Ingredients composition were analyzed (AOAC, 1995AOAC. ASSOCIATION OF OFFICIAL ANALYTICAL CHEMISTS. Official methods of analysis of the association of the official analysis chemists. 16.ed. Arlington, 1995. 1750p.) and the diets (Table 1) were formulated based on nutritional requirements established through the historic growth performance of farms or the standard animal profile (SAP). Food program was ad libitum for all phases and PS. The diet and food programs of the SAP were used in the PS.

Data collection in the scenarios was conducted in randomly selected bays throughout the experimental period, representing at least 20% of the animals housed, with a maximum limit of four bays. This procedure was performed based on the literature (DE LANGE et al., 2001DE LANGE, C.F.M. et al. Application of pig growth models in commercial pork production. Canadian Journal of Animal Science, v.81, p.1-8, 2001. Available from: <http://pubs.aic.ca/doi/pdf/10.4141/A00-006>. Accessed: Feb. 11, 2014.

http://pubs.aic.ca/doi/pdf/10.4141/A00-0...

). In each scenario, data on animal performance were collected (age, weight and accumulated consumption of diets) of all pigs in the sample bays for each phase, according to the diet program.

The diet composition data, feed intake and animal performance, from each PS and SAP, were entered into InraPorc(r) software (INRAPORC(r), 2010INRAPORC(r). InraPorc(r): a tool to evaluate nutritional strategies in pigs. Saint-Gilles, France, 2010. 1.5.3.1.) to parameterize the model. Parameterization allows characterizing the animal profile of the respective production scenario (VAN MILGEN et al., 2008VAN MILGEN, J. et al. InraPorc: a model and decision support tool for the nutrition of growing pigs. Animal Feed Science and Technology, v.143, p.387-405, 2008. Available from: <http://www.sciencedirect.com/science/article/pii/S0377840107001782>. Accessed: Feb. 5, 2014. doi: 10.1016/j.anifeedsci.2007.05.020.

http://www.sciencedirect.com/science/art...

). The data for each scenario were modeled based on the average animal for all the parameters and 2% diet loss was estimated (BROSSARD et al., 2009BROSSARD, L. et al. Modelling the variation in performance of a population of growing pig as affected by lysine supply and feeding strategy. Animal, v.3, p.1114-1123, 2009. Available from: <http://dx.doi.org/10.1017/S1751731109004546>. Accessed: Feb. 19, 2014. doi: 10.1017/S1751731109004546.

http://dx.doi.org/10.1017/S1751731109004...

). The animal performance curves were calibrated and the nutritional requirements were modeled (ROSSI et al., 2013ROSSI, C.A.R. et al. Dietas ajustadas para suínos através do modelo InraPorc(r): desempenho, características de carcaça e impacto econômico. Ciência Rural, v.43, p.689-695, 2013. Available from: <http://www.scielo.br/pdf/cr/v43n4/a9513cr2012-0721.pdf>. Accessed: Feb. 23, 2014. doi: 10.1590/S0103-84782013005000020.

http://www.scielo.br/pdf/cr/v43n4/a9513c...

) to the standard animal profile and the six animal profiles evaluated. The data were submitted to descriptive statistical analysis and compared using absolute relation to the standard deviation.

RESULTS AND DISCUSSION:

The performance data of the PS are shown in table 2. The characteristics of the animals in each PS were an average age of 65±7 days old and weight of 22.11±1.41kg. These values are similar to the SAP, although the minimum age was 55 days (6PS) and the maximum was 72 days (1PS), which generated a variation of nine days in the scenarios for the SAP. Likewise, the minimum weight was 19.64kg (3PS) and the maximum was 23.74kg (1PS), with a variation of 2.05kg. Variations in age and weight at the beginning of the growing and finishing phases are determined by several factors such as weaning weight and nutrition program (MAHAN & LEPINE, 1991MAHAN, D.C.; LEPINE, A.J. Effect of pig weaning weight and associated nursery feeding programs on subsequent performance to 105 kilograms body weight. Journal of Animal Science, v.69, p.1370-1378, 1991. Available from: <http://www.journalofanimalscience.org/content/69/4/1370.long>. Accessed: Jan. 8, 2014.

http://www.journalofanimalscience.org/co...

). These factors are difficult to control (TOKACH et al., 2007TOKACH, M. et al. New tools to manage variability throughout the pork production chain London Swine Conference - Today's Challenges... Tomorrow's Opportunities. London, 2007.p19-33. Available from: <http://www.londonswineconference.ca/proceedings/2007/LSC2007_MTokach.pdf>. Accessed: Feb. 21, 2014.

http://www.londonswineconference.ca/proc...

) and are accepted as a natural component of the process or disregarded due to their complexity.

At the end of the period of 94±7 days, the animals were slaughtered with an average weight of 121.18±7kg and age of 159±10 days old. Average slaughter weight of the scenarios was higher by only 1.18kg and age was lower by 9 days compared to the SAP. The small variation in age and uniformity in weight is explained by the need for homogeneous carcasses. The variations between the scenarios were caused by intrinsic factors of production and/or goals and deadlines set by the industry.

The average performance of the scenarios for daily consumption was higher by 0.27±0.13kg vs. the SAP; the minimum consumption was 2.11kg (1PS) and the maximum was 2.37kg (5PS). The scenarios presented a daily weight gain of 1.06±0.05kg or 0.12kg greater than the SAP. The lowest weight housing in PS resulted in the minimum daily gain of 1.01kg (3PS), while 6PS generated 0.19kg as the maximum gain, exceeding the standard. Feed conversion was irregular between scenarios and throughout the stages, but the final average of 2.14±0.13 was equivalent to the standard.

The data collected in different scenarios show the growth behavior of the animals. This is a complex biological process, which involves an increase in the shape and composition of body mass over time. Mathematical modeling allows for the simulation of real systems to predict animal performance behavior and their nutritional requirements in different production scenarios (LOVATTO & SAUVANT, 2001LOVATTO, P.A.; SAUVANT, D. Modelagem aplicada aos processos digestivos e metabólicos do suíno. Ciência Rural, v.31, p.663-670, 2001. Available from: <http://www.scielo.br/pdf/cr/v31n4/a17v31n4.pdf>. Accessed: Feb. 5, 2014. doi: 10.1590/S0103-84782001000400017.

http://www.scielo.br/pdf/cr/v31n4/a17v31...

). Therefore, data from the diets and food programs and the animal profile were used as a basis for modeling simulations (VAN MILGEN et al., 2008VAN MILGEN, J. et al. InraPorc: a model and decision support tool for the nutrition of growing pigs. Animal Feed Science and Technology, v.143, p.387-405, 2008. Available from: <http://www.sciencedirect.com/science/article/pii/S0377840107001782>. Accessed: Feb. 5, 2014. doi: 10.1016/j.anifeedsci.2007.05.020.

http://www.sciencedirect.com/science/art...

).

Overall, the diet program and feeding program developed for the SAP supplied the lysine requirements in all phases. The requirement of daily digestible lysine estimated by InraPorc(r) for the SAP was of 15.95±2.69g and the amount provided was 18.61±1.70g (Figure 1). In this way, throughout the total period, an excess of 278.85g per animal was expected, understood as a safety margin to adjust for the diversity of scenarios. This procedure is a common practice in conventional nutritional programs, according to the ARC (1981ARC. The nutrients requirements of pigs: technical review. London, England: Commonwealth Agricultural Bureaux, 1981. 307p.), NRC (1998NRC. National Research Council, nutrient requirements of swine. Washington: NRC, National Academy of Science, 1998. 189p.) and ROSTAGNO et al. (2011ROSTAGNO, H.S. et al. Tabelas brasileiras para aves e suínos: composição de alimentos e exigências nutricionais. 3.ed. Viçosa: UFV, 2011. 252p.), and is justified only by the impossibility of determining the requirements of the scenarios.

Daily supplied levels and digestible lysine requirements and turning points for the Standard Animal Profile (SAP) and Production Scenarios (PS).

In general, there was excess lysine in all scenarios, and the animals got on average 17.6% more lysine than required. When comparing the average daily requirements for lysine, it was found that the scenarios had requirements1.60g higher than that of the SAP, but ingested 2.67g more than expected. The InraPorc(r) software modeled the requirements and the supply of lysine of each scenario; therefore, it was possible to identify excesses in the phases and in the total period. With nutritional specificities, it is possible to suit the nutritional levels and set diet programs to reduce costs and nutrient excretion without affecting the maximum performance.

The inflection point was 18.51g and occurred at 152 days or 103.32kg of weight. The average of the scenarios resulted in demand for 20.40g lysine at 138 days or 97.65kg of weight. The inflection point indicates the age of the maximum lysine requirement for protein deposition (VAN MILGEN, 2008VAN MILGEN, J. et al. InraPorc: a model and decision support tool for the nutrition of growing pigs. Animal Feed Science and Technology, v.143, p.387-405, 2008. Available from: <http://www.sciencedirect.com/science/article/pii/S0377840107001782>. Accessed: Feb. 5, 2014. doi: 10.1016/j.anifeedsci.2007.05.020.

http://www.sciencedirect.com/science/art...

). The average of the scenarios shows that the animals had an early inflection point at 14±16 days and at a 5.67kg lower weight, but the maximum lysine requirement was superior to the standard by 1.89g. Among the scenarios, the greate stage difference for the inflection point was 42 days between 3PS (157 days) and 6PS (115 days). The biggest difference in weight for the maximum requirement of lysine was 42.7kg, found between 2PS and 5PS. These scenarios also showed the greatest difference between the maximum lysine required, with a difference of 3.6g.

Animals nutritional requirements are influenced by factors intrinsic to the animal, food, environment, and their interactions (NOBLET & QUINIOU, 1999NOBLET, J.; QUINIOU, N. Principaux facteurs de variation du besoin en acides aminés du porc en croissance. Techni Porc, v.22, p.9-16, 1999. Available from: <http://www.ifip.asso.fr/sites/default/files/pdf-documentations/tp1999n4noblet.pdf>. Accessed: Feb. 5, 2014.

http://www.ifip.asso.fr/sites/default/fi...

), so the requirements should not be taken as fixed values (FULLER, 2004FULLER, M.F. The encyclopedia of farm animal production. Wallingford, USA: CABI Publishing, 2004. 620p.). Based on the data collected in each PS, associated with pig nutrition concepts used by InraPorc(r), it was possible to study the heterogeneity between animal performance and specific nutritional requirements. Differences in nutritional requirements are verifiable, but the adjustment of diet programs and food programs to various production scenarios requires further investigation.

CONCLUSION:

The production scenarios studied differed for performance, supply and nutrient requirements for pigs in the growing and finishing phases. Modeling is a tool that can be used to describe and compare the characteristics of each production scenario.

ACKNOWLEDGMENTS

The authors thank the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) for the scholarships awarded.

- AOAC. ASSOCIATION OF OFFICIAL ANALYTICAL CHEMISTS. Official methods of analysis of the association of the official analysis chemists. 16.ed. Arlington, 1995. 1750p.

- ARC. The nutrients requirements of pigs: technical review. London, England: Commonwealth Agricultural Bureaux, 1981. 307p.

- BROSSARD, L. et al. Modelling the variation in performance of a population of growing pig as affected by lysine supply and feeding strategy. Animal, v.3, p.1114-1123, 2009. Available from: <http://dx.doi.org/10.1017/S1751731109004546>. Accessed: Feb. 19, 2014. doi: 10.1017/S1751731109004546.

» https://doi.org/10.1017/S1751731109004546.» http://dx.doi.org/10.1017/S1751731109004546 - DE LANGE, C.F.M. et al. Application of pig growth models in commercial pork production. Canadian Journal of Animal Science, v.81, p.1-8, 2001. Available from: <http://pubs.aic.ca/doi/pdf/10.4141/A00-006>. Accessed: Feb. 11, 2014.

» http://pubs.aic.ca/doi/pdf/10.4141/A00-006 - FABIAN, J. et al. Growth performance, dry matter and nitrogen digestibilities, serum profile, and carcass and meat quality of pigs with distinct genotypes. Journal of Animal Science, v.81, p.1142-1149, 2003. Available from: <http://www.journalofanimalscience.org/content/81/5/1142.full.pdf+html>. Accessed: Jan. 15, 2014.

» http://www.journalofanimalscience.org/content/81/5/1142.full.pdf+html - FULLER, M.F. The encyclopedia of farm animal production. Wallingford, USA: CABI Publishing, 2004. 620p.

- HAUSCHILD, L. et al. Systematic comparison of the empirical and factorial methods used to estimate the nutrient requirements of growing pigs. Animal, v.4, p.714-723, 2010. Available from: <http://www.ncbi.nlm.nih.gov/pubmed/22444124>. Accessed: Feb. 10, 2014. doi: 10.1017/S1751731109991546.

» https://doi.org/10.1017/S1751731109991546.» http://www.ncbi.nlm.nih.gov/pubmed/22444124 - INRAPORC(r). InraPorc(r): a tool to evaluate nutritional strategies in pigs. Saint-Gilles, France, 2010. 1.5.3.1.

- LOVATTO, P.A.; SAUVANT, D. Modelagem aplicada aos processos digestivos e metabólicos do suíno. Ciência Rural, v.31, p.663-670, 2001. Available from: <http://www.scielo.br/pdf/cr/v31n4/a17v31n4.pdf>. Accessed: Feb. 5, 2014. doi: 10.1590/S0103-84782001000400017.

» https://doi.org/10.1590/S0103-84782001000400017.» http://www.scielo.br/pdf/cr/v31n4/a17v31n4.pdf - MAHAN, D.C.; LEPINE, A.J. Effect of pig weaning weight and associated nursery feeding programs on subsequent performance to 105 kilograms body weight. Journal of Animal Science, v.69, p.1370-1378, 1991. Available from: <http://www.journalofanimalscience.org/content/69/4/1370.long>. Accessed: Jan. 8, 2014.

» http://www.journalofanimalscience.org/content/69/4/1370.long - NOBLET, J.; QUINIOU, N. Principaux facteurs de variation du besoin en acides aminés du porc en croissance. Techni Porc, v.22, p.9-16, 1999. Available from: <http://www.ifip.asso.fr/sites/default/files/pdf-documentations/tp1999n4noblet.pdf>. Accessed: Feb. 5, 2014.

» http://www.ifip.asso.fr/sites/default/files/pdf-documentations/tp1999n4noblet.pdf - NRC. National Research Council, nutrient requirements of swine. Washington: NRC, National Academy of Science, 1998. 189p.

- POMAR, C. et al. Applying precision feeding techniques in growing-finishing pig operations. Revista Brasileira de Zootecnia, v.38, p.226-237, 2009. Available from: <http://www.scielo.br/pdf/rbz/v38nspe/v38nspea23.pdf>. Accessed: Jan. 23, 2014. doi: 10.1590/S1516-35982009001300023.

» https://doi.org/10.1590/S1516-35982009001300023.» http://www.scielo.br/pdf/rbz/v38nspe/v38nspea23.pdf - ROSSI, C.A.R. et al. Dietas ajustadas para suínos através do modelo InraPorc(r): desempenho, características de carcaça e impacto econômico. Ciência Rural, v.43, p.689-695, 2013. Available from: <http://www.scielo.br/pdf/cr/v43n4/a9513cr2012-0721.pdf>. Accessed: Feb. 23, 2014. doi: 10.1590/S0103-84782013005000020.

» https://doi.org/10.1590/S0103-84782013005000020.» http://www.scielo.br/pdf/cr/v43n4/a9513cr2012-0721.pdf - ROSTAGNO, H.S. et al. Tabelas brasileiras para aves e suínos: composição de alimentos e exigências nutricionais. 3.ed. Viçosa: UFV, 2011. 252p.

- SAUVANT, D. et al. Systèmes d'unités d'alimentation et lois de réponse du porc aux régimes alimentaires. Journées Recherche Porcine, v.27, p.237-244, 1995. Available from: <http://www.journees-recherche-porcine.com/texte/1995/95txtAlim/A9507.pdf>. Accessed: Jan. 3, 2014.

» http://www.journees-recherche-porcine.com/texte/1995/95txtAlim/A9507.pdf - TOKACH, M. et al. New tools to manage variability throughout the pork production chain London Swine Conference - Today's Challenges... Tomorrow's Opportunities. London, 2007.p19-33. Available from: <http://www.londonswineconference.ca/proceedings/2007/LSC2007_MTokach.pdf>. Accessed: Feb. 21, 2014.

» http://www.londonswineconference.ca/proceedings/2007/LSC2007_MTokach.pdf - VAN MILGEN, J. et al. InraPorc: a model and decision support tool for the nutrition of growing pigs. Animal Feed Science and Technology, v.143, p.387-405, 2008. Available from: <http://www.sciencedirect.com/science/article/pii/S0377840107001782>. Accessed: Feb. 5, 2014. doi: 10.1016/j.anifeedsci.2007.05.020.

» https://doi.org/10.1016/j.anifeedsci.2007.05.020.» http://www.sciencedirect.com/science/article/pii/S0377840107001782

Publication Dates

-

Publication in this collection

Oct 2015

History

-

Received

17 Sept 2014 -

Accepted

26 Feb 2015