ABSTRACT:

This study aimed to obtain the best dose of waste cooking oil inclusion for the co-digestion of substrates prepared with dairy cattle and swine manure in order to maximize solids reductions and biogas yield. Analyses of total solids (TS), volatile solids (VS), and neutral detergent fiber (NDF) were performed during the loading and unloading of digesters, while biogas yield was measured twice a week. The maximum reduction in VS (51.4%) was reached with the inclusion of up to 54.6g waste cooking oil.kg manure-1. Maximum NDF degradation occurred with inclusions of up to 69.4g waste cooking oil.kg manure-1. Inclusions of up to 64g of waste cooking oil.kg manure-1 provided specific biogas yield of 291.4 and 251.0L biogas.kg VS-1 added to substrates with swine and cattle manure, respectively. Adding oil at doses between 45.1 and 69.4g waste cooking oil kg manure-1 to substrates composed of cattle or swine manure maximizes reductions of solids and fibrous constituents and enhances specific biogas yield. Furthermore, swine manure supports higher doses of waste cooking oil.

Key words:

digestion; biogas; energy recycling

RESUMO:

Objetivou-se encontrar a melhor dose de inclusão de óleo residual durante a co-digestão de substratos preparados com dejetos de bovinos leiteiros e suínos, com o intuito de maximizar as reduções de sólidos e as produções de biogás. Foram realizadas no abastecimento e desabastecimento dos biodigestores as análises de sólidos totais (ST), sólidos voláteis (SV) e fibra em detergente neutro (FDN), enquanto as mensurações de biogás duas vezes por semana. A máxima redução de SV (51,4%) foi possibilitada pela inclusão de até 54,6g de óleo de descarte kg dejetos-1, já as máximas degradações de FDN ocorreram com adições de até 69,4g de óleo de descarte kg dejetos-1. As inclusões de até 64g de óleo de descarte kg dejetos-1 possibilitaram produções específicas de biogás de 291,4 e 251,0 L de biogás.kg SV-1 adicionado, para substratos contendo dejetos de suínos e bovinos respectivamente. A adição de óleo em doses entre 45,1 e 69,4g.kg-1 a substratos contendo dejetos de bovinos ou suínos maximiza as reduções dos constituintes sólidos e fibrosos bem como potencializa as produções específicas de biogás, sendo que o dejeto de suíno ainda suporta maiores doses de inclusão de óleo residual.

Palavras-chave:

biodigestão; biogás; reciclagem energética

INTRODUCTION:

Brazil slaughtered 10.62 million swines and produced 5.63 million liters of milk during the second quarter of 2017 (IBGE, 2017IBGE - Instituto Brasileiro de Geografia e Estatística. Indicadores do IBGE - Estatística da produção pecuária setembro de 2017, 2017. 47 p. CEPAGRO.); consequently, generating large amounts of waste from the farming of those animals. Another major source of residues is waste cooking oil; i.e., the oil used in food processing, which has few uses and whose destination is troublesome (MONGKOLTHANARUKA & DHARMSTHITI, 2002MONGKOLTHANARUKA, W.; DHARMSTHITI, S. Biodegradation of lipid-richwastewater by a mixed bacterial consortium. International Biodeterioration & Biodegradation, v. 50, p. 101 - 105, 2002. Available from: http://www.sciencedirect.com/science/article/pii/S0964830502000574>. Accessed: Nov. 10, 2017. doi: 10.1016/S0964-8305(02)00057-4.

http://www.sciencedirect.com/science/art...

).

Animal waste is highly polluting and its high organic content, in addition to the fact it is a source of pathogenic microorganisms, makes it hazardous to human health and to the environment. Biological treatments, such as anaerobic biodigestion, can be applied to stabilize these residues so they can be turned into simpler, more assimilable forms to the microorganisms in the medium. This process promotes nutrient recycling, provides a great source of renewable energy, and reduces environmental impact (FIERRO et al., 2014FIERRO, J. et al. Valorisation of used cooking oil sludge by codigestion with swine manure. Waste Management, v.34, p.1537-1545, 2014. Available from: https://www.sciencedirect.com/science/article/pii/S0956053X14000580>. Accessed: Nov. 10, 2017. doi: 10.1016/j. wasman.2014.02.006.

https://www.sciencedirect.com/science/ar...

).

Anaerobic biodigestion by itself adds value to animal manure due to the benefits of energy recycling, as pointed out in studies that reported yields of up to 238L biogas.kg volatile solids (VS)-1 for swine manure (ORRICO et al., 2015ORRICO, ACA. et al. Anaerobic co-digestion of swine manure and increasing levels of discarded oil. Engenharia Agrícola, v. 35, p. 657-664, 2015. Available from: http://www.scielo.br/scielo.php?script=sci_abstract&pid=S0100-69162015000400657&lng=en&nrm=iso&tlng=en>. Accessed: Nov. 09, 2017. doi: 10.1590/1809-4430.

http://www.scielo.br/scielo.php?script=s...

) and 250 L biogas.kg VS-1 for cattle manure (SIMM et al., 2017SIMM, S. et al. Crude glycerin in anaerobic co-digestion of dairy cattle manure increases methane production. Scientia Agricola, v. 74, p. 175-179, 2017. Available from: http://www.scielo.br/scielo.php?script=sci_arttext&pid=S010390162017000300175&lng=en&tlng=en>. Accessed: Nov. 09, 2017. doi: 10.1590/1678-992x-2016-0057.

http://www.scielo.br/scielo.php?script=s...

).

Such high biogas yields could be further potentialized since the process is impacted by nutrient availability in the fermentation substrate. Swine manure is a nitrogen-rich compound and has a toxic effect against anaerobic microorganisms at high levels (MATA-ALVAREZ et al., 2014MATA-ALVAREZ, J. et al. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renewable and Sustainable Energy Reviews, v.36, p.412-27, 2014. Available from: http://www.sciencedirect.com/science/article/pii/S1364032114002664>. Accessed: Mar. 15, 2015. doi: 10.1016/j.rser.2014.04.039.

http://www.sciencedirect.com/science/art...

). The same is true for cattle manure, which is characterized by high fiber contents that limit breakdown due to the complexity of the structure (YAMASHIRO et al., 2013YAMASHIRO, T. et al. Anaerobic co-digestion of dairy cow manure and high concentrated food processing waste. Journal of Material Cycles and Waste Management, v.15, p.539-547, 2013. Available from: https://link.springer.com/journal/10163>. Accessed: Jan. 16, 2015.

https://link.springer.com/journal/10163...

). Overall biogas yield from ruminant manure is lower than the yield from non-ruminants. However, regardless of manure type, yield can be maximized when substrates that enhance these characteristics are used.

The process of anaerobic co-digestion is the digestion of two or more substrates that are complementary, thus accelerating the degradation of organic matter and;consequently, the yield of biogas and methane, generating higher specific yield and organic fertilizer with better quality. According to HUNTER LONG et al. (2012HUNTER LONG, J. et al. Anaerobic co-digestion of fat, oil, and grease (FOG): A review of gas production and process limitations. Process Safety and Environmental Protection, v.90, p.231-245, 2012. Available from: http://www.sciencedirect.com/science/article/pii/S0957582011001054>. Accessed: Fev. 7, 2015. doi: 10.1016/j.psep.2011.10.001.

http://www.sciencedirect.com/science/art...

), the use of lipid waste has been identified as a way to expand biogas yield by 30% or more, as this type of substrate improves the concentrations of degradable carbon in the characteristics of the waste. This behavior can be verified in a study carried out by ORRICO JUNIOR & ORRICO (2015ORRICO JUNIOR, MAP.; ORRICO, ACA. Quantification, characterization, and anaerobic digestion of sheep manure: the influence of diet and addition of crude glycerin. Environmental Progress & Sustainable Energy, v.34, p.1038-1043, 2015. Available from: http://onlinelibrary.wiley.com/wol1/doi/10.1002/ep.12097/full>. Accessed: Nov. 09, 2017. doi: 10.1002/ep.12097.

http://onlinelibrary.wiley.com/wol1/doi/...

) on cattle waste and addition of 15% crude glycerin with high lipid content. Those authors reported yields of up to 422.09L biogas.kg VS added-1, a 53% increase in relation to not using glycerin. The same was reported by FIERRO et al. (2014FIERRO, J. et al. Valorisation of used cooking oil sludge by codigestion with swine manure. Waste Management, v.34, p.1537-1545, 2014. Available from: https://www.sciencedirect.com/science/article/pii/S0956053X14000580>. Accessed: Nov. 10, 2017. doi: 10.1016/j. wasman.2014.02.006.

https://www.sciencedirect.com/science/ar...

) when assessing swine waste co-digestion with oily residues, yielding 783L biogas.kg VS added-1, 67% higher compared to simple digestion.

Despite the beneficial effects, some factors limit the use of those substrates due to operational concerns, such as system clogging, as well as the toxic action of long-chain fatty acids against degrading microorganisms (MATA-ALVAREZ et al., 2014MATA-ALVAREZ, J. et al. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renewable and Sustainable Energy Reviews, v.36, p.412-27, 2014. Available from: http://www.sciencedirect.com/science/article/pii/S1364032114002664>. Accessed: Mar. 15, 2015. doi: 10.1016/j.rser.2014.04.039.

http://www.sciencedirect.com/science/art...

) since those fatty acids limit the transport of nutrients from the membrane surface into the cells (WAN et al., 2011WAN, C. et al. Semi-continuous anaerobic co-digestion of thickened waste activated sludge and fat, oil and grease. Waste Management, v.31, p.1752-1758, 2011. Available from: http://www.sciencedirect.com/science/article/pii/S0956053X11001772>. Accessed: Jan. 13, 2015. doi: 10.1016/j.wasman.2011.03.025.

http://www.sciencedirect.com/science/art...

; ZHANG et al.; 2013ZHANG, C. et al. The anaerobic co-digestion of food waste and cattle manure. Bioresource Technology , v.129, p.170-176, 2013. Available from: http://www.sciencedirect.com/science/article/pii/S0960852412016471>. Accessed: Fev. 20, 2015. doi: 10.1016/j.biortech.2012.10.138

http://www.sciencedirect.com/science/art...

) as reported by RODRIGUES et al. (2014RODRIGUES, JP. et al. Adding oil and lipase on the anaerobic digestion of pig manure. Ciência Rural, v.44, n.3, p.544-547, 2014. Available from: http://www.scielo.br/pdf/cr/v44n3/a9014cr2013-0212.pdf>. Accessed: Nov. 09, 2017. doi: 10.1590/S0103-84782014000300025.

http://www.scielo.br/pdf/cr/v44n3/a9014c...

). In that study, this toxicity factor was attributed to the low specific yields of biogas reported (77.1L biogas.kg waste-1) when using swine manure added with waste cooking oil and a lipolytic enzyme.

This study aimed to find the optimal doses of waste cooking oil inclusion in co-digestion with dairy cattle manure or swine manure in order to maximize reductions in solids and fibrous constituents, as well as enhance specific yields of biogas, thus reducing the environmental impact caused by these residues and promoting energy recycling.

MATERIALS AND METHODS:

The biodigesters were fed residues collected in 2014 at commercial establishments in the city of Dourados, Center-West region of Brazil, 22° 13’ 16” S and 54° 48’ 20” W. Dairy cattle and swine manure were obtained from the cleaning of animal pens and the oil, in waste condition after successive uses, was donated by a pastry shop. A completely randomized 7x2 factorial design was adopted with seven levels of waste cooking oil inclusion (at 0, 20, 40, 60, 80, 100, and 120 g.kg total solids (TS) added-1) and two types of manure (dairy cattle and swine) with two replicates (digesters).

Prior to the preparation of substrates, an inoculum was produced from the feed of batch digesters with cattle manure and diluted in water at a concentration of 4% TS. The inoculum was considered ready when the highest yield of biogas was observed, which remained constant with average concentration of 78% methane in its composition, representing 15% of the dry mass added to the digesters at the beginning of the experimental period.

Biodigesters employed in the co-digestion assay were fed according to the level of waste cooking oil addition (at 0, 20, 40, 60, 80, 100, and 120 g.kg TS added-1) and manure (swine or bovine) to be used up to a volume of 1.3L. To that end, on the day the biodigesters were fed, the substrates had the following composition: Swine manure had concentration of 28.9g TS.kg manure-1, 22.6g VS.kg manure-1, and chemical oxygen demand (COD) of 680g O2.kg manure-1; while dairy cattle manure had 19.2g TS.kg manure-1, 15.5g VS.kg manure-1, and COD of 592g O2.kg manure-1; the inoculum had 1.44g TS.L substrate-1 with 0.97g VS.L substrate-1 and COD of 293g of O2 L substrate-1; and the waste cooking oil consisted of 98g TS.kg waste cooking oil-1 and COD of 2,000g O2.L waste cooking oil-1.

This study used benchtop batch biodigesters made with two straight PVC cylinders with diameters of 150 and 100mm and a container for storing the material to be fermented that was 65mm in diameter. Digesters are also described as bench-scale batch digesters with average capacity of 1.3L of fermentation substrate each. The cylinder of 100mm diameter was inserted into the one with 150mm diameter so that the gap between the outer wall of the inner cylinder and the inner wall of the outer cylinder could hold a volume of water (“water seal”). One end of the inner cylinder was closed and the other end was left open for the release of biogas. The open end was kept submerged in the water seal to provide anaerobic condition and store the gas produced.

Analyses were performed on the affluents feeding the biodigesters as well as on the effluents to determine TS, VS, and pH according to the methodology described by APHA (2005)APHA - American Public Health Association. Standard methods for examination of water and wastewater. 21th ed. American Water Works Association, 2005., while neutral detergent fiber (NDF) contents were determined using the methodology proposed by DETMANN et al. (2012DETMANN, E. et al. Métodos para análise de alimentos. INCT-Ciência Animal. 1 ed: 214p. 2012.). In order to determine the COD in the affluents and effluents, the colorimetric method was employed using a HACH DR/2000 spectrophotometer and a COD digestion block according to the methodology described by APHA (2005)APHA - American Public Health Association. Standard methods for examination of water and wastewater. 21th ed. American Water Works Association, 2005.. Daily biogas yield was determined by measuring the vertical shift of the gasometers and multiplying it by the area of the internal cross-section of the gasometers. After each reading, the gasometers were reset using the biogas outlet valve. Specific biogas yields were calculated by dividing yield values by the quantities of TS and VS added and reduced, and results were expressed in liters of biogas per kg (L biogas.kg-1) of each of the constituents evaluated.

Results were submitted to analysis of variance, in which oil levels were considered a source of variation. The results were submitted to orthogonal contrasts to assess the linear, quadratic, and cubic effects of oil levels. All statistical analyses were carried out with the software R (version 3.1.0 for Windows).

RESULTS AND DISCUSSION:

Reductions of solid and fiber constituents

Reductions in levels of TS, VS, and NDF (Table 1 and Figure 1) were similar between the types of manure evaluated in this experiment. Mean increases by 42.4 and 49.5% were observed in reduction values of constituents assessed for swine and cattle waste, respectively, up to maximum inclusion levels of 69.4g waste cooking oil.kg manure-1. When those inclusion levels were exceeded, values decreased. The values reported were higher than those reported by researches using animal waste and residues with high lipid contents. SIMM et al. (2017SIMM, S. et al. Crude glycerin in anaerobic co-digestion of dairy cattle manure increases methane production. Scientia Agricola, v. 74, p. 175-179, 2017. Available from: http://www.scielo.br/scielo.php?script=sci_arttext&pid=S010390162017000300175&lng=en&tlng=en>. Accessed: Nov. 09, 2017. doi: 10.1590/1678-992x-2016-0057.

http://www.scielo.br/scielo.php?script=s...

) assessed co-digestion of dairy cattle waste with crude glycerin and found mean values of 46.8%, while ORRICO et al. (2015ORRICO, ACA. et al. Anaerobic co-digestion of swine manure and increasing levels of discarded oil. Engenharia Agrícola, v. 35, p. 657-664, 2015. Available from: http://www.scielo.br/scielo.php?script=sci_abstract&pid=S0100-69162015000400657&lng=en&nrm=iso&tlng=en>. Accessed: Nov. 09, 2017. doi: 10.1590/1809-4430.

http://www.scielo.br/scielo.php?script=s...

) assessed the joint digestion of swine manure and waste cooking oil and obtained mean reduction values of 38.5%.

Reduction (%) of TS, VS (A), and NDF (B) in substrates prepared with dairy cattle or swine manure and increasing levels of waste cooking oil inclusion.

The maximum reductions of solid and fibrous constituents were reported in substrates containing cattle manure. The inclusion of waste cooking oil provided sources of more readily degradable carbon than dietary fibers present in the diet of those animals, while fibers could be more easily digested after medium acidification since hemicellulose is more soluble in acid conditions (NEVES et al., 2009NEVES, L. et al. Co-digestion of cow manure, food waste and intermittent input of fat. Bioresource Technology , v.100, p.1957-196, 2009. Available from: http://www.sciencedirect.com/science/article/pii/S0960852408008821>. Accessed: Fev. 15, 2015. doi: 10.1016/j.biortech.2008.10.030.

http://www.sciencedirect.com/science/art...

; OGEDA & PETRI, 2010OGEDA, T.L.; PETRI, D.F.S. Biomass Enzymatic Hydrolysis. Química. Nova, v.33, p.1549-1558, 2010. Available from: http://www.scielo.br/scielo.php?pid=S0100-40422010000700023&script=sci_abstract&tlng=ES>. Accessed: Fev. 10, 2015. doi: 10.1590/S0100-40422010000700023.

http://www.scielo.br/scielo.php?pid=S010...

). It is believed the ideal waste cooking oil inclusion levels (Table 1), which maximized reductions, complemented the characteristics of the substrates by providing sources of more easily degradable carbon, which enabled favorable nutrient concentrations for the process as observed by ORRICO et al. (2015ORRICO, ACA. et al. Anaerobic co-digestion of swine manure and increasing levels of discarded oil. Engenharia Agrícola, v. 35, p. 657-664, 2015. Available from: http://www.scielo.br/scielo.php?script=sci_abstract&pid=S0100-69162015000400657&lng=en&nrm=iso&tlng=en>. Accessed: Nov. 09, 2017. doi: 10.1590/1809-4430.

http://www.scielo.br/scielo.php?script=s...

) when working with swine manure co-digestion and different levels of oil addition that research reported increases in COD, and; consequently, in carbon similar to those in the present study.

Conversely, when the levels of waste cooking oil inclusion were exceeded, the process was hampered with decreased reduction values of these constituents. This behavior may be related to lipid metabolism by microorganisms, as considered by SILVESTRE et al. (2011SILVESTRE, G. et al. Biomass adaptation over anaerobic co-digestion of sewage sludge and trapped grease waste. Bioresource Technology , v.102, p.6830-6836, 2011. Available from: http://www.sciencedirect.com/science/article/pii/S096085241100513X>. Accessed: Jan. 20, 2015. doi: 10.1016/j.biortech.2011.04.019.

http://www.sciencedirect.com/science/art...

), who reported that, at first, fats are hydrolyzed into long-chain fatty acids (LCFA) and glycerol. LCFA may inhibit the degradation process due to the toxicity caused by the accumulation of acids in the digestion medium, which leads to excess acidity and hinders nutrient transfer into the cells by depositing onto the microbial cell membrane (NEVES et al., 2009NEVES, L. et al. Co-digestion of cow manure, food waste and intermittent input of fat. Bioresource Technology , v.100, p.1957-196, 2009. Available from: http://www.sciencedirect.com/science/article/pii/S0960852408008821>. Accessed: Fev. 15, 2015. doi: 10.1016/j.biortech.2008.10.030.

http://www.sciencedirect.com/science/art...

). After this initial degradation of lipid residues with formation of LCFA and glycerol, the residues can be processed into methane and, consequently, the fermenting material will reduce (SILVESTRE et al., 2011SILVESTRE, G. et al. Biomass adaptation over anaerobic co-digestion of sewage sludge and trapped grease waste. Bioresource Technology , v.102, p.6830-6836, 2011. Available from: http://www.sciencedirect.com/science/article/pii/S096085241100513X>. Accessed: Jan. 20, 2015. doi: 10.1016/j.biortech.2011.04.019.

http://www.sciencedirect.com/science/art...

). Thus, reductions in solid constituents are directly associated with biogas yield since anaerobes produce biogas when they break down organic matter.

Specific biogas yield

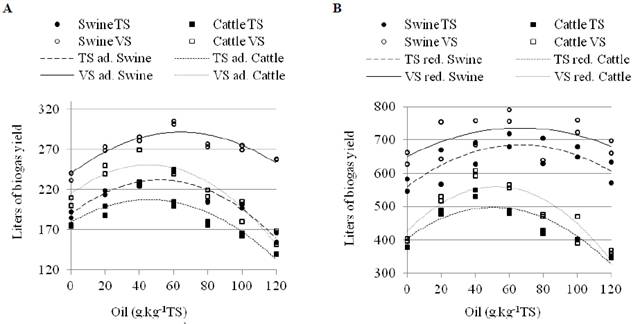

Results of specific biogas yield (Table 1 and Figure 2) followed the trend seen for the reduction of solid and fibrous constituents, i.e., adding waste cooking oil at up to certain levels (45.1 to 52.3 g waste cooking oil.kg cattle manure-1 and 52 to 66.7 g waste cooking oil.kg swine manure-1) benefited the breakdown process since this component complements manures characteristics.

Regardless of the parameter assessed, swine manure was able to receive higher oil concentrations and; consequently, had higher specific yields of biogas. The highest values of TS and VS added (232.1 and 291.2L biogas.kg manure-1, respectively) (Table 1 and Figure 2) were obtained by adding 52 and 64g waste cooking oil.kg manure-1, respectively. These values are similar to the ones reported by ORRICO et al. (2015ORRICO, ACA. et al. Anaerobic co-digestion of swine manure and increasing levels of discarded oil. Engenharia Agrícola, v. 35, p. 657-664, 2015. Available from: http://www.scielo.br/scielo.php?script=sci_abstract&pid=S0100-69162015000400657&lng=en&nrm=iso&tlng=en>. Accessed: Nov. 09, 2017. doi: 10.1590/1809-4430.

http://www.scielo.br/scielo.php?script=s...

) when studying co-digestion of swine manure and different levels of waste cooking oil inclusions. Those authors reported maximum yield of 263.6L biogas.kg VS added-1 when 6.08% oil were added, which justified recommending co-digestion.

Specific yield of biogas (in L.kg-1) per kg of TS and VS added (A) or reduced (B) per substrate prepared with dairy cattle or swine manure and increasing levels of waste cooking oil inclusion.

Likewise, specific biogas yields by dairy cattle manure were enhanced (251L biogas.kg VS added-1) when 45.1g waste cooking oil.kg manure-1 were added, which matches YAMASHIRO et al. (2013YAMASHIRO, T. et al. Anaerobic co-digestion of dairy cow manure and high concentrated food processing waste. Journal of Material Cycles and Waste Management, v.15, p.539-547, 2013. Available from: https://link.springer.com/journal/10163>. Accessed: Jan. 16, 2015.

https://link.springer.com/journal/10163...

) and SIMM et al. (2017SIMM, S. et al. Crude glycerin in anaerobic co-digestion of dairy cattle manure increases methane production. Scientia Agricola, v. 74, p. 175-179, 2017. Available from: http://www.scielo.br/scielo.php?script=sci_arttext&pid=S010390162017000300175&lng=en&tlng=en>. Accessed: Nov. 09, 2017. doi: 10.1590/1678-992x-2016-0057.

http://www.scielo.br/scielo.php?script=s...

). Those studies reported, respectively, 254.6L biogas.kg VS-1 and 250L biogas.kg TS added-1 during the co-digestion of cattle manure and residues with high lipid content. These values; however, were lower than the ones observed for swine substrates since biogas yield may have been hampered by the high fiber content in the material, which is difficult for anaerobic microorganisms to break down. Adding a more easily degradable material, i.e., waste cooking oil, may have allowed more available sources of C for microbial metabolization to be added and; consequently, increased biogas yield (ORRICO JUNIOR & ORRICO, 2015ORRICO JUNIOR, MAP.; ORRICO, ACA. Quantification, characterization, and anaerobic digestion of sheep manure: the influence of diet and addition of crude glycerin. Environmental Progress & Sustainable Energy, v.34, p.1038-1043, 2015. Available from: http://onlinelibrary.wiley.com/wol1/doi/10.1002/ep.12097/full>. Accessed: Nov. 09, 2017. doi: 10.1002/ep.12097.

http://onlinelibrary.wiley.com/wol1/doi/...

).

Specific biogas yields increased regardless of the animal manure used when associated with certain levels of waste cooking oil (45.1 to 52.3g waste cooking oil.kg cattle manure-1 and 52 to 66.7g waste cooking oil.kg swine manure-1). That may be related to what HUNTER LONG et al. (2012HUNTER LONG, J. et al. Anaerobic co-digestion of fat, oil, and grease (FOG): A review of gas production and process limitations. Process Safety and Environmental Protection, v.90, p.231-245, 2012. Available from: http://www.sciencedirect.com/science/article/pii/S0957582011001054>. Accessed: Fev. 7, 2015. doi: 10.1016/j.psep.2011.10.001.

http://www.sciencedirect.com/science/art...

) describe regarding nutrient supply to fermenting microorganisms since meeting this requirement would provide better nutritional conditions for the microorganisms involved in the process and; consequently, for biogas yield. ZHANG et al. (2013ZHANG, C. et al. The anaerobic co-digestion of food waste and cattle manure. Bioresource Technology , v.129, p.170-176, 2013. Available from: http://www.sciencedirect.com/science/article/pii/S0960852412016471>. Accessed: Fev. 20, 2015. doi: 10.1016/j.biortech.2012.10.138

http://www.sciencedirect.com/science/art...

) recommends using a 15:1 ratio of carbon during the co-digestion process, which will change as a function of substrates analyzed. Using animal manure provides the greatest source of nitrogen and oily residues (HUNTER LONG et al., 2012HUNTER LONG, J. et al. Anaerobic co-digestion of fat, oil, and grease (FOG): A review of gas production and process limitations. Process Safety and Environmental Protection, v.90, p.231-245, 2012. Available from: http://www.sciencedirect.com/science/article/pii/S0957582011001054>. Accessed: Fev. 7, 2015. doi: 10.1016/j.psep.2011.10.001.

http://www.sciencedirect.com/science/art...

), thus, adding waste cooking oil to animal manure enhances organic matter breakdown and; consequently, biogas yield.

Adding over 66.7g waste cooking oil.kg manure-1 decreased specific biogas yields likely due to the accumulation of acids in the digestion medium as reported by RODRIGUES et al. (2014RODRIGUES, JP. et al. Adding oil and lipase on the anaerobic digestion of pig manure. Ciência Rural, v.44, n.3, p.544-547, 2014. Available from: http://www.scielo.br/pdf/cr/v44n3/a9014cr2013-0212.pdf>. Accessed: Nov. 09, 2017. doi: 10.1590/S0103-84782014000300025.

http://www.scielo.br/pdf/cr/v44n3/a9014c...

) when studying swine manure co-digestion with different levels of oil and lipase, which was attributed to excess of LCFA yields from the breakdown of oily compounds. Decrease in biogas yield is related to the metabolism of lipids since they are hydrolyzed into LCFA and glycerol (SILVESTRE et al., 2011SILVESTRE, G. et al. Biomass adaptation over anaerobic co-digestion of sewage sludge and trapped grease waste. Bioresource Technology , v.102, p.6830-6836, 2011. Available from: http://www.sciencedirect.com/science/article/pii/S096085241100513X>. Accessed: Jan. 20, 2015. doi: 10.1016/j.biortech.2011.04.019.

http://www.sciencedirect.com/science/art...

) and later processed into biogas, which causes toxicity to the system because LCFA are adsorbed onto microbial cell membranes and affect their functionality (ASTALS et al., 2014ASTALS, S. et al. Identification of synergistic impacts during anaerobic co-digestion of organic wastes. Bioresource Technology, v.169, p.421-427, 2014. Available from: http://www.sciencedirect.com/science/article/pii/S0960852414009894>. Accessed: Fev. 10, 2015. doi: 10.1016/j.biortech.2014.07.024.

http://www.sciencedirect.com/science/art...

; MATA-ALVAREZ et al., 2014MATA-ALVAREZ, J. et al. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renewable and Sustainable Energy Reviews, v.36, p.412-27, 2014. Available from: http://www.sciencedirect.com/science/article/pii/S1364032114002664>. Accessed: Mar. 15, 2015. doi: 10.1016/j.rser.2014.04.039.

http://www.sciencedirect.com/science/art...

). In contrast, FIERRO et al. (2014FIERRO, J. et al. Valorisation of used cooking oil sludge by codigestion with swine manure. Waste Management, v.34, p.1537-1545, 2014. Available from: https://www.sciencedirect.com/science/article/pii/S0956053X14000580>. Accessed: Nov. 10, 2017. doi: 10.1016/j. wasman.2014.02.006.

https://www.sciencedirect.com/science/ar...

) reported no effect of toxicity when assessing the co-digestion of swine manure and lipid-rich residues since they worked with low inclusions (maximum of 25g waste cooking oil.kg manure-1). However, those authors reported acids initially accumulated in the medium (1,674±229mg.L acetic acid-1 on day 8), which were then converted into biogas. If the concentration of acids in the medium after digestion were higher, that could cause the process to fail.

Thus, it can be assumed that inclusions above 66.7g waste cooking oil.kg manure-1 cause system overload since those conditions led to low pH values, characterizing an acid medium in the biodigester, possibly because of LCFA accumulation in the digestion medium and consequent hindrance of nutrient transport through the membrane into microbial cells, culminating in process failure.

CONCLUSION:

Results obtained indicate that waste cooking oil can be used as co-substrate in anaerobic biodigestion processes using cattle and swine manure. Reductions of solids and fibrous constituents are maximized when 47.4 to 69.4g waste cooking oil.kg manure-1 are added and specific biodigestion yields are enhanced when 45.6 to 66.7g waste cooking oil.kg manure-1 are added. Inclusions can be higher for swine manure due to the easy breakdown of organic compounds.

ACKNOWLEDGMENTS

This research was carried out with the financial support of the Federal University of Grande Dourados (UFGD) and of the Foundation for the Support to the Development of Teaching, Science and Technology of the state of Mato Grosso do Sul (Fundect), besides the post-doctorate scholarship provided by the Coordination for the Improvement of Higher Level Personnel (CAPES).

REFERENCES:

- APHA - American Public Health Association. Standard methods for examination of water and wastewater. 21th ed. American Water Works Association, 2005.

- ASTALS, S. et al. Identification of synergistic impacts during anaerobic co-digestion of organic wastes. Bioresource Technology, v.169, p.421-427, 2014. Available from: http://www.sciencedirect.com/science/article/pii/S0960852414009894>. Accessed: Fev. 10, 2015. doi: 10.1016/j.biortech.2014.07.024.

» https://doi.org/10.1016/j.biortech.2014.07.024.» http://www.sciencedirect.com/science/article/pii/S0960852414009894 - DETMANN, E. et al. Métodos para análise de alimentos. INCT-Ciência Animal. 1 ed: 214p. 2012.

- FIERRO, J. et al. Valorisation of used cooking oil sludge by codigestion with swine manure. Waste Management, v.34, p.1537-1545, 2014. Available from: https://www.sciencedirect.com/science/article/pii/S0956053X14000580>. Accessed: Nov. 10, 2017. doi: 10.1016/j. wasman.2014.02.006.

» https://doi.org/10.1016/j. wasman.2014.02.006.» https://www.sciencedirect.com/science/article/pii/S0956053X14000580 - HUNTER LONG, J. et al. Anaerobic co-digestion of fat, oil, and grease (FOG): A review of gas production and process limitations. Process Safety and Environmental Protection, v.90, p.231-245, 2012. Available from: http://www.sciencedirect.com/science/article/pii/S0957582011001054>. Accessed: Fev. 7, 2015. doi: 10.1016/j.psep.2011.10.001.

» https://doi.org/10.1016/j.psep.2011.10.001.» http://www.sciencedirect.com/science/article/pii/S0957582011001054 - IBGE - Instituto Brasileiro de Geografia e Estatística. Indicadores do IBGE - Estatística da produção pecuária setembro de 2017, 2017. 47 p. CEPAGRO.

- MATA-ALVAREZ, J. et al. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renewable and Sustainable Energy Reviews, v.36, p.412-27, 2014. Available from: http://www.sciencedirect.com/science/article/pii/S1364032114002664>. Accessed: Mar. 15, 2015. doi: 10.1016/j.rser.2014.04.039.

» https://doi.org/10.1016/j.rser.2014.04.039.» http://www.sciencedirect.com/science/article/pii/S1364032114002664 - MONGKOLTHANARUKA, W.; DHARMSTHITI, S. Biodegradation of lipid-richwastewater by a mixed bacterial consortium. International Biodeterioration & Biodegradation, v. 50, p. 101 - 105, 2002. Available from: http://www.sciencedirect.com/science/article/pii/S0964830502000574>. Accessed: Nov. 10, 2017. doi: 10.1016/S0964-8305(02)00057-4.

» https://doi.org/10.1016/S0964-8305(02)00057-4.» http://www.sciencedirect.com/science/article/pii/S0964830502000574 - NEVES, L. et al. Co-digestion of cow manure, food waste and intermittent input of fat. Bioresource Technology , v.100, p.1957-196, 2009. Available from: http://www.sciencedirect.com/science/article/pii/S0960852408008821>. Accessed: Fev. 15, 2015. doi: 10.1016/j.biortech.2008.10.030.

» https://doi.org/10.1016/j.biortech.2008.10.030.» http://www.sciencedirect.com/science/article/pii/S0960852408008821 - OGEDA, T.L.; PETRI, D.F.S. Biomass Enzymatic Hydrolysis. Química. Nova, v.33, p.1549-1558, 2010. Available from: http://www.scielo.br/scielo.php?pid=S0100-40422010000700023&script=sci_abstract&tlng=ES>. Accessed: Fev. 10, 2015. doi: 10.1590/S0100-40422010000700023.

» https://doi.org/10.1590/S0100-40422010000700023.» http://www.scielo.br/scielo.php?pid=S0100-40422010000700023&script=sci_abstract&tlng=ES - ORRICO, ACA. et al. Anaerobic co-digestion of swine manure and increasing levels of discarded oil. Engenharia Agrícola, v. 35, p. 657-664, 2015. Available from: http://www.scielo.br/scielo.php?script=sci_abstract&pid=S0100-69162015000400657&lng=en&nrm=iso&tlng=en>. Accessed: Nov. 09, 2017. doi: 10.1590/1809-4430.

» https://doi.org/10.1590/1809-4430.» http://www.scielo.br/scielo.php?script=sci_abstract&pid=S0100-69162015000400657&lng=en&nrm=iso&tlng=en - ORRICO JUNIOR, MAP.; ORRICO, ACA. Quantification, characterization, and anaerobic digestion of sheep manure: the influence of diet and addition of crude glycerin. Environmental Progress & Sustainable Energy, v.34, p.1038-1043, 2015. Available from: http://onlinelibrary.wiley.com/wol1/doi/10.1002/ep.12097/full>. Accessed: Nov. 09, 2017. doi: 10.1002/ep.12097.

» https://doi.org/10.1002/ep.12097.» http://onlinelibrary.wiley.com/wol1/doi/10.1002/ep.12097/full - RODRIGUES, JP. et al. Adding oil and lipase on the anaerobic digestion of pig manure. Ciência Rural, v.44, n.3, p.544-547, 2014. Available from: http://www.scielo.br/pdf/cr/v44n3/a9014cr2013-0212.pdf>. Accessed: Nov. 09, 2017. doi: 10.1590/S0103-84782014000300025.

» https://doi.org/10.1590/S0103-84782014000300025.» http://www.scielo.br/pdf/cr/v44n3/a9014cr2013-0212.pdf - SILVESTRE, G. et al. Biomass adaptation over anaerobic co-digestion of sewage sludge and trapped grease waste. Bioresource Technology , v.102, p.6830-6836, 2011. Available from: http://www.sciencedirect.com/science/article/pii/S096085241100513X>. Accessed: Jan. 20, 2015. doi: 10.1016/j.biortech.2011.04.019.

» https://doi.org/10.1016/j.biortech.2011.04.019.» http://www.sciencedirect.com/science/article/pii/S096085241100513X - SIMM, S. et al. Crude glycerin in anaerobic co-digestion of dairy cattle manure increases methane production. Scientia Agricola, v. 74, p. 175-179, 2017. Available from: http://www.scielo.br/scielo.php?script=sci_arttext&pid=S010390162017000300175&lng=en&tlng=en>. Accessed: Nov. 09, 2017. doi: 10.1590/1678-992x-2016-0057.

» https://doi.org/10.1590/1678-992x-2016-0057.» http://www.scielo.br/scielo.php?script=sci_arttext&pid=S010390162017000300175&lng=en&tlng=en - WAN, C. et al. Semi-continuous anaerobic co-digestion of thickened waste activated sludge and fat, oil and grease. Waste Management, v.31, p.1752-1758, 2011. Available from: http://www.sciencedirect.com/science/article/pii/S0956053X11001772>. Accessed: Jan. 13, 2015. doi: 10.1016/j.wasman.2011.03.025.

» https://doi.org/10.1016/j.wasman.2011.03.025.» http://www.sciencedirect.com/science/article/pii/S0956053X11001772 - YAMASHIRO, T. et al. Anaerobic co-digestion of dairy cow manure and high concentrated food processing waste. Journal of Material Cycles and Waste Management, v.15, p.539-547, 2013. Available from: https://link.springer.com/journal/10163>. Accessed: Jan. 16, 2015.

» https://link.springer.com/journal/10163 - ZHANG, C. et al. The anaerobic co-digestion of food waste and cattle manure. Bioresource Technology , v.129, p.170-176, 2013. Available from: http://www.sciencedirect.com/science/article/pii/S0960852412016471>. Accessed: Fev. 20, 2015. doi: 10.1016/j.biortech.2012.10.138

» https://doi.org/10.1016/j.biortech.2012.10.138» http://www.sciencedirect.com/science/article/pii/S0960852412016471

-

0

CR-2017-0517.R2

Publication Dates

-

Publication in this collection

2018

History

-

Received

26 July 2017 -

Accepted

30 May 2018 -

Reviewed

25 June 2018