Abstracts

The sustainability of intensive swine production demands alternative destinations for the generated residues. Ashes from swine rice husk-based deep bedding were tested as a mineral addition for cement mortars. The ashes were obtained at 400 to 600ºC, ground and sieved through a 325 mesh sieve (# 0.045 mm). The characterization of the ashes included the determination of the index of pozzolanic activity with lime. The ashes were also tested as partial substitutes of Portland cement. The mortars were prepared using a cement:sand proportion of 1:1.5, and with water/cement ratio of 0.4. Three percentages of mass substitution of the cement were tested: 10, 20 and 30%. Mortar performances were assessed at 7 and 28 days determining their compressive strength. The chosen condition for calcinations at the laboratory scale was related to the maximum temperature of 600ºC since the resulting ashes contained vitreous materials and presented satisfactory values for the pozzolanic index under analysis. The pozzolanic activity indicated promising results for ashes produced at 600ºC as a replacement of up to 30% in cement masses.

rice husk; pozzolanicity; vitreous silica; sustainability

A sustentabilidade das regiões de produção intensiva de suínos requer destinos alternativos para os resíduos gerados. Cinzas de cama sobreposta de suínos à base casca de arroz, foram testadas como adição mineral em substituição ao cimento. As cinzas foram obtidas nas temperaturas de 400 a 600ºC, moídas e passadas por peneira ABNT 325 (# 0,045 mm). A caracterização de cinzas incluiu a determinação do índice de atividade pozolânica com a cal. As cinzas também foram testadas como substitutos parciais de cimento Portland. As argamassas foram preparadas na proporção cimento:areia de 1:1,5 e com fator água-cimento de 0,4. Três porcentagens de substituição do cimento comercial foram usadas: 10, 20 e 30% em massa. O desempenho das argamassas foi avaliado aos 7 e aos 28 dias com a determinação da resistência à compressão axial. A condição escolhida para calcinações em escala laboratorial foi associada à temperatura máxima de 600ºC, uma vez que as cinzas resultantes continham material vítreo e apresentavam valores satisfatórios para o índice de pozolanicidade em análise. A atividade pozolânica indicou resultados promissores para as cinzas produzidas a 600ºC e com substituição de até 30% em massa de cimento.

casca de arroz; pozolanicidade; sílica vítrea; sustentabilidade

AGRICULTURAL ENGINEERING

Swine deep bedding ashes as a mineral additive for cement based mortar

Cinzas de cama sobreposta de suínos como adição mineral em argamassas de cimento

Melissa Selaysim Di CamposI; Normando Perazzo BarbosaII; Holmer Savastano Jr.I, * * Corresponding author < holmersj@usp.br>

IUSP/FZEA - Depto. de Engenharia de Alimentos, C.P. 23 - 13635-900 - Pirassununga, SP - Brasil

IIUFPB - Centro de Tecnologia, Cidade Universitária - 58059-900 - João Pessoa, PB - Brasil

ABSTRACT

The sustainability of intensive swine production demands alternative destinations for the generated residues. Ashes from swine rice husk-based deep bedding were tested as a mineral addition for cement mortars. The ashes were obtained at 400 to 600ºC, ground and sieved through a 325 mesh sieve (# 0.045 mm). The characterization of the ashes included the determination of the index of pozzolanic activity with lime. The ashes were also tested as partial substitutes of Portland cement. The mortars were prepared using a cement:sand proportion of 1:1.5, and with water/cement ratio of 0.4. Three percentages of mass substitution of the cement were tested: 10, 20 and 30%. Mortar performances were assessed at 7 and 28 days determining their compressive strength. The chosen condition for calcinations at the laboratory scale was related to the maximum temperature of 600ºC since the resulting ashes contained vitreous materials and presented satisfactory values for the pozzolanic index under analysis. The pozzolanic activity indicated promising results for ashes produced at 600ºC as a replacement of up to 30% in cement masses.

Key words: rice husk, pozzolanicity, vitreous silica, sustainability

RESUMO

A sustentabilidade das regiões de produção intensiva de suínos requer destinos alternativos para os resíduos gerados. Cinzas de cama sobreposta de suínos à base casca de arroz, foram testadas como adição mineral em substituição ao cimento. As cinzas foram obtidas nas temperaturas de 400 a 600ºC, moídas e passadas por peneira ABNT 325 (# 0,045 mm). A caracterização de cinzas incluiu a determinação do índice de atividade pozolânica com a cal. As cinzas também foram testadas como substitutos parciais de cimento Portland. As argamassas foram preparadas na proporção cimento:areia de 1:1,5 e com fator água-cimento de 0,4. Três porcentagens de substituição do cimento comercial foram usadas: 10, 20 e 30% em massa. O desempenho das argamassas foi avaliado aos 7 e aos 28 dias com a determinação da resistência à compressão axial. A condição escolhida para calcinações em escala laboratorial foi associada à temperatura máxima de 600ºC, uma vez que as cinzas resultantes continham material vítreo e apresentavam valores satisfatórios para o índice de pozolanicidade em análise. A atividade pozolânica indicou resultados promissores para as cinzas produzidas a 600ºC e com substituição de até 30% em massa de cimento.

Palavras-chave: casca de arroz, pozolanicidade, sílica vítrea, sustentabilidade

INTRODUCTION

Environmental sustainability in intensive production areas is a challenge for swine producers. According to data of the Swine Breeders Association from the State of Rio Grande do Sul, Brazil, the number of animals ready for consumption increased 1,000% in some municipal districts in the last five years (ACSURS, 2005), demanding alternative ways for the utilization of the generated residues.

The production of swines in deep bedding elicits the use of excrements for manuring instead of discarding them in the environment. Deep bedding usually includes rice husk, sugar cane bagasse or other available straws. However, the use of the deep bedding for fertilization is restricted to intensive planted areas and can cause soil and water contamination as a result of high content of organic and chemical nitrogen (Konzen et al., 2002). In association with considerable costs, storage and transportation difficulties, this fact demands for alternative destinations for swine bedding.

Calcination is a common way to reduce the volume of these materials. If this operation is carried out under controlled atmosphere and temperature, the generated ashes can meet the requirements for specific uses in civil construction (Ghavami et al., 1999). A good example is the incorporation of the ashes or other residual material with pozzolanic activity in cementitious composites for the improvement of their properties and of their durability as well. The use of those pozzolans can also contribute to the economy of energy and reduction of the environmental contamination usually related to the ordinary cement industry (John & Zordan, 2001).

The objective of this study was to evaluate different calcination temperatures (400 - 600ºC) of swine deep rice husk bedding and the performance of the obtained ashes as partial substitutes for Portland cement.

MATERIAL AND METHODS

Rice husk swine deep bedding was collected in the municipal district of Rio Verde, State of Goiás, Brazil (17°47' S; 50°55' W, 715 m altitude), coming from two finished swine lots at the final production stage. The average content of animal manure in the bedding varied from 40 to 50% (m/m). Its bromatological composition was determined as recommended by AOAC (1996).

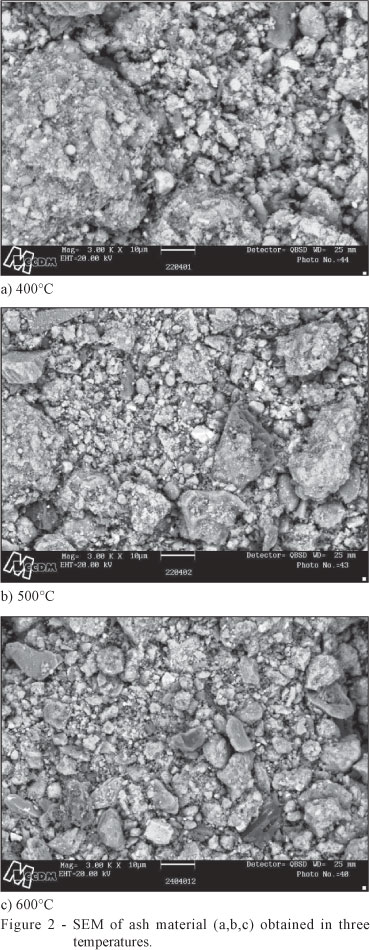

Ashes were produced by calcination of the bedding material in a muffle (Elektro Therm brand, Linn model, with controller model 50RP) with a heating ramp of 10ºC min-1 and a stabilization temperature during 2 h, followed by gradual cooling. Three different temperatures were used for calcination: 400, 500 and 600ºC. The ashes were ground in a ball mill with steel grinding media for 1 h and then passed through a 325 mesh sieve (# 0.045 mm). The physical characterization of the burned residues included the determination of density in accordance to Brazilian Standards NBR NM10 (ABNT, 2004), specific surface area using the Blaine air permeability apparatus according to NBR NM76 (ABNT, 1998), and particle size analysis by the sieving process NBR NM248 (ABNT, 2003b). The ashes were also submitted to: (i) chemical analysis, according to NBR NM10 (ABNT, 2004); (ii) X-Ray diffraction (XRD) carried out by a PANalytical equipment, model X'Pert PRO, operated with iron K-alpha radiation, 30 kV and 30 mA, scanning between 2q 15º and 110º, with X'Celerator detector. The analysis of the X-ray diffraction (XRD) has a qualitative character because it is based on the identification of substances (crystalline phases) present in each sample. The peaks that appear in the diffractograms are characteristic for each substance. In the case of the rice husk ash, the absence of big peaks indicates the amorphous silica. The identification of crystalline phases was obtained by comparison of the sample diffractogram with the database of ICDD (2003); (iii) scanning electron microscopy (SEM) as described by Anjos et al. (2003), for the observation of the influence of calcinating temperatures on the morphology of calcinated ashes; (iv) carbon content, determined by the gravimetric method, by titration using barium hydroxide solution as described in Vogel & Jeffery (1989).

The mortar production demanded CH-I lime type (density = 2.42) following the NBR 7175 (ABNT, 2003a) specifications, CP-IIF cement type (density = 3.10) with carbonatic addition according to NBR 11578 (ABNT, 1991), normalized river sand (density = 2.61) as specified at NBR 7214 (ABNT, 1982) and polycarboxylate superplasticizer (solid contents of 30% and density = 1.12).

The index of pozzolanic activity of the ashes was performed with lime. This test followed the procedures defined in the Brazilian Standards NBR 5751 (ABNT, 1992) for the direct measurement of the pozzolanicity degree based on the axial compressive strength of the mortar specimens (NBR 7215, ABNT, 1996) at 7 days of total age. The mortar formulation was defined to contain one part of lime and nine parts of normalized sand by mass. By volume, the amount of ashes was twice as much as that of lime. The water amount in the mortar was chosen to correspond to the consistency index of (225 ± 5) mm in the flow table test (NBR 7215, ABNT, 1996). The relation between water and binder (lime + ashes) content was equal to 0.48 (m/m).

The study of cement-based mortars observed the % influence of the commercial cement substitution by the pozzolanic material obtained at 600ºC. The mortars were prepared in a 1:1.5 binder:sand proportion, and with a water-binder factor of 0.4. The amount of superplasticizer in the mixture was chosen to reach the consistency index of (225 ± 5) mm in the flow table test (NBR 7215, ABNT, 1996). Three substitutions of cement were tested: 0, 10, 20 and 30% (m/m). Three repetitions were molded for each mixture for the determination of the compressive strength after 7 and 28 days of age under curing by immersion in cold tap water.

RESULTS AND DISCUSSION

Bromatologic composition

The bromatologic composition of the swine deep bedding (% by mass) resulted in: dry matter at 105ºC, 90.07; crude protein, 13.25; crude fiber, 23.48; ether extract, 0.50; mineral matter, 28.50; acid detergent fiber, 45.41; neutral detergent fiber, 53.17; and lignin, 12.24. The mineral matter is related to the mass of ashes resulting from calcination. It is obtained by heating the sample at 600ºC during 4 h or until the total organic components combustion (AOAC, 1996).

Ash characterization

The average density of the ashes was equal to 2.16. The specific surface areas were equal to 154; 93 and 21 m2 g-1 for the ashes deriving from the calcinations at 400, 500 and 600ºC, respectively. Nagai et al. (1998) reported specific surface area of approximately 147 m2 g-1 for husk ashes calcined at 400ºC, of 5 m2 g-1 at 700ºC, and values varying from 0.4 to 0.8 m2 g-1 at calcination temperatures higher than 900ºC. The tendency of reduction of the specific surface area is related to the particle agglomeration with temperature increase. The moisture content of the air-dry ashes was around 3% (m/m), no matter the calcination temperature. Della et al. (2001) considered the range of moisture from 1 to 4% as acceptable. Table 1 presents the results of the particle size distribution of the dry ashes by mesh sieving after preparation by grinding for 2 h.

The ashes from the three calcination conditions showed similar compositions (Table 2). The loss due to ignition for the three calcination temperatures are 9.2% (400ºC), 9.4% (500ºC) and 9.7% (600ºC), and the average carbon content was 8.6% (400ºC), 8.8% (500ºC) and 9.0% (600ºC). The increase or decrease in the amount of carbon in the rice husk ash is a consequence of the availability of free oxygen during the combustion process. The sum of silica, aluminum and iron oxides contents varied from 68 to 70%, which is near to the 65% inferior limit of these oxides defined by ASTM C-618 (2003). The high content of sodium and potassium oxides are not desirable for several applications as they can bring potential problems of efflorescence and alkali-aggregate reaction in cement based mortars (Taylor, 1997). The high content of calcium, phosphorus, aluminum and iron oxides are not in agreement with the chemical composition of rice husk ashes found in the literature (John et al., 2003 and Salas et al., 1988). Such a discrepancy could be understood by the presence of manure and food wastes in the swine deep bedding. Konzen et al. (2002) determined the following composition of nutrients in the swine deep bedding (kg t-1): nitrogen, 29.6; phosphorus, 40.0; potassium, 37.5; calcium, 22.0 and magnesium, 6.9.

The limit values for the chemical composition of silica fume as stated in the Brazilian Standards NBR 13956 (ABNT, 1997), did not reach the minimum amount of silica (Table 3). The comparison of the experimental results with the limits suggested by the international Standards ASTM C-618 (2003) for calcined natural pozzolans and coal fly ashes seems to be more appropriate for the residual material under evaluation.

The deep bedding ashes presented values of loss by ignition higher than the recommended limit as shown in Tables 2 and 3. Dafico (2001) and Ismail & Waliuddin (1996) encountered values of 11.8% and 8.9% in their determinations on the loss by ignition of rice husk ash. According to Oda (2003), this fact is not a problem and it only indicates that the time of calcination was not enough for the total removal of the carbon under determined calcination conditions, even if the temperature is equal to that considered as ideal. The dark color of the ashes indicate the presence of carbon.

The X-ray diffraction analyses indicate peaks of crystalline compounds based on silicon (Figure 1), aluminum, calcium and iron, which could be related to the main ash constituents (Table 2). The X-ray patterns for 400ºC and 500ºC presented two different forms of silica: quartz and coesite. At 400ºC a quartz and at 500ºC b quartz were detected, however, in both cases the quartzes are in the crystalline form. Dafico (2001) observed this transformation from a to b quartz at 573ºC in a study of rice husk ash. In the present case the transformation of phase took place at lower temperatures than 500ºC, probably due to the impurities of the material under consideration. At 600ºC b quartz and coesite still remained present in the X-ray patterns and at this temperature hedenbergite (Calcium Iron Silicate - Ca FeSi2O6) and a polymorph formation were also detected with the increase of the temperature with hexagonal structure (beta-tridymite). Cristobalite was not observed in the present range of temperatures from 400 - 600ºC.

The presence of reactive (vitreous) or inert (crystalline) silica is directly related to the temperature and method used for ash production. Della et al. (2001) noticed the vitreous silica predominance in the rice husk ash composition resulting from the exposure to high temperatures in the interval from 500 to 700ºC and during short periods of time. Mehta (1992) carried out experimental studies aiming to the determination of optimum conditions of calcination for the production of ashes with pozzolanic reactivity. The results indicated the predominance of amorphous silica with internal porosity varying from 50 to 100 m2 g-1 measured with nitrogen adsorption, for calcination temperatures in the interval of 500 to 700ºC.

The images produced by SEM provide a visual indication of the distribution of the particle sizes, but this technique is very difficult to be used as a routine method (Oda, 2003). The SEM analyses (Figure 2) indicate the presence of rounded grains. This morphology could be favorable for packing with other constituents of cement based materials and also for pozzolanic reactions with calcium hydroxide released from cement hydration (Taylor, 1997). One could observe that the particles are agglomerated, but it is possible to distinguish the spherical morphology of the grains. The dimension of grains was lower than 0.045 mm (passing thru # 325 sieve). Oda (2003) obtained particles with dimensions in the 0.1-0.5 µm interval when studying rice husk ash addition to Portland cement matrixes.

Index of pozzolanic activity with lime

The pozzolanicity index acquisition with lime for the ashes produced at the three different temperatures (Table 4) shows that the material is considered a pozzolan if the mechanical strength of the mortars molded in cylindrical specimens and tested in axial compression is equal or greater than 5.5 MPa at 7 days (NBR 5751, ABNT, 1992). The pozzolanic activity increased in an almost linear way inside the chosen range of temperatures. The 400ºC calcination resulted in mortars under the inferior acceptable limit. At the 500ºC calcination, the performance of the mortar was equal to 5.5 MPa. The increase of the calcination temperature to 600ºC resulted in satisfactory performance of the ashes, which is similar to that obtained with commercial silica fume (compressive strength of 6.2 MPa) in another stage of this experimental work (Di Campos, 2005). Salas et al. (1986) obtained average results of 7.0 MPa, when they tested the rice husk ashes (7 days of age) incinerated at 700ºC.

Mechanical performance of cement-based mortars

The compressive strength of cement-based mortars with 7 and 28 days of age are depicted in Table 5. Ashes obtained at 600ºC were applied in three different amounts as partial substitutes of the main binder. A control series with 0% (m/m) of ashes achieved 24.9 and 28.1 MPa of average compressive strength at 7 and 28 days, respectively.

Mortars with partial substitution of cement by ashes at the age of 7 days showed compressive strength in excess of 30 MPa. This mechanical behavior can be a consequence of both chemical reaction of pozzolanic material and packing effect due to the mixture of particles with different dimensions. The chemical reaction of the constituents of ordinary Portland cement and between the calcium hydroxide originated from OPC hydration and the vitreous silica are the main reason for the increase of the mechanical strength from 7 until 28 days of age. The reaction of silica fume is slower than the hydration of OPC because it depends on the liberation of the calcium hydroxide originated from OPC hydration (Taylor, 1997).

The apparent difference between the three series with 10, 20 and 30% of ashes content can be explained by the use of the average result for each series. There is a considerable variation between the individual results of each series under analysis (Table 5). In the relation to technology of cement based materials it is acceptable to consider the highest individual value as the potential strength since the smaller results could be a consequence of improper preparation of the specimens. According to this approach one could consider that there is no significant difference between the compressive strength of the three mortars with partial substitution of OPC for 7 and 28 days of age.

Although the specimens of mortar with 10% of ashes reached the higher average strength at 28 days, the corresponding values for 20 and 30% of substitution were very similar and should not be disregarded in this exploratory study. These results are, at least, 22% greater than the control series of strength.

CONCLUSIONS

Ashes from calcination of rice husk deep bedding contained 42% (m/m) of silica oxide and the sum of silica, aluminum and iron oxides was in the vicinity of 70% (m/m). These figures are lower than those obtained from sole rice husk calcination and such characteristics can be explained by the presence of manure and other impurities in the raw material collected after swine production. The chosen condition for calcination at the laboratory scale was related to the maximum temperature of 600ºC as the resulting ashes contained vitreous material and presented satisfactory values for the pozzolanic index under analysis. The compressive strength of cement based mortars increased in relation to the reference mortar even for the 30% (m/m) substitution in Portland cement using the produced ashes.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the financial support and grants received from Capes Procad and CNPq. They are also in debt with Antônio Correia Braga Filho, Flávio Eduardo Gomes Diniz, Marília Pereira de Oliveira and Sérgio Ricardo Honório de Assis of the Center of Technology of the Federal University of Paraíba (CT - UFPB) for their skilful assistance.

Received August 30, 2005

Accepted November 14, 2007

- American Society for Testing and Materials - ASTM. ASTM C618-03: Standard specification for coal fly ash and raw or calcined natural pozzolan for use as a mineral admixture in concrete. West Conshohocken: ASTM, 2003. 3p.

- ANJOS, M.A.S.; GHAVAMI, K.; BARBOSA, N.P. Compósitos à base de cimento reforçado com polpa celulósica de bamboo. Parte II. uso de resíduos cerâmicos na matriz. Revista Brasileira de Engenharia Agrícola e Ambiental, v.7, p.346-349, 2003.

- Associação Brasileira de Normas Técnicas - ABNT. NBR 7214: areia normal para ensaio de cimento. Rio de Janeiro: ABNT, 1982. 7p.

- Associação Brasileira de Normas Técnicas - ABNT. NBR 11578: cimento Portland composto. Rio de Janeiro: ABNT, 1991. 5p.

- Associação Brasileira de Normas Técnicas - ABNT. NBR 5751: materiais pozolânicos; determinação da atividade pozolânica;- índice de atividade pozolânica com cal. Rio de Janeiro: ABNT, 1992. 3p.

- Associação Brasileira de Normas Técnicas - ABNT. NBR 7215: cimento Portland; determinação da resistência à compressão. Rio de Janeiro: ABNT, 1996. 8p.

- Associação Brasileira de Normas Técnicas - ABNT. NBR 13956: sílica ativa para uso em cimento Portland; concreto, argamassa e pasta de cimento Portland; especificação. Rio de Janeiro: ABNT, 1997. 3p.

- Associação Brasileira de Normas Técnicas - ABNT. NBR NM76: cimento Portland; determinação da finura pelo método de permeabilidade ao ar (método de Blaine). Rio de Janeiro: ABNT, 1998. 12p.

- Associação Brasileira de Normas Técnicas - ABNT. NBR 7175: Cal hidratada para argamassas; requisitos. Rio de Janeiro: ABNT, 2003a. 4p.

- Associação Brasileira de Normas Técnicas - ABNT. NBR NM248: Agregado; determinação da composição granulométrica. Rio de Janeiro: ABNT, 2003b. 6p.

- Associação Brasileira de Normas Técnicas - ABNT. NBR NM10: cimento Portland; análise química; disposições gerais. Rio de Janeiro: ABNT, 2004. 5p.

- Associação dos criadores de suínos do Rio Grande do Sul - ACSURS. Swine Creators Association of Rio Grande do Sul, Brazil Available at: http://www.acsurs.com.br/Os%20Desafios%20Globais%20dos%20Mercados%20de%20 Carne%20Suína.pdf . Accessed 08 Jul. 2005.

- Association of Official Analytical Chemists - AOAC. Official methods of analysis 16.ed. Hellis Horwood: AOAC International, 1996. 2v.

- DAFICO, D.A. Estudo da dosagem de alto desempenho utilizando pozolanas provenientes da casca de arroz. Florianópolis: Universidade Federal de Santa Catarina, 2001. 191p. Tese (Doutorado).

- DELLA, V.P.; KUHN, I.; HOTZA, D. Characterization of rice husk ash for use as raw material in the manufacture of silica refractory. Química Nova, v.24, p.778-782, 2001.

- DI CAMPOS, M.S. Aproveitamento das cinzas da queima da cama sobreposta de suínos como substituição parcial do cimento Portland. Pirassununga: USP/FZEA, 2005. 134p. Dissertação (Mestrado).

- GHAVAMI, K.; TOLÊDO FILHO, R.D.; BARBOSA, N.P. Behavior of composite soil reinforced with natural fibers. Cement & Concrete Composites, v.21, p.39-48, 1999.

- INTERNATIONAL CENTRE FOR DIFFRACTION DATA - ICDD. Characterization techniques for miniature lowpower x-ray tubes. Advances in X-ray Analysis, v.47, p.89, 2004.

- ISMAIL, M.S.; WALIUDDIN, A.M. Effect of rice husk ash on high strength concrete. Construction and Building Materials, v.10, p.521-526, 1996.

- JOHN, V.M.; ZORDAN, S.E. Research & development methodology for recycling residues as building materials: a proposal. Waste Management, v.21, p.213-219, 2001.

- JOHN, V.M.; CINCOTTO, M.A.; SILVA, M.G. Cinzas e aglomerantes alternativos. In: FREIRE, W.J.; BERALDO, A.L. (Ed.) Tecnologias e materiais alternativos de construção Campinas: Unicamp, 2003. cap.6, p.145-190.

- KONZEN, E.A.; MENEZES, J.F.S.; ALVARENGA, R.C. Monitoramento ambiental do uso de dejetos líquidos de suínos como insumo na agricultura. 3. Efeito de doses na produtividade de milho. In: CONGRESSO NACIONAL DE MILHO E SORGO - MEIO AMBIENTE E A NOVA AGENDA PARA O AGRONEGÓCIO DE MILHO E SORGO, 14., Florianópolis, 2002. Anais Florianópolis: EMBRAPA, 2002. p.24-27.

- MEHTA, P.K. Rice husk ash: a unique supplementary cementing material. Advances in Concrete Technology, v.2, p.407-431, 1992.

- NAGAI, H.; NAKATA, Y.; SUZUKI, M.; OKUTANI, T. Structure and morphology of phenylsilanes polymer films synthesized by the plasma polymerization method. Journal of Materials Science, v.7, p.1897-1905, 1998.

- ODA, G.A. Estudo da atividade pozolânica da sílica da casca de arroz em matrizes de cimento Portland. São Carlos: EESC/USP, 2003. 115p. Dissertação (Mestrado).

- SALAS, J.; ALVAREZ, M.; GÓMEZ, G.; VERAS, J. Effect of the curing regime on compressive strength - crucial curing of rice husk ash concrete. Building Research and Practice, v.6, p.367-376, 1988.

- SALAS, J.; CASTILLO, P.; ROJAS, M.I.S. DE. Empleo de cenizas de cáscara de arroz como adiciones em morteros. Materiales de Construccion, v.36, p.21-39, 1986.

- TAYLOR, H.F.W. Cement chemistry London: Thomas Telford, 1997. 459p.

- VOGEL, A.I.; JEFFERY, G.H. Vogel's textbook of quantitative chemical analysis 5 ed. Harlow: Logman Scientific and Technical, 1989. 451p.

Publication Dates

-

Publication in this collection

31 Mar 2008 -

Date of issue

Apr 2008

History

-

Accepted

14 Nov 2007 -

Received

30 Aug 2005