Abstract

A comparative study was performed on the effect of the addition of silane coupling agents (SCA), vinyltrimethoxysilane (VTMS) and 3-aminopropyltriethoxysilane (APTES) to a mixture of styrene butadiene rubber SBR1502 with Telinne Monspessulana flour (TMF). SCA was directly added into the mixture using untreated and mercerized TMF. Also, TMF and SBR1502 mixing trials were conducted with the TMF previously mercerized and injected with each of the silanes. The rubber compounds were subjected to tensile tests in order to evaluate the coupling power of both SCA. It was found that the vinyl silane type produced the best results in the tensile strength.

Keywords:

composite; natural fiber; SBR1502; silanes

1. Introduction

Using natural fibers or wood flour as a potential filler to, at least partially, replace mineral fillers for the production of polymeric compounds is important because of the benefits offered by plant fibers. These include the fact that their low density allows the development of lighter compounds, that they are non toxic, they are biodegradable, their production can be sustainable, and they are less abrasive, increasing the service life of machinery.

SBR styrene butadiene rubber is an elastomer, widely used in the manufacture of items such as tires, hoses, footwear, packing, conveyor belts, mats, and others[11 Mark, J. E. (1999). Polymer Data Handbook. Oxford: Oxford University Press.].

There are also numerous studies that examine the effect of incorporating natural fiber with SBR rubber. For example, Kumar et al.[22 Kumar, R. P., Nair, K. C. M., Thomas, S., Schit, S. C., & Ramamurthy, K. (2000). Morphology and melt rheological behaviour of short-sisal-fibre-reinforced SBR composites. Composites Science and Technology, 60(9), 1737-1751. http://dx.doi.org/10.1016/S0266-3538(00)00057-9.

http://dx.doi.org/10.1016/S0266-3538(00)...

] analyzed the rheological behavior of SBR1502 compounds with sisal fiber, finding that these acquire pseudo-plastic behavior upon chemical treatments owing to the strong interfacial adhesion between the fibre and the rubber matrix. Wang et al blended 50 parts of SBR1502 with 50 parts of linear low density polyethylene (LLPE) with rice husks and used maleic anhydride (MA) as a compatibilizer. The mechanical properties were optimal when the concentration of MA was 2.5 parts per hundred of rubber (phr). They also mention that when more than 25 phr of rice husk was used, the dielectric properties of the composite decreased[33 Khalf, A. I., & Ward, A. (2010). Use of rice husks as potential filler in styrene butadiene rubber/linear low density polyethylene blends in the presence of maleic anhydride. Materials & Design, 31(5), 2414-2421. http://dx.doi.org/10.1016/j.matdes.2009.11.056.

http://dx.doi.org/10.1016/j.matdes.2009....

]. Kumar and Thomas[44 Kumar, R. P., & Thomas, S. (1995). Short fibre elastomer composites: effect of fibre length, orientation, loading and bonding agent. Bulletin of Materials Science, 18(8), 1021-1029. http://dx.doi.org/10.1007/BF02745189.

http://dx.doi.org/10.1007/BF02745189...

] analyzed SBR 1502 compounds with sisal fibers, finding that the tensile strength and tear resistance improved when the fiber orientation was longitudinal and its size was 6 mm in length. They also mention that the optimal concentration of sisal fiber was 35 phr.

Regarding the use of silanes to improve compatibility of natural fiber with SBR, Wang et al mixed Si69 silane with SBR 1502 and 20 phr of silica, varying the concentration of hemp flour. Adding the flour improved the vulcanization conditions, and imparted stiffness and toughness to the compound, although the excess in flour concentration leads to decrease of these mechanical properties[55 Wang, J., Wu, W., Wang, W., & Zhang, J. (2011). Preparation and characterization of hemp hurd powder filled SBR and EPDM elastomers. Journal of Polymer Research, 18(5), 1023-1032. http://dx.doi.org/10.1007/s10965-010-9503-4.

http://dx.doi.org/10.1007/s10965-010-950...

].

Generally, natural fibers are subjected to mercerization as a prelude to treatment with type SCA cupping agents; NaOH treatment allows the OH groups of cellulose to be exposed directly and thus better fiber-SCA coupling can be achieved. The grafted fiber is then mixed with the polymer[66 Fuqua, M., Huo, S., & Ulven, C. A. (2012). Natural Fiber Reinforced Composites. Polymer Reviews, 52(3), 259-320. http://dx.doi.org/10.1080/15583724.2012.705409.

http://dx.doi.org/10.1080/15583724.2012....

,77 Changjie, Y., Zhang, Q., Junwei, G., Junping, Z., Youqiang, S., & Yuhang, W. (2011). Cure characteristics and mechanical properties of styrene-butadiene rubber/hydrogenated acrylonitrile-butadiene rubber/silica composites. Journal of Polymer Research, 18(6), 2487-2494. http://dx.doi.org/10.1007/s10965-011-9670-y.

http://dx.doi.org/10.1007/s10965-011-967...

]. The coupling agent can also be added directly during the mixing of the fiber with the polymer[88 Maldas, D., Kokta, B. V., & Daneault, C. (1989). Influence of coupling agents and treatments on the mechanical properties of cellulose fiber–polystyrene composites. Journal of Applied Polymer Science, 37(3), 751-775. http://dx.doi.org/10.1002/app.1989.070370313.

http://dx.doi.org/10.1002/app.1989.07037...

].

It is important to note that any SBR compound must be cross-linked with sulfur (vulcanization), using peroxide or radiation in order to increase mechanical, chemical and thermal resistance to the respective compound[99 Basfar, A. A., Abdel-Aziz, M., & Mofti, S. (2002). Influence of different curing systems on the physico-mechanical properties and stability of SBR and NR rubbers. Radiation Physics and Chemistry, 63(1), 81-87. http://dx.doi.org/10.1016/S0969-806X(01)00486-8.

http://dx.doi.org/10.1016/S0969-806X(01)...

10 Nabil, H., Ismail, A., & Azura, R. (2014). Properties of natural rubber/recycled ethylene–propylene–diene rubber blends prepared using various vulcanizing systems. Iranian Polymer Journal, 23(1), 37-45. http://dx.doi.org/10.1007/s13726-013-0197-4.

http://dx.doi.org/10.1007/s13726-013-019...

11 Changjie, Y., Zhang, Q., Junwei, G., Junping, Z., Youqiang, S., & Yuhang, W. (2011). Cure characteristics and mechanical properties of styrene-butadiene rubber/hydrogenated acrylonitrile-butadiene rubber/silica composites. Journal of Polymer Research, 18(6), 2487-2494. http://dx.doi.org/10.1007/s10965-011-9670-y.

http://dx.doi.org/10.1007/s10965-011-967...

-1212 Shih, R.-S., Kuo, S.-W., & Chang, F.-C. (2011). Thermal and mechanical properties of microcellular thermoplastic SBS/PS/SBR blend: effect of crosslinking. Polymer, 52(3), 752-759. http://dx.doi.org/10.1016/j.polymer.2010.12.026.

http://dx.doi.org/10.1016/j.polymer.2010...

].

In our research, we analyzed the effect of the incorporation of VTMS and APTES on composites prepared with untreated SBR1502 + TMF, SBR1502 + mercerized TMF and SBR1502 + grafted TMF with SCA. By measuring the tensile properties and hardness, we comparatively evaluated the coupling effect of both silanes.

2. Materials and Methods

2.1 Materials

The following materials were used:

Telinne Monspessulana flour with a particle diameter of 400-800 µm and a humidity of 0.20%. Rubber: SBR1502 manufactured by INSA® S.A. Mexico. Coupling Agents: APTES YAC A110® of 98.41% purity produced by Nanjing Lanya Chem®. Co. Ltd., VTMS Struktol® SCA 971 of > 98.6% purity manufactured by Struktol®. Processing aid: Struktol® WB16 of Struktol®. Antioxidant: Irganox® 1076 manufactured by BASF®. Cross-linking agent DCP Perkadox® BC FF, purity 99%, produced by Akzo Nobel®.

2.2 Methods

2.2.1 Experimental design

Seven (7) tests were conducted with the base formula as seen in Table 1. All quantities remained constant.

The “Control” test was defined for the compound of SBR1502 with TMF, untreated and free of SCA. Two (2) modes of silane addition were tested: 1) direct addition of SCA during mixing of SBR1502 with TMF with no surface treatment.

Direct addition of SCA during the mixing of SBR1502 with mercerized TMF. 2) Pretreatment of mercerized TMF with SCA and later mixing with SBR1502 (see Table 2). The tensile properties of the silane were measured to assess its ability to couple the flour and the rubber.

2.2.2 Surface treatment TMF

Mercerization: Telinne Monspessulana flour was mercerized in NaOH solution at 8% for 4 hours at 35 °C, according to the methodology used by Buitrago et al.[1313 Buitrago, O., Delgado, A., & Aperador, W. (2014). Surface treatment of straight Retamo Liso (Telinne monspessulana) by silane coupling agents (SCA). Ciência e Técnica Vitivinícola, 29(12), 11-23.].

Graft silane-TMF: The flour previously mercerized was grafted with silane. The amount of SCA was 10% based on the weight of TMF. Silane was pre-hydrolyzed for one hour, the time of TMF immersion was 4 hours and drying was performed at 45 °C for 24 hours. The above procedure was performed for the APTES and VTMS following the methodology used by Buitrago et al.[1313 Buitrago, O., Delgado, A., & Aperador, W. (2014). Surface treatment of straight Retamo Liso (Telinne monspessulana) by silane coupling agents (SCA). Ciência e Técnica Vitivinícola, 29(12), 11-23.].

2.2.3 Preparation of compounds

Compounding: The preparation of the mixture was performed in a roller mill with a capacity of 600 cm3. The SBR1502 was placed on rollers until band formation. Then, immediately, 1/3 of the total TMF was added, next the SCA was added (see Table 2). TMF continued to be added slowly. When the incorporation of the flour was completed, the processing aid and antioxidant were added. The DCP was added three (3) minutes before the end of the stage. The compounding temperature was 115 ± 5 °C; the processing time was 13 minutes.

Compression molding: We used a hydraulic press heated by electrical resistance. Mold dimensions: 17 cm*17 cm and 3.6 mm of thickness.

The operating parameters were: mold temperature 160 ± 1 °C, 5.24 MPa of specific pressure, pressing time of 6 minutes.

2.2.4 Methods of analysis

Gel Percentage: It quantifies the degree of crosslinking of the compound. It was determined following the indications of ASTM D 2765-01, method A[1414 American Society for Testing and Materials – ASTM. (2001). ASTM D2765-01: standard test methods for determination of gel content and swell ratio of crosslinked ethylene plastics. West Conshohocken: ASTM.]. It is interesting to observe that soxhlet extraction diluted the non-cross-linked polymer, although it swelled the rubber compound. To determine the final weight, the samples that were subjected to extraction were dried at 50 °C for 4 hours. Subsequently they were cooled in liquid nitrogen for 24 hours, then they were pulverized and heated again at 80 °C for 4 hours to remove the solvent. The sample calculation is shown in the Equation 1.

WF and WI represent, respectively, the final and initial weight of the rubber compound, and f is the fraction of fiber in the composite.

Tensile tests: The specimen type B was used according to ASTM D412-06a standard[1515 American Society for Testing and Materials – ASTM. (2013). ASTM D412-06a: standard test methods for vulcanized rubber and thermoplastic elastomers. West Conshohocken: ASTM.]. The tests were performed on a universal machine Shimadzu® AGS-X. Test Parameters: travel speed of 50 mm/min, temperature 24 °C, and relative humidity 45%. Five specimens were used for each formulation.

Hardness: Hardness was determined according to ASTM D2240-05 standard[1616 American Society for Testing and Materials – ASTM. (2010). ASTM D2240-05: standard test methods for rubber property: durometer hardness. West Conshohocken: ASTM.] at 24 °C and 45% of relative humidity. INSIZE® durometer of A type was used. Five (5) measurements were performed for each test.

SEM: The fractured surface of the specimens under tensile strength were observed by scanning electron microscopy (SEM), the procedure was performed following the methodology used by Tobón et al.[1717 Tobón, A. E. D., Chaparro, W. A. A., & Rivera, W. G. (2014). Mejoramiento de las propiedades de tensión en WPC de LDPE: HIPS/fibra natural mediante entrecruzamiento con DCP. Polímeros, 24(3), 291-299. http://dx.doi.org/10.4322/polimeros.2014.026.

http://dx.doi.org/10.4322/polimeros.2014...

].

3. Results and Discussions

3.1 Gel content

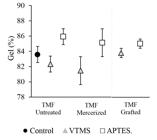

In Figure 1 an increase is observed in the percentage of gel when incorporating the SCA compared to the control, regardless of the means of addition.

This could mean that there was no competition between the silane coupling reactions with the flour and the cross-linking reaction of the polymer chains with DCP[1717 Tobón, A. E. D., Chaparro, W. A. A., & Rivera, W. G. (2014). Mejoramiento de las propiedades de tensión en WPC de LDPE: HIPS/fibra natural mediante entrecruzamiento con DCP. Polímeros, 24(3), 291-299. http://dx.doi.org/10.4322/polimeros.2014.026.

http://dx.doi.org/10.4322/polimeros.2014...

18 Ahmad, E. E. M., & Luyt, A. S. (2012). Effects of organic peroxide and polymer chain structure on morphology and thermal properties of sisal fibre reinforced polyethylene composites. Composites. Part A, Applied Science and Manufacturing, 43(4), 703-710. http://dx.doi.org/10.1016/j.compositesa.2011.12.011.

http://dx.doi.org/10.1016/j.compositesa....

-1919 Mokoena, M. A., Djoković, V., & Luyt, A. S. (2004). Composites of linear low density polyethylene and short sisal fibres: The effects of peroxide treatment. Journal of Materials Science, 39(10), 3403-3412. http://dx.doi.org/10.1023/B:JMSC.0000026943.47803.0b.

http://dx.doi.org/10.1023/B:JMSC.0000026...

]. When comparing the two silanes difference in values was observed between them, it shows that the percentage of gel APTES was higher independent of the method of addition.

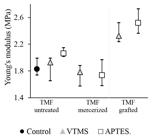

3.2 Young’s modulus

The modulus of elasticity was significantly higher in composites prepared with fiber previously grafted with APTES and VTMS silanes, with an increase in the modulus of elasticity of 28% and 37%, respectively, compared to the control (see Figure 2). These results in the modulus match the trends of other studies of hemp and wood with silane coupling agents[77 Changjie, Y., Zhang, Q., Junwei, G., Junping, Z., Youqiang, S., & Yuhang, W. (2011). Cure characteristics and mechanical properties of styrene-butadiene rubber/hydrogenated acrylonitrile-butadiene rubber/silica composites. Journal of Polymer Research, 18(6), 2487-2494. http://dx.doi.org/10.1007/s10965-011-9670-y.

http://dx.doi.org/10.1007/s10965-011-967...

,2020 Ryu, S. R., & Lee, D. J. (2007). Effects of short-fiber shape on tensile properties of reinforced rubber. Journal of Materials Science, 42(3), 1019-1025. http://dx.doi.org/10.1007/s10853-006-1397-5.

http://dx.doi.org/10.1007/s10853-006-139...

21 Ismail, H., Shaari, S. M., & Othman, N. (2011). The effect of chitosan loading on the curing characteristics, mechanical and morphological properties of chitosan-filled natural rubber (NR), epoxidised natural rubber (ENR) and styrene-butadiene rubber (SBR) compounds. Polymer Testing, 30(7), 784-790. http://dx.doi.org/10.1016/j.polymertesting.2011.07.003.

http://dx.doi.org/10.1016/j.polymertesti...

-2222 Wang, J., Wu, W., Wang, W., & Zhang, J. (2011). Effect of a coupling agent on the properties of hemp-hurd-powder-filled styrene–butadiene rubber. Journal of Applied Polymer Science, 121(2), 681-689. http://dx.doi.org/10.1002/app.33744.

http://dx.doi.org/10.1002/app.33744...

] where the modulus of elasticity improved because the presence of the coupling agent allowed a more uniform dispersion in the rubber matrix allowing a strong interfacial bonding with fiber. The direct addition of the silanes did not significantly affect the modulus of elasticity regardless of the fiber treatment. Comparatively, it was not observed that the silane type influenced the Young's modulus.

3.3 Tensile strength

In Figure 3 the tensile strength results are presented. The incorporation of APTES as a coupling agent did not affect the values of tensile strength compared to the control, while the incorporation of VTMS increased tensile strength regardless of the mode of addition; the maximum value was obtained with direct addition using untreated flour and was 30% higher compared to the control, due to the improvement of the transfer of stress in particle-polymer interface[2020 Ryu, S. R., & Lee, D. J. (2007). Effects of short-fiber shape on tensile properties of reinforced rubber. Journal of Materials Science, 42(3), 1019-1025. http://dx.doi.org/10.1007/s10853-006-1397-5.

http://dx.doi.org/10.1007/s10853-006-139...

,2222 Wang, J., Wu, W., Wang, W., & Zhang, J. (2011). Effect of a coupling agent on the properties of hemp-hurd-powder-filled styrene–butadiene rubber. Journal of Applied Polymer Science, 121(2), 681-689. http://dx.doi.org/10.1002/app.33744.

http://dx.doi.org/10.1002/app.33744...

].

The other compounds, which have VTMS, increased traction by 15% compared to the control.

The above results support the conclusion that the vinyl type silane VTMS has superior performance compared to APTES in composites prepared with SBR1502. It is shown that mercerized flour affected the tensile strength negatively in both silanes when these were added directly to the mixture. This phenomenon may be attributed in particular to the conditions used in the mercerization process, where the concentration of NaOH at 8% could possibly generate the presence of large amounts of Na+ ions, which could in turn cause interference in the coupling[2323 Gwon, J. G., Lee, S. Y., Doh, G. H., & Kim, J. H. (2010). Characterization of chemically modified wood fibers using FTIR spectroscopy for biocomposites. Journal of Applied Polymer Science, 116(6), 3212-3219. http://dx.doi.org/10.1002/app.31746.

http://dx.doi.org/10.1002/app.31746...

].

3.4 SEM fractography analysis

All SEM images show dark layers (SBR matrix), the wood flour particle is white; also voids formed by the release of the particle when breaking the specimen in the tensile test are observed.

Variation is observed in the shape and size of wood flour, for example many are below the nominal specification written at the beginning of the experimental part (400-800 µm). This is because subsequent reduction or breaking of the particles during the shear mixing step.

There are morphological differences in fracture zones of some specimens, specifically on the surface of the wood particle. The SEM image of the composite VTMS With TMF-untreated (Figure 4a), has filament formation which corresponds to the formation of grafts between natural fiber and polymer, which is consistent because this specimen showed the highest value tensile strength (Figure 3).

SEM 1000x. Fractography of specimens. Direct adition of silanes. (a) VTMS-TMF untreated; (b) APTES-TMF untreated; (c) VTMS-TMF mercerized; (d) APTES-TMF mercerized.

Similarly in Figure 4b forming grafts shown in APTES with TMF-untreated compound, precisely this specimen showed the highest tensile strenght value when the amino silane is used.

No evidence of grafting is evident in the specimens where the silanes were added to the previously mercerized wood flour (Figure 4b,c), this is consistent as the results of tensile strength were low.

The SEM of specimens of wood flour previously grafted with silanes (Figure 5a, b) have different morphology compared to the control (Figure 6). It was observed that the particles have surface modification, but this change was not sufficient to achieve grafting between the particle with SBR matrix.

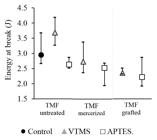

3.5 Elongation at break

Figure 7 shows no significant difference between both silanes. The compounds prepared with APTS yielded lower values compared to the control, confirming that the addition of the amino type silane does not contribute to the coupling between TMF with SBR1502. It is also noted that the compound prepared with VTMS grafted fiber was lower compared to the forms of addition.

3.6 Energy at break

The results of the energy required to break rubber compounds with TMF indicate that it is not possible to determine any significant differences in all of the tests (Figure 8).

3.7 Hardness

The results of hardness tests are seen in Figure 9; the compounds made with VTMS have a slight increase in hardness compared to the control. The maximum increase in hardness was achieved by the compound prepared with fiber grafted with APTES and VTMS. The addition of silanes can in some way increase the hardness, which is consistent with other studies into chitosan and sisal[77 Changjie, Y., Zhang, Q., Junwei, G., Junping, Z., Youqiang, S., & Yuhang, W. (2011). Cure characteristics and mechanical properties of styrene-butadiene rubber/hydrogenated acrylonitrile-butadiene rubber/silica composites. Journal of Polymer Research, 18(6), 2487-2494. http://dx.doi.org/10.1007/s10965-011-9670-y.

http://dx.doi.org/10.1007/s10965-011-967...

,2020 Ryu, S. R., & Lee, D. J. (2007). Effects of short-fiber shape on tensile properties of reinforced rubber. Journal of Materials Science, 42(3), 1019-1025. http://dx.doi.org/10.1007/s10853-006-1397-5.

http://dx.doi.org/10.1007/s10853-006-139...

,2121 Ismail, H., Shaari, S. M., & Othman, N. (2011). The effect of chitosan loading on the curing characteristics, mechanical and morphological properties of chitosan-filled natural rubber (NR), epoxidised natural rubber (ENR) and styrene-butadiene rubber (SBR) compounds. Polymer Testing, 30(7), 784-790. http://dx.doi.org/10.1016/j.polymertesting.2011.07.003.

http://dx.doi.org/10.1016/j.polymertesti...

]. There is a relationship of hardness to elastic modulus, the highest hardness values also have greater Young’s modulus (Figure 2).

4. Conclusions

Adding silanes did not decrease the percentage of gel; it was not possible to identify interference between the coupling reaction and cross-linking; comparatively gel percentage was higher in the compounds having APTES that VTMS.

VTMS and APTES improve tensile strength in SBR-wood flour composites, the vinyl silane produced the highest values. It is possible that the presence of the double bond of the vinyl group contributed to the formation of bonds with the fiber surface and rubber. This silane is recommended by the manufacturer for coupling silica type loads with SBR1502.

When the silanes were added directly on SBR-wood flour untreated, yielded values greater of tensile strength compared to other modes of incorporation, which is confirmed by the observation of grafting on surface particle through of SEM images.

It was expected that mercerization of the fiber would help to improve the coupling of the vegetable flour with rubber, especially with VTMS silane. This did not happen, possibly due to the conditions used in the mercerization.

APTES amino type silane increased rigidity and hardness, but no positive effect was observed on tensile strength.

Further studies are recommended to treat TMF mercerizing, specifically by varying the concentration of NaOH. In the SEM images can be seen a change in morphology of wood flour mercerized vs untreated, but these effects did not ensure coupling between with SBR matrix.

5. Acknowledgements

This study is derived from the project INV-ING-1547 sponsored by “Vicerrectoria de Investigaciones de la Universidad Militar Nueva Granada” - One year term 2014.

6. References

-

1Mark, J. E. (1999). Polymer Data Handbook Oxford: Oxford University Press.

-

2Kumar, R. P., Nair, K. C. M., Thomas, S., Schit, S. C., & Ramamurthy, K. (2000). Morphology and melt rheological behaviour of short-sisal-fibre-reinforced SBR composites. Composites Science and Technology, 60(9), 1737-1751. http://dx.doi.org/10.1016/S0266-3538(00)00057-9

» http://dx.doi.org/10.1016/S0266-3538(00)00057-9 -

3Khalf, A. I., & Ward, A. (2010). Use of rice husks as potential filler in styrene butadiene rubber/linear low density polyethylene blends in the presence of maleic anhydride. Materials & Design, 31(5), 2414-2421. http://dx.doi.org/10.1016/j.matdes.2009.11.056

» http://dx.doi.org/10.1016/j.matdes.2009.11.056 -

4Kumar, R. P., & Thomas, S. (1995). Short fibre elastomer composites: effect of fibre length, orientation, loading and bonding agent. Bulletin of Materials Science, 18(8), 1021-1029. http://dx.doi.org/10.1007/BF02745189

» http://dx.doi.org/10.1007/BF02745189 -

5Wang, J., Wu, W., Wang, W., & Zhang, J. (2011). Preparation and characterization of hemp hurd powder filled SBR and EPDM elastomers. Journal of Polymer Research, 18(5), 1023-1032. http://dx.doi.org/10.1007/s10965-010-9503-4

» http://dx.doi.org/10.1007/s10965-010-9503-4 -

6Fuqua, M., Huo, S., & Ulven, C. A. (2012). Natural Fiber Reinforced Composites. Polymer Reviews, 52(3), 259-320. http://dx.doi.org/10.1080/15583724.2012.705409

» http://dx.doi.org/10.1080/15583724.2012.705409 -

7Changjie, Y., Zhang, Q., Junwei, G., Junping, Z., Youqiang, S., & Yuhang, W. (2011). Cure characteristics and mechanical properties of styrene-butadiene rubber/hydrogenated acrylonitrile-butadiene rubber/silica composites. Journal of Polymer Research, 18(6), 2487-2494. http://dx.doi.org/10.1007/s10965-011-9670-y

» http://dx.doi.org/10.1007/s10965-011-9670-y -

8Maldas, D., Kokta, B. V., & Daneault, C. (1989). Influence of coupling agents and treatments on the mechanical properties of cellulose fiber–polystyrene composites. Journal of Applied Polymer Science, 37(3), 751-775. http://dx.doi.org/10.1002/app.1989.070370313

» http://dx.doi.org/10.1002/app.1989.070370313 -

9Basfar, A. A., Abdel-Aziz, M., & Mofti, S. (2002). Influence of different curing systems on the physico-mechanical properties and stability of SBR and NR rubbers. Radiation Physics and Chemistry, 63(1), 81-87. http://dx.doi.org/10.1016/S0969-806X(01)00486-8

» http://dx.doi.org/10.1016/S0969-806X(01)00486-8 -

10Nabil, H., Ismail, A., & Azura, R. (2014). Properties of natural rubber/recycled ethylene–propylene–diene rubber blends prepared using various vulcanizing systems. Iranian Polymer Journal, 23(1), 37-45. http://dx.doi.org/10.1007/s13726-013-0197-4

» http://dx.doi.org/10.1007/s13726-013-0197-4 -

11Changjie, Y., Zhang, Q., Junwei, G., Junping, Z., Youqiang, S., & Yuhang, W. (2011). Cure characteristics and mechanical properties of styrene-butadiene rubber/hydrogenated acrylonitrile-butadiene rubber/silica composites. Journal of Polymer Research, 18(6), 2487-2494. http://dx.doi.org/10.1007/s10965-011-9670-y

» http://dx.doi.org/10.1007/s10965-011-9670-y -

12Shih, R.-S., Kuo, S.-W., & Chang, F.-C. (2011). Thermal and mechanical properties of microcellular thermoplastic SBS/PS/SBR blend: effect of crosslinking. Polymer, 52(3), 752-759. http://dx.doi.org/10.1016/j.polymer.2010.12.026

» http://dx.doi.org/10.1016/j.polymer.2010.12.026 -

13Buitrago, O., Delgado, A., & Aperador, W. (2014). Surface treatment of straight Retamo Liso (Telinne monspessulana) by silane coupling agents (SCA). Ciência e Técnica Vitivinícola, 29(12), 11-23.

-

14American Society for Testing and Materials – ASTM. (2001). ASTM D2765-01: standard test methods for determination of gel content and swell ratio of crosslinked ethylene plastics West Conshohocken: ASTM.

-

15American Society for Testing and Materials – ASTM. (2013). ASTM D412-06a: standard test methods for vulcanized rubber and thermoplastic elastomers West Conshohocken: ASTM.

-

16American Society for Testing and Materials – ASTM. (2010). ASTM D2240-05: standard test methods for rubber property: durometer hardness West Conshohocken: ASTM.

-

17Tobón, A. E. D., Chaparro, W. A. A., & Rivera, W. G. (2014). Mejoramiento de las propiedades de tensión en WPC de LDPE: HIPS/fibra natural mediante entrecruzamiento con DCP. Polímeros, 24(3), 291-299. http://dx.doi.org/10.4322/polimeros.2014.026

» http://dx.doi.org/10.4322/polimeros.2014.026 -

18Ahmad, E. E. M., & Luyt, A. S. (2012). Effects of organic peroxide and polymer chain structure on morphology and thermal properties of sisal fibre reinforced polyethylene composites. Composites. Part A, Applied Science and Manufacturing, 43(4), 703-710. http://dx.doi.org/10.1016/j.compositesa.2011.12.011

» http://dx.doi.org/10.1016/j.compositesa.2011.12.011 -

19Mokoena, M. A., Djoković, V., & Luyt, A. S. (2004). Composites of linear low density polyethylene and short sisal fibres: The effects of peroxide treatment. Journal of Materials Science, 39(10), 3403-3412. http://dx.doi.org/10.1023/B:JMSC.0000026943.47803.0b

» http://dx.doi.org/10.1023/B:JMSC.0000026943.47803.0b -

20Ryu, S. R., & Lee, D. J. (2007). Effects of short-fiber shape on tensile properties of reinforced rubber. Journal of Materials Science, 42(3), 1019-1025. http://dx.doi.org/10.1007/s10853-006-1397-5

» http://dx.doi.org/10.1007/s10853-006-1397-5 -

21Ismail, H., Shaari, S. M., & Othman, N. (2011). The effect of chitosan loading on the curing characteristics, mechanical and morphological properties of chitosan-filled natural rubber (NR), epoxidised natural rubber (ENR) and styrene-butadiene rubber (SBR) compounds. Polymer Testing, 30(7), 784-790. http://dx.doi.org/10.1016/j.polymertesting.2011.07.003

» http://dx.doi.org/10.1016/j.polymertesting.2011.07.003 -

22Wang, J., Wu, W., Wang, W., & Zhang, J. (2011). Effect of a coupling agent on the properties of hemp-hurd-powder-filled styrene–butadiene rubber. Journal of Applied Polymer Science, 121(2), 681-689. http://dx.doi.org/10.1002/app.33744

» http://dx.doi.org/10.1002/app.33744 -

23Gwon, J. G., Lee, S. Y., Doh, G. H., & Kim, J. H. (2010). Characterization of chemically modified wood fibers using FTIR spectroscopy for biocomposites. Journal of Applied Polymer Science, 116(6), 3212-3219. http://dx.doi.org/10.1002/app.31746

» http://dx.doi.org/10.1002/app.31746

Publication Dates

-

Publication in this collection

29 June 2017 -

Date of issue

Apr-Jun 2017

History

-

Received

19 June 2015 -

Reviewed

21 Mar 2016 -

Accepted

29 June 2016