Abstract

In this work we discuss the wettability, chemical composition, surface morphology and optical transmittance of polyvinyl chloride (PVC) samples treated by Plasma Immersion and by Plasma Immersion Ion Implantation. The total pressure of N2 or SF6 was 6.66 Pa, for treatments of 900 s, applied rf power of 25 and 100 W, and the substrate temperature was about 298 K. In PIII, high voltage pulses of -2400 V at a cycle time of 30 µs and a frequency of 300 Hz were used. The wettability of the samples was assessed via contact angle measurements, which indicated either hydrophilicity or hydrophobicity, depending on the plasma composition. X-ray Photoelectron Spectroscopic analysis confirmed strong fluorine attachment to the surface after treatments using SF6 plasmas, and the presence of oxygen after treatments using nitrogen plasmas. Atomic Force Microscopy images showed that the roughness Rrms, depends on the plasma conditions. Optical transmittance in the visible region, T (λ), was increased by plasma immersion. The greatest contact angle observed was 142º (PI cathode), while the highest roughness was 213.2 nm. The highest optical transmittance in the visible region was around to 90% (PI anode).

Keywords:

PVC; plasma immersion techniques; contact angle; XPS; AFM; optical transmittance

1. Introduction

Low-pressure plasma treatment, an environmentally friendly alternative to conventional methods of surface modification, can improve the surface properties of polymers without changing their bulk properties[11 Juang, R. S., Hou, W. T., Huang, Y. C., Tseng, Y. C., & Huang, C. (2016). Surface hydrophilic modifications on polypropylene membranes by remote methane/oxygen mixture plasma discharges. Journal of the Taiwan Institute of Chemical Engineers, 65, 420-426. http://dx.doi.org/10.1016/j.jtice.2016.04.032.

http://dx.doi.org/10.1016/j.jtice.2016.0...

]. Surface modification in plasmas fed different gases has several advantages, such as a simple and rapid control of the process rate and economic efficiency[22 Nazarov, V. G., Stolyarov, V. P., & Gagarin, M. V. (2014). Simulation of chemical modification of polymer surface. Journal of Fluorine Chemistry, 161, 120-127. http://dx.doi.org/10.1016/j.jfluchem.2014.01.021.

http://dx.doi.org/10.1016/j.jfluchem.201...

]. Radiofrequency plasma technologies using fluorinated gases are currently employed in materials science, offering low-temperature reactions (often the treatment can be achieved at room temperature, which avoids the thermal degradation of the material). Direct fluorination is an effective method for improving the surface properties of pristine polymer materials, including barrier, gas separation and bactericide properties, adhesion, printability, chemical resistance, and biocompatibility[33 Kharitonov, A. P., Simbirtseva, G. V., Tressaud, A., Durand, E., Labrugère, C., & Dubois, M. (2014). Comparison of the surface modifications of polymers induced by direct fluorination and rf-plasma using fluorinated gases. Journal of Fluorine Chemistry, 165, 49-60. http://dx.doi.org/10.1016/j.jfluchem.2014.05.002.

http://dx.doi.org/10.1016/j.jfluchem.201...

]. One of the purposes of fluorinating polymers is to increase their surface hydrophobicity for use in the polymer packaging of foodstuffs, leading to improvements in anti-sticking, friction, corrosion resistance, flammability, refractive index, dielectric constant, and water/oil repellence. Improved hydrophilization is also useful since it improves adhesion in such processes as painting, coating or gluing[44 Gancarz, I., Bryjak, M., Kujawski, J., Wolska, J., Kujawa, J., & Kujawski, W. (2015). Plasma deposited fluorinated films on porous membranes. Materials Chemistry and Physics, 151, 233-242. http://dx.doi.org/10.1016/j.matchemphys.2014.11.059.

http://dx.doi.org/10.1016/j.matchemphys....

]. To our best knowledge, different PI electrical configurations for the surface functionalization of PVC have not been previously reported. Other results concerning hydrophobic/hydrophilic surface treatments of PET[55 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2017). Study of wettability and optical transparency of PET polymer modified by plasma immersion techniques. Revista Brasileira de Aplicações de Vácuo, 36(2), 68-74. http://dx.doi.org/10.17563/rbav.v36i2.1050.

http://dx.doi.org/10.17563/rbav.v36i2.10...

] and PVC[66 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

] in low-pressure plasmas have been reported. In those treatments, plasma immersion techniques (PI) and Plasma Immersion Ion Implantation (PIII) were employed, to modify surface wetting, roughness and optical transmission. Higher contact angles were observed after plasma fluorination and lower ones after plasma nitrogenation, while maintaining low surface roughness and high transparency[77 Sant’Ana, P. L., Bortoleto, J. R. R., Rangel, E. C., Cruz, N. C., Durrant, S. F., Botti, L. C. M., Anjos, C. R., Teixeira, V., Azevedo, S., Silva, C. I., Soares, N. F. F., & Medeiros, E. A. A. (2018). Surface properties of PET polymer treated by plasma immersion techniques for food packaging. International Journal of Nano Research, 1(1), 33-41. Retrieved in 2020, August 17, from https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging

https://www.innovationinfo.org/internati...

,88 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., Botti, L. C. M., Anjos, C. A. R., Medeiros, E. A. A., Soares, N. F. F., Azevedo, S., Teixeira, V., Carneiro, J., & Silva, C. I. (2018). Surface properties and morphology of PET treated by plasma immersion ion implantation for food packaging. Nanomedicine & Nanotechnology Open Access, 3(3), 1-13. http://dx.doi.org/10.23880/NNOA-16000145.

http://dx.doi.org/10.23880/NNOA-16000145...

]. Substrate cooling was used since high substrate temperatures can reduce optical transmittance in the visible range.

In the present study, plasma immersion techniques were used to modify the surface properties of PVC, to change the wettability from intermediate to hydrophobic using fluorine plasma or to hydrophilic using nitrogen plasmas. These results are important since wettability influences the exclusion of water and the possibility of adhesion between different polymers. An additional objective was to maintain or improve the optical transparency of ‘blue’ PVC in the visible region, which is necessary in packaging applications, where the product must remain clearly visible.

2. Methods

The experimental setup used consists of a stainless-steel vacuum chamber (30 cm in height and 25 cm in diameter) with two internal, horizontal, circular stainless-steel electrodes of 11 cm diameter. Substrates were placed on the driven or biased electrode and the system was evacuated by a rotary pump (18 m3/h) down to ~0.7 Pa. Needle valves were employed to control the gas feed (gases of purity 99.9995%), and a capacitive pressure sensor to monitor the chamber pressure. Samples were exposed directly to the plasma environment established by the application of radiofrequency power (13.56 MHz) at 25 and 100 W for both gases (N2 and SF6). Twenty four substrates of blue PVC (2.5 cm × 1.5 cm, and 1 cm of thickness) were used. Eight substrates were treated in three different rf plasma immersion modes, as indicated in previous literature[66 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

7 Sant’Ana, P. L., Bortoleto, J. R. R., Rangel, E. C., Cruz, N. C., Durrant, S. F., Botti, L. C. M., Anjos, C. R., Teixeira, V., Azevedo, S., Silva, C. I., Soares, N. F. F., & Medeiros, E. A. A. (2018). Surface properties of PET polymer treated by plasma immersion techniques for food packaging. International Journal of Nano Research, 1(1), 33-41. Retrieved in 2020, August 17, from https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging

https://www.innovationinfo.org/internati...

8 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., Botti, L. C. M., Anjos, C. A. R., Medeiros, E. A. A., Soares, N. F. F., Azevedo, S., Teixeira, V., Carneiro, J., & Silva, C. I. (2018). Surface properties and morphology of PET treated by plasma immersion ion implantation for food packaging. Nanomedicine & Nanotechnology Open Access, 3(3), 1-13. http://dx.doi.org/10.23880/NNOA-16000145.

http://dx.doi.org/10.23880/NNOA-16000145...

-99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.], and summarized as follows:

-

i

The sample holder and the chamber walls were grounded while rf power was connected to the opposite electrode (driven electrode): PI ‘anode’; (eight samples);

-

ii

The rf power was connected to the sample holder (driven electrode) while the other electrode and chamber walls were grounded: PI ‘cathode’; (eight samples);

-

iii

The rf power was connected to the upper electrode (driven electrode) while negative pulses of high voltage were applied to the substrate holder: PIII, (eight samples).

A high voltage source (model RUP-6) and an oscilloscope (TDS from Tektroniks) were employed for the PIII experiments. The negative pulses, -2400 V, were supplied at 300 Hz and period (duty cycle) was calculated as being: ton/(ton + toff), which value was ~3.3 ms for ton fixed to 30µs, for all PIII experiments. Twelve PVC samples were treated in SF6 plasmas and twelve in N2 plasmas. Fig. 1 shows the electrical configuration of the plasma immersion and plasma immersion ion implantation techniques used in our experiments.

Electrical configuration of plasma immersion techniques applied in our experiments. (a) Plasma Immersion anode; (b) Plasma Immersion cathode; (c) Plasma Immersion Ion Implantation[66 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

7 Sant’Ana, P. L., Bortoleto, J. R. R., Rangel, E. C., Cruz, N. C., Durrant, S. F., Botti, L. C. M., Anjos, C. R., Teixeira, V., Azevedo, S., Silva, C. I., Soares, N. F. F., & Medeiros, E. A. A. (2018). Surface properties of PET polymer treated by plasma immersion techniques for food packaging. International Journal of Nano Research, 1(1), 33-41. Retrieved in 2020, August 17, from https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging

https://www.innovationinfo.org/internati...

8 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., Botti, L. C. M., Anjos, C. A. R., Medeiros, E. A. A., Soares, N. F. F., Azevedo, S., Teixeira, V., Carneiro, J., & Silva, C. I. (2018). Surface properties and morphology of PET treated by plasma immersion ion implantation for food packaging. Nanomedicine & Nanotechnology Open Access, 3(3), 1-13. http://dx.doi.org/10.23880/NNOA-16000145.

http://dx.doi.org/10.23880/NNOA-16000145... -99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.].

As temperature changes can change the optical transmittance, during treatment the sample holder was cooled with water at room temperature. Immediately after removing the treated samples from the reactor, the samples were characterized. The surface contact angle, Ɵ, was measured using a Goniometer (100-00, Ramé- Hart) with three drops of deionized water. Ten measurements were taken for each drop. The drops had a volume of 0.6 µl. Surface morphologies of four different samples were examined using an Atomic Force Microscope (XE-100, Park Instruments) operating in air, generating 5 μm x 5 μm images. From the images acquired in the non-contact mode, the root mean square roughness, Rrms, was calculated using the PicoView 1.2 software.

The effect of the plasma treatment on the chemical composition of the PVC surface was evaluated from X-Ray Photoelectron Spectroscopy, XPS, survey spectra. Data were collected for the untreated PVC (one sample) and plasma-treated PVC (four samples). A Microtech - ESCA 3000 Spectrometer was employed, which achieved a base pressure of 2 × 10-8 Pa. The samples were studied using Mg Kα radiation. A resolution of about 0.8 eV was achieved. The spectra show intensity as function of binding energy from zero to 800 eV[99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.]. The binding energies (BEs) of the peaks in the spectra were referenced to that of the 1s electrons in carbonaceous carbon (284.6 eV)[1010 Cruz, S. A., Zanin, M., Nascente, P. A. P., & Bica de Moraes, M. A. (2010). Superficial modification in recycled PET by plasma etching for food packaging. Journal of Applied Polymer Science, 115(5), 2728-2733. http://dx.doi.org/10.1002/app.29958.

http://dx.doi.org/10.1002/app.29958...

]. Shirley background correction was used.

Optical transmittance, T (λ), of Blue PVC was measured for six samples, using a UV-vis-NIR Spectrometer (Perkin Elmer Lambda 750) over the wavelength range from 190 nm to 3300 nm. Table 1 shows the technical parameters.

3. Results

Table 2 shows the values of contact angles, immediately after the treatment and after 30 days (ageing). Also, the optical transmittance of visible light (at 550 nm) was investigated for PVC after the different plasma treatments: PI cathode, PI anode and PIII, at low and high applied rf power using fluorine or nitrogen plasma[66 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

7 Sant’Ana, P. L., Bortoleto, J. R. R., Rangel, E. C., Cruz, N. C., Durrant, S. F., Botti, L. C. M., Anjos, C. R., Teixeira, V., Azevedo, S., Silva, C. I., Soares, N. F. F., & Medeiros, E. A. A. (2018). Surface properties of PET polymer treated by plasma immersion techniques for food packaging. International Journal of Nano Research, 1(1), 33-41. Retrieved in 2020, August 17, from https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging

https://www.innovationinfo.org/internati...

8 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., Botti, L. C. M., Anjos, C. A. R., Medeiros, E. A. A., Soares, N. F. F., Azevedo, S., Teixeira, V., Carneiro, J., & Silva, C. I. (2018). Surface properties and morphology of PET treated by plasma immersion ion implantation for food packaging. Nanomedicine & Nanotechnology Open Access, 3(3), 1-13. http://dx.doi.org/10.23880/NNOA-16000145.

http://dx.doi.org/10.23880/NNOA-16000145...

-99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.].

PVC is a slightly hydrophobic polymer with a water contact angle of around 76°[66 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

,99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.]. According to the data of Table 2, wettability after treatment depends on the plasma configuration. Plasma immersion using nitrogen decreases contact angles[55 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2017). Study of wettability and optical transparency of PET polymer modified by plasma immersion techniques. Revista Brasileira de Aplicações de Vácuo, 36(2), 68-74. http://dx.doi.org/10.17563/rbav.v36i2.1050.

http://dx.doi.org/10.17563/rbav.v36i2.10...

], while plasma immersion using fluorine increases them[66 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

], independent of the plasma technique. Owing to the plasma action, the breaking of covalent chemical bonds, such as C-H or C-O and their subsequent recombination may lead to the formation of C-F bonds after the fluoride treatment by PI[55 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2017). Study of wettability and optical transparency of PET polymer modified by plasma immersion techniques. Revista Brasileira de Aplicações de Vácuo, 36(2), 68-74. http://dx.doi.org/10.17563/rbav.v36i2.1050.

http://dx.doi.org/10.17563/rbav.v36i2.10...

,66 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

,99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.] which explains the increased hydrophobic character of the polymers undergoing this treatment. For treatment by PI, the increasing power supplied to the SF6 plasma enhances ion bombardment. Thus, a greater number of fragmented species impinging on the surface offers a greater number of active sites for binding C-F, which justifies the higher θ values after fluorination[55 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2017). Study of wettability and optical transparency of PET polymer modified by plasma immersion techniques. Revista Brasileira de Aplicações de Vácuo, 36(2), 68-74. http://dx.doi.org/10.17563/rbav.v36i2.1050.

http://dx.doi.org/10.17563/rbav.v36i2.10...

6 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

7 Sant’Ana, P. L., Bortoleto, J. R. R., Rangel, E. C., Cruz, N. C., Durrant, S. F., Botti, L. C. M., Anjos, C. R., Teixeira, V., Azevedo, S., Silva, C. I., Soares, N. F. F., & Medeiros, E. A. A. (2018). Surface properties of PET polymer treated by plasma immersion techniques for food packaging. International Journal of Nano Research, 1(1), 33-41. Retrieved in 2020, August 17, from https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging

https://www.innovationinfo.org/internati...

8 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., Botti, L. C. M., Anjos, C. A. R., Medeiros, E. A. A., Soares, N. F. F., Azevedo, S., Teixeira, V., Carneiro, J., & Silva, C. I. (2018). Surface properties and morphology of PET treated by plasma immersion ion implantation for food packaging. Nanomedicine & Nanotechnology Open Access, 3(3), 1-13. http://dx.doi.org/10.23880/NNOA-16000145.

http://dx.doi.org/10.23880/NNOA-16000145...

-99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.]. In the reactor there are also the effects of ionic bombardment for all PI configurations[99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.]. In addition, as the ageing time increases, Ɵ gradually recovers its initial character, particularly after treatment in nitrogen plasmas. The chemical composition of the treated material can change upon ageing. Furthermore, we believe that the structural reorganization of the polymer chains may play an important role in the modification of the polymer’s wettability[66 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

7 Sant’Ana, P. L., Bortoleto, J. R. R., Rangel, E. C., Cruz, N. C., Durrant, S. F., Botti, L. C. M., Anjos, C. R., Teixeira, V., Azevedo, S., Silva, C. I., Soares, N. F. F., & Medeiros, E. A. A. (2018). Surface properties of PET polymer treated by plasma immersion techniques for food packaging. International Journal of Nano Research, 1(1), 33-41. Retrieved in 2020, August 17, from https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging

https://www.innovationinfo.org/internati...

8 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., Botti, L. C. M., Anjos, C. A. R., Medeiros, E. A. A., Soares, N. F. F., Azevedo, S., Teixeira, V., Carneiro, J., & Silva, C. I. (2018). Surface properties and morphology of PET treated by plasma immersion ion implantation for food packaging. Nanomedicine & Nanotechnology Open Access, 3(3), 1-13. http://dx.doi.org/10.23880/NNOA-16000145.

http://dx.doi.org/10.23880/NNOA-16000145...

-99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.,1111 Milella, A., Colapricio, V., Favia, P., Iacobelli, L., & d’Agostino, R. (2001). Plasma treatments of polymers for reducing ageing. In Proceedings of the 15th International Symposium on Plasma Chemistry (pp. 2416-2420). Orléans, France: International Plasma Chemistry Society. Retrieved in 2020, August 17, from https://www.ispc-conference.org/ispcdocs/ispc15/content/15/15-2416.pdf

https://www.ispc-conference.org/ispcdocs...

]. An increase in optical transmittance was observed for the different plasma configurations, except for sample ‘Nit2’, which used a nitrogen plasma in the ‘cathode’ mode.

3.1 Effect of ageing on θ

This section discusses the evolution of contact angles as a function of ageing time for samples treated by plasma immersion and plasma immersion ion implantation, using SF6 and N2, respectively, under different conditions. After fluorination treatments the contact angles were stable over time, while the nitrogen treatments presented a clear tendency to become hydrophobic. After treatment, short chain molecules reorient towards the surface and oxidized functional groups may diffuse into the interior of the material[1212 Foerch, R., Kill, G., & Walzak, M. (1993). Plasma surface modification of polypropylene: shortterm vs. Long-term plasma treatment. Journal of Adhesion Science and Technology, 7(10), 1077-1089. http://dx.doi.org/10.1163/156856193X00592.

http://dx.doi.org/10.1163/156856193X0059...

]. The literature also indicates that ageing causes the incorporation of oxygen as C-O and C=O, and also as -OH. This is typical of plasma polymers, which upon deposition usually have a high density of free-radicals that react with oxygen and water vapor. As mentioned previously, immediately after being withdrawn from the reactor, samples treated with nitrogen are highly hydrophilic. This wettability was linked to the chemical composition obtained by XPS. Incorporation of oxygen-containing polar groups explains the wettability of samples treated with nitrogen[55 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2017). Study of wettability and optical transparency of PET polymer modified by plasma immersion techniques. Revista Brasileira de Aplicações de Vácuo, 36(2), 68-74. http://dx.doi.org/10.17563/rbav.v36i2.1050.

http://dx.doi.org/10.17563/rbav.v36i2.10...

6 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

7 Sant’Ana, P. L., Bortoleto, J. R. R., Rangel, E. C., Cruz, N. C., Durrant, S. F., Botti, L. C. M., Anjos, C. R., Teixeira, V., Azevedo, S., Silva, C. I., Soares, N. F. F., & Medeiros, E. A. A. (2018). Surface properties of PET polymer treated by plasma immersion techniques for food packaging. International Journal of Nano Research, 1(1), 33-41. Retrieved in 2020, August 17, from https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging

https://www.innovationinfo.org/internati...

8 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., Botti, L. C. M., Anjos, C. A. R., Medeiros, E. A. A., Soares, N. F. F., Azevedo, S., Teixeira, V., Carneiro, J., & Silva, C. I. (2018). Surface properties and morphology of PET treated by plasma immersion ion implantation for food packaging. Nanomedicine & Nanotechnology Open Access, 3(3), 1-13. http://dx.doi.org/10.23880/NNOA-16000145.

http://dx.doi.org/10.23880/NNOA-16000145...

-99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.,1313 Dong, H., & Bell, T. (1999). State-of-the-art overview. Ion beam surface modification of polymer towards improving tribological properties. Surface and Coatings Technology, 111(1), 29-40. http://dx.doi.org/10.1016/S0257-8972(98)00698-7.

http://dx.doi.org/10.1016/S0257-8972(98)...

]. The use of reactive nitrogen plasma surface modification promotes an increase in surface hydrophilicity. As a result of the high instability of the species generated during and after plasma modification, however, the hydrophilic properties achieved by plasma surface modification are quickly lost. This process is well known as hydrophobic recovery[1414 Huang, C., Ma, W. C., Tsai, C. Y., Hou, W. T., & Juang, R. S. (2013). Surface modification of polytetrafluorethylene membranes by radio frequency methane/nitrogen mixture plasma polymerization. Surface and Coatings Technology, 231, 42-46. http://dx.doi.org/10.1016/j.surfcoat.2012.03.005.

http://dx.doi.org/10.1016/j.surfcoat.201...

]. Changes in contact angle with ageing can be much smaller for polymers that contain many crosslinks since these limit the mobility of polymeric chains[1515 Sadeek, S. A. (2005). Synthesis, thermogravimetric analysis, infrared, electronic and mass spectra of Mn(II), Co(II) and Fe(III) norfloxacin complexes. Journal of Molecular Structure, 753(1-3), 1-12. http://dx.doi.org/10.1016/j.molstruc.2005.06.011.

http://dx.doi.org/10.1016/j.molstruc.200...

] and therefore impede the reorganization of polar groups[99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.].

3.2 Composition (XPS analysis)

As is clear from Fig. 2, treatment in SF6 plasmas introduces fluorine into the treated polymer surfaces.

XPS survey spectra of untreated PVC and PVC treated under different conditions: PIII associated with fluorine or nitrogen treatment, and PI associated with fluorine treatment (cathode or anode electrical configuration).

For virgin PVC the following peaks were observed in the spectra: C 1s located at 300 eV, Cl 2s at ~280 eV and O 1s at ~538 eV. After fluorination, C 1s was set to 300 eV, Cl 2s at 280 eV, O 1s at 540 eV and F 1s at 695 eV. After nitrogen ion implantation, C 1s was located at 292 eV, Cl 2s at 274 eV, O 1s at 538e V, and N 1s was located at 408 eV[99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.]. After the treatment, XPS analyses revealed the following: carbon, oxygen, nitrogen and chlorine at, respectively, 52 at.(%), 33 at.(%), 12 at.(%) and 3 at.(%). In this situation, Ɵ changed from 9º (immediately after the treatment) to 102° after 30 days. The corresponding atomic concentrations for the untreated and treated PVC are presented in Table 2 (which also shows the binding energies). PVC is composed of about (50 at.%) carbon, (38 at.%) chlorine and few percent hydrogen[99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.,1616 Zha, J., Ali, S. S., Peyroux, J., Batisse, N., Claves, D., Dubois, M., Kharitonov, A. P., Monier, G., Darmanin, T., Guittard, F., & Alekseiko, L. N. (2017). Superhydrophobic of polymer films via fluorine atoms covalent attachment and surface nano-texturing. Journal of Fluorine Chemistry, 200, 123-132. http://dx.doi.org/10.1016/j.jfluchem.2017.06.011.

http://dx.doi.org/10.1016/j.jfluchem.201...

]. As hydrogen is not detected by XPS, the atomic concentrations obtained for the untreated PVC are consistent. A small amount (~11 at.%) of oxygen is detected even in the as-received material[1717 Rangel, E. C., dos Santos, N. M., Bortoleto, J. R. R., Durrant, S. F., Schreiner, W. H., Honda, R. Y., Rangel, R. C. C., & Cruz, N. C. (2006). Treatment of PVC using an alternative low energy ion bombardment procedure. Applied Surface Science, 258(5), 1854-1861. http://dx.doi.org/10.1016/j.apsusc.2011.10.061.

http://dx.doi.org/10.1016/j.apsusc.2011....

]. After the fluorination treatment the oxygen content did not change, except for the cathode configuration at 100 W, where it was only 3 at.(%). Nevertheless, substantial fluorine incorporation was observed, while chlorine was removed, (virgin PVC contained 38 at.(%) Cl, and after SF6 bombardment, this had decreased to about 2 at.(%). These results support the explanation of the wettability and the fluorination mechanism[55 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2017). Study of wettability and optical transparency of PET polymer modified by plasma immersion techniques. Revista Brasileira de Aplicações de Vácuo, 36(2), 68-74. http://dx.doi.org/10.17563/rbav.v36i2.1050.

http://dx.doi.org/10.17563/rbav.v36i2.10...

,66 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

]. Substitution of fluorine, displacing chlorine or hydrogen atoms in polymers decreases their surface energy because of the strong covalence and small polarizability of the C-F bonds. The surface energy of a material depends on the character of terminal groups, and decreases from -CH2 → -CH → -CF → -CF3. Nevertheless, the presence of fluorinated groups (CF, CF2 and CF3) and the subsequent surface energy decrease are not enough to reach superhydrophobicity[55 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2017). Study of wettability and optical transparency of PET polymer modified by plasma immersion techniques. Revista Brasileira de Aplicações de Vácuo, 36(2), 68-74. http://dx.doi.org/10.17563/rbav.v36i2.1050.

http://dx.doi.org/10.17563/rbav.v36i2.10...

]. Flat surfaces terminated with –CF3 groups, which have the lowest free energy, exhibit a maximum contact angle of around 120º[1616 Zha, J., Ali, S. S., Peyroux, J., Batisse, N., Claves, D., Dubois, M., Kharitonov, A. P., Monier, G., Darmanin, T., Guittard, F., & Alekseiko, L. N. (2017). Superhydrophobic of polymer films via fluorine atoms covalent attachment and surface nano-texturing. Journal of Fluorine Chemistry, 200, 123-132. http://dx.doi.org/10.1016/j.jfluchem.2017.06.011.

http://dx.doi.org/10.1016/j.jfluchem.201...

]. On the other hand, when nitrogen ions were implanted into the surface of PVC, the oxygen content increased, from 11 at.% to 33 at.%. It is believed that residual oxygen bonds with active sites on the surface caused by ion bombardment. After nitrogen plasma immersion ion implantation the surface composition was as follows: (52% C), (33%O), (12% N) and (3% Cl). For sample Nit1 (PIII), hydrophilization may be caused by the formation of oxygen-containing groups[55 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2017). Study of wettability and optical transparency of PET polymer modified by plasma immersion techniques. Revista Brasileira de Aplicações de Vácuo, 36(2), 68-74. http://dx.doi.org/10.17563/rbav.v36i2.1050.

http://dx.doi.org/10.17563/rbav.v36i2.10...

,77 Sant’Ana, P. L., Bortoleto, J. R. R., Rangel, E. C., Cruz, N. C., Durrant, S. F., Botti, L. C. M., Anjos, C. R., Teixeira, V., Azevedo, S., Silva, C. I., Soares, N. F. F., & Medeiros, E. A. A. (2018). Surface properties of PET polymer treated by plasma immersion techniques for food packaging. International Journal of Nano Research, 1(1), 33-41. Retrieved in 2020, August 17, from https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging

https://www.innovationinfo.org/internati...

8 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., Botti, L. C. M., Anjos, C. A. R., Medeiros, E. A. A., Soares, N. F. F., Azevedo, S., Teixeira, V., Carneiro, J., & Silva, C. I. (2018). Surface properties and morphology of PET treated by plasma immersion ion implantation for food packaging. Nanomedicine & Nanotechnology Open Access, 3(3), 1-13. http://dx.doi.org/10.23880/NNOA-16000145.

http://dx.doi.org/10.23880/NNOA-16000145...

-99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.]. The high concentration of oxygen is consistent with the reduction in θ. The binding energy of O 1s observed for virgin PVC and PVC treated with nitrogen is the same: 538 eV. Under these conditions there is expected to be a high degree of bond fragmentation and the emission of species from the solid. As hydrogen and chlorine atoms are side groups in PVC, they are very prone to be lost upon bombardment[66 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

]. Carbon atoms can also be ejected and O incorporation can be observed. Free radicals generated by Cl and H emission can react with atmospheric H2O and O2, thereby incorporating oxygen groups.

3.3 Surface morphology

Another property of great importance in the wettability of solids is surface roughness[1818 Nakae, H., Iuni, R., Hirata, Y., & Saito, H. (1998). Effects of surface roughness on wettability. Acta Materialia, 46(7), 2313-2318. http://dx.doi.org/10.1016/S1359-6454(97)00387-X.

http://dx.doi.org/10.1016/S1359-6454(97)...

]. Roughness alters the contact area between the liquid drop and the surface, resulting in higher values of θ in hydrophobic materials and lower ones in hydrophilic surfaces[1919 Hazlett, R. D. (1992). On surface roughness effects in wetting phenomena. Journal of Adhesion Science and Technology, 6(6), 625-633. http://dx.doi.org/10.1163/156856192X01006.

http://dx.doi.org/10.1163/156856192X0100...

]. To investigate the morphology of PVC, two-dimensional AFM images (5 µm × 5 µm) were obtained for the untreated and treated PVC, as shown in Fig. 3. Although the tip of equipment is very fine and the spatial resolution should be high, the images are not all as well-defined as was expected.

AFM images of: (a) Virgin PVC surface, R = 7.8 nm [20]; Plasma treatments in SF6 (b) Flu4: PI (cathode) 100 W, R = 213.2 nm (c) Flu1: PIII 25W, R = 27.3 nm and (d) Flu6: PI (anode) 100W R= 18.7 nm[99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.].

The roughness of the non-treated PVC (a) is 7.8 nm. According to Fig. 3a, virgin PVC possesses a high density of pinholes[1616 Zha, J., Ali, S. S., Peyroux, J., Batisse, N., Claves, D., Dubois, M., Kharitonov, A. P., Monier, G., Darmanin, T., Guittard, F., & Alekseiko, L. N. (2017). Superhydrophobic of polymer films via fluorine atoms covalent attachment and surface nano-texturing. Journal of Fluorine Chemistry, 200, 123-132. http://dx.doi.org/10.1016/j.jfluchem.2017.06.011.

http://dx.doi.org/10.1016/j.jfluchem.201...

], which is caused by the absence of polymeric chains in those regions. These pinholes have depths of a few nanometers, being of the same order as the Rrms of PVC (7.8 nm). In relation to PVC treated by plasma immersion, Fig. 3b, there is a considerable increase in roughness, to about 213.2 nm, which reinforces the explanation of the increase in hydrophobicity. Increased cross-linking between the neighboring polymer chains has reduced the presence of pinholes. This usually occurs when acquiring images of polymers. In relation to virgin PVC, there was a small increase in roughness for the sample treated by PIII; 27.3 nm at 25 W. As shown in Fig. 3d, there was no significant reduction in the density of pinholes, which implies a relatively low number of lateral links, or a lower degree of intertwining. The roughness was 18.7 nm.

The polymer surface in the plasma is exposed to a broad spectrum of ions, electrons, excited neutrals, radicals, visible and ultraviolet radiation that cause etching and, consequently, increase surface roughness and change surface chemistry. Plasma roughening, however, was not regarded as a method for producing useful patterns. Recent published work has changed this view, and in fact, interesting regular surface topographies after plasma treatment of polymer surfaces under defined conditions have recently been reported[2020 D’Sa, R. A., Burke, G. A., & Meenan, B. J. (2010). Protein adhesion and cell response on atmospheric pressure dielectric barrier discharge-modified polymer surfaces. Acta Biomaterialia, 6(7), 2609-2620. http://dx.doi.org/10.1016/j.actbio.2010.01.015. PMid:20096386.

http://dx.doi.org/10.1016/j.actbio.2010....

].

In all cases, we hypothesize that on the surface of treated PVC, pointed peaks are aligned, like a “grass”. For roughnesses of a few tens of nanometers, we characterize the surface as smooth. Both treated and untreated PVC have low roughnesses, producing low reflectance.

3.4 Optical transmittance – T (λ)

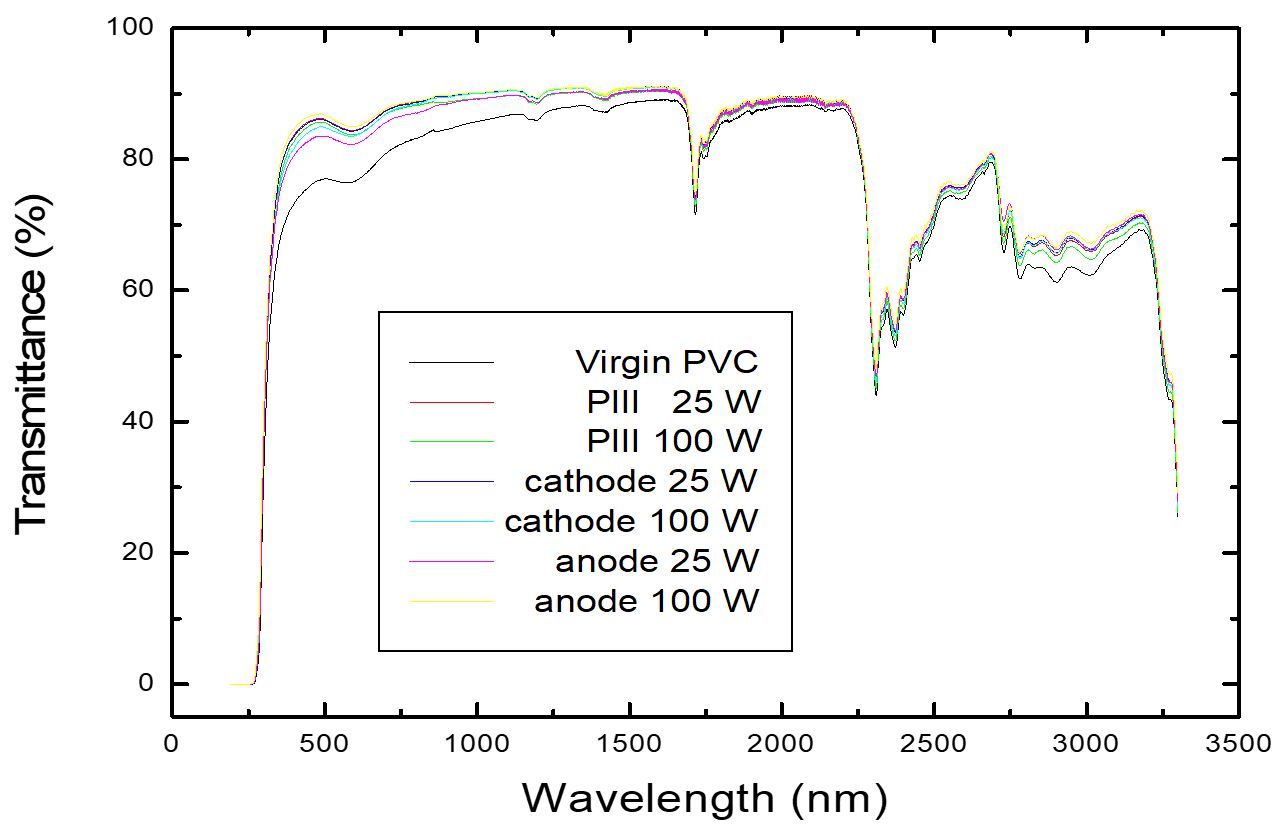

Fig. 4 shows the optical transmittance spectra of blue PVC treated with SF6 under different conditions. Each spectrum was generated at high resolution, ~0.2 nm/pixel.

Optical transmittance as function of wavelength for blue PVC treated using SF6 under different conditions: PIII 25 W or 100 W; PI cathode 25 W or 100 W; and PI anode 25 W or 100 W (Flu 1 to Flu6).

Whatever the treatment, the transmittance of all blue PVC samples in visible light increased. PIII is most appropriate for maintaining high transparency in the visible. Thus, plasma treatment distinctively influenced the transmittance of blue PVC. At high powers there is a greater fragmentation of molecules, and subsequent recombination between different plasma species, causing greater distortions of the polymer chains, thus producing voids among them, which increase the mean free path of the incident radiation. This effect, however, was limited owing to the low temperature treatment[77 Sant’Ana, P. L., Bortoleto, J. R. R., Rangel, E. C., Cruz, N. C., Durrant, S. F., Botti, L. C. M., Anjos, C. R., Teixeira, V., Azevedo, S., Silva, C. I., Soares, N. F. F., & Medeiros, E. A. A. (2018). Surface properties of PET polymer treated by plasma immersion techniques for food packaging. International Journal of Nano Research, 1(1), 33-41. Retrieved in 2020, August 17, from https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging

https://www.innovationinfo.org/internati...

,88 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., Botti, L. C. M., Anjos, C. A. R., Medeiros, E. A. A., Soares, N. F. F., Azevedo, S., Teixeira, V., Carneiro, J., & Silva, C. I. (2018). Surface properties and morphology of PET treated by plasma immersion ion implantation for food packaging. Nanomedicine & Nanotechnology Open Access, 3(3), 1-13. http://dx.doi.org/10.23880/NNOA-16000145.

http://dx.doi.org/10.23880/NNOA-16000145...

].

4. Discussions

4.1 Physico-chemical modifications

After fluorine insertion into the polymer backbone, the surface becomes hydrophobic. Although C-F bonds are highly polar, when these species are present on the surface of a material, they will increase its hydrophobicity. The repulsion between the oxygen in the water and the fluoride surface is greater than attraction of the fluorine for hydrogen, which implies a non-chemical attraction between the fluorinated surface and the test fluid[2121 Sant’Ana, P. L. (2014). Commercial polymers treated by plasma for optical devices and food packaging (Doctoral thesis). Universidade Estadual Paulista, Sorocaba.]. The incorporation of fluorine resulted in the formation of different functional groups on the surface, such as CF, CHF, CF2 and CF3[2222 Vandencasteele, N., Fairbrother, H., & Reniers, F. (2005). Selected effect of the ions and the neutrals in the plasma treatment of PTFE surfaces: an OES‐AFM‐contact angle and XPS study. Plasma Processes and Polymers, 2(6), 493-500. http://dx.doi.org/10.1002/ppap.200500010.

http://dx.doi.org/10.1002/ppap.200500010...

]. Two factors were instrumental in the increase of hydrophobicity: (i) the degree of fluorination; (ii) the surface roughness[55 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2017). Study of wettability and optical transparency of PET polymer modified by plasma immersion techniques. Revista Brasileira de Aplicações de Vácuo, 36(2), 68-74. http://dx.doi.org/10.17563/rbav.v36i2.1050.

http://dx.doi.org/10.17563/rbav.v36i2.10...

]. The degree of wetting of the samples immediately after treatment has its effect amplified by the increased surface roughness, which increases the area available for ions or even for neutral species from the plasma to bind chemically with the surface atoms. On the other hand, the main mechanism responsible for the hydrophilic behavior of the samples treated with N2, is the incorporation of polar groups[55 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2017). Study of wettability and optical transparency of PET polymer modified by plasma immersion techniques. Revista Brasileira de Aplicações de Vácuo, 36(2), 68-74. http://dx.doi.org/10.17563/rbav.v36i2.1050.

http://dx.doi.org/10.17563/rbav.v36i2.10...

6 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

7 Sant’Ana, P. L., Bortoleto, J. R. R., Rangel, E. C., Cruz, N. C., Durrant, S. F., Botti, L. C. M., Anjos, C. R., Teixeira, V., Azevedo, S., Silva, C. I., Soares, N. F. F., & Medeiros, E. A. A. (2018). Surface properties of PET polymer treated by plasma immersion techniques for food packaging. International Journal of Nano Research, 1(1), 33-41. Retrieved in 2020, August 17, from https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging

https://www.innovationinfo.org/internati...

8 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., Botti, L. C. M., Anjos, C. A. R., Medeiros, E. A. A., Soares, N. F. F., Azevedo, S., Teixeira, V., Carneiro, J., & Silva, C. I. (2018). Surface properties and morphology of PET treated by plasma immersion ion implantation for food packaging. Nanomedicine & Nanotechnology Open Access, 3(3), 1-13. http://dx.doi.org/10.23880/NNOA-16000145.

http://dx.doi.org/10.23880/NNOA-16000145...

-99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.,1616 Zha, J., Ali, S. S., Peyroux, J., Batisse, N., Claves, D., Dubois, M., Kharitonov, A. P., Monier, G., Darmanin, T., Guittard, F., & Alekseiko, L. N. (2017). Superhydrophobic of polymer films via fluorine atoms covalent attachment and surface nano-texturing. Journal of Fluorine Chemistry, 200, 123-132. http://dx.doi.org/10.1016/j.jfluchem.2017.06.011.

http://dx.doi.org/10.1016/j.jfluchem.201...

]. Although the treatment results in the incorporation of polar groups, polymer wettability does not involve only oxidative reactions. Loss and incorporation of new species, other than O, may occur as ageing time increases[2323 Gengenbach, T. R., & Griesser, H. J. (1999). Post-deposition ageing reactions differ markedly between plasma polymers deposited from siloxane and silazane monomers. Polymer, 40(18), 5079-5094. http://dx.doi.org/10.1016/S0032-3861(98)00727-7.

http://dx.doi.org/10.1016/S0032-3861(98)...

]. XPS analysis shows an increase in [O] from 11 at.% to 33 at.% on PVC samples after N2 treatment by PIII. This leads to the hypothesis that the presence of oxygen in the reactor, deriving either from residual gas or gas released from the glass chamber near the electrode region, may also account for the hydrophilization process[1212 Foerch, R., Kill, G., & Walzak, M. (1993). Plasma surface modification of polypropylene: shortterm vs. Long-term plasma treatment. Journal of Adhesion Science and Technology, 7(10), 1077-1089. http://dx.doi.org/10.1163/156856193X00592.

http://dx.doi.org/10.1163/156856193X0059...

,1313 Dong, H., & Bell, T. (1999). State-of-the-art overview. Ion beam surface modification of polymer towards improving tribological properties. Surface and Coatings Technology, 111(1), 29-40. http://dx.doi.org/10.1016/S0257-8972(98)00698-7.

http://dx.doi.org/10.1016/S0257-8972(98)...

]. Chemical modifications can occur upon ageing and reorganize chemical groups of the polymeric chains, which favor the reduction of the surface free energy until chemical stabilization occurs. Thus, the stability of the treated surface is determined by the extent to which polar species are allowed to move. A way of restraining reorientation is by an increase in cross-linking[2424 Yasuda, H., Sharma, A., & Yasuda, T. (1981). Effect of orientation and mobility of polymer molecules at surfaces on contact angle and its hysteresis. Journal of Polymer Science. Polymer Physics Edition, 19(9), 1285-1291. http://dx.doi.org/10.1002/pol.1981.180190901.

http://dx.doi.org/10.1002/pol.1981.18019...

], which may be produced by ion implantation. An increase in the density of covalent bonds among neighboring chains, known as anchor points, limits vibrational and rotational movements. As a consequence, the polymer structure becomes strongly connected and the backbone more rigid[99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.,1616 Zha, J., Ali, S. S., Peyroux, J., Batisse, N., Claves, D., Dubois, M., Kharitonov, A. P., Monier, G., Darmanin, T., Guittard, F., & Alekseiko, L. N. (2017). Superhydrophobic of polymer films via fluorine atoms covalent attachment and surface nano-texturing. Journal of Fluorine Chemistry, 200, 123-132. http://dx.doi.org/10.1016/j.jfluchem.2017.06.011.

http://dx.doi.org/10.1016/j.jfluchem.201...

].

The change in the surface hydrophilicity is caused by the replacement of C–C or C–H group on the surface of PVC by C–O or C=O groups[2525 Chu, P. K. (2004). Recent Developments and applications of plasma immersion ion implantation (PIII). Journal of Vacuum Science & Technology. B, Microelectronics and Nanometer Structures : Processing, Measurement, and Phenomena : An Official Journal of the American Vacuum Society, 22(1), 289-296. http://dx.doi.org/10.1116/1.1632920.

http://dx.doi.org/10.1116/1.1632920...

26 Chu, P. K., Tang, B. Y., Wang, L. P., Wang, X. F., Wang, S. Y., & Huang, N. (2001). Third-generation plasma immersion ion implanter for biomedical materials and research. The Review of Scientific Instruments, 72(3), 1660-1665. http://dx.doi.org/10.1063/1.1340029.

http://dx.doi.org/10.1063/1.1340029...

27 Guruvenket, S., Rao, G. M., Komath, M., & Raichur, A. M. (2004). Plasma surface modification of polystyrene and polyethylene. Applied Surface Science, 236(1–4), 278-284. http://dx.doi.org/10.1016/j.apsusc.2004.04.033.

http://dx.doi.org/10.1016/j.apsusc.2004....

28 Triandafillu, K., Balazs, D. J., Aronsson, B. O., Descouts, P., Tu Quoc, P., van Delden, C., Mathieu, H. J., & Harms, H. (2003). Adhesion of pseudomonas aeruginosa strains to untreated and oxygen-plasma treated poly(vinyl chloride) (PVC) from endotracheal intubation devices. Biomaterials, 24(8), 1507-1518. http://dx.doi.org/10.1016/S0142-9612(02)00515-X. PMid:12527292.

http://dx.doi.org/10.1016/S0142-9612(02)...

-2929 Park, Y. W., & Inagaki, N. (2003). Surface modification of poly (vinylidene fluoride) film by remote Ar, H2, and O2 plasmas. Polymer, 44(5), 1569-1575. http://dx.doi.org/10.1016/S0032-3861(02)00872-8.

http://dx.doi.org/10.1016/S0032-3861(02)...

]. A small quantity of nitrogen was detected on the treated sample surface and may be caused by atmospheric N2 reacting with the active surface functional groups[3030 Zhang, W., Chu, P. K., Ji, J., Zhang, Y., Liu, X., Fu, R. K., Ha, P. C., & Yan, Q. (2006). Plasma surface modification of poly vinyl chloride for improvement of antibacterial properties. Biomaterials, 27(1), 44-51. http://dx.doi.org/10.1016/j.biomaterials.2005.05.067. PMid:16005957.

http://dx.doi.org/10.1016/j.biomaterials...

]. Interactions between the nitrogen and the surface can also result in the diffusion of the nitrogen on the substrate surface[3131 Santjojo, D. J., Istiroyah, T., & Aizawa, T. (2015). Dynamics of nitrogen and hydrogen species in a high rate plasma nitriding of martensitic stainless steel. In: Proceedings of the 9th South East Asia Technical University Consortium - SEATUC (pp. 311-314). Nakhon Ratchasima, Thailand: Suranaree University of Technology.]. Indeed, the XPS analysis (sample Nit1), presents a low N concentration after PIII[3232 Choudhury, A. J., Barve, S. A., Chutia, J., Pal, A. R., Chowdhury, D., Kishore, R., Jagannath, Mithal, N., Pandey, M., & Patil, D. S. (2011). Investigations of the hydrophobic and scratch resistance behavior of polystyrene films deposited on bell metal using RF-PACVD process. Applied Surface Science, 257(9), 4211-4218. http://dx.doi.org/10.1016/j.apsusc.2010.12.022.

http://dx.doi.org/10.1016/j.apsusc.2010....

]. Hydrogen atoms may also be liberated from the polymer, causing cross-linking. For engineering applications, the degree of cross-linking and scission as well the depth of the modified layer can be tailored by the electronic-to-nuclear interactions via a judicious choice of ion species and ion energy[3333 Klapperich, C., Komvopoulos, K., & Pruitt, K. (1999). Tribological properties and microstructure evolution of ultra-high molecular weight polyethylene. Journal of Tribology, 121(2), 394-402. http://dx.doi.org/10.1115/1.2833952.

http://dx.doi.org/10.1115/1.2833952...

]. Experimental results suggest that unsaturation can occur when ion pairs in two neighboring chains overlap[3434 Lee, E. H., Rao, G. R., & Mansur, L. (1996). Super-hard-surfaced polymers by high-energy ion-beam irradiation. Trends in Polymer Science (Regular Ed.), 4(7), 229-237.]. Although both electronic and nuclear processes cause cross-linking as well as scissions, it has been found that the most important parameter to achieve a high degree of cross-linking is electronic, while nuclear collisions tends to cause degradation[3535 Lee, E. H. (1999).Ion-beam modification of polymeric materials – fundamental principles and applications. Nuclear Instruments & Methods in Physics Research. Section B, Beam Interactions with Materials and Atoms, 151(1-4), 29-41. http://dx.doi.org/10.1016/S0168-583X(99)00129-9.

http://dx.doi.org/10.1016/S0168-583X(99)...

].

Correlating the three different plasma immersion configurations with the wettability results, the key parameters are seen to be the ion flux and energy. When the sample is placed on the driven electrode (PI cathode), the self-bias will guarantee a high average negative potential relative to the plasma, so that the energy of the ions reaching the sample holder will be high, causing high recombination rates and therefore high production rates of C-F bonds in fluorine-containing plasmas. However, when the substrate holder is grounded together with the chamber walls (PI anode), the average potential drop in electrode sheath is not so high. In PIII ion energy is controlled by the HV pulses, being much more intense than in PI configurations. Another important point is that PVC is an insulating material. Consequently, independent of the substrate holder potential, the sample will be at floating potential, and possibly the charged particle flux onto the sample is not so different in the three PI configurations when the sample is at floating potential. Thus θ is influenced much more by ion energy than by the ion flux of charged particles.

4.2 Spectroscopy

The increase in optical transmittance of polymers can be explained by changes in chemical structures and bonds that occur on the surface of samples owing to rf plasma treatment. Under plasma treatment some bonds in the polymer structure will break and some new chains will form. In this case, plasma treatment may affect optical properties of the material[55 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2017). Study of wettability and optical transparency of PET polymer modified by plasma immersion techniques. Revista Brasileira de Aplicações de Vácuo, 36(2), 68-74. http://dx.doi.org/10.17563/rbav.v36i2.1050.

http://dx.doi.org/10.17563/rbav.v36i2.10...

6 Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115.

http://dx.doi.org/10.17563/rbav.v37i3.11...

7 Sant’Ana, P. L., Bortoleto, J. R. R., Rangel, E. C., Cruz, N. C., Durrant, S. F., Botti, L. C. M., Anjos, C. R., Teixeira, V., Azevedo, S., Silva, C. I., Soares, N. F. F., & Medeiros, E. A. A. (2018). Surface properties of PET polymer treated by plasma immersion techniques for food packaging. International Journal of Nano Research, 1(1), 33-41. Retrieved in 2020, August 17, from https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging

https://www.innovationinfo.org/internati...

8 Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., Botti, L. C. M., Anjos, C. A. R., Medeiros, E. A. A., Soares, N. F. F., Azevedo, S., Teixeira, V., Carneiro, J., & Silva, C. I. (2018). Surface properties and morphology of PET treated by plasma immersion ion implantation for food packaging. Nanomedicine & Nanotechnology Open Access, 3(3), 1-13. http://dx.doi.org/10.23880/NNOA-16000145.

http://dx.doi.org/10.23880/NNOA-16000145...

-99 Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging. Mauritius: Scholar’s Press.,1616 Zha, J., Ali, S. S., Peyroux, J., Batisse, N., Claves, D., Dubois, M., Kharitonov, A. P., Monier, G., Darmanin, T., Guittard, F., & Alekseiko, L. N. (2017). Superhydrophobic of polymer films via fluorine atoms covalent attachment and surface nano-texturing. Journal of Fluorine Chemistry, 200, 123-132. http://dx.doi.org/10.1016/j.jfluchem.2017.06.011.

http://dx.doi.org/10.1016/j.jfluchem.201...

]. Summarizing, PIII did not change optical transmittance, that is, the samples treated at the same rf power of 100 W presented high optical transmittance for SF6 plasma or N2 plasmas, affecting only the wettability (samples Nit1 vs. Flu2). On the other hand, PI cathode changed the wettability, presenting the most extreme values of Ɵ, (1º for nitrogen plasma; 142º for fluorine plasmas). In addition, the PI cathode treatment at rf = 100 W changed the optical transmittance only for the sample treated with fluorine-containing plasmas (Flu4), producing an increase in optical transmittance from 75% to 84% in the visible range. Moreover it is possible with fluorine ion implantation to maintain the low roughness, which presented a slight increase of 10 nm (sample Flu1), or even to considerably increase the roughness from 7.8 to 213.2 nm using PI cathode (sample Flu3).

5. Conclusions

Plasma treatments of PVC samples can increase hydrophobicity by using SF6 or increase hydrophilicity using N2. AFM images showed that low energy ion implantation is more effective in maintaining the original low roughness of the polymer surface. Thus, roughness did not significantly affect the high transmittance of blue PVC. When plasma treatment increased the surface roughness, the incorporated surface species increased the change in wettability for all samples. The pinholes typically present in PVC substrates were only suppressed when the PI cathode (sample Flu4) was employed. Roughnesses were of a few nanometers, and influenced the optical properties. XPS analysis revealed the surface incorporation of fluorine for all techniques that used SF6. No significant nitrogenation of PVC was observed in nitrogen plasmas but considerable amounts of oxygen were introduced into the treated surface. Optical transmittance was increased for all plasma-treated samples. More specifically, PI cathode and PIII plasmas with fluorine produced hydrophobicity and maintained high optical transparency. The chemical composition was influential in changing the transmittance, causing a decrease in the absorption coefficient.

6. Acknowledgements

The authors are grateful to the Brazilian agencies Fundação de Amparo à Pesquisa do Estado de São Paulo - FAPESP (Project 2017/15853-0) and Conselho Nacional de Desenvolvimento Científico e Tecnológico - CNPq for financial support. This study was also financed in part by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – Brasil, CAPES - Finance Code 001.

-

How to cite: Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., & Schreiner, W. H. (2020). Surface functionalization of polyvinyl chloride by plasma immersion techniques. Polímeros: Ciência e Tecnologia, 30(4), e2020044. https://doi.org/10.1590/0104-1428.06020

7. References

-

1Juang, R. S., Hou, W. T., Huang, Y. C., Tseng, Y. C., & Huang, C. (2016). Surface hydrophilic modifications on polypropylene membranes by remote methane/oxygen mixture plasma discharges. Journal of the Taiwan Institute of Chemical Engineers, 65, 420-426. http://dx.doi.org/10.1016/j.jtice.2016.04.032

» http://dx.doi.org/10.1016/j.jtice.2016.04.032 -

2Nazarov, V. G., Stolyarov, V. P., & Gagarin, M. V. (2014). Simulation of chemical modification of polymer surface. Journal of Fluorine Chemistry, 161, 120-127. http://dx.doi.org/10.1016/j.jfluchem.2014.01.021

» http://dx.doi.org/10.1016/j.jfluchem.2014.01.021 -

3Kharitonov, A. P., Simbirtseva, G. V., Tressaud, A., Durand, E., Labrugère, C., & Dubois, M. (2014). Comparison of the surface modifications of polymers induced by direct fluorination and rf-plasma using fluorinated gases. Journal of Fluorine Chemistry, 165, 49-60. http://dx.doi.org/10.1016/j.jfluchem.2014.05.002

» http://dx.doi.org/10.1016/j.jfluchem.2014.05.002 -

4Gancarz, I., Bryjak, M., Kujawski, J., Wolska, J., Kujawa, J., & Kujawski, W. (2015). Plasma deposited fluorinated films on porous membranes. Materials Chemistry and Physics, 151, 233-242. http://dx.doi.org/10.1016/j.matchemphys.2014.11.059

» http://dx.doi.org/10.1016/j.matchemphys.2014.11.059 -

5Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2017). Study of wettability and optical transparency of PET polymer modified by plasma immersion techniques. Revista Brasileira de Aplicações de Vácuo, 36(2), 68-74. http://dx.doi.org/10.17563/rbav.v36i2.1050

» http://dx.doi.org/10.17563/rbav.v36i2.1050 -

6Sant’Ana, P. L., Prestes, S. M. D., Mancini, S. D., Rangel, R. C., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., & Durrant, S. F. (2019). Comparative analysis between the degree of wettability of recycled PVC and PET polymers treated by immersion or deposition of organic films in fluorinated plasmas. Revista Brasileira de Aplicações de Vácuo, 37(3), 120-128. http://dx.doi.org/10.17563/rbav.v37i3.1115

» http://dx.doi.org/10.17563/rbav.v37i3.1115 -

7Sant’Ana, P. L., Bortoleto, J. R. R., Rangel, E. C., Cruz, N. C., Durrant, S. F., Botti, L. C. M., Anjos, C. R., Teixeira, V., Azevedo, S., Silva, C. I., Soares, N. F. F., & Medeiros, E. A. A. (2018). Surface properties of PET polymer treated by plasma immersion techniques for food packaging. International Journal of Nano Research, 1(1), 33-41. Retrieved in 2020, August 17, from https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging

» https://www.innovationinfo.org/international-journal-of-nano-research/article/Surface-Properties-of-PET-Polymer-Treated-by-Plasma-Immersion-Techniques-for-Food-Packaging -

8Sant’Ana, P. L., Bortoleto, J. R. R., Cruz, N. C., Rangel, E. C., Durrant, S. F., Botti, L. C. M., Anjos, C. A. R., Medeiros, E. A. A., Soares, N. F. F., Azevedo, S., Teixeira, V., Carneiro, J., & Silva, C. I. (2018). Surface properties and morphology of PET treated by plasma immersion ion implantation for food packaging. Nanomedicine & Nanotechnology Open Access, 3(3), 1-13. http://dx.doi.org/10.23880/NNOA-16000145

» http://dx.doi.org/10.23880/NNOA-16000145 -

9Sant’Ana, P. L. (2018). Polymers treated by plasma for optical devices and food packaging Mauritius: Scholar’s Press.

-

10Cruz, S. A., Zanin, M., Nascente, P. A. P., & Bica de Moraes, M. A. (2010). Superficial modification in recycled PET by plasma etching for food packaging. Journal of Applied Polymer Science, 115(5), 2728-2733. http://dx.doi.org/10.1002/app.29958

» http://dx.doi.org/10.1002/app.29958 -

11Milella, A., Colapricio, V., Favia, P., Iacobelli, L., & d’Agostino, R. (2001). Plasma treatments of polymers for reducing ageing. In Proceedings of the 15th International Symposium on Plasma Chemistry (pp. 2416-2420). Orléans, France: International Plasma Chemistry Society. Retrieved in 2020, August 17, from https://www.ispc-conference.org/ispcdocs/ispc15/content/15/15-2416.pdf

» https://www.ispc-conference.org/ispcdocs/ispc15/content/15/15-2416.pdf -

12Foerch, R., Kill, G., & Walzak, M. (1993). Plasma surface modification of polypropylene: shortterm vs. Long-term plasma treatment. Journal of Adhesion Science and Technology, 7(10), 1077-1089. http://dx.doi.org/10.1163/156856193X00592

» http://dx.doi.org/10.1163/156856193X00592 -

13Dong, H., & Bell, T. (1999). State-of-the-art overview. Ion beam surface modification of polymer towards improving tribological properties. Surface and Coatings Technology, 111(1), 29-40. http://dx.doi.org/10.1016/S0257-8972(98)00698-7

» http://dx.doi.org/10.1016/S0257-8972(98)00698-7 -

14Huang, C., Ma, W. C., Tsai, C. Y., Hou, W. T., & Juang, R. S. (2013). Surface modification of polytetrafluorethylene membranes by radio frequency methane/nitrogen mixture plasma polymerization. Surface and Coatings Technology, 231, 42-46. http://dx.doi.org/10.1016/j.surfcoat.2012.03.005

» http://dx.doi.org/10.1016/j.surfcoat.2012.03.005 -

15Sadeek, S. A. (2005). Synthesis, thermogravimetric analysis, infrared, electronic and mass spectra of Mn(II), Co(II) and Fe(III) norfloxacin complexes. Journal of Molecular Structure, 753(1-3), 1-12. http://dx.doi.org/10.1016/j.molstruc.2005.06.011

» http://dx.doi.org/10.1016/j.molstruc.2005.06.011 -

16Zha, J., Ali, S. S., Peyroux, J., Batisse, N., Claves, D., Dubois, M., Kharitonov, A. P., Monier, G., Darmanin, T., Guittard, F., & Alekseiko, L. N. (2017). Superhydrophobic of polymer films via fluorine atoms covalent attachment and surface nano-texturing. Journal of Fluorine Chemistry, 200, 123-132. http://dx.doi.org/10.1016/j.jfluchem.2017.06.011

» http://dx.doi.org/10.1016/j.jfluchem.2017.06.011 -

17Rangel, E. C., dos Santos, N. M., Bortoleto, J. R. R., Durrant, S. F., Schreiner, W. H., Honda, R. Y., Rangel, R. C. C., & Cruz, N. C. (2006). Treatment of PVC using an alternative low energy ion bombardment procedure. Applied Surface Science, 258(5), 1854-1861. http://dx.doi.org/10.1016/j.apsusc.2011.10.061

» http://dx.doi.org/10.1016/j.apsusc.2011.10.061 -

18Nakae, H., Iuni, R., Hirata, Y., & Saito, H. (1998). Effects of surface roughness on wettability. Acta Materialia, 46(7), 2313-2318. http://dx.doi.org/10.1016/S1359-6454(97)00387-X

» http://dx.doi.org/10.1016/S1359-6454(97)00387-X -

19Hazlett, R. D. (1992). On surface roughness effects in wetting phenomena. Journal of Adhesion Science and Technology, 6(6), 625-633. http://dx.doi.org/10.1163/156856192X01006

» http://dx.doi.org/10.1163/156856192X01006 -

20D’Sa, R. A., Burke, G. A., & Meenan, B. J. (2010). Protein adhesion and cell response on atmospheric pressure dielectric barrier discharge-modified polymer surfaces. Acta Biomaterialia, 6(7), 2609-2620. http://dx.doi.org/10.1016/j.actbio.2010.01.015 PMid:20096386.

» http://dx.doi.org/10.1016/j.actbio.2010.01.015 -

21Sant’Ana, P. L. (2014). Commercial polymers treated by plasma for optical devices and food packaging (Doctoral thesis). Universidade Estadual Paulista, Sorocaba.

-

22Vandencasteele, N., Fairbrother, H., & Reniers, F. (2005). Selected effect of the ions and the neutrals in the plasma treatment of PTFE surfaces: an OES‐AFM‐contact angle and XPS study. Plasma Processes and Polymers, 2(6), 493-500. http://dx.doi.org/10.1002/ppap.200500010

» http://dx.doi.org/10.1002/ppap.200500010 -

23Gengenbach, T. R., & Griesser, H. J. (1999). Post-deposition ageing reactions differ markedly between plasma polymers deposited from siloxane and silazane monomers. Polymer, 40(18), 5079-5094. http://dx.doi.org/10.1016/S0032-3861(98)00727-7

» http://dx.doi.org/10.1016/S0032-3861(98)00727-7 -

24Yasuda, H., Sharma, A., & Yasuda, T. (1981). Effect of orientation and mobility of polymer molecules at surfaces on contact angle and its hysteresis. Journal of Polymer Science. Polymer Physics Edition, 19(9), 1285-1291. http://dx.doi.org/10.1002/pol.1981.180190901

» http://dx.doi.org/10.1002/pol.1981.180190901 -

25Chu, P. K. (2004). Recent Developments and applications of plasma immersion ion implantation (PIII). Journal of Vacuum Science & Technology. B, Microelectronics and Nanometer Structures : Processing, Measurement, and Phenomena : An Official Journal of the American Vacuum Society, 22(1), 289-296. http://dx.doi.org/10.1116/1.1632920

» http://dx.doi.org/10.1116/1.1632920 -

26Chu, P. K., Tang, B. Y., Wang, L. P., Wang, X. F., Wang, S. Y., & Huang, N. (2001). Third-generation plasma immersion ion implanter for biomedical materials and research. The Review of Scientific Instruments, 72(3), 1660-1665. http://dx.doi.org/10.1063/1.1340029

» http://dx.doi.org/10.1063/1.1340029 -

27Guruvenket, S., Rao, G. M., Komath, M., & Raichur, A. M. (2004). Plasma surface modification of polystyrene and polyethylene. Applied Surface Science, 236(1–4), 278-284. http://dx.doi.org/10.1016/j.apsusc.2004.04.033

» http://dx.doi.org/10.1016/j.apsusc.2004.04.033 -

28Triandafillu, K., Balazs, D. J., Aronsson, B. O., Descouts, P., Tu Quoc, P., van Delden, C., Mathieu, H. J., & Harms, H. (2003). Adhesion of pseudomonas aeruginosa strains to untreated and oxygen-plasma treated poly(vinyl chloride) (PVC) from endotracheal intubation devices. Biomaterials, 24(8), 1507-1518. http://dx.doi.org/10.1016/S0142-9612(02)00515-X PMid:12527292.

» http://dx.doi.org/10.1016/S0142-9612(02)00515-X -

29Park, Y. W., & Inagaki, N. (2003). Surface modification of poly (vinylidene fluoride) film by remote Ar, H2, and O2 plasmas. Polymer, 44(5), 1569-1575. http://dx.doi.org/10.1016/S0032-3861(02)00872-8

» http://dx.doi.org/10.1016/S0032-3861(02)00872-8 -

30Zhang, W., Chu, P. K., Ji, J., Zhang, Y., Liu, X., Fu, R. K., Ha, P. C., & Yan, Q. (2006). Plasma surface modification of poly vinyl chloride for improvement of antibacterial properties. Biomaterials, 27(1), 44-51. http://dx.doi.org/10.1016/j.biomaterials.2005.05.067 PMid:16005957.

» http://dx.doi.org/10.1016/j.biomaterials.2005.05.067 -

31Santjojo, D. J., Istiroyah, T., & Aizawa, T. (2015). Dynamics of nitrogen and hydrogen species in a high rate plasma nitriding of martensitic stainless steel. In: Proceedings of the 9th South East Asia Technical University Consortium - SEATUC (pp. 311-314). Nakhon Ratchasima, Thailand: Suranaree University of Technology.

-

32Choudhury, A. J., Barve, S. A., Chutia, J., Pal, A. R., Chowdhury, D., Kishore, R., Jagannath, Mithal, N., Pandey, M., & Patil, D. S. (2011). Investigations of the hydrophobic and scratch resistance behavior of polystyrene films deposited on bell metal using RF-PACVD process. Applied Surface Science, 257(9), 4211-4218. http://dx.doi.org/10.1016/j.apsusc.2010.12.022

» http://dx.doi.org/10.1016/j.apsusc.2010.12.022 -

33Klapperich, C., Komvopoulos, K., & Pruitt, K. (1999). Tribological properties and microstructure evolution of ultra-high molecular weight polyethylene. Journal of Tribology, 121(2), 394-402. http://dx.doi.org/10.1115/1.2833952

» http://dx.doi.org/10.1115/1.2833952 -

34Lee, E. H., Rao, G. R., & Mansur, L. (1996). Super-hard-surfaced polymers by high-energy ion-beam irradiation. Trends in Polymer Science (Regular Ed.), 4(7), 229-237.

-

35Lee, E. H. (1999).Ion-beam modification of polymeric materials – fundamental principles and applications. Nuclear Instruments & Methods in Physics Research. Section B, Beam Interactions with Materials and Atoms, 151(1-4), 29-41. http://dx.doi.org/10.1016/S0168-583X(99)00129-9

» http://dx.doi.org/10.1016/S0168-583X(99)00129-9

Publication Dates

-

Publication in this collection

23 Apr 2021 -

Date of issue

2020

History

-

Received

17 Dec 2020 -

Reviewed

25 Jan 2021 -

Accepted

05 Feb 2021