ABSTRACT

Stem conicity and the sawing pattern, besides the presence of hollows and sapwood, are among the principal factors that are responsible for the low yield of lumber from harvested wood in the Amazon. Therefore, the objective of this study was to analyze of logs and stem conicity, and its effect on yield of sawn wood from the species Handroanthus impetiginosus (Mart. ex DC.) Mattos, Lecythis lurida (Miers) S. A. Mori, Manilkara huberi (Ducke) Chevalier, Astronium lecointei Ducke and Couratari sp., which are currently the most important commercial species in the study area. The data used were obtained from six production units in the Tapajós National Forest, Pará. The variables analyzed were conicity (obtained as a function of the difference between diameters at the base and top) between logs, DBH classes (diameter at breast height) and species, as well as yield (estimated using the Software MaxiTora) between logs and species. The majority of the species showed differences in conicity between logs, with the first log being the most conic, which was directly reflected by the lower yield for this log. There was a tendency of increase in conicity in the larger DBH classes, and differences in conicity and yield between species. The estimated yields were superior to the percent yields observed for Amazonian species in studies done using samples with similar characteristics. Therefore, it was concluded that conicity can vary between species, logs, and DBH classes, and is a characteristic that directly effects the yield of lumber. Furthermore, the incorporation of cutting templates represents an alternative for maximizing lumber yield.

Keywords:

Native Amazonian tree species; Stem form; Regional sawmill industry; Sawn patterns

INTRODUCTION

The extraction of timber from native forests has become one of the principal economic activities in all the States that make up the Legal Amazon at the beginning of the XXI century (Homma, 2011HOMMA, A. K. O. Madeira na Amazônia: Extração, Manejo ou Reflorestamento? Amazônia: Ciência & Desenvolvimento , v. 7, n. 13, p. 147-161, 2011.). However, this region is also a large generator of residuals that come from the process of conversion of logs into lumber and this principally occurs due to lack of knowledge of the characteristics of the raw material, which complicates the pre-selection process (Melo et al., 2012MELO, L. E. L.; SILVA, C. J.; LOPES, K. V.; BRITO, P. G. M.; SANTOS, I. S. Resíduos de Serraria no Estado do Pará: Caracterização, Quantificação e Utilização Adequada. Floresta e Ambiente, v. 19, n. 1, p. 113-116, 2012.).

In Amazonian sawmills low lumber yield is a common occurrence and is estimated at approximately 41% in a report presented by Hummel (Hummel et al., 2010HUMMEL, A. C., ALVES, M. V. S., PEREIRA, D., VERÍSSIMO, A. V., & SANTOS, D. A atividade madeireira na Amazônia brasileira: produção, receita e mercados. Serviço Floresta l Brasileiro. 2010. 28 p. Belém, PA: Instituto do Homem e Meio Ambiente da Amazônia. Available at: <https://imazon.org.br/PDFimazon/Portugues/livretos/a-atividade-madeireira-na amazoniabrasileira.pdf>

https://imazon.org.br/PDFimazon/Portugue...

). This creates economic and environmental problems because a greater volume of raw material must be consumed in order to compensate for the volume of wood lost (Braz et al., 2014BRAZ, R. L., NUTTO, L., BRUNSMEIER, M., BECKER, G., SILVA, D. A. Resíduos da colheita florestal e do processamento da madeira na Amazônia - Uma análise da cadeia produtiva. Journal of Biotechnology and Biodiversity, v. 5, n. 2, p. 168-181, 2014.). The Conama resolution Nº 474/2016 reduced to 35% the coefficient of volumetric yield for sawn wood with the goal of being more in sync with the realities faced by the sawmill industry in the region (BRASIL, 2016BRASIL. Resolução nº 474, de 6 de abril de 2016. Altera a Resolução no 411, de 6 de maio de 2009, que dispõe sobre procedimentos para inspeção de indústrias consumidoras ou transformadoras de produtos e subprodutos florestais madeireiros de origem nativa, bem como os respectivos padrões de nomenclatura e coeficientes de rendimento volumétricos, inclusive carvão vegetal e resíduos de serraria, e dá outras providências. Diário Oficial da União da República Federativa do Brasil, Brasília, DF, 06, may, 2016. Seção 1, p. 74-75. Available at: Available at: http://www2.mma.gov.br/port/conama/legiabre.cfm?codlegi=720

. Accessed in: April 20th 2019.

http://www2.mma.gov.br/port/conama/legia...

), thus sanctioning the low yield of lumber from raw material.

Stem conicity and method of log sawing are among the principal factors responsible for losses due to log sawing, resulting in considerable waste of raw material in the form of residues (Steele, 1984STEELE, P. H. Factors determining lumber recovery in sawmilling. General Technical Report FPL-39. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 1984. 10p. Available at: https://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr39.pdf doi:10.2737/FPL-GTR-39.

https://www.fpl.fs.fed.us/documnts/fplgt...

; Rocha, 2007ROCHA, M. P. Técnicas de serrarias. In: OLIVEIRA, J. T. S.; FIEDLER, N. C.; NOGUEIRA, M, organizadores. Tecnologias aplicadas ao setor madeireiro. Jerônimo Monteiro: Suprema. 2007. p. 209-270.).

It is known that the stems of trees have highly variable forms and vary as a function of species, tree size, and environmental conditions, among other factors (Husch et al., 2003HUSCH, B.; BEERS, T. W.; KERSHAW JR, J. A. Forest mensuration. (4th ed.) New Jersey: Hoboken. 2003. 456p.; Guo et al., 2011GUO, Y.; FOURCAUD, T.; JAEGER, M.; ZHANG, X.; LI B. Plant growth and architectural modelling and its applications. Annals of botany, v. 107, n. 5, p. 723-727, 2011.; Iida et al., 2011IIDA, Y.; KOHYAMA, T. S.; KUBO, T.; KASSIM, A. R.; POORTER, L.; STERCK, F.; POTTS, M. D. Tree architecture and lifehistory strategies across 200 co-occurring tropical tree species. Functional Ecology, v. 25, n. 6, p. 1260-1268, 2011.). In tropical forests, conicity along the trunk can be highly irregular (Nunes and Görgens, 2016NUNES, M. H.; GÖRGENS, E. B. Artificial Intelligence Procedures for Tree Taper Estimation within a Complex Vegetation Mosaic in Brazil. Plos One , v. 11, n. 5, e0154738, 2016.), therefore, studies examining conicity of commercial stems in these forests have great importance for the optimization of wood yield.

The conventional method of log sawing, in which the saw operator determines how the cuts will be made, still predominates in the Amazon region (Melo et al., 2019MELO, R. R.; DACROCE, J. M. D.; RODOLFO JUNIOR, F.; LISBOA, G. S.; FRANÇA, L. C. J. Lumber Yield of Four Native Forest Species of the Amazon Region. Floresta e Ambiente, v. 26, n. 1, e20160311, 2019.). In most cases the decision is random, and this will rarely result in a high level of yield (Biasi and Rocha, 2007ROCHA, M. P. Técnicas de serrarias. In: OLIVEIRA, J. T. S.; FIEDLER, N. C.; NOGUEIRA, M, organizadores. Tecnologias aplicadas ao setor madeireiro. Jerônimo Monteiro: Suprema. 2007. p. 209-270.). Currently, with the advent of computer programs it is possible to create a method for log cutting that involves their classification and the establishment of sawn pattern which allow for optimization of yield and, up to a certain point, minimization of costs (Ikonen et al., 2003IKONEN, V-P.; KELLOMÄKI, S.; PELTOLA, H. Linking tree stem properties of Scots pine (Pinus sylvestris L) to sawn timber properties through simulated sawing. Forest Ecology and Management, v. 174, p. 251-263., 2003.; Wery et al., 2018WERY, J.; GAUDREAULT, J.; THOMAS, A.; MARIER, P. Simulation-optimisation based framework for Sales and Operations Planning taking into account new products opportunities in a co-production context. Forest Ecology and Management , v. 94, p. 41-51, 2018.).

Furthermore, modeling and computational simulation of cuts allows for the generation of information that can serve as a base for economic and financial analyses of the lumber processing operation (Biasi and Rocha 2007ROCHA, M. P. Técnicas de serrarias. In: OLIVEIRA, J. T. S.; FIEDLER, N. C.; NOGUEIRA, M, organizadores. Tecnologias aplicadas ao setor madeireiro. Jerônimo Monteiro: Suprema. 2007. p. 209-270.). In spite of being a technique that has been evaluated and used in a large diversity of scenarios for many years (Richards, 1973RICHARDS, D. B. Hardwood lumber yield by various simulated sawing methods. Forest products journal, v. 23, n. 10, p. 50-58, 1973.; Hallock et al., 1976HALLOCK, H.; STERN, A. R.; LEWIS, D. W. Is there a “best” sawing method? Research Paper FPL-280. Madison, WIS: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 1978. 11p. Available at: https://www.fpl.fs.fed.us/documnts/fplrp/fplrp280.pdf.

https://www.fpl.fs.fed.us/documnts/fplrp...

; Todoroki, 1994TODOROKI, C. L. Effect of edging and docking methods on volume and grade recoveries in the simulated production of flitches. Annals Science Forest, v. 51, p. 241-248, 1994.; Pinto et al., 2006PINTO, I.; KNAPIC, S.; PEREIRA, H.; USENIUS, A. Simulated and realised industrial yields in sawing of maritime pine (Pinus pinaster Ait.). Holz als Roh- und Werkstoff, v. 64, p. 30-36, 2006.; Knapic et al., 2011KNAPIC, S.; SEPPA, I. P.; USENIUS, A.; PEREIRA, H. Stem modeling and simulation of conversion of cork oak stems for quality wood products. European Journal of Forest Research, v. 130, p. 745-751, 2011.; Fredriksson et al., 2015FREDRIKSSON, M.; BERGLUND, A.; BROMAN, O. Validating a crosscutting simulation program based on computed tomography scanning of logs. European Journal Wood Products, v. 73, p. 143-150, 2015.), for tropical species this technique has rarely been employed (Ah Shenga et al., 2015AH SHENGA, P. A., BOMARK, P., BROMAN, O., SANDBERG, D. Simulation of tropical hardwood processing: Sawing methods, log positioning, and outer shape. BioResources, v. 10, n. 4, p. 7640-7652, 2015.; 2017AH SHENGA, P. A., BOMARK, P., BROMAN, O., SANDBERG, D. Log sawing positioning optimization and log bucking of tropical hardwood species to increase the volume yield. Wood Material Science & Engineering, v. 12, n. 4, p. 257-262, 2017.), especially for species from Amazonian forests. Therefore, studies that can indicate the potential for use of this technique in Amazonian sawmills are essential.

In this context, knowledge of the pattern of conicity of logs as well as for the whole commercial stems, and evaluation of estimated yield of sawn lumber using a computer program, as well as verification of relationships between these variables becomes valuable information for the forest management and timber industry, principally with respect to Amazonian commercial species. Therefore, the objective of this study was to analyze stem and log conicity of five important Amazonian commercial species and measure their effects on estimated sawn lumber yield using a computer program.

MATERIAL AND METHODS

Study area

This study was conducted in the Tapajós National Forest (TNF), a Federal Conservation Unit (CU) located in the west of the State of Pará on the margin of the Santarém-Cuiabá highway (BR-163), located in the municipalities of Belterra, Aveiro, Placas and Rurópolis, between the geographic coordinates 2º 45 to 4º 10´ S and 54º 45´ to 55º 30´W. The CU occupies and area of approximately 544,927 hectares. The soil predominant in the region is of the type Dystrophic Yellow Latosol, deep and well drained (Oliveira Junior et al., 2015OLIVEIRA JUNIOR, R. C.; KELLER, M. M.; RAMOS, J. F. F.; BELDINI, T. P.; CRILL, P. M.; CAMARGO, P. B.; HAREN, J. V. Chemical analysis of rainfall and throughfall in the Tapajos National Forest, Belterra, Pará, Brazil. Ambiente & Água - An Interdisciplinary Journal of Applied Science, v. 10, n. 2, p. 264-285, 2015.). The vegetation is classified as Dense Ombrophilous Forest, characterized by the presence of large trees and by the abundance of woody lianas, palms and epiphytes (IBGE, 2012INSTITUTO BRASILEIRO DE GEOGRAFIA E ESTATÍSTICA - IBGE. Manual técnico da vegetação brasileira: sistema fitogeográfico, inventário das formações florestais e campestres, técnicas e manejo de coleções botânicas, procedimentos para mapeamentos. Rio de Janeiro: IBGE - Diretoria de Geociências, 2012. 271p.). Rainfall is concentrated between January and May, with average annual precipitation of 1,820 mm, and climate is classified as Ami in the Köppen system (hot and humid), with an average annual temperature of 25.5 ºC (Alvares et al., 2013ALVARES, C.A.; STAPE, J.L.; SENTELHAS, P.C.; MORAES, G.; LEONARDO, J.; SPAROVEK, G. Koppen’s climate classification map for Brasil. Meteorologische Zeitschrift, v. 22, n. 6, p. 711-728, 2013.).

Data acquisition

The data used in this study were taken from 100% forest inventories and rigorous volumetric measurements of trees with a DBH ≥ 50.0 cm) for the species Ipê-roxo (Handroanthus impetiginosus), Jarana (Lecythis lurida), Maçaranduba (Manilkara huberi), Muiracatiara (Astronium lecointei) and Tauari (Couratari sp.), measured in six Annual Production Units (APUs) that were managed between 2010 and 2015 in the area of forest management of the TNF by the Mixed Cooperative of the TNF (Coomflona).

Among all the species that are managed in the TNF (approximately 45), these species have the greatest commercial importance, especially as a function of higher market demand and elevated abundance of individuals. This group of species represents 55.2% and 55.9% of the total number of trees and the total volume extracted, respectively, in the six APUs. Therefore, analyses related to stem form, and consequently lumber yield from these species can contribute in a relevant manner to the improvement of processing techniques in the forest products industry with the goal of optimizing use of raw material.

Data analysis

Sample selection and description

The pattern of stem conicity and its effect on estimated yield of sawn lumber for five species at the levels of logs and species was evaluated, and the pattern of conicity was analyzed at the level of DBH classes. At the level of logs, stem conicity and log yield were used, while at the species level data for conicity and yield of the whole commercial stem were used, as well as for the analysis of conicity at the level of DBH class. Trees with DBH ≥ 60.0 cm were selected, and these were distributed in three diameter classes (Table 1).

Average diameter (DBH) and commercial height (Hc) of the selected sample trees by diameter class for each species.

For each species, 20 trees from each DBH class were selected for a total of 60 trees and a total sample size for the study of 300 sample trees. With the objective of demonstrating the possible effects of conicity on yield of sawn wood, only trees that did not have hollows along the commercial stem were used. Nevertheless, it should be emphasized that the incidence of hollows in trees extracted in Amazonia is frequent, and this can obviously affect sawn wood yield.

The majority of trees that were extracted from the annual management units were sectioned into 4 logs with an average length of 6 meters. In this way, only trees that produced 4 logs were selected in order to standardize the number of logs per tree, as well as their length. Therefore, the total number of logs sampled per species was 240 (1,200 logs in total).

This log length standardization procedure was important because length can maximize the effect of conicity on yield, since the longer the conic log the greater the quantity of residuals (Steele, 1984STEELE, P. H. Factors determining lumber recovery in sawmilling. General Technical Report FPL-39. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 1984. 10p. Available at: https://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr39.pdf doi:10.2737/FPL-GTR-39.

https://www.fpl.fs.fed.us/documnts/fplgt...

). Furthermore, using this standardized division, possible differences in geometric form between sections could be described and verified with information from the literature (Husch et al., 2003HUSCH, B.; BEERS, T. W.; KERSHAW JR, J. A. Forest mensuration. (4th ed.) New Jersey: Hoboken. 2003. 456p.). Consequently, there was no relevant variation in length between the whole commercial stems of the sample trees (an average of 24 meters).

Conicity

Absolute conicity (degree of stem taper) of logs and commercial stems was obtained using Equation 1, where: c = conicity of the log or commercial stem (cm.m-1); db = diameter at the log base or commercial stem (cm); dt = diameter at the top of the log or commercial stem (cm); l = length of the log or commercial stem (m).

Yield

Individual log yield was obtained from Equation 2, where: Rms = yield of sawn wood from a log without bark (%); vms = estimated volume of sawn wood without bark, using the program MaxiTora (m³); vt = volume of the log with bark, obtained using the Smalian method (m³).

The volume of sawn lumber was estimated using the software Software MaxiTora, from the company Optimber - Optimization and Computing (Manhiça et al., 2013MANHIÇA, A. A.; ROCHA, M. P.; TIMOFEICZYK JUNIOR, R. Eficiência operacional no desdobro de Pinus utilizando modelos de corte numa serraria de pequeno porte. Cerne, v. 19, n. 2, p. 339-346, 2013. ; Murara Júnior et al., 2013MURARA JÚNIOR, M. I.; ROCHA, M. P.; TRUGILHO, P. F. Estimativa do rendimento em madeira serrada de Pinus para duas metodologias de desdobro. Floresta e Ambiente, v. 20, n. 4, p. 556-563, 2013.; Bonato Junior et al., 2013BONATO JUNIOR, A. I.; ROCHA, M. P.; JUIZO, C. G. F.; KLITZKE, R. J. K. Efeito do sistema de desdobro e das Classes diamétricas no rendimento em madeira Serrada de Araucaria angustifólia. Floresta e Ambiente, v. 24, p. 1-8, 2017.). The program estimated maximum yield in sawn lumber that could be obtained from each log as a function of the best cutting pattern that was programed. The MaxiTora program is basically a simulator of log sawing which allows sawmill professionals to visualize the obtained products and yield for each log before sawing occurs. This program can be accessed through the company Optimber on its internet site, and it is operated in a simple and objective manner, which makes it a tool that can aid in daily decision making. However, the software is still not very well-known in the wood transformation industries, especially in the Amazon, but there is great potential for its use.

Besides maximizing yield for each log, MaxiTora informs the number of pieces of sawn wood generated by each ideal cutting model. This characteristic of the program allowed for the possibility of conducting the analyses presented in this study, so that by multiplying the dimensions of the pieces by the length of the log, an estimate of the volume of sawn lumber was obtained.

To this end, data were entered into MaxiTora for the thickness and length (dimensions with which MaxiTora works) of the principal pieces of sawn wood researched in sawmills in the City of Santarém, State of Pará, namely: Piece 1: 25 mm x 150 mm, Piece 2: 26 mm x 155 mm, Piece 3: 30 mm x 50 mm, Piece 4: 32 mm x 100 mm, Piece 5: 35 mm x 160 mm, Piece 6: 55 mm x 90 mm and Piece 7: 60 mm x 190 mm.

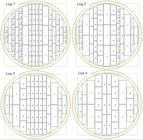

The thicknesses of the vertical (3 mm) and the horizontal (4 mm) saws were also input into the program, as well as an average bark thickness of 20 mm for all species. This information was obtained from a sawmill in the city of Santarém, Pará. The average bark thickness was determined through a random selection of 34 logs from 5 species that were stocked on the landing area of the sawmill, taking 3 measurements of bark thickness for each log. The final procedure for the program to be able to generate an ideal cutting model and the respective number of possible pieces of sawn wood (Figure 1) was the insertion of the diameter of the of thinnest extremity of each log.

Schematic image of the cutting models established for four logs of average diameters (log 1 = 70 cm; log 2 = 65 cm; log 3 = 61 cm; log 4 = 56 cm), for the five species. The four logs represent, respectively, the 1st, 2nd, 3rd and 4th logs of the commercial stems.

It is known that the diameter of the lower extremity of logs is a decisive factor for yield in sawn wood. However, in this study, the logs from the selected sample trees did not demonstrate important variation in average diameter of the lower extremity between species, with 63.2, 62.9, 62.5, 63.1, 64.1 cm, para H. impetiginosus, L. lurida, M. huberi, A. lecointei and Couratari sp., respectively. This gave results for estimated yield that were without significant interference in variation of log diameter between species and allowed for a clear expression and interpretation of conicity. The presence of sapwood was not included in the programming of the cutting models despite being a common characteristic of some commercial species from the Amazon.

The volume of the log was calculated using the Smalian formula (Equation 3), where: vt = log volume with bark (m³); g1 and g2 = transversal areas of the base and the top of the log (m²); l = log length (m).

In order to obtain the yield of the whole commercial stem used in the analysis at the species level, volumes were summed (for logs and for sawn wood) for the four logs per species in order to subsequently calculate the yield according to Equation 2.

Artificial form factor

As an auxiliary aid to the conicity analysis, an artificial form factor (f1.3) was calculated from the trees by DBH class (Equation 4), and an Analysis of Variance (ANOVA) was conducted (α = 0.05) in order to compare the average artificial form factor for the different classes, where: f1.3 = average artificial form factor ; vCUBi = volume with bark of the ith sample tree in DBH class (i = 1, 2, ... , n) in m³; vCILi = cylindrical volume with bark of the ith sample tree in DBH class (obtained as a function of DBH and commercial height - hc), in m³.

Pearson correlation

A Pearson correlation (r) between conicity and yield was also calculated in order to verify the existence of a relationship between these variables.

Statistical analysis

Differences in conicity between logs, DBH classes and species, as well as estimated yield between logs and between species were analyzed. Analyses were conducted in a completely randomized experimental design (CR) where the treatments for logs were 4 logs (1st, 2nd, 3rd and 4th log), with 60 repetitions (20 logs per DBH class). For DBH classes the treatment was 3 classes with 20 repetitions (20 trees per class), and for species the 5 species were the treatments with 60 repetitions (trees).

Treatment effects were verified by ANOVA, and the Bartlett test was applied to test for homogeneity of variances, and the Kolmogorov-Smirnov test was used to check the normality of the data, and when necessary the data were transformed using the natural log (ln). When the null hypothesis was rejected by the ANOVA the Tukey multiple comparison test was used. The significance level for all analyses was α= 0.05. All the statistical analyzes were performed using the R software (R Core Team, 2018R CORE TEAM. R: A language and environment for statistical computing. Vienna: R Foundation for Statistical Computing, Vienna, Austria. 2018. Available at: Available at: https://www.R-project.org

. Accessed in: Set 17th 2018.

https://www.R-project.org...

) and scripts from the ExpDes.pt data package version 1.2 (Ferreira et al., 2018FERREIRA, E. B.; CAVALCANTI, P. P.; NOGUEIRA, D. A. Package ‘ExpDes.pt’. 2018. Available at Available at https://cran.r-project.org/web/packages/ExpDes.pt/ExpDes.pt.pdf

. Accessed in: Oct 16th 2018.

https://cran.r-project.org/web/packages/...

).

RESULTS

Conicity and yield for logs

The Bartlett’s showed that the variances for conicity and yield were not homogeneous, and the Kolmogorov-Smirnov test showed the same result, thus requiring data transformation to a neperian logarithmic scale. Subsequently, the ANOVA showed significant differences for conicity and estimated yield between logs, at a 5% probability level. The result from the Tukey test, except for Couratari sp., showed that all species had statistically significant differences for conicity between logs, with the first log having greater conicity than the rest (Table 2).

Average log conicity was 1.20, 1.19, 1.08, 0.88 and 0.84 cm.m-1 for H. impetiginosus, L. lurida, M. huberi, A. lecointei and Couratari sp., respectively, and the respective estimated yields for these species were 58.6, 58.8, 58.4, 60.4 and 60.9%, resulting in an average yield for logs of 59% for the 5 species.

In Table 2, for L. lurida, M. huberi, A. lecointei and Couratari sp., the pattern of conicity did not present a linear reduction along the stem from the base to the top. This was due to a reduction in the third log followed by an increase in the fourth, in spite of the absence of significant statistical differences between these species, except for A. lecointei. This demonstrates that the middle of the stem tends to be more cylindrical, and at the top conicity becomes accentuated. Taking into consideration log length (average of 6 m), it can be affirmed that for the majority of species the interval between approximately 12 to 18 m in commercial stem height is the most cylindrical part of the stem.

The difference in yield between the logs occurred for all species, and the Tukey test indicated that the 2nd, 3rd and 4th logs were statistically different than the 1st and were superior in terms of yield for all species, except for Couratari sp. (Table 2), which had a lower yield for the fourth log.

Log conicity directly influenced yield, and even when it had greater volume, due to its larger dimensions, the first log had lower yield compared to the others for H. impetiginosus, L. lurida, M. huberi and A. lecointei (Table 2). Table 2 shows that the middle of the stem (2nd and 3rd logs) had greater yield for all five species, and that this part of the stem also had a tendency to be more cylindrical than the base and top, confirming that logs that are more cylindrical result in greater yield of sawn lumber.

Conicity of the stem in DBH classes

According to the results presented in Table 3 for DBH classes, only the species H. impetiginosus showed significant variation for conicity, where class 3 (≥ 100 cm) was statistically different than class 1 (60.0 - 79.9 cm), resulting in greater conicity. In spite of the lack of statistical differences, conicity values for L. lurida, M. huberi and A. lecointei increased with an increase in DBH class.

Table 3 also shows the averages for form factors (f 1.3) for DBH class for the five species. The values decrease from the smallest to the largest class, and even though there were no statistical differences among these averages, there was a tendency for greater conicity for trees in larger DBH classes, and without regard to species the average for f 1,3 was 0.61.

Conicity and yield by species

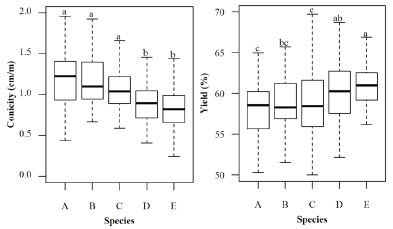

The pattern for conicity and estimated yield differed statistically between species, according to the analysis of variance at 5% probability. The species H. impetiginosus, L. lurida and M. huberi, had similar conicity, and by the Tukey test these three were different than A. lecointei and Couratari sp. which had lower conicity (Figure 2).

Conicity (cm.m-1) and estimated yield (%) for the whole commercial stems of Amazonian timber species, Tapajós National Forest, Pará, Brazil. Treatments followed by the same letters are not significantly different by the Tukey test at 5% probability. A: Handroanthus impetiginosus; B: Lecythis lurida; C: Manilkara huberi; D: Astronium lecointei and E: Couratari sp.

The estimated average yield for the whole commercial stem for the five species was 59%. The Tukey test showed that yield for Couratari sp. was greater than that for H. impetiginosus, L. lurida and M. huberi, and was similar to that for A. lecointei (Figure 2). As expected, when conicity was lower there was greater estimated yield for sawn lumber, so that the species A. lecointei and Couratari sp. had lower stem conicity, and consequently, were the species with the greatest estimated yields.

DISCUSSION

The results indicate that the butt log of the stem tends to be the most conic than the remainder of the stem for all evaluated species. The middle log (second and third logs) of the trunks had lower conicity, signifying that the logs are more cylindrical in this part of the trunk. Garcia et al. (2012GARCIA, F. M.; MANFIO, D. R.; SANSÍGOLO, C. A.; MAGALHÃES, P. A. D. Rendimento no desdobro de toras de Itaúba (Mezilaurus itauba) e Tauari (Couratari guianensis) segundo a classificação da qualidade da tora. Floresta e Ambiente, v. 19, n. 4, p. 468-474, 2012.), analyzing conicity in Couratari sp. logs, observed a similar result. These authors studied the stem divided into three logs and found conicity of 2.32, 1.53 and 3.55 cm m-1 for the 1st, 2nd and 3rd logs, respectively, relating that the middle of the stem is the most cylindrical.

Campos and Leite (2017CAMPOS, J. C. C.; LEITE, H. G. Mensuração florestal: Perguntas e respostas. 5th ed. Editora UFV, 2017. 636p.) relate that the bole of a tree can present different forms, from cylindrical to conic. According to Husch et al. (2003HUSCH, B.; BEERS, T. W.; KERSHAW JR, J. A. Forest mensuration. (4th ed.) New Jersey: Hoboken. 2003. 456p.), when a stem is divided into logs, the base tends to have a neiloid form, the central part approximates a cylinder, or in some cases a paraboloid or cone and the top tends to assume the form of a cone. In general, this tendency was identified in commercial stems of the species analyzed in this study.

Different geometric forms of stem sections is a characteristic that is widely known in forestry science. Nevertheless, for tropical species from the Amazon, which have specific characteristics, information about this type of variation is scarce, and this highlights the relevance of the results observed in this study.

In spite of the fact that it is known that Couratari sp. has a high degree of stem conicity (Garcia et al., 2012GARCIA, F. M.; MANFIO, D. R.; SANSÍGOLO, C. A.; MAGALHÃES, P. A. D. Rendimento no desdobro de toras de Itaúba (Mezilaurus itauba) e Tauari (Couratari guianensis) segundo a classificação da qualidade da tora. Floresta e Ambiente, v. 19, n. 4, p. 468-474, 2012.), in this study conicity of the first log was not statistically different from the other logs, as observed in the other species. This could be related to the fact that in the timber extraction process, a section of the base of the first log is generally removed in order to eliminate buttresses, a characteristic that is common in this species. This peculiarity of the technical process of extraction of this species is done to facilitate transport and cutting of the first log, and measurement of this log is only done after having done this procedure.

In spite of the existence of a diversity of factors that can influence yield (Rocha, 2007ROCHA, M. P. Técnicas de serrarias. In: OLIVEIRA, J. T. S.; FIEDLER, N. C.; NOGUEIRA, M, organizadores. Tecnologias aplicadas ao setor madeireiro. Jerônimo Monteiro: Suprema. 2007. p. 209-270.), the effect of conicity was demonstrated in this study, especially due to the care that was taken to homogenize the sample in terms of length, absence of hollows, final sawn products, besides the effort taken to not influence the decisions of the saw operator. It is important to emphasize that the diameter of the logs can also influence yield for certain species (Biasi and Rocha, 2007BIASI, C. P.; ROCHA, M. P. Rendimento em madeira serrada e quantificação de resíduos para três espécies tropicais. Floresta, v. 37, n. 1, p. 95-108, 2007.; Melo et al., 2019MELO, R. R.; DACROCE, J. M. D.; RODOLFO JUNIOR, F.; LISBOA, G. S.; FRANÇA, L. C. J. Lumber Yield of Four Native Forest Species of the Amazon Region. Floresta e Ambiente, v. 26, n. 1, e20160311, 2019.). However, there was no observed pattern of increase or decrease in yield with reduction of diameter from the base to the top of the stem, indicating that conicity probably had a greater influence.

Conicity has a direct influence on the final yield of wood from logs and has been cited as one of the principal factors responsible for low yields in Amazonian sawmills (Garcia et al., 2012GARCIA, F. M.; MANFIO, D. R.; SANSÍGOLO, C. A.; MAGALHÃES, P. A. D. Rendimento no desdobro de toras de Itaúba (Mezilaurus itauba) e Tauari (Couratari guianensis) segundo a classificação da qualidade da tora. Floresta e Ambiente, v. 19, n. 4, p. 468-474, 2012.; Mendoza et al., 2017MENDOZA, Z. M. S. H.; BORGES, P. H. M.; PIERIN, L. C. Coeficiente de rendimento em madeira serrada de oito espécies nativas de Mato Grosso. Nativa, v. 5, p. 568-573, 2017.; Lima et al., 2019LIMA, R. B.; FERREIRA, R. L. C.; JOSÉ ANTÔNIO ALEIXO DA SILVA, J. A.; GUEDES, M. C.; SILVA, D. A. S.; OLIVEIRA, C. P.; RABELO, F. G.; SILVA, L. F. C. Effect of species and log diameter on the volumetric yield of lumber in northern Brazilian Amazonia: preliminary results. Journal of Sustainable Forestry, 2019. ). In the present study, in spite of using estimated values for percent volumetric yield, effects of conicity are possibly present with respect to yield of wood. The results indicate that variation in yield from a single stem occurred as a function of the variable form of logs. Garcia et al. (2012) also observed variation in volumetric yield between logs for two native tropical species and attributed this result to differences in log conicity, among other factors.

Lima et al. (2019LIMA, R. B.; FERREIRA, R. L. C.; JOSÉ ANTÔNIO ALEIXO DA SILVA, J. A.; GUEDES, M. C.; SILVA, D. A. S.; OLIVEIRA, C. P.; RABELO, F. G.; SILVA, L. F. C. Effect of species and log diameter on the volumetric yield of lumber in northern Brazilian Amazonia: preliminary results. Journal of Sustainable Forestry, 2019. ) stressed that conicity has a strong influence on the variation in final products obtained from logs, for example, logs with small diameters and high conicity can result in products with heterogeneous dimensions. Furthermore, these authors stated that there is an excessive loss of raw material due to excessive conicity because the sawing method takes into account the end of the log with the smallest diameter.

According to Steele (1984STEELE, P. H. Factors determining lumber recovery in sawmilling. General Technical Report FPL-39. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 1984. 10p. Available at: https://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr39.pdf doi:10.2737/FPL-GTR-39.

https://www.fpl.fs.fed.us/documnts/fplgt...

), logs that are more conic result in lower yield due to the difficulty in obtaining rectangular blocks of sawn wood. The author stated that when log conicity is greater the width and thickness of the central rectangular block, and the rectangular blocks that can be extracted from the external part of the log are shorter. According to Richards (1973RICHARDS, D. B. Hardwood lumber yield by various simulated sawing methods. Forest products journal, v. 23, n. 10, p. 50-58, 1973.), the quality of sawn wood from conic logs can be reduced because if the cut is done parallel to axis of the log the resulting pieces will have slope of grain.

The problem of conicity with respect to yield of sawn wood is even greater when longer logs are used (Steele, 1984STEELE, P. H. Factors determining lumber recovery in sawmilling. General Technical Report FPL-39. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 1984. 10p. Available at: https://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr39.pdf doi:10.2737/FPL-GTR-39.

https://www.fpl.fs.fed.us/documnts/fplgt...

). Conic logs that are very long have greater potential to generate a larger quantity of residuals, especially in the form of slabs. For this reason, Bennett (2014BENNETT, N. Sawing methods for improving lumber yield recovery of out-of-shape hardwood saw logs. General Technical Report NRS-130. Newtown Square, PA: U.S. Department of Agriculture, Forest Service,Northern Research Station. 2014. 8 p.) recommended the use of shorter logs as a way to maximize yield from conic stem sections.

Therefore, based on the results from the present study, it is suggested that at least one butt log from a commercial stem be divided into shorter logs. These logs can be used for the creation of specific wood pieces that need a shorter length and that have a high demand in the consumer market for Amazonian wood.

The relatively high average yield found in the present study (59%) can vary due to the presence of factors inherent to logs from Amazonian trees, such as the ratio of heartwood to sapwood, cracks and curvatures. In general, such factors are not taken into account by the program MaxiTora (Bonato Junior et al., 2017). The presence of hollows in the logs, despite being a factor that has a significant effect on the yield of sawn wood of Amazonian species, did not affect the results of this study, since only logs absent of this defect were selected. As a function of this characteristic of the samples, the results were compared to studies wherein indices of yield were obtained for logs without hollows.

Lima et al. (2019LIMA, R. B.; FERREIRA, R. L. C.; JOSÉ ANTÔNIO ALEIXO DA SILVA, J. A.; GUEDES, M. C.; SILVA, D. A. S.; OLIVEIRA, C. P.; RABELO, F. G.; SILVA, L. F. C. Effect of species and log diameter on the volumetric yield of lumber in northern Brazilian Amazonia: preliminary results. Journal of Sustainable Forestry, 2019. ) determined the volumetric yield in sawn wood of 10 commercial species in Amapá using 50 logs per species with an average diameter of the smallest end of 64.2 cm, and an average length of 7.6 m. These authors identified the presence of hollows in just two species, and the average yield of the remaining 8 species varied between 37.8 and 54.1%, with an average of 43.2%. In a sawmill in the state of Roraima, Danielli et al. (2016DANIELLI, F. E.; GIMENEZ, B. O.; OLIVEIRA, C. K. A.; SANTOS, L.; HIGUCHI, N. Modelagem do rendimento no desdobro de toras de Manilkara spp. (Sapotaceae) em serraria do estado de Roraima, Brasil. Scientia Forestalis, v. 44, n. 111, p. 641-651, 2016.) evaluated log sawing methods and reported a volumetric yield of 31.7% for M. huberi for 40 logs free from hollows with an average diameter of the smallest end of approximately 60 cm, and an average length of 6.7 m.

Melo et al. (2019MELO, R. R.; DACROCE, J. M. D.; RODOLFO JUNIOR, F.; LISBOA, G. S.; FRANÇA, L. C. J. Lumber Yield of Four Native Forest Species of the Amazon Region. Floresta e Ambiente, v. 26, n. 1, e20160311, 2019.) evaluated yield of sawn wood for four tropical species in three sawmills in the state of Mato Grosso, using 12 logs for each species and log sawing method. The authors reported an average percent yield of 57.3% (Erisma uncinatum Warm), 52.5% (Apuleia leiocarpa Voguel) and 47.3% (Qualea paraensis Ducke), values which are very similar to those in the present study. For the species Dipteryx odorata Aublet, the authors identified two logs with hollows, which reduced yield, but they also found that logs with low conicity and without defects had an average yield of 68.3%.

In comparison with the results from the studies cited, the estimated yields for the species in the present study were superior, in general. Gomide (1974GOMIDE, J. L. Serraria. Universidade Federal de Viçosa, Imprensa Universitária, Viçosa/MG, 1974.119p.) related that yield from Amazonian commercial species can vary between 40 to 55%. In this context it is important to emphasize that even though these estimated values are greater they are within the ange of values that are commonly found in sawmills currently operating in the Amazon. This suggests that the use of computer programming to create cutting templates can be a promising alternative for maximizing yield of sawn lumber in sawmills that work with native Amazonian species.

Computational simulations of log cutting have been tested for specific variables and scenarios, as well as for different species, and the results have shown the importance of this technique for the optimization of the industrial process of log sawing methods and maximization of yield (Buehlmann and Thomas, 2001BUEHLMANN, U.; THOMAS, R. E. Lumber yield optimization software validation and performance review. Robotics and Computer Integrated Manufacturing, v. 17, p. 27-32, 2001.; Ikonen et al., 2003IKONEN, V-P.; KELLOMÄKI, S.; PELTOLA, H. Linking tree stem properties of Scots pine (Pinus sylvestris L) to sawn timber properties through simulated sawing. Forest Ecology and Management, v. 174, p. 251-263., 2003.; Moberg and Nordmark, 2006MOBERG, L.; NORDMARK, U. Predicting lumber volume and grade recovery for Scots pine stems using tree models and sawmill conversion simulation. Forest Products Journal, v. 56, n. 4, p. 68-74, 2006.; Pinto et al., 2006PINTO, I.; KNAPIC, S.; PEREIRA, H.; USENIUS, A. Simulated and realised industrial yields in sawing of maritime pine (Pinus pinaster Ait.). Holz als Roh- und Werkstoff, v. 64, p. 30-36, 2006.; Knapic et al., 2011KNAPIC, S.; SEPPA, I. P.; USENIUS, A.; PEREIRA, H. Stem modeling and simulation of conversion of cork oak stems for quality wood products. European Journal of Forest Research, v. 130, p. 745-751, 2011.; Berglund et al., 2013BERGLUND, A.; BROMAN, O.; GRONLUND, A.; FREDRIKSSON, M. Improved log rotation using information from a computed tomography scanner. Computers and Electronics in Agriculture, v. 90, n. 2, p. 152-158, 2013.; Fredriksson et al., 2015FREDRIKSSON, M.; BERGLUND, A.; BROMAN, O. Validating a crosscutting simulation program based on computed tomography scanning of logs. European Journal Wood Products, v. 73, p. 143-150, 2015.; Stängle et al., 2015STÄNGLE, S. M.; BRÜCHERT, F.; HEIKKILA, A.; USENIUS, T.; USENIUS, A.; SAUTER, U. H. Potentially increased sawmill yield from hardwoods using X-ray computed tomography for knot detection. Annals of Forest Science , v. 72, p. 57-65, 2015.; Wery et al., 2018WERY, J.; GAUDREAULT, J.; THOMAS, A.; MARIER, P. Simulation-optimisation based framework for Sales and Operations Planning taking into account new products opportunities in a co-production context. Forest Ecology and Management , v. 94, p. 41-51, 2018.).

Currently in Brazil, it is very common to find studies related to programming of cutting templates for species grown in tree plantations (Murara Júnior et al., 2010MURARA JÚNIOR, M. I.; ROCHA, M. P.; TIMOFEICZYK JÚNIOR, R. Análise dos custos do rendimento em madeira serrada de Pinus taeda para duas metodologias de desdobro. Floresta , v. 40, n. 3, p. 477-484, 2010.; 2013; Manhiça et al., 2012MANHIÇA, A. A.; ROCHA, M. P.; TIMOFEICZYK JUNIOR, R. Rendimento no desdobro de Pinus sp. utilizando modelos de corte numa serraria de pequeno porte. Floresta , v. 42, n. 2, p. 409-420, 2012.; 2013; Bonato Júnior et al., 2017). In spite of these planted species, or native ones from other biomes, having characteristics that are distinct from those of Amazonian species, it is important to emphasize that these studies reported that the cutting programmed by MaxiTora significantly increased yield of sawn lumber compared to the conventional method.

The choice of sawing pattern greatly influences lumber yield (Ah Shenga et al., 2015). In the conventional method of sawing the heterogeneous nature of the raw material, among other factors, greatly interferes in the decisions taken by saw operators and is reflected in lower yield (Steele, 1984STEELE, P. H. Factors determining lumber recovery in sawmilling. General Technical Report FPL-39. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 1984. 10p. Available at: https://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr39.pdf doi:10.2737/FPL-GTR-39.

https://www.fpl.fs.fed.us/documnts/fplgt...

).

On the other hand, computer programs that are capable of generating cutting templates are important in order to resolve this problem (Richards, 1973RICHARDS, D. B. Hardwood lumber yield by various simulated sawing methods. Forest products journal, v. 23, n. 10, p. 50-58, 1973.; Steele, 1984STEELE, P. H. Factors determining lumber recovery in sawmilling. General Technical Report FPL-39. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 1984. 10p. Available at: https://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr39.pdf doi:10.2737/FPL-GTR-39.

https://www.fpl.fs.fed.us/documnts/fplgt...

). Such templates provide information that can be used to test, in a computational environment, different scenarios of log sawing methods for each log and identify patterns that result in greater yield, thus supporting product research and production, and generating information that will aid in management, decision-making, and process control (Hallock et al., 1976; Pinto et al., 2006PINTO, I.; KNAPIC, S.; PEREIRA, H.; USENIUS, A. Simulated and realised industrial yields in sawing of maritime pine (Pinus pinaster Ait.). Holz als Roh- und Werkstoff, v. 64, p. 30-36, 2006.). For tropical forests, which have their own peculiar characteristics, simulation technologies are especially important (Ah Shenga et al., 2015).

In the Amazon region, however, initiatives to stimulate the use programming tools for planning of cutting patterns is unknown in sawmills. Interest among lumber businesses in new tools that can maximize lumber yield appears to be very low.

The majority of wood transformation industries that are active in the Amazon region currently function using inadequate log sawing methods, technology and equipment that are outdated, and unqualified labor (Clement and Higuchi, 2006CLEMENT, C. R., HIGUCHI, N. A floresta amazônica e o futuro do Brasil. Ciência E Cultura, v. 58, p. 44-49, 2006.; Confederação Nacional da Indústria - CNI, 2018CNI - CONFEDERAÇÃO NACIONAL DA INDÚSTRIA. Perspectivas e desafios na promoção do uso das florestas nativas no Brasil. Brasília, DF: CNI, 2018. 94p. ). The apparent abundance of timber can, in part, explain the lack of preoccupation with waste of raw material.

It should be emphasized that in spite of the reduction in timber harvest in the Amazon at the beginning of this century (Hummel et al., 2010HUMMEL, A. C., ALVES, M. V. S., PEREIRA, D., VERÍSSIMO, A. V., & SANTOS, D. A atividade madeireira na Amazônia brasileira: produção, receita e mercados. Serviço Floresta l Brasileiro. 2010. 28 p. Belém, PA: Instituto do Homem e Meio Ambiente da Amazônia. Available at: <https://imazon.org.br/PDFimazon/Portugues/livretos/a-atividade-madeireira-na amazoniabrasileira.pdf>

https://imazon.org.br/PDFimazon/Portugue...

), the annual volume extracted is still large (Lima et al., 2018LIMA, L. S.; MERRY, F.; SOARES-FILHO, B.; RODRIGUES, H. O.; DAMACENO, C. S.; BAUCH, M. A. Illegal logging as a disincentive to the establishment of a sustainable forest sector in the Amazon. Plos One , v. 13, n. 12, e0207855, 2018.). This situation could, eventually, lead to scarcity of raw material, thus making the need for optimization tools inevitable. The need for technological improvement in the wood industry is an essential condition for maximum yield of raw material, a factor directly related to the conservation of forest resources (Biasi and Rocha, 2007ROCHA, M. P. Técnicas de serrarias. In: OLIVEIRA, J. T. S.; FIEDLER, N. C.; NOGUEIRA, M, organizadores. Tecnologias aplicadas ao setor madeireiro. Jerônimo Monteiro: Suprema. 2007. p. 209-270.).

In this context, information such as that generated in the present study, in spite of being hypothetical, represent estimates of real situations, and are therefore essential to the search for improvement of techniques of industrial processing of wood in the Amazon region.

The results for the evaluation of conicity between DBH classes indicate that, for the studied species, larger trees tend to have a more conical commercial stem. This result is confirmed by the average form factor (f 1.3) for DBH class for the five species wherein the values reduced with an increase in class diameter.

It has been shown that stem conicity has a tendency to vary with tree size (Iida et al., 2011IIDA, Y.; KOHYAMA, T. S.; KUBO, T.; KASSIM, A. R.; POORTER, L.; STERCK, F.; POTTS, M. D. Tree architecture and lifehistory strategies across 200 co-occurring tropical tree species. Functional Ecology, v. 25, n. 6, p. 1260-1268, 2011.; Nunes and Görgens, 2016NUNES, M. H.; GÖRGENS, E. B. Artificial Intelligence Procedures for Tree Taper Estimation within a Complex Vegetation Mosaic in Brazil. Plos One , v. 11, n. 5, e0154738, 2016.). Ramos (2012RAMOS, M. Comparação de métodos para estimar o volume comercial em Floresta Ombrófila Densa no Estado do Amazonas. 2012. 54 p. MSc dissertation, Universidade Estadual do Centro-Oeste, Irati.), in a study conducted using 268 trees from 38 species in the Amazon obtained a result similar to that of the present study. The author concluded that in the smaller DBH classes the trees tended to have more cylindrical stems and that with an increase in DBH class the value of the form factor diminished with stems being less cylindrical. Studies conducted by Nogueira et al. (2008aNOGUEIRA, E. M.; FEARNSIDE, P. M.; NELSON, B. W.; BARBOSA, R. I.; KEIZER, E. W. H. Estimates of forest biomass in the Brazilian Amazon: New allometric equations and 53 adjustments to biomass from wood-volume inventories. Forest Ecology and Management , v. 256, n. 11, p. 1853-1867, 2008a.) suggest that in central Amazonia trees are more conical as they grow, meaning that the form factor is lower for larger trees.

The fact is that, in the case of native Amazonian forests, trees with larger diameters are generally higher and are found in the upper canopy of the forest. As related by Larson (1963LARSON, P. R. Stern from development of forest trees. Forest Science, v. 9, p. 1-42, 1963.) and Scolforo and Figueiredo Filho (1998SCOLFORO, J. R. S.; FIGUEIREDO FILHO, A. Biometria Floresta l: medição e volumetria de árvores. 1st ed. UFLA: FAEP. 1998. 310p.), dominant trees have greater stem taper due to their very large canopy length, and this variable is the decisive factor for the form of a tree. For these authors, the large canopy length for dominant trees leads to greater relative growth in height in relation to diameter, thus turning the stem more tapered, contrary to what occurs in dominated trees that have a smaller canopy length. Furthermore, the greater height and girth of native trees demands greater growth at the base of the stem in order to support the weight of the tree.

It is important to emphasize that this growth habit can vary between species that are from different forest formations. The analysis of the form of the bole of Araucaria angustifolia in a plantation in the State of Paraná by Figueiredo Filho et al. (2015)FIGUEIREDO FILHO, A; RETSLAFF, F. A. S.; KOHLER, S. V.; BECKER, M.; BRANDES, D. Efeito da idade no afilamento e sortimento em povoamentos de Araucaria angustifolia. Floresta e Ambiente, v. 22, n. 1, p. 50-59, 2015. showed that older trees (26 to 30 years), and that had larger DBH had more cylindrical stems.

As for between logs and DBH classes, conicity also presented relevant variation between species. In an evaluation of yield and the log sawing methods employed for twenty species in the Amazon, Iwakiri (1990IWAKIRI, S. Rendimento e condições de desdobro de 20 espécies de madeiras da Amazônia. Acta Amazonica, v. 20, p. 271-281, 1990.) showed that conicity of stems of these species varied between 0.88 and 0.96 cm.m-1, similar to values found in the present study for A. lecointei and Couratari sp. Garcia et al. (2012GARCIA, F. M.; MANFIO, D. R.; SANSÍGOLO, C. A.; MAGALHÃES, P. A. D. Rendimento no desdobro de toras de Itaúba (Mezilaurus itauba) e Tauari (Couratari guianensis) segundo a classificação da qualidade da tora. Floresta e Ambiente, v. 19, n. 4, p. 468-474, 2012.) identified average conicities of 2.5 and 1.8 cm m-1 for Couratari guianensis and Mezilaurus itauba, respectively, and Araújo et al. (2014ARAÚJO, J. A.; COSTA, N. S.; LIMA, R. S.; CALDERON, C. M. A.; CALDERON, R. A. Rendimento e eficiência operacional do desdobro da madeira de Faveira (Parkia multijuga Benth. - Fabaceae). Enciclopédia Biosfera, v. 10, n. 19, p. 1656-1667, 2014.) reported average conicity of 1.0 cm m-1 for Parkia multijuga Benth.

Soares et al. (2011SOARES, C. P. B.; PAULA NETO, F.; SOUZA, A. L. Dendrometria e inventário florestal. 2nd ed. Editora UFV. 2011. 272p.) and Nunes and Görgens (2016NUNES, M. H.; GÖRGENS, E. B. Artificial Intelligence Procedures for Tree Taper Estimation within a Complex Vegetation Mosaic in Brazil. Plos One , v. 11, n. 5, e0154738, 2016.) related that the degree of conicity is variable between species. However, there is a diversity of factors that can cause the species to have stems with different forms, and this can complicate any attempts at describing patterns in this phenomenon.

It is well established that genetic characteristics of a species, together with environmental conditions, including edaphic variables and climate conditions, as well as geographic location, can influence the growth form of trees and consequently the degree of stem conicity (Scolforo and Figueiredo Filho, 1998SCOLFORO, J. R. S.; FIGUEIREDO FILHO, A. Biometria Floresta l: medição e volumetria de árvores. 1st ed. UFLA: FAEP. 1998. 310p.; Socha and Kulej, 2007SOCHA, J.; KULEJ, M. Variation of the tree form factor and taper in European larch of Polish provenances tested under conditions of the Beskid Sądecki mountain range (southern Poland). Journal of Forest Science , v. 53, n. 12, p. 538-547, 2007.; Nogueira et al., 2008bNOGUEIRA, E. M.; NELSON, B. W.; FEARNSIDE, P. M.; MABIANE BATISTA FRANÇA, M. B.; OLIVEIRA, A. C. A. Tree height in Brazil’s ‘arc of deforestation’: Shorter trees in south and southwest Amazonia imply lower biomass. Forest Ecology and Management , v. 255, p. 2963-2972, 2008b.; Kempes et al., 2011KEMPES, C. P.; WEST, G. B.; CROWELL, K.; GIRVAN, M. Predicting Maximum Tree Heights and Other Traits from Allometric Scaling and Resource Limitations. Plos One, v. 6, n. 6, e20551, 2011.; Soares et al., 2011SOARES, C. P. B.; PAULA NETO, F.; SOUZA, A. L. Dendrometria e inventário florestal. 2nd ed. Editora UFV. 2011. 272p.; Lines et al., 2012LINES, E. R.; ZAVALA, M. A.; PURVES, D. W.; COOMES, D. A. Predictable changes in aboveground allometry of trees along gradients of temperature, aridity and competition. Global Ecology and Biogeography, v. 21, n. 10, p. 1017-1028, 2012.; Campos and Leite, 2017CAMPOS, J. C. C.; LEITE, H. G. Mensuração florestal: Perguntas e respostas. 5th ed. Editora UFV, 2017. 636p.).

The stem form of trees tends to vary with forest conditions, normally as a response to nearby species and competition (Guo et al., 2011GUO, Y.; FOURCAUD, T.; JAEGER, M.; ZHANG, X.; LI B. Plant growth and architectural modelling and its applications. Annals of botany, v. 107, n. 5, p. 723-727, 2011.). All these factors can be responsible for variations in patterns of conicity between species, between trees, and within a singular tree that were observed in the present study, in spite of not having measured them, due to study conditions.

Grosser (1980GROSSER, D. Defeitos da madeira. (Série Técnica), Curitiba: FUPEF. 1980.) affirmed that conicity significantly influences yield in sawn lumber when it is above 1.0 cm.m-1, therefore contributing to the explanation for the results from the current study. Furthermore, the correlation between conicity and yield was - 69%, - 51%, - 53%, - 60% and - 59% for H. impetiginosus, L. lurida, M. huberi, A. lecointei and Couratari sp., respectively.

This inverse relationship between these variables confirms the fact that yield diminishes as conicity increases. This result was observed for logs, and therefore it is also expected for the evaluation for the whole commercial stem. Iwakiri (1990IWAKIRI, S. Rendimento e condições de desdobro de 20 espécies de madeiras da Amazônia. Acta Amazonica, v. 20, p. 271-281, 1990.) also related the influence of conicity on yield of Amazonian timber species.

CONCLUSIONS

Logs of the same length possess different values of conicity along the stem, with the first log being the most conic, as expected. The second and third log are the most cylindrical and therefore have larger estimated yield than logs at the base and top. In light of this, the use of short logs from the butt log of the commercial stem is recommended in order to minimize the effect of conicity on yield.

The conicity of the stem of the evaluated species varies with the size of the trees, where trees with greater DBH have more conic stem. Conicity also varies as a function of species, which consequently generates variation in lumber yield of sawn wood. Among the five species, H. impetiginosus tended to have a greater degree of stem conicity and larger yield, in contrast to Couratari sp.

In general, the estimated yield from the MaxiTora program was superior when compared to yield obtained for logs with characteristics similar to those that were sawn using conventional methods in sawmills in Amazonia. Therefore, the use of this program could be a promising alternative for maximizing yield. Future studies using this program should be conducted to help to fill this gap in the literature and to promote its incorporation into sawmills in this region.

ACKNOWLEDGEMENTS

The authors thank the Mixed Cooperative of the Tapajós National Forest (Coomflona), for providing the data that formed the base of this study.

REFERENCES

- AH SHENGA, P. A., BOMARK, P., BROMAN, O., SANDBERG, D. Simulation of tropical hardwood processing: Sawing methods, log positioning, and outer shape. BioResources, v. 10, n. 4, p. 7640-7652, 2015.

- AH SHENGA, P. A., BOMARK, P., BROMAN, O., SANDBERG, D. Log sawing positioning optimization and log bucking of tropical hardwood species to increase the volume yield. Wood Material Science & Engineering, v. 12, n. 4, p. 257-262, 2017.

- ALVARES, C.A.; STAPE, J.L.; SENTELHAS, P.C.; MORAES, G.; LEONARDO, J.; SPAROVEK, G. Koppen’s climate classification map for Brasil. Meteorologische Zeitschrift, v. 22, n. 6, p. 711-728, 2013.

- ARAÚJO, J. A.; COSTA, N. S.; LIMA, R. S.; CALDERON, C. M. A.; CALDERON, R. A. Rendimento e eficiência operacional do desdobro da madeira de Faveira (Parkia multijuga Benth. - Fabaceae). Enciclopédia Biosfera, v. 10, n. 19, p. 1656-1667, 2014.

- BENNETT, N. Sawing methods for improving lumber yield recovery of out-of-shape hardwood saw logs. General Technical Report NRS-130. Newtown Square, PA: U.S. Department of Agriculture, Forest Service,Northern Research Station. 2014. 8 p.

- BERGLUND, A.; BROMAN, O.; GRONLUND, A.; FREDRIKSSON, M. Improved log rotation using information from a computed tomography scanner. Computers and Electronics in Agriculture, v. 90, n. 2, p. 152-158, 2013.

- BIASI, C. P.; ROCHA, M. P. Rendimento em madeira serrada e quantificação de resíduos para três espécies tropicais. Floresta, v. 37, n. 1, p. 95-108, 2007.

- BONATO JUNIOR, A. I.; ROCHA, M. P.; JUIZO, C. G. F.; KLITZKE, R. J. K. Efeito do sistema de desdobro e das Classes diamétricas no rendimento em madeira Serrada de Araucaria angustifólia Floresta e Ambiente, v. 24, p. 1-8, 2017.

- BRASIL. Resolução nº 474, de 6 de abril de 2016. Altera a Resolução no 411, de 6 de maio de 2009, que dispõe sobre procedimentos para inspeção de indústrias consumidoras ou transformadoras de produtos e subprodutos florestais madeireiros de origem nativa, bem como os respectivos padrões de nomenclatura e coeficientes de rendimento volumétricos, inclusive carvão vegetal e resíduos de serraria, e dá outras providências. Diário Oficial da União da República Federativa do Brasil, Brasília, DF, 06, may, 2016. Seção 1, p. 74-75. Available at: Available at: http://www2.mma.gov.br/port/conama/legiabre.cfm?codlegi=720 Accessed in: April 20th 2019.

» http://www2.mma.gov.br/port/conama/legiabre.cfm?codlegi=720 - BRAZ, R. L., NUTTO, L., BRUNSMEIER, M., BECKER, G., SILVA, D. A. Resíduos da colheita florestal e do processamento da madeira na Amazônia - Uma análise da cadeia produtiva. Journal of Biotechnology and Biodiversity, v. 5, n. 2, p. 168-181, 2014.

- BUEHLMANN, U.; THOMAS, R. E. Lumber yield optimization software validation and performance review. Robotics and Computer Integrated Manufacturing, v. 17, p. 27-32, 2001.

- CAMPOS, J. C. C.; LEITE, H. G. Mensuração florestal: Perguntas e respostas. 5th ed. Editora UFV, 2017. 636p.

- CLEMENT, C. R., HIGUCHI, N. A floresta amazônica e o futuro do Brasil. Ciência E Cultura, v. 58, p. 44-49, 2006.

- CNI - CONFEDERAÇÃO NACIONAL DA INDÚSTRIA. Perspectivas e desafios na promoção do uso das florestas nativas no Brasil. Brasília, DF: CNI, 2018. 94p.

- DANIELLI, F. E.; GIMENEZ, B. O.; OLIVEIRA, C. K. A.; SANTOS, L.; HIGUCHI, N. Modelagem do rendimento no desdobro de toras de Manilkara spp. (Sapotaceae) em serraria do estado de Roraima, Brasil. Scientia Forestalis, v. 44, n. 111, p. 641-651, 2016.

- FERREIRA, E. B.; CAVALCANTI, P. P.; NOGUEIRA, D. A. Package ‘ExpDes.pt’. 2018. Available at Available at https://cran.r-project.org/web/packages/ExpDes.pt/ExpDes.pt.pdf Accessed in: Oct 16th 2018.

» https://cran.r-project.org/web/packages/ExpDes.pt/ExpDes.pt.pdf - FIGUEIREDO FILHO, A; RETSLAFF, F. A. S.; KOHLER, S. V.; BECKER, M.; BRANDES, D. Efeito da idade no afilamento e sortimento em povoamentos de Araucaria angustifolia Floresta e Ambiente, v. 22, n. 1, p. 50-59, 2015.

- FREDRIKSSON, M.; BERGLUND, A.; BROMAN, O. Validating a crosscutting simulation program based on computed tomography scanning of logs. European Journal Wood Products, v. 73, p. 143-150, 2015.

- GARCIA, F. M.; MANFIO, D. R.; SANSÍGOLO, C. A.; MAGALHÃES, P. A. D. Rendimento no desdobro de toras de Itaúba (Mezilaurus itauba) e Tauari (Couratari guianensis) segundo a classificação da qualidade da tora. Floresta e Ambiente, v. 19, n. 4, p. 468-474, 2012.

- GOMIDE, J. L. Serraria. Universidade Federal de Viçosa, Imprensa Universitária, Viçosa/MG, 1974.119p.

- GROSSER, D. Defeitos da madeira. (Série Técnica), Curitiba: FUPEF. 1980.

- GUO, Y.; FOURCAUD, T.; JAEGER, M.; ZHANG, X.; LI B. Plant growth and architectural modelling and its applications. Annals of botany, v. 107, n. 5, p. 723-727, 2011.

- HALLOCK, H.; STERN, A. R.; LEWIS, D. W. Is there a “best” sawing method? Research Paper FPL-280. Madison, WIS: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 1978. 11p. Available at: https://www.fpl.fs.fed.us/documnts/fplrp/fplrp280.pdf

» https://www.fpl.fs.fed.us/documnts/fplrp/fplrp280.pdf - HOMMA, A. K. O. Madeira na Amazônia: Extração, Manejo ou Reflorestamento? Amazônia: Ciência & Desenvolvimento , v. 7, n. 13, p. 147-161, 2011.

- HUMMEL, A. C., ALVES, M. V. S., PEREIRA, D., VERÍSSIMO, A. V., & SANTOS, D. A atividade madeireira na Amazônia brasileira: produção, receita e mercados. Serviço Floresta l Brasileiro. 2010. 28 p. Belém, PA: Instituto do Homem e Meio Ambiente da Amazônia. Available at: <https://imazon.org.br/PDFimazon/Portugues/livretos/a-atividade-madeireira-na amazoniabrasileira.pdf>

» https://imazon.org.br/PDFimazon/Portugues/livretos/a-atividade-madeireira-na amazoniabrasileira.pdf - HUSCH, B.; BEERS, T. W.; KERSHAW JR, J. A. Forest mensuration. (4th ed.) New Jersey: Hoboken. 2003. 456p.

- IIDA, Y.; KOHYAMA, T. S.; KUBO, T.; KASSIM, A. R.; POORTER, L.; STERCK, F.; POTTS, M. D. Tree architecture and lifehistory strategies across 200 co-occurring tropical tree species. Functional Ecology, v. 25, n. 6, p. 1260-1268, 2011.

- IKONEN, V-P.; KELLOMÄKI, S.; PELTOLA, H. Linking tree stem properties of Scots pine (Pinus sylvestris L) to sawn timber properties through simulated sawing. Forest Ecology and Management, v. 174, p. 251-263., 2003.

- INSTITUTO BRASILEIRO DE GEOGRAFIA E ESTATÍSTICA - IBGE. Manual técnico da vegetação brasileira: sistema fitogeográfico, inventário das formações florestais e campestres, técnicas e manejo de coleções botânicas, procedimentos para mapeamentos. Rio de Janeiro: IBGE - Diretoria de Geociências, 2012. 271p.

- IWAKIRI, S. Rendimento e condições de desdobro de 20 espécies de madeiras da Amazônia. Acta Amazonica, v. 20, p. 271-281, 1990.

- KEMPES, C. P.; WEST, G. B.; CROWELL, K.; GIRVAN, M. Predicting Maximum Tree Heights and Other Traits from Allometric Scaling and Resource Limitations. Plos One, v. 6, n. 6, e20551, 2011.

- KNAPIC, S.; SEPPA, I. P.; USENIUS, A.; PEREIRA, H. Stem modeling and simulation of conversion of cork oak stems for quality wood products. European Journal of Forest Research, v. 130, p. 745-751, 2011.

- LARSON, P. R. Stern from development of forest trees. Forest Science, v. 9, p. 1-42, 1963.

- LIMA, L. S.; MERRY, F.; SOARES-FILHO, B.; RODRIGUES, H. O.; DAMACENO, C. S.; BAUCH, M. A. Illegal logging as a disincentive to the establishment of a sustainable forest sector in the Amazon. Plos One , v. 13, n. 12, e0207855, 2018.

- LIMA, R. B.; FERREIRA, R. L. C.; JOSÉ ANTÔNIO ALEIXO DA SILVA, J. A.; GUEDES, M. C.; SILVA, D. A. S.; OLIVEIRA, C. P.; RABELO, F. G.; SILVA, L. F. C. Effect of species and log diameter on the volumetric yield of lumber in northern Brazilian Amazonia: preliminary results. Journal of Sustainable Forestry, 2019.

- LINES, E. R.; ZAVALA, M. A.; PURVES, D. W.; COOMES, D. A. Predictable changes in aboveground allometry of trees along gradients of temperature, aridity and competition. Global Ecology and Biogeography, v. 21, n. 10, p. 1017-1028, 2012.

- MANHIÇA, A. A.; ROCHA, M. P.; TIMOFEICZYK JUNIOR, R. Rendimento no desdobro de Pinus sp. utilizando modelos de corte numa serraria de pequeno porte. Floresta , v. 42, n. 2, p. 409-420, 2012.

- MANHIÇA, A. A.; ROCHA, M. P.; TIMOFEICZYK JUNIOR, R. Eficiência operacional no desdobro de Pinus utilizando modelos de corte numa serraria de pequeno porte. Cerne, v. 19, n. 2, p. 339-346, 2013.

- MELO, L. E. L.; SILVA, C. J.; LOPES, K. V.; BRITO, P. G. M.; SANTOS, I. S. Resíduos de Serraria no Estado do Pará: Caracterização, Quantificação e Utilização Adequada. Floresta e Ambiente, v. 19, n. 1, p. 113-116, 2012.

- MELO, R. R.; DACROCE, J. M. D.; RODOLFO JUNIOR, F.; LISBOA, G. S.; FRANÇA, L. C. J. Lumber Yield of Four Native Forest Species of the Amazon Region. Floresta e Ambiente, v. 26, n. 1, e20160311, 2019.

- MENDOZA, Z. M. S. H.; BORGES, P. H. M.; PIERIN, L. C. Coeficiente de rendimento em madeira serrada de oito espécies nativas de Mato Grosso. Nativa, v. 5, p. 568-573, 2017.

- MOBERG, L.; NORDMARK, U. Predicting lumber volume and grade recovery for Scots pine stems using tree models and sawmill conversion simulation. Forest Products Journal, v. 56, n. 4, p. 68-74, 2006.

- MURARA JÚNIOR, M. I.; ROCHA, M. P.; TIMOFEICZYK JÚNIOR, R. Análise dos custos do rendimento em madeira serrada de Pinus taeda para duas metodologias de desdobro. Floresta , v. 40, n. 3, p. 477-484, 2010.

- MURARA JÚNIOR, M. I.; ROCHA, M. P.; TRUGILHO, P. F. Estimativa do rendimento em madeira serrada de Pinus para duas metodologias de desdobro. Floresta e Ambiente, v. 20, n. 4, p. 556-563, 2013.

- NOGUEIRA, E. M.; FEARNSIDE, P. M.; NELSON, B. W.; BARBOSA, R. I.; KEIZER, E. W. H. Estimates of forest biomass in the Brazilian Amazon: New allometric equations and 53 adjustments to biomass from wood-volume inventories. Forest Ecology and Management , v. 256, n. 11, p. 1853-1867, 2008a.

- NOGUEIRA, E. M.; NELSON, B. W.; FEARNSIDE, P. M.; MABIANE BATISTA FRANÇA, M. B.; OLIVEIRA, A. C. A. Tree height in Brazil’s ‘arc of deforestation’: Shorter trees in south and southwest Amazonia imply lower biomass. Forest Ecology and Management , v. 255, p. 2963-2972, 2008b.

- NUNES, M. H.; GÖRGENS, E. B. Artificial Intelligence Procedures for Tree Taper Estimation within a Complex Vegetation Mosaic in Brazil. Plos One , v. 11, n. 5, e0154738, 2016.

- OLIVEIRA JUNIOR, R. C.; KELLER, M. M.; RAMOS, J. F. F.; BELDINI, T. P.; CRILL, P. M.; CAMARGO, P. B.; HAREN, J. V. Chemical analysis of rainfall and throughfall in the Tapajos National Forest, Belterra, Pará, Brazil. Ambiente & Água - An Interdisciplinary Journal of Applied Science, v. 10, n. 2, p. 264-285, 2015.

- PINTO, I.; KNAPIC, S.; PEREIRA, H.; USENIUS, A. Simulated and realised industrial yields in sawing of maritime pine (Pinus pinaster Ait.). Holz als Roh- und Werkstoff, v. 64, p. 30-36, 2006.

- RAMOS, M. Comparação de métodos para estimar o volume comercial em Floresta Ombrófila Densa no Estado do Amazonas. 2012. 54 p. MSc dissertation, Universidade Estadual do Centro-Oeste, Irati.

- R CORE TEAM. R: A language and environment for statistical computing. Vienna: R Foundation for Statistical Computing, Vienna, Austria. 2018. Available at: Available at: https://www.R-project.org Accessed in: Set 17th 2018.

» https://www.R-project.org - RICHARDS, D. B. Hardwood lumber yield by various simulated sawing methods. Forest products journal, v. 23, n. 10, p. 50-58, 1973.

- ROCHA, M. P. Técnicas de serrarias. In: OLIVEIRA, J. T. S.; FIEDLER, N. C.; NOGUEIRA, M, organizadores. Tecnologias aplicadas ao setor madeireiro. Jerônimo Monteiro: Suprema. 2007. p. 209-270.

- SCOLFORO, J. R. S.; FIGUEIREDO FILHO, A. Biometria Floresta l: medição e volumetria de árvores. 1st ed. UFLA: FAEP. 1998. 310p.

- SOARES, C. P. B.; PAULA NETO, F.; SOUZA, A. L. Dendrometria e inventário florestal. 2nd ed. Editora UFV. 2011. 272p.

- SOCHA, J.; KULEJ, M. Variation of the tree form factor and taper in European larch of Polish provenances tested under conditions of the Beskid Sądecki mountain range (southern Poland). Journal of Forest Science , v. 53, n. 12, p. 538-547, 2007.

- STÄNGLE, S. M.; BRÜCHERT, F.; HEIKKILA, A.; USENIUS, T.; USENIUS, A.; SAUTER, U. H. Potentially increased sawmill yield from hardwoods using X-ray computed tomography for knot detection. Annals of Forest Science , v. 72, p. 57-65, 2015.

- STEELE, P. H. Factors determining lumber recovery in sawmilling. General Technical Report FPL-39. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 1984. 10p. Available at: https://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr39.pdf doi:10.2737/FPL-GTR-39.

» https://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr39.pdf - TODOROKI, C. L. Effect of edging and docking methods on volume and grade recoveries in the simulated production of flitches. Annals Science Forest, v. 51, p. 241-248, 1994.

- WERY, J.; GAUDREAULT, J.; THOMAS, A.; MARIER, P. Simulation-optimisation based framework for Sales and Operations Planning taking into account new products opportunities in a co-production context. Forest Ecology and Management , v. 94, p. 41-51, 2018.

HIGHLIGHTS

-

1

The bases of stems have accentuated conicity while the middle is more cylindrical.

-

2

Larger trees tend to have stems that are more conic.

-

3

Yield varies between logs and species as a function of the conicity of the commercial stem.

-

4

The use of cutting templates can increase lumber yield, attaining an average of 59%.

Publication Dates

-

Publication in this collection

30 Mar 2020 -

Date of issue

Oct-Dec 2019

History

-

Received

06 June 2019 -

Accepted

09 Dec 2019