Abstracts

This paper focuses on the sequencing and scheduling problem of open pit mining, with the allocation of loading equipment considering a medium-term horizon. This study considers the existence of a heterogeneous loading equipment fleet and two types of mineable material, namely ore or waste rock. For the mining of ore, the following requirements are taken under consideration: the mixture quality, a crusher, the processing plant capacity and a stockpile, called ROM stockpile. In this context, we present a mathematical model in mixed integer linear programming, supported by an algorithm that is responsible for moving the time horizon at each model run, aiming to generate mining orders resolved with optimality. Together, these orders describe the loading equipment mining plan.

mixed integer linear programming; scheduling; mining planning

Esse trabalho tem seu foco no problema de sequenciamento e programação da lavra em mina a céu aberto com a alocação de equipamentos de carregamento, considerando um período de médio prazo. Nesse estudo, considera-se a existência de uma frota heterogênea de equipamentos de carga e de dois tipos de materiais lavráveis, sendo minério ou estéril. Para a lavra de minério, são contemplados requisitos de qualidade da mistura, um britador, capacidade da usina de beneficiamento e uma pilha de estoque, denominada pilha de ROM. Nesse contexto, apresenta-se um modelo matemático em programação linear inteira mista, apoiado por um algoritmo responsável por mover o horizonte de tempo, a cada execução do modelo, com intuito de gerar ordens de lavra resolvidas com otimalidade. Juntas, essas ordens descreverão o plano de lavra dos equipamentos de carga.

programação linear inteira mista; programação da produção; planejamento de lavra

MINING MINERAÇÃO

Mathematical model and supporting algorithm to aid the sequencing and scheduling of mining with loading equipment allocation

Modelo matemático e algoritmo de apoio para auxílio ao sequenciamento e à programação de lavra com alocação de equipamentos de carga

Arthur AndradeI; Miguel SantoroII; Giorgio de TomiIII

IPrograma de Pós Graduação Engenharia de Sistemas Logísticos. Universidade de São Paulo. São Paulo - São Paulo - Brasil. arthurquintao@yahoo.com.br

IIAv. Prof. Almeida Prado, Travessa 2, Nº 128 Universidade de São Paulo, Departamento de Engenharia de Produção. São Paulo São Paulo - Brasil. santoro@usp.br

IIIUniversidade de São Paulo, Departamento de Engenharia de Minas e Petróleo. São Paulo São Paulo - Brasil. gdetomi@usp.br

ABSTRACT

This paper focuses on the sequencing and scheduling problem of open pit mining, with the allocation of loading equipment considering a medium-term horizon. This study considers the existence of a heterogeneous loading equipment fleet and two types of mineable material, namely ore or waste rock. For the mining of ore, the following requirements are taken under consideration: the mixture quality, a crusher, the processing plant capacity and a stockpile, called ROM stockpile. In this context, we present a mathematical model in mixed integer linear programming, supported by an algorithm that is responsible for moving the time horizon at each model run, aiming to generate mining orders resolved with optimality. Together, these orders describe the loading equipment mining plan.

Keywords: mixed integer linear programming, scheduling, mining planning.

RESUMO

Esse trabalho tem seu foco no problema de sequenciamento e programação da lavra em mina a céu aberto com a alocação de equipamentos de carregamento, considerando um período de médio prazo. Nesse estudo, considera-se a existência de uma frota heterogênea de equipamentos de carga e de dois tipos de materiais lavráveis, sendo minério ou estéril. Para a lavra de minério, são contemplados requisitos de qualidade da mistura, um britador, capacidade da usina de beneficiamento e uma pilha de estoque, denominada pilha de ROM. Nesse contexto, apresenta-se um modelo matemático em programação linear inteira mista, apoiado por um algoritmo responsável por mover o horizonte de tempo, a cada execução do modelo, com intuito de gerar ordens de lavra resolvidas com otimalidade. Juntas, essas ordens descreverão o plano de lavra dos equipamentos de carga.

Palavras-chave: programação linear inteira mista, programação da produção, planejamento de lavra.

1. Introduction

This paper proposes a system for the Sequencing and Scheduling Problem in Open Pit Mining with Loading Equipment Allocation, which is responsible for developing a sequence of blocks and respective production rates to be implemented by the loading equipment (wheel loaders or excavators) over a mediumterm horizon through the generation of mining orders.

The function of a proposed "Mining Order" is to feasibly guide the material extraction and ROM feeding, run-of-mine (raw ore extracted from the pit face) in the processing plant to be implemented for a certain period of time. For this purpose, blocks of material, ore or waste rock, are allocated to the available loading equipment, and the extraction rate of each resource is defined aiming at maximizing the use of the equipment, minimizing deviations from the quality goals generated in the mixture of mining rates imposed for each ore block as well as minimizing the displacement between the source block and the block to be allocated.

In this context, the current study proposes a system composed of a mathematical model and moving-horizon supporting algorithm for the Open Pit Mine Sequencing and Scheduling Problem with Loading Equipment Allocation (OPMSS + LEA). It aims at supporting mining companies' decisions by generating successive mining orders.

2. Literature review

Since 1965, Operational Research techniques have been applied in open pit mines by using the dynamic programming algorithm proposed by Lerchs-Grossmann in order to design the optimal pit of a mine, i.e., to define the blocks which mining maximizes the profit (Newman et al. [1]). According to Amaral & Pinto [2], from this milestone, several algorithms and models were developed to deal with this and other problems, having a large scale as a common feature in the context of real instances and they are considered as NP-hard. It makes the use of exact methods result in a computational time which is impracticable in some cases. Among them, the most related to the purpose of this study are: mining sequencing and mining operational planning.

Mining sequencing consists in determining the mine excavation advances in a long or medium-term horizon aiming at ensuring the maintenance of the slope angle for safe excavation. Different mathematical models have been proposed with the purpose of generating mining sequencing. They define, in general, in which period t each block will be extracted in order to maximize the extraction profitability, taking under consideration the blocks contained in the optimal pit. (CHICOISNE et al. [3]; CACCETTA & HILL [4]).

Slope angle constraints stand out among the challenges of defining an efficient mining sequencing (Newman, et al. [1]). Figure 1 presents two of the most common constraints: 1-5 (five blocks up) and 1-9 (nine blocks up).

On the other hand, the mining operational planning generates a solution assigned to the short-term horizon, generally taking under consideration the goal programming in which penalties are assigned to production deviations, deviations in the ore mixture quality and deviations in meeting waste rock-ore ratio (WOR). It allocates loading and transport equipment in spots at the mine surface which may turn into an active pit face.

Amaral [5] and Amaral & Pinto [2] present a hybrid heuristic containing a mixed integer programming model for generating mining orders that take into account the loading and transport optimization.

According to the authors, the clear division between mining sequencing and operational planning hinders the construction of more flexible models that can support decisions based on more than one planning horizon.

As for the mining industry, research and investment opportunities in planning and control strategies may, therefore, be related to the development of integrated planning models based on medium-term horizons, which contemplate both the removal of blocks from the geological model and operational aspects regarding equipment allocation in the mine.

3. Problem

The problem to be addressed is the generation of a detailed mining plan in which loading equipment allocations and its mining rate (t/h) are described over a planning horizon discretized in periods that are not necessarily uniform.

The mine is represented by a block model, in which each element receives a sequence number that is used for mapping its location which is described by a set of coordinates: row (R), column (C) and level (H). Assigned to each block are: parameters of quality, location, mass and type of material - in the case of the current study, ore or waste rock - according to a cut-off grade established by the long-term planning.

The loading process and transportation are important functions in mining. The material loading is performed by wheel loaders and excavators that are directed to different parts of the mine and are responsible for performing "bucket" movements in order to fill each truck directed to its location. Once loaded, the trucks are directed according to the material to be transported. Waste rock material is directed to waste stockpiles.

In the studied process, the ROM extracted by the loading equipment allocated with ore blocks is sent to the crusher in order to be reduced. Once reduced, it can be directly shipped to a processing plant and if the amount exceeds the plant's demand, it is sent to a ROM stockpile by the baffle. If the total mining rate (t/h) of the ore pit face is not able to supply the processing capacity assigned to the plant, the ROM is removed from the stockpile in order to meet the demand. Figure 2 illustrates the described process.

The raised problem does not directly contemplate three activities that may belong to mine planning, block drilling, disassembling (detonation), and material transportation. In the current research, it is considered that there are sufficient means of transportation to meet the loading equipment's maximum production rate. According to Amaral & Pinto [2], in some cases, drilling and disassembling are not required due to the material's physical characteristics.

4. Mathematical method for the problem

The Open Pit Mine Sequencing and Scheduling with Loading Equipment Allocation (OPMSS + LEA) proposed in the current study consists of a mathematical model and a supporting algorithm. The algorithm consists of seven steps which support successive iterations of the mathematical model by using the moving horizon technique to generate mining orders that will create mining sequencing and scheduling.

The proposed system particularly differs from the others by considering a new mathematical model for mixed integer linear programming that takes under consideration the existence of a ROM stockpile that represents a stock already processed by the crusher. It also eases the constraint to obey the waste rock-ore ratio whose main goal is to prevent pit strangulation, which means, to prevent that only waste rock blocks are available for long periods of time. A more effective ROM extraction is allowed when the stockpile is below the demand level. Once it reached its capacity limit, the ROM extraction is limited to the plant's processing capacity.

Throughout the sequencing and scheduling processes, there may be periods of time in which the lack of ROM to be processed by the plant might be recorded, i.e., there will be insufficient ore mining by the loading equipment, and the ROM stockpile will be completely empty. In this case, the following mining orders will aim to supply such loss by increasing the plant's processing capacity until the loss has been compensated.

Thus, in a real application, the plant's processing capacity can be linked to the calculated ROM demand (t/h) obtained by examining all the ore to be mined within a year and dividing it by the worked hours. However, the extra capacity can be, for example, the plant's maximum operating speed.

Mathematical model for the loading equipment allocation problem in an open pit mine taking under consideration the ROM stockpile existence

The developed mathematical model belongs to the Mixed Integer Linear Programming (MILP) class in which the integer variables are related to loading equipment allocation, to blocks and to the stockpile movement. In real applications, it takes under consideration the information coming from the mine and production control.

Mine Data:

B' - Set of ratings for the available blocks.

R - Set of coordinates for representing the blocks model. Coordinates (R, C and H).

V - Set of physicochemical variables.

prb- Position of block b with respect to coordinate r.

Tvb- Content of physicochemical variable v in block b.

TPv- Content of physicochemical variable v in stockpile.

Cb - Crusher's processing capacity (t/h).

ROM Stockpile Data:

MP - Capacity assigned to the ROM stockpile.

PercP - Demand level for ROM stockpile replenishment (capacity %).

VolP - ROM stockpile's current tonnage.

Cr - Capacity to recover (t/h) the ROM from the stockpile.

NNLS - Maximum level of mine levels that may be simultaneously mined.

Set of goals and requirements:

cap - Capacity assigned to the plant (t/h).

Trv - Content of physicochemical variable v required in the ROM mixture.

Tuv - Maximum content of physicochemical variable v in the ROM mixture.

Tlv - Minimum content of physicochemical variable v in the ROM mixture.

NNLS - Maximum level of mine levels that may be simultaneously mined.

dmaxr - Maximum displacement allowed in coordinate r.

Loading Equipments Data:

I - Set of available loading equipment.

poir - Initial position of the loading equipment i in relation to the coordinate r.

Pmini - Minimum hourly output for loading equipment i operation.

Pmaxi - Maximum hourly output for loading equipment i operation.

Benefits:

BM - Benefits attributed to the ROM mining.

BS - Benefits attributed to the waste rock mining.

Penalties:

α+v - Penalty due to deviation lower than the goal of quality parameter v.

α-v - Penalty due to deviation higher than the goal of quality parameter v.

γir - Penalty due to displacement of resource i in coordinate r.

δ- - Penalty for negative deviation of ROM production (t / h) added to its removal from the stockpile in relation to the demand of ROM.

ω-v- Negative deviation in relation to the specified minimum physicochemical parameter v.

ω+v - Positive deviation in relation to specified maximum physicochemical parameter v.

Decision variables:

Pb - Hourly production in block b (t/h).

DP- - Negative deviation of total mining rate (t/h) in relation to the demand for ROM.

DP+ - Positive deviation of total mining rate (t/h) in relation to the demand for ROM.

DM- - Negative deviation of the extracted total amount (t/h) added to ROM removal from the stockpile in relation to ROM demand (t/h).

RP - Amount of ROM removed from the stockpile in order to fulfill the demand (t/h).

Nmin - Number of the lower levels with allocated resource.

Nmax - Number of the higher levels with allocated resource.

dTv - Negative deviation in relation to the recommended content of quality v.

dT+v - Positive deviation in relation to the recommended content of quality v.

de-v - Negative deviation in relation to the specified minimum content of quality v.

de+v - Positive deviation in relation to the specified minimum content of quality v.

deir - Number of blocks displaced by resource i with respect to coordinate r.

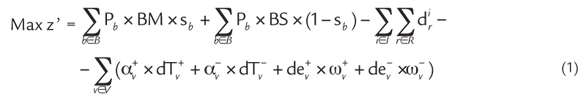

The developed mixed integer programming mathematical model is described below: Maximize ore and waste rock production. Minimize displacements between origin and destination blocks, quality deviations and lack of ROM.

Subject to the following constraints: Set the quality deviation of the mixture coming from the ore mining faces. Calculate the existence of quality deviation in relation to the maximum and minimum content of the mixture.

All loading equipment must be allocated to a block.

Each mineable block can be allocated to at most one loading equipment.

The mining rate applied by the equipment i in block b must be between the minimum and maximum production assigned to equipment i.

Constraints (9-13) were adapted from the mathematical model proposed by Amaral (2008) and aim to limit the mine operation vertical range, i.e., to limit the difference between the block allocated to the top of the mine and the block allocated to the bottom of the mine.

Limit the displacement between the block where the loading equipment lies and the block to be allocated.

Limit the ore mining (t/h) to the crusher capacity. Calculate the deviation of the amount of mined ROM in relation to the plant's processing capacity. Limit the amount of mined ROM if the ROM stockpile is above the demand level.

Limit the ore mining (t/h) to the crusher capacity. Calculate the deviation of the amount of mined ROM in relation to the plant's processing capacity. Limit the amount of mined ROM if the ROM stockpile is above the demand level.

Calculate the deviation of the mined ROM amount added to the ROM amount recovered from the stockpile in relation to the plant's capacity. Determine whether ROM must be recovered from the stockpile, i.e., whether the ROM production in the pit face meets or does not meet the demand. Re-covering material from the stockpile is only allowed when there is material in it. Limit the rate of material recovery from the stockpile (t/h) to the capacity assigned to the operation of removing the material from the stockpile and sending it to the plant. The stockpile receives ROM (mining rate (t/h) higher than the plant's capacity) or provides ROM (mining rate (t/h) lower than the plant's capacity) or, still, when the extraction rate (t/h) is equal to the plant's demand, the stockpile does not receive and does not send material.

Algorithm to address the moving horizon

The mining sequencing and scheduling identify the operations to be performed by each loading equipment, in each not necessarily uniform period of planning, up to the end of the total period to be studied or the depletion of the material in the advance. Such material is formed by hundreds or thousands of blocks to be mined taking under consideration requirements typically met in studies that address mining planning based on a short-term scenario and those addressing the medium/long-term planning.

The proposed method for preparing mining sequencing and scheduling can be described by the seven steps below:

In the first step, the reading of necessary parameters is performed.

Step 2 is responsible for checking the mineable blocks at the surface of the advance region.

Step 3 runs the described mathematical programming model aiming to allocate available resources to mineable blocks.

If a response is infeasible, Step 4 runs where, in the presented model, an infeasible response is mainly associated with resources displacement by gradually easing the constraint associated with the maximum number of displacements. In other cases, when there are not enough mineable blocks and the vertical operating range is restrictive, the loading equipment that prevents the solution from being temporarily eliminated.

Step 5 weighs up the current situation of the mine and the mathematical model response in order to define the duration of the mining order k. In each mining order, the first occurring event defines the end of the order. Three occurrences are taken into account:

Completion of a block being mined;

The stockpile getting full or empty.

Step 6 records the order (*txt) informing the allocation and the rate of extraction of each load equipment. Then, it updates the parameters according to the mining order and its duration. In particular, this study allows the processing plant capacity to be automatically increased, trying to compensate, in the following of orders, the production deficits accumulated from previous mining orders, which were trying to compensate the production loss.

Step 6 ends the algorithm checks whether all blocks have been eliminated or given planning horizon (tplan) ended. If yes, finishes, if not, back to Step 2.

6. Computational results

In order to perform the tests, the current study used a website that provides real instances and instances created by authors (ESPINOZA [6]) described by Espinoza [7]. "Arizona's Copper Deposit (KD)", an open pit mine that contains copper, was chosen among the instances. The mine has 14,153 blocks with dimensions of 20x20x15 m.

One thousand seven hundred and ninety-five (1795) of these blocks to be mined within a year, were selected as an advance. It is important to emphasize that the advance has several layers of piled blocks and the mining of each block must obey the five-blocks-up precedence rule.

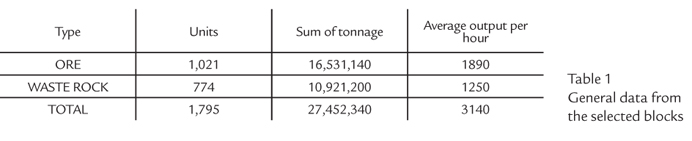

Table 1 shows general data on the selected advance. Among the information, the average output per hour stands out, as a result from dividing the material mass (ore and waste rock) for one year, 8760 hours (365 days x 24 hours). By adding the mining rate set for ore and the one set for waste rock, the study obtained 3,140 t/h.

Model parameters

The following weights were used associated with the objective function:

BM=100; BS=40; α+v=10; α-v=100; δ-= 100; γiL=1000; γiC=1000; γiH=2000.

These penaltie were adjusted based on preliminary tests and the solution quality showed to be dependent on such adjustment.

The adopted operational constraints are shown below:

Cap=1890(t/h) (ideal rate), 2080(t/h) (loss recovery rate); Cb=2540(t/h); Cr=1890(t/h).

The maximum ROM stockpile weight is 600,000 tons, and the demand level is 95%.

The following quality parameters were used in all mining orders

Tlv=0.6%; Trv=0.92%, Tuv=1.4%.

The study took under consideration a fleet composed of up to six loading machines with minimum and maximum mining rates, as described below:

Equip. A (300-600); Equip. B (325-650); Equip. C (350-700); Equip. D (275-550); Equip. E (320-640) e Equip. F (300-600).

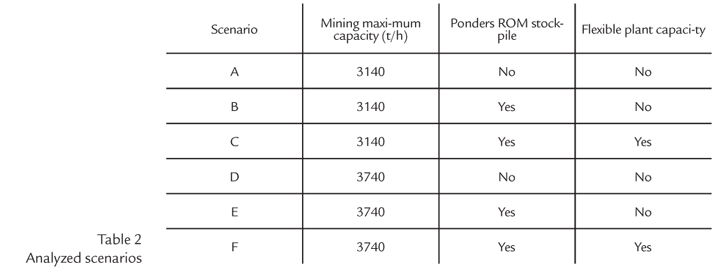

Scenarios

Scenarios with different operational configurations were studied in order to investigate the behavior of Mining Sequencing and Scheduling with Loading Equipment Allocation, as described in Table 2.

Scenarios A, B and C used the first five described loading equipment (from Equip. A to Equip. E), which have, together, enough capacity of mining all the material from the advance within a year, once they operate at full capacity. Scenarios D, E and F used the six described loading machines aiming to study the proposed system behavior when the mining capacity is higher than the annual demand, by investigating whether this situation can be detrimental to the waste rock/ore ratio, i.e., whether there would be predatory ore mining hampering future operations.

Generated solutions

In all scenarios, tplan (planning horizon) is a sufficiently large number. Thus, successive orders are generated until all the blocks are completely mined. The value assigned to torder (minimum duration of each mining order) is of 30 minutes.

Table 3 shows the computational time required to generate solutions and print the results, the amount of material in the stockpile at the end of the block mining, the days needed for mining the entire advance. The "PLANT" column inform the days needed to process the entire ROM. The time assigned to the plant is composed of the time needed for mining all the ore added by the time need-ed for processing the ore in the stockpile.

Scenario description (F)

For illustrative purposes, further information about the Scenario F will be described below. Such scenario showed the best response with the use of 99.5% of the plant, leading to the development of 1,615 mining orders in order to mine the 1795 blocks:

The duration of each mining order: Each mining order has on average 5.5 hours duration, but there is great variation between them (30 min to 25 hours). The ore blocks were the majority in the advance to be mined, but they were mostly covered by waste rock blocks. This can hinder the ore blocks availability especially in the early mining because it forces the equipment to extract the waste rock in order to release the ore. As the waste rock blocks are mainly at the surface layers, ore blocks are gradually released and waste rock blocks availability is reduced along the orders.

Figure 3 shows the mining rate calculated for each mining order. It is noticed that the hourly production of ore and waste rock obtained up to order n. 350 fluctuates considerably.

This can be attributed to the lack of ore blocks during this period, which implies ostensible waste rock mining in order to release ore blocks.

This practice impacted especially after order n. 1350, which had exhausted all of the waste rock, forcing the loading equipment to operate beyond the capacity assigned to the plant (2080) because the plant lost productivity at the beginning of the operation and had not yet recovered it.

Moreover, after the order 350 for greater availability of ore provides the gradual increase in stockpile. Finally, it is possible to verify that the ore mix met the quality requirements on most mining orders.

7. Conclusion

The current study addressed the Open Pit Mine Sequencing and Scheduling with Loading Equip-ment Allocation (OPMSS + LEA). The problem aimed to maximize the productivity of the loading equipment and processing plant, throughout the mining operation of a given advance of blocks by means of successive mining orders, penalizing quality parameter deviations, displacements of loading equipment and the non-compliance with plant's ore demand.

Unlike studies found in literature and seeking to develop models that are closer to the reality within the mines, in addition to the loading equipment, the current study took under consideration a crusher, a ROM stockpile (stock) and the capacity assigned to the processing plant.

In order to test the proposed OPMSS + LEA, we sought a real instance available on the internet and determined resources which were consistent with the deposit and the desired production goal. Different load capacities were compared, as well as the existence or non-existence of a ROM stockpile and the permission to increase ore production in order to overcome accumulated losses when the production was lower than the production goal. The experiments showed that taking under consideration the ROM stockpile existence and assigning a varying production capacity to the plant significantly contributed to the quality of the solution.

The research thus contributed to the development of a new mathematical model and algorithm which has a different approach from the reviewed literature regarding optimization. It aimed to develop the sequencing and scheduling of feasible mining. According to the results, it was observed that the OPMSS + LEA was capable of generating solutions close to the operational reality, by dealing with problems such as the lack of physical space for depositing the extra ore, as well as dealing with moments with lack of ore and other moments with lack of waste rock, without generating infeasible solutions.

It is noteworthy that the generation of production orders, which is common in manufacturing contexts with large-scale production, was adapted to the needs of a mine in the current study and could significantly contribute to the planning and control of mining and processing operations in mining companies that use open pit mining as the mining method. Although the research presents the outcomes of a copper deposit, tests show that the system can be applied to different ore deposits that use open pit mining. More than one quality parameter can also be simultaneously evaluated.

8. References

Received: 4 September 2014

Accepted: 29 September 2014.

- NEWMAN, A., RUBIO, E., CARO, R., WEINTRAUB, A., EUREK, K.. A review of operations research in mine planning. Interfaces, n.3, v. 40, p. 222 -245, 2010.

- AMARAL, M. PINTO, L., R., Planejamento de operações de lavra em minas a céu aberto com alocação de equipamentos de carga e transporte. SOBRAPO, 42. 2009.

- CHICOISNE, R., ESPINOZA, E., GOYCOOLEA, M., MORENO, E., RUBIO,E. A new algoritm for the open pit mine production scheduling problem. Operations Research, v. 60, n.3, p.517-528, 2012.

- CACCETA, L., HILL, S. P., An application of branch and cut to open pit mine scheduling. Journal of Global Optimization, v.27, p.349-365, 2003.

- AMARAL, M. Modelos matemáticos e heurísticas para auxílio ao planejamento de operações de lavra em minas a céu aberto Belo Horizonte: Escola de Engenharia da UFMG, 2008. 108p. (Dissertação de Mestrado em Engenharia de Produção).

- ESPINOZA, D., GOYCOOLEA, M., MORENO, E., NEWMAN, A. 2012. <http://mansci-web.uai.cl/minelib/kd.xhtml>

» link - ESPINOZA, D., GOYCOOLEA, M., MORENO, E., NEWMAN, A. (2012).Mine-Lib: a library of open pit problems Library of Open Pit Mining Problems. Annals Operations Reserch, New York, Springer US, 2012.22 p.

Publication Dates

-

Publication in this collection

07 Nov 2014 -

Date of issue

Dec 2014

History

-

Received

04 Sept 2014 -

Accepted

29 Sept 2014