Abstract

This paper shows the work conducted at the Experimental Mine of the Research Center of Responsible Mining of the University of São Paulo, taking into account the theoretical issues presented in the first part of the article. The research was performed without changing the production cycle and without resorting to investments in new types of equipment: it has attempted to increase the productivity of the quarry, by lowering production costs and improving the quality of the product. Some Key Performance Indicators (KPIs) were established to monitor the results. A new blast design method, a more appropriate initiation sequence and some simple, inexpensive and effective solutions were identified and applied. The results show that the proper selection of delay timing can be of significant benefit to downstream processes as well as enhanced fragmentation itself.

Keywords:

Drill & blast; bench blasting; rock fragmentation; downstream processing; KPIs

1. The quarry under study

This research has been performed at the Experimental Mine of the Research Center for Responsible Mining of the University of São Paulo, Brazil. This is an open-pit limestone quarry, located in the north of the state of São Paulo, which operates under normal production conditions, and at the same time collaborates with experimental research conducted within its premises. The local availability of equipment, explosives and initiation accessories determine the limits of the research material. The equipment available for this research consisted of: 2 rotatory-percussive pneumatic drills, 6 wheel loaders, 3 hydraulic excavators, and 5 trucks. One heavy hydraulic hammer performs the secondary breaking to achieve the threshold size of 500 mm for the feeding of the primary crusher. The exploitation is performed by drilling and blasting. The main blast parameters are reported in Table 1. The holes are charged with 50.8 mm cartridges of explosive emulsion and primed by a strand of detonating cord along the hole, leaving an upper stemming of about 2 m. The blast is fired by a safety fuse and fire cap that initiate the main line of detonating cord; delays are provided by means of relays (17 ms series). At the beginning of the research, the blasting sequence was generally arranged by the blasters in a V-pattern (Mohanty & Chung, 1990MOHANTY B., CHUNG S. An integrated approach in evaluation of blast - a case study. In: INT. SYMP.ON ROCK FRAG. BY BLASTING, 3. Proc. Aust.: Institute of Mines and Met., 1990. p. 353-360.), regardless of the position of the free surfaces and of number of holes that detonate simultaneously. The blasting method in use at the beginning of the research involved some problems, such as: the need for secondary blasting; waste of energy (vibrations, fly-rocks, air-blast); damaged residual bench; lack of precision in timing; excess of fine materials; shape of the muck-pile that does not allow easy loading. By analyzing such a system, observed was the need for operational changes in order to increase productivity and decrease the cost of blasting and downstream processes (Persson et al., 1994PERSSON P.A., HOLMBERG, R., LEE J. Rock Blasting and Explosives Engineering. USA: CRC Press LLC, 1994. (ISBN 0-8493-8978-X).; Mancini et al., 1991MANCINI, R., FORNARO, M., CARDU, M., DE ANTONIS, L. The equivalent crusher of quarry blasting operations. In: ATTI INT. CONGR. ON ENGINEERING BLASTING TECHNIQUE, BEIJING (CHINA), p. 338-345, 1991.; Nielsen, K. and Kristiansen, J., 1996NIELSEN, K., KRISTIANSEN, J., 1996, Blasting - crushing - grinding: optimization of an integrated comminution system. Balkema, Rotterdam: Rock Fragmentation by Blasting, 1996. p. 269-277.; Chakraborty et al., 2002CHAKRABORTY, A.K., RAINA, A.K., RAMULU, M., CHOUDHURY, P.B., HALDAR, A., SAHU, P., BANDOPADHYAY, C. Development of innovative models for optimisation of blast fragmentation and Muck profile applying images analysis technique and subsystems utilisation concept in Indian surface coal mining regime. India: Ministry of Coal, Govt. of India, 2002. 125 p. (Project nº. MT/103); Da Gama, 1983DA GAMA, D.C. Use of comminution theory to predict fragmentation of jointed rock mass subjected to blasting. In: INT. SYMP. ON ROCK FRAG., 1. Proc. Blasting, Lulea, Sweden: 1983. p. 563-579.; Da Gama & Jimeno, 1993DA GAMA, D.C, JIMENO, C.L. Rock fragmentation control for blasting cost minimisation and environmental impact abatement. In: INTERNATIONAL SYMPOSIUM ON ROCK FRAGMENTATION BY BLASTING, 4. Procedings. Balkema, Vienna, Austria, July 5-8, 1993. p. 273-279.). Due to budget restrictions, changes must meet certain conditions: not to involve any financial investment; not to change the excavation technique; and not to interfere with the well-known way to work of the operators. The methods employed and described below were designed to attend such conditions.

2. The performance indicators monitored

To monitor any changes that a modification of P.F., blasting pattern or timing can cause to the downstream process, some Key Performance Indicators (KPIs) have been chosen. They possess the common characteristics of being representative and simple to obtain on field: the objective is to create a database that can provide some valid correlations between different factors, and this is possible only if the operators can autonomously and simply obtain these values. The KPIs selected are listed, defined and described in Table 2.

3. Blast tests

Seven test blasts were performed in a three-month period, gradually adapting the blast method from the one traditionally adopted in the quarry to the method proposed above. The main aspects of the new blast designs were:

(a) Rational determination of the P.F. based on the desired top particle size;

(b) Adjustment of the P.F. based on the average drilling speed encountered in each bench;

(c) Rationalization of the blasting sequence according to the free surfaces and oriented to the dispersion of the holes detonating simultaneously.

Changes had to be introduced gradually for practical and economic reasons. Only the last 2 of the 7 test blasts were completely designed and performed according to the new blasting method. As an example, some details of blast n.7 (the last of the experimental campaign) are shown in Figure 1. The geometry, drilling, and charging details are shown in Table 3 and Figure 2. The objective of this blast was to further increase the distance between the holes that detonate simultaneously. The project involved a delay between each blast-hole; moreover, relays delayed by 42ms have been used for the first time, so as to increase the time difference between the ignition of the blast-holes of a row and those of the next. The measured parameters show good results for the blast. The muck-pile is homogeneous, with a low percentage of fine materials and a reduced volume of blocks whose size requires secondary breaking. The final wall is of good quality, with acceptable values of HCF and Bb. No fly-rock was observed. The cost of the blast corresponds to the average cost for this quarry. The high cost caused by a high number of delay units is compensated by a reduction in the cost of drilling, thanks to the increase of spacing that has allowed realizing fewer holes to cover the entire surface to be drilled.

General view of the bench before (above) and after (below) the blast. The free surface, being left by the previous blast, dimensioned according to the proposed method,is smooth and slightly damaged.The muckpile generated by the blast has a suitablegeometry.

4. Results and discussion

Figure 3 shows the KPIs of the project in chronological order. Considering the results obtained, it can be noticed that:

- The shape of the muck-pile Sm improved significantly over time: this has the strong advantage of increasing the productivity of the loader, reducing the idle time that consisted in gathering the material spread away from the pile;

- The back-break Bb is strongly reduced. Thanks to a lower loading/hole, and to a different timing, it was possible to obtain a better precision of the residual wall;

- The evaluation of the parameter Sb is obtained by the work of the hydraulic hammer, which is greatly reduced. Despite some blasts were made in an area where the rock was particularly strong, a better dimensioning of both the charging and timing of the blast has led to a better quality of the product. By comparing the performance of Sb with the PF employed in the examined blasts, it can be noticed that: a greater amount of explosive/m3does not necessarily correspond to greater fragmentation;

- The accuracy of the result obtained after the two last blasts as the regularity of the residual wall is concerned is greatly increased, giving rise to a very high HCF;

- As can be seen on the performance of Fy, fly-rock is completely absent in the last two blasts. This results in increased safety and reduced projections of material away from the pile;

- The trend of costs is maintained roughly constant, but can be observed as one of the last two blasts has resulted in a lower cost than other cases. Basically, the contribution of the cost items due to explosives and drilling is kept almost constant, while the cost of secondary breaking and sieving can be greatly reduced by adopting the proposed method.

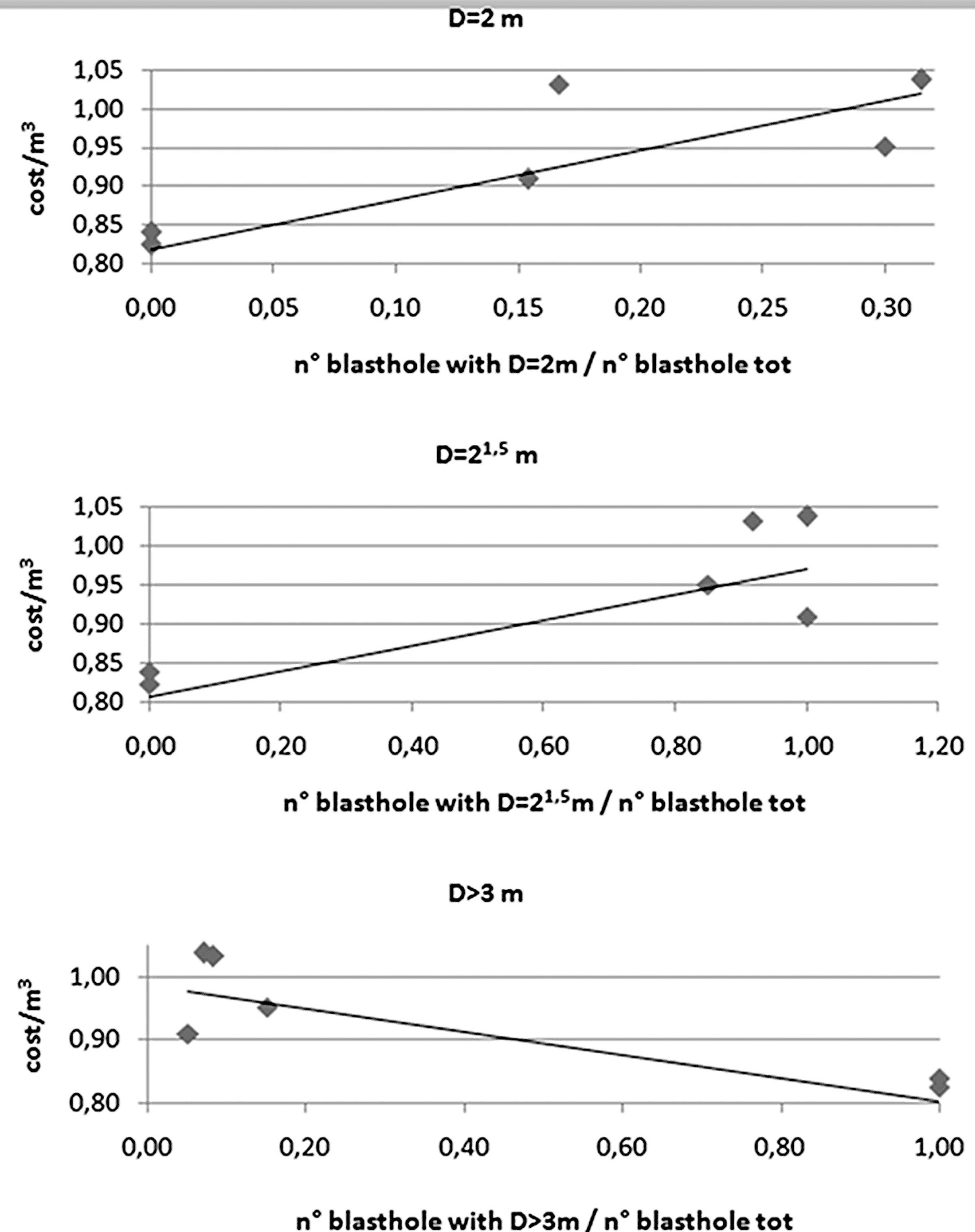

In order to understand the influence of the blasting sequence on the downstream operations, the distance of holes detonating at the same nominal delay has been considered. Three classes of distance where evaluated:

• D = 2m, when two simultaneous holes are along the spacing or burden lines of the square drilling mesh;

• D =21.5m when two simultaneous holes are along the diagonal of the square drilling mesh;

• D > 3m, when two simultaneous holes do not belong to the same square of the drilling mesh.

The scattering of real delay times around the nominal value of 17 or 42 ms has not been taken into consideration, due to the impossibility of evaluating it case by case. Two holes with the same nominal delay calculated on the firing pattern have been considered detonating simultaneously also on field. This was acceptable for the purposes of the present research. Future research should be oriented to take into account this uncertainty. For each class of distance, the ratio between the number of holes falling in the given class over the total number of holes of the blast was analyzed. It has been noticed that this parameter has a direct influence on two KPIs that control the outcome of the influence of the blast: secondary breaking (Figure 4) and cost of the fine material to be separated (Figure 5). It must be highlighted that the lines shown in the graphs of Figures 3 and 4 are mere trends and not statistical regression lines, since the population of data is too scarce and the records too scattered to give any regression statistical significance. The higher the number of blast-holes that detonate with spacing>3m, the lower the volume of oversize blocks that need secondary breaking. Conversely, the greater the number of blast-holes that detonates simultaneously with lower spacing, the higher the number of oversize blocks. This is a consequence of the phenomenon by which, if more blast-holes detonate simultaneously, the result is the rock detachment, and if, instead, detonate with different delay, the result is fragmentation. The aim of the research was also to find a high enough spacing between the blast-holes that detonate simultaneously to generate the maximum fragmentation. It may be noted that even a slight variation of the distance D between the first two graphs of Figure 4 leads to a variation of the trend line: this further demonstrates what was said above. So there is a clear shift, increasing the distance between the blast-holes that detonate with the same delay, to the ideal case of greater homogeneity of the muck-pile. Regarding the costs, by increasing the distance between the holes that detonate simultaneously, the cost of excavation is reduced. This result can be attributed to a greater homogeneity of the muck-pile obtained and to the reduction of secondary breaking. The increase of the spacing has been achieved either by changing the firing sequence or by widening the geometry of the drilling mesh. This has certainly allowed an economic saving, given the high cost of the drilling phase. The Powder Factor does not vary significantly among the blasts observed. As seen, moreover, the cost of the explosives contributes for the most part on the total cost. It thus appears as the difference of cost of the blasts analyzed. Depending on the spacing of the blast-holes that detonate simultaneously, it is actually generated by a change in the quality of the product, and not by a simple reduction of the amount of explosive. This is the most significant result of the research, as it was able to demonstrate the possibility of improvement, without increasing the cost and without the need for new materials and technologies. These two combined results suggest that managing a better decomposition of the blast by increasing the distance between simultaneous holes could provide the following advantages:

• induce the explosive to work along the burden towards the free surface instead along the spacing between holes, obtaining a more homogeneous fragmentation and reducing the production of coarser material

• reduce the overall cost of the blast by reducing the incidence of secondary operations.

5. Concluding remarks

The Experimental Mine provides a wide scenery about future tests and research, as characterized by a relatively simple organization of blasts and control of downstream conditions. Future research will also focus on monitoring the energy consumption of each machine at the comminution plant, in order to provide information on grinding productivity, especially in terms of WI of the blasted material (Kiliç et al., 2009KILIÇ, A.M., YAŞAR, E., ERDOĞAN, Y., RANJITHP. G. 2009. Influence of rock mass properties on blasting efficiency. Scientific Research and Essay. v.4, n. 11, p. 1213-1224, 2009. Available online at http://www.academicjournals.org/SRE, ISSN 1992-2248 (c) 2009 Academic Journals.

http://www.academicjournals.org/SRE...

). Furthermore, an effort was made to find a solution to the waste of energy because of an ineffective stemming. Although more extensive grain size distribution was used during the tests, an excessive dispersion of energy to the surroundings was observed. Other methods are currently being tested, such as plastic plugs, able to greatly increase energy confinement. Regarding the blast initiation, as previously discussed, the organization of the circuit with detonating cord leads to various drawbacks. In particular, the risk of severing the circuit is common and it is essential to avoid cross connection lines. The goal for the medium term is the shift towards shock-tube or electronic systems. This would allow the chance to experience various combinations of delay times. Another goal is to continue the recording of the drilling speed, in order to create a three-dimensional map of variation of geomechanical strength along the whole quarry. The influence of timing, within the possibilities offered by detonating cord, was examined in this study. As far as fragmentation and the importance of timing are concerned, results indicate that timing, leading to stress wave interaction, is important. Therefore, selection of delay time can be of significant benefit to downstream processes as well as enhance fragmentation itself. Blasting is an application of energy and energy distribution. Powder factor, distribution of charges and timing affect the outcome as a complex system. The work needs to be further improved by additional experiments, also with the aim of assessing the mutual influence between some important parameters, such as examining how blasting results are affected by the rock mechanics properties of the rocks and the effects of charge distribution and initiation timing on the breakage. Since electronic detonators are finding acceptance in the industry (Bilodeau et al., 2008BILODEAU, M., LABRIE, D., BOISCLAIR, M., BEAUDOIN, R., ROY, D., CARON, G. Impact of electronic blasting detonators on downstream operations of a quarry. Mineral & Metallurgical Processing, v. 25, n. 1, p. 32-40, 2008.; Cardu et al., 2013CARDU, M., GIRAUDI, A., ORESTE, P. A review of the benefits of electronic detonators. REM: R. Esc. Minas, Ouro Preto, v. 66, n. 3, p. 369-376, 2013.), there may be significant advantages from precise initiation in future works.

References

- BILODEAU, M., LABRIE, D., BOISCLAIR, M., BEAUDOIN, R., ROY, D., CARON, G. Impact of electronic blasting detonators on downstream operations of a quarry. Mineral & Metallurgical Processing, v. 25, n. 1, p. 32-40, 2008.

- CARDU, M., GIRAUDI, A., ORESTE, P. A review of the benefits of electronic detonators. REM: R. Esc. Minas, Ouro Preto, v. 66, n. 3, p. 369-376, 2013.

- CHAKRABORTY, A.K., RAINA, A.K., RAMULU, M., CHOUDHURY, P.B., HALDAR, A., SAHU, P., BANDOPADHYAY, C. Development of innovative models for optimisation of blast fragmentation and Muck profile applying images analysis technique and subsystems utilisation concept in Indian surface coal mining regime. India: Ministry of Coal, Govt. of India, 2002. 125 p. (Project nº. MT/103)

- DA GAMA, D.C. Use of comminution theory to predict fragmentation of jointed rock mass subjected to blasting. In: INT. SYMP. ON ROCK FRAG., 1. Proc. Blasting, Lulea, Sweden: 1983. p. 563-579.

- DA GAMA, D.C, JIMENO, C.L. Rock fragmentation control for blasting cost minimisation and environmental impact abatement. In: INTERNATIONAL SYMPOSIUM ON ROCK FRAGMENTATION BY BLASTING, 4. Procedings Balkema, Vienna, Austria, July 5-8, 1993. p. 273-279.

- KILIÇ, A.M., YAŞAR, E., ERDOĞAN, Y., RANJITHP. G. 2009. Influence of rock mass properties on blasting efficiency. Scientific Research and Essay v.4, n. 11, p. 1213-1224, 2009. Available online at http://www.academicjournals.org/SRE, ISSN 1992-2248 (c) 2009 Academic Journals.

» http://www.academicjournals.org/SRE - MANCINI, R., FORNARO, M., CARDU, M., DE ANTONIS, L. The equivalent crusher of quarry blasting operations. In: ATTI INT. CONGR. ON ENGINEERING BLASTING TECHNIQUE, BEIJING (CHINA), p. 338-345, 1991.

- MOHANTY B., CHUNG S. An integrated approach in evaluation of blast - a case study. In: INT. SYMP.ON ROCK FRAG. BY BLASTING, 3. Proc. Aust.: Institute of Mines and Met., 1990. p. 353-360.

- NIELSEN, K., KRISTIANSEN, J., 1996, Blasting - crushing - grinding: optimization of an integrated comminution system Balkema, Rotterdam: Rock Fragmentation by Blasting, 1996. p. 269-277.

- PERSSON P.A., HOLMBERG, R., LEE J. Rock Blasting and Explosives Engineering USA: CRC Press LLC, 1994. (ISBN 0-8493-8978-X).

Publication Dates

-

Publication in this collection

Oct-Dec 2015

History

-

Received

13 Nov 2014 -

Accepted

20 May 2015