Abstract

An experiment was carried out to evaluate the effect of environmental enrichment in a free-range chicken production system on live performance as a function of microclimate, physiological parameters, and performance parameters. Four production modules were divided into four pens with 10 birds each, totaling 60 birds. The following treatments were applied: access to a paddock (TEST), access to a paddock with perches (PER), access to a paddock with artificial shade (SHA), and access to the paddock with perches and artificial shade (PESH). The PESH production module presented the best globe temperature (Tbg,ºC) and enthalpy (h, kJ/kg), and thereby, the best thermal environmental conditions, which ensured the longest permanence time of the birds in the paddock. The SHA and PESH modules promoted the lowest respiratory rate and shank and comb temperatures. Live performance was influenced by the presence of environmental enrichment (modules SHA and PESH), with the highest live weight (LW) and weight gain (WG) and the lowest feed conversion ratio (FCR) and metabolizable energy intake (MEI). Parts yield, such as giblets, were not influenced by production modules, except for PESH, which promoted higher offal weight. In general, chickens reared in enriched production modules presented greatest performance and comfort results and were considered close to optimal rearing conditions.

Animal behavior; physiological parameters; poultry production; thermal comfort

Performance of free-range chickens reared in production modules enriched with shade net and perches

Santos MJBI; Pandorfi HII; Rabello CBVI; Silva EPI; Torres TRI; Santos PAI; Morril WBII; Duarte NMII

IAnimal Science Department, Universidade Federal Rural de Pernambuco (UFRPE), Recife, PE. 52171-900, Brazil

IIDepartment of Agricultural Engineering, Universidade Federal Rural de Pernambuco (UFRPE), Recife, PE. 52171-900, Brazil

Corresponding author Corresponding author Marcos José Batista dos Santos Dom Manoel de Medeiros, s/n, Dois Irmãos 52171-900 - Recife, Brazil Tel.: +55 8196923237, fax: +55 81 81-3320-6555 E-mail address: marcoszootecnista@gmail.com

ABSTRACT

An experiment was carried out to evaluate the effect of environmental enrichment in a free-range chicken production system on live performance as a function of microclimate, physiological parameters, and performance parameters. Four production modules were divided into four pens with 10 birds each, totaling 60 birds. The following treatments were applied: access to a paddock (TEST), access to a paddock with perches (PER), access to a paddock with artificial shade (SHA), and access to the paddock with perches and artificial shade (PESH). The PESH production module presented the best globe temperature (Tbg,ºC) and enthalpy (h, kJ/kg), and thereby, the best thermal environmental conditions, which ensured the longest permanence time of the birds in the paddock. The SHA and PESH modules promoted the lowest respiratory rate and shank and comb temperatures. Live performance was influenced by the presence of environmental enrichment (modules SHA and PESH), with the highest live weight (LW) and weight gain (WG) and the lowest feed conversion ratio (FCR) and metabolizable energy intake (MEI). Parts yield, such as giblets, were not influenced by production modules, except for PESH, which promoted higher offal weight. In general, chickens reared in enriched production modules presented greatest performance and comfort results and were considered close to optimal rearing conditions.

Keywords: Animal behavior, physiological parameters, poultry production, thermal comfort.

INTRODUCTION

Animal welfare has been in the forefront of the international debate on animal production over the last decade, especially in the European Union. The need for low-cost animal products has led poultry companies to apply rearing practices that increase broiler efficiency without considering their welfare, including thermal comfort and air quality aspects, which poses health, economic, and biosecurity risks.

Nääs & Curto (2001) reported that air quality inside and around commercial broiler houses is directly related with health and environmental stressors. On the other hand, in semi-intensive rearing systems, there are less excreta inside the broiler house, reducing pollution and the contact of birds with the excreta.

Genetic selection for fast growth has also had negative effects on broiler welfare, such as metabolic disorders that may cause ascitis and sudden death (Bessei, 2006). Consequently, broiler production has become the focus of many animal welfare studies.

The concept of semi-intensive production systems of free-range chickens is different from that of commercial systems, aiming to be less aggressive to the environment and to the birds.

Animal welfare and health are positively affected when housing area is increased as there is more freedom of birds' movement. On the other hand, rearing broilers in total confinement causes extreme stress (Jones & Millis, 1999), and the physiological and behavioral responses to stress (Marin et al., 2001) may result in serious health, production, and welfare problems (Abeyesinghe et al., 2001; Hall, 2001). There is an increasing demand for alternative food products that are healthier, and that derive from production systems that cause less environmental pollution and that consider the welfare of livestock.

Free-range chicken products are slowly attracting consumers. This production model uses low stocking density, slow-growing broilers, and late slaughter, around 85 days of age. In addition, birds have free access to pastures and insects, providing different meat physical-chemical characteristics than conventional chicken meat (Castellini et al., 2002), particularly relative to texture, color, flavor, and pH.

However, there are few studies in the literature on the nutritional requirements, genetics, thermal comfort range, and other aspects of free-range broilers. The best production system, promoting animal welfare and superior productivity, still needs to be determined.

In this context, an investigation was carried out to evaluate the effect of environmental enrichment in a free-range chicken production system on live performance as a function of microclimate, physiological parameters, and performance parameters.

MATERIALS AND METHODS

The experiment was carried in the Small Animal Experimental Farm (EEPAC/UFRPE) located in the city of Carpina, state of Pernambuco, Brazil (7.85º S latitude, 35.24º W longitude, and 180 m altitude). The climate, according to Köppen classification is megathermal (As') with rainfall during winter and a dry season from summer to autumn (Pereira, 2002).

In total, 500 one-day-old free-range Embrapa 041, broilers were used. Birds were reared in an experimental broiler house (10-m long, 10-m wide, 3-m high), covered with 4-mm fibercement tiles, until day 30. Birds were vaccinated in the hatchery against Marek's disease and infectious bursal disease (IBD). On day 12th, they were also vaccinated against Newcastle disease, IBD, and infectious bronchitis. Birds were initially housed in brooding circles equipped with mixed 160-W lamps hanging 0.50 m above the litter and were managed according to chick distribution profile.

On the 30th day of growth, the birds were transferred to production module with access to paddocks, where they remained for more 57 days, totaling a production cycle of 87 days.

Production modules (3.2 m long, 3.2 m wide, 3.0 m high) were built in the east-west direction and were made of bricks and had a concrete floor. The roof was made of 4mm-thick fibercement tiles, had no dropped ceiling, and eaves were 0.7 m long. Sidewalls were 0.4 m high, and the remaining height was covered with a wire mesh. Each module was divided into four pens separated by wire mesh. Each pen had an opening, allowing the birds' access to the paddock between 07:00 A.M and 05:00 P.M, GMT, BRT.

Birds were housed at densities of 3m2/bird (paddock) and 10 birds/m2 (pen). Four treatments with four replicates each, totaling 16 experimental units with 10 birds each, were applied: production module with no environmental enrichment (TEST), production module with perches (PER), production module with artificial shade (SHA), and production module with perches and artificial shade (PESH).

Perches were made of wood and were 1.2m high and 2.0 wide in the shape of a pyramid and placed at the center of the paddock. Shade was provided by a black shade net (70%) that covered 60% of the paddock (1.8m of the shaded area per bird) in order to ensure protection from direct solar radiation.

Feeders and nipple drinkers that were adequate for each production period were placed at the geometric center of each pen. Feed and water were supplied ad libitum during the entire rearing period. Feeding was divided into grower and finisher phases (diets shown in Table 1), according to Embrapa's manual.

The thermal environment was assessed by recording meteorological data at the different production modules and in the external environment. The following meteorological parameters were recorded: dry bulb temperature (Tdb, ºC), wet bulb temperature (Twb, ºC), black globe temperature (Tbg, ºC), and wind speed (Wv, m/s) to characterize the thermal efficiency of the production model using the outside environment as reference.

These parameters were recorded daily at 2-h intervals, between 07:00 and 17:00 hours. The parameters Tdb and Twb were measured using a thermo-hygrometer (Incoterm®), with a -10 to 50 ºC scale, with ± 1 ºC precision. Tbg was recorded using a standard thermometer (-20 to 110 ºC) coupled to a hollow sphere made of high-density polyethylene and painted dull black.

The thermometers were placed at the geometric center of each pen at a 0.30 m height. In the external area, thermometers were placed at 1.5 m height inside a meteorological shed to characterize the local microclimate. Wind speed was measured at the same time as temperature measurements, both inside the modules and in the external environment, using a thermo-anemometer (AZ Instrumentos®, model 8908).

The thermal efficiency of the facilities was determined as a function of the meteorological parameter values recorded in the studied environments. Globe temperature and humidity index (GTHI) as proposed by Buffington et al. (1981), radiant heat load (RHL) expressed in Wm-2 as proposed by Esmay (1982), and enthalpy (h; kJ kg dry air-1), as proposed by Albright (1990), were calculated.

The physiological parameters measured were respiratory rate (mov/min) and bird surface temperature as these were not invasive. Shank, crest, and wattle temperatures were measured at four-hour intervals (09:00 am, 01:00 pm and05:00 pm, GMT, BRT), three days weekly, using an infrared thermometer (RayTempTM 3) with 0.1ºC resolution and ±1ºC accuracy. Two birds per replicate, totaling 32 birds, were randomly selected and then properly identified to assess those body temperatures always in the same birds.

On 30th day, the gate to access the paddock was opened, allowing free access of the birds to the external environment. After seven days of adaptation, bird behavior started to be weekly monitored until the end of the experiment (days 38 to 87th), totaling seven evaluations.

Observers were positioned in strategic locations, in the production modules, and the paddocks, allowing monitoring bird behavior between 07:00 AM and 05:00 PM in two-hour intervals and the frequency birds entered the paddock and behavior (time remaining under and out of the shade) were recorded every five minutes. Behavior was recorded in six randomly selected and properly identified birds per treatment, totaling 24 birds.

The next live performance parameters were weekly recorded: live weight, weight gain, feed conversion ratio, and feed intake. At the end of the experimental period, birds were sacrificed at the processing plant at the Small Animal Experimental Farm (EEPAC/UFRPE), to determine carcass and parts yields.

Birds were stunned, bled, scalded, plucked, eviscerated and cut up to determine eviscerated carcass weight, giblet weight (liver, gizzard, and heart), offal weight (intestines and fat), and parts weight (breast, thigh, drumstick, wings, back).

Data normality was tested by the tests of Shapiro-Wilk and Kolmogorov-Smirnov, and the test of Bartlett was used to determine homoscedasticity. When those assumptions were confirmed, data were submitted to analysis of variance.

Behavioral variables were submitted to frequency analysis, using the statistical package Statistical Analysis System (SAS, 2009). Performance parameters (weight gain, feed intake, feed conversion ratio, crude protein intake, metabolizable energy intake) were analyzed according to a fully randomized split-plot experimental design, with weeks as the main plot and production module (TEST, PER, SHA, PESH) as subplot. Carcass yield and parts yield were analyzed according to a fully randomized experimental design, with four treatments (production modules) of four replicates each. Means were compared by the Tukey test at 5% probability level.

RESULTS

Environmental and physiological parameters

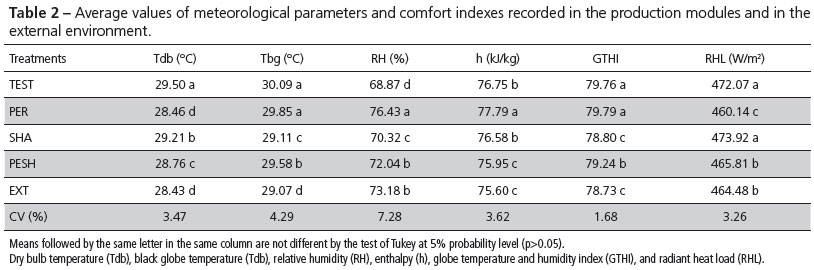

Meteorological parameters and comfort indexes were significantly different between production modules and external environment, considering dry bulb temperature (Tdb, ºC). The highest temperature was recorded in the module with no environmental enrichment (TEST), as it had no means to reduce the internal temperature as in the module with perch and artificial shade (PESH) as shown in Table 2, with more than 1oC difference between the TEST and the PESH modules.

Production modules and external environment influenced black globe temperature (Tbg), which was higher in the TEST and PER modules compared with SHA and PESH modules, whereas the external environment (EXT) presented the lowest value during the analyzed period.

The lowest average relative humidity value (RH) was obtained in the module with the perch (PER), followed by the module with perch and artificial shade (PESH) and the external environment. The lowest RH values were obtained in the module with shade (SHA) and the module with no environmental enrichment (TEST).

The highest average enthalpy value was recorded in the PER module, and was significantly different from the TEST and the SHA modules, which were also different from PESH and external environment, presenting average values of 77.79, 76.58, 75.95, and 75.60 kJ/kg dry air.

Production modules and the external environment significantly affected globe temperature and humidity index (GTHI). The highest average values were obtained in the modules with no artificial shade (TEST and PER), which were different from the modules with both perch and artificial shade (PESH) and artificial shade only (SHA). The lowest GTHI values were recorded in the SHA module and the external environment.

Radiant heat load (RHL) was not affected by environmental enrichment. Despite the difference of up to 1.1% in RHL, the RHL of the TEST and the SHA modules was not statistically different from that obtained in the PER and the PESH modules.

The broilers reared in the production module with perch and shade (PESH) were the most stimulated to be out of the shelter, with 141 observations of birds in the paddock (Table 3). There were 130 observations of the presence of birds of the SHA module in the paddock while TEST and PER birds were less frequently recorded in the paddock, with 108 and 102 observations, respectively.

Broiler respiratory rate (mov/min) was influenced by the treatments, with higher rates recorded in birds in the TEST and PER modules compared with those in the SHA and PESH modules. However, there was no difference between TEST and PER or between SHA and PESH production modules (Table 4).

The broilers housed in the PER, and TEST production modules presented higher average respiratory rate, which was reduced in the PESH birds, followed by SHA birds; however, all values were 74.5, 65.9, 42.5, and 29.7% higher, respectively, than the optimal rate established by Silva et al. (2003).

The lowest average feed temperatures were observed in SHA broilers, followed by PESH broilers, with up to 1ºC difference relative to the treatments that were not provided with shade in the paddocks. The production modules SHA and PESH also promoted lower comb temperatures (averages of 32.7 and 33ºC, respectively) that the TEST and the PER modules, which values did not differ and, in average, were 1.6ºC higher than those obtained in the SHA and PESH modules.

The lowest wattle temperature was recorded in the SHA birds (average of 34.4ºC), whereas there was no difference among the TEST, PER, and PESH modules.

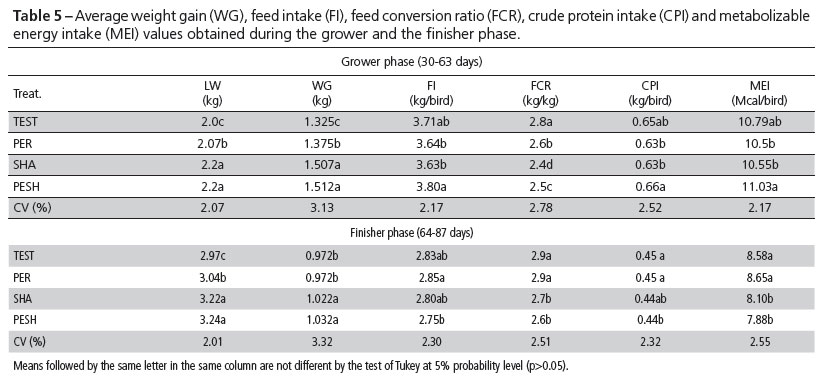

Performance

The production modules SHA and PESH promoted higher weight gain in both rearing phases (grower and finisher). However, despite birds in the SHA module having 4% better feed conversion ratio than PESH during the grower phase, these treatments were not different during the finisher phase (Table 5).

In the grower phase, broilers housed in the PESH and TEST production module presented higher feed intake (3.80 and 3.71 kg/bird, respectively). In the finisher phase, PESH birds presented the lowest feed intake, which, however, was not different from TEST and SHA birds. This was reflected in higher CP intake, with significant effect in the finisher phase for the treatments TEST and PER. Live weight was higher in the SHA and PESH modules in both rearing phases, being, in average, 8.4% higher than in the other treatments in the finisher phase. Treatments significantly influenced live weight, weight gain, feed conversion ratio, and metabolizable energy intake during the total experimental period (30-87 days) as shown in Table 6.

Broilers in the SHA and PESH treatments presented 10% higher weight gain compared to the TEST treatment. During the entire experimental period, birds in the SHA and PESH modules presented significantly lower feed conversion ratio, and the TEST treatment resulted in the worst feed conversion ratio among treatments.

Feed intake and crude protein intake during the entire experimental period were not influenced by treatments. Metabolizable energy intake was higher for TEST birds, followed by PER birds, with averages of 8.4 and 8.15 Mcal/bird.

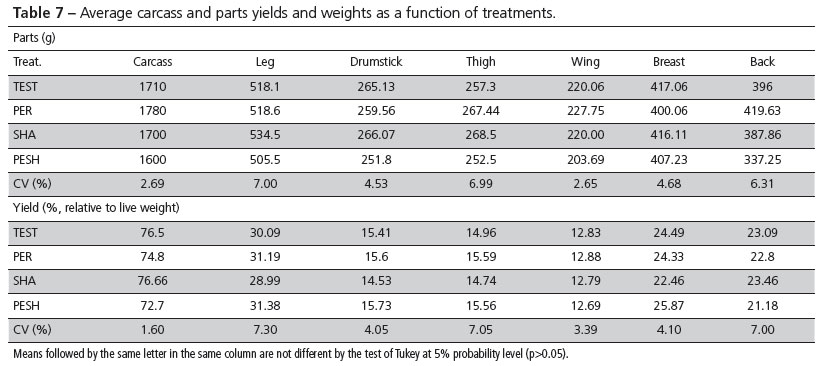

There was no effect of production module on carcass and parts (leg, thigh, drumstick, wing, breast, back) yields or weights (Table 7).

Giblet weight and yield were not affected by production module (Table 8). However, offal yield was significantly higher in broilers reared in the PESH production module.

DISCUSSION

The placement of a shade net covering 60% of the paddock area improved the environmental conditions of the production module, promoting better comfort rate and changed the energy balance around the production sheds, thereby stimulating the permanence of the birds in the paddocks.

The external environment (EXT) presented the lowest black globe temperature (Tbg,ºC) during the evaluated period. The heat stress caused by diffuse solar radiation accounts for a significant proportion of heat exchange (Pereira, 2002). However, Tbg was also higher inside the production shed due to the heat irradiated by the birds, which may increase by the heat increment produced during the metabolism of some feedstuffs. These results are consistent with the findings of Silva et al. (2003), who found that the rearing environment which promotes better thermal comfort provides better animal welfare.

When considering RH, the production modules provided with shade nets allowed lower water vapor retention, and; therefore, lower RH values were recorded in these modules, except for the module with no environmental enrichment (TEST), which presented the lowest relative humidity value compared with the other treatments.

Enthalpy indicated the amount of energy present in the air, and it is directly influenced by Tdb. The temperature recorded in all production modules was higher than the upper limit of the comfort zone, using the reference values of 67.2-51.5 kJ kg-1, according to Barbosa Filho et al. (2006) for commercial broilers, because the comfort zone for free-range broilers is not yet determined. The presence of shade net and perch provided the best thermal comfort for the birds reared in this module, as the environment presented less energy per kg of dry air.

Considering the globe temperature and humidity index (GTHI), the absence of shade nets stimulated the longer permanence of the birds inside the sheds, significantly changing their comfort index.

The use of average Tdb and radiant heat load does not allow determining the best thermal condition of broiler housing, particularly if the associative effect of the studied parameters is taken into account. However, the obtained enthalpy (h) and globe temperature and humidity index (GTHI) values indicate that the PESH module was the most adequate due to the presence of a perch and artificial shade in the paddock area.

The broilers in the PESH module remained longer in the paddock due to the additive effect of environmental enrichment mechanisms (artificial shade and perch). The results of the module with perch only do not suggest that the perch encourage the birds to stay in the paddock, differently from the reports of Young (2008). Another factor to be considered in the TEST and PER modules is the lack of a physical object, which could be considered as a refuge by the birds, and may have generated fear and frustration, reducing grazing activities.

High respiratory rate indicates the sensitivity of the free-range broilers to the environmental conditions inside the sheds as previously observed by Hellmeister Filho et al. (2003). High respiratory rates indicate that air temperature is above the upper critical limit for poultry (Hoffmann et al., 1968). Heat is stored in the body, and when body temperature is above normal levels, the heat center of the hypothalamus is directly stimulated, activating the cardiorespiratory system, making birds pant in an effort to remove heat by evaporation. This may explain the high respiratory rate recorded in all production modules in the present experiment.

Featherless areas, such as comb, wattle, and shank are essential for thermoregulation in poultry (Macari et al., 2002). Yahav (2000) also mentions that shank temperature may be valuable because it does not have feathers, and, therefore, can be used to dissipate heat by conduction. Silva et al. (2003) mention that comb temperature can be a valuable indicator of bird comfort as it is used to dissipate heat by convection due to its high blood supply. Wattle can also be used as a comfort indicator because, as the crest, it is also a peripheral region with abundant blood supply.

The production modules provided with artificial shade (SHA and PESH) positively influenced the physiological and performance parameters, as a result of better ambient conditions, providing less heat to reared birds, agreeing with the findings of Medeiros et al. (2005).

The lower enthalpy values obtained in the SHA and PESH modules were directly reflected in the better weight gain, and feed conversion ratio recorded in the broilers housed in these modules due to the lower energy required for heat dissipation, which was used for body nutrient buildup. Environmental temperature can be considered that physical factor with the strongest influence on broiler performance, considering feed intake, weight gain, and feed conversion ratio.

Live weight recorded in broilers reared in the SHA, and PESH modules in both rearing phases (8.4% higher than the other treatments in the finisher phase) indicates the efficiency of the presence of the shade nets. These provided better bird comfort and welfare compared with those that were reared in modules with no shade in the paddock (TEST and PER), making these birds stay longer inside the sheds, impairing their live performance. Moreira et al. (2004) reported the increasing bird density results in weight gain and live weight reduction, particularly during the finisher phase.

These results are consistent with the findings of Barbosa Filho et al. (2006), who worked with free-range chickens of the "caipirinha" strain, and obtained higher weight gain in broilers reared under a shade net; however, feed conversion ratio was not affected. The high energy intake of the birds in the production modules with no artificial shade (TEST, followed by PER) did not ensure their better performance relative to birds in the other treatments. Their live weight and feed conversion ratio average values were lower than those of the other birds. This is probably due to the low efficiency of utilization of energy for weight gain as a result of the heat stress caused by the environmental conditions.

Regardless the differences in environmental temperature, energy intake depends on bird's requirements (Beterchini et al., 1991) on the feedstuffs, and on dietary energy level. Energy intake control is beneficial not only for its effects on growth rate, but also for the negative effects of excessive intake on carcass quality, which may accumulate more fat. Reductions in dietary energy levels result in lower fat accumulation in the carcass (Leeson et al., 1996).

The different production modules influenced the performance of free-range broilers. The modules with artificial shade (PESH and SHA) promoted the best weight gain, feed conversion ratio, metabolizable energy intake, and live weight, considering the entire experimental period. The evaluated treatments did not affect carcass and parts yields or weights, differently from Castellini et al. (2002), who recorded 70.3% carcass yield in 56-d-old broilers reared under a semi-intensive system. These results may have been influenced by feed type, genetic strain, age, dietary energy level, and pre-slaughter conditions. Castellini et al. (2002) found out that broilers reared in the semi-intensive system presented higher locomotion activity, higher muscle development, and lower carcass fat content because they were calmer and less stressed.

It was expected that abdominal fat yield of the broilers reared in the TEST and PER would be higher due to their higher energy intake. Their lower carcass yield may be explained by losses during evisceration, particularly visceral fat losses, which were not quantified during processing. Abdominal fat quantification allows inferences on possible changes in body fat deposition, and in broilers that accumulate fat in different regions, fat content may be misestimated due to the high coefficient of variation.

The production modules enriched with shade nets promoted the best performance and comfort results. Therefore, they may be considered close to the optimal environment, allowing broilers to express their natural behavior, with consequent improvements in performance.

Submitted: March/2013

Approved: August/2013

- Abeyesinghe S M, Wathes C, Nicol C J, Randall J M. The aversion of broiler chickens to concurrent vibrational and thermal stressors. Applied Animal Behavior Science 2001;73(3): 199-215.

- Albright L D. Environment control for animals and plants. Madison: American Society of Agricultural Engineers; 1990.

- Barbosa Filho J, Silva M, Silva I, Coelho A. Egg quality in layers housed in different production systems and submitted to two environmental conditions. Revista Brasileira de Ciência Avícola 2006;8(3):23-28.

- Bessei W. Welfare of broilers: a review. World's Poultry Science Journal 2006;62(03):455-466.

- Beterchini A G, Rostagno H S, Fonseca J B, Oliveira A I G. Efeitos da temperatura ambiente e do nível de energia da ração sobre o desempenho e a carcaça de frangos de corte. Revista da Sociedade Brasileira de Zootecnia 1991;3(20):218-228.

- Buffington D, Collazo-Arocho A, Canton G, Pitt D. Black globe-humidity index (BGHI) as comfort equation for dairy cows. Transactions of the ASABE 1981; 24(3):711-714.

- Castellini C, Mugnai C, Dal Bosco A. Effect of organic production system on broiler carcass and meat quality. Meat Science 2002;60(3):219-25.

- Esmay M. Principles of animal environment. London: Avi Publishing Company; 1982.

- Hall A L. The Effect of stocking density on the welfare and behaviour of broiler chickens reared commercially. Animal Welfare 2001;10(1):23-40.

- Hellmeister Filho P, Menten J F M, Silva M A N de, Coelho A A D, Savino V J M. Efeito de genótipo e do sistema de criação sobre o desempenho de frangos tipo caipira. Revista Brasileira de Zootecnia 2003;32(6):1883-1889.

- Hoffmann G, Völker H, Arenillas J R M. Anatomía y fisiología de las aves domésticas. Zaragoza: Acribia; 1968.

- Jones M, Millis A D. Divergent selection for social reinstatement and behaviors in Japanese quail: effects on sociality and social discrimination. Poultry and Avian Biology 1999;3(10):13-223.

- Leeson S, Caston L, Summers J D. Broiler response to energy or energy and protein dilution in the finisher diet. Poultry Science 1996;75(4):522-8.

- Macari M, Furlan R L, Gonzales E. Fisiologia aviária aplicada a frangos de corte. Jaboticabal: FUNEP/UNESP; 2002.

- Marin R H, Freytes P, Guzman D, Bryan Jones R. Effects of an acute stressor on fear and on the social reinstatement responses of domestic chicks to cagemates and strangers. Applied animal Behavioral Science 2001;71(1):57-66.

- Medeiros C M, Baêta F D C, Oliveira R F M D, Tinôco I D F F, Albino L F T, Cecon P R. Índice térmico ambiental de produtividade para frangos de corte. Revista Brasileira de Engenharia Agrícola e Ambiental 2005;9(4):660-665.

- Moreira J, Mendes A A, Roça R D O, Garcia E A, Naas I D A, Garcia R G, Paz I C L D A. Effect of stocking density on performance, carcass yield and meat quality in broilers of different commercial strains. Revista Brasileira de Zootecnia 2004;33(6):1506-1519.

- Nääs I A, Curto F P F. Avicultura de precisão. Piracicaba: FUNEP; 2001.

- Pereira A R. Agrometeorologia: fundamentos e aplicações práticas. Guaíba: Agropecuária; 2002.

- SAS. SAS/ACCESS 9.1 interface to PeopleSoft: user's guide. SAS Publication; 2009.

- Silva M A N de, Hellmeister Filho P, Rosário M F D, Coelho A A de, Savino V J M, Garcia A A F, Silva I J O de, Menten J F M. Influência do sistema de criação sobre o desempenho, a condição fisiológica e o comportamento de linhagens de frangos para corte. Revista Brasileira de Zootecnia 2003; 32(1):208-213.

- Yahav S. Domestic fowl-strategies to confront environmental conditions. Poultry and Avian Biology Reviews 2000;1(11):81-95.

- Young R J. Environmental enrichment for captive animals. London: John Wiley & Sons; 2008.

Corresponding author

Publication Dates

-

Publication in this collection

16 May 2014 -

Date of issue

Mar 2014

History

-

Accepted

Aug 2013 -

Received

Mar 2013