ABSTRACT

Additive manufacturing (AM) technology refers to the process of producing 3D objects by adding material in successive layers. Fused deposition modeling (FDM) is one of the AM technologies where objects are built by adding layers of melted thermoplastic filament onto the printing surface. Mechanical properties of FDM printed part depend on many influencing factors such as material composition, extruding temperature, printing parameters and environment temperature.

Keywords

additive manufacturing; FDM; mechanical properties

1. INTRODUCTION

3D printing technology is an automated, additive manufacturing (AM) process for producing 3D solid objects based on digital 3D model 0. In contrast to the conventional subtractive manufacturing process, in additive manufacturing, an object is built by adding material in successive layers, rather than removing from it. Some of the advantages of Rapid Prototyping (RP) process are: capability to produce parts of any complicated geometry in least time, without requiring extra expense for tooling [22 UPCRAFT, S., FLETCHER, R., “The rapid prototyping technologies”, Assembly Automation, v. 23, n. 4, pp. 318-330, Apr. 2003.,33 MANSOUR, S., HAGUE, R., “Impact of rapid manufacturing on design for manufacture for injection moulding”, In: Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, v. 217, n. 4, pp. 453-461, Apr. 2003.0; capability to produce functional assemblies by merging sub-assemblies into single unit in computer-aided design (CAD) stage, reducing part count, handling time, storage requirements and fitting problems 044 HOPKINSON, N., HAGUE, R., DICKENS, P., Rapid manufacturing: an industrial revolution for the digital age, Chichester, John Wiley & Sons, 2006.,55 BERNARD, A., FISCHER, A., “New trends in rapid product development” CIRP Annals-Manufacturing Technology, v. 51, n. 2, pp.635-652, Jan. 2002.0; capability to optimize material consumption by constructing parts that are complicated or even impossible to produce using conventional manufacturing process; and finally, capability to reduce waste and therefore minimize impact on the environment. In recent years, 3D printing shifted its primary usage from RP to industrial usage as well as domestic production of final products intended for everyday use [66 BERMAN, B., “3-D printing: The new industrial revolution”, Business horizons, v. 55, n. 2, pp. 155-162, Apr. 2012., 77 CHULILLA, J.L., “The Cambrian explosion of popular 3D printing”, International Journal of Interactive Multimedia and Artificial Intelligence, v. 1, n. 4, pp. 31-33, Dec. 2011., 88 ESPALIN, D., MUSE, D.W., MACDONALD, E., et al., “3D Printing multifunctionality: structures with electronics”, The International Journal of Advanced Manufacturing Technology, v. 72, n. 5-8, pp. 963-978, May 2014., 99 CHUA, C.K., LEONG, K.F. AND LIM, C.S., Rapid prototyping: principles and applications, 3 ed., Singapore, World Scientific Publishing, 2010.0, in biomedical engineering 0, functional printing of Braille alphabet and tactile objects, maps and floor plans for visually impaired persons 011, 120 and manufacturing of embossing tools in graphic industry 0.

Fused Deposition Modeling (FDM) is one of the most commercialized 3D printing processes. This process is also referred to as “plastic jet printing”, “thermoplastic extrusion” or the “fused filament method”, due to of the trademark protection 0. FDM printer was developed in 1988 by Scott Crump but was commercialized by Stratasys company in the 1990s 0. In FDM process thermoplastic filament is used as a printing material. The filament is drawn into the print head, melted and extruded through the nozzle onto printing surface in the form of semi-melted plastic threads. Cooling, threads solidify to form a layer of material. Additional layers are deposited on top of each other to form a 3D object. The FDM printer deposits material in a directional way thus producing parts with anisotropic behavior 0. FDM additive manufacturing technology has gained popularity due to its simple-to-use, low-cost and environment-friendly features and it is widely used in prototyping as well as in the production of real industrial products 0.

1.1 Commonly used thermoplastic materials in FDM process

There are many different FDM filament manufacturers on the market, and the exact filament composition is rarely available to the end user. Filaments made of thermoplastic materials like acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polycarbonate (PC), polyether-ether-ketone (PEEK), nylon and other composites are used in FDM printing process. Two of the most commonly used thermoplastics for FDM 3D printers are ABS and PLA. Acrylonitrile Butadiene Styrene (ABS) is an oil-based thermoplastic copolymer. Its three structural units provide a balance of properties with the acrylonitrile providing heat resistance, butadiene providing good impact strength and the styrene gives the copolymer its rigidity 0. ABS parts are sufficiently resistant to heat, chemicals, and moisture that allows FDM parts to be used for a variety of applications. Polylactic acid is a biodegradable polymer produced by ring-opening polymerization of lactide, and the lactic acid monomers are obtained from the fermentation of sugar feedstock 0. In most cases, PLA appears to be stronger than ABS, but more brittle [1919 DRUMMER, D., CIFUENTES-CUÉLLAR, S., RIETZEL, D., “Suitability of PLA/TCP for fused deposition modeling”, Rapid Prototyping Journal, v. 18, n. 6, pp. 500-507, Sep. 2012., 2121 TYMRAK, B.M., KREIGER, M. PEARCE, J.M., “Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions”, Materials & Design, v. 58, pp. 242-246, June, 2014., 3939 LETCHER, T., WAYTASHEK, M., “Material property testing of 3D-printed specimen in PLA on an entry-level 3D printer”, In: ASME 2014 International Mechanical Engineering Congress and Exposition (pp. V02AT02A014-V02AT02A014). American Society of Mechanical Engineers, Nov. 2014., 4040 BENIAK, J., KRIŽAN, P., MATÚŠ, M., A, “A comparison of the tensile strength of plastic parts produced by a fused deposition modeling device”, Acta Polytechnica, v. 55, n. 6, pp. 359-365, Dec. 2015.0.

1.2 Factors that influence mechanical properties of FDM printed parts

Mechanical properties of FDM printed parts depend on various process-related parameters. Many authors investigated the influence of: extruder temperature 0, layer thickness 0, bead (road) width (width of the deposited filament), orientation of model on printing plate 0, raster angle (direction of raster relative to the x-axis of build table) [1515 AHN, S.H., MONTERO, M., ODELL, D., et al., “Anisotropic material properties of fused deposition modeling ABS”, Rapid prototyping journal, v. 8, n. 4, pp. 248-257, Oct. 2002., 2121 TYMRAK, B.M., KREIGER, M. PEARCE, J.M., “Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions”, Materials & Design, v. 58, pp. 242-246, June, 2014., 2222 BELLINI, A., GÜÇERI, S., “Mechanical characterization of parts fabricated using fused deposition modeling”, Rapid Prototyping Journal, v. 9, n. 4, pp. 252-264, Oct. 2003., 2323 MITROVIĆ, R., MIKOVI, Ž., “Investigation on influence of 3D printing direction on mechanical properties of abs plastic prototypes”, In: Conference on Mechanical Engineering Technologies and Applications, pp. 293-300, Dec. 2016.0, part raster width (width of raster pattern used to fill interior regions of part curves), air gap (space between the beads of FDM material), temperature of environment surrounding object, nozzle diameter, part fill style (infill) and number of shells (contour width). Žarko et al. 0, investigated influence of printing speed on accuracy of FDM printed elements. They discovered that printing speed had certain influence on quality of prints and bonds between deposited layers but only in relation to visual quality with lack of discussion about influence on mechanical properties.

1.3 Testing mechanical properties of FDM printed parts

For parts manufactured using AM technologies, it is of great importance to know their mechanical properties, e.g. tensile and compressive strength. In several previous studies, ASTM D638 standard tensile test methods are utilized to determine the correlation between tensile properties and raster orientation of the specimens 01515 AHN, S.H., MONTERO, M., ODELL, D., et al., “Anisotropic material properties of fused deposition modeling ABS”, Rapid prototyping journal, v. 8, n. 4, pp. 248-257, Oct. 2002., 2121 TYMRAK, B.M., KREIGER, M. PEARCE, J.M., “Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions”, Materials & Design, v. 58, pp. 242-246, June, 2014., 2525 GIANNATSIS, J., SOFOS, K., CANELLIDIS, V., et al., “Investigating the influence of build parameters on the mechanical properties of FDM parts”, In: Innovative Developments in Virtual and Physical Prototyping -Proceedings of the 5th International Conference on Advanced Research and Rapid Prototyping, pp. 525–529, Sep. 2012., 3232 MONTERO, M., ROUNDY, S., ODELL, D., et al., “Material characterization of fused deposition modeling (FDM) ABS by designed experiments”, Society of Manufacturing Engineers, v. 10, Jul. 2001.0. ES-SAID et al.0; THOMAS and RENAUD 0; PEREZ et al. 0 discovered that road-to-road and layer-to-layer adhesion, shrinkage of the roads, and porosity in object structure influence tensile mechanical properties of the printed parts which cause anisotropy.

Tensile strength values of ABS printed parts on FDM printer have been reported to be between 11 and 40 MPa 02121 TYMRAK, B.M., KREIGER, M. PEARCE, J.M., “Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions”, Materials & Design, v. 58, pp. 242-246, June, 2014., 2222 BELLINI, A., GÜÇERI, S., “Mechanical characterization of parts fabricated using fused deposition modeling”, Rapid Prototyping Journal, v. 9, n. 4, pp. 252-264, Oct. 2003., 3434 TORRADO, A.R., SHEMELYA, C.M., ENGLISH, J.D., et al., “Characterizing the effect of additives to ABS on the mechanical property anisotropy of specimens fabricated by material extrusion 3D printing”, Additive Manufacturing, v. 6, pp. 16-29, Apr. 2015., 3535 CROCCOLO, D., DE AGOSTINIS, M., OLMI, G., “Experimental characterization and analytical modelling of the mechanical behaviour of fused deposition processed parts made of ABS-M30”, Computational Materials Science, v. 79, pp.506-518, Nov. 2013.0. The possible explanation for these distinct values can be in anisotropic nature of printed parts 0. AHN et al. 0 found that injection molded ABS P400 thermoplastic had the tensile strength of 26 MPa and FDM printed samples with raster orientations of 45°/45° crisscrossed and 0°/90° cross had the tensile strength between 65 and 72 percent of injection molded P400. In research of NOVAKOVA-MARCINOVA and NOVAK-MARCINCIN 0, FDM 3D printed ABS samples showed an average tensile strength of 28.1 MPa and elongation at break of 4.88 %. WENG et al. 0 presented tensile strength of FDM 3D printed ABS samples. Although their primary focus was on ABS thermoplastic enriched with nanocomposites they had control samples made with pure ABS that showed 27.59 MPa tensile strength and 1.2 GPa elastic modulus values. CARRASCO et al. 0 presented average values for mechanical properties of PLA compared to PS, i-PP and PET polymers. Its tensile yield strength varies between 48 and 110 MPa, elongation at break from 2.5% to 100% and elastic modulus between 3.5 GPa and 3.8 GPa. DRUMMER et al. 0 showed that extruding temperature in 3D printers’ nozzle also has a significant influence on mechanical properties of PLA samples. Samples manufactured at the nozzle temperature of 225° showed best mechanical properties in comparison to samples extruded at 215° and 235°. At nozzle temperature of 215°, samples had tensile strength values between 20 and 25 MPa, elongation at break around 0.75 % and elastic modulus between 2.5 and 3 GPa. In work of LETCHER and WAYTASHEK 0 FDM 3D printing technology on MakerBot Replicator 2x was used for printing of PLA tensile samples. In the case of 0°, 45° and 90° raster angle samples showed average values for tensile strength of 58.45 MPa, 64.03 MPa and 54.01 MPa with the elongation at break of 2.02 %, 2.50 % and 4.14 % respectively. In 2014, TYMRAK et al. 0 investigate mechanical properties of ABS and PLA components printed with open-source FDM 3D printer RepRap. They tested two different raster orientations (0°/90° and 45°/-45° crisscrossed) and three different layer heights (0.2, 0.3 and 0.4 mm). Average tensile strength for ABS on 0°/90° raster angle was 27.7 MPa with 1.92 % elongation at break and elastic modulus of 1.867 GPa. For PLA samples these values at the same raster angle were significantly greater (54.9 MPa tensile strength, 1.88 % elongation at break and elastic modulus of 3.336 GPa). In research of BENIAK et al. 0, ABS samples had lower tensile strength but greater elongation at break than PLA. These values were recorded at 0°, 45° and 90° raster angle separately rather than 0°/90° crisscross raster angle of infill. They also reported tensile strength values for injection molded ABS and PLA of 40 MPa and 50 MPa respectively and showed that 3D printed samples have weaker tensile strength than injection molded samples and around ten times lower elongation at break values. Weaker tensile strength values of 3D printed parts are the consequence of the process of forming FDM samples by depositing thin semi-melted fibers side by side and layer by layer forming the porous structure with air gaps between deposited fibers. If the filaments are deposited tightly together with minimum filament diameter and with 100 % infill structure, density close to conventionally built samples can be achieved. In research of WU et al. 0, it was found that injection molded ABS parts had the tensile strength of 37 MPa, and FDM printed samples had the tensile strength of 27.1 MPa.

There are few researches concerning compression tests on samples printed using FDM technology. WU et al. 0 investigated the influence of layer thickness and raster angle on the mechanical properties of FDM printed ABS and PEEK parts. They were able to determine a unique compressive strength of ABS samples beyond which material only deforms without the increase in stress. The compressive strength of PEEK material was difficult to determine because of more ductile material behavior. Both materials showed no break point but only squeezing and sliding of printed layers. DIVYATHEJ et al. 0 examined the influence of FDM printed layer thickness on mechanical properties of ABS material. They compared 0.1 mm, 0.15 mm and 0.2 mm layer thickness and found that parts printed with the layer thickness of 0.2 mm showed better compressive strength values compared even to injection molded parts. The average yield strength of ABS samples was between 2.467 MPa and 3.056 MPa which is surprisingly low compared to work of WU et al. 0. In work of AHN et al. 0, compressive strength of ABS material was investigated. They examined the influence of build direction (orientation) on compressive strength and found that specimens with layers axial to loading force had higher compressive strength values compared to parts built from layers transverse to loading force. Average compressive strength for both build directions were between 30 and 40 MPa, however they did not provide exact values and graphs to see the exact behavior of each FDM printed part under the applied compressive force. SOOD et al. 0 investigate the influence of five processing factors (orientation, layer thickness, raster angle, raster width and air gap) on compressive strength. Values for compressive strength provided in this paper were between 7.448 MPa and 16.98 MPa, which depends on the observed influencing factor. LEE et al. 0 investigated the influence of build direction on compressive strength of ABS parts using FDM technology. Parts that were built with layers axial to loading force had a higher compressive strength (41.26 MPa) than parts with the transversal direction (36.47 MPa). Previous investigations reveal that FDM produced parts show anisotropic behavior in testing mechanical properties. Printing process parameters affect these properties because of the variable inner structure and fiber-to-fiber bond strength of printed parts. Uneven heating and cooling cycles during FDM printing process can also affect bonding of fibers and thus the part strength 0. It remains unclear how the values for ultimate compressive strength in these investigations are obtained having in mind very ductile nature of thermoplastic polymers. In these investigations, influence of diverse spectrum of processing parameters is examined without detailed reports about the consistency of mechanical properties by constraining these parameters.

The aim of this research is to investigate how consistent mechanical properties of FDM printed samples are, using ABS and PLA thermoplastic materials and constrained printing parameters. Taking into account the anisotropic structure of FDM printed parts, the lack of standard specially designed for this 3D printing process and inconsistency in a number of tested samples throughout the listed literature, it is of great importance to investigate repeatability of mechanical properties of elements produced by FDM additive manufacturing technology.

In this research we presented the data for tensile stress, strain and Young modulus and compression yield strength for each specimen separately which can contribute to better understanding of mechanical properties consistency of ABS and PLA thermoplastic materials under constrained printing parameters.

2. MATERIALS AND METHODS

To investigate mechanical properties, consistency of the elements produced by FDM additive manufacturing technology, mechanical tensile and compression tests were conducted on 3D printed PLA and ABS thermoplastic material specimens. Due to equipment construction, MakerBot Replicator 5th does not have enclosed printing chamber, so PLA printing was done at room temperature of 23 ±2°C. MakerBot Replicator 2x has enclosed printing chamber with enclosure lid and printing bed heated at 120°C, as required for printing of ABS and the chamber temperature of 50 ±5°C.

2.1 Specimens

There are no defined standards related to FDM printing technology and the common choice for covering this issue is ASTM D638-14 standard 0 or its ISO 527-1 technical equivalent for tensile test and ASTM D695-15 standard 0 or its ISO 604 equivalent for compression test. These standards are used by the majority of authors 02121 TYMRAK, B.M., KREIGER, M. PEARCE, J.M., “Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions”, Materials & Design, v. 58, pp. 242-246, June, 2014., 3636 NOVAKOVA-MARCINCINOVA, L., NOVAK-MARCINCIN, J., “Verification of mechanical properties of ABS materials used in FDM rapid prototyping technology”, In: Proceedings in Manufacturing Systems, v. 8, n. 2, pp.87-92, Jun. 2013., 3737 WENG, Z., WANG, J., SENTHIL, T., et al., “Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing”, Materials & Design, v. 102, pp. 276-283, Jul. 2016., 4141 WU, W., GENG, P., LI, G., ZHAO, D., et al., “Influence of layer thickness and raster angle on the mechanical properties of 3D-printed PEEK and a comparative mechanical study between PEEK and ABS”, Materials, v. 8, n. 9, pp. 5834-5846, Sep. 2015., 4444 LEE, C.S., KIM, S.G., KIM, H.J., et al., “Measurement of anisotropic compressive strength of rapid prototyping parts”, Journal of materials processing technology, v. 187, pp. 627-630, Jun. 2007.0.

2.2 Procedure

CAD model was created after choosing appropriate specimen geometry, using Autodesk Inventor Professional 2016. CAD model was then converted to STL (Stereolithography) file format which approximates the surfaces of a solid model with triangles and is required by pre-processing software MakerBot Desktop, which prepares a model for the 3D printing process. Ten specimens of each material were produced using two FDM 3D printers. PLA samples were printed using MakerBot Replicator 5th generation and ABS samples using MakerBot Replicator 2x. Printing parameters for both materials were set to same values (Table 1) with the exception of extruding and printing bed temperature which was different due to processing requirements for each type of polymer.

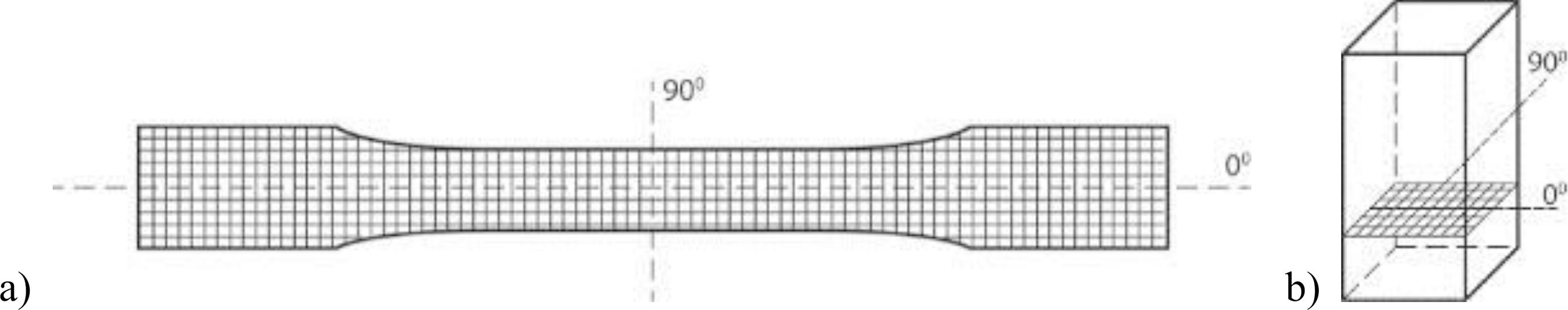

For tensile test, printing was done one specimen at a time, centred on the building plate to avoid possible printing problems due to differences in plate levelling. Layers were printed perpendicular to each other (Figure 1). First layer at raster angle of 0° along the specimen length and next layer at raster angle of 90° (criss-cross), and so on, up to the final 22nd layer. Finished specimens were separated from the raft and cleaned.

Illustration of a criss-cross 0°/90° raster angles used in printing process for a) tensile and b) compression sample

Figure 2a and 2b presents appearance of top surface of ABS and PLA tensile test samples respectively taken with light microscope Leitz Orthoplan with 20× magnification setting. The top layer of ABS was printed in the axial direction, having filaments along the longer side of the sample and PLA had filaments printed perpendicular to the longer side of the sample. The appearance of side surface formed by deposited layers along z axis of the 3D printer for both material are shown in Figure 2c and Figure 2d.

Microscopic pictures of top layer surface of a) ABS and b) PLA and side staircase surface of c) ABS and d) PLA at 20x magnification setting

For compression test, printing was done ten specimens at a time, centred on the building plate, because they occupy small area compared to tensile specimens, and influence of the building plate levelling is insignificant. Layers were printed perpendicular to each other in criss-cross alignment. A total number of 167 layers per sample were deposited. Figure 3a and 3b present printed samples of compression specimens.

Printed ABS thermoplastic specimens and b) printed PLA thermoplastic specimens for compression test according to ASTM D695-15 standard

After printing, tensile test was performed using Shimadzu Compact Tabletop Testing Machine EZ-LX (Figure 4a and 4b) equipped with a 2.5 kN load cell. Samples were loaded and tested at 5 mm/min loading rate. All tests are carried out at the temperature 23± 2°C and relative humidity 50 ±5% as per ISO R291:2008 0. Data for tensile stress and strain were collected using Trapezium X software, and maximum tensile stress, strain and elastic modulus were automatically calculated.

a) Shimadzu Compact Tabletop Testing Machine EZ-LX; b) close up view of tensile gauges; c) universal testing machine VEB ZDM 5/91; d) close up view of compression gauges

For compression test, specimens were built of layers deposited transversal to loading direction, using ABS and PLA materials (Figure 1b). Universal testing machine VEB ZDM 5/91 (Figure 4c and 4d) with 50 kN load cell was used to test compressive strength at 2 mm/min loading rate. According to the specimens’ plastic behavior and visible deformations before the maximum loading force was applied, stress value at yield point was recorded and yield strength value of specimens was calculated accordingly.

To acquire the information on surface roughness properties of the samples, TR200 (Time Group Inc, China) surface roughness tester was used (five 0.8 mm cutoffs; range of ±80 µm; RC filter,). A total number of ten samples of both ABS and PLA material were measured five times in each direction (filament direction, and perpendicular to filament direction). The average values of surface roughness parameters Ra and Rq were presented.

Finally, digital microscope Veho VMS-004D with magnification of up to 400x was used to acquire images of cross section in fracture zones of both ABS and PLA samples.

Tensile and compressive tests were conducted in order to determine mechanical properties of two thermoplastic materials: ABS and PLA. In this experiment, ten samples of both materials were used to analyse repeatability of mechanical properties of elements produced by FDM additive manufacturing technology. The tensile test gives important parameters describing the beginning of plastic deformation (the yield strength), an estimate of the maximum load that can be supported (the ultimate tensile strength) and a variety of measures of ductility 0.

3. RESULTS

3.1 Tensile test

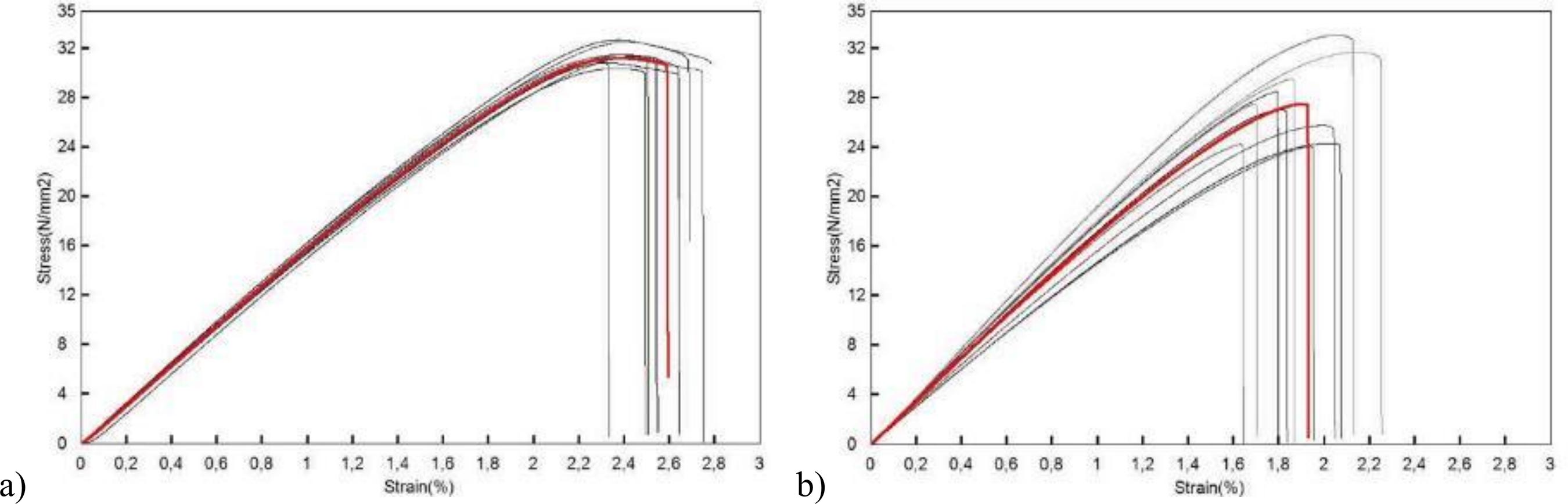

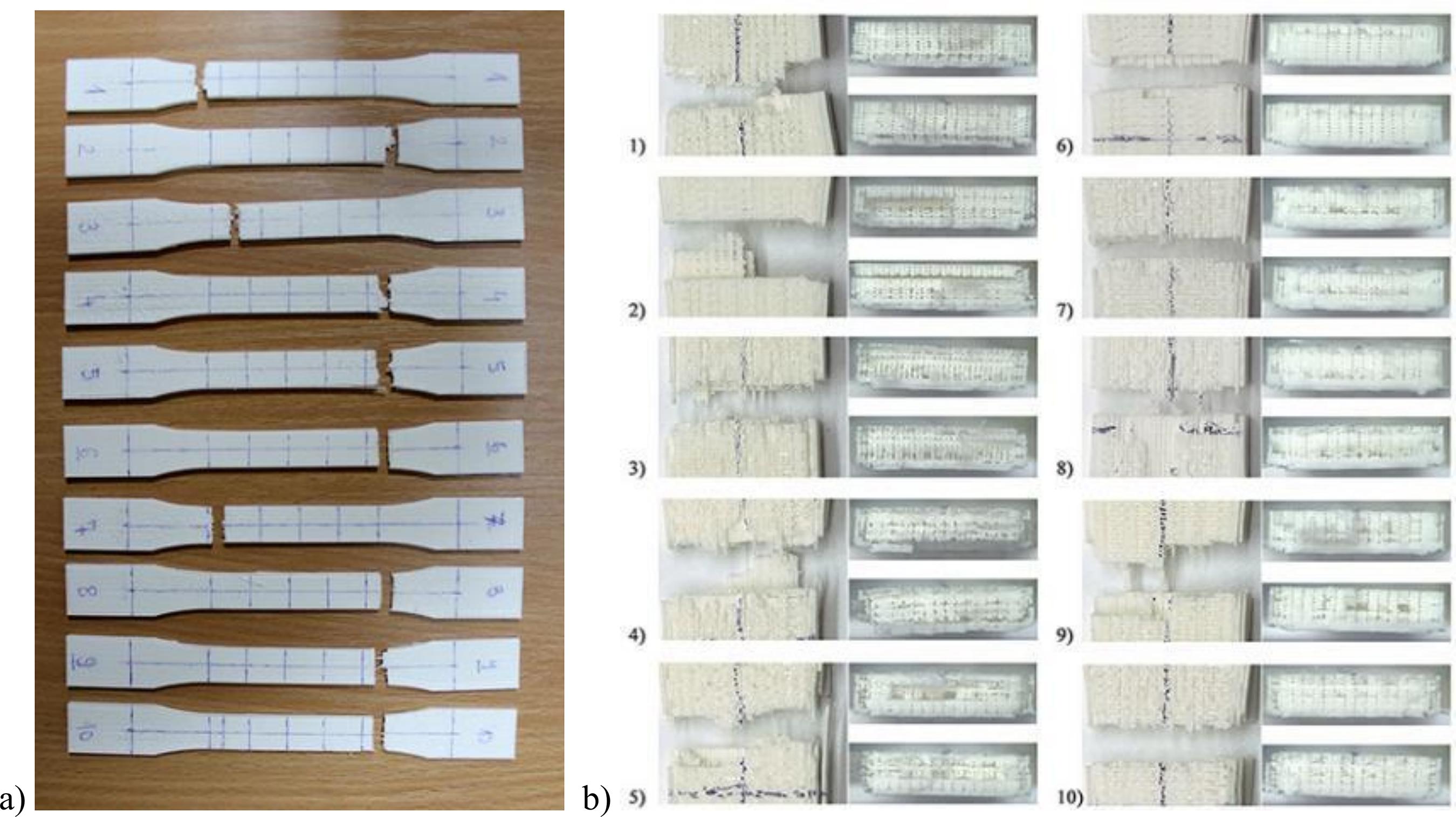

Mean values and standard deviations for tensile strength for ABS and PLA samples printed with FDM process are shown in Figure 10 and stress-strain curves for all specimens are shown in Figure 5a and 5b. Fracture zones of ABS and PLA samples after tensile tests are presented in Figure 6a and 7a respectively.

The ABS specimens showed smaller differences between samples, compared to PLA specimens. Ultimate tensile strength values varied by 2.31 MPa, or 7.35% from average, elongation at break varied by 0.42%, or 16%, while elastic modulus varied by 119.88 MPa or 7.46%. Average ultimate tensile strength value was 31.39 MPa (standard deviation (SD) = 0.70913 MPa; coefficient of variation (CV) = 2.26%). Average elongation at break value was 2.57 % (SD = 0.12622%; CV = 4.91%), and average modulus of elasticity was 1.607 GPa (SD = 0.037 GPa; CV = 2.3%). The thick red line on Figure 5a represents the average curve of ten samples.

The PLA specimens showed greater variability between samples. Ultimate tensile strength values varied by 8.991 MPa, or 28.65% from average, elongation at break values varied by 0.61%, or 31.68% while elastic modulus varied by 408.77 MPa or 23.2%. Average ultimate tensile strength value was 27.54 MPa (SD = 3.14217 MPa; CV = 11.41%). Average elongation at break value was 1.93 % (SD = 0.19514%; CV = 10.13%), and average modulus of elasticity was 1.761 GPa (SD = 0.132 GPa; CV = 7.47%). Again, the thick red line represents the average curve of ten samples (Figure 5b).

Figures 6b and 7b present close-up view of fracture zones for all ten samples on ABS and PLA respectively. It can be seen that ABS samples had a denser structure of bonded filaments in cross section areas, less air gap, and there is a less visible filament mesh compared to PLA samples.

FDM 3D printed ABS samples after conducting the tensile test and b) close-up view of fracture zone and cross-section area

a) FDM 3D printed PLA samples after conducting the tensile test and b) close-up view of fracture zone and cross-section area

The PLA, samples on the other hand, were more brittle during failure so there were visible filaments sticking out of cross section. PLA samples had looser structure of bonded filaments in cross section areas and bigger air gaps between filaments. Filaments were not bonded as firmly as it was the case for ABS samples. There is also an obvious appearance of layers separation.

Comparison of the stress-strain curve of two examined thermoplastic materials is presented in Figure 8. It can be seen that, compared to PLA samples, ABS specimens showed greater average values for tensile strength but lower values regarding elastic modulus. During tensile test, ABS samples showed greater elongation at break, hence greater plastic behaviour. PLA samples were more brittle, resulting in average elongation at break of less than 2%.

The average values of selected surface roughness parameters of the top surface and the side surface of both PLA and ABS materials are presented in Table 2. It can be seen that surface roughness of the top surface of the PLA samples are nearly twice as high as the surface roughness of the ABS samples, measured in both directions. The recorded surface roughness values on the side surfaces were similar for both materials in both directions. The roughness average Ra represents the arithmetical mean of the deviations of the roughness profile from the central line along the measurement, while root mean square average roughness Rq parameter is more affected by isolated errors and therefore detects the surface roughness better 0. ABS samples had a more consistent surface roughness of top layer. The four out of ten PLA samples showed top layer surface roughness that was out of the device’s measuring range and had to be discarded. The rougher surface of PLA prints can be observed in presented microscopic images (Figure 2) and even in close-up view in Figure 7b.

Average values of surface roughness of top printed layer and side staircase surface for PLA and ABS samples

3.2 Compression test

Measured values for compression yield strength for ten samples of each material were collected and processed. Average yield strength was 17.781 MPa for ABS and 9.655 MPa for PLA material. Concerning consistency of mechanical properties, compression tests showed that PLA material had a more consistent yield strength values with SD = 0.215 MPa and CV = 2.23% compared to ABS material (SD = 2.803 MPa; CV = 15.76%). ABS samples had greater deviation from average value as can be seen in Figure 9. Greater consistency in yield strength values of PLA samples is also visible.

Yield strength and standard deviation values obtained from compression test for ABS and PLA thermoplastic materials.

4. DISCUSSION

4.1 Tensile test

Results showed that, compared to PLA samples, ABS samples had greater consistency concerning ultimate tensile strength, break strain and elastic modulus. Also, eight out of ten ABS samples failed within narrow section of the specimen. Two samples (Sample 3 and Sample 7) failed outside of the narrow section of the specimen. The PLA samples failed close to narrow section in eight cases. Only two specimens (Sample 3 and Sample 7) failed within the narrow section. There have been reports of premature failure of 3D printed parts during tensile testing due to accumulated stress concentration at fillet areas 02020 LETCHER, T., RANKOUHI, B., JAVADPOUR, S., “Experimental study of mechanical properties of additively manufactured ABS plastic as a function of layer parameters”, In: ASME 2015 International Mechanical Engineering Congress and Exposition, American Society of Mechanical Engineers, pp. V02AT02A018-V02AT02A018, Nov. 2015., 3434 TORRADO, A.R., SHEMELYA, C.M., ENGLISH, J.D., et al., “Characterizing the effect of additives to ABS on the mechanical property anisotropy of specimens fabricated by material extrusion 3D printing”, Additive Manufacturing, v. 6, pp. 16-29, Apr. 2015., 3535 CROCCOLO, D., DE AGOSTINIS, M., OLMI, G., “Experimental characterization and analytical modelling of the mechanical behaviour of fused deposition processed parts made of ABS-M30”, Computational Materials Science, v. 79, pp.506-518, Nov. 2013.0. AHN et al. 0, address these complications to large stress concentrations caused by the termination of the longitudinal roads used to approximate the large radii. That might be the reason why specimens failed outside of narrow section by breaking at the stress concentrations, while the rest of the sample remained intact. RANKOUHI et al. 0 propose that increasing the number of layers can help alleviate the effects of this stress concentration. But in the case of thin samples that only consist of a single or only a few layers, failure outside of narrow section will still be caused by the discretization of rasters at fillets. In our experiment, layer height of extruded filament was 0.15 mm, leading to denser structure of specimens and finer discretization of rasters in fillet radius. Nevertheless, the issue of premature failure can be the possible cause of higher deviations of ultimate tensile strength values in the case of PLA specimens.

Other possible explanation of inconsistency in tensile strength of PLA samples can be in the strength of inter-layer bonds formed during melting and cooling of the filament. Separation of layers, bigger air gap between deposited filaments and looser structure of cross section area can be seen in Figure 7b. PLA specimens were printed in open printer chamber and were melted at lower extruder temperature. It is known that extruder temperature affects mechanical properties of FDM printed parts 0. Deposition surface during printing of PLA had a temperature around 23 °C ± 2 °C compared to the temperature of 120 °C of deposition surface during printing of ABS samples. ABS samples had better-controlled printing environment which could lead to stronger bonds between deposited layers and more consistent mechanical properties as can be seen in Figure 6b.

The effects of surface roughness on mechanical properties and inconsistencies between tested PLA samples can also be observed. As it can be seen from Figure 2a and 2b and Table 2, there is obvious distinction between the top surface roughness of PLA and ABS samples. First, the top layer was printed in a different direction. In the case of ABS filaments of the top layer was deposited at 0° relative to axial force direction. PLA samples had filament orientation on a top deposited layer at 90° relative to axial force direction. This occurrence would have a greater effect on mechanical properties if all layers of the sample were printed in the same direction. But because every layer was printed perpendicular to each other, the effect of this factor is minor. However, it is obvious that Ra and Rq surface roughness values of PLA samples were greater in both measuring directions comparing to ABS samples. This effect also confirms the above mentioned inter-layer bonds during melting and cooling of the filament. ABS samples had a better bond not only between layers (which can be seen in Figure 6b and 7b) but also between deposited roads of filaments. From Figure 2c and 2d and Table 2, the superiority of inter-layer bonds of ABS filaments is not as obvious as in cross-section view (Figure 6b). Both materials had similar surface roughness of side staircase surface. As it was mentioned, the processing temperature of ABS was higher, and samples were printed in a closed environment. The higher temperature during printing process contributed to the better bonding of filaments (Figure 2a and 6b). Along side other factors this was the reason for higher tensile stress values of ABS compared to PLA samples.

In Figure 10, comparison of our results of tensile strength, strain and Young modulus with different findings from the literature is presented. It can be noted that ABS showed similar results as in other studies compared to PLA (Figure 10a) concerning tensile strength. PLA samples showed similar values of maximum tensile strain as in other studies compared to ABS samples (Figure 10b). In the case of Young modulus our values were lower compared to values obtained from [1515 AHN, S.H., MONTERO, M., ODELL, D., et al., “Anisotropic material properties of fused deposition modeling ABS”, Rapid prototyping journal, v. 8, n. 4, pp. 248-257, Oct. 2002., 1919 DRUMMER, D., CIFUENTES-CUÉLLAR, S., RIETZEL, D., “Suitability of PLA/TCP for fused deposition modeling”, Rapid Prototyping Journal, v. 18, n. 6, pp. 500-507, Sep. 2012.,02020 LETCHER, T., RANKOUHI, B., JAVADPOUR, S., “Experimental study of mechanical properties of additively manufactured ABS plastic as a function of layer parameters”, In: ASME 2015 International Mechanical Engineering Congress and Exposition, American Society of Mechanical Engineers, pp. V02AT02A018-V02AT02A018, Nov. 2015., 2121 TYMRAK, B.M., KREIGER, M. PEARCE, J.M., “Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions”, Materials & Design, v. 58, pp. 242-246, June, 2014., 3636 NOVAKOVA-MARCINCINOVA, L., NOVAK-MARCINCIN, J., “Verification of mechanical properties of ABS materials used in FDM rapid prototyping technology”, In: Proceedings in Manufacturing Systems, v. 8, n. 2, pp.87-92, Jun. 2013., 3737 WENG, Z., WANG, J., SENTHIL, T., et al., “Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing”, Materials & Design, v. 102, pp. 276-283, Jul. 2016., 3838 CARRASCO, F., PAGÈS, P., GÁMEZ-PÉREZ, J., et al., “Processing of poly (lactic acid): characterization of chemical structure, thermal stability and mechanical properties”, Polymer Degradation and stability, v. 95, n. 2, pp. 116-125, Feb. 2010.0, 4040 BENIAK, J., KRIŽAN, P., MATÚŠ, M., A, “A comparison of the tensile strength of plastic parts produced by a fused deposition modeling device”, Acta Polytechnica, v. 55, n. 6, pp. 359-365, Dec. 2015.0 (Figure 10c).

Comparison of average values and standard deviation for a) tensile stress, b) strain and c) Young modulus of FDM 3D printed ABS and PLA samples presented in this research with average values gathered from different literature sources 01515 AHN, S.H., MONTERO, M., ODELL, D., et al., “Anisotropic material properties of fused deposition modeling ABS”, Rapid prototyping journal, v. 8, n. 4, pp. 248-257, Oct. 2002., 1919 DRUMMER, D., CIFUENTES-CUÉLLAR, S., RIETZEL, D., “Suitability of PLA/TCP for fused deposition modeling”, Rapid Prototyping Journal, v. 18, n. 6, pp. 500-507, Sep. 2012.,02020 LETCHER, T., RANKOUHI, B., JAVADPOUR, S., “Experimental study of mechanical properties of additively manufactured ABS plastic as a function of layer parameters”, In: ASME 2015 International Mechanical Engineering Congress and Exposition, American Society of Mechanical Engineers, pp. V02AT02A018-V02AT02A018, Nov. 2015., 2121 TYMRAK, B.M., KREIGER, M. PEARCE, J.M., “Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions”, Materials & Design, v. 58, pp. 242-246, June, 2014., 3636 NOVAKOVA-MARCINCINOVA, L., NOVAK-MARCINCIN, J., “Verification of mechanical properties of ABS materials used in FDM rapid prototyping technology”, In: Proceedings in Manufacturing Systems, v. 8, n. 2, pp.87-92, Jun. 2013., 3737 WENG, Z., WANG, J., SENTHIL, T., et al., “Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing”, Materials & Design, v. 102, pp. 276-283, Jul. 2016., 3838 CARRASCO, F., PAGÈS, P., GÁMEZ-PÉREZ, J., et al., “Processing of poly (lactic acid): characterization of chemical structure, thermal stability and mechanical properties”, Polymer Degradation and stability, v. 95, n. 2, pp. 116-125, Feb. 2010., 4040 BENIAK, J., KRIŽAN, P., MATÚŠ, M., A, “A comparison of the tensile strength of plastic parts produced by a fused deposition modeling device”, Acta Polytechnica, v. 55, n. 6, pp. 359-365, Dec. 2015.0.

Besides extruding temperature, another reason for these inconsistencies could be ageing of PLA thermoplastic material 0. The samples were printed during two days’ time span (five samples during the first and other five during the second day) so perhaps this difference in time that elapsed from extrusion to tensile test could have affected the final results.

4.2 Compression test

Using compression test we wanted to examine compression yield strength of ABS and PLA samples. This value showed the elastic/plastic behavior of these two materials. The measured compressive yield strength showed that PLA samples made by FDM printer had better consistency of mechanical properties compared to ABS samples. ABS material withstands more load pressure before the plastic deformation takes place.

Higher values of yield strength for ABS samples coincide with results acquired through the tensile test. ABS material showed greater elastic behavior in both tests. As in research of 01919 DRUMMER, D., CIFUENTES-CUÉLLAR, S., RIETZEL, D., “Suitability of PLA/TCP for fused deposition modeling”, Rapid Prototyping Journal, v. 18, n. 6, pp. 500-507, Sep. 2012., 2121 TYMRAK, B.M., KREIGER, M. PEARCE, J.M., “Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions”, Materials & Design, v. 58, pp. 242-246, June, 2014., 3939 LETCHER, T., WAYTASHEK, M., “Material property testing of 3D-printed specimen in PLA on an entry-level 3D printer”, In: ASME 2014 International Mechanical Engineering Congress and Exposition (pp. V02AT02A014-V02AT02A014). American Society of Mechanical Engineers, Nov. 2014., 4040 BENIAK, J., KRIŽAN, P., MATÚŠ, M., A, “A comparison of the tensile strength of plastic parts produced by a fused deposition modeling device”, Acta Polytechnica, v. 55, n. 6, pp. 359-365, Dec. 2015.0, our PLA material was more brittle than ABS thus showing lower values of the load which it can withstand before plastic deformation. However, compressive test data showed a greater consistency of results for PLA samples, which was not the case for data collected from the tensile test. This can be attributed to material properties and nature of testing procedures. In tensile test, applied force tends to separate bonded layers of FDM printed part. In this case, the connection formed between layers plays a significant role. If the inter-layer bond is strong, tensile strength will be better. Quality and consistency of these bonds throughout each sample affects their mechanical properties 01515 AHN, S.H., MONTERO, M., ODELL, D., et al., “Anisotropic material properties of fused deposition modeling ABS”, Rapid prototyping journal, v. 8, n. 4, pp. 248-257, Oct. 2002., 2828 PEREZ, A.R.T., ROBERSON, D.A., WICKER, R.B., “Fracture surface analysis of 3D-printed tensile specimens of novel ABS-based materials”, Journal of Failure Analysis and Prevention, v. 14, n. 3, pp. 343-353, Jun. 2014., 3030 ES-SAID, O.S., FOYOS, J., NOORANI, R., et al., “Effect of layer orientation on mechanical properties of rapid prototyped samples”, Materials and Manufacturing Processes, v. 15, n. 1, pp. 107-122, Jan. 2000., 3333 THOMAS, J.P., RENAUD, J.E., “Design of fused-deposition ABS components for stiffness and strength”, Journal of Mechanical Design, v. 125, n. 3, pp.545-551, Sep. 2003., 5050 RANKOUHI, B., JAVADPOUR, S., DELFANIAN, F., et al., “Failure analysis and mechanical characterization of 3D printed ABS with respect to layer thickness and orientation”, Journal of Failure Analysis and Prevention, v. 16, n. 3, pp.467-481, Jun. 2016.] On the other hand, in compression tests, mechanical properties of used FDM material are more important than inter-layer bonds, because applied force tends to squeeze layers, rather than separate them. In this case, PLA samples had more consistent mechanical properties and were, as in tensile test, more brittle, causing appearances of permanent deformations earlier than in the case of ABS. More elastic properties of ABS material were noticeable in both tests, causing inconsistencies in mechanical properties during the compression test.

In works of AHN et al. 0, WU et al. 0, SOOD et al. 0 and LEE et al. 0, information about compressive yield strength were not provided, thus it is not known at which point samples lost their elastic behaviour. DIVYATHEJ et al.0, used the same shape and dimensions of specimens as we did, however, reported yield strength values of FDM printed ABS parts are significantly lower (2.51 MPa) compared to those of our tests. Such low yield strength values for ABS specimens of standard dimensions are questionable.

5. CONCLUSIONS

The purpose of this study was to investigate mechanical properties consistency of elements produced by FDM additive manufacturing technology in constrained conditions. Mechanical tensile tests were conducted on 3D printed PLA and ABS thermoplastic material. The ABS thermoplastic material showed greater consistency in mechanical properties during tensile tests. Compared to results obtained from the literature, a tensile strength of ABS material had similar values. Tensile strength values for PLA material varied between samples thus showing greater inconsistency in repeatability of mechanical properties. Compared to findings in other literature, PLA had lower values for tensile stress and Young modulus, but similar values for the elongation at break. After conducting compression test, results showed that PLA samples had better consistency in mechanical properties compared to ABS. Compression yield strength was calculated for this purpose. Information about the elastic behavior of FDM printed parts are important in order to know the threshold value beyond which they deform permanently. In both tests, it was confirmed that ABS material showed more ductile behavior than PLA which in the case of compression test affected the consistency of mechanical properties.

It was also found that during the tensile test, the inter-layer bond strength of FDM printed parts had a greater influence on the consistency of mechanical properties. On the other hand, during compression strength, these bonds have less importance than properties of used material. It was found in the literature that for both types of tests FDM printed parts showed anisotropic behavior, but in a certain degree, this behavior had a greater effect on the consistency of mechanical properties of PLA specimens.

These results can serve as fundamental data for manufacturing functional RP parts. Mechanical properties including tensile and compression test are to be tested further for different parameters and different types of process. In order to have a good consistency of mechanical properties for tested FDM parts, it is required to take into consideration all influencing factors and try to constrain them as much as possible.

ACKNOWLEDGMENTS

The research is supported by the Ministry of Education, Science and Technology Development of the Republic of Serbia, project number: 35027 “Development of software model for scientific and production improvement in graphic industry”.

BIBLIOGRAPHY

-

1BOGUE, R., “3D printing: the dawn of a new era in manufacturing?”Assembly Automation, v. 33, n.4, pp. 307-311, Sep. 2013.

-

2UPCRAFT, S., FLETCHER, R., “The rapid prototyping technologies”, Assembly Automation, v. 23, n. 4, pp. 318-330, Apr. 2003.

-

3MANSOUR, S., HAGUE, R., “Impact of rapid manufacturing on design for manufacture for injection moulding”, In: Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, v. 217, n. 4, pp. 453-461, Apr. 2003.

-

4HOPKINSON, N., HAGUE, R., DICKENS, P., Rapid manufacturing: an industrial revolution for the digital age, Chichester, John Wiley & Sons, 2006.

-

5BERNARD, A., FISCHER, A., “New trends in rapid product development” CIRP Annals-Manufacturing Technology, v. 51, n. 2, pp.635-652, Jan. 2002.

-

6BERMAN, B., “3-D printing: The new industrial revolution”, Business horizons, v. 55, n. 2, pp. 155-162, Apr. 2012.

-

7CHULILLA, J.L., “The Cambrian explosion of popular 3D printing”, International Journal of Interactive Multimedia and Artificial Intelligence, v. 1, n. 4, pp. 31-33, Dec. 2011.

-

8ESPALIN, D., MUSE, D.W., MACDONALD, E., et al, “3D Printing multifunctionality: structures with electronics”, The International Journal of Advanced Manufacturing Technology, v. 72, n. 5-8, pp. 963-978, May 2014.

-

9CHUA, C.K., LEONG, K.F. AND LIM, C.S., Rapid prototyping: principles and applications, 3 ed., Singapore, World Scientific Publishing, 2010.

-

10RICHARD, R.C., OLIVEIRA, R.N., SOARES, G.D., et al, “Direct-write assembly of 3D scaffolds using colloidal calcium phosphates inks”, Matéria (R.J), v. 19, n. 1, pp. 61-67, Mar. 2014.

-

11STANGL, A., KIM, J., YEH, T., “3D printed tactile picture books for children with visual impairments: a design probe”, In: Proceedings of the 2014 conference on Interaction design and children, pp. 321-324, Jun. 2014.

-

12URBAS, R., PIVAR, M., STANKOVIČ ELESINI, U., “Development of tactile floor plan for the blind and the visually impaired by 3D printing technique”, Journal of graphic engineering and design, v. 7, n. 1, pp. 19-26, Jun. 2016.

-

13DELIĆ, G., VLADIĆ, G., PÁL, M., et al, “Performance evaluation of paper embossing tools produced by fused deposition modeling additive manufacturing technology”, Journal of graphic engineering and design, v. 8, n. 2, Dec. 2017.

-

14STRATASYS LTD., http://www.stratasys.com. Accessed in December 2016.

» http://www.stratasys.com. Accessed in December -

15AHN, S.H., MONTERO, M., ODELL, D., et al, “Anisotropic material properties of fused deposition modeling ABS”, Rapid prototyping journal, v. 8, n. 4, pp. 248-257, Oct. 2002.

-

16MASOOD, S.H., SONG, W.Q., “Development of new metal/polymer materials for rapid tooling using fused deposition modelling”, Materials & Design, v. 25, n. 7, pp. 587-594, Oct. 2004.

-

17NOORANI, R., Rapid prototyping: principles and applications, New Jersey, John Wiley & Sons Incorporated, 2006.

-

18LUNT, J., “Large-scale production, properties and commercial applications of polylactic acid polymers”, Polymer degradation and stability, v. 59, n. 1-3, pp. 145-152, Jan. 1998.

-

19DRUMMER, D., CIFUENTES-CUÉLLAR, S., RIETZEL, D., “Suitability of PLA/TCP for fused deposition modeling”, Rapid Prototyping Journal, v. 18, n. 6, pp. 500-507, Sep. 2012.

-

20LETCHER, T., RANKOUHI, B., JAVADPOUR, S., “Experimental study of mechanical properties of additively manufactured ABS plastic as a function of layer parameters”, In: ASME 2015 International Mechanical Engineering Congress and Exposition, American Society of Mechanical Engineers, pp. V02AT02A018-V02AT02A018, Nov. 2015.

-

21TYMRAK, B.M., KREIGER, M. PEARCE, J.M., “Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions”, Materials & Design, v. 58, pp. 242-246, June, 2014.

-

22BELLINI, A., GÜÇERI, S., “Mechanical characterization of parts fabricated using fused deposition modeling”, Rapid Prototyping Journal, v. 9, n. 4, pp. 252-264, Oct. 2003.

-

23MITROVIĆ, R., MIKOVI, Ž., “Investigation on influence of 3D printing direction on mechanical properties of abs plastic prototypes”, In: Conference on Mechanical Engineering Technologies and Applications, pp. 293-300, Dec. 2016.

-

24ŽARKO, J., VLADIĆ, G., PÁL, M., et al, “Influence of printing speed on production of embossing tools using FDM 3D printing technology”, Journal of graphic engineering and design, v. 8, n. 1, pp. 19-27, Jun. 2017.

-

25GIANNATSIS, J., SOFOS, K., CANELLIDIS, V., et al, “Investigating the influence of build parameters on the mechanical properties of FDM parts”, In: Innovative Developments in Virtual and Physical Prototyping -Proceedings of the 5th International Conference on Advanced Research and Rapid Prototyping, pp. 525–529, Sep. 2012.

-

26HILL, N., HAGHI, M., “Deposition direction-dependent failure criteria for fused deposition modeling polycarbonate”, Rapid Prototyping Journal, v. 20, n. 3, pp. 221-227, Apr. 2014.

-

27WITTBRODT, B., PEARCE, J.M., “The effects of PLA color on material properties of 3-D printed components”, Additive Manufacturing, v. 8, pp. 110-116, Oct. 2015.

-

28PEREZ, A.R.T., ROBERSON, D.A., WICKER, R.B., “Fracture surface analysis of 3D-printed tensile specimens of novel ABS-based materials”, Journal of Failure Analysis and Prevention, v. 14, n. 3, pp. 343-353, Jun. 2014.

-

29TORRADO, A.R., ROBERSON, D.A., “Failure analysis and anisotropy evaluation of 3D-printed tensile test specimens of different geometries and print raster patterns”, Journal of Failure Analysis and Prevention, v. 16, n. 1, pp. 154-164, Feb. 2016.

-

30ES-SAID, O.S., FOYOS, J., NOORANI, R., et al, “Effect of layer orientation on mechanical properties of rapid prototyped samples”, Materials and Manufacturing Processes, v. 15, n. 1, pp. 107-122, Jan. 2000.

-

31AHN, S.H., BAEK, C., LEE, S., et al, “Anisotropic tensile failure model of rapid prototyping parts-fused deposition modeling (FDM)”, International Journal of Modern Physics B, v. 17, n. 08n09, pp. 1510-1516, Apr. 2003.

-

32MONTERO, M., ROUNDY, S., ODELL, D., et al, “Material characterization of fused deposition modeling (FDM) ABS by designed experiments”, Society of Manufacturing Engineers, v. 10, Jul. 2001.

-

33THOMAS, J.P., RENAUD, J.E., “Design of fused-deposition ABS components for stiffness and strength”, Journal of Mechanical Design, v. 125, n. 3, pp.545-551, Sep. 2003.

-

34TORRADO, A.R., SHEMELYA, C.M., ENGLISH, J.D., et al, “Characterizing the effect of additives to ABS on the mechanical property anisotropy of specimens fabricated by material extrusion 3D printing”, Additive Manufacturing, v. 6, pp. 16-29, Apr. 2015.

-

35CROCCOLO, D., DE AGOSTINIS, M., OLMI, G., “Experimental characterization and analytical modelling of the mechanical behaviour of fused deposition processed parts made of ABS-M30”, Computational Materials Science, v. 79, pp.506-518, Nov. 2013.

-

36NOVAKOVA-MARCINCINOVA, L., NOVAK-MARCINCIN, J., “Verification of mechanical properties of ABS materials used in FDM rapid prototyping technology”, In: Proceedings in Manufacturing Systems, v. 8, n. 2, pp.87-92, Jun. 2013.

-

37WENG, Z., WANG, J., SENTHIL, T., et al, “Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing”, Materials & Design, v. 102, pp. 276-283, Jul. 2016.

-

38CARRASCO, F., PAGÈS, P., GÁMEZ-PÉREZ, J., et al, “Processing of poly (lactic acid): characterization of chemical structure, thermal stability and mechanical properties”, Polymer Degradation and stability, v. 95, n. 2, pp. 116-125, Feb. 2010.

-

39LETCHER, T., WAYTASHEK, M., “Material property testing of 3D-printed specimen in PLA on an entry-level 3D printer”, In: ASME 2014 International Mechanical Engineering Congress and Exposition (pp. V02AT02A014-V02AT02A014). American Society of Mechanical Engineers, Nov. 2014.

-

40BENIAK, J., KRIŽAN, P., MATÚŠ, M., A, “A comparison of the tensile strength of plastic parts produced by a fused deposition modeling device”, Acta Polytechnica, v. 55, n. 6, pp. 359-365, Dec. 2015.

-

41WU, W., GENG, P., LI, G., ZHAO, D., et al, “Influence of layer thickness and raster angle on the mechanical properties of 3D-printed PEEK and a comparative mechanical study between PEEK and ABS”, Materials, v. 8, n. 9, pp. 5834-5846, Sep. 2015.

-

42DIVYATHEJ, M.V., VARUN, M., RAJEEV, P., “Analysis of mechanical behavior of 3D printed ABS parts by experiments”, International Journal of Scientific & Engineering Research, v. 7, n. 3, Mar. 2016.

-

43SOOD, A.K., OHDAR, R.K., MAHAPATRA, S.S., “Experimental investigation and empirical modelling of FDM process for compressive strength improvement”, Journal of Advanced Research, v. 3, n. 1, pp. 81-90, Jan. 2012.

-

44LEE, C.S., KIM, S.G., KIM, H.J., et al, “Measurement of anisotropic compressive strength of rapid prototyping parts”, Journal of materials processing technology, v. 187, pp. 627-630, Jun. 2007.

-

45SOOD, A.K., OHDAR, R.K., MAHAPATRA, S.S., “Parametric appraisal of mechanical property of fused deposition modelling processed parts”, Materials &Design, v. 31, n. 1, pp.287-295, Jan. 2010.

-

46ASTM INTERNATIONALASTM D638-14, Test Method for Tensile Properties of Plastics. Pennsylvania, United States, 2014.

-

47ASTM International ASTM D695-15, Standard Test Method for Compressive Properties of Rigid Plastics. Pennsylvania, United States, 2015.

-

48ISO 291:2008, Plastics – Standard Atmospheres for Conditioning and Testing, 2008.

-

49PEREZ, C.L., “Analysis of the surface roughness and dimensional accuracy capability of fused deposition modelling processes”, International Journal of Production Research, v. 40, n. 12, pp. 2865-2881, Jan. 2002.

-

50RANKOUHI, B., JAVADPOUR, S., DELFANIAN, F., et al, “Failure analysis and mechanical characterization of 3D printed ABS with respect to layer thickness and orientation”, Journal of Failure Analysis and Prevention, v. 16, n. 3, pp.467-481, Jun. 2016.

-

51WANG, H., SUN, X., SEIB, P., “Properties of poly (lactic acid) blends with various starches as affected by physical aging”, Journal of applied polymer science, v. 90, n. 13, pp. 3683-3689, Dec. 2003.

Publication Dates

-

Publication in this collection

2018

History

-

Received

14 July 2017 -

Accepted

24 Jan 2018