Abstract

Sandblasting is a common method to try to improve the Y-TZP/veneer bond strength of dental prostheses, however, it may put stress on zirconia surfaces and could accelerate the t→m phase transformation. Y-TZP sandblasting before sintering could be an alternative to improve surface roughness and bonding strength of veneering ceramic.

Objectives.

The aim of this study was to analyze the effect of Y-TZP pre-sintering sandblasting on surface roughness, phase transformation, and the Y-TZP/veneer shear bond strength.

Material and Methods.

The Y-TZP specimen surface underwent sandblasting with aluminum oxide (50 μm) pre-sintering (Z-PRE) and post-sintering (Z-POS). Z-CTR was not subjected to surface treatment. After ceramic veneer application, the specimens were subjected to shear bond testing. Surface roughness was analyzed by confocal microscopy. Y-TZP monoclinic and tetragonal phases were evaluated by micro-Raman spectroscopy. Shear bond strength and surface roughness data were analyzed by One-way ANOVA and Tukey tests (α=0.05). Differences in the wave numbers and the broadening bands of the Raman spectra were compared among groups.

Results.

Z-POS (9.73±5.36 MPa) and Z-PRE (7.94±2.52 MPa) showed the highest bond strength, significantly higher than that of Z-CTR (5.54±2.14 MPa). The Ra of Z-PRE (1.59±0.23 µm) was much greater and significantly different from that of Z-CTR (0.29±0.05 µm) and Z-POS (0.77±0.13 µm). All groups showed bands typical of the tetragonal (T) and monoclinic (M) phases. Y-TZP sandblasting before sintering resulted in rougher surfaces but did not increase the shear bond strength compared to post-sintering and increased surface defects.

Conclusions.

Surface treatment with Al3O2, regardless of the moment and application, improves the results of Y-TZP/veneer bonding and is not a specific cause of t→m transformation.

Keywords:

Zirconium; Ceramics; Surface properties; Shear strength

Introduction

The employment of yttria-stabilized tetragonal zirconia (Y-TZP) by computer-aided design/computeraided manufacturing (CAD-CAM) systems is an accomplished approach to reduce the number of steps in prosthetic manufacturing. Moreover, Y-TZP presents properties such as fracture toughness66- Casellas D, Cumbrera FL, Sanchez-Bajo F, Forsling W, Llanes L, Anglada M. On the transformation toughening of Y-ZrO2 ceramics with mixed Y-TZP/PSZ microstructures. J Eur Ceram Society. 2001;21(6):765-77., strength1212- Filser F, Kocher P, Weibel F, Luthy H, Scharer P, Gauckler LJ. Reliability and strength of all-ceramic dental restorations fabricated by direct ceramic machining (DCM). Int J Comput Dent. 2001;4(2):89-106.,2222- Luthy H, Filser F, Loeffel O, Schumacher M, Gauckler LJ, Hammerle CH. Strength and reliability of four-unit all-ceramic posterior bridges. Dent Mater. 2005;21(10):930-7., and biocompatibility3333- Vagkopoulou T, Koutayas SO, Koidis P, Strub JR. Zirconia in dentistry: Part 1. Discovering the nature of an upcoming bioceramic. Eur J Esthet Dent. 2009;4(2):130-51., which allow it to be employed as a substitute for metal-support fixed dental prosthesis. Ceramic veneers are applied to Y-TZP for esthetic reasons, and their effective bonding is needed for the long-term performance of all ceramic restoration1818- Kirmali O, Akin H, Ozdemir AK. Shear bond strength of veneering ceramic to zirconia core after different surface treatments. Photomed Laser Surg. 2013;31(6):261-8.,3535- Zhang Y, Lawn B. Long-term strength of ceramics for biomedical applications. J Biomed Mater Res B Appl Biomater. 2004;69(2):166-72..

A zirconia-feldspathic veneer has a 13% to 15% rate of failure for up to 5 years2626- Sailer I, Feher A, Filser F, Gauckler LJ, Luthy H, Hammerle CH. Five-year clinical results of zirconia frameworks for posterior fixed partial dentures. Int J Prosthodont. 2007;20(4):383-8.. This clinical failure may be associated with chipping, cohesive within the feldspathic layer, or by delamination with adhesive failure at the zirconia-veneer interface11- Aboushelib MN, Feilzer AJ, Kleverlaan CJ. Bridging the gap between clinical failure and laboratory fracture strength tests using a fractographic approach. Dent Mater. 2009;25(3):383-91.,1010- Choi BK, Han JS, Yang JH, Lee JB, Kim SH. Shear bond strength of veneering porcelain to zirconia and metal cores. J Adv Prosthodont. 2009;1(3):129-35.. The differences in coefficients of thermal expansion of each ceramic1212- Filser F, Kocher P, Weibel F, Luthy H, Scharer P, Gauckler LJ. Reliability and strength of all-ceramic dental restorations fabricated by direct ceramic machining (DCM). Int J Comput Dent. 2001;4(2):89-106., the resultant stress of temperature that varies at the Y-TZP/veneer interface22- Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Part II: Zirconia veneering ceramics. Dent Mater. 2006;22(9):857-63.,1313- Fischer J, Stawarzcyk B, Trottmann A, Hammerle CH. Impact of thermal misfit on shear strength of veneering ceramic/zirconia composites. Dent Mater. 2009;25(4):419-23., and poor thermal diffusivity44- Bonfante EA, Rafferty B, Zavanelli RA, Silva NR, Rekow ED, Thompson VP, et al. Thermal/mechanical simulation and laboratory fatigue testing of an alternative yttria tetragonal zirconia polycrystal core-veneer all-ceramic layered crown design. Eur J Oral Sci. 2010;118(2):202-9. are factors, either isolated or in conjunction, that may be responsible for delamination (adhesive failures), which is the most common failure11- Aboushelib MN, Feilzer AJ, Kleverlaan CJ. Bridging the gap between clinical failure and laboratory fracture strength tests using a fractographic approach. Dent Mater. 2009;25(3):383-91.. Even veneer cohesive failures (chipping) occur on fragile components of the set. The origin of this type of failure is the most tensile area of the interface between two ceramics1919- Komine F, Saito A, Kobayashi K, Koizuka M, Koizumi H, Matsumura H. Effect of cooling rate on shear bond strength of veneering porcelain to a zirconia ceramic material. J Oral Sci. 2010;52(4):647-52.. Therefore, improving the bond between the veneer and the zirconia leads to avoidance of interface failures.

The maneuvers to increase surface roughness in an attempt to improve the Y-TZP/veneer bond strength are not always satisfactory due to Y-TZP polycrystalline microstructure and physical properties3232- Thompson JY, Stoner BR, Piascik JR, Smith R. Adhesion/cementation to zirconia and other non-silicate ceramics: where are we now? Dent Mater. 2011;27(1):71-82.. The use of hydrofluoric acid does not imply surface roughness for mechanical retention3232- Thompson JY, Stoner BR, Piascik JR, Smith R. Adhesion/cementation to zirconia and other non-silicate ceramics: where are we now? Dent Mater. 2011;27(1):71-82.. Therefore, more aggressive mechanical abrasion methods are required, possibly creating surface flaws and reducing the strength of the material1616- Kern M, Wegner SM. Bonding to zirconia ceramic: adhesion methods and their durability. Dent Mater. 1998;14(1):64-71.,2121- Luthardt RG, Holzhuter M, Sandkuhl O, Herold V, Schnapp JD, Kuhlisch E, et al. Reliability and properties of ground Y-TZP-zirconia ceramics. J Dent Res. 2002;81(7):487-91..

Different surface treatments on Y-TZP were evaluated, mostly on the surface of post-sintered zirconia, such as sandblasting, mechanical grinding, silica coating, plasma spray treatment, liner, and laser-etching77- Chaiyabutr Y, McGowan S, Phillips KM, Kois JC, Giordano RA. The effect of hydrofluoric acid surface treatment and bond strength of a zirconia veneering ceramic. J Prosthet Dent. 2008;100(3):194-202.,99- Chintapalli RK, Mestra Rodriguez A, Garcia Marro F, Anglada M. Effect of sandblasting and residual stress on strength of zirconia for restorative dentistry applications. J Mech Behav Biomed Mater. 2014;29:126-37.,1717- Kim HJ, Lim HP, Park YJ, Vang MS. Effect of zirconia surface treatments on the shear bond strength of veneering ceramic. J Prosthet Dent. 2011;105(5):315-22.,1818- Kirmali O, Akin H, Ozdemir AK. Shear bond strength of veneering ceramic to zirconia core after different surface treatments. Photomed Laser Surg. 2013;31(6):261-8.,2727- Saka M, Yuzugullu B. Bond strength of veneer ceramic and zirconia cores with different surface modifications after microwave sintering. J Adv Prosthodont. 2013;5(4):485-93.. Sandblasting is a useful method, however, it may put stress on zirconia surfaces and accelerate tetragonal-to-monoclinic (t→m) phase transformation2020- Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999;15(6):426-33.. A recent study1414- He M, Zhang Z, Zheng D, Ding N, Liu Y. Effect of sandblasting on surface roughness of zirconia-based ceramics and shear bond strength of veneering porcelain. Dent Mater J. 2014;33(6):778-85. shows that sandblasting before (and not after) Y-TZP sintering improves surface roughness by over 500% and could improve the bonding strength of veneering ceramic. Considering that the post-sintered surface treatments weaken the structure of zirconia, increasing the risk of fracture and zirconia damage, the use of pre-sintering surface treatment could be an important way to increase the strength of the zirconia-veneer interface.

The aim of this study, therefore, was to analyze the effect of Y-TZP pre-sintering sandblasting on surface roughness, phase transformation, and Y-TZP/veneer shear bond strength.

Material and methods

Specimen preparation

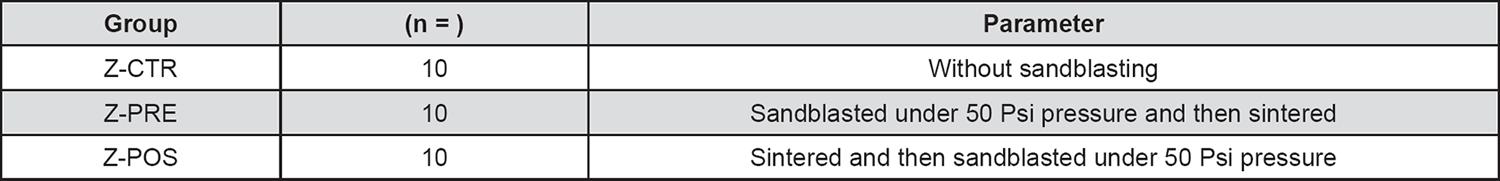

Pre-sintered zirconia blocks (IPS e.max Zircad, Ivoclar Vivadent AG), which consisted of 95% ZrO2 and 5% HfO2+Al2O3+Y2O3+Others, were cut with a diamond saw (Isomet 4000, Buehler) into 15 mm diameter and 2.4 mm thickness under water (n=10), and then the surface of each disk was polished with waterproof silicon-carbide paper until reaching 1,000#. The specimens were randomly divided into three groups (Figure 1) according to the surface treatment. Groups Z-PRE (sandblasted before sintering) and Z-POS (sandblasted after sintering) were sandblasted with 50 μm aluminum oxide particles under 50 Psi pressure for 10 s from a distance of 15 mm2525- Rekow D, Thompson VP. Engineering long term clinical success of advanced ceramic prostheses. J Mater Sci Mater Med. 2007;18(1):47-56. by a sandblasting instrument (Trijato, Essence Dental). All the Y-TZP specimens were sintered in a programmable furnace (Infire HTC, Sirona, Dental GmbH) at a cycle of 7 h and 52 min (12°C per min until 1500°C; 120 min in 1500°C; cooling at 12°C per min; and 1 h and 27 min of holding time) according to the manufacturer's sintering specifications.

Specimens of each group were veneered with Ceramic Veneer IPS e.max Ceram (Ivoclar Vivadent AG) for shear bond testing. According to the manufacturer's instructions, a thin layer (0.1 mm) of liner ceramic (Zirliner, Ivoclar Vivadent AG) was applied on all the Y-TZP disks after firing (EDG Equipamentos) at 900°C for 30 min. A custom-designed metallic device2323- Ramos CM, Cesar PF, Lia Mondelli RF, Tabata AS, Santos JS, Borges AF. Bond strength and Raman analysis of the zirconia-feldspathic porcelain interface. J Prosthet Dent. 2014;112(4):886-94. was employed for the standardized application of the ceramic veneer (5 mm diameter and 5 mm thickness). The specimens were sintered at 820°C for 30 min (Figure 2) and placed in a PVC cylinder of 10 mm in diameter with acrylic resin (JET, Classico).

Heating condition for IPS e.max Ceramic Veneer application recommended by the manufacturer (Ivoclar Vivadent AG, Schaan, Liechtenstein)

Shear Bond Test

Specimens (n = 10) were subjected to a shear test with a universal testing machine with a load cell of 50 Kgf and a mechanical testing device with stainless steel tape that provided sliding between the two tested surfaces30 at a speed of 1 mm/min until fracture. This device was developed by Ramos, et al.2323- Ramos CM, Cesar PF, Lia Mondelli RF, Tabata AS, Santos JS, Borges AF. Bond strength and Raman analysis of the zirconia-feldspathic porcelain interface. J Prosthet Dent. 2014;112(4):886-94. (2014) to minimize bending stress. For that, stainless steel tape produced smaller tensile and compression forces on the interface, as described by Sinhoreti, et al.3030- Sinhoreti MA, Consani S, Goes MF, Correr L Sobrinho, Knowles JC. Influence of loading types on the shear strength of the dentin-resin interface bonding. J Mater Sci Mater Med. 2001;12(1):39-44. (2001) than those obtained from other tests using a chisel and orthodontic wires. Moreover, the support was adapted to the upper face of the stainless steel tape to minimize any possible bending stresses and cleavage2323- Ramos CM, Cesar PF, Lia Mondelli RF, Tabata AS, Santos JS, Borges AF. Bond strength and Raman analysis of the zirconia-feldspathic porcelain interface. J Prosthet Dent. 2014;112(4):886-94. (Figure 3).

Custom-designed metallic device for shear bond testing with stainless steel tape and metallic support to avoid bending stress during the test

Failure mode analysis

The analysis of the Y-TZP/veneer interface was performed for all specimens with optical microscopy (Discovery V8 Stereo, Carl Zeiss Microimaging GmbH) at 32x magnification. A failure between the zirconia and ceramic veneer was defined as "adhesive", while a failure within either the zirconia or ceramic veneer was defined as "cohesive". The term "mixed" failure was employed to describe the combination of these two types of failure.

Surface roughness

Surface roughness (n = 3) was measured using confocal microscopy (Leica Microsystems, Wetzlar). For each Y-TZP specimen, surface roughness was measured at three different locations, then these values were averaged to obtain the average surface roughness (Ra).

The 3D roughness of one specimen in each group was also analyzed by scanning electron microscopy.

Phase analysis

Y-TZP specimens (n=3) were evaluated by micro-Raman spectroscopy (Jobin Yvon Raman Micro, model T64000, Groupe Horiba) to identify the typical bands of the crystalline phase (monoclinic and tetragonal)2424- Ramos CM, Tabata AS, Cesar PF, Rubo JH, Fracisconi PA, Borges AF. Application of micro-raman spectroscopy to the study of yttria-stabilized tetragonal zirconia polycrystal (Y-TZP) Phase transformation. Appl Spectrosc. 2015;69(7):810-4.. For this, argon laser scanning (SpectraPhysic, Inc.) was performed for excitation at 514.5 nm radiation and was kept at 10 mW to avoid any thermal damage. With microscope magnification of 500x, the beam was focused and scanning was performed in five regions.

The spectra of each specimen were recorded with a CCD camera (Spectra Group One-Horiba) after analysis of the double monochromator with a focal length of 0.64 mm and diffraction grating (1800 grooves/mm)2424- Ramos CM, Tabata AS, Cesar PF, Rubo JH, Fracisconi PA, Borges AF. Application of micro-raman spectroscopy to the study of yttria-stabilized tetragonal zirconia polycrystal (Y-TZP) Phase transformation. Appl Spectrosc. 2015;69(7):810-4..

Statistical analysis

Shear bond strength and surface roughness data were analyzed by One-way ANOVA and pairwise multiple comparison Tukey test (α=0.05). The failure types were classified with optical microscopy and calculated as a percentage for each group. Differences in the wave numbers and the broadening bands of the Raman spectra were compared among groups.

Results

Shear Bond Test

Figure 4 shows the results of the shear bond strength test. Z-PRE (7.94±2.52 MPa) and Z-POS (9.73±5.36 MPa) showed the highest strength, significantly higher than that of Z-CTR (5.54±2.14 MPa), but not significantly different from each other.

Shear bond strength of each group. Vertical bars indicate the standard deviation and similar letters indicate non-significant differences (p>0.05)

Failure mode analysis

Failure mode and distribution for each group are presented in Figures 5 and 6. All groups showed adhesive type failures, especially Z-PRE and Z-POS, which showed 60% adhesive failures. Few cohesive failures were observed, and none of the specimens were fractured within the zirconia.

Failure types: adhesive failure (zirconia), mixed failure (zirconia and ceramic veneer), and cohesive failure (ceramic veneer)

Surface roughness

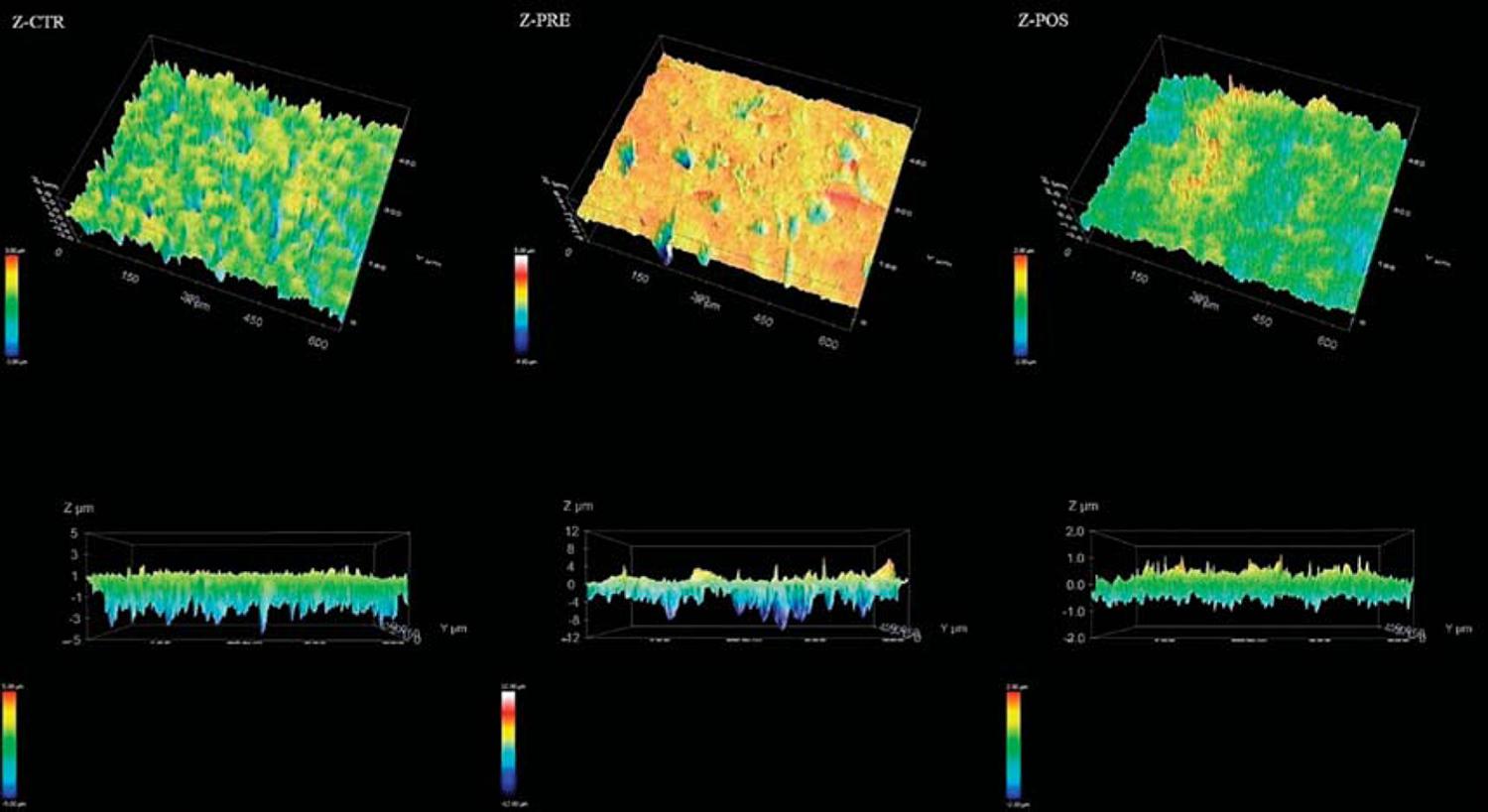

The comparison of surface roughness is shown in Figure 7. A comparison of the average surface roughness (Ra) for Z-CTR (0.29±0.05 µm), Z-PRE (1.59±0.23 µm), and Z-POS (0.77±0.13 µm) shows that the Ra of Z-PRE is much greater than and significantly different from that of Z-CTR and Z-POS (p<0.001). Z-CTR and Z-POS Ra values are not significantly different. The reconstructed images of 3D roughness representative of each group are shown in Figure 8, and surface images at 20x magnification are shown in Figure 9. Z-PRE showed more irregular profiles.

Surface roughness after surface treatment. Vertical bars indicate standard deviation and similar letters indicate non-significant differences (p>0.05)

3D representative images of view of surface. Z-CTR – prominent deep valleys (blue sites) and crests distributed homogeneously over the surface. In the deep view of the surface, the values are under -5 µm, and there are slight crests along the surface. Z-POS – deep valleys (blue sites) and crests (red sites) concentrated in certain areas of the surface, with more heterogeneous distribution, ranging from 1 µm to -1 µm. Z-PRE – absence of crests over the surface and areas of localized and prominent deep valleys under -12 µm in size

Surface image at 20 × magnification. Z-CTR – homogenous surface with no evident visible signs of damage. Z-POS – surface pattern after post-sintering treatment showing irregularities along the surface. Z-PRE – areas of localized irregularities along the surface after pre-sintering treatment

Phase analysis

All groups showed bands typical of the tetragonal (T) and monoclinic (M) phases. The most prominent peaks found related to monoclinic phases were approximately ~178 and ~474cm-1, while those related to tetragonal phases were ~142 and ~256 (Figure 10).

Discussion

Surface treatments have been recommended to improve the Y-TZP/veneer bond strength by micromechanical interlocking77- Chaiyabutr Y, McGowan S, Phillips KM, Kois JC, Giordano RA. The effect of hydrofluoric acid surface treatment and bond strength of a zirconia veneering ceramic. J Prosthet Dent. 2008;100(3):194-202.,99- Chintapalli RK, Mestra Rodriguez A, Garcia Marro F, Anglada M. Effect of sandblasting and residual stress on strength of zirconia for restorative dentistry applications. J Mech Behav Biomed Mater. 2014;29:126-37., even knowing that other factors can influence bond strength, such as the sintering cycle of veneer, cooling rate, and thermal variations1818- Kirmali O, Akin H, Ozdemir AK. Shear bond strength of veneering ceramic to zirconia core after different surface treatments. Photomed Laser Surg. 2013;31(6):261-8.,2323- Ramos CM, Cesar PF, Lia Mondelli RF, Tabata AS, Santos JS, Borges AF. Bond strength and Raman analysis of the zirconia-feldspathic porcelain interface. J Prosthet Dent. 2014;112(4):886-94.. The sandblasting method was expected to increase surface roughness. Sandblasting at different moments (pre- or post-sintering) resulted in different roughness of Y-TZP1414- He M, Zhang Z, Zheng D, Ding N, Liu Y. Effect of sandblasting on surface roughness of zirconia-based ceramics and shear bond strength of veneering porcelain. Dent Mater J. 2014;33(6):778-85.. The roughness of Z-PRE was significantly higher than that of Z-POS and Z-CTR. These results could be explained by the much lower hardness of Y-TZP before being sintered, which resulted in a rougher zirconia surface through sandblasting and thus a larger surface area available for mechanical interlocking1414- He M, Zhang Z, Zheng D, Ding N, Liu Y. Effect of sandblasting on surface roughness of zirconia-based ceramics and shear bond strength of veneering porcelain. Dent Mater J. 2014;33(6):778-85..

The approach of performing pre-sintering surface treatment is justified as it improves the shear bond strength between Y-TZP and veneer, when compared to an untreated surface1818- Kirmali O, Akin H, Ozdemir AK. Shear bond strength of veneering ceramic to zirconia core after different surface treatments. Photomed Laser Surg. 2013;31(6):261-8.. In this study, sandblasting before sintering (Z-PRE) resulted in similar shear bond strength to after sintering (Z-POS), but significantly greater strength than the untreated surface method (Z-CTR). One of the limitations of the current study is that it did not consider the aging of the specimens. Polycrystalline ceramics under wet and cyclic loading conditions are most susceptible to subcritical crack growth2828- Salazar Marocho SM, Studart AR, Bottino MA, Bona AD. Mechanical strength and subcritical crack growth under wet cyclic loading of glass-infiltrated dental ceramics. Dent Mater. 2010;26(5):483-90.. Nevertheless, thermocycling does not necessarily make a difference in bond strength results2323- Ramos CM, Cesar PF, Lia Mondelli RF, Tabata AS, Santos JS, Borges AF. Bond strength and Raman analysis of the zirconia-feldspathic porcelain interface. J Prosthet Dent. 2014;112(4):886-94..

The higher roughness obtained by pretreatment did not result in more bond strength. Thus, the surface roughness/shear bond strength relation may not be linear1919- Komine F, Saito A, Kobayashi K, Koizuka M, Koizumi H, Matsumura H. Effect of cooling rate on shear bond strength of veneering porcelain to a zirconia ceramic material. J Oral Sci. 2010;52(4):647-52. and the excessive rough surface may lead to stress concentration, which could consequently weaken the interfacial bonding1515- Jager N, Feilzer AJ, Davidson CL. The influence of surface roughness on porcelain strength. Dent Mater. 2000;16(6):381-8.. Considering that more adhesive failures were found for all studied groups (Figure 4), which is expected for shear bond tests3030- Sinhoreti MA, Consani S, Goes MF, Correr L Sobrinho, Knowles JC. Influence of loading types on the shear strength of the dentin-resin interface bonding. J Mater Sci Mater Med. 2001;12(1):39-44., the device with support adapted to the upper face2323- Ramos CM, Cesar PF, Lia Mondelli RF, Tabata AS, Santos JS, Borges AF. Bond strength and Raman analysis of the zirconia-feldspathic porcelain interface. J Prosthet Dent. 2014;112(4):886-94. was effective in tension distribution along the Y-TZP/veneer interface33- Anusavice KJ, Dehoff PH, Fairhurst CW. Comparative evaluation of ceramic-metal bond tests using finite element stress analysis. J Dent Res. 1980;59(3):608-13..

The presence of surface irregularities generated in pretreatment (Figure 9C) indicates that the use of mechanical abrasion in pre-sintering methods can be more aggressive, leading to surface flaws, microfractures that would reduce functional strength, and premature and catastrophic failure of material2121- Luthardt RG, Holzhuter M, Sandkuhl O, Herold V, Schnapp JD, Kuhlisch E, et al. Reliability and properties of ground Y-TZP-zirconia ceramics. J Dent Res. 2002;81(7):487-91.,3535- Zhang Y, Lawn B. Long-term strength of ceramics for biomedical applications. J Biomed Mater Res B Appl Biomater. 2004;69(2):166-72.. Porosity has a negative effect on the cohesive strength of the materials by reducing the pore cross-section area, through which a load is applied, acting as a stress concentrator55- Callister WD Jr. Material science and engineering: an introduction. 8th ed. New York: John Wiley & Sons, Inc; 2012.. The untreated surface shows no visible evidence of irregularities (Figure 9A). Sandblasting modifies the surface, as seen in Figure 8, and increases the shear bond strength, regardless of treatment time.

Sandblasting is a useful tool to improve retention, however, it may put stress on zirconia surfaces and accelerate the t→m phase transformation2020- Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999;15(6):426-33.,3131- Tholey MJ, Swain MV, Thiel N. SEM observations of porcelain Y-TZP interface. Dent Mater. 2009;25(7):857-62.. Hydrothermal or mechanical stress may be responsible for phase transformation1111- Deville S, Gremillard L, Chevalier J, Fantozzi G. A critical comparison of methods for the determination of the aging sensitivity in biomedical grade yttria-stabilized zirconia. J Biomed Mater Res B Appl Biomater. 2005;72(2):239-45.. Moreover, the contact with the veneering ceramic may be the cause of the important phase transformation at the interface between zirconia and veneer due to an influence of the amount of moisture present in the veneering porcelain on the faceting grain of zirconia3131- Tholey MJ, Swain MV, Thiel N. SEM observations of porcelain Y-TZP interface. Dent Mater. 2009;25(7):857-62..

The effects of t→m phase transformation are governed by the transformation toughening mechanism that occurs at superficial grains on the ceramic surface, leading to volume increase (~3 to 5%) at a localized area around the superficial defects2828- Salazar Marocho SM, Studart AR, Bottino MA, Bona AD. Mechanical strength and subcritical crack growth under wet cyclic loading of glass-infiltrated dental ceramics. Dent Mater. 2010;26(5):483-90.. After that, t→m phase transformation spreads throughout the material subsurface, resulting in grain pullout and an increase in roughness2929- Sato T, Shimada M. Transformation of yttria-doped tetragonal Zro2 polycrystals by annealing in water. J Am Ceram Soc. 1985;68(6):356-9., jeopardizing the strength, fracture toughness, and density of Y-TZP structures88- Chevalier J, Gremillard L, Deville S. Low-temperature degradation of Zirconia and implications for biomedical implants. Annu Rev Mater Res. 2007;37:1-32., which is known as low-temperature degradation88- Chevalier J, Gremillard L, Deville S. Low-temperature degradation of Zirconia and implications for biomedical implants. Annu Rev Mater Res. 2007;37:1-32.,2828- Salazar Marocho SM, Studart AR, Bottino MA, Bona AD. Mechanical strength and subcritical crack growth under wet cyclic loading of glass-infiltrated dental ceramics. Dent Mater. 2010;26(5):483-90..

Micro-Raman spectra of Y-TZP contain important information that can be obtained from the band positions, their intensities, and shapes3434- Wulfman C. SM, Lamy de la Chapelle M. Interest of Raman spectroscopy for the study of dental material: the zirconia material example. IRBM. 2010;31(5-6):257-62.. The micro-Raman analysis to detect crystalline phases in polycrystalline ceramics is a very useful tool2424- Ramos CM, Tabata AS, Cesar PF, Rubo JH, Fracisconi PA, Borges AF. Application of micro-raman spectroscopy to the study of yttria-stabilized tetragonal zirconia polycrystal (Y-TZP) Phase transformation. Appl Spectrosc. 2015;69(7):810-4.. Even peaks are distinguished in the tetragonal phase (~142, ~256, ~320, ~466, and ~637 cm–1), and the most characteristic are a sharp band at 142 cm–1 and a broader band at 256 cm–1. For the monoclinic phase (~178, ~190, ~219, ~303, ~331, ~345, ~379, ~474, ~500, ~534, ~559, ~615, and ~638 cm–1), there is a notable doublet at 178 and 190 cm–13434- Wulfman C. SM, Lamy de la Chapelle M. Interest of Raman spectroscopy for the study of dental material: the zirconia material example. IRBM. 2010;31(5-6):257-62.. Peaks of tetragonal (~142; ~256) and monoclinic (~178; ~474) crystal structures were identified in all studied groups. Pre-sintering sandblasting presented the same Raman bands as post-sintered and untreated Y-TZP surfaces, even with the differences in roughness.

Conclusions

Within this limited study, the experimental results show that Y-TZP sandblasting before sintering resulted in rougher surfaces, but did not increase the shear bond strength compared to post-sintering treatment and increased surface defects. The surface treatment with Al3O2, regardless of the moment and application, improved the results of Y-TZP/veneer bonding. The tested approaches for surface treatment did not result in different metastability of tetragonal zirconia. The long-term consequence of the pre-sintered treatment on the zirconia-veneer interface needs to be further investigated.

Acknowledgments

The authors thank Bruna Carolina Costa and Marlyni Aparecida Zens for collaborating with us. This study was supported by grants from FAPESP – São Paulo Research Foundation (#2011/18061-0, #2013/23464-2).

References

-

1- Aboushelib MN, Feilzer AJ, Kleverlaan CJ. Bridging the gap between clinical failure and laboratory fracture strength tests using a fractographic approach. Dent Mater. 2009;25(3):383-91.

-

2- Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Part II: Zirconia veneering ceramics. Dent Mater. 2006;22(9):857-63.

-

3- Anusavice KJ, Dehoff PH, Fairhurst CW. Comparative evaluation of ceramic-metal bond tests using finite element stress analysis. J Dent Res. 1980;59(3):608-13.

-

4- Bonfante EA, Rafferty B, Zavanelli RA, Silva NR, Rekow ED, Thompson VP, et al. Thermal/mechanical simulation and laboratory fatigue testing of an alternative yttria tetragonal zirconia polycrystal core-veneer all-ceramic layered crown design. Eur J Oral Sci. 2010;118(2):202-9.

-

5- Callister WD Jr. Material science and engineering: an introduction. 8th ed. New York: John Wiley & Sons, Inc; 2012.

-

6- Casellas D, Cumbrera FL, Sanchez-Bajo F, Forsling W, Llanes L, Anglada M. On the transformation toughening of Y-ZrO2 ceramics with mixed Y-TZP/PSZ microstructures. J Eur Ceram Society. 2001;21(6):765-77.

-

7- Chaiyabutr Y, McGowan S, Phillips KM, Kois JC, Giordano RA. The effect of hydrofluoric acid surface treatment and bond strength of a zirconia veneering ceramic. J Prosthet Dent. 2008;100(3):194-202.

-

8- Chevalier J, Gremillard L, Deville S. Low-temperature degradation of Zirconia and implications for biomedical implants. Annu Rev Mater Res. 2007;37:1-32.

-

9- Chintapalli RK, Mestra Rodriguez A, Garcia Marro F, Anglada M. Effect of sandblasting and residual stress on strength of zirconia for restorative dentistry applications. J Mech Behav Biomed Mater. 2014;29:126-37.

-

10- Choi BK, Han JS, Yang JH, Lee JB, Kim SH. Shear bond strength of veneering porcelain to zirconia and metal cores. J Adv Prosthodont. 2009;1(3):129-35.

-

11- Deville S, Gremillard L, Chevalier J, Fantozzi G. A critical comparison of methods for the determination of the aging sensitivity in biomedical grade yttria-stabilized zirconia. J Biomed Mater Res B Appl Biomater. 2005;72(2):239-45.

-

12- Filser F, Kocher P, Weibel F, Luthy H, Scharer P, Gauckler LJ. Reliability and strength of all-ceramic dental restorations fabricated by direct ceramic machining (DCM). Int J Comput Dent. 2001;4(2):89-106.

-

13- Fischer J, Stawarzcyk B, Trottmann A, Hammerle CH. Impact of thermal misfit on shear strength of veneering ceramic/zirconia composites. Dent Mater. 2009;25(4):419-23.

-

14- He M, Zhang Z, Zheng D, Ding N, Liu Y. Effect of sandblasting on surface roughness of zirconia-based ceramics and shear bond strength of veneering porcelain. Dent Mater J. 2014;33(6):778-85.

-

15- Jager N, Feilzer AJ, Davidson CL. The influence of surface roughness on porcelain strength. Dent Mater. 2000;16(6):381-8.

-

16- Kern M, Wegner SM. Bonding to zirconia ceramic: adhesion methods and their durability. Dent Mater. 1998;14(1):64-71.

-

17- Kim HJ, Lim HP, Park YJ, Vang MS. Effect of zirconia surface treatments on the shear bond strength of veneering ceramic. J Prosthet Dent. 2011;105(5):315-22.

-

18- Kirmali O, Akin H, Ozdemir AK. Shear bond strength of veneering ceramic to zirconia core after different surface treatments. Photomed Laser Surg. 2013;31(6):261-8.

-

19- Komine F, Saito A, Kobayashi K, Koizuka M, Koizumi H, Matsumura H. Effect of cooling rate on shear bond strength of veneering porcelain to a zirconia ceramic material. J Oral Sci. 2010;52(4):647-52.

-

20- Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999;15(6):426-33.

-

21- Luthardt RG, Holzhuter M, Sandkuhl O, Herold V, Schnapp JD, Kuhlisch E, et al. Reliability and properties of ground Y-TZP-zirconia ceramics. J Dent Res. 2002;81(7):487-91.

-

22- Luthy H, Filser F, Loeffel O, Schumacher M, Gauckler LJ, Hammerle CH. Strength and reliability of four-unit all-ceramic posterior bridges. Dent Mater. 2005;21(10):930-7.

-

23- Ramos CM, Cesar PF, Lia Mondelli RF, Tabata AS, Santos JS, Borges AF. Bond strength and Raman analysis of the zirconia-feldspathic porcelain interface. J Prosthet Dent. 2014;112(4):886-94.

-

24- Ramos CM, Tabata AS, Cesar PF, Rubo JH, Fracisconi PA, Borges AF. Application of micro-raman spectroscopy to the study of yttria-stabilized tetragonal zirconia polycrystal (Y-TZP) Phase transformation. Appl Spectrosc. 2015;69(7):810-4.

-

25- Rekow D, Thompson VP. Engineering long term clinical success of advanced ceramic prostheses. J Mater Sci Mater Med. 2007;18(1):47-56.

-

26- Sailer I, Feher A, Filser F, Gauckler LJ, Luthy H, Hammerle CH. Five-year clinical results of zirconia frameworks for posterior fixed partial dentures. Int J Prosthodont. 2007;20(4):383-8.

-

27- Saka M, Yuzugullu B. Bond strength of veneer ceramic and zirconia cores with different surface modifications after microwave sintering. J Adv Prosthodont. 2013;5(4):485-93.

-

28- Salazar Marocho SM, Studart AR, Bottino MA, Bona AD. Mechanical strength and subcritical crack growth under wet cyclic loading of glass-infiltrated dental ceramics. Dent Mater. 2010;26(5):483-90.

-

29- Sato T, Shimada M. Transformation of yttria-doped tetragonal Zro2 polycrystals by annealing in water. J Am Ceram Soc. 1985;68(6):356-9.

-

30- Sinhoreti MA, Consani S, Goes MF, Correr L Sobrinho, Knowles JC. Influence of loading types on the shear strength of the dentin-resin interface bonding. J Mater Sci Mater Med. 2001;12(1):39-44.

-

31- Tholey MJ, Swain MV, Thiel N. SEM observations of porcelain Y-TZP interface. Dent Mater. 2009;25(7):857-62.

-

32- Thompson JY, Stoner BR, Piascik JR, Smith R. Adhesion/cementation to zirconia and other non-silicate ceramics: where are we now? Dent Mater. 2011;27(1):71-82.

-

33- Vagkopoulou T, Koutayas SO, Koidis P, Strub JR. Zirconia in dentistry: Part 1. Discovering the nature of an upcoming bioceramic. Eur J Esthet Dent. 2009;4(2):130-51.

-

34- Wulfman C. SM, Lamy de la Chapelle M. Interest of Raman spectroscopy for the study of dental material: the zirconia material example. IRBM. 2010;31(5-6):257-62.

-

35- Zhang Y, Lawn B. Long-term strength of ceramics for biomedical applications. J Biomed Mater Res B Appl Biomater. 2004;69(2):166-72.

Publication Dates

-

Publication in this collection

Nov-Dec 2017

History

-

Received

13 Apr 2017 -

Reviewed

18 June 2017 -

Accepted

27 June 2017