Abstract

Contact of facades with degradation agents and direct incidence of ultraviolet radiation on external coatings make them more opaque over time, affecting their colour and reflectance characteristics. This study evaluated the effect of adding different TiO2 contents to mortars applied in concrete substrates in order to verify the reflectance maintenance on surfaces after exposure over time. Mortar with different concentrations of TiO2 (1%, 5%, 10%) were produced in relation to the total dry premix, added as a powder and compared to unpainted mortar without TiO2 (type "A") and painted mortar without TiO2 (type "B"), both used as a reference for colour and reflectance. Exposed over 16 months to climate conditions in São Paulo, regarding the maintenance of reflectance and solar radiation, the results showed that type "B" (0%TiO2) painted mortar presented the best performance. Type "C" (1%TiO2) and type "D" (5%TiO2) unpainted mortar remained more stable. Type "A" (0%TiO2) and type "E" (10%TiO2) unpainted mortar showed greater differences according to the Just Noticeable Difference (JND) range caused by dirt pick up.

Keywords:

Self-cleaning mortar; Solar and luminous radiation reflectance; Heterogeneous photocatalysis; CIELAB; Dirt pick up

Resumo

O contato das fachadas com agentes de degradação e a incidência direta da radiação ultravioleta sobre os revestimentos externos os tornam mais opacos com o passar do tempo, afetando suas características de cor e refletância. O estudo avaliou argamassas contendo TiO2 aplicadas em substratos de concreto, buscando manter suas características iniciais de alta reflexão com baixa manutenção, visando a sua utilização em fachadas. Foram produzidas argamassas com diferentes concentrações de TiO2 (1%, 5%, 10%) expressas em relação ao total da pré-mistura seca, adicionadas em forma de pó e comparadas com argamassa sem TiO2 e sem pintura (tipo "A") e argamassa sem TiO2 pintada (tipo "B"), ambas usadas como referência de cor e refletância. Expostas durante 16 meses às condições climáticas da cidade de São Paulo, os resultados demonstraram que a argamassa que melhor apresentou desempenho quanto à manutenção da refletância à radiação solar e luminosa foi a argamassa do tipo "B" (0%TiO2 pintada). As argamassas do tipo "C" (1%TiO2) e "D" (5%TiO2) sem pintura se mantiveram mais estáveis. As argamassas do tipo "A" (0%TiO2) e "E" (10%TiO2) sem pintura apresentaram maiores diferenças para a Mínima Diferença Perceptível (JND) causada pela pega de sujeira.

Palavras-chave:

Argamassas autolimpantes; Refletância à radiação solar e luminosa; Fotocatálise heterogênea; CIELAB; Pega de sujeira

Introduction

Discoloration, appearances of stains, accelerated wear, fouling due to soot particles and corrosion or erosion caused by acids are some problems caused by the accumulation of pollutants on the building envelope. Due to these shells being constantly in contact with degradation agents and the direct incidence of ultraviolet radiation, coatings tend to become more opaque over time affecting their colour and reflectance characteristics.

According to Seker and Tavil (1996)SEKER, D. Z.; TAVIL, A. U. Evaluation of Exterior Building Surface Roughness Degrees by Photogrammetric Methods. Building and Environment, v. 31, p. 393-398, 1996., Santamouris, Synnefa and Karlessiet (2011)SANTAMOURIS, M; SYNNEFA, A; KARLESSIET, T. Using Advanced Cool Materials in the Urban Built Environment to Mitigate Heat islands and improve thermal comfort conditions. Solar Energy, v. 85, n. 12, p. 3085-3102, 2011. and Alchapar, Correa and Cantón (2012)ALCHAPAR, N. L.; CORREA, E. N.; CANTÓN, M. A. Índice de Reflectancia Solar de Revestimentos Verticales: potencial para la mitigación de la isla de calor urbana. Ambiente Construído, Porto Alegre, v. 12, n. 3, p.107-123, jul./sept. 2012., heat gained through opaque surfaces, due to solar radiation, greatly influences the thermal comfort conditions of the internal environment. According to Pérez-Lombard, Ortiz and Pout (2007)PÉREZ-LOMBARD, L.; ORTIZ, J.; POUT, C. A Review on Buildings Energy Consumpto Information. Energy and Buildings. Sevilha, 2007. p. 394-398. Available at: <http://www.esi2.us.es/∼jfc/Descargas/ARTICULOS/PAPER_LPL_1_OFF-PRINT.pdf>. Accessed on: 18 Dec. 2015.

http://www.esi2.us.es/∼jfc/Descargas/ART...

, the demand for thermal comfort, artificial climate systems and their associated energy consumption have become unavoidable assets, accounting for almost half of the energy consumed in buildings and about 10% - 20% of total energy consumption in developed countries. Santamouris, Synnefa and Karlessiet (2011)SANTAMOURIS, M; SYNNEFA, A; KARLESSIET, T. Using Advanced Cool Materials in the Urban Built Environment to Mitigate Heat islands and improve thermal comfort conditions. Solar Energy, v. 85, n. 12, p. 3085-3102, 2011. state that the materials used in facades have an important role in the thermal balance of a city, where high reflective coatings result in an efficient passive technique to reduce the demand for electrical energy in the thermal conditioning of environments. Alchapar, Correa and Cantón (2012)ALCHAPAR, N. L.; CORREA, E. N.; CANTÓN, M. A. Índice de Reflectancia Solar de Revestimentos Verticales: potencial para la mitigación de la isla de calor urbana. Ambiente Construído, Porto Alegre, v. 12, n. 3, p.107-123, jul./sept. 2012. point out that if high reflective materials were used for building facades, there would be a decrease in the thermal loads in building interiors.

Therefore, the aim is to search for new technologies that allow for greater durability of external coatings minimising the effect of pollution on them and that help the thermal control of buildings without requiring major interventions in terms of maintenance. In this respect, "advanced photocatalytic oxidation", using semiconductors such as TiO2, as process catalysts capable of self-cleaning these surfaces may offer a solution to this problem, not only because they last longer than what is expected of such a technique in terms of maintaining the facades for longer, but also to save time and money on cleaning and restoration, especially in very tall buildings whose maintenance can be very difficult and expensive.

TiO2 has two crystallographic forms considered predominant: rutile and anatase. Rutile is a mineral composed essentially of TiO2, which can contain up to 10% of impurities and is widely used as an opacifier and as a pigment for paints and plastics. Anatase contains 98.4 to 99.8% of TiO2, and is the most investigated and used for photocatalysis, mainly because it has a higher bandgap and greater photocatalytic activity. Studies such as those carried out by Poon and Cheung (2007)POON, C.; CHEUNG, E. No Removal Efficiency of Photocatalytic Paving Blocks Prepared with Recycled Materials. Construction And Building Materials, v. 21, p. 1746-1753, 2007., Chen and Poon (2009)CHEN, J.; POON, C. Photocatalytic Construction and Building Materials: from fundamentals to applications. Building and Environment, v. 44, p. 1899-1906, jan. 2009., Maranhão (2009)MARANHÃO, F. L. Método Para Redução de Mancha nas Vedações Externas de Edifícios. São Paulo, 2009. 107 f. Tese (Doutorado em Engenharia Civil) - Escola Politécnica, Universidade de São Paulo, São Paulo, 2009., Pereira, Torgal and Jalali (2010)PEREIRA, M. A. C.; TORGAL, F. P.; JALALI, S. Capacidade de Auto-Limpeza de Argamassas Contendo Dióxido de Titânio (TiO2). In: CONGRESSO NACIONAL DE ARGAMASSAS DE CONSTRUÇÃO, 3., Lisboa, 2010. Proceedings... Lisboa, 2010. and Melo (2011)MELO, J. V. S. de, Desenvolvimento de Peças Pré-Moldadas de Concreto Fotocatalíticas Para Pavimentação e Purificação do Ar. Florianópolis, 2011. 208 f. Dissertação (Mestrado em Engenharia Civil) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal de Santa Catarina, Florianópolis, 2011. demonstrated that TiO2 can be efficient mainly when promoting photodegradation of some organic and inorganic compounds found in the urban atmosphere and deposited on building facades. Thus, heterogeneous photocatalysis has also opened up opportunities not only concerning studies on decontaminating the environment, but also for manufacturing self-cleaning materials.

Regarding cementitious materials, studies found in the literature mainly address photodegradation of NOx and SOx pollutants, as well as manufacturing concrete blocks for paving and producing mortar used on a laboratory scale, measuring the reduction of stains caused by dyes such as methyl orange, methylene blue and rhodamine. The aim of this research is to fill a gap regarding studies on reflectivity of coating mortar adding TiO2, carried out essentially under natural conditions of exposure to solar radiation, using large-scale tests, whose TiO2 concentrations were added to the mixture in relation to the total dry mass and without having had any previous treatment of surface water repellent

Literature Review

According to Fujishima, Rao and Tryk (2000)FUJISHIMA, A.; RAO, T. N.; TRYK, D. A. Titanium Dioxide Photocatalysis. Journal of Photochemistry and Photobiology C: Photochemistry Reviews 1, p. 1-21, Mar. 2000., since 1977 when Frank and Bard examined the possibilities of using TiO2 to decompose cyanide in water, interest has grown in using this material in environmental applications. They emphasized that adding a photocatalyst to external surfaces of buildings or coatings of facades containing a photocatalyst, could provide a surface with hydrophilic characteristics and would certainly decrease the degree of dirtiness on these surfaces, which could be washed in the rain, or alternatively sprayed with water occasionally, thus promoting a self-cleaning effect. According to Chen and Poon (2009)CHEN, J.; POON, C. Photocatalytic Construction and Building Materials: from fundamentals to applications. Building and Environment, v. 44, p. 1899-1906, jan. 2009. for the construction industry, the advantages of adding and/or using these particles in building materials have attracted many industrial interests.

Considering the use of TiO2 containing photocatalysts for building materials, two important aspects related to the nature of these materials were discovered:

-

the effect of self-cleaning due to the reactions caused by the incidence of sunlight on the photocatalyst surface; and

-

the photo-induced hydrophilicity of the catalyst surface, consequently leading to a significant self-cleaning effect.

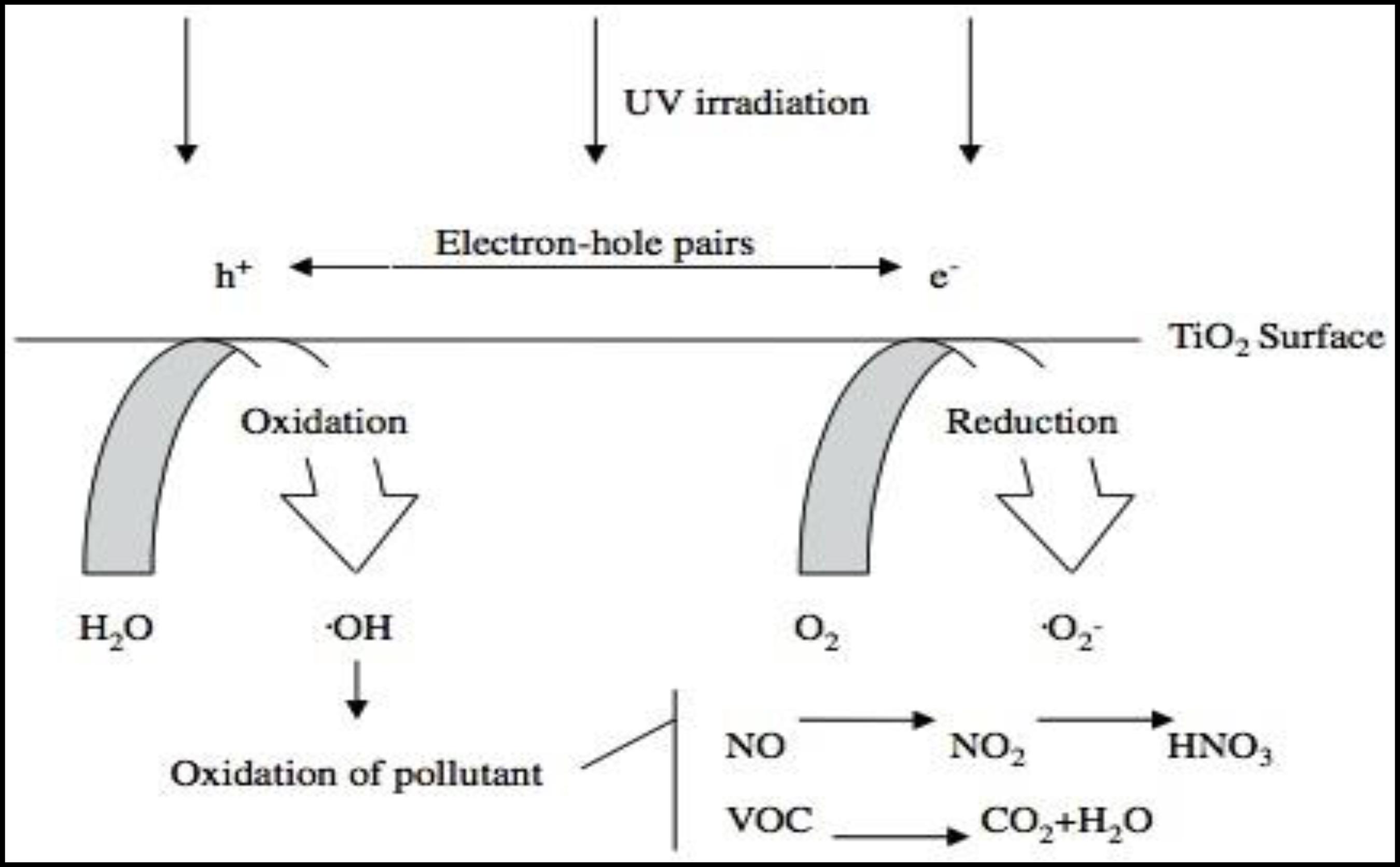

The principle of heterogeneous photocatalysis involves activating a semiconductor (usually TiO2) by sunlight or artificial light. A semiconductor is characterized by Valence Bands (VB) and Conduction Bands (CB) and the region between them is called a bandgap. The absorption of photons with energy higher than the bandgap energy can promote an electron from the valence band to the conduction band with a concomitant generation of a gap (h +) in the valence band. These gaps show very positive potentials in the range of +2.0 to +3.5 V measured against a saturated calomel electrode, depending on the semiconductor and pH. This potential is sufficiently positive to generate HOº radicals from water molecules adhered to the surface of the semiconductor, which can subsequently oxidize the organic contaminant. The efficiency of photocatalysis depends on the competition between the process in which the electron is withdrawn from the surface of the semiconductor and the electron/gap pair recombination process, which results in heat release (NOGUEIRA; JARDIM, 1998NOGUEIRA, R. F. P.; JARDIM, W. F. A Fotocatálise Heterogênea e Sua Aplicação ambiental. Química Nova, Campinas, v. 21, n. 1, p.69-72, jan. 1998.).

The self-cleaning and depolarizing action of the surfaces by the photocatalytic action act together. During the day, the surface is excited by the ultraviolet radiation of the sun resulting in the oxidation of the organic compounds that have been deposited. Simultaneously, the contact angle is reduced making the surface hydrophilic. The rainwater found on this surface turns into a water film removing all the adhered particles. The self-cleaning mechanism and depolarizing action can be observed in Figure 1.

Since the year 2000, buildings have been constructed in different countries aiming to meet high aesthetic standards and seek the benefits of using the photocatalysis process. Among these buildings, two of them particularly stand out:

-

Cité de la Music et des Beaux-Arts in Chambéry, France (2001);

-

the Dives in Misericórdia Church in Rome, Italy (2002).

Using the CIELAB colorimetric system, the first building was monitored for 5 years and the second for 7 years, regarding the maintenance of the colour of their facades. After this period the results confirmed the maintenance of the primary colour of their facades.

According to Johnston and Kao (1989)JOHNSTON, W. M.; KAO, E. C. Assessment of Appearance Match by Visual Observation and Clinical Colorimetry. Journal of Dental Research, Ohio, p. 819-822, May 1989., human perception of colour is complex and includes both subjective and objective phenomena. The colour matching perception factor can be as subjective as "hot" and "cold" for any individual in any environment. Therefore, colour evaluation by visual comparisons may not be a reliable method, given the results of inconsistencies inherent in perception and specifications among observers. The authors point out that the colour of natural teeth depends on their capacity to modify the colour of incident light. The colour of natural teeth is a result of the combination of the light reflected from the enamel surface, and light scattered and reflected by the enamel and dentin. They report that the instrumental colour difference and the wide range of colour differences found within each visually determined colour match criterion, suggest that the perceived appearance within the dental environment is too complex to be completely defined by three colour parameters. Since the perception of appearance includes concepts of colour and translucency, the simple specification of the three-colour parameters by an instrument for a given illumination and observation geometry would be incomplete to determine the appearance of a translucent material. They argue that the lack of a clear delimitation between the visual evaluation criteria and the colour difference by instrumental colorimetry indicates that other factors besides the colour difference alone can influence the visual perception between dental structures. Thus, in the absence of a consistent assessment of colour, they propose a threshold of perception according to the CIELAB system of 3.7 points to evaluate a set of teeth in the oral environment. According to Souza (2009)SOUZA, R. C. C. de. Avaliação de Imagens Através de Similaridade Estrutural e do Conceito de Mínima Diferença de Cor Perceptível. Rio de Janeiro, 2009. 117 f. Dissertação (Mestrado em Engenharia Eletônica, Sistemas Inteligentes e Automação) - Universidade do Estado do Rio de Janeiro, Rio de Janeiro, 2009., the CIELAB colour space has an important characteristic: the measured distance between colours in this space is a good approximation of perceived visual distance. Thus, the perceived colour threshold, known as Just Noticeable Difference (JND), can be used in order to increase the correlation of objective assessments with subjective assessments. When calculating the distance between colours, the JND is the threshold from which two colours are perceived as distinct colours by the human eye. There is no consensus about the precise value of JND. References to the ranges of values that the JND can assume in two scenarios are:

-

generic scenarios are defined as:

-

- between: 0.38 - 0.73 | CIELAB units | Just Noticeable Difference (JND);

-

- around: 1.75 | CIELAB units | difference above JND; and

-

- above: 5.0 | CIELAB units | large colour differences.

-

-

however, from an industrial perspective (for example, for colour reproduction in manufactured goods), the author indicates that for colour differences:

-

- between: 1.1 and 2.8 | CIELAB units | accurate colour tolerance;

-

- between: 2.8 and 5.6 | CIELAB units | normal tolerance; and

-

- above: 5.6 | CIELAB units | loose tolerance.

-

According to Diamanti et al. (2013)DIAMANTI, M. V. et al. Photocatalytic and Self-Cleaning Activity of Colored Mortar Containing TiO2. Construction And Building Materials, v. 46, p.167-174, Sept. 2013., TiO2 clearly enhances the brightness of the materials, which is a typical effect of TiO2 powders given their high refractive index, as well as a variation in the colour coordinates a* and b*. In studies conducted, a loss of saturation was observed when TiO2 was added to a mortar with low pigment content, while saturation increased (or at least, the loss was reduced) in samples containing the highest pigment content. In all cases, the variation in the colour saturation was not perceptible because according to the authors, the threshold for the visual perception of the human eye is the brightness variation (L) greater than 1 and the hue (a* or b*) greater than 3. Munafò, Goffredo and Quagliarini (2015)MUNAFÒ, P.; GOFFREDO, G. B.; QUAGLIARINI, E. TiO2-Based Nanocoatings for Preserving Architectural Stone Surfaces: an overview. Construction And Building Materials, v. 84, p. 201-218, jun. 2015. point out that the colour difference ∆E is defined as the Euclidean distance between two different points. Conventionally, ∆E=1 is considered the only noticeable difference (JND) by the human eye. In a study conducted by Bellan, Salmon and Cass (2000)BELLAN, L. M.; SALMON, L. G.; CASS, G. R. A Study on the Human Ability to Detect Soot Deposition Onto Works of Art. Environmental Science and Technology, 2000; v. 34, p. 1946-1952, 2000., the minimum surface coverage (3.6%) required to trigger the detection of dirt by the human eye between clean and dirty surfaces corresponds to ∆E≈1. However, various authors have reported different values of JND in a more generic range of 2-3 units.

In the analyses carried out by Munafò, Goffredo and Quagliarini (2015)MUNAFÒ, P.; GOFFREDO, G. B.; QUAGLIARINI, E. TiO2-Based Nanocoatings for Preserving Architectural Stone Surfaces: an overview. Construction And Building Materials, v. 84, p. 201-218, jun. 2015. in almost all their studies, colour variations were below or at least very close to the threshold of human perception. The authors cite that aqueous colloidal suspensions (sols) caused less colour changes compared to other hybrid products containing additives. Under these conditions, the colour changes were generally very close to the JND, to totally negligible values or at least less than the greatest colour variation suitable for restoration. Hybrid sols caused more and less uniform changes related to the material used in their composition. The only exceptions were found in studies conducted by Pinho and Mosquera (2013)PINHO, L.; MOSQUERA, M. J. Photocatalytic Activity of TiO2-SiO2 Nanocomposites Applied to Buildings: influence of particle size and loading. Applied Catalysis B: Environmental, v. 134-135, p.205-221, May, 2013. and La Russa et al. (2012)LA RUSSA, M. F. et al. Multifunctional TiO2 Coatings for Cultural Heritage. Progress in Organic Coatings, v. 74, n. 1, p. 186-191, May 2012. where part of the newly developed nanocomposites of TiO2-SiO2 and the commercial polymer under analysis showed very few colour changes. Colour differences between an aqueous commercial product and a novel non-TiO2-linkable polysiloxane were monitored by Luvidi et al. (2010)LUVIDI, L. et al. Application of TiO2 Based Coatings on Stone Surfaces of Interest in the Field of Cultural Heritage. In: FERRARI, A. (Ed.). INTERNATIONAL CONGRESS SCIENCE AND TECHNOLODY FOR THE SAFEGUARD OF CULTURAL HERITAGE IN THE MEDITERRANEAN BASIN, 4., Napoli, 2010. Proceedings... Napoli: Grafica Elettronica, 2010.. Both coatings altered the appearance of the stones insignificantly, however the commercial treatment generally showed lower ∆E values. Red and black limestone used in the study, as well as white marble were subjected to stronger colour modification. This behaviour is mainly linked to the original colour of the stones as TiO2 particles usually cause a whitening effect and may be less noticeable on light-coloured surfaces.

Method

Mortar with and without the addition of TiO2, produced in the laboratory, were compared to the behaviour of the reflectance variation to solar and luminous radiation over time. The mortars were divided into two types according to the composition:

-

mortar with the addition of TiO2; and

-

the reference mortar.

For type 1 mortar, three samples with different concentrations of TiO2 (1%, 5%, 10%) were produced. For type 2 mortar, two samples with 0% TiO2 were produced: one tyoe with its initial finishing and the other one coated with white paint. The product used was called "Sempre Nova" from Suvinil, which is a water-based 100% acrylic resin "semi-satin" paint. According to the manufacturer´s recommendations, it is a coating for facades and other external uses and is recommended for painting and repainting external areas, allowing the self-removal of airborne dirt deposited on the painted surface, when the wall contact occurs with rainwater or water spray. Both samples were taken as a reference for measuring reflectance and neither of them had water repellents treatment on their surfaces.

The mortar was produced using non-structural type 1 White Portland Cement (WPC) and dolomites. The choice of materials was based on the assumption that studies such as Alchapar et al. (2012)ALCHAPAR, N. L.; CORREA, E. N.; CANTÓN, M. A. Índice de Reflectancia Solar de Revestimentos Verticales: potencial para la mitigación de la isla de calor urbana. Ambiente Construído, Porto Alegre, v. 12, n. 3, p.107-123, jul./sept. 2012. have shown that white coatings reflect higher reflectance to solar radiation, which is why no coloured pigments were added to the mixture. The samples were classified into five types (A, B, C, D, E) and used in a total of twenty specimens divided into four different groups (1, 2, 3, 4). This division is shown in Table 1.

The TiO2 concentrations used were based on a scale considering the levels presented in the studies consulted by literature revue. However, contrary to what was found in the literature, the concentrations adopted were not taken in relation to the cement (a standard comparison that is widely used in most research), but concerning the total dry premix. This means that the stipulated contents relate to other research only for reference and should not be seen as a direct comparison as they were not based on the same component of the mixture, i.e., the cement. Thus, the choice of the first content (1% in relation to the total mass of the dry premix) can be compared to the results of the studies carried out using 5% of the cement mass, and the other two concentrations are extrapolations to analyze the significant increase of TiO2 in mixture, as few studies have ever tested concentrations higher than 8% of TiO2 in relation to the cement mass. The titanium dioxide (TiO2) used was Cristal ACTiVTM PC105 Ultrafine. According to manufacturer´s data sheet has medium-sized agglomerate: ≈1.1µm, 100% anatase and recommended for application in photocatalytic processes. The characteristic and components used in the preparation are described in Tables 2 and 3.

Proportion (in mass) of the mixing components compared to the cement (except for water) which refers to the proportion in relation to the total mixture and the TiO2, shown according to the legend below

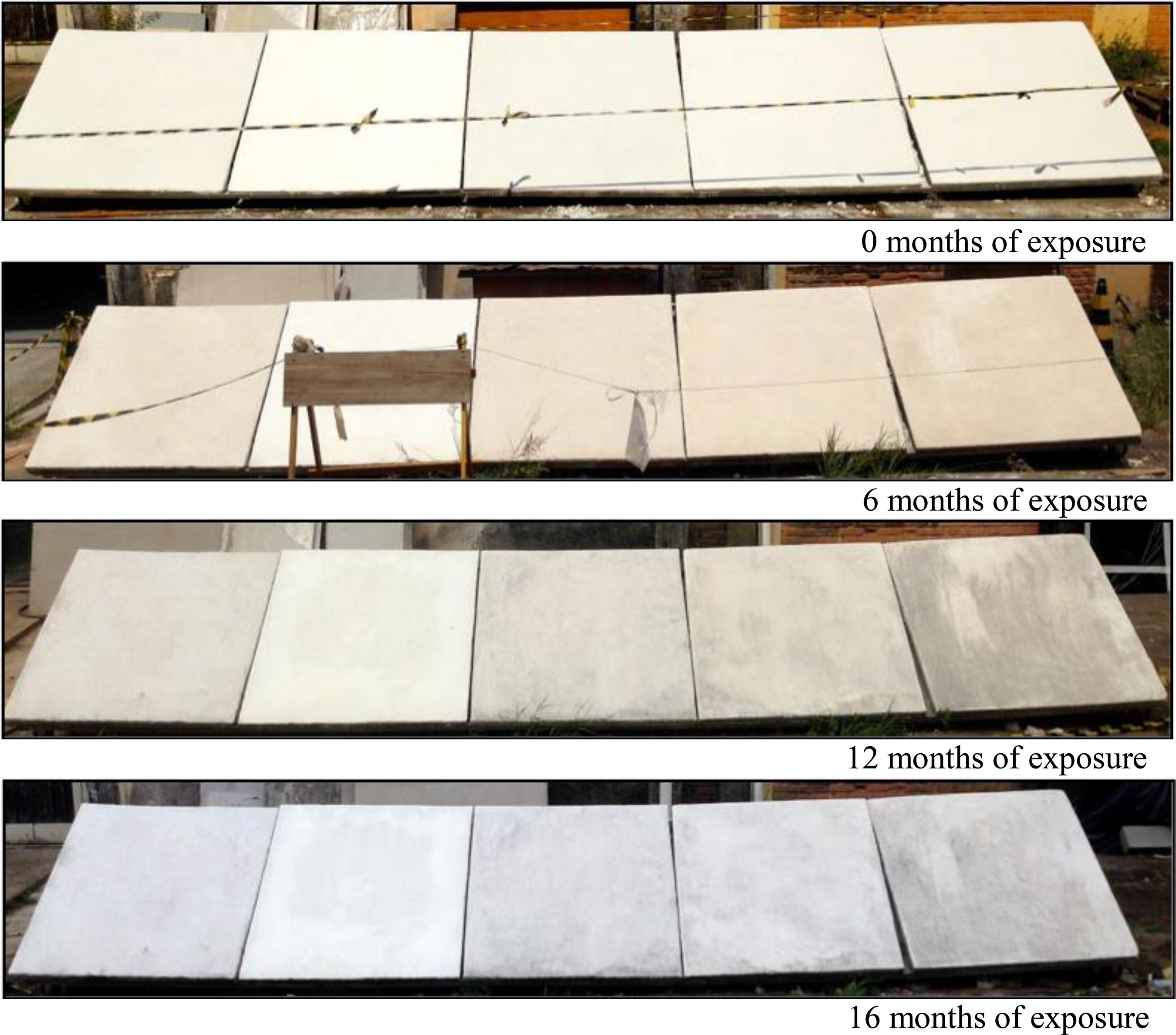

Mortar studied was applied on concrete substrates with dimensions of 1.20m by 1.20m with maximum thickness of 1cm and with less roughness possible to obtain high reflectance. According to Seker and Tavil (1996)SEKER, D. Z.; TAVIL, A. U. Evaluation of Exterior Building Surface Roughness Degrees by Photogrammetric Methods. Building and Environment, v. 31, p. 393-398, 1996., rough surfaces tend to present higher absorbance values. Finally, out of a total of twenty specimens, fifteen were exposed to the urban atmosphere in the open field in the city of São Paulo, facing northwest in order to maximize exposure to sunlight. A slope of 33° was adopted in relation to the soil aiming at meeting the objectives:

-

higher solar radiation index; and

-

avoiding rainwater stagnating on the specimens´ surfaces, and consequent microorganism proliferation.

Figure 2 shows the exposure after studying it for 16 months.

Process of Measuring Reflectance Indices

Reflectance to solar radiation is defined as the ratio of the flux of radiant energy reflected by a surface to the incident solar energy flux. In order to determine the reflectance to the solar radiation of the Thus, based on the numbers based on the norms:

-

ASTM E1918-06 (2015)AMERICAN SOCIETY FOR TESTING AND MATERIAL. E1918-06: standard test method for measuring solar reflectance of horizontal and low-sloped surfaces in the field. West Conshohocken, 2015. - "Standard Test Method for Measuring Solar Reflectance of Horizontal and Low-Sloped Surfaces in the Field", and

-

ANSI/ ASHRAE 74 (1988)AMERICAN SOCIETY OF HEATING AND AIR-CONDITIONING ENGINEERS. ANSI/ASHRAE 74: method for measuring solar-optical properties of materials, procedure E. Atlanta, 1988. - "Method for Measuring Solar-Optical Properties of Materials, procedure E".

The measurements were carried out at the same time of day - between 11h and 13h - searching for the period with the highest incidence of UV radiation on the specimens. The process generated a total of 270 measurements, 90 were studied in each group, 54 per type of mortar, considering all groups and 18 individual measurements for each type of mortar. The collection period was 16 months and the first measurements were taken at weekly intervals moving on to a monthly interval. In order to carry out the measurement procedures, the following equipment was used: Kipp & Zonen pyranometers, Delft/Holland model CM3; an ALMEMO data acquisition system, model 2890-9 and a metal shaft with 70cm.

The data were collected in loco from the fixation of two pyranometers at the tip of the metal rod. The rod was positioned so that the lower pyranometer was placed at a distance (height) of approximately 30cm from the surface of the specimen and on the axis passing through its center, perpendicular to its surface. The pyranometers were positioned one facing up to capture the incident solar energy flow, and the other returned and positioned parallel to the surface of the test specimens in order to capture the radiant energy flux reflected by the surface. Once the pyranometers were positioned on the specimen to be measured, the surfaces of the adjacent specimens were covered to prevent the radiant energies reflected from these surfaces from interfering with the results of the surface to be measured. After positioning the pyranometers and shading the adjacent test specimens, measurements were taken every 1 second, totalling at least 20 readings. The measurement procedure is shown in Figure 3.

Quantitative Evaluation of Surface Colour

The CIEL*a*b* system is derived from the CIE Standard Colour Table by transforming the original X, Y and Z coordinates into the three new reference values of L, a and b. The objective of this transformation is a colour-space to aid the numerical classification of colour differences. For the quantitative evaluation of the colour of specimens, the CIE1 colour system L* a* b* was used. The three coordinates (L, a, b) determine the following colour components:

a*: red/magenta and green;

b*: blue and yellow; and

L*: black/white (luminance/brightness).

The lightness, L*, represents the darkest black at L*=0 and the brightest white at L*=100. The color channels, a* and b*, will represent true neutral gray values at a*=0 and b*=0. The red/green opponent colors are represented along the a* axis, with green at negative a* values and red at positive a* values. The yellow/blue opponent colors are represented along the b* axis, with blue at negative b* values and yellow at positive b* values. The colour coordinates are shown in Figure 4.

Colour coordinate system (CIELAB) - Source: Centro Multidisciplinar para o Desenvolvimento de Materiais Cerâmicos (2017).

The colour evaluation was done according ASTM D2244-16AMERICAN SOCIETY FOR TESTING AND MATERIAL. D2244-16: standard practice for calculation of color tolerances and color differences from instrumentally measured color coordinates. West Conshohocken, 2016. (American Society for Testing and Material) (AMERICAN..., 2016AMERICAN SOCIETY FOR TESTING AND MATERIAL. D2244-16: standard practice for calculation of color tolerances and color differences from instrumentally measured color coordinates. West Conshohocken, 2016.) using a Colour Guide Sphere d/8° spin spectrocolorimeter with geometric measurements of 45 circ./0, d/8. With 400-700nm measurement area, 20nm spectral resolution, 0-100% photometric área (0.01) and standard observer D65 with 10° aperture angle.

Result and Discussion

Reflectance Indices

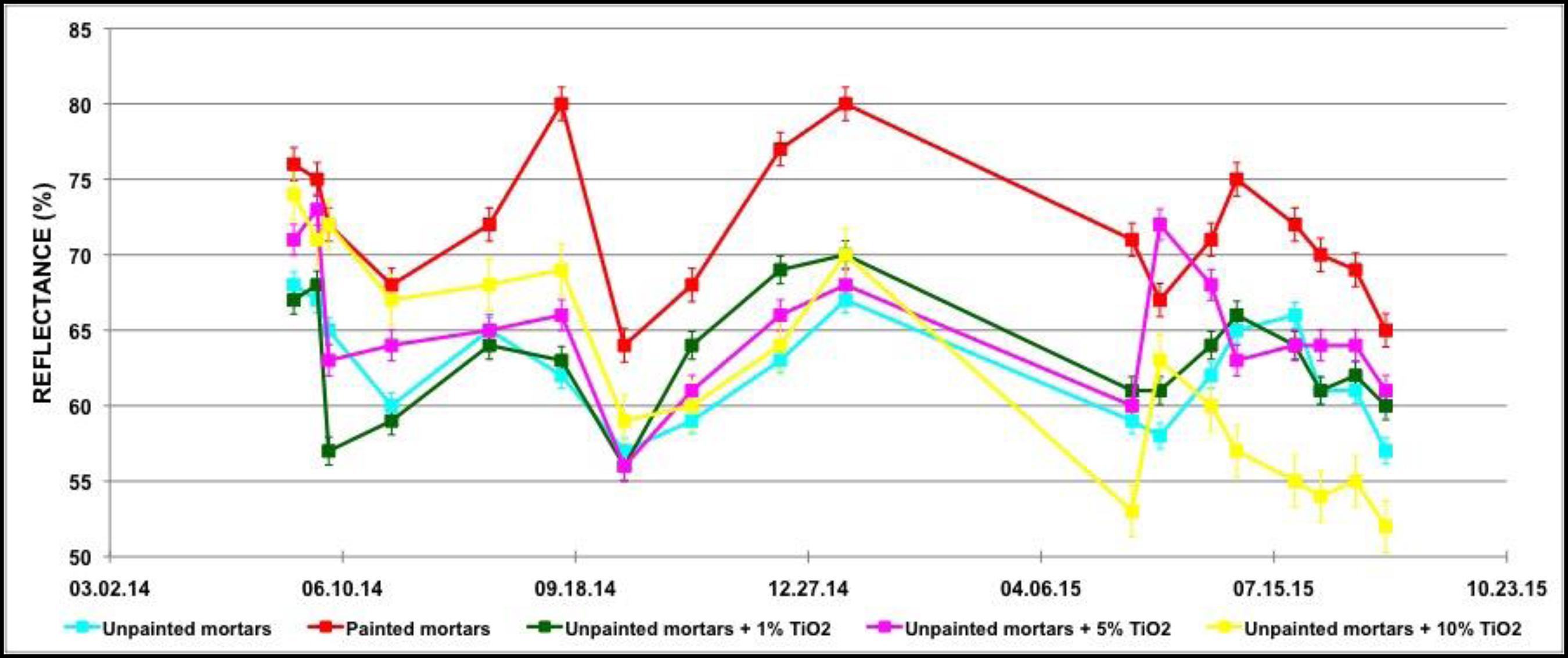

According to Dantas (2016)DANTAS, S. R. A. A Eficácia da Adição do TiO2 em Argamassas Quanto à Manutenção das Condições Iniciais em Termos da Sua Refletância à Radiação Solar. São Paulo, 2016. 137 f. Dissertação (Mestrado Profissional) - Instituto de Pesquisas Tecnológicas do Estado de São Paulo, São Paulo, 2016., the evaluation of reflectance graphs for mortar, either individually or in groups, presented results that can be considered as similar. A total of 90 measurements per group were collected throughout the whole experiment and solar reflectance graphs were generated to evaluate the behaviour of the mortar over the months they were exposed. The results can be seen in Figures 5 to 7.

The graphs show that in September and December 2014, the reflectance values of the mortars were higher than the values found in the first measurements carried out in May of the same year. It was expected that for the mortar painted in white, there would be higher values at the beginning compared to the others, given the paint on a white surface, which would already provide an increase in these indices. However, the "peaks" observed in the reflectance indices over time were not expected, especially those observed in Group 2, which exceeded their initial values up to 5 points.

The increase in the reflectance values occurred after the first measurements in all the specimens. It is understood to be connected to the fact that during the first measurements, the specimens were not really clean but possibly covered by a thin layer of dust. This is due to the many days without rainfall, and the restoration work of the pavement around the test field. After being washed by rain in September, there was an increase in the reflectance indices.

As for the other "reflectance peaks" in the painted mortar, they can be associated to two factors: the non-degradation of the acrylic film (resin) of the paint during the exposure period, allowing mortar to remain at higher levels, even though their indexes decreased; and the rainfall that helped to clean these surfaces more effectively, which, as they are less rough, resulted in less soil impregnation. Regarding the other mortar, the evaluation from September and December also showed reflectance values greater than their initial measurements, however differently in each group. For Group 1, there was an increase in December; in Group 3, the increase was identified in September. However, for Group 2, the mortar did not follow the same pattern, as their indices were high, but had values below their initial measurements. In the case of this mortar, the "recoveries" in the indices seem to be more associated to cleaning the specimens due to rainfall than by the presence of TiO2, as the mortar with no TiO2 addition presented higher values than some mortar with TiO2 addition.

In view of the results obtained, the mortar were grouped according to their composition, and from these groups, new reflectance graphs by mortar type were made, containing the data of the three groups studied, so as to observe the behaviour of each type of mortar when compared to corresponding specimens. Although there are some exceptions, the results show that mortar tends to exhibit very similar behaviour regarding solar radiation reflectance when compared to corresponding specimens, and can be considered the same. The results pointed out that, despite some variations, it cannot be stated, as happens when evaluated in larger groups, that there was a prominence of the mortar, leading to the belief that the results for each mortar studied can be presented in averages as pointed out by Dantas and Vittorino (2016)DANTAS, S. R. A.; VITTORINO, F. A Eficácia da Adição do TiO₂ em Argamassas Quanto à Manutenção das Condições Iniciais em Termos da Sua Refletância à Radiação Solar. In: ENCONTRO NACIONAL DE TECNOLOGIA DO AMBIENTE CONSTRUÍDO: DESAFIOS E PERSPECTIVAS DA INTERNACIONALIZAÇÃO DA CONSTRUÇÃO, 16., São Paulo, 2016 . Anais... São Paulo: ANTAC, 2016. and observed in Figure 8.

Except for the last five months, when the mortars presented lower decay rates, indicating a possible stability in the indexes, the graph shows two relevant aspects: first, the highlight obtained by the painted mortar, in which, even though there are points of approximation with the others, it remains at a higher level most of the time; and, secondly, the "entanglement" in which the other mortar is shown, alternating positions in such a manner and various times, makes it hard to make any statement concerning their prominence and can be considered equal in their indexes. For mortar with TiO2 addition, lower reflectance levels were accepted during the first measurements. However, considering the photocatalysis process, it was expected that their initial values found remained stable or at least close to them over time, even though presenting small differences due to the different levels of TiO2 tested. In contrast, for painted and unpainted mortar, a decline in the reflectance rates was expected more rapidly due to the natural ageing process of the materials, caused by the accumulation of soils, causing over time a reversal in the reflectance indices measured initially.

For painted mortar, a better performance was observed due to the maintenance of the reflectance. After 16 months of exposure, the painted surface, due to the smoother surface, less roughness and less permeability to water penetration resulted in less soil retention and less microorganisms growth. For mortar with TiO2 addition, after exposure, even when a photocatalytic process was observed, there was still a greater impregnation of soil on the specimens' surfaces, affecting the reflectance indices directly. As for the unpainted mortar without TiO2, the behaviour followed the deterioration pattern for surfaces that did not receive any type of previous treatment and are more prone to actions of time.

Concerning the decay rate of performance, in general, the decrease in the performance of the mortar, i.e., when considering the beginning and the end of the experiment, the following results are obtained: type "A" mortar reached 83% of their initial performance (final reflectance 57); type "B" mortar reached a plateau of 84% in their initial performance (final reflectance 65); types "C" and "D" reached a level of 86% each one (final reflectance 59 and 60) and type "E" reached a level of 75% of its initial value (final reflectance 54). According to these values, it can be evaluated that, except for type "E" mortar, the percentages indicate that the performance decay process is very similar to all the other specimens.

Although they remain more stable in relation to the reflectance, the observations made over the last five months also seem to indicate that type "B" mortar has less change in this property than the others. Considering the variation in terms of percentage points in the reflectance indices, it can be observed that while the other mortar fell from 4 to 6 points in their indices, type "B" fell 10 points. This new configuration may indicate that over time painted mortar tends to match the others, as the other mortar seems to have reached a stability plateau or at least lower decay rates.

Regarding the TiO2 concentrations used, it was observed that except for the last five months of the experiment, as well as what occurred for the reflectance indices, the different contents used showed a slight change, presenting very similar results. When the TiO2 contents used in relation to the reflectance were evaluated, the results showed that there was an improvement in the indices from 1% to 5% of TiO2. Considering this improvement in the reflectance results with an increase in the dosage from 1% to 5%, it was expected that another increase from 5% to 10% could present even better results, but this phenomenon was not observed. Considering the application conditions and the grain size characteristics of the type of TiO2 used, the reason for these worse results for the mortar with 10% TiO2 can be associated with the low concentration of the material on the surfaces of the mortar caused by a dispersion problem. Thus, it is considered that the behaviour presented by the mortar with 10% content is associated to a high number of relatively large particles, which caused a scattering problem and the formation of TiO2 agglomerates in mortar; the presence of higher porosity; low distribution of active sites and a high concentration of inorganic components on the surfaces.

Concerning the fluctuations in the indices, the studies indicate that this behaviour seems to be associated with rainfall as the mortar showed behaviour that was not consistent with the hypothesis pointed out mainly for mortar with TiO2 addition. Crossing the information from the average reflectance graph with the rainfall indices obtained from the DAEE observation stations, the E3-145 / CTH Prefixes (University City) and E3-035 / IAG (USP Observatory) show the rainfall effect of the indices, observed in Figure 9.

In Figure 9, the variations of the reflectance indices in the months of high rainfall indices can be observed, and the specimens were coated or not with the mortar with TiO2 addition. Therefore, it can be considered that in 2014, the lack of rainfall and the increase in the concentration of pollutants in the atmosphere in São Paulo, which was expected to be precisely a contrast, contributed significantly to the greater accumulation of dirt on the specimens, making it difficult to clean during the few days of rainfall.

As the reflectance to solar radiation normally has higher indices on a smoother surface, it is believed that for type "A", "C", "D" and "E" specimens, the reflectance indices found are results of surfaces with greater roughness. This phenomenon, however, was not observed in type "B" mortar, which presented a less rough surface to the naked eye and posterior electron microscopy, possibly due to the coating provided by using the paint, thus avoiding possible losses of aggregates, and also performing the pore cover, increasing its reflectance indices. Therefore, the results indicated lead to the conclusion that, for the experiment, the indicated concentration for the good spreading of the compound and the triggering of photocatalytic processes, which could directly influence the reflectance measurements, is the addition of 5% of TiO2, in relation to the total mass of the dry premix. Moreover, this concentration (from the tests carried out) is the one that presented the best performance.

COLOUR COORDINATES OF SPECIMENS

For the study, the images of the control group after the 16-month experiment showed that the original white colour of the mortar was not maintained. However, the visual and instrumental evaluation showed that this mortar did not have the same wear presented by the mortar from the other groups, since it was covered most of the time. The colours of the mortar from the control group can be observed in Figure 10.

The observation of the images from Group 1 shows the difference of shades between the painted mortar and the others in the first six months of exposure. For the type "A" mortar, the beginning of the process of displacement of the mortar can be observed for the same period of exposure. For the type "E" mortar, the images show that after 1 year of exposure, the mortar is quite dirty and has white spots at different points of the specimens. In the case of the type "C" and "D" specimens, a very similar colour loss process was observed, presenting very similar behaviour regarding the colour variation of their surfaces. The colour variations can be seen in Figure 11.

Except for the type "A" specimen in Group 1, the other phenomena seem to be very similar for the mortar in Groups 2 and 3. Similarly, after twelve months of exposure, the type "E" mortar was more impregnated with dirt than the others and had white patches on the surfaces of the specimens. The colour variations can be seen in Figures 12 and 13.

For instrumental evaluation of the colour loss of the mortar, CIELAB measurements were used. The results are presented in Tables 4 to 7 and confirm what was visually observed in the images. The reference values considered for the original white colour of the mortar are presented in Table 4. Values after 16 months of exposure to the natural weathering group presented conditions, as follows: Group 1 (Table 5), Group 2 (Table 6) and Group 3 (Table 7).

If the thresholds proposed by Souza (2009)SOUZA, R. C. C. de. Avaliação de Imagens Através de Similaridade Estrutural e do Conceito de Mínima Diferença de Cor Perceptível. Rio de Janeiro, 2009. 117 f. Dissertação (Mestrado em Engenharia Eletônica, Sistemas Inteligentes e Automação) - Universidade do Estado do Rio de Janeiro, Rio de Janeiro, 2009. were adopted as a reference base and were compared with the results of the colour component for the white colour (∆L*) obtained through CIELAB, it could be concluded that all the specimens had changed their colours when compared to the control group. However, this change occurred very differently for each type of mortar. Taking the mean of the values of ∆L*, the following values of the white colour loss per type of mortar are in descending order: "E" (14.4); "A" (13.5); "D" (6.77); "C" (5.40); "B" (2.87) CIELAB units. According to the CIELAB units lost by each mortar, the "B" type specimens were the only ones that remained within a tolerance for a supra JND difference. Mortar from types "C" and "D" according to the JND bands showed significant differences in colour. Type "A" and "E" mortar presented values that are more distant from the original colour. Thus, based on the numbers found, it is considered that:

-

both the visual evaluation based on the images and the results obtained by the instrumental measurements indicate that the type "B" mortar has the most characteristics of the original colour;

-

type "C" and "D" specimens were the ones that remained more stable according to the range presented for the Just Noticeable Difference (JND); and

-

type "A" and "E" specimens were the ones that showed the greatest differences in the original colour according to the JND reference.

Final Considerations

The research presented studies on the efficiency of adding TiO2 to coating mortar, aiming to maintain its initial characteristics in terms of reflectance to solar and light radiation. Results showed that type "B" mortar (0% TiO2 painted) performed better regarding maintaining the reflectance. After 16 months of exposure, the painted surfaces resulted in smoother surfaces, with less roughness and less permeability to water, therefore with less possibility for soil retention and development of microorganisms. For mortar with TiO2 addition, even adopting the photocatalytic process, after the period of exposure, there was still more impregnation of dirt on the surface of specimens that directly affected the reflectance indices. As for "A" type (0% TiO2 unpainted) mortar, the behaviour followed the natural ageing pattern for surfaces that did not receive any previous treatment, such as water repellent or paint which are more prone to actions of time.

Regarding maintaining the colour of the mortar, the measurements showed that the maintenance of the primary white colour occurred in a different way. Considering the visual evaluation and the results obtained from the CIE L* a* b* colorimetric system, the indices show that the type "B" mortar (0%TiO2 painted) presented less dirt and better maintenance of its initial characteristics; the type "C" (1%TiO2) and type "D" (5% TiO2) unpainted mortars presented medium results; the type "A" (0%TiO2) and type "E" (10% TiO2) unpainted mortars showed greater differences between their initial colours, according to the Just Noticeable Difference (JND) range caused by dirt pick up.

Acknowledgements

We woud like to thank the São Paulo Research Foundation (Fundação de Amparo à Pesquisa do Estado de São Paulo - FAPESP), Cristal Pigmentos do Brasil and Ibratin industria e Comércio Ltda for their support to this research.

References

- ALCHAPAR, N. L.; CORREA, E. N.; CANTÓN, M. A. Índice de Reflectancia Solar de Revestimentos Verticales: potencial para la mitigación de la isla de calor urbana. Ambiente Construído, Porto Alegre, v. 12, n. 3, p.107-123, jul./sept. 2012.

- AMERICAN SOCIETY FOR TESTING AND MATERIAL. D2244-16: standard practice for calculation of color tolerances and color differences from instrumentally measured color coordinates. West Conshohocken, 2016.

- AMERICAN SOCIETY FOR TESTING AND MATERIAL. E1918-06: standard test method for measuring solar reflectance of horizontal and low-sloped surfaces in the field. West Conshohocken, 2015.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 15077: tintas para construção civil: método para avaliação de desempenho de tintas para edificações não industriais: determinação da cor e da diferença de cor por medida instrumental. Rio de Janeiro, 2004.

- AMERICAN SOCIETY OF HEATING AND AIR-CONDITIONING ENGINEERS. ANSI/ASHRAE 74: method for measuring solar-optical properties of materials, procedure E. Atlanta, 1988.

- BELLAN, L. M.; SALMON, L. G.; CASS, G. R. A Study on the Human Ability to Detect Soot Deposition Onto Works of Art. Environmental Science and Technology, 2000; v. 34, p. 1946-1952, 2000.

- CENTRO MULTIDISCIPLINAR PARA O DESENVOLVIMENTO DE MATERIAIS CERÂMICOS. Pigmentos Disponível em: <http://www.cmdmc.com.br/pesquisa/pigmentos/page2.php>. Acesso em: 16 abr. 2017.

» http://www.cmdmc.com.br/pesquisa/pigmentos/page2.php - CHEN, J.; POON, C. Photocatalytic Construction and Building Materials: from fundamentals to applications. Building and Environment, v. 44, p. 1899-1906, jan. 2009.

- DANTAS, S. R. A. A Eficácia da Adição do TiO2 em Argamassas Quanto à Manutenção das Condições Iniciais em Termos da Sua Refletância à Radiação Solar São Paulo, 2016. 137 f. Dissertação (Mestrado Profissional) - Instituto de Pesquisas Tecnológicas do Estado de São Paulo, São Paulo, 2016.

- DANTAS, S. R. A.; VITTORINO, F. A Eficácia da Adição do TiO₂ em Argamassas Quanto à Manutenção das Condições Iniciais em Termos da Sua Refletância à Radiação Solar. In: ENCONTRO NACIONAL DE TECNOLOGIA DO AMBIENTE CONSTRUÍDO: DESAFIOS E PERSPECTIVAS DA INTERNACIONALIZAÇÃO DA CONSTRUÇÃO, 16., São Paulo, 2016 . Anais... São Paulo: ANTAC, 2016.

- DIAMANTI, M. V. et al Photocatalytic and Self-Cleaning Activity of Colored Mortar Containing TiO2 Construction And Building Materials, v. 46, p.167-174, Sept. 2013.

- FUJISHIMA, A.; RAO, T. N.; TRYK, D. A. Titanium Dioxide Photocatalysis. Journal of Photochemistry and Photobiology C: Photochemistry Reviews 1, p. 1-21, Mar. 2000.

- JOHNSTON, W. M.; KAO, E. C. Assessment of Appearance Match by Visual Observation and Clinical Colorimetry. Journal of Dental Research, Ohio, p. 819-822, May 1989.

- LA RUSSA, M. F. et al Multifunctional TiO2 Coatings for Cultural Heritage. Progress in Organic Coatings, v. 74, n. 1, p. 186-191, May 2012.

- LUVIDI, L. et al Application of TiO2 Based Coatings on Stone Surfaces of Interest in the Field of Cultural Heritage. In: FERRARI, A. (Ed.). INTERNATIONAL CONGRESS SCIENCE AND TECHNOLODY FOR THE SAFEGUARD OF CULTURAL HERITAGE IN THE MEDITERRANEAN BASIN, 4., Napoli, 2010. Proceedings... Napoli: Grafica Elettronica, 2010.

- MARANHÃO, F. L. Método Para Redução de Mancha nas Vedações Externas de Edifícios São Paulo, 2009. 107 f. Tese (Doutorado em Engenharia Civil) - Escola Politécnica, Universidade de São Paulo, São Paulo, 2009.

- MELO, J. V. S. de, Desenvolvimento de Peças Pré-Moldadas de Concreto Fotocatalíticas Para Pavimentação e Purificação do Ar Florianópolis, 2011. 208 f. Dissertação (Mestrado em Engenharia Civil) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal de Santa Catarina, Florianópolis, 2011.

- MUNAFÒ, P.; GOFFREDO, G. B.; QUAGLIARINI, E. TiO2-Based Nanocoatings for Preserving Architectural Stone Surfaces: an overview. Construction And Building Materials, v. 84, p. 201-218, jun. 2015.

- NOGUEIRA, R. F. P.; JARDIM, W. F. A Fotocatálise Heterogênea e Sua Aplicação ambiental. Química Nova, Campinas, v. 21, n. 1, p.69-72, jan. 1998.

- PEREIRA, M. A. C.; TORGAL, F. P.; JALALI, S. Capacidade de Auto-Limpeza de Argamassas Contendo Dióxido de Titânio (TiO2). In: CONGRESSO NACIONAL DE ARGAMASSAS DE CONSTRUÇÃO, 3., Lisboa, 2010. Proceedings... Lisboa, 2010.

- PÉREZ-LOMBARD, L.; ORTIZ, J.; POUT, C. A Review on Buildings Energy Consumpto Information. Energy and Buildings Sevilha, 2007. p. 394-398. Available at: <http://www.esi2.us.es/∼jfc/Descargas/ARTICULOS/PAPER_LPL_1_OFF-PRINT.pdf>. Accessed on: 18 Dec. 2015.

» http://www.esi2.us.es/∼jfc/Descargas/ARTICULOS/PAPER_LPL_1_OFF-PRINT.pdf - PINHO, L.; MOSQUERA, M. J. Photocatalytic Activity of TiO2-SiO2 Nanocomposites Applied to Buildings: influence of particle size and loading. Applied Catalysis B: Environmental, v. 134-135, p.205-221, May, 2013.

- POON, C.; CHEUNG, E. No Removal Efficiency of Photocatalytic Paving Blocks Prepared with Recycled Materials. Construction And Building Materials, v. 21, p. 1746-1753, 2007.

- SANTAMOURIS, M; SYNNEFA, A; KARLESSIET, T. Using Advanced Cool Materials in the Urban Built Environment to Mitigate Heat islands and improve thermal comfort conditions. Solar Energy, v. 85, n. 12, p. 3085-3102, 2011.

- SEKER, D. Z.; TAVIL, A. U. Evaluation of Exterior Building Surface Roughness Degrees by Photogrammetric Methods. Building and Environment, v. 31, p. 393-398, 1996.

- SOUZA, R. C. C. de. Avaliação de Imagens Através de Similaridade Estrutural e do Conceito de Mínima Diferença de Cor Perceptível Rio de Janeiro, 2009. 117 f. Dissertação (Mestrado em Engenharia Eletônica, Sistemas Inteligentes e Automação) - Universidade do Estado do Rio de Janeiro, Rio de Janeiro, 2009.

Publication Dates

-

Publication in this collection

Jul-Sep 2017

History

-

Received

28 Nov 2016 -

Accepted

06 Mar 2017

Source:

Source:

Source:

Source: Source:

Source: Source:

Source:

Source:

Source:

Source:

Source:

Source:

Source:

Source:

Source:

Source:

Source: Source:

Source: Source:

Source: Source:

Source: Source:

Source: