Abstract

Current production and quality control activities performed on-site are based either on manual procedures or on different automatic data collection technologies. A major problem in these controls is that they are often applied in isolation. Therefore, there are opportunities for improving the performance of construction projects by integrating quality and production control systems supported by digital systems and considering concepts and principles from Lean Philosophy. This article describes a conceptual framework that make it possible to integrate production and quality control in construction sites, considering the combination of BIM and the Last Planner System™ (LPS). This investigation was based on two empirical studies, carried out in companies that develop and build residential building projects. The main contribution of the study is the ability of the model to surpass the limitations of commercial software available to cope with the flexibility demanded by LPS. The results indicated that the proposed framework enables timely feedback to be provided to production managers, and BIM models to be quickly updated with progress monitoring and product quality data.

Keywords:

Production control; Quality control; Product model; Process model; Construction phase; BIM; Last Planner; Lean construction

Resumo

As atividades de controle de produção e qualidade realizadas no canteiro de obras são baseadas em procedimentos manuais ou em diferentes tecnologias de coleta automática de dados. Um grande problema é esses controles são muitas vezes aplicados de forma isolada. Existem oportunidades para melhorar o desempenho das obras, integrando sistemas de controle de qualidade e produção utilizando sistemas digitais e considerando conceitos e princípios da Produção Enxuta. Este artigo descreve uma estrutura conceitual que possibilita a integração da produção e do controle de qualidade em canteiros de obras, considerando a combinação do BIM e do Last Planner System™ (LPS). Esta pesquisa baseou-se em dois estudos empíricos, realizados em empresas que desenvolvem e constroem projetos de edifícios residenciais. A principal contribuição do estudo é a capacidade o modelo proposto de superar as limitações dos softwares comerciais disponíveis para fazer frente à flexibilidade exigida pelo LPS. Os resultados indicaram que a estrutura conceitual proposta permite que um feedback oportuno seja fornecido aos gerentes de produção e que os modelos BIM sejam rapidamente atualizados com monitoramento do progresso e dados de qualidade do produto.

Palavras-chave:

Controle de produção; Controle de qualidade; Modelo do produto; Modelo de processo; Fase de construção; BIM; Last Planner; Construção enxuta

Introduction

Construction industry has been considered as a traditional, conservative, and slow to change industry in comparison to the other sectors (TEICHOLZ; GOODRUM; HAAS, 2001TEICHOLZ, P.; GOODRUM, P. M.; HAAS, C. T. U. S. Construction Labor Productivity Trends, 1970-1998. Journal of Computer Civil Engineering, v. 127, p. 427-429, 2001.; BOWDEN et al., 2005BOWDEN, S. et al. Making the case for mobile IT in construction. Journal of Computing in Civil Enginnering, p. 1-12, 2005.; NAVON; SACKS, 2007NAVON, R.; SACKS, R. Assessing research issues in Automated Project Performance Control (APPC). Automation in Construction , v. 16, p. 474-484, 2007.). In order to improve construction performance, academics and practitioners have been trying to translate principles and practices from lean production into the context of the construction industry since the early nineties. Under the name of lean construction, this effort has resulted in significant performance improvements in terms of productivity and quality (KOSKELA, 1992KOSKELA, L. Application of the new philosophy to construction. Salford: Center for Integrated Facility Engineering, 1992.).

The Last Planner System™ (LPS), initially proposed by Ballard and Howell (1998)BALLARD, G.; HOWELL, G. Shielding production: essential step in production control. Journal of Construction Engineering and Management,v. 124, p. 11-17, 1998. and Ballard (2006)BALLARD, G. Rethinking project definition in terms of target costing. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 14., Fortaleza, 2006. Proceedings [...] Fortaleza, 2006. , is probably one of the most well-known contributions to adapt lean production to project-based production systems as the construction industry, promoting production stability, improving production workflow, and reducing waste (BALLARD; TOMMELEIN, 2021)BALLARD, G.; TOMMELEIN, I. Current proccess benchmark for the Last Planner™ System of project planning and control. Berkeley: University of California, Project Production Systems Laboratory (P2SL), 2021..

Originally aimed at planning and controlling production in construction projects, the LPS has been challenged to consider other dimensions of project performance, such as quality management. Poor integration between production and quality control is a common problem in construction sites, as illustrated by the lack of timely identification of defects (AKINCI et al., 2006AKINCI, B. et al. A formalism for utilization of sensor systems and integrated project models for active construction quality control. Automation in Construction, v. 15, p. 24-138, 2006.) and repetition of defective work (MAROSSZEKY et al., 2002MAROSSZEKY, M. et al. Quality management tools for lean production-moving from enforcement to empowerment. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 10., Gramado, 2002. Proceedings [...] Gramado, 2002.).

Site monitoring activities demand large and intensive computational support (REINHARDT; AKINCI; GARRETT, 2004REINHARDT, J.; AKINCI, B.; GARRETT, J. H. Navigational models for computer supported project management tasks on construction sites. Journal of Computer Civil Engineering, v. 18, p. 281-290, 2004.; CHEN; KAMARA, 2008CHEN, Y.; KAMARA, J. M. Using mobile computing for construction site information management. Engineering, Construction and Architectural Management, v. 15, n. 1, p. 7-20. Jan. 2008. ; LEÃO; FORMOSO; ISATTO, 2014LEÃO, C. F.; FORMOSO, C. T.; ISATTO, E. L. Integrating Production and Quality Control with the Support of Information Technology. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 22., Oslo, 2014. Proceedings [...] Oslo, 2014.). The integration of quality and production control in LPS suffers from the same problem, due to the large amount of data involved, as well as the significant effort on data collection (LEÃO; FORMOSO; ISATTO, 2014LEÃO, C. F.; FORMOSO, C. T.; ISATTO, E. L. Integrating Production and Quality Control with the Support of Information Technology. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 22., Oslo, 2014. Proceedings [...] Oslo, 2014.).

Synergies between lean construction and Building Information Modeling (BIM) have been suggested by several researchers (DAVE; BROODY; KOSKELA, 2011DAVE, B.; BODDY, S.; KOSKELA, L. Visilean: designing a production management system with lean and BIM. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 19., Lima, 2011. Proceedings [...] Lima, 2011.; SACKS; TRECKMANN; ROZENFELD, 2009SACKS, R.; TRECKMANN, M.; ROZENFELD, O. Visualization of work flow to support Lean construction. Journal of Construction Engineering and Management, v. 135, p. 1307-1315, 2009.; DAVE, 2013DAVE, B. Developing a construction management system based on lean construction and Building Information Modelling. England, 2013. (Doctoral Dissertation) - University of Saldford Manchester, England, 2013. ; SACKS et al., 2013)SACKS, R. et al. KanBIM workflow management system: prototype implementation and field testing. Lean Construction Journal, p. 19-35, 2013.. According to Sacks, Treckmann and Rozenfeld (2009SACKS, R.; TRECKMANN, M.; ROZENFELD, O. Visualization of work flow to support Lean construction. Journal of Construction Engineering and Management, v. 135, p. 1307-1315, 2009.), the joint use of both combines the strengths of a digital representation of construction outcome and the work involved in its production, thus facilitating and supporting site monitoring activities (SACKS; TRECKMANN; ROZENFELD, 2009SACKS, R.; TRECKMANN, M.; ROZENFELD, O. Visualization of work flow to support Lean construction. Journal of Construction Engineering and Management, v. 135, p. 1307-1315, 2009.).

Many initiatives have been taken in order to combine the use of BIM and the LPS for production planning and control, also seeking for more efficient and feasible solutions for data collection on construction sites (KOPSIDA; BRILAKIS; VELA, 2015KOPSIDA, M.; BRILAKIS, I.; VELA, P. A review of automated construction progress and inspection methods. In: CIB W78 CONFERENCE CONTRUCTION, 32., Eindhoven, 2015. Proceedings […] Eindhoven, 2015.; HEIGERMOSER et al., 2019HEIGERMOSER, D. et al. BIM-based Last Planner System tool for improving construction project management. Automation in Construction , v. 104, p. 246-254, 2019. ). However, these focus on production planning and control and progress monitoring, without an explicit considering the need for an appropriate data representation for implementing production and quality control in an integrated environment. On the one hand, LPS does not explicitly include formal procedures for quality control, relying on existing quality management systems to ensure the quality of completed work packages. On the other hand, quality control with BIM has been mostly targeted to the design coordination (LEITE, 2020LEITE, F. BIM for Design Coordination. Hoboken: Wiley, 2020.), or to the assessment of product geometry and dimensional tolerances (HARTMANN; GAO; FISCHER, 2008HARTMANN, T.; GAO, J; FISCHER, M. Areas of application for 3D and 4D models on construction projects. Journal of Construction Engineering and Management , v. 134, n. 10, p. 776-785, 2008.).

Moreover, another limitation of existing software is concerned with the definition of operational (weekly) work packages, which is often used as a basic unit of control. Previous research has addressed the connection between the BIM model and LPS plans by increasing the granularity of the master plan work packages, which would include an extensive list of operational tasks organized in a comprehensive WBS (RODRIGUES et al., 2018RODRIGUES, P. B. de F. et al. Uma proposta de integração do modelo BIM ao sistema last planner. Ambiente Construído , Porto Alegre, v. 18, n. 4, p. 301-317, oct./dec. 2018.). Although this strategy has proved to be successful in integrating BIM models and LPS plans, it does not support the decomposition of work packages from the master plan to the operational level (BALLARD; TOMMELEIN, 2021BALLARD, G.; TOMMELEIN, I. Current proccess benchmark for the Last Planner™ System of project planning and control. Berkeley: University of California, Project Production Systems Laboratory (P2SL), 2021.; HEIGERMOSER et al., 2019HEIGERMOSER, D. et al. BIM-based Last Planner System tool for improving construction project management. Automation in Construction , v. 104, p. 246-254, 2019. ). Applications that implement LPS are required to be flexible enough to adjust the work package content according to the operational level needs, or even to include unplanned work packages that have been executed by the workers (FIREMAN; FORMOSO; ISATTO, 2013FIREMAN, M. C. T.; FORMOSO, C. T.; ISATTO, E. L. Integrating production and quality control: monitoring making-do and informal work packages. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 21., Fortaleza, 2013. Proceedings [...] Fortaleza, 2013.; LEÃO; FORMOSO; ISATTO, 2014LEÃO, C. F.; FORMOSO, C. T.; ISATTO, E. L. Integrating Production and Quality Control with the Support of Information Technology. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 22., Oslo, 2014. Proceedings [...] Oslo, 2014.).

This research study proposes a conceptual framework that consists of a product-process model that can be used to integrate production and quality control on construction sites. This model was devised considering the combined use of BIM and LPS. As a secondary contribution, this study proposes a method for data collection and analysis, including the structure and representation of production and quality data. This model makes it possible to surpass limitations of available commercial software to cope with the flexibility demanded by LPS work packages. The proposed model was implemented and assessed in two empirical studies, and there is evidence that it is a useful and applicable alternative to provide timely feedback to production managers, as well as to keep the BIM model updated with progress monitoring and product quality information.

Background

Data structure requirements for integrating production and quality control

The influence of quality control over production stability is well known (VAN DER BIJ; VAN ECKERT, 1999VAN DER BIJ, H.; VAN EKERT, J. H. W. Interaction between production control and quality control. International Journal of Operation and Production Management, v. 19, p. 674-690, 1999.). If tasks are inspected by quality control while they are being executed, defects may be corrected on time, preventing propagation of problems to subsequent tasks (MAROSSZEKY et al., 2002MAROSSZEKY, M. et al. Quality management tools for lean production-moving from enforcement to empowerment. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 10., Gramado, 2002. Proceedings [...] Gramado, 2002.; FIREMAN; FORMOSO; ISATTO, 2013FIREMAN, M. C. T.; FORMOSO, C. T.; ISATTO, E. L. Integrating production and quality control: monitoring making-do and informal work packages. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 21., Fortaleza, 2013. Proceedings [...] Fortaleza, 2013.). Despite the quality management systems in construction projects, product quality is still a major concern regarding project delivery costs and customer satisfaction (LEÃO; FORMOSO; ISATTO, 2014LEÃO, C. F.; FORMOSO, C. T.; ISATTO, E. L. Integrating Production and Quality Control with the Support of Information Technology. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 22., Oslo, 2014. Proceedings [...] Oslo, 2014.).

Akinci et al. (2006)AKINCI, B. et al. A formalism for utilization of sensor systems and integrated project models for active construction quality control. Automation in Construction, v. 15, p. 24-138, 2006. points out that an active project quality control implies identifying critical spatial-temporal and material quality related deviations of the work in place and assessing whether these deviations constitute defects during construction projects. These require frequent, complete, and accurate assessments of the status of as-built conditions at construction sites.

Nonetheless, the poor integration between production and quality assessment still poses a major problem for production management in construction (ARENTSEN; TIEMERSMA; KALS, 1996ARENTSEN, A. L.; TIEMERSMA, J.; KALS, J. The integration of quality control and shop floor control. International Journal of Computer Integrrated Manufacturing, v. 9, p. 113-130, 1996.; VAN DER BIJ; VAN ECKERT, 1999VAN DER BIJ, H.; VAN EKERT, J. H. W. Interaction between production control and quality control. International Journal of Operation and Production Management, v. 19, p. 674-690, 1999.; LEÃO; FORMOSO; ISATTO, 2014LEÃO, C. F.; FORMOSO, C. T.; ISATTO, E. L. Integrating Production and Quality Control with the Support of Information Technology. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 22., Oslo, 2014. Proceedings [...] Oslo, 2014.; LEÃO; ISATTO; FORMOSO, 2016LEÃO, C. F.; ISATTO, E. L.; FORMOSO, C. T. Proposta de modelo para controle integrado da produção e da qualidade com apoio da computação móvel. Ambiente Construído, Porto Alegre, v. 16, n. 4, p. 109-124, out./dez. 2016.). Quality controls are usually performed independently of production planning and control (LEÃO; FORMOSO; ISATTO, 2014LEÃO, C. F.; FORMOSO, C. T.; ISATTO, E. L. Integrating Production and Quality Control with the Support of Information Technology. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 22., Oslo, 2014. Proceedings [...] Oslo, 2014.), resulting in waste and rework (FIREMAN; FORMOSO; ISATTO, 2013FIREMAN, M. C. T.; FORMOSO, C. T.; ISATTO, E. L. Integrating production and quality control: monitoring making-do and informal work packages. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 21., Fortaleza, 2013. Proceedings [...] Fortaleza, 2013.).

According to Chen and Luo (2014)CHEN, L.; LUO, H. A BIM-based construction quality management model and its applications. Automation in Construction , v. 46, p. 64-73, 2014., there are three main difficulties in integrating quality and production controls in construction:

-

scattering of quality criteria in different norms and procedures;

-

contractual and procedural construction complexities; and

-

controls that place the attention on final components rather than on the execution processes.

Therefore, the integration of production and quality control would require a formal data representation capable of combining in a single data schema the relevant production and quality information entities (LEÃO; FORMOSO; ISATTO, 2014LEÃO, C. F.; FORMOSO, C. T.; ISATTO, E. L. Integrating Production and Quality Control with the Support of Information Technology. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 22., Oslo, 2014. Proceedings [...] Oslo, 2014.).

Leão, Isatto and Formoso (2016)LEÃO, C. F.; ISATTO, E. L.; FORMOSO, C. T. Proposta de modelo para controle integrado da produção e da qualidade com apoio da computação móvel. Ambiente Construído, Porto Alegre, v. 16, n. 4, p. 109-124, out./dez. 2016. proposed a model to integrate quality control into the Last Planner System™ (LPS) aiming to reduce the time between detection and correction of quality problems and avoiding the propagation and aggravation of defects. This model combines the use of mobile devices for data collection with a formal data representation to reduce the effort involved in data collection and processing (Figure 1).

As shown in Figure 1, the data schema comprises three groups of entities:

-

production management;

-

quality management; and

-

work package structuring.

An important contribution of that research work is that the integration between quality and production is based on the work package structuring, which are briefly described in Figure 1. Therefore, the way in which LPS breaks down the project into work packages and assigns it to specific crews plays a key role in the implementation of the model.

The Generic Work Package (GWP) consists of a work package defined for a generic element (e.g., installing openings of a house). A batch is an instantiation of one or more generic elements (e.g., houses 104 and 105). A Specific Work Package (SWP) is the instantiation of a GWP to a specific batch (e.g., installing openings for houses 104 and 105).

According to the production part of the schema, a weekly plan is a collection of SWPs, each of them assigned to a specific crew. It can also be associated with making-do situations and causes of non-completion.

Regarding quality management, quality attributes (QA) are associated with GWPs by means of product or process specifications. Every QA requires a corresponding quality control procedure, which instructs how to assess the product or process quality according to that attribute. A quality inspection results in a quality record (QR), which corresponds to the instantiation of a QA in relation to a particular SWP.

One important contribution of that research work is that the integration between quality and production relies on the work package structuring. Therefore, the way in which LPS breaks down the project into work packages and assigns it to specific crews plays a key role in the implementation of the model.

Even not explicitly considered, a connection between such schema and a BIM model is possible by means of the instance and batch entities, corresponding to the elements or set of elements of the BIM product model. All the other entities of the schema have to be implemented outside the BIM model, e.g., in a relational database.

Therefore, those previous studies suggest that the combination of BIM and LPS for the sake of integration of production and quality management would need to consider both product and process models.

Product and process models

The use of product and process models to represent construction project information has been discussed since the early stages of BIM development (STUMPF et al., 1996STUMPF, A. L. et al. Object-oriented model for integrating construction product and process information. Journal of Computer Civil Engineering , v. 10, p. 204-212, 1996.; FROESE et al., 1999FROESE, T. et al. Industry foundation classes for project management: a trial implementation. Journal of Information Technology in Construction, v. 4, p. 17-36, 1999.; REINHARDT; AKINCI; GARRET, 2004REINHARDT, J.; AKINCI, B.; GARRETT, J. H. Navigational models for computer supported project management tasks on construction sites. Journal of Computer Civil Engineering, v. 18, p. 281-290, 2004.; REINHARDT; GARRET; AKINCI, 2005REINHARDT, J.; GARRETT, J. H.; AKINCI, B. Framework for providing customized data representations for effective and efficient interaction with mobile computing solutions on construction sites. Journal of Computer Civil Engineering , v. 19, p. 109-118, 2005.). According to Stumpf et al. (1996)STUMPF, A. L. et al. Object-oriented model for integrating construction product and process information. Journal of Computer Civil Engineering , v. 10, p. 204-212, 1996., product models are conceptual structures used to organize and communicate building product information among project participants, while process models represent important steps throughout a project life cycle stages (i.e., design, construction, facility operations) (STUMPF et al., 1996STUMPF, A. L. et al. Object-oriented model for integrating construction product and process information. Journal of Computer Civil Engineering , v. 10, p. 204-212, 1996.). The product-process model paradigm is a cornerstone of the Industry Foundation Classes (IFC) schema, implemented in every BIM model.

Both product and process information can be combined into a single model, based on relationships associating building components (product information) to construction tasks (process information) (STUMPF et al., 1996STUMPF, A. L. et al. Object-oriented model for integrating construction product and process information. Journal of Computer Civil Engineering , v. 10, p. 204-212, 1996.; REINHARDT; AKINCI; GARRET, 2004REINHARDT, J.; AKINCI, B.; GARRETT, J. H. Navigational models for computer supported project management tasks on construction sites. Journal of Computer Civil Engineering, v. 18, p. 281-290, 2004.). The resulting model can be rendered into one or more visual representations (REINHARDT; GARRET; AKINCI, 2005REINHARDT, J.; GARRETT, J. H.; AKINCI, B. Framework for providing customized data representations for effective and efficient interaction with mobile computing solutions on construction sites. Journal of Computer Civil Engineering , v. 19, p. 109-118, 2005.), thus supporting many control activities such as progress monitoring, and quality control.

Previous studies have explored the possible advantages of integrating product and process models for information management in the construction phase (STUMPF et al., 1996STUMPF, A. L. et al. Object-oriented model for integrating construction product and process information. Journal of Computer Civil Engineering , v. 10, p. 204-212, 1996.; FROESE et al., 1999FROESE, T. et al. Industry foundation classes for project management: a trial implementation. Journal of Information Technology in Construction, v. 4, p. 17-36, 1999.; SACKS; TRECKMANN; ROZENFELD, 2009SACKS, R.; TRECKMANN, M.; ROZENFELD, O. Visualization of work flow to support Lean construction. Journal of Construction Engineering and Management, v. 135, p. 1307-1315, 2009.; DAVE; BODDY; KOSKELA, 2013DAVE, B.; BODDY, S.; KOSKELA, L. Challenges and opportunities in implementing lean and bim on an infrastructure project. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 21., Fortaleza, 2013. Proceedings [...] Fortaleza, 2013.; KOPSIDA; BRILAKIS; VELA, 2015KOPSIDA, M.; BRILAKIS, I.; VELA, P. A review of automated construction progress and inspection methods. In: CIB W78 CONFERENCE CONTRUCTION, 32., Eindhoven, 2015. Proceedings […] Eindhoven, 2015.). Stumpf et al. (1996)STUMPF, A. L. et al. Object-oriented model for integrating construction product and process information. Journal of Computer Civil Engineering , v. 10, p. 204-212, 1996. presented an object-oriented model that integrated product information (i.e., design components) and process information (i.e., production progress monitoring). Additionally, two prototype construction agents for planning and monitoring the construction process were developed (STUMPF et al., 1996STUMPF, A. L. et al. Object-oriented model for integrating construction product and process information. Journal of Computer Civil Engineering , v. 10, p. 204-212, 1996.).

Reinhardt, Akinci and Garret (2004)REINHARDT, J.; AKINCI, B.; GARRETT, J. H. Navigational models for computer supported project management tasks on construction sites. Journal of Computer Civil Engineering, v. 18, p. 281-290, 2004. proposed a navigational model that provided a flexible and dynamic way of grouping and structuring entities of product and process models. Entities that needed to be related to one task were linked directly to minimize navigation through a given model (REINHARDT; AKINCI; GARRET, 2004REINHARDT, J.; AKINCI, B.; GARRETT, J. H. Navigational models for computer supported project management tasks on construction sites. Journal of Computer Civil Engineering, v. 18, p. 281-290, 2004.). These navigational models also structured the data contained in product and process models in hierarchies, facilitating interaction with entities at multiple levels of detail (REINHARDT; AKINCI; GARRET, 2004REINHARDT, J.; AKINCI, B.; GARRETT, J. H. Navigational models for computer supported project management tasks on construction sites. Journal of Computer Civil Engineering, v. 18, p. 281-290, 2004.), by using labeled data sets that were organized in hierarchies and represented as tree structures instead of individual entities (REINHARDT; GARRET; AKINCI, 2005REINHARDT, J.; GARRETT, J. H.; AKINCI, B. Framework for providing customized data representations for effective and efficient interaction with mobile computing solutions on construction sites. Journal of Computer Civil Engineering , v. 19, p. 109-118, 2005.). Thus, construction managers can efficiently select large numbers of entities and enter information about, or access information from them (REINHARDT; GARRET; AKINCI, 2005REINHARDT, J.; GARRETT, J. H.; AKINCI, B. Framework for providing customized data representations for effective and efficient interaction with mobile computing solutions on construction sites. Journal of Computer Civil Engineering , v. 19, p. 109-118, 2005.).

Dave, Boddy and Koskela (2013)DAVE, B.; BODDY, S.; KOSKELA, L. Challenges and opportunities in implementing lean and bim on an infrastructure project. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 21., Fortaleza, 2013. Proceedings [...] Fortaleza, 2013. highlighted the importance of using parametric representations, with attributes and defined values for individual identification of objects in product models in order to effectively connect them to items or tasks in process models. Those authors also proposed the use of building object hierarchies in tree structures for facilitating the selection and linking of objects to tasks, which is aligned with one of the main features of the navigational model proposed by Reinhardt, Akinci and Garret (2004)REINHARDT, J.; AKINCI, B.; GARRETT, J. H. Navigational models for computer supported project management tasks on construction sites. Journal of Computer Civil Engineering, v. 18, p. 281-290, 2004..

Nonetheless, one of the most important benefits of product-process integration lies in providing richer semantics (STUMPF et al., 1996STUMPF, A. L. et al. Object-oriented model for integrating construction product and process information. Journal of Computer Civil Engineering , v. 10, p. 204-212, 1996.). According to Stumpf et al. (1996)STUMPF, A. L. et al. Object-oriented model for integrating construction product and process information. Journal of Computer Civil Engineering , v. 10, p. 204-212, 1996., a semantically rich information framework enables the development of computer systems that support life-cycle information management, and ultimately can provide better integration of management information, and improve the current practice of system integration in the construction industry.

BIM 4D modeling essentially consists of an association of BIM model components to corresponding production tasks. As the product-process model is a foundation of BIM models (FROESE et al., 1999FROESE, T. et al. Industry foundation classes for project management: a trial implementation. Journal of Information Technology in Construction, v. 4, p. 17-36, 1999.), it would be expected that such mapping would occur seamlessly. However, well-known difficulties that arise when developing BIM 4D model expose and challenge some implicit assumptions of such rationale.

Firstly, operational tasks are difficult to be anticipated in the long and medium term, which is the very reason why those tasks are left to be explicitly defined only at the LPS short- term planning level (commitment planning), based on current production conditions at that moment (BALLARD; HOWELL, 1998BALLARD, G.; HOWELL, G. Shielding production: essential step in production control. Journal of Construction Engineering and Management,v. 124, p. 11-17, 1998.). Secondly, the assumption of a one-to-one association between a task and its corresponding model element demands a strict synchronicity between the level of development (LOD) of BIM model elements and the granularity used to define work packages. This synchronicity is not compatible with the progressive nature of both work scheduling and product development (LEACH, 2000LEACH, L. P. Critical chain project management. Boston: Artech House Professional Development Library, 2000.; EASTMAN et al., 2011EASTMAN, C. M. et al. BIM Handbook: a guide to Building Information Modeling for owners, managers, designers, engineers, and contractors. 2nd . ed. Hoboken: John Wiley & Sons, 2011.). Finally, Fireman, Formoso and Isatto (2013)FIREMAN, M. C. T.; FORMOSO, C. T.; ISATTO, E. L. Integrating production and quality control: monitoring making-do and informal work packages. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 21., Fortaleza, 2013. Proceedings [...] Fortaleza, 2013. pointed out that operational tasks that are actually confirmed by production and quality control as completed may not have been included among the planned ones. Moreover, those situations, which may include rework packages or completion work packages may represent a relatively large share of tasks in execution (FIREMAN; FORMOSO; ISATTO, 2013FIREMAN, M. C. T.; FORMOSO, C. T.; ISATTO, E. L. Integrating production and quality control: monitoring making-do and informal work packages. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 21., Fortaleza, 2013. Proceedings [...] Fortaleza, 2013.; LEÃO; FORMOSO; ISATTO, 2014LEÃO, C. F.; FORMOSO, C. T.; ISATTO, E. L. Integrating Production and Quality Control with the Support of Information Technology. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 22., Oslo, 2014. Proceedings [...] Oslo, 2014.). Those situations confirm the need for a flexible definition of realistic construction activities and consideration of spatial requirements associated with construction as key problems for connecting BIM components and construction tasks at the operational level, as pointed out by Froese et al. (1999)FROESE, T. et al. Industry foundation classes for project management: a trial implementation. Journal of Information Technology in Construction, v. 4, p. 17-36, 1999..

Some studies on the integration of BIM with production control that relied on the use of commercial tools have been reported in the literature (DAVIES; HARTY, 2013DAVIES, R.; HARTY, C. Implementing ‘Site BIM’: a case study of ICT innovation on a large hospital Project. Automation in Construction , v. 30, p. 15-24, 2013.; MATTHEWS et al., 2015MATTHEWS, J. et al. Real time progress management: re-engineering processes for cloud-based BIM in construction. Automation in Construction , v. 58, p. 38-47, 2015.), but none of these provide the flexibility demanded by the LPS regarding the scope definition of work packages, nor consider the possibility of including unplanned work packages during data collection.

BIM-based systems have also been used for visual tracking activities on site, such as the ConBIM-SM system (TSERNG; HO; JAN, 2014TSERNG, H. P.; HO, S. P.; JAN, S. H. Developing BIM-assisted as-built schedule management system for general contractors. Journal of Civil Engineering and Management, v. 20, p. 47-58, 2014.). However, these authors reported many issues to be solved before this type of solution is applicable:

-

the high level LOD required for an adequate mapping of activities inside BIM;

-

the high computational requirements for information enrichment to BIM models inside a specific modeling software; and

-

the reluctance to adopt such a system by the site managers.

Some other commercial systems have added new features that are expected to provide additional support to implement lean principles and practices in BIM-based production environments, as BIM™ 360 Plan (AUTODESK, 2016AUTODESK. Lean Construction Planning Software | BIM 360 Plan. 2016. Available: Available: http://www.autodesk.com/products/bim-360-plan/overview . Access: Sep. 10th, 2017.

http://www.autodesk.com/products/bim-360...

) and Plexos (plexosproject.com). However, existing software solutions do not offer the same quality and richness of information as provided by the model proposed by Leão, Isatto and Formoso (2016)LEÃO, C. F.; ISATTO, E. L.; FORMOSO, C. T. Proposta de modelo para controle integrado da produção e da qualidade com apoio da computação móvel. Ambiente Construído, Porto Alegre, v. 16, n. 4, p. 109-124, out./dez. 2016. integrate the LPS and quality control.

Research method

Research strategy and research method outline

Design Science Research (DSR) was the methodological approach adopted in this study. DSR seeks to produce scientific knowledge in conjunction with the development of an artifact to solve classes of real problems (MARCH; SMITH, 1995MARCH, S. T.; SMITH, G. F. Design and natural science research on information technology. Decision Support System, v. 15, p. 251-266, 1995.; VAISHNAVI; KUECHLER, 2015VAISHNAVI, V.; KUECHLER, B. Design science research in information systems: overview of design science research. Available: http://desrist.org/desrist/content/design-science-research-in-information-systems.pdf. Access: Aug. 21, 2015.

http://desrist.org/desrist/content/desig...

). The artifact devised in this research is an integrated product and process model that combines BIM and LPS to support the integration between production and quality planning and control activities at the level of the construction site.

The artifact was developed through two empirical studies, both carried out in residential building projects built by two different companies. Study 1 was a 19,700 m² low-cost housing project built in the South of Brazil, while Study 2 was a 32,100 m² higher middle-class project built in the Northeast of Brazil. The durations of the studies were 8 and 16 weeks, respectively. Three criteria were considered in the choice of these companies: both had a mature implementation of the Last Planner System®, they have used BIM models in their projects, and they had a well-established quality management system. The empirical studies were carried out after that (i.e., the results of Study 1 were used to improve the model in Study 2).

The development and implementation of the proposed model were conducted by the research team, in parallel with the companies’ existing production and quality control routines. Due to constraints in terms of time and resources, production controls were limited to the short-term horizon of LPS, and the checklists used for quality inspections were based on the quality procedures adopted by each company.

Sources of evidence and data collection methods

The main sources of evidence used in this investigation were:

-

data from the existing planning and control systems;

-

participant observation during weekly planning meetings;

-

direct observation of the construction sites (including quality problems and visual devices); and

-

in-depth interviews performed with managerial staff.

An overview of the data collected during the research is presented in Table 1.

The interviews conducted with the managers and site staff of both companies gave important feedback on the proposed model and pointed out issues and challenges for the future. Data collection and analysis were carried out in weekly cycles, in both case studies. Data on the planned tasks were gathered at the LPS weekly planning meetings, when the tasks to be accomplished in the following week were defined. Then, the planned tasks were registered in the B3F system (see more information below) to prepare production data collection.

Data collection regarding production and quality controls was performed on a daily basis at the construction site. At the end of the week, and before the next weekly planning meeting, the collected data about production and quality was mapped back to the BIM model.

The results were presented to the managers every week, at the beginning of the weekly planning meetings, by means of reports and BIM model visualisations. The reports included some performance indicators used by the LPS (BALLARD; TOMMELEIN, 2021BALLARD, G.; TOMMELEIN, I. Current proccess benchmark for the Last Planner™ System of project planning and control. Berkeley: University of California, Project Production Systems Laboratory (P2SL), 2021.; FIREMAN; FORMOSO; ISATTO, 2013FIREMAN, M. C. T.; FORMOSO, C. T.; ISATTO, E. L. Integrating production and quality control: monitoring making-do and informal work packages. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 21., Fortaleza, 2013. Proceedings [...] Fortaleza, 2013.):

-

Percent Plan Complete (PPC): the ratio between the number of scheduled work packages completed and the total number of scheduled work packages;

-

Percentage of Planned Work Packages: the ratio between the number of scheduled work packages completed and the total number of observed work packages;

-

Percentage of Unplanned Work Packages: the ratio between the number of unplanned work packages completed and the total number of observed work packages;

-

Percentage of completed work packages that were approved in terms of quality (PPCQP), calculated for planned and unplanned work packages; and

-

Percentage of work packages that were concluded in time and approved in terms of quality (PPCQR), also calculated for planned and unplanned work packages.

Software infrastructure

The software infrastructure to implement long-term and medium-term levels of the conceptual framework did not represent a challenge, as it basically involves a 4D modeling workflow. However, as the short-term level links planning and execution, a number of issues had to be solved in order to adapt the software infrastructure to the information dealt with by LPS.

A preliminary assessment of existing software solutions led to the choice of Autodesk BIM 360™ Field (B3F) (Figure 2), a web-based application oriented for field data collection chosen due to the possibility of integrating production and quality data collection with the BIM model visualisation,

Along with B3F, Autodesk Navisworks Manage® was chosen to create the product sets that were linked to the work packages, as well as to display production and quality assessment as 4D simulations. The connection of the 4D model between Navisworks 4D and B3F also required another application from the B360 family, the BIM 360™ Glue.

Model evaluation

The model was evaluated according to two constructs: usefulness, and applicability. The first was evaluated based on the value perceived by construction managers from the production and quality assessment of construction activities; and the effectiveness in coordinating the use of BIM in the LPS weekly planning cycle. The latter was evaluated based on the effort involved in implementing the model by comparing the time spent in data collection and analysis with the time usually spent in the existing routine, and the perception of construction managers regarding the implementation cost.

The product-process model for integrated product and quality control

The proposed model is strongly based on the concept of the product-process model, borrowed from the navigational models proposed by Reinhardt, Akinci and Garret (2004)REINHARDT, J.; AKINCI, B.; GARRETT, J. H. Navigational models for computer supported project management tasks on construction sites. Journal of Computer Civil Engineering, v. 18, p. 281-290, 2004., previously discussed. Moreover, it also adapts the data schema proposed by Leão, Isatto and Formoso (2016)LEÃO, C. F.; ISATTO, E. L.; FORMOSO, C. T. Proposta de modelo para controle integrado da produção e da qualidade com apoio da computação móvel. Ambiente Construído, Porto Alegre, v. 16, n. 4, p. 109-124, out./dez. 2016., as described in Section 2, to map the data schema to the product model.

The model is divided into three parts. The first is the supporting conceptual framework, derived from the literature review and previous work of Leão, Isatto and Formoso (2016)LEÃO, C. F.; ISATTO, E. L.; FORMOSO, C. T. Proposta de modelo para controle integrado da produção e da qualidade com apoio da computação móvel. Ambiente Construído, Porto Alegre, v. 16, n. 4, p. 109-124, out./dez. 2016. and Rocha (2015)ROCHA, G. S. Proposta de refinamento de modelo de controle integrado da produção e qualidade com o uso de dispositivos móveis. Porto Alegre, 2015. Dissertação (Mestrado em Engenharia Civil) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2015.. The second is the software infrastructure that is necessary to implement data storage and mapping between process and product models. Finally, the third part consists of the data collection method for integrated quality and production control at the construction site.

Conceptual framework

The conceptual framework is represented by a product-process model, shown in Figure 3. The product domain is implemented through BIM, whereas the process domain is based on the LPS. Both product and process dimensions are organised at multiple hierarchical levels, similarly to the levels that are adopted at both LPS and BIM-based design processes, which are summarized in Figure 3 and Table 2.

Conceptual framework for the process-product model for production and quality management in construction projects

The framework top level corresponds to the master planning phase in the process dimension, and to the initial versions of the architectural BIM model, e.g., at LOD 200. At this level, some long-term planning techniques are needed, such as the Critical Path Method (CPM), Line of Balance (LOB) and Location Based Planning. The aggregation level of the activities has to be kept as low as possible to avoid excessive complexity (LEACH, 2000LEACH, L. P. Critical chain project management. Boston: Artech House Professional Development Library, 2000.), but enough to set the scope of the various subcontractors and coordinate the main deliveries among them. The association between the master plan and the BIM model is implemented as a low detailed 4D model. As product and process are highly interdependent, the 4D model is expected to provide valuable feedback to refine both the BIM model and the master plan (BIOTTO; FORMOSO; ISATTO, 2015BIOTTO, C. N.; FORMOSO, C. T.; ISATTO, E. L. Uso de modelagem 4D e Building Information Modeling na gestão de sistemas de produção em empreendimentos de construção. Ambiente Construído, Porto Alegre, v. 15, n. 2, p. 79-96, 2015.). Moreover, product specification and quality control procedures for the critical processes have to be defined at this level.

The intermediate phase corresponds to the medium-term (or look-ahead) planning level. At this level, work packages are refined to match the execution sequence, and the plans are used for coordination among sub-contractors and suppliers. Moreover, as suggested by Biotto, Formoso and Isatto (2015)BIOTTO, C. N.; FORMOSO, C. T.; ISATTO, E. L. Uso de modelagem 4D e Building Information Modeling na gestão de sistemas de produção em empreendimentos de construção. Ambiente Construído, Porto Alegre, v. 15, n. 2, p. 79-96, 2015., a more detailed analysis of production sequence takes place, when flow activities (inspection, storage, and transportation) are identified and planned, as well as layout details are defined. The required LOD of most BIM model elements is 300 (construction) or 400 (fabrication), and a federated model must incorporate the subsystems models (e.g., MEP). The resulting as-planned 4D model can then be used to support further refinement of construction methods, sequence, and layout (BIOTTO; FORMOSO; ISATTO, 2015BIOTTO, C. N.; FORMOSO, C. T.; ISATTO, E. L. Uso de modelagem 4D e Building Information Modeling na gestão de sistemas de produção em empreendimentos de construção. Ambiente Construído, Porto Alegre, v. 15, n. 2, p. 79-96, 2015.), as well as to make explicit the specifications of elements and components that are expected to be used as a reference for quality assessment.

The operational phase corresponds to the short-term planning level, and usually has one-week planning horizon. These plans contain very detailed work packages to be carried out in the following week, each one assigned to a specific crew. At this level, work packages may need to be broken down in order to achieve a “sound” definition (BALLARD, 2000BALLARD, G. The Last Planner System of production control. Birmin’gham, 2000. (Doctor Dissertation) - Faculty of Engineering, University of Birmingham, Birmin’gham, 2000.), which is critical to achieve the completeness of work packages and the reliability of the work plan. The connection between all work packages and their corresponding objects in the BIM model has to be made explicit at this level, requiring that every particular connection is unique in the context of a project.

Data collection method

The data collection method is based on the model proposed by Leão, Isatto and Formoso (2016)LEÃO, C. F.; ISATTO, E. L.; FORMOSO, C. T. Proposta de modelo para controle integrado da produção e da qualidade com apoio da computação móvel. Ambiente Construído, Porto Alegre, v. 16, n. 4, p. 109-124, out./dez. 2016., as presented in Figure 1. As mentioned before, Generic Work Packages (GWP) are work packages or tasks that can be performed repeatedly in distinct production units or places. Those production units or places are herein called instances. A batch is an arbitrary collection of those instances. A Specific Work Package (SWP) is the defined by a GWP that is carried out on a specific batch.

The data collection method is summarized in Figure 4. In the proposed method, batches and GWPs are defined previously for the preparation of work schedules and constitute a vocabulary to be used in order to define SWP based on the association among them.

Plans are represented as work schedules, comprising a collection of SWPs. At the operational level (short-term planning), these work packages are SWPs for which execution dates are associated. Those work schedules are then combined with the BIM model, resulting in a BIM 4D model that represents the association of every SWP of the work schedule with sets of elements that correspond to the SWP corresponding batch.

These associations among SWPs and BIM element sets are then stored via CSV files in an external database as the one presented in Figure 1, in the form of a table representing each of the relationships between the element unique id and the SWP.

The same work schedules are used to guide data collection at construction sites. All data collection is done daily, using B3F and mobile devices, at predefined cycles, according to the short-term planning level.

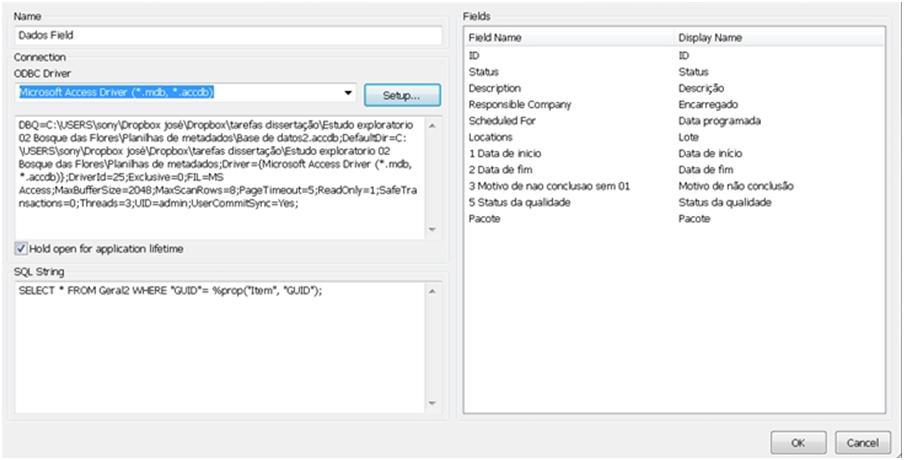

At the end of the week, the data collected is uploaded to the database via a CSV file at the end of the day. Except for the unplanned packages, all those SWPs have already been inserted into the database, associated with BIM element sets by means of their GUIDs. The database is then connected to Navisworks Manage® via ODBC drivers. This approach has the advantage of detaching the 4D model from B3F, allowing the 4D model to be modified as changes are made on the BIM model, or as a result of updates in the master and look-ahead plans.

All data collection is based on short-term work packages and is made on a weekly basis. The weekly data collection cycle is divided into three routines:

-

the preparation of the weekly plan, at the start of the cycle;

-

data collection, that is performed daily during the time of the cycle and also at the end of the period; and

-

the weekly data update, when the data collected is uploaded to the BIM model.

-

These routines are described below.

Preparation of the weekly plan (at the start of each cycle)

The preparation of data for the weekly plan involves the following tasks:

-

database update: for every planned task in the weekly plan, a specific work package (SWP) is created by associating an existing generic work package to a batch of BIM elements (e.g., the beams of a specific floor). New SWPs may need to be created if they are not available yet in the upper-level plans. Then, schedule information (start and end dates) is associated to each SWP, which is then assigned to a crew;

-

B3F task lists update: each of the SWP is uploaded to B3F as a task list item;

-

BIM model update: each SWP is then associated with the BIM model elements that correspond to its batch, by creating a model set inside the Navisworks Manage® that corresponds to the batch of the SWP. If the set already exists, the SWP is manually mapped to that set (Figure 5).

Data collection (daily routine)

Data collection should be performed in a daily routine. For every work package that is observed as being executed, the steps below must be taken:

-

is the task in the weekly plan? If not, it is the case of an unplanned work package. To record that, a specific work package is created by combining the existing generic work package (GWP) and batch, or by creating new ones if they are not available. Then, the start date and the crew are registered;

-

is it scheduled for execution in the current week? In an affirmative case, the research has to query B3F for any pending quality attribute (QA). If a pending QA exists, perform quality assessment and update quality record (QR) accordingly;

-

is there a making-do situation? If affirmative, record making-do category and causes; and

-

is the task finished? In order to identify completed tasks, it is necessary to query B3F from time to time, to see if there are any planned tasks along the route that should be in execution but have not been observed. In such a case, query B3F for any pending QA, perform quality assessment, and update QR accordingly. If there is no pending QA, mark the work packaged as approved by quality control (“done”), and update completion date.

Creation of work packages inside BIM models using the same IDs previously registered in B3F

Weekly data update (at the end of each cycle)

The weekly data update involves the following activities:

-

revise data collected with B3F: this should be done particularly regarding work packages that require creating new general work packages or batches during the week. The BIM model may need to be adjusted to map newly created batches;

-

database update: Download B3F records, and update database records; and

-

BIM model update: Update the BIM model to Navisworks Manage® through ODBC drivers by importing production data that was previously updated to the database with their respective GUIDs (Figure 6). SWP are then automatically reconnected with BIM entities based on the GUID associated with each SWP. Prepare BIM 4D visualizations for the weekly planning meeting.

Model implementation

Empirical study 1

During that first study, 983 work packages were observed (approximately 123 work packages per week). The main purpose of this study was to test the implementation of the proposed model alongside the normal managerial routines of a construction project that has already implemented LPS. Thus, the model implementation did not include the use of a database engine but aimed at the integration between B3F/B3G and Navisworks Manage® by mediating spreadsheets and CVS files.

Besides this difference, the data collection method presented in the previous section was implemented, and data were shown to construction managers at weekly planning meetings. Figure 7 and Figure 8 illustrate some examples of the data analysis that was produced in the empirical study.

Figure 7 demonstrates the possibilities for temporal analysis of the data collected along the eight weeks in terms of production and quality assessment. In Figure 7a, the percentage of planned work packages (PPC) that were concluded during the week indicates a that few of the work packages planned at the start of the week were translated into effective action. This means that the planning process and the production control could be significantly improved if the causes of non-completion of the work packages were identified, and the sources of these problems were adequately addressed. Figure 7b indicates that the number of unplanned work packages executed is relatively large, indicating a low level of control in relation to production plans over what was actually being executed. Figure 7c indicates the percentage of planned and unplanned work tasks that were partially approved by quality or not approved, and Figure 7d shows the possible causes of non-conformance.

Database query in Navisworks Manage to import database information to be linked to BIM model by using the element GUID

Figure 7a also provides an assessment of the quality control by the PPCQ indicator, the percentage of completed work packages that were approved in terms quality, which was generally low and varied significantly along the period. The indicator PPCR, i.e., the percentage of work packages that were concluded in time and approved in terms of quality, represents a measure of global effectiveness of production planning and execution.

Figure 7 indicates that except for week 8, general performance was very poor in weeks 1 and 2, but improved significantly in the subsequent weeks, mostly due to the quality performance. It is noteworthy that these data were presented to construction managers weekly as soon as they became available, which they perceived as having contributed positively to this performance improvement.

The visual representation of these data by means of the BIM 4D model was one of the positive contributions highlighted by the construction managers. Figure 8 shows an example of quality and production reports that were prepared using the updated BIM 4D model. These reports were able to provide an overview of quality assessment and progress monitoring, also indicating the spatial location of performance deviations of quality and schedule and helping to identify their possible causes.

This empirical study provided evidence that the model can support the integrated data collection and analysis of production and quality data, which were connected to the use of LPS. Furthermore, it extended previous applications of the data schema proposed by Leão, Isatto and Formoso (2016)LEÃO, C. F.; ISATTO, E. L.; FORMOSO, C. T. Proposta de modelo para controle integrado da produção e da qualidade com apoio da computação móvel. Ambiente Construído, Porto Alegre, v. 16, n. 4, p. 109-124, out./dez. 2016. by associating that information to the BIM 4D model, thus providing visual feedback to site managers.

However, much effort was necessary to update the BIM model due to design changes, as well as to include new tasks. Any of these changes requires an update of the links among Navisworks Manage® sets and the work packages, assuring the coherence among the tables representing generic and specific work packages, instances, and locations. As a consequence, the weekly data update, performed at the end of each cycle, was increasingly difficult and prone to errors. These problems led the research to using relational databases to store the associations between work packages and BIM element sets.

Empirical study 2

In the second empirical study, the aim was to extend the model so that progress monitoring information could be updated for long-term, medium-term, and short-term planning (Figure 3 and Table 2). Moreover, the research team decided to adopt a database engine to assure the integrity of the data among the different tables, and to use the GlobalId (GUID) parameter as a primary key for the association between work packages and the BIM model, as already discussed.

Long-term planning schedules were also combined with the BIM model to create 4D simulations of as-planned models (Figure 9). These models were then compared to as-built models, previously placing them in the same time frame, promptly detecting deviations from the original schedule.

The analysis of deviations was also enriched by the visual interface, enabling identification of spatial-related causes. As the models are derived from data collected weekly at the construction site, the analysis can be looked at in more depth considering each week individually. Figure 10 shows an example of the comparison between as-built and as-planned models for a particular week. The BIM objects in blue represent the current activities developed on site, while the objects in translucent yellow represent the long-term’s expected advance for the same date.

Model evaluation

Usefulness

During interviews, construction managers considered it very useful to include BIM model analysis in their activities, in particular pointing out that the visualization helped to avoid duplicate quality assessments, to identify spatial interference among crews, and to provide additional feedback for design coordination.

The data analysis that took place during the case studies has shown that the model implementation enabled a much better assessment of the effectiveness of production and quality control than would be possible without using the model. It also provided additional information that helped to identify possible causes of non-completion of scheduled tasks and non-conformance of work results.

Moreover, the wide range of analysis that were made possible illustrates the usefulness of the integrated product-process model to support production and quality management activities at the construction site.

Applicability

The time for data collection and analysis was registered in both empirical studies. In the first case study, the average time spent on data collection was 2h 09 min per day, and significantly reduced to 1h 18 min per day in the second case study. These figures can be considered compatible with the time construction managers dedicated in their daily routine to perform site control activities, ranging from 1 to 2 hours per day. However, the weekly routine of uploading collected data and preparing the plan for the next week took an average of 4 hours per week, which was considerably higher than the time previously used to prepare the weekly meetings (about 2 hours). Therefore, the proposed model proved to be feasible to be implemented during the regular working hours available on-site for the data collection routine, but it will require additional time for the weekly routine activities (uploading collected data and preparing the plan for the next week). Nonetheless, it is worth noting that this extra effort may be outweighed by the perceived usefulness of the model, as discussed above, based on the personal judgment of the construction manager.

As mentioned before, an assumption made beforehand by the researchers was that construction managers would prefer to use existing commercial software solutions, rather than developing a software application specially tailored to support production and quality management in the construction site. However, the impact of the cost for the data collection software was considered by them as a major barrier. In the particular case of the empirical study 2, the construction company decided to develop a proprietary software in order to implement the model.

Conclusions

This paper proposed a conceptual framework that is represented by a product-process model aimed to integrate production and quality control in construction sites with the support of BIM technology. The proposed solution considers the combined use of LPS control routines and BIM 4D modeling to monitor construction progress, to assess the quality of production, as well as the effectiveness of production and quality management. A method for data collection and analysis, based on that product-process model, was also devised, and represents a secondary contribution of this investigation. The model was implemented in two construction sites, adopting BIM models with low LOD (200-300) and available commercial software, to keep the system simple to be used by site personnel, as well as economically feasible for small- and medium-sized companies. The model was evaluated in terms of usefulness and applicability, based on the results of the implementation in two empirical studies, considering the perception of the construction managers that took part in the study.

The product-process model proposed in this research showed to be flexible enough to accommodate the activities observed at the construction site, and capable to provide a feasible alternative for construction companies to implement an integrated quality and production control by combining the Last Planner System™ and BIM, integrated in construction site daily routines.

The results also indicate that construction managers are highly sensitive to the cost of implementation. If the cost of existing commercial software is too high, they would tend to resort to a combination of technologies already in use, or of easy access, for data collection at the construction site. Relational databases and low-cost cloud development platforms (e.g., AppSheet - appsheet.com) may be feasible alternatives for implementing the model described here, along with BIM 4D software, tailored to the specific needs of the company.

Finally, it can be inferred that the proposed model is not limited to the integration of production and quality information to a 3D representation. It is adaptable to graphically display any kind of data in the process domain (e.g., cost estimates, subcontractor payment or procurement processes). Thus, it can be considered as a starting point for further research efforts in the product-process domain integration.

However, it is important to note that the approach adopted in this research study for the decomposition of the work packages from long-term to short-term planning was limited to changing the size of the batches that define the SWPs. Other criteria may show to be more appropriate in different situations. This seems to be a relevant investigation opportunity, which is suggested for future studies.

Acknowledgments

The authors would like to acknowledge the support provided by the construction industry partners who participated in this research project. The authors would also like to acknowledge the support provided by the Coordenação de Aperfeiçoamento de Pessoal de Nivel Superior (CAPES) and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPQ) for funding this research.

References

- AKINCI, B. et al A formalism for utilization of sensor systems and integrated project models for active construction quality control. Automation in Construction, v. 15, p. 24-138, 2006.

- ARENTSEN, A. L.; TIEMERSMA, J.; KALS, J. The integration of quality control and shop floor control. International Journal of Computer Integrrated Manufacturing, v. 9, p. 113-130, 1996.

- AUTODESK. Lean Construction Planning Software | BIM 360 Plan. 2016. Available: Available: http://www.autodesk.com/products/bim-360-plan/overview Access: Sep. 10th, 2017.

» http://www.autodesk.com/products/bim-360-plan/overview - BALLARD, G. Rethinking project definition in terms of target costing. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 14., Fortaleza, 2006. Proceedings [...] Fortaleza, 2006.

- BALLARD, G. The Last Planner System of production control. Birmin’gham, 2000. (Doctor Dissertation) - Faculty of Engineering, University of Birmingham, Birmin’gham, 2000.

- BALLARD, G.; HOWELL, G. Shielding production: essential step in production control. Journal of Construction Engineering and Management,v. 124, p. 11-17, 1998.

- BALLARD, G.; TOMMELEIN, I. Current proccess benchmark for the Last Planner™ System of project planning and control. Berkeley: University of California, Project Production Systems Laboratory (P2SL), 2021.

- BIOTTO, C. N.; FORMOSO, C. T.; ISATTO, E. L. Uso de modelagem 4D e Building Information Modeling na gestão de sistemas de produção em empreendimentos de construção. Ambiente Construído, Porto Alegre, v. 15, n. 2, p. 79-96, 2015.

- BOWDEN, S. et al Making the case for mobile IT in construction. Journal of Computing in Civil Enginnering, p. 1-12, 2005.

- CHEN, Y.; KAMARA, J. M. Using mobile computing for construction site information management. Engineering, Construction and Architectural Management, v. 15, n. 1, p. 7-20. Jan. 2008.

- CHEN, L.; LUO, H. A BIM-based construction quality management model and its applications. Automation in Construction , v. 46, p. 64-73, 2014.

- DAVE, B. Developing a construction management system based on lean construction and Building Information Modelling. England, 2013. (Doctoral Dissertation) - University of Saldford Manchester, England, 2013.

- DAVE, B.; BODDY, S.; KOSKELA, L. Challenges and opportunities in implementing lean and bim on an infrastructure project. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 21., Fortaleza, 2013. Proceedings [...] Fortaleza, 2013.

- DAVE, B.; BODDY, S.; KOSKELA, L. Visilean: designing a production management system with lean and BIM. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 19., Lima, 2011. Proceedings [...] Lima, 2011.

- DAVIES, R.; HARTY, C. Implementing ‘Site BIM’: a case study of ICT innovation on a large hospital Project. Automation in Construction , v. 30, p. 15-24, 2013.

- EASTMAN, C. M. et al BIM Handbook: a guide to Building Information Modeling for owners, managers, designers, engineers, and contractors. 2nd . ed. Hoboken: John Wiley & Sons, 2011.

- FIREMAN, M. C. T.; FORMOSO, C. T.; ISATTO, E. L. Integrating production and quality control: monitoring making-do and informal work packages. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 21., Fortaleza, 2013. Proceedings [...] Fortaleza, 2013.

- FROESE, T. et al Industry foundation classes for project management: a trial implementation. Journal of Information Technology in Construction, v. 4, p. 17-36, 1999.

- HARTMANN, T.; GAO, J; FISCHER, M. Areas of application for 3D and 4D models on construction projects. Journal of Construction Engineering and Management , v. 134, n. 10, p. 776-785, 2008.

- HEIGERMOSER, D. et al BIM-based Last Planner System tool for improving construction project management. Automation in Construction , v. 104, p. 246-254, 2019.

- KOPSIDA, M.; BRILAKIS, I.; VELA, P. A review of automated construction progress and inspection methods. In: CIB W78 CONFERENCE CONTRUCTION, 32., Eindhoven, 2015. Proceedings […] Eindhoven, 2015.

- KOSKELA, L. Application of the new philosophy to construction. Salford: Center for Integrated Facility Engineering, 1992.

- LEACH, L. P. Critical chain project management. Boston: Artech House Professional Development Library, 2000.

- LEÃO, C. F. Proposta de modelo para controle integrado da produção e da qualidade utilizando tecnologia de informação. Porto Alegre, 2014. Dissertação (Mestrado em Engenharia Civil) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2014.

- LEÃO, C. F.; FORMOSO, C. T.; ISATTO, E. L. Integrating Production and Quality Control with the Support of Information Technology. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 22., Oslo, 2014. Proceedings [...] Oslo, 2014.

- LEÃO, C. F.; ISATTO, E. L.; FORMOSO, C. T. Proposta de modelo para controle integrado da produção e da qualidade com apoio da computação móvel. Ambiente Construído, Porto Alegre, v. 16, n. 4, p. 109-124, out./dez. 2016.

- LEITE, F. BIM for Design Coordination. Hoboken: Wiley, 2020.

- MARCH, S. T.; SMITH, G. F. Design and natural science research on information technology. Decision Support System, v. 15, p. 251-266, 1995.

- MAROSSZEKY, M. et al Quality management tools for lean production-moving from enforcement to empowerment. In: ANNUAL CONFERENCE OF THE INTERNATIONAL GROUP FOR LEAN CONSTRUCTION, 10., Gramado, 2002. Proceedings [...] Gramado, 2002.

- MATTHEWS, J. et al Real time progress management: re-engineering processes for cloud-based BIM in construction. Automation in Construction , v. 58, p. 38-47, 2015.

- NAVON, R.; SACKS, R. Assessing research issues in Automated Project Performance Control (APPC). Automation in Construction , v. 16, p. 474-484, 2007.

- REINHARDT, J.; AKINCI, B.; GARRETT, J. H. Navigational models for computer supported project management tasks on construction sites. Journal of Computer Civil Engineering, v. 18, p. 281-290, 2004.

- REINHARDT, J.; GARRETT, J. H.; AKINCI, B. Framework for providing customized data representations for effective and efficient interaction with mobile computing solutions on construction sites. Journal of Computer Civil Engineering , v. 19, p. 109-118, 2005.

- ROCHA, G. S. Proposta de refinamento de modelo de controle integrado da produção e qualidade com o uso de dispositivos móveis. Porto Alegre, 2015. Dissertação (Mestrado em Engenharia Civil) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2015.

- RODRIGUES, P. B. de F. et al Uma proposta de integração do modelo BIM ao sistema last planner. Ambiente Construído , Porto Alegre, v. 18, n. 4, p. 301-317, oct./dec. 2018.

- SACKS, R. et al KanBIM workflow management system: prototype implementation and field testing. Lean Construction Journal, p. 19-35, 2013.

- SACKS, R.; TRECKMANN, M.; ROZENFELD, O. Visualization of work flow to support Lean construction. Journal of Construction Engineering and Management, v. 135, p. 1307-1315, 2009.

- STUMPF, A. L. et al Object-oriented model for integrating construction product and process information. Journal of Computer Civil Engineering , v. 10, p. 204-212, 1996.

- TEICHOLZ, P.; GOODRUM, P. M.; HAAS, C. T. U. S. Construction Labor Productivity Trends, 1970-1998. Journal of Computer Civil Engineering, v. 127, p. 427-429, 2001.

- TSERNG, H. P.; HO, S. P.; JAN, S. H. Developing BIM-assisted as-built schedule management system for general contractors. Journal of Civil Engineering and Management, v. 20, p. 47-58, 2014.

- VAISHNAVI, V.; KUECHLER, B. Design science research in information systems: overview of design science research. Available: http://desrist.org/desrist/content/design-science-research-in-information-systems.pdf Access: Aug. 21, 2015.

» http://desrist.org/desrist/content/design-science-research-in-information-systems.pdf - VAN DER BIJ, H.; VAN EKERT, J. H. W. Interaction between production control and quality control. International Journal of Operation and Production Management, v. 19, p. 674-690, 1999.

- VILLAMAYOR IBARRA, J. F. Integração de modelos de processo e produto na fase de construção para o controle da produção e da qualidade com o apoio de BIM. Porto Alegre, 2016. Dissertação (Mestrado em Engenharia Civil) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2016.

Errata

-

1

No artigo “BIM+Lean for integrating production and quality control at the construction site”, com número de DOI: <http://dx.doi.org/10.1590/s1678-86212022000200591>, publicado no periódico Ambiente Construído, 22(2):7-25.

-

2

Na página 13, Figure 2:

-

3

Onde se via:

- 4

-

5

Vê-se:

- 6

-

7

Na página 15, Table 2:

-

8

Onde se via:

- 9

-

10

Vê-se:

- 11

Publication Dates

-

Publication in this collection

16 Mar 2022 -

Date of issue

Apr-Jun 2022

History

-

Received

26 Mar 2021 -

Accepted

10 Oct 2021

Source: based on

Source: based on

Source:

Source: