Abstract

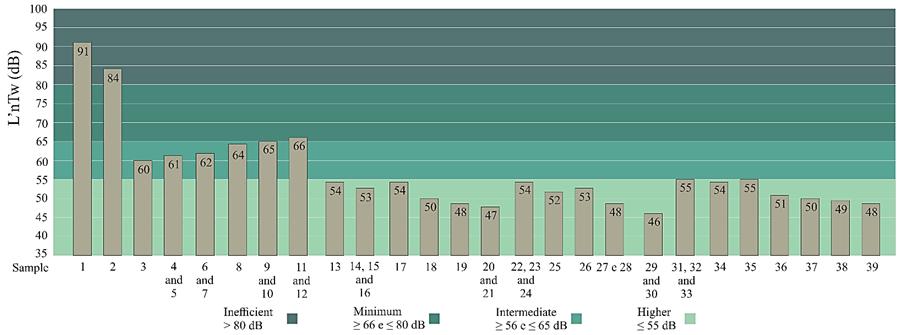

This research aims to discuss and determine acoustic performance values for impact noise insulation (L’nT,w) for 39 floor system compositions that have different resilient materials and wooden laminate floor finishing. The methodology is organized according to ISO 16283-2, ISO 717-2 and NBR 15575-3 for classification. The results obtained demonstrate that the prefabricated ribbed slab with prestressed joists and ceramic slabs, as well as the slab and subfloor system do not meet the minimum requirements for acoustic insulation, comprising values of 91 and 84 dB, respectively. Among the other 37 samples, it is worth mentioning that wooden laminate floors with better abrasion resistance is more efficient concerning acoustic performance, comprising impact noise insulation values ranging from 60 to 62 dB, due to its surface density. In the samples that use resilient materials, the performance values vary from 55 to 46 dB.

Keywords:

Architectural acoustics; Sound insulation; Building performance

Resumo

Esta pesquisa tem como objetivo discutir e determinar valores de desempenho acústico para ruído de impacto (L' nTw ), para 39 composições de sistemas de pisos, com diferentes materiais resilientes e acabamento de pisos laminados de madeira, a metodologia organiza-se conforme a ISO 16283-2, ISO 717-2 e NBR 15575-3 para classificação. Os resultados obtidos demonstram que a laje pré-fabricada nervurada com vigotas protendidas e tavelas cerâmicas e o sistema de laje e contrapiso não atingem os requisitos mínimos de isolamento acústico, com valores de 91 e 84 dB respectivamente. Dentre as outras 37 amostras, vale ressaltar que pisos laminados de madeira com melhor resistência à abrasão são mais eficientes em relação ao desempenho acústico, com valores de isolamento de ruído de impacto variando de 60 a 62 dB, devido sua densidade superficial. Nas amostras que usam materiais resilientes, os valores de desempenho variam de 55 a 46 dB.

Palavras-chave:

Acústica arquitetônica; Isolamento sonoro; Desempenho de edificações

Introduction

The advent of technology, mainly from the industrial revolution, introduced new materials and construction methods that provided benefits and drawbacks in terms of architectural acoustics. It is well known that excessive human exposure to noise may cause an increase in heart frequency, blood pressure, hearing loss and, in more severe cases, mental and emotional disorders (WORLD…, 2011WORLD HEALTH ORGANIZATION. Burden of disease from environmental noise. Copenhagen, 2011.).

The built environment must provide the user with a good acoustic response to support the activities that occur within a space (ELLIOTT, 2019ELLIOTT, A. Measurement of in-room impact noise reduction. Applied Acoustics, v. 148, p. 97-118, 2019.; PARK; LEE; JEONG, 2018PARK, S. H.; LEE, P. J.; JEONG, J. H. Effects of noise sensitivity on psychophysiological responses to building noise. Building and Environment, v. 136, p. 302-311, 2018.). For instance, acoustics in a classroom should allow intelligibility so that there is effective communication between the teacher and students, avoiding background noise interference in their understanding or even distraction.

It is argued, as an example, that noise has the potential to delay the recovery of patients in two Edinburgh hospitals, in the United Kingdom. Therefore, a hospital environment should promote a peaceful environment without background noise, which may interfere in patient’s rest and recovery, as well as in user communication and receiving medical alerts (MACKENZIE; GALBRUN, 2007MACKENZIE, D. J.; GALBRUN, L. G. U. Noise levels and noise sources in acute care hospital wards. Building Services Engineering Research and Technology, v. 28, n. 2, p. 117-131, 2007.).

A floating floor is a constructive technique that uses porous and resilient materials to dampen sound transmission between solid and rigid structures, such as the slab and subfloor (PARK et al., 2015PARK, H. S. et al. Low-frequency impact sound transmission of floating floor: case study of mortar bed on concrete slab with continuous interlayer. Building and Environment, v. 94, p. 793-801, 2015.). Studies also address adding aggregates to the subfloor layer, which also contribute to the attenuation of impact noise (BORGES et al., 2018BORGES, J. K. et al. An experimental study on the use of waste aggregate for acoustic attenuation: EVA and rice husk composites for impact noise reduction. Construction and Building Materials, v. 161, p. 501-508, 2018.; NAJIM; HALL, 2012NAJIM, K. B.; HALL, M. R. Mechanical and dynamic properties of self-compacting crumb rubber modified concrete. Construction and Building Materials, v. 27, n. 1, p. 521-530, 2012.).

In Brazil, floor coverings are classified according to NBR 14833-1 (ABNT, 2014ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 14833-1: revestimento de pisos laminados melamínicos de alta resistência: parte 1: requisitos, características, classificações e métodos de ensaio. Brasília, 2014.) referring to their abrasion resistance, and are categorized as abrasion classes: Abrasion Class (AC) 1 to AC5. AC1 to AC3 ratings are recommended for residential use (1 related to light foot traffic, 2 for medium and, 3 to high). On the other hand, AC4 and AC5 ratings are recommended for commercial use, indicated for low, medium and high use, respectively (ABNT, 2014)ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 14833-1: revestimento de pisos laminados melamínicos de alta resistência: parte 1: requisitos, características, classificações e métodos de ensaio. Brasília, 2014..

The floor impact noise level is influenced by the physical characteristics of the floor covering, in addition to the boundary conditions (volume of the room, finishing materials of walls and ceiling) (NA et al., 2019NA, S. et al. Evaluation of the floor impact sound insulation performance of a voided slab system applied to a high-rise commercial residential-complex building. International Journal of Concrete Structures and Materials, v. 13, n. 1, 2019.; YU; KANG, 2009YU, C. J.; KANG, J. Environmental impact of acoustic materials in residential buildings. Building and Environment, v. 44, n. 10, p. 2166-2175, 2009.). Floor systems are elements of horizontal compartmentalization that separate housing units in buildings, whose sound transmission of impact noise occurs on a daily basis, due to falling objects, dragging furniture and footsteps.

It is noted that the floor systems composed of non-homogeneous slabs (prefabricated joists and block slabs due to using different materials, and the characteristic of full and empty) present more complex propagations in relation to homogeneous systems, such as solid concrete slabs with variables that are more difficult to estimate (GALBRUN, 2010GALBRUN, L. Vibration transmission through plate/beam structures typical of lightweight buildings: Applicability and limitations of fundamental theories. Applied Acoustics, v. 71, n. 7, p. 587-596, 2010.; HOPKINS, 2004HOPKINS, C. Airborne sound insulation of beam and block floors : direct and flanking transmission. Building Acoustics, v. 11, n. 1, p. 1-25, 2004.).

The acoustic behavior of floor systems comprising joist/tile system slabs shows differences compared to solid slabs, as they present heterogeneous and orthotropic characteristics (HOPKINS; TURNER, 2005HOPKINS, C.; TURNER, P. Field measurement of airborne sound insulation between rooms with non- diffuse sound fields at low frequencies. Applied Acoustics, v. 66, p. 1339-1382, 2005.; OLIVEIRA, 2017OLIVEIRA, M. F. de. Impact noise of non-homogeneous floors: analysis of different input parameters for computational modeling predictions. Journal of Civil Engineering and Architecture, v. 11, p. 274-281, 2017.). In this context, the heterogeneous properties in filling elements in slabs result in significant differences in flank transmission mechanisms, causing different isolations for each composition (OLIVEIRA; PATRÍCIO, 2016OLIVEIRA, M. F. de.; PATRÍCIO, J. V. Different input parameters in modelling for predicting impact noise of non-homogenous floors. In: INTERNATIONAL CONGRESS ON ACOUSTICS STRUCTURAL, 22., Buenos Aires, 2016. Proceedings [...] Buenos Aires, 2016.).

In addition, research indicates that wooden laminate floors have different acoustic behaviors between light and heavy categories. Light wood flooring systems have better insulation for medium and high-frequency ranges compared to the heavy ones. As a consequence, the low-frequency influence needs to be further investigated (BOLMSVIK; BRANDT, 2013BOLMSVIK, A.; BRANDT, A. Damping assessment of light wooden assembly with and without damping material. Engineering Structures, v. 49, p. 334-347, 2013.; CANIATO et al., 2015CANIATO, M. et al. Recycled materials for noise reduction in floating floors. In: INTERNATIONAL CONGRESS ON SOUND AND VIBRATION, 22., Florence, 2015. Proceedings [...] Florence, 2015.; HIRAMITSU; HASEMI; KAKU, 2014HIRAMITSU, A.; HASEMI, Y.; KAKU, T. Floor impact sound insulation of timber three-story school building for final full scale fire test. In: INTERNATIONAL CONGRESS ON NOISE CONTROL ENGINEERING: IMPROVING THE WORLD THROUGH NOISE CONTROL, INTERNOISE, 43., Melbourne, 2014. Proceedings [...] Melbourne, 2015.; LJUNGGREN; ÅGREN, 2013LJUNGGREN, F.; ÅGREN, A. Elastic layers to reduce sound transmission in lightweight buildings. Building Acoustics, v. 20, p. 25-42, 2013.; CANIATO et al., 2016CANIATO, M. et al. Time- depending performance of resilient layers under floating floors. Construction and Building Materials, v. 102, p. 226-232, 2016.; MEDVE; INGELEARE; GEETERE, 2014MEDVE, J.; INGELEARE, B.; GEETERE, L. D. Impact sound insulation concept for lightweight timber floor. Advanced Materials Research, v. 855, p. 245-251, 2014.; QUIRT; NIGHTINGALE; KING, 2006QUIRT, J. D.; NIGHTINGALE, T. R. T.; KING, F. Guide for sound insulation in wood frame construction. Toronto: Institute for Research in Construction, 2006. Report n. RR-219, National Research Council of Canada.). Moreover, studies show that T-beam/hollow-block slabs present most of the sound transmission in the spaces of the ceramic tiles because they allow the internal reverberation of sound and amplify the sound waves in some central frequency bands (HOPKINS, 2012HOPKINS, C. Sound Insulation. 2nd . ed. Liverpool: Elsevier, 2012.). Other studies show that adding subfloors can compensate for the lower sound insulation compared to solid concrete slabs due to the mass law which increases the mass of the entire set (OLIVEIRA et al., 2021OLIVEIRA, M. F. et al. Desempenho acústico de laje com vigota e lajota: isolamento ao som aéreo e de impacto. Ambiente Construído, Porto Alegre, v. 21, n. 3, p. 243-254, jul./set. 2021.).

In the construction industry, the differences between laboratory and field measurements for impact noise, especially in low frequencies for floating floors, have been an important issue for sound insulation. The vibroacoustic investigation into the effect of factors that contribute to the resonance frequency (such as plates used in the laboratory method) should improve understanding of the low-frequency impact sound of floating floors (CHO, 2013CHO, T. Vibro-acoustic characteristics of floating floor system: the influence of frequency-matched resonance on low frequency impact sound. Journal of Sound and Vibration, v. 332, n. 1, p. 33-42, 2013.; KIM; KIM; KIM, 2018KIM, T. M.; KIM, J. T.; KIM, J. S. Effect of structural vibration and room acoustic modes on low frequency impact noise in apartment house with floating floor. Applied Acoustics, v. 142, p. 59-69, 2018.; LEE et al., 2016LEE, J. Y. et al. Evaluation of the long-term sound reduction performance of resilient materials in floating floor systems. Journal of Sound and Vibration, v. 366, p. 199-210, 2016.).

This research aims to discuss and determine acoustic performance values for impact noise insulation (L’nTw) for 39 floor system compositions with different resilient materials and wooden laminate floor finishing. In view of this fact, the samples of the tested floor system configurations comprised a prefabricated ribbed slab with prestressed joists and ceramic slabs, using 40 mm of mortar subfloor, wooden laminate floors, and 10 different resilient materials. It also addresses the use, or not, of mortar screed in impact sound insulation and different resilient materials were tested when there was a floating floor.

Method

The Brazilian Standard, called residential buildings - performance, NBR 15575-1 (ABNT, 2021aASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 15575-1: edificações habitacionais: desempenho: parte 1: requisitos gerais. Brasília, 2021a.) is divided into six parts, establishing minimum requirements for constructive quality in the country. It provides the requirements and performance criteria that apply to residential buildings, as an integrated whole, as well as how they should be assessed for one or more specific systems. These requirements are for different issues, such as: acoustics, thermal, lighting, structural and fire safety, water tightness, etc.

The performance criteria required for impact noise are categorized, as minimum (M), intermediate (I) and superior (S) as given in the Brazilian Standard NBR 15575-3 (ABNT, 2021bASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 15575-3: edificações habitacionais: desempenho: parte 3: requisitos para os sistemas de pisos. Brasília, 2021b.), whose specified methodology for measurements in the field must be performed according to the ISO 16283-2 standard (ABNT, 2020ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ISO 16283-2:acoustics: field measurement of sound insulation in buildings and of building elements: part 2: impact sound insulation. Brasília, 2020.).

Table 1 shows the values established by the performance standard of residential buildings for impact noise.

Object of study

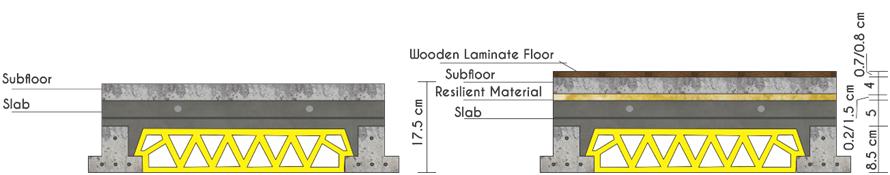

The floor systems tested for the approach of this study consist of a prefabricated ribbed slab with prestressed joists and ceramic slabs, a 40 mm thick mortar screed and five samples of wooden laminate floor laid over a regularization blanket indicated by the manufacturer.

The precast slab with prestressed joists used in the tests has the following characteristics:

-

joist with a width of 10 cm, height of 8.5 cm and a combination of 4 prestressed wires of 5 mm; and

-

ceramic slabs with a width of 37 cm, height of 8 cm and depth of 20 cm, and interaxle distance of 47 cm.

A 5 cm compression table with machined concrete of 25 MPa is considered with the addition of a 15 cm x 15 cm steel mesh, 4.2 mm in diameter. Moreover, 3/4 conduits were also added inside, aiming to bring the sample closer to the reality of field measurements, totaling the final height of 13.5 cm. The wooden laminate floor has AC3 and AC4 resistance (ABNT, 2014ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 14833-1: revestimento de pisos laminados melamínicos de alta resistência: parte 1: requisitos, características, classificações e métodos de ensaio. Brasília, 2014.) and fire reaction Class III A (ABNT, 2013bASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 8660: ensaio de reação ao fogo em pisos: determinação do comportamento com relação à queima utilizando uma fonte radiante de calor. Brasília, 2013b.).

Figure 1 shows the graphic detailing of the floor system and its thickness. The test sample is located on a 1×1 m subfloor plate defining the floor system over which the standard impact machine will be positioned. This sample cut is only for the subfloor and floor system (and/or resilient material) and the slab was built in the full dimension of the laboratory rooms. This procedure is standardized by ISO 16283-2 (ABNT, 2020ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ISO 16283-2:acoustics: field measurement of sound insulation in buildings and of building elements: part 2: impact sound insulation. Brasília, 2020.).

Table 2 specifies the 39 test Samples used in this research. Five types of wooden laminate floor coverings were used in “Tests C and D”. However, for “Tests E, F and G” only three of these floors were used. They were selected because they presented the best, the intermediate and the worst performance in previous tests.

Figure 2 shows the 39 samples of the tests carried out, from the bone slab, to the subfloor and the floating floor system. Table 3 describes the details and properties of the test materials.

Laboratory test

The Brazilian Standard NBR 15575-3 (ABNT, 2021bASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 15575-3: edificações habitacionais: desempenho: parte 3: requisitos para os sistemas de pisos. Brasília, 2021b.) recommends the methodological procedure for field tests covered by ISO 16283-2 (ABNT, 2020ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ISO 16283-2:acoustics: field measurement of sound insulation in buildings and of building elements: part 2: impact sound insulation. Brasília, 2020.). The tests were carried out in a laboratory that simulates situations in the field because there are rigid connections between the slab and the adjacent structural elements and there are electrical cables.

Laboratory test

The Brazilian Standard NBR 15575-3 (ABNT, 2021bASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 15575-3: edificações habitacionais: desempenho: parte 3: requisitos para os sistemas de pisos. Brasília, 2021b.) recommends the methodological procedure for field tests covered by ISO 16283-2 (ABNT, 2020ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ISO 16283-2:acoustics: field measurement of sound insulation in buildings and of building elements: part 2: impact sound insulation. Brasília, 2020.). The tests were carried out in a laboratory that simulates situations in the field because there are rigid connections between the slab and the adjacent structural elements and there are electrical cables.

ISO 16283-2 (ABNT, 2020ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ISO 16283-2:acoustics: field measurement of sound insulation in buildings and of building elements: part 2: impact sound insulation. Brasília, 2020.) determines the procedures for impact noise isolation tests by obtaining sound pressure level measurements generated by a standardized impact source in rooms with a volume between 10 m³ and 250 m³, for 1/3 octave frequency bands between 50 Hz to 3150 Hz.

Regarding the positioning of the standard impact machine and the fixed microphone (the microphone used is for free field, however the sound level meter used has the correction inside it for a diffuse field measurement), Table 4 summarizes the characteristics explained in the ISO 16283-2 standard (ABNT, 2020ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ISO 16283-2:acoustics: field measurement of sound insulation in buildings and of building elements: part 2: impact sound insulation. Brasília, 2020.).

The steps of the field approach are:

-

equipment calibration;

-

reverberation time measurement in reception room (T 60);

-

measurement of sound pressure levels in all machine and microphone positions; and

-

mathematical development to calculate the single performance value (L’nTw).

The measurement types of equipment are described in Table 5. For the measurements, the equipment provided by the Thermoacoustics Laboratory (LaTA) at the Federal University of Santa Maria, Brazil was used.

According to the sound level meter, Black Solo model, the technical specifications are:

-

precision class 1;

-

measurement range of 20-137 (1 range);

-

peak measurement range of 60-140;

-

resolution of 0.1 dB;

-

reference range of 20-137;

-

reference level is 94 dB;

-

it can use 1/3 or 1/1 octave band filter;

-

analogue high-pass filter is 0.3 Hz - 10 Hz (software-selected); and

-

the frequency range is 1/1 spectrum (16 Hz or 31.5 Hz-16kHz, depending on high-pass filter) or 1/3 spectrum (12.5 Hz or 25 Hz-20kHz, depending on high-pass filter).

The technical specifications of the microphone, model MCE 212, are:

-

class 1;

-

rated sensitivity (250 Hz) of 50 mv/Pa;

-

frontal volume of 50 mm³;

-

maximum level (3% distortion) is 146 dB;

-

static pressure coefficient is -0.008 dB/kPa;

-

temperature coefficient of 0.01 dB/ºC;

-

maximum temperature is 70 ºC;

-

polarization of 0 V;

-

capacity of 20 pF;

-

storage relative humidity is 95% RH; and

-

storage temperature is 0 ºC to + 50 ºC.

The sound pressure level meter and sound level calibrator are calibrated according to the internal technical procedure CETAC-LCA-PC06 “sound level meter calibration” and CETAC-LCA-PC-03 “sound level calibrator calibration” that meets the requirements of IEC 61672-3 (INTERNATIONAL…, 2013INTERNATIONAL ELECTROTECHNICAL COMMISSION. IEC 61672-3: electroacoustics: sound level meters: part 3: periodic tests. Geneva, 2013.) and IEC 60942 (INTERNATIONAL…, 2017INTERNATIONAL ELECTROTECHNICAL COMMISSION. IEC 60942: electroacoustics: sound calibrators. Geneva, 2017.), respectively. These procedures were carried out by the accredited company “Instituto de PesquisasTecnológicas” (IPT) using methods and issuing calibration certificates for the equipment used in this research.

Figures 3 and 4 show details of the floor plan and the schematic section AA of the reception, and emission (open type) room. Table 6 presents the sound absorption coefficients of the constructive elements of the reception room, characterizing them by frequency.

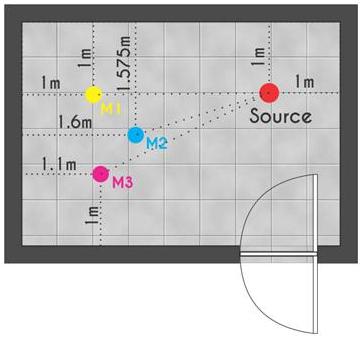

In the field measurements, one of the parameters used in the mathematical development of the single value is the reverberation time (T 60) (ABNT, 2020ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ISO 16283-2:acoustics: field measurement of sound insulation in buildings and of building elements: part 2: impact sound insulation. Brasília, 2020.). The two source positions and the six microphone positions described in the method established by the Brazilian standard NBR ISO 3382-2 (ABNT, 2017ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR ISO 3382-2: acústica: medição de parâmetros de acústica de salas: parte 2: tempo de reverberação em salas comuns. Brasília, 2017.) are shown in Figures 5 and 6.

Source positions 1 and microphone positions (M1, M2 and M3) to measure the reverberation time

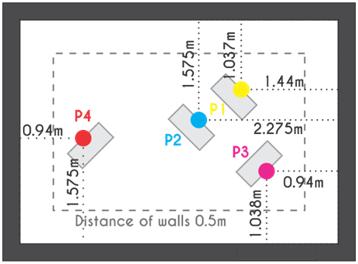

The sound pressure level measurements, regarding the positioning of the standard tapping machine and microphones, are shown in Figures 7 and 8. A minimum distance of 0.5 m from the walls was maintained and the standard impact machine was positioned in a 45-degree angle in relation to the direction of the slab’s joists under study. The background noise was also measured, for each microphone position, and checked if there were differences greater than 10 dB. It was found that no measurement needed correction, the standard impact machine is placed at a 45º angle to the joists, as stipulated in ISO 16283-2 (ABNT, 2020ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ISO 16283-2:acoustics: field measurement of sound insulation in buildings and of building elements: part 2: impact sound insulation. Brasília, 2020.).

The average impact sound pressure level, L’nT, is computed, by the relationship (Equation 1):

The values obtained as a result of the measurements were processed according to standard ISO 717-2 (ABNT, 2013aASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ISO 717-2: acoustics: rating sound insulation in buildings and of building elements: part 2: impact sound insulation. Brasília, 2013a.). Values of L’nT, must be unified with the purpose of defining a unique value of L’nT,w, in order to express the acoustic performance of the floor system, in dB.

To reach this unique number, the reference curve has to be moved by 1 dB until the sum of the unfavorable deviations is as large as possible as long as it is within the defined limit of 32 dB. The adopted value is located at 500 Hz on the reference curve, according to Figure 9.

A graphic scheme of the methodology is presented in Figure 10. There are four methodological steps:

-

measurement of the reverberation time;

-

impact noise measurement;

-

development of the unique performance value of the tested samples;

-

comparison of measured values with the Brazilian performance standard;

-

results and discussions; and

-

conclusions.

Results and discussions

The research initially used five wooden laminate floors, and among the tested materials, the wooden laminate floor with the best acoustic performance (without insulation materials, AC3), the intermediate value (called the acoustic floor) and the worst performance (without insulation materials, AC4) were used to construct the test samples with the insulations.

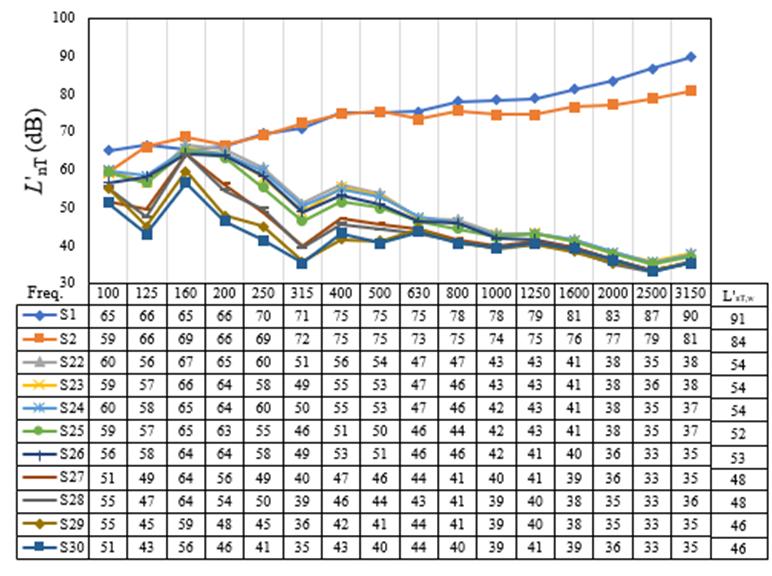

Figure 11 shows the acoustic behavior of Samples 1 to 7 (Groups A, B and C), whose samples S3 to S7 have the same subfloor and different laminate floors with different thicknesses (mass and density). The sample of “bare slab” (Sample 1), at low frequencies, presents performance below 70 dB.

A growth that reaches up to 90 dB is obtained, starting from 250 Hz and up to 3150 Hz. The spectrum of the acoustic behavior of Sample 2, in the low frequency bands, up to 200 Hz, does not exceed the performance of 70 dB. However, from the 315 Hz band onwards, an increasing curve is observed, whose apex reaches 81 dB. The value of L’nT,wis 84 dB.

The performance of Sample 3, comparing the reference values of the bare slab (Sample 1) and slab with subfloor (Sample 2), presents a curve with an inverse behavior, that is, descending. This behavior is inextricably linked to the damping and surface density found in the wooden laminate floor coverings (OLIVEIRA et al., 2021OLIVEIRA, M. F. et al. Desempenho acústico de laje com vigota e lajota: isolamento ao som aéreo e de impacto. Ambiente Construído, Porto Alegre, v. 21, n. 3, p. 243-254, jul./set. 2021.), which shows the highest performance values at low frequencies (68 dB) and the lowest values at high frequencies (37 dB). The value of L'nT,wis 60 dB, which in the performance standard is the intermediate category, even without using insulation.

For Sample 4, a slab with a subfloor with an acoustic coating and its specific EVA mat coupled to the wooden laminate floor is used. A downward curve is denoted where the highest value occurs in the low-frequency bands at 250 Hz (68 dB) and the lowest value is 37 dB in the 2500 Hz frequency band. The value of L'nT,w is 60 dB.

The performance of the floor slab with the AC3 wooden laminate floor of Sample 5 is presented in Figure 11. The performance curve is descending and presents the highest values at low frequencies (68 dB) at 250 Hz and the lowest values (39 dB) at 3150 Hz. The value of L'nT,w is 61 dB.

The performance of the slab with subfloor with the AC4 laminate coating (Sample 6) is shown in Figure 11. The curve descends from the medium frequency bands with values of 71 dB in the 160 Hz band and decays to 37 dB in the 2500 Hz frequency band. The value of L'nT,w is 62 dB.

The performance of the slab with subfloor with the AC4 wooden laminate floor (Sample 7) is presented in Figure 11. The downward curve assigns values in the low frequency band of 71 dB at 125 Hz and reaches 37 dB in the frequency band of 2500 Hz. The value of L'nT,w is 62 dB.

Thus, in samples from S3 to S7, it was observed that the addition of a laminate flooring in the system improved sound insulation at medium and high frequencies, noting that the increase in mass caused by the addition of laminate flooring was negligible when considering the total mass of the system (mass + subfloor). This phenomenon was also observed in the work by Oliveira et al. (2021)OLIVEIRA, M. F. et al. Desempenho acústico de laje com vigota e lajota: isolamento ao som aéreo e de impacto. Ambiente Construído, Porto Alegre, v. 21, n. 3, p. 243-254, jul./set. 2021., in which the addition of 4 cm of subfloor and porcelain tile coating reduced sound levels from the 400Hz band, but there was no change in the graphic profile because it is a system that is a damping resource.

Figure 12 shows the acoustic behavior of Samples 8 to 12 (Group D) that are samples without a subfloor with different laminate floors with different thicknesses (mass). The performance of the AC3 wooden laminate floor covering (Sample 8), which is also used in Sample 3, presents a downward curve from 71 dB at 160 Hz to 43 dB at 2.500 Hz. The value of L'nT,w is 64 dB, contributing negatively to the value shown in Sample 3 with the use of the subfloor, presenting higher values in the low and high frequencies. It is observed that 4 cm of the subfloor attenuated 4 dB.

The acoustic laminate floor has an EVA mat attached to its lower face, which determines a specific acoustic behavior (Figure 12). Its curve is descending, which in the 200 Hz frequency band is 67 dB and decays down to 48 dB in the 3.150 Hz frequency band. The value of L'nT,w is 65 dB, which results in a performance loss of 4 dB without using the subfloor. The behavior in the frequency ranges differs, significantly, at high frequencies by up to 10 dB in the 2000 Hz frequency band.

The impact noise performance of Sample 10 (AC3 laminate floor, which did not use subfloor resulted in a loss of performance of 4 dB in the value of L'nT,w in relation to Sample 5 (with the use of the subfloor). Although both behavior curves in the frequency bands are descending, there is a discrepancy in values of 6 dB for medium-high frequencies, up to 2000 Hz.

Sample 11 comprises slab with wooden laminate floor covering AC4, with a downward curve expressed in Figure 12 which, compared with Sample 6 (of the same material, with the use of the subfloor), there is a difference in the behavior in the low frequencies of up to 6 dB in the 2500 Hz frequency band. The value of L'nT,w impaired the performance from 62 dB to 66 dB with the absence of the subfloor.

Sample 12 consists of a slab with wooden laminate floor AC4, the value of L'nT,w decreases the performance from 62 dB (Sample 7) to 66 dB (Sample 12). However, there is a behavior in certain frequency ranges that differ by up to 6 dB as in the frequency band of 3150 Hz.

For the analysis of resilient materials, three of the five floors tested in the previous steps were listed: the one with the best performance (wooden laminate floor 1 AC3 corresponding to Sample 3), intermediate (acoustic wooden laminate corresponding to Sample 4), and the worst performance (wooden laminate floor 5 AC4 corresponding to Sample 7). Thus, Figure 13 shows the acoustic behavior of Samples 13 to 21 (Group E) which is with the same subfloor and laminate flooring 1 and there is a variation of the basic materials in the floating floor that has different properties. The same is analyzed for Figure 14 (Group F) and 15 (Group G) where the type of laminate flooring was changed (laminate floors 2 and 3, respectively).

The acoustic behavior of Samples 13 and 14 with the use of the floating floor was made with an expanded polypropylene blanket of 2 mm and 5 mm, respectively. The increase in the thickness of the expanded polypropylene mat caused a performance improvement, specifically in the 125 Hz frequency band. However, in high-frequency bands, an identical acoustic behavior is observed. The value of L'nT,w of Samples 13 and 14 are 54 dB and 55 dB, respectively.

The acoustic behavior of Samples 15 and 16 was analyzed in which both uses 5 mm and 10 mm polyethylene blankets, respectively. The results for the value of L’nT,w is 53 dB; however, the behavior in low-frequency bands is different, with a discrepancy of up to 3 dB in the frequency band of 315 Hz. Sample 17 uses a blanket of 5 mm recycled rubber for the floating floor technique. Its performance for value of L'nT,w is 54 dB, presenting a downward curve from 160 Hz.

The acoustic behavior of three floating floor Samples using polyester wool (PET), with Samples 18, 19, and 20 (thicknesses of 5 mm, 8 mm, and 10 mm respectively) and the values for L'nT,w Samples are 50 dB, 48 dB, and 47 dB, respectively. The acoustic behavior curve of these materials allows analyzing a loss of efficiency in the 160 Hz frequency band, and later presents a similar curve for the three samples at high frequencies. The significant differences are in low frequencies, presenting different results for L'nT,w.

The acoustic behavior of Sample 21, which uses glass wool for the manufacture of the floating floor, presents a sound energy valley in the performance for low-frequency bands between 54 dB (in 100 Hz), 45 dB (125 Hz) and 58 dB (160 Hz). Subsequently a downward curve from the central frequency band of 160 Hz presenting its greatest efficiency in frequency bands of 315 Hz of 36 dB. Its value for L’nT,w is 47 dB. These samples with floating floors (S13 to S21) present a decay of sound levels from the 160 Hz band due to the fact that the vibrational response of the system is significantly attenuated at the point of primary mechanical excitation.

The acoustic behavior in the frequency ranges of the Samples 22 to 30 are demonstrated in Figure 14. Samples 22 and 23 use an acoustic wooden laminate floor (which has an EVA mat attached to its lower surface). Both samples show L'nT,w of 54 dB, and a downward curve from 160 Hz that reaches its best performance in the 2500 Hz frequency band.

The performance of Samples 24 and 25 is on a downward curve with a specific efficiency for the frequency of 315 Hz, differentiate the trend from the graph, showing the best behavior in the frequency band of 2500 Hz for both Samples. However, increasing the thickness from 5 mm to 10 mm of polyethylene results in an improvement for the range between 160 Hz and 1000 Hz. The values of L’nT,w are 54 dB and 52 dB, respectively.

The floating floor Sample 26 with 5 mm of recycled rubber, presents a downward curve along the frequency bands with the acoustic behavior of an efficiency gain in the frequency band of 315 Hz and the best efficiency in the frequency band of 2500 Hz. The value for L’nT,w is 53 dB. In samples 27, 28 and 29, with PET polyester wool, it can be seen that even with an increase in thickness and surface density there were no significant differences in sound insulation.

The glass wool sample (15 mm) showed good results at low and medium frequencies, being the material with the best final performance (L’nT,w = 46 dB) for this grouping (Figure 14). This was due to the fact that this material has the highest density (60 kg/m³) and thickness compared to the others.

Samples 31 to 39 have similar behaviors found in samples 22 to 30 and this demonstrates that changing the floor with little difference in surface density minimally affects the performance results (Figure 15). Thus, floating floor applications impact more significantly with changes in thickness and densities than floor coverings of the same type, as in this case where both are wooden laminate floors.

The use of the subfloor in the tested samples makes it possible to analyze that each centimeter of subfloor contributes, in general, to 1 dB in the value of L'nT,w, as demonstrated in the samples with the use of the subfloor (3 to 7) and in those without use (8 to 12). Under this bias, one must analyze specifically for each slab typology, as the answer is causally linked to questions of mass and the vibrational response of the rigid elements (slabs and sub-floors).

This was also confirmed in the study by Oliveira et al. (2021)OLIVEIRA, M. F. et al. Desempenho acústico de laje com vigota e lajota: isolamento ao som aéreo e de impacto. Ambiente Construído, Porto Alegre, v. 21, n. 3, p. 243-254, jul./set. 2021. who studied the acoustic performance of t-beam and hollow-block slabs: airborne and impact noise insulation and concluded that with the progressive addition of layers in the slab, it resulted in lower L ’nT values. Thus, it is denoted that when adding more mass to the system, due to the mass law, L’nTw tends to improve.

In both samples with (S3 to S7) or without subfloor (S8 to S12) and in samples with floating floor (S13 to S39), there was a decay in sound levels from 400 Hz. It is noteworthy that the composition with only wooden laminate floor cannot be conceptualized as a floating floor because it does not have enough mass in the upper layer and also because it does not have a characteristic damping in the elastic layer (OLIVEIRA et al., 2021OLIVEIRA, M. F. et al. Desempenho acústico de laje com vigota e lajota: isolamento ao som aéreo e de impacto. Ambiente Construído, Porto Alegre, v. 21, n. 3, p. 243-254, jul./set. 2021.).

The results in Figures 12 to 15 are consistent with the studies that highlighted the importance of using resilient materials in order to obtain greater insulation from impact noise in floor systems (HOPKINS, 2012HOPKINS, C. Sound Insulation. 2nd . ed. Liverpool: Elsevier, 2012.; OLIVEIRA et al., 2021OLIVEIRA, M. F. et al. Desempenho acústico de laje com vigota e lajota: isolamento ao som aéreo e de impacto. Ambiente Construído, Porto Alegre, v. 21, n. 3, p. 243-254, jul./set. 2021.; PANOSSO; PAUL, 2020PANOSSO, A. da S.; PAUL, S. Performance ratings of impact noise insulation materials using the tapping machine and a non-standardized source. Ambiente Construído, Porto Alegre, v. 20, n. 2, p. 231-243, abr./jun. 2020.; XAVIER; MELO; FERREIRA, 2020XAVIER, L. A. A.; MELO, A. B.; FERREIRA, E. T. Isolamento do ruído de impacto no sistema de piso com aplicação de revestimento sobre o piso original. Ambiente Construído, PortoAlegre, v. 20, n. 4, p. 445-463, out./dez. 2020.). When analyzing the samples with floating floor (S13 to S39), it was observed that there was a decay of sound levels from the 160 Hz band in all samples. This was because it is a typical floating floor system whose vibrational response of the system is sensitively attenuated at the point of primary mechanical excitation (also observed in works such as (MEDVE; INGELEARE; GEETERE, 2014MEDVE, J.; INGELEARE, B.; GEETERE, L. D. Impact sound insulation concept for lightweight timber floor. Advanced Materials Research, v. 855, p. 245-251, 2014.; OLIVEIRA et al., 2021OLIVEIRA, M. F. et al. Desempenho acústico de laje com vigota e lajota: isolamento ao som aéreo e de impacto. Ambiente Construído, Porto Alegre, v. 21, n. 3, p. 243-254, jul./set. 2021.; PARK et al., 2015PARK, H. S. et al. Low-frequency impact sound transmission of floating floor: case study of mortar bed on concrete slab with continuous interlayer. Building and Environment, v. 94, p. 793-801, 2015.; PARK; YOON; CHO, 2020PARK, H. S.; YOON, D. Y.; CHO, T. Influence of plan configuration on low frequency vibroacoustic behaviour of floating floor with low natural frequency. Applied Acoustics, v. 158, p. 107040, 2020.).

The best performances on floating floors were found in samples tested with glass wool (Samples 21, 30, and 39) with L'nT,w of 47 dB, 46 dB, and 48 dB, respectively, and also for PET polyester wool (Samples 20, 29, and 38) with 47 dB, 46 dB, and 49 dB, for the value of L'nT.w. However, it should be considered that the glass wool tested is 15 mm thick while polyester wool is 10 mm thick, therefore it needs a specific analysis on these materials and their thickness.

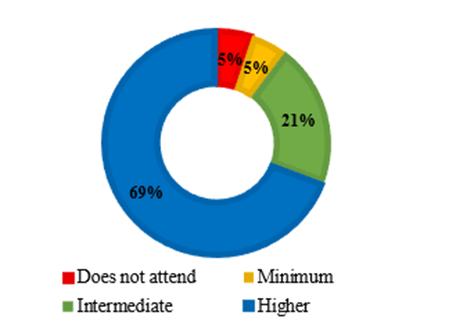

The 39 samples were tested with different construction types, and if compared to the performances established by the housing performance standard, it results in the conclusive graph represented in Figure 16.

Among the samples, only two (5%) do not meet the criteria stipulated by the Brazilian standard NBR 15575 (ABNT, 2021bASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 15575-3: edificações habitacionais: desempenho: parte 3: requisitos para os sistemas de pisos. Brasília, 2021b.) (Samples 1 and 2), two (5%) are in the minimum performance category (Samples 11 and 12), eight Samples (21%) configure the intermediate performance (Samples 3 to 10), and twenty-seven Samples (69%) perform the upper level established by the standard (Samples 13 to 39), which generate the conclusive graph shown in Figure 17.

Among the 39 samples tested, only Samples 13 to 39 obtained the required performance level (minimum) when compared to the performance levels for floor systems in areas of collective use, emphasising Samples 18, 19, 20, 27, 28, 29, 30, 37, 38 and 39, which reached intermediate performance using the floating floor technique. The samples that use only floor covering did not reach the performance required for the type of use of collective areas.

Conclusive graph of the percentage of Samples and their performance of impact noise insulation

Conclusions

Understanding the acoustic behavior of construction materials is a major factor in improving the quality of life of users in any type of building. The acoustic parameter is intrinsic to materiality and construction techniques. Therefore, it is necessary to deepen this knowledge to improve people’s quality of life. Therefore, the Brazilian standard NBR 15575 (ABNT, 2021aASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 15575-1: edificações habitacionais: desempenho: parte 1: requisitos gerais. Brasília, 2021a.) establishes the performance for homes, and one of the parameters is the acoustic issue of the floor.

In a slab with lower performance, any intervention represents a significant gain in the insulation presented between Samples 1 and 3 (MELLER et al., 2019MELLER, G. et al. Transmissão e isolamento do som quanto ao ruído de impacto. In: OLIVEIRA, T. D. (org.). DIÁLOGOS Multidisciplinares: coleção desenvolvimento regional e Meio Ambiente e Educação. São Carlos: Pedro e João, 2019.; NUNES; ZINI; PAGNUSSAT, 2014NUNES, M.F.O.; ZINI, A.; PAGNUSSAT, D. T. Desempenho Acústico de Sistemas de Piso: Estudos de Caso Para Isolamento ao Ruído Aéreo e de Impacto. Acústica e Vibrações, v. 46, p. 13-19, 2014.; PEDROSO, 2007PEDROSO, M. Estudo comparativo entre as modernas composições de pisos flutuantes quanto ao desempenho no isolamento ao ruído de impacto. Santa Maria, 2007. Dissertação (Mestrado em Engenharia Civil) - Universidade Federal de Santa Maria, Santa Maria, 2007.). Therefore, this analysis shows that the use of floor coverings is important to contribute to the acoustic quality in buildings.

This research highlights the necessary physical properties for the reduction of the L'nT.w parameter of flooring systems. Additionally, wooden laminate floor coverings present better performances, in relation to ceramic floors, due to their surface density, which helps in insulation mainly at medium and high frequencies (HAAS et al., 2022HAAS, A. et al. Isolamento ao ruído de impacto de laje pré-fabricada nervurada com vigotas protendidas e lajotas cerâmicas. Ambiente Construído, Porto Alegre, v. 22, n. 1, p. 105-23, jan./mar. 2022.).

Concomitant to surface density issues, it can also be concluded that the addition of mass in floor systems also contributes to better performance values. Thus, the 4 cm subfloor element contributes 4 dB of insulation, acting mainly in low and medium frequencies.

The data and critical discussions of this research contribute to the improvement in the acoustic quality of buildings regarding the issue of impact noise in prefabricated ribbed slabs with prestressed joists, wooden laminate floors and on the floating floor technique. The acoustic characterization of civil construction materials allows the improvement both in the design and in the execution stage, enabling environments with better acoustic comfort and allowing to fulfill the social function of architecture, civil engineering and scientific research.

References

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ISO 16283-2:acoustics: field measurement of sound insulation in buildings and of building elements: part 2: impact sound insulation. Brasília, 2020.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ISO 717-2: acoustics: rating sound insulation in buildings and of building elements: part 2: impact sound insulation. Brasília, 2013a.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 14833-1: revestimento de pisos laminados melamínicos de alta resistência: parte 1: requisitos, características, classificações e métodos de ensaio. Brasília, 2014.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 15575-1: edificações habitacionais: desempenho: parte 1: requisitos gerais. Brasília, 2021a.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 15575-3: edificações habitacionais: desempenho: parte 3: requisitos para os sistemas de pisos. Brasília, 2021b.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 8660: ensaio de reação ao fogo em pisos: determinação do comportamento com relação à queima utilizando uma fonte radiante de calor. Brasília, 2013b.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR ISO 3382-2: acústica: medição de parâmetros de acústica de salas: parte 2: tempo de reverberação em salas comuns. Brasília, 2017.

- BOLMSVIK, A.; BRANDT, A. Damping assessment of light wooden assembly with and without damping material. Engineering Structures, v. 49, p. 334-347, 2013.

- BORGES, J. K. et al An experimental study on the use of waste aggregate for acoustic attenuation: EVA and rice husk composites for impact noise reduction. Construction and Building Materials, v. 161, p. 501-508, 2018.

- BRANDÃO, E. et al On the performance investigation of distinct algorithms for room acoustics simulation. Applied Acoustics, v. 187, 2022.

- CANIATO, M. et al Recycled materials for noise reduction in floating floors. In: INTERNATIONAL CONGRESS ON SOUND AND VIBRATION, 22., Florence, 2015. Proceedings [...] Florence, 2015.

- CANIATO, M. et al Time- depending performance of resilient layers under floating floors. Construction and Building Materials, v. 102, p. 226-232, 2016.

- CHO, T. Vibro-acoustic characteristics of floating floor system: the influence of frequency-matched resonance on low frequency impact sound. Journal of Sound and Vibration, v. 332, n. 1, p. 33-42, 2013.

- ELLIOTT, A. Measurement of in-room impact noise reduction. Applied Acoustics, v. 148, p. 97-118, 2019.

- GALBRUN, L. Vibration transmission through plate/beam structures typical of lightweight buildings: Applicability and limitations of fundamental theories. Applied Acoustics, v. 71, n. 7, p. 587-596, 2010.

- HAAS, A. et al Isolamento ao ruído de impacto de laje pré-fabricada nervurada com vigotas protendidas e lajotas cerâmicas. Ambiente Construído, Porto Alegre, v. 22, n. 1, p. 105-23, jan./mar. 2022.

- HIRAMITSU, A.; HASEMI, Y.; KAKU, T. Floor impact sound insulation of timber three-story school building for final full scale fire test. In: INTERNATIONAL CONGRESS ON NOISE CONTROL ENGINEERING: IMPROVING THE WORLD THROUGH NOISE CONTROL, INTERNOISE, 43., Melbourne, 2014. Proceedings [...] Melbourne, 2015.

- HOPKINS, C.; TURNER, P. Field measurement of airborne sound insulation between rooms with non- diffuse sound fields at low frequencies. Applied Acoustics, v. 66, p. 1339-1382, 2005.

- HOPKINS, C. Airborne sound insulation of beam and block floors : direct and flanking transmission. Building Acoustics, v. 11, n. 1, p. 1-25, 2004.

- HOPKINS, C. Sound Insulation. 2nd . ed. Liverpool: Elsevier, 2012.

- INTERNATIONAL ELECTROTECHNICAL COMMISSION. IEC 60942: electroacoustics: sound calibrators. Geneva, 2017.

- INTERNATIONAL ELECTROTECHNICAL COMMISSION. IEC 61672-3: electroacoustics: sound level meters: part 3: periodic tests. Geneva, 2013.

- KIM, T. M.; KIM, J. T.; KIM, J. S. Effect of structural vibration and room acoustic modes on low frequency impact noise in apartment house with floating floor. Applied Acoustics, v. 142, p. 59-69, 2018.

- LEE, J. Y. et al Evaluation of the long-term sound reduction performance of resilient materials in floating floor systems. Journal of Sound and Vibration, v. 366, p. 199-210, 2016.

- LJUNGGREN, F.; ÅGREN, A. Elastic layers to reduce sound transmission in lightweight buildings. Building Acoustics, v. 20, p. 25-42, 2013.

- MACKENZIE, D. J.; GALBRUN, L. G. U. Noise levels and noise sources in acute care hospital wards. Building Services Engineering Research and Technology, v. 28, n. 2, p. 117-131, 2007.

- MEDVE, J.; INGELEARE, B.; GEETERE, L. D. Impact sound insulation concept for lightweight timber floor. Advanced Materials Research, v. 855, p. 245-251, 2014.

- MELLER, G. et al Transmissão e isolamento do som quanto ao ruído de impacto. In: OLIVEIRA, T. D. (org.). DIÁLOGOS Multidisciplinares: coleção desenvolvimento regional e Meio Ambiente e Educação. São Carlos: Pedro e João, 2019.

- NA, S. et al Evaluation of the floor impact sound insulation performance of a voided slab system applied to a high-rise commercial residential-complex building. International Journal of Concrete Structures and Materials, v. 13, n. 1, 2019.

- NAJIM, K. B.; HALL, M. R. Mechanical and dynamic properties of self-compacting crumb rubber modified concrete. Construction and Building Materials, v. 27, n. 1, p. 521-530, 2012.

- NUNES, M.F.O.; ZINI, A.; PAGNUSSAT, D. T. Desempenho Acústico de Sistemas de Piso: Estudos de Caso Para Isolamento ao Ruído Aéreo e de Impacto. Acústica e Vibrações, v. 46, p. 13-19, 2014.

- OLIVEIRA, M. F. de. Impact noise of non-homogeneous floors: analysis of different input parameters for computational modeling predictions. Journal of Civil Engineering and Architecture, v. 11, p. 274-281, 2017.

- OLIVEIRA, M. F. et al Desempenho acústico de laje com vigota e lajota: isolamento ao som aéreo e de impacto. Ambiente Construído, Porto Alegre, v. 21, n. 3, p. 243-254, jul./set. 2021.

- OLIVEIRA, M. F. de.; PATRÍCIO, J. V. Different input parameters in modelling for predicting impact noise of non-homogenous floors. In: INTERNATIONAL CONGRESS ON ACOUSTICS STRUCTURAL, 22., Buenos Aires, 2016. Proceedings [...] Buenos Aires, 2016.

- PANOSSO, A. da S.; PAUL, S. Performance ratings of impact noise insulation materials using the tapping machine and a non-standardized source. Ambiente Construído, Porto Alegre, v. 20, n. 2, p. 231-243, abr./jun. 2020.

- PARK, H. S. et al Low-frequency impact sound transmission of floating floor: case study of mortar bed on concrete slab with continuous interlayer. Building and Environment, v. 94, p. 793-801, 2015.

- PARK, H. S.; YOON, D. Y.; CHO, T. Influence of plan configuration on low frequency vibroacoustic behaviour of floating floor with low natural frequency. Applied Acoustics, v. 158, p. 107040, 2020.

- PARK, S. H.; LEE, P. J.; JEONG, J. H. Effects of noise sensitivity on psychophysiological responses to building noise. Building and Environment, v. 136, p. 302-311, 2018.

- PEDROSO, M. Estudo comparativo entre as modernas composições de pisos flutuantes quanto ao desempenho no isolamento ao ruído de impacto. Santa Maria, 2007. Dissertação (Mestrado em Engenharia Civil) - Universidade Federal de Santa Maria, Santa Maria, 2007.

- QUIRT, J. D.; NIGHTINGALE, T. R. T.; KING, F. Guide for sound insulation in wood frame construction. Toronto: Institute for Research in Construction, 2006. Report n. RR-219, National Research Council of Canada.

- WORLD HEALTH ORGANIZATION. Burden of disease from environmental noise. Copenhagen, 2011.

- XAVIER, L. A. A.; MELO, A. B.; FERREIRA, E. T. Isolamento do ruído de impacto no sistema de piso com aplicação de revestimento sobre o piso original. Ambiente Construído, PortoAlegre, v. 20, n. 4, p. 445-463, out./dez. 2020.

- YU, C. J.; KANG, J. Environmental impact of acoustic materials in residential buildings. Building and Environment, v. 44, n. 10, p. 2166-2175, 2009.

Publication Dates

-

Publication in this collection

09 Sept 2022 -

Date of issue

Oct-Dec 2022

History

-

Received

16 Dec 2021 -

Accepted

25 Feb 2022