Abstract

There is no doubt that concrete is one of the most consumed materials all over the world. It is a composite mix widely used for constructing structures and infrastructures to sustain environmentally induced stresses such as thermal and seismic. As the mainstream of construction industry is tended to find out feasible solutions, Roller Compacted Concrete (RCC) was introduced to play an essential role in the development of dams and pavements, where over 550 RCC dams were created by the end of 2012. In fact, this material has the same basic constituents of conventional concrete with a zero-slump and a significant difference in the placing process. The majority of available studies in the literature are composed of numerical investigations to assess the thermal and seismic behavior of RCC dams and to provide a clear view on how to improve its performance under various loading conditions. This paper summarizes and compares the general conclusions of recent works on evaluating the structural performance of RCC dams.

Keywords:

Roller compacted concrete; dams; numerical analysis; finite element modeling; thermal stress; seismic behavior

1 INTRODUCTION

Throughout history, people have paid great attention to building dams across a river to establish a reservoir in the valley based on the topography. Dam as a vital facility plays different significant roles in providing a wide range of economic, environmental, and social benefits such as flood control, water supply, hydroelectric power, and so on. Consequently, great care should be taken in the design, evaluation, and implementation of a dam to ensure its effectiveness, safety, stability, and reduce the risks of catastrophic failures (Gharibdoust et al., 2019Gharibdoust, A., Aldemir, A., & Binici, B. (2019). Seismic behaviour of roller compacted concrete dams under different base treatments. Structure and Infrastructure Engineering, 1-12.). Nowadays, roller compacted concrete (RCC) dam has a promising future due to its fast construction process, low engineering cost, strong environmental adaptability, and good control of heat generation (Hu et al., 2019Hu, W., Zhong, D., Wu, B., & Li, Z. (2019). Construction phase oriented dynamic simulation: taking RCC dam placement process as an example. Journal of Civil Engineering and Management, 25(7), 654-672.; Huang & Wan, 2018Huang, Y., & Wan, Z. (2018). Study on Viscoelastic Deformation Monitoring Index of an RCC Gravity Dam in an Alpine Region Using Orthogonal Test Design. Mathematical Problems in Engineering.; Zheng et al., 2020Zheng, X., Zhou, J., Chen, G., & Chen, S. (2020). Exposure Assessment for Roller Compacted Concrete Dam Construction Integrated Real-Time Location Information. KSCE Journal of Civil Engineering, 24(3), 703-714.). RCC is a strong material with unique properties that can preserve the stability of heavy-duty and mass concreting operations in structures and infrastructures. In general, RCC is a zero-slump concrete in its fresh state (ACI, 2011; Rao et al., 2016aRao, S. K., Sravana, P., & Rao, T. C. (2016a). Abrasion resistance and mechanical properties of Roller Compacted Concrete with GGBS. Construction and Building Materials, 114, 925-933., 2016b), handled by vibrating drums and rollers (Chhorn et al., 2018Chhorn, C., Hong, S. J., & Lee, S. W. (2018). Relationship between compressive and tensile strengths of roller-compacted concrete. Journal of Traffic and Transportation Engineering (English Edition), 5(3), 215-223.). It has the same components of conventional concrete (CC) (Courard et al., 2010Courard, L., Michel, F., & Delhez, P. (2010). Use of concrete road recycled aggregates for Roller Compacted Concrete. Construction and Building Materials, 24(3), 390-395.), and its importance comes from the ability to provide a similar strength as CC (Harrington et al., 2010Harrington, D., Abdo, F., Adaska, W., Hazaree, C. V., Ceylan, H., & Bektas, F. (2010). Guide for roller-compacted concrete pavements. National Concrete Pavement Technology Center.; Kokubu et al., 1996Kokubu, K., Cabrerab, J. G., & Uenoa, A. (1996). Compaction Properties of Roller Compacted Concrete.) with good durability and low maintenance requirements (Mohammed, 2018Mohammed, H. A. (2018). Design and evaluation of two-layer roller compacted concrete. University of Nottingham.) at a significantly reduced cost (Courard et al., 2010; Nagayama & Jikan, 2003Nagayama, I., & Jikan, S. (2003). 30 Years’ History of Roller-compacted Concrete Dams in Japan. Fourth Int. Symp. on Roller Compacted Concrete Dams,; Warren, 2013Warren, T. (2013). Roller-compacted concrete dams: a brief history and their advantages. Dams and Reservoirs, 22(2), 87-90.). Furthermore, RCC has a good reputation across the world to erect various types of infrastructures, including pavements and hydraulic structures (Atiş, 2005Atiş, C. D. (2005). Strength properties of high-volume fly ash roller compacted and workable concrete, and influence of curing condition. Cement and Concrete Research, 35(6), 1112-1121.; Chi & Huang, 2014Chi, M., & Huang, R. (2014). Effect of circulating fluidized bed combustion ash on the properties of roller compacted concrete. Cement and Concrete Composites, 45, 148-156.; C. Wang et al., 2018aWang, C., Chen, W., Hao, H., Zhang, S., Song, R., & Wang, X. (2018a). Experimental investigations of dynamic compressive properties of roller compacted concrete (RCC). Construction and building materials, 168, 671-682.). Currently, the literature is indeed lack of a detailed review that highlights the findings of these studies. This paper is intended to shortly review and summarize the remarks of recent investigations on the performance of RCC dams. As a part of this study, several aspects of RCC dams such as thermal and seismic behavior will be discussed, and the missing points in the literature will be underlined. This review is expected to help researchers in the field of civil engineering by presenting useful information about RCC dams.

2 Roller Compacted Concrete in Brief

The American Concrete Institute (ACI) defines RCC in ACI 116 as “concrete compacted by roller compaction; concrete that, in its unhardened state, will support a roller while being compacted” (ACI, 1985). Furthermore, RCC can be described as concrete that requires pavers for placement and rollers for compaction with the formation of many horizontal construction joints (Chen & Liu, 2019Chen, H., & Liu, Z. (2019). Temperature control and thermal-induced stress field analysis of GongGuoQiao RCC dam. Journal of Thermal Analysis and Calorimetry, 135(4), 2019-2029.; Q. Wang et al., 2018cWang, Q., Huang, Z., & Wang, D. (2018c). Influence of high-volume electric furnace nickel slag and phosphorous slag on the properties of massive concrete. Journal of Thermal Analysis and Calorimetry, 131(2), 873-885.; Zhou et al., 2016Zhou, H., Zhou, Y., Zhao, C., & Liang, Z. (2016). Optimization of the temperature control scheme for roller compacted concrete dams based on finite element and sensitivity analysis methods. Civil Engineering Journal-Stavebni Obzor, 3(14), 1-16.).

2.1 History

RCC was firstly used as a construction material for pavements in Sweden 1930s, Figure 1. Thereafter, its applications intensively started in the early 1960s with the industry orientation towards eco-friendly and cost-effectively materials to face the challenges and meet objectives of the expanded and diverse applications in the construction sector. Since the early 1980s, RCC was accepted as a suitable material for dams, and by the end of 2012, over 550 RCC dams were erected worldwide (Ashtankar & Chore, 2014Ashtankar, V. B., & Chore, H. S. (2014). Development of design mix roller compacted concrete dam at Middle Vaitarana. Advances in concrete construction, 2(2), 125-144.). Currently, several researches are investigating the use of recycled aggregates in RCC towards sustainable concrete.

The history of RCC (mainly collected from (Harrington et al., 2010Harrington, D., Abdo, F., Adaska, W., Hazaree, C. V., Ceylan, H., & Bektas, F. (2010). Guide for roller-compacted concrete pavements. National Concrete Pavement Technology Center.))

2.2 Constituents

RCC is composed of aggregates (both fine and coarse), water, cementitious materials (including cement, fly ash and etc.), which are the same constituents used in CC. Despite the fact that the materials used in RCC are the same as in CC, the mix proportion is totally different (Tun et al., 2016Tun, Z. P., Kyaw, N. M., & Htwe, K. S. S. (2016). Properties of Roller Compacted Concrete with Pozzolan as Cement Replacement Material. INTERNATIONAL JOURNAL FOR INNOVATIVE RESEARCH IN MULTIDISCIPLINARY FIELD 2(12), 247-255.) in the sense of RCC contains a higher fine aggregate amount in comparison to CC resulting in a stiffer material that requires more energy to the place and compact (Harrington et al., 2010Harrington, D., Abdo, F., Adaska, W., Hazaree, C. V., Ceylan, H., & Bektas, F. (2010). Guide for roller-compacted concrete pavements. National Concrete Pavement Technology Center.). The relatively small amount of water added to the RCC mixture makes it suitable to be placed and compacted in a similar way to the asphalt pavement (Saleh et al., 2017Saleh, S. F., Rather, F. F., & Jabbar, M. J. (2017). Roller-compacted concrete (RCC) and its application in modern world of Technology. International Research Journal of Engineering and Technology 4(4).). Even though cement is the main cementitious material in RCC, pozzolan, such as fly ash, can partially replace cement to decrease cost, heat generation and/or CO2 emission (ACI, 2011). Furthermore, various chemical admixtures can be added to achieve the targeted characteristics of concrete, where the most common ones are water-reducing and air-entraining admixtures (Al Baghdady & Khan, 2018Al Baghdady, S., & Khan, L. (2018). Designing Roller compacted concrete (RCC) dams. KTH ROYAL INSTITUTE OF TECHNOLOGY.).

2.3 Mix Proportioning of Roller Compacted Concrete

In general, RCC are divided into two main categories which are the lean paste RCC (cement content > 99 kg/m3) and the high paste RCC (cement content < 180 kg/m3) (Liapichev, 2003Liapichev, Y. P. (2003). Seismic stability and stress-strain state of a new type of FSH-RCC dams. 4th International Symposium on Roller Compacted Concrete Dams, MADRID.). As a result, the proportioning methods of RCC can be classified into soil and concrete approaches, which arise from the fact that RCC behaves in the beginning as soil and then develops as a true concrete (Choi & Groom, 2001Choi, Y. K., & Groom, J. L. (2001). RCC mix design-soils approach. Journal of materials in Civil Engineering, 13(1), 71-76.). The soil approach is useful for lean paste RCC in which the mix is considered as an embankment where its properties are evaluated based on the moisture-density relationship, which represents the cement content and moisture of the mixture by determining the maximum dry density under compaction effort using the standard proctor test (Armanpour & Tajdini, 2016Armanpour, A., & Tajdini, M. (2016). An Introduction to Rolling Compacted Concrete (RCC) in Construction of Roads. Bulletin de la Société Royale des Sciences de Liège, 85, 735-740.). On the other hand, the concrete approach is used for both CC and RRC in which RCC mixture is designed to achieve the required consistency with controlling water/cement ratio, aggregate/fine ratio and cement/pozzolan ratio to decrease the voids in the mixture by increasing the total aggregate content and filling the fine aggregate voids with cement paste. Therefore, the basic proportioning approach is similar in both normal and RCC concretes (Army, 1987Army, U. (1987). TM 5-822-7: Standard Practice for Concrete Pavements. United States Department of the Army.) with significantly lower water content and higher fly ash /sand ratio in RCC to limit the occurrence segregation (Bauchkar & Chore, 2012Bauchkar, S. D., & Chore, H. S. (2012). Roller compacted concrete: A literature review. IOSR Journal of Mechanical and Civil Engineering, 28-32.).

2.4 Properties of Roller Compacted Concrete

The density of RCC ranges between 1% and 3% higher than the CC. (Army, 2000Army, U. (2000). Roller-Compacted Concrete. United States Department of the Army.), due to the low water amount and insufficient air entrained in the mix resulting in more dense material (Al Baghdady & Khan, 2018Al Baghdady, S., & Khan, L. (2018). Designing Roller compacted concrete (RCC) dams. KTH ROYAL INSTITUTE OF TECHNOLOGY.). On the other hand, the compressive strength values are similar to those in CC and mainly affected by water/cement ratio, compaction effort and content, and type of aggregate. The tensile strength of RCC is an important parameter for the seismic analysis of RCC dams and can be controlled by the aggregate bond (Al Baghdady & Khan, 2018; Army, 2006). Therefore, this parameter must be tested in the lift joints where the weakest zones in RCC are located. In fact, the tensile strength testing methodologies can be divided into direct and indirect approaches (Al Houri et al., 2020Al Houri, A., Habib, A., Elzokra, A., & Habib, M. (2020). Tensile Testing of Soils: History, Equipment and Methodologies. Civil Engineering Journal, 6(3), 591-601.). The direct method is used to measure the strength between the lifts while the indirect splitting one is used when the tensile strength of the unjointed RCC is desired. Besides that, strength properties, the shear strength of RCC is used to define the critical measures for the design in the lift joints (Army, 2000). In dam’s construction, the required modulus of elasticity needs to be low to reduce the possibility of development of cracks by controlling the stress and increasing the deformation (Al Baghdady & Khan, 2018), whereas, the Poisson’s ratio in RCC is comparable to that in CC and ranging from 0.17 to 0.22 (ACI, 2011). In general, excessive seepage is often undesirable due to its negative impact on the structural stability, durability, and economic value associated with lost water and the adverse appearance of water seepage on the downstream face. Thus, controlling seepage is indeed vital for the long-term efficiency of dams; this can be done by taking precautions for the factors affecting the permeability of RCC represented by the method of placement, proportioning of the mixture, and degree of the compaction. (Army, 2000). As a matter of fact, concrete mixtures with high modulus of elasticity and high strength have relatively low creep, while those with low strength and modulus of elasticity have larger creep values. In general, it is desirable for the concrete mixes in RCC dams to have high creep properties in order to relieve stress and strain buildup due to foundation restraint and thermal and exterior loadings (Al Baghdady & Khan, 2018). On the other hand, in dam construction, all types of shrinkage must be controlled in all types of dams to reduce the uncontrolled cracking associated with the volume changes. Since drying shrinkage is related to the amount of water and properties of aggregates, its values in RCC is comparable or less than the CC (Army, 2000) whereas, autogenous shrinkage is related to material properties, exhibits higher values with an increase in the concrete strength. However, as the hydration starts to occur, the temperature of concrete starts to exceed the ambient temperature, but later as is starts to cool down to reach the ambient temperature, the contraction takes place resulting in the thermal shrinkage (Abdulrazeg et al., 2010Abdulrazeg, A. A., Noorzaei, J., Khanehzaei, P., Jaafar, M. S., & Mohammed, T. A. (2010). Effect of temperature and creep on roller compacted concrete dam during the construction stages. Computer Modeling in Engineering and Sciences (CMES), 68(3), 239-268.). The thermal properties of RCC mixes are highly affected by the type and content of aggregate and cementitious materials in which mixtures with low cementitious materials shows low rise in temperature (Dunstan, 2003Dunstan, M. (2003). The state‐of‐the‐art of RCC dams in 2003-an update of ICOLD bulletin No. 125. 4th International Symposium on Roller Compacted Concrete Dams, MADRID.). Thus, testing the properties of RCC using the full RCC mixture is recommended (ACI, 2011). Generally, the adiabatic temperature increase in mass concrete is normally tested for 28 days, where most mixes produce little temperature rise beyond that time. On the other hand, a high-pozzolan RCC mixture may have a considerable delay in early-age temperature rise in which it significantly increases beyond 28 days. Therefore, RCC mixtures with over 30% pozzolan should be tested for adiabatic temperature rise and other properties to an age of at least 56 days (ACI, 2011).

2.5 RCC as a Mass Concrete Material

ACI CT-18 (ACI, 2013) defines mass concrete as “Any volume of structural concrete in which a combination of dimensions of the member being cast, the boundary conditions, the characteristics of the concrete mixture, and the ambient conditions can lead to undesirable thermal stresses, cracking, deleterious chemical reactions, or reduction in the long-term strength as a result of elevated concrete temperature due to heat from hydration.” This material is designed to reach adequate durability demands and resist the thermal effects in an economical way with minor concerns about its strength capacity (ACI, 2005). There are some variations between the conventional mass concrete and the RCC, but the essential difference can be noticed in the consistency of the mixture and its compaction technique in which internal one is applied to CC by immersion-type vibrators method and an external one for RCC through spreading equipment and vibrating rollers (Bauchkar & Chore, 2012Bauchkar, S. D., & Chore, H. S. (2012). Roller compacted concrete: A literature review. IOSR Journal of Mechanical and Civil Engineering, 28-32.). Nowadays, RCC is deemed as the most practical solution for designing and constructing major hydropower and water resource projects across the globe due to the considerable cost difference along with the construction and casting speed compared to CC (ACI, 1995; Rooholamini et al., 2018Rooholamini, H., Hassani, A., & Aliha, M. R. M. (2018). Fracture properties of hybrid fibre-reinforced roller-compacted concrete in mode I with consideration of possible kinked crack. Construction and Building Materials, 187, 248-256.; L. Wang et al., 2018bWang, L., Zhang, G., Wang, P., & Yu, S. (2018b). Effects of fly ash and crystalline additive on mechanical properties of two-graded roller compacted concrete in a high RCC arch dam. Construction and Building Materials, 182, 682-690.; Warren, 2012Warren, T. (2012). Roller Compacted Concrete for Dam Construction. Volume, 22, 87-90.; Yang & Shi, 2009Yang, L., & Shi, J. J. (2009). Experimental study on the impact of rainfall on RCC construction. Journal of Construction Engineering and Management, 136(5), 477-483.).

2.6 Advantages and Disadvantages

For many years RCC has been used in constructing dams, lumber storage yards, heavy haul roads, loading docks, intermodal port facilities, and parking lots (Aghaeipour & Madhkhan, 2019Aghaeipour, A., & Madhkhan, M. (2019). Mechanical properties and durability of roller compacted concrete pavement (RCCP)-a review. Road Materials and Pavement Design, 1-24.). The main benefits of this type of concrete, when used in dams, comes from its reduced cost that ranges from 25% to 50% compared to the CC ones in addition to its rapid construction process that helps in saving 1 to 2 years less than the CC dams (Zarrin et al., 2016Zarrin, O., Shirazi, M. R., Moniri, H., & Moniri, M. (2016). Roller-compacted concrete dams rehabilitation in terms of different problem. Journal of Civil & Environmental Engineering, 6(2), 1-4.). On the other hand, RCC dams are built up in layers by applying large quantities of concrete to form a monolithic mass-concrete structure (Husein Malkawi & Qiu, 2003Husein Malkawi, A. I., Mutasher, S. A., & Qiu, T. J. (2003). Thermal-structural modeling and temperature control of roller compacted concrete gravity dam. Journal of performance of constructed facilities, 17(4), 177-187.). However, this construction process results in increased risks for bedding slip and seepage problems (Liu et al., 2018Liu, G., Lu, W., Lou, Y., Pan, W., & Wang, Z. (2018). Interlayer shear strength of Roller compacted concrete (RCC) with various interlayer treatments. Construction and Building Materials, 166, 647-656.; Rongmei & Wei, 2007Rongmei, J., & Wei, F. (2007). Impact of Interlayer and Size Effect on the Mechanical Performances of Fully Graded RCC. Water Power, 4.; Su et al., 2018Su, H., Wen, Z., Yan, X., Liu, H., & Yang, M. (2018). Early-warning model of deformation safety for roller compacted concrete arch dam considering time-varying characteristics. Composite Structures, 203, 373-381.; Yahui & Guowei, 1995Yahui, D., & Guowei, L. (1995). Study on failure mechanism of roller compacted concrete fravity dam. Journal of Hydraulic Engineering, 5, 55-59.).

3 Roller Compacted Concrete Dams

A dam in civil engineering discipline refers to an artificial barrier together with its related works that are built to impound, divert water, or liquid material. This structure might compose of timber, rock, CC, RCC, earth, steel, or a combination of these materials (DEQ, 2007).

3.1 Advantages and Disadvantages

Two types of RCC dams are widely applied: (1) the gravity dam, Figure 2-a, which is commonly known as the oldest structure that can withstand the external loads through its self-weight only (PCA, 2003; Punmia et al., 2009Punmia, B. C., Lal, P. B. B., Jain, A. K., & Jain, A. K. (2009). Irrigation and water power engineering. Laxmi Publications, Ltd.), (2) the arch dam, Figure 2-b, is a curvy, thinner dam as compared to the gravity one and can transfer high water loads to the abutments in the horizontal direction using the arch action (Al Baghdady & Khan, 2018Al Baghdady, S., & Khan, L. (2018). Designing Roller compacted concrete (RCC) dams. KTH ROYAL INSTITUTE OF TECHNOLOGY.; Punmia et al., 2009). A comparison between the pros and cons of these dams is presented in Table 1.

Advantages and disadvantages of gravity and arch dams (collected mainly from (Punmia et al., 2009Punmia, B. C., Lal, P. B. B., Jain, A. K., & Jain, A. K. (2009). Irrigation and water power engineering. Laxmi Publications, Ltd.))

3.2 Advantages and Disadvantages

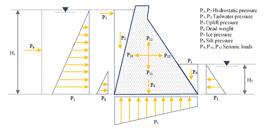

Concrete dams are massively large structures that are designed taking into consideration the cost, time schedule, tightness of water, a semblance of the RCC dam and method of construction and maintenance to achieve the stability and fulfill the requirements of long-life spans and water tightness by sustaining the application of different loading and environmental conditions. The loadings selected for the stability analysis, an example of a gravity dam is shown in Figure 3, which must represent the actual loads that are going to act on the concrete dam during its entire life span (Broberg & Thorwid, 2015Broberg, L., & Thorwid, M. (2015). Evaluation of failure modes for concrete dams. KTH Royal Institute of Technology.). In many cases, these loads are of such a nature that cannot exactly be determined. Thus, the designing engineer is then responsible for estimating their intensity, direction, and location-based on all available facts, judgment, and experience (FERC, 2002).

An example of the loads acting on a gravity dam (reproduced from (Broberg & Thorwid, 2015Broberg, L., & Thorwid, M. (2015). Evaluation of failure modes for concrete dams. KTH Royal Institute of Technology.))

In similar to CC dam, the RCC failure is considered as one of the most catastrophic events and defined as a collapse or movement of part of a dam or its foundation/ abutments so that this structure cannot retain water anymore (ICOLD, 1995). Therefore, this structure is designed to maintain safe behavior against sliding, overturning, and induced stresses. Sliding, Figure 4-a, can occur in dams due to the movement and friction between the horizontal planes of the dam or at the connections between the material used in the foundation and the dam and this can be prevented by ensuring the full transfer of all horizontal forces from the dam to the foundation. On the other hand, overturning, Figure 4-b, can occur at the connection between the foundation and the dam or in the foundation itself, which can be prevented by ensuring that the ratio of stabilizing moment to overturning moment is higher than the safety value against overturning action (Hansen & Reinhardt, 1991Hansen, K. D., & Reinhardt, W. G. (1991). Roller-compacted concrete dams. McGraw-Hill.).

(a) Sliding failure, (b) overturning failure (reproduced from (Broberg & Thorwid, 2015Broberg, L., & Thorwid, M. (2015). Evaluation of failure modes for concrete dams. KTH Royal Institute of Technology.))

In construct, to CC dams, the RCC ones are constructed in many thin horizontal layers, which increase the risk for strength, stability, and seepage of the dam. Generally, the anti-sliding stability is ignored, as discussed by Sha et al. (Sha et al., 2016Sha, S., Lei, Z., & Zhang, X. (2016). Study on failure mechanism of roller compacted concrete gravity dams by an isotropic damage model. International Conference on Smart City and Systems Engineering (ICSCSE), IEEE.), in RCC gravity dams of 100 m in height, but for dams with 200 m high, this issue is very prominent and must be considered to prevent the failure mechanism composed of shear slipping along the layer surfaces and the foundation surface. Further attention must be taken obviously to prohibit a failure in the dam’s cross-section that occurs when the stresses in the foundation or in the concrete surpass the allowable stresses.

4 Finite Element Modeling and Analysis

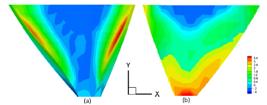

Nowadays, Finite Element (FE) modeling is widely accepted as a powerful tool for conducting a comprehensive study and evaluating the behavior of structural elements under different loading conditions (Habib et al., 2020Habib, A., Yildirim, U., & Eren, O. (2020). Column repair and strengthening using RC jacketing: a brief state-of-the-art review. Innovative Infrastructure Solutions, 5(3), 75.; Lampropoulos & Dritsos, 2011Lampropoulos, A. P., & Dritsos, S. E. (2011). Concrete shrinkage effect on the behavior of RC columns under monotonic and cyclic loading. Construction and Building Materials, 25(4), 1596-1602.). In general, dams are simulated in 2D or 3D, Figure 5, and the observed variation between the analysis results of these two modeling methods in the case of seismic performance, Figure 6, is emerged from the change in the stiffness, fundamental periods and the geometrical effects, which increase the capacity of the stiffer model under earthquake excitations (Arici et al., 2014Arici, Y., Binici, B., & Aldemir, A. (2014). Comparison of the expected damage patterns from two-and three-dimensional nonlinear dynamic analyses of a roller compacted concrete dam. Structure and Infrastructure Engineering, 10(3), 305-315.). The numerical findings in the thermal analysis have relied on various factors such as the time of the year, the ambient air temperature, RCC placement temperature, and heat of hydration of the cementitious materials (Husein Malkawi & Qiu, 2003Husein Malkawi, A. I., Mutasher, S. A., & Qiu, T. J. (2003). Thermal-structural modeling and temperature control of roller compacted concrete gravity dam. Journal of performance of constructed facilities, 17(4), 177-187.; Xia, 2017Xia, S. F. (2017). Simulation analysis of temperature control on RCC arch dam of hydropower station. In IOP Conference Series: Earth and Environmental Science, Singapore, SINGAPORE.).

It is possible to simulate the effects of incremental construction stages in mass concrete structures using commercially available FE software packages with sufficient laboratory data (Husein Malkawi & Qiu, 2003Husein Malkawi, A. I., Mutasher, S. A., & Qiu, T. J. (2003). Thermal-structural modeling and temperature control of roller compacted concrete gravity dam. Journal of performance of constructed facilities, 17(4), 177-187.). Therefore, the FE method provides an effective way for estimating the seismic, Figure 7, and thermal, Figure 8, the behavior of RCC dams when appropriate boundary conditions are sufficient (Chen & Liu, 2019Chen, H., & Liu, Z. (2019). Temperature control and thermal-induced stress field analysis of GongGuoQiao RCC dam. Journal of Thermal Analysis and Calorimetry, 135(4), 2019-2029.; Gharibdoust et al., 2019Gharibdoust, A., Aldemir, A., & Binici, B. (2019). Seismic behaviour of roller compacted concrete dams under different base treatments. Structure and Infrastructure Engineering, 1-12.; Jia et al., 2010Jia, C., Shao, A., Li, Y., & Ren, Q. (2010). Analyses of thermal stress field of high concrete dams during the process of construction. In 2010 Asia-Pacific Power and Energy Engineering Conference, Chengdu, PEOPLES R CHINA.). Kartal (Kartal, 2012Kartal, M. E. (2012). Three-dimensional earthquake analysis of roller-compacted concrete dams. Natural Hazards and Earth System Sciences, 12(7), 2369-2388.) also mentioned that in order to carry out a seismic performance analysis of RCC dam both gravity loads and hydrostatic pressure should be taken into account before applying the earthquake shaking intensities, in addition, the material, geometrical and connection nonlinearities must be defined be considered to predict a reliable dam behavior.

((a)2D (Bayagoob & Bamaga, 2019Bayagoob, K. H., & Bamaga, S. O. (2019). Construction of Roller Compacted Concrete Dams in Hot Arid Regions. Materials, 12(19).), (b) 3D (Kartal, 2012Kartal, M. E. (2012). Three-dimensional earthquake analysis of roller-compacted concrete dams. Natural Hazards and Earth System Sciences, 12(7), 2369-2388.) simulation of RCC dam and its foundation

Crest displacement under earthquake excitation for 2D and 3D models (Arici et al., 2014Arici, Y., Binici, B., & Aldemir, A. (2014). Comparison of the expected damage patterns from two-and three-dimensional nonlinear dynamic analyses of a roller compacted concrete dam. Structure and Infrastructure Engineering, 10(3), 305-315.)

A comparison between the experimental and numerical base shear-induced in RCC dam under dynamic loading (Gharibdoust et al., 2019Gharibdoust, A., Aldemir, A., & Binici, B. (2019). Seismic behaviour of roller compacted concrete dams under different base treatments. Structure and Infrastructure Engineering, 1-12.)

The accuracy of FE analysis is mainly based on the defined geometrical and material properties and laws used in developing the governing equations (Perumal & Mon, 2011Perumal, L., & Mon, D. T. T. (2011). Finite elements for engineering analysis: a brief review. In Proceedings of the International Conference on Modeling, Simulation and Control, Singapore.) then the modeling phase should be addressed carefully. Jia et al. (Jia et al., 2010Jia, C., Shao, A., Li, Y., & Ren, Q. (2010). Analyses of thermal stress field of high concrete dams during the process of construction. In 2010 Asia-Pacific Power and Energy Engineering Conference, Chengdu, PEOPLES R CHINA.) provided a process for thermal analysis of RCC dam in FE environment, as indicated in Figure 9. Typically, the FE modeling of dams is similar to any other structure and goes through several stages, which consist of definition, calculation, and results interpretation.

A comparison between the experimental and numerical results of temperature (Jia et al., 2010Jia, C., Shao, A., Li, Y., & Ren, Q. (2010). Analyses of thermal stress field of high concrete dams during the process of construction. In 2010 Asia-Pacific Power and Energy Engineering Conference, Chengdu, PEOPLES R CHINA.)

Flowchart of RCC dam thermal analysis using Ansys APDL (Jia et al., 2010Jia, C., Shao, A., Li, Y., & Ren, Q. (2010). Analyses of thermal stress field of high concrete dams during the process of construction. In 2010 Asia-Pacific Power and Energy Engineering Conference, Chengdu, PEOPLES R CHINA.)

There are different tools for performing a FE analysis, such as a commercially available software package like Abaqus (Abaqus, 2010), Ansys (Ansys, 2012), Diana (Wang & Chopra, 2008Wang, J., & Chopra, A. K. (2008). EACD-3D-2008: A computer program for three-dimensional earthquake analysis of concrete dams considering spatially-varying ground motion. Earthquake Engineering Research Center.), and SAP 2000 (Wilson & Habibullah, 1989Wilson, E. L., & Habibullah, A. (1989). SAP90: A Series of Computer Programs for the Static and Dynamic Finite Element Analysis of Structures: Users Manual. Computers & Structures, Incorporated.) or a coded program in FORTRAN or another language. Table 2 shows a summary of the used software in the analysis of previous studies.

5 Previous Works on RCC Dams

In fact, the majority of previous works in this field were numerical investigations. Thus, this section provides a summary of the objective of previous numerical studies available in literature as a table format, Table 3, and Table 4.

6 Stress Analysis

Dam, as a complex structure, is constructed to resist all applied loads during its intended life such that arising from gravity or lateral loads or thermal changes (DEQ, 2007). In fact, FE analysis has a wide range of roles, yet one of the key targets of this method is to calculate the stress in each portion of the structure. Thus, by using the FE approach, the stress state at each construction stage of the dam can be computed (Xia, 2017Xia, S. F. (2017). Simulation analysis of temperature control on RCC arch dam of hydropower station. In IOP Conference Series: Earth and Environmental Science, Singapore, SINGAPORE.). These stresses can then be used, as discussed by Noorzaei et al. (Noorzaei et al., 2006Noorzaei, J., Bayagoob, K. H., Thanoon, W. A., & Jaafar, M. S. (2006). Thermal and stress analysis of Kinta RCC dam. Engineering Structures, 28(13), 1795-1802.), to calculate an indicator, crack index I_cr, for the probability of damage occurring using the following formula:

where f_ct (t) and σ(t) is the RCC tensile strength and tensile stresses, respectively, at the time t. The importance of this parameter is that it can give a good prediction to the crack occurrence over time and hence, evaluate the dam’s safety against cracking (Noorzaei et al., 2006Noorzaei, J., Bayagoob, K. H., Thanoon, W. A., & Jaafar, M. S. (2006). Thermal and stress analysis of Kinta RCC dam. Engineering Structures, 28(13), 1795-1802.).

Basically, the most critical stresses in RCC dam are achieved by considering the thermal and seismic effects at the same time (Kartal, 2012Kartal, M. E. (2012). Three-dimensional earthquake analysis of roller-compacted concrete dams. Natural Hazards and Earth System Sciences, 12(7), 2369-2388.). Noorzaei et al. (Noorzaei et al., 2006Noorzaei, J., Bayagoob, K. H., Thanoon, W. A., & Jaafar, M. S. (2006). Thermal and stress analysis of Kinta RCC dam. Engineering Structures, 28(13), 1795-1802.) performed a stress analysis at all construction stages and computed the crack index with regard to the instantaneous RCC tensile capacity. It was concluded that the downstream part is a likely cracking area in which there is high restraint coming from the nearby rock foundation and the reduced tensile stresses caused by the self-weight of the dam in comparison to the upstream side due to the sloping effect downstream. Furthermore, Khanzaei et al. (Khanzaei et al., 2015Khanzaei, P., Abdulrazeg, A. A., Samali, B., & Ghaedi, K. (2015). Thermal and structural response of RCC dams during their service life. Journal of Thermal Stresses, 38(6), 591-609.) observed that considerable tensile stresses are developed mainly in the upstream and downstream faces, which are mainly caused by the restraint against environmental thermal variations, and at the bottom part of the dam because of the external restraint imposed by the foundation rock. Abdulrazeg et al. (Abdulrazeg et al., 2014Abdulrazeg, A. A., Noorzaei, J., Jaafar, M. S., Khanehzaei, P., & Mohamed, T. A. (2014). Thermal and structural analysis of RCC double-curvature arch dam. Journal of Civil Engineering and Management, 20(3), 434-445.) elucidated that the compressive stress contours in arch dams, Figure 10, are located primarily in the downstream region and slowly decrease toward the boundaries, which is attributed to the arch action.

Principal stress distribution (σ1) in (a) downstream; (b) upstream face of an arch dam (Abdulrazeg et al., 2014Abdulrazeg, A. A., Noorzaei, J., Jaafar, M. S., Khanehzaei, P., & Mohamed, T. A. (2014). Thermal and structural analysis of RCC double-curvature arch dam. Journal of Civil Engineering and Management, 20(3), 434-445.)

7 Thermal Analysis

The stresses developed in RCC dams are highly related to its temperature field (Kuzmanovic et al., 2013Kuzmanovic, V., Savic, L., & Mladenovic, N. (2013). Computation of thermal-stresses and contraction joint distance of RCC dams. Journal of Thermal Stresses, 36(2), 112-134.). The generated heat in a dam depends primarily on the continuous hydration of cement. Normally, the RCC temperature gradually rises at the early setting time stage and rapidly increases in the following early few days (Chen & Liu, 2019Chen, H., & Liu, Z. (2019). Temperature control and thermal-induced stress field analysis of GongGuoQiao RCC dam. Journal of Thermal Analysis and Calorimetry, 135(4), 2019-2029.; Q. Wang et al., 2018cWang, Q., Huang, Z., & Wang, D. (2018c). Influence of high-volume electric furnace nickel slag and phosphorous slag on the properties of massive concrete. Journal of Thermal Analysis and Calorimetry, 131(2), 873-885.; Zhou et al., 2016Zhou, H., Zhou, Y., Zhao, C., & Liang, Z. (2016). Optimization of the temperature control scheme for roller compacted concrete dams based on finite element and sensitivity analysis methods. Civil Engineering Journal-Stavebni Obzor, 3(14), 1-16.), where the maximum temperature gradient occurs (Jia et al., 2010Jia, C., Shao, A., Li, Y., & Ren, Q. (2010). Analyses of thermal stress field of high concrete dams during the process of construction. In 2010 Asia-Pacific Power and Energy Engineering Conference, Chengdu, PEOPLES R CHINA.; Shamsai et al., 2009Shamsai, A., Ghaemian, M., & Azimfar, S. M. (2009). Thermo-Mechanical Analysis of Roller Compacted Concrete (RCC) Dams (Jahgin Dam). In Symposium on the Application of Geophysics to Engineering and Environmental Problems,). Dam, in most cases, needs a long time to cool after erection as observed by Bayagoob and Bamaga (Bayagoob & Bamaga, 2019Bayagoob, K. H., & Bamaga, S. O. (2019). Construction of Roller Compacted Concrete Dams in Hot Arid Regions. Materials, 12(19).), Figure 11, in which the dam body temperature stayed at a moderate level even after one year of construction. Moreover, the temperature of the outer node falls quickly to the annual average, while the internal ones may take several or over 10 years to stabilize the temperature field (Jia et al., 2010). Stress and temperature levels in the dam are highly influenced by heat conductivity rate and temperature field, which in turn is dependent and controlled by many factors, including starting date, construction plan, and air temperature (Chen et al., 2003; Zhang et al., 2011Zhang, X. F., Li, S. Y., Li, Y. L., Ge, Y., & Li, H. (2011). Effect of superficial insulation on roller-compacted concrete dams in cold regions. Advances in Engineering Software, 42(11), 939-943.).

Temperature distributions: (a) immediately after constructing the dam; (b) one year later as observed (Bayagoob & Bamaga, 2019Bayagoob, K. H., & Bamaga, S. O. (2019). Construction of Roller Compacted Concrete Dams in Hot Arid Regions. Materials, 12(19).)

As a matter of fact, the temperature during the placing of RCC plays a significant role in developing the temperature gradient (Abdulrazeg et al., 2014Abdulrazeg, A. A., Noorzaei, J., Jaafar, M. S., Khanehzaei, P., & Mohamed, T. A. (2014). Thermal and structural analysis of RCC double-curvature arch dam. Journal of Civil Engineering and Management, 20(3), 434-445.; Zhou et al., 2016Zhou, H., Zhou, Y., Zhao, C., & Liang, Z. (2016). Optimization of the temperature control scheme for roller compacted concrete dams based on finite element and sensitivity analysis methods. Civil Engineering Journal-Stavebni Obzor, 3(14), 1-16.). Kuzmanović et al. (Kuzmanović et al., 2015Kuzmanović, V., Savić, L., & Mladenović, N. (2015) . Thermal-stress behaviour of RCC gravity dams. FME Transactions, 43(1), 30-34.) stated that the best indicator of thermal behavior is stressed in the direction of dam axes. Zhou et al. (Zhou et al., 2016) found that a casting temperature of 20 °C results in increasing the maximum tensile stress and temperature beyond the specified provision limits, while the optimum one at placement can be either 12 °C or 15 °C for controlled stresses. Moreover, casting a dam in hot weather can cause high temperatures at the low body part due to the larger thickness at this portion leading to higher insulation requirements (Abdulrazeg et al., 2014). The temperature variation between central and surface nodes is attributed to the temperature at casting and should be monitored while constructing an RCC dam in hot weather, in addition, the nodes in central and surface zones are affected noticeably by solar radiation at later age of placement (Jiang et al., 2013Jiang, S., Zhan, S. L., & Xiao, N. (2013). Influence of casting temperature and solar radiation on the thermal field in roller compacted concrete during construction. Applied Mechanics and Materials, 405-408, 2550-2554.).

Proper scheduling of concrete placement optimizes high-temperature regions and reduces the tension developed at the critical locations. Chen et al. (Chen et al., 2003Chen, Y. L., Wang, C. J., Li, S. Y., & Chen, L. J. (2003). The effect of construction designs on temperature field of a roller compacted concrete dam-a simulation analysis by a finite element method. Canadian Journal of Civil Engineering, 30(6), 1153-1156.) indicated that the highest temperature developed in the dam could be controlled by decreasing the casting temperature. Furthermore, thermal insulation can be used to reduce the tensile stresses zone, temperature gradient, and the difference between the internal and external temperatures, and to stop any possible crack formation on the surfaces of upstream and downstream (Zhang et al., 2011Zhang, X. F., Li, S. Y., Li, Y. L., Ge, Y., & Li, H. (2011). Effect of superficial insulation on roller-compacted concrete dams in cold regions. Advances in Engineering Software, 42(11), 939-943.). Moreover, using a 10 cm insulation layer can keep the maximum tensile stress under the standard limitations (Zhou et al., 2016Zhou, H., Zhou, Y., Zhao, C., & Liang, Z. (2016). Optimization of the temperature control scheme for roller compacted concrete dams based on finite element and sensitivity analysis methods. Civil Engineering Journal-Stavebni Obzor, 3(14), 1-16.). The probability of crack, as preceding findings revealed, is affected by thermal insulation thickness (Zhou et al., 2016) and crack index (Noorzaei et al., 2006Noorzaei, J., Bayagoob, K. H., Thanoon, W. A., & Jaafar, M. S. (2006). Thermal and stress analysis of Kinta RCC dam. Engineering Structures, 28(13), 1795-1802.). Noorzaei et al. (Noorzaei et al., 2006) mentioned that the real thermal response of the RCC dam is based on the material properties, actual RCC placement plan, and the recorded ambient temperatures. On the other hand, Luna and Wu (Luna & Wu, 2000Luna, R., & Wu, Y. (2000). Simulation of temperature and stress fields during RCC dam construction. Journal of Construction Engineering and Management, 126(5), 381-388.) suggested simulating RCC dams in low-temperature seasons, where it is possible to use a lesser quantity of cement in comparison to the CC dam, which ultimately reduces peak temperature, thermal stresses, and prevent development of thermal cracks.

8 Seismic Behavior of RCC Dams

Ghaedi et al. (Ghaedi et al., 2016Ghaedi, K., Jameel, M., Ibrahim, Z., & Khanzaei, P. (2016). Seismic analysis of Roller Compacted Concrete (RCC) dams considering effect of sizes and shapes of galleries. KSCE Journal of Civil Engineering, 20(1), 261-272.) performed a nonlinear time history analysis for Kinta RCC dam in Malaysia. Their findings present that small stresses in the dam are noticeably growing when large openings are considered in modeling of RCC dam’s cross-section. The pattern and propagation of crack are affected by the size and shape of the gallery, where circular one provides an enhanced damage response in comparison to square and octagon. Cheng and Zhang (Cheng & Zhang, 2012Cheng, H., & Zhang, L. (2012). Study on Ultimate Anti-Seismic Capacity of High Arch Dam. Journal of Aerospace Engineering, 26(4), 648-656.) reported that upper, lower, and middle parts of the arch crown are often the weakest portions under earthquake. Moreover, for any seismic resisting high arch dam project, only a nonlinear foundation should be taken into account. Gharibdoust et al. (Gharibdoust et al., 2019Gharibdoust, A., Aldemir, A., & Binici, B. (2019). Seismic behaviour of roller compacted concrete dams under different base treatments. Structure and Infrastructure Engineering, 1-12.) conducted an experimental study composed of a pushover and dynamic at the Operational Based Earthquake (OBE), the Maximum Design Earthquake (MDE) and the Maximum Credible Earthquake (MCE) levels on a scaled specimen of RCC dam with rough and smooth bases. The results have shown that the roughened base specimen did not exhibit sliding motion, but the specimen with a smooth base undergone sliding displacements up to 70% of the total tip displacement which produced less cracks as shown in Figure 12. Although the slipping and inclined body cracking are unacceptable, appropriate treatment of the dam base foundation interface should be introduced due to its significant impact on seismic behavior and crack propagation in gravity dams.

Crack propagation patterns: (a) smooth base (SB) and (b) roughened base (RB) (Gharibdoust et al., 2019Gharibdoust, A., Aldemir, A., & Binici, B. (2019). Seismic behaviour of roller compacted concrete dams under different base treatments. Structure and Infrastructure Engineering, 1-12.)

From their numerical study, the coefficient of friction changes in accordance with the load history, and its value seems like a substantial challenge to be calculated since it helps in defining the dam’s failure mode. Zhang et al. (L. Zhang et al., 2019aZhang, L., Zhai, Y., Chen, D., & Cui, X. (2019a). Study on influence of dam foundation damage on seismic safety of gravity dam under combined action of main shock and aftershock. In IOP Conference Series: Earth and Environmental Science,) mentioned that in comparison to the dam body, its foundation faces greater damage under the cumulative effect of the main aftershock, as shown in Figure 13.

Dam induced damage: (a) mainshock; (b) combined mainshock and aftershock (L. Zhang et al., 2019aZhang, L., Zhai, Y., Chen, D., & Cui, X. (2019a). Study on influence of dam foundation damage on seismic safety of gravity dam under combined action of main shock and aftershock. In IOP Conference Series: Earth and Environmental Science,)

9 CONCLUSION

This paper has focused on reviewing available studies in the field of RCC dams. On the bases of the above statements, the following points are drawn:

-

Two types of RCC dams, according to their design and structural system, are mainly constructed, which are the gravity dam and the arch one each with has several advantages and disadvantages.

-

Commercial FE software packages are capable of estimating the stresses and response of RCC dams under thermal and seismic actions.

-

The crack index is a good indicator of the failure occurring probability in RCC dams.

-

The heat in RCC dams is gradually raised during the early stage of casting and increases significantly in the following early few days.

-

Opening in the cross-section of the dam remarkably increases the stress applied due to seismic actions.

Currently, the literature presents a rich content about the FE modeling of RCC dams and its behavior under thermal effects. However, more information regarding its performance under earthquake excitations is still required and needs to be discussed in detail to highlight points like the expected failure modes and the possible mitigation strategies.

References

- Abaqus. (2010). Abaqus theory manual. Abaqus Inc.

- Abdulrazeg, A. A., Noorzaei, J., Jaafar, M. S., Khanehzaei, P., & Mohamed, T. A. (2014). Thermal and structural analysis of RCC double-curvature arch dam. Journal of Civil Engineering and Management, 20(3), 434-445.

- Abdulrazeg, A. A., Noorzaei, J., Khanehzaei, P., Jaafar, M. S., & Mohammed, T. A. (2010). Effect of temperature and creep on roller compacted concrete dam during the construction stages. Computer Modeling in Engineering and Sciences (CMES), 68(3), 239-268.

- ACI. (1985). Cement and concrete terminology.

- ACI. (1995). ACI 325.10 R: Roller-compacted concrete pavements.

- ACI. (2005). ACI 207.1 R-05: Guide to mass concrete.

- ACI. (2011). ACI207.5R-11: Report on Roller-Compacted Mass Concrete.

- ACI. (2013). ACI CT-13: ACI Concrete Terminology.

- Aghaeipour, A., & Madhkhan, M. (2019). Mechanical properties and durability of roller compacted concrete pavement (RCCP)-a review. Road Materials and Pavement Design, 1-24.

- Al Baghdady, S., & Khan, L. (2018). Designing Roller compacted concrete (RCC) dams. KTH ROYAL INSTITUTE OF TECHNOLOGY.

- Al Houri, A., Habib, A., Elzokra, A., & Habib, M. (2020). Tensile Testing of Soils: History, Equipment and Methodologies. Civil Engineering Journal, 6(3), 591-601.

- Ansys. (2012). Swanson Analysis Systems Inc.

- Arici, Y., Binici, B., & Aldemir, A. (2014). Comparison of the expected damage patterns from two-and three-dimensional nonlinear dynamic analyses of a roller compacted concrete dam. Structure and Infrastructure Engineering, 10(3), 305-315.

- Armanpour, A., & Tajdini, M. (2016). An Introduction to Rolling Compacted Concrete (RCC) in Construction of Roads. Bulletin de la Société Royale des Sciences de Liège, 85, 735-740.

- Army, U. (1987). TM 5-822-7: Standard Practice for Concrete Pavements. United States Department of the Army.

- Army, U. (2000). Roller-Compacted Concrete. United States Department of the Army.

- Army, U. (2006). Roller compacted concrete, EM 1110-2-2006.

- Ashtankar, V. B., & Chore, H. S. (2014). Development of design mix roller compacted concrete dam at Middle Vaitarana. Advances in concrete construction, 2(2), 125-144.

- Atiş, C. D. (2005). Strength properties of high-volume fly ash roller compacted and workable concrete, and influence of curing condition. Cement and Concrete Research, 35(6), 1112-1121.

- Bauchkar, S. D., & Chore, H. S. (2012). Roller compacted concrete: A literature review. IOSR Journal of Mechanical and Civil Engineering, 28-32.

- Bayagoob, K. H. (2008). Thermal and Structural Analysis of RCC Dams. Ph.D. Thesis. University Putra Malaysia.

- Bayagoob, K. H., & Bamaga, S. O. (2019). Construction of Roller Compacted Concrete Dams in Hot Arid Regions. Materials, 12(19).

- Broberg, L., & Thorwid, M. (2015). Evaluation of failure modes for concrete dams. KTH Royal Institute of Technology.

- Chen, H., & Liu, Z. (2019). Temperature control and thermal-induced stress field analysis of GongGuoQiao RCC dam. Journal of Thermal Analysis and Calorimetry, 135(4), 2019-2029.

- Chen, Y., Wang, C., Li, S., Wang, R., & He, J. (2001). Simulation analysis of thermal stress of RCC dams using 3-D finite element relocating mesh method. Advances in engineering software, 32(9), 677-682.

- Chen, Y. L., Wang, C. J., Li, S. Y., & Chen, L. J. (2003). The effect of construction designs on temperature field of a roller compacted concrete dam-a simulation analysis by a finite element method. Canadian Journal of Civil Engineering, 30(6), 1153-1156.

- Cheng, H., & Zhang, L. (2012). Study on Ultimate Anti-Seismic Capacity of High Arch Dam. Journal of Aerospace Engineering, 26(4), 648-656.

- Chhorn, C., Hong, S. J., & Lee, S. W. (2018). Relationship between compressive and tensile strengths of roller-compacted concrete. Journal of Traffic and Transportation Engineering (English Edition), 5(3), 215-223.

- Chi, M., & Huang, R. (2014). Effect of circulating fluidized bed combustion ash on the properties of roller compacted concrete. Cement and Concrete Composites, 45, 148-156.

- Choi, Y. K., & Groom, J. L. (2001). RCC mix design-soils approach. Journal of materials in Civil Engineering, 13(1), 71-76.

- Courard, L., Michel, F., & Delhez, P. (2010). Use of concrete road recycled aggregates for Roller Compacted Concrete. Construction and Building Materials, 24(3), 390-395.

- DEQ. (2007). Dam operation, maintenance, and inspection manual. Department of Environment and Natural Resources.

- Dunstan, M. (2003). The state‐of‐the‐art of RCC dams in 2003-an update of ICOLD bulletin No. 125. 4th International Symposium on Roller Compacted Concrete Dams, MADRID.

- Fang, C. H., Chen, J., Duan, Y. H., & Xiao, K. (2017). A new method to quantify breach sizes for the flood risk management of concrete arch dams. Journal of Flood Risk Management, 10(4), 511-521.

- FERC. (2002). Chapter III Gravity Dams. In Engineering guidelines for evaluation of hydropower projects. Federal Energy Regulatory Commission, Office of Hydropower Licensing. .

- Ghaedi, K., Jameel, M., Ibrahim, Z., & Khanzaei, P. (2016). Seismic analysis of Roller Compacted Concrete (RCC) dams considering effect of sizes and shapes of galleries. KSCE Journal of Civil Engineering, 20(1), 261-272.

- Gharibdoust, A., Aldemir, A., & Binici, B. (2019). Seismic behaviour of roller compacted concrete dams under different base treatments. Structure and Infrastructure Engineering, 1-12.

- Gu, C. S., Wei, B. W., Xu, Z. K., & Liu, D. W. (2013). Fluid-solid coupling model based on endochronic damage for roller compacted concrete dam. Journal of Central South University, 20(11), 3247-3255.

- Habib, A., Yildirim, U., & Eren, O. (2020). Column repair and strengthening using RC jacketing: a brief state-of-the-art review. Innovative Infrastructure Solutions, 5(3), 75.

- Hansen, K. D., & Reinhardt, W. G. (1991). Roller-compacted concrete dams. McGraw-Hill.

- Harrington, D., Abdo, F., Adaska, W., Hazaree, C. V., Ceylan, H., & Bektas, F. (2010). Guide for roller-compacted concrete pavements. National Concrete Pavement Technology Center.

- Heirany, Z. (2017). Seismic Behavior of RCC Dams Including the Effect of Foundation. Journal of Applied Engineering Sciences, 7(2), 39-43.

- Hu, W., Zhong, D., Wu, B., & Li, Z. (2019). Construction phase oriented dynamic simulation: taking RCC dam placement process as an example. Journal of Civil Engineering and Management, 25(7), 654-672.

- Huang, Y., & Wan, Z. (2018). Study on Viscoelastic Deformation Monitoring Index of an RCC Gravity Dam in an Alpine Region Using Orthogonal Test Design. Mathematical Problems in Engineering.

- Husein Malkawi, A. I., Aufleger, M., & Al-Jammal, M. R. (2004). Temperature distribution in Al-Mujib roller compacted concrete (RCC) gravity dam. In Geo Jordan 2004: Advances in Geotechnical Engineering with Emphasis on Dams, Highway Materials, and Soil Improvement,

- Husein Malkawi, A. I., Mutasher, S. A., & Qiu, T. J. (2003). Thermal-structural modeling and temperature control of roller compacted concrete gravity dam. Journal of performance of constructed facilities, 17(4), 177-187.

- ICOLD. (1995). Dam failures statistical analysis. International Commission on Large Dams (ICOLD), Bulletin 99.

- J. G. M., v. M. (1997). Fracture process of concrete: Assessment of material parameters for fracture models. CRC Press, Inc.

- Jaafar, M. S., Bayagoob, K. H., Noorzaei, J., & Thanoon, W. A. M. (2007). Development of finite element computer code for thermal analysis of roller compacted concrete dams. Advances in Engineering Software, 38(11-12), 886-895.

- Jia, C., Shao, A., Li, Y., & Ren, Q. (2010). Analyses of thermal stress field of high concrete dams during the process of construction. In 2010 Asia-Pacific Power and Energy Engineering Conference, Chengdu, PEOPLES R CHINA.

- Jiang, S., Zhan, S. L., & Xiao, N. (2013). Influence of casting temperature and solar radiation on the thermal field in roller compacted concrete during construction. Applied Mechanics and Materials, 405-408, 2550-2554.

- Kartal, M. E. (2012). Three-dimensional earthquake analysis of roller-compacted concrete dams. Natural Hazards and Earth System Sciences, 12(7), 2369-2388.

- Khanzaei, P., Abdulrazeg, A. A., Samali, B., & Ghaedi, K. (2015). Thermal and structural response of RCC dams during their service life. Journal of Thermal Stresses, 38(6), 591-609.

- Kokubu, K., Cabrerab, J. G., & Uenoa, A. (1996). Compaction Properties of Roller Compacted Concrete.

- Kuzmanovic, V., Savic, L., & Mladenovic, N. (2013). Computation of thermal-stresses and contraction joint distance of RCC dams. Journal of Thermal Stresses, 36(2), 112-134.

- Kuzmanović, V., Savić, L., & Mladenović, N. (2015) . Thermal-stress behaviour of RCC gravity dams. FME Transactions, 43(1), 30-34.

- Lampropoulos, A. P., & Dritsos, S. E. (2011). Concrete shrinkage effect on the behavior of RC columns under monotonic and cyclic loading. Construction and Building Materials, 25(4), 1596-1602.

- Li, M. C., Guo, X. Y., Shi, J., & Zhu, Z. B. (2015). Seepage and stress analysis of anti-seepage structures constructed with different concrete materials in an RCC gravity dam. Water Science and Engineering, 8(4), 326-334.

- Li, S., Ren, J., Yang, T., & Chen, P. (2010). Analysis of the Influence of Concrete Mixed with MgO on the Mass Concrete Thermal Stress. In 2010 Asia-Pacific Power and Energy Engineering Conference, Chengdu, PEOPLES R CHINA.

- Liapichev, Y. P. (2003). Seismic stability and stress-strain state of a new type of FSH-RCC dams. 4th International Symposium on Roller Compacted Concrete Dams, MADRID.

- Liu, G., Lu, W., Lou, Y., Pan, W., & Wang, Z. (2018). Interlayer shear strength of Roller compacted concrete (RCC) with various interlayer treatments. Construction and Building Materials, 166, 647-656.

- Luna, R., & Wu, Y. (2000). Simulation of temperature and stress fields during RCC dam construction. Journal of Construction Engineering and Management, 126(5), 381-388.

- Mohammed, H. A. (2018). Design and evaluation of two-layer roller compacted concrete. University of Nottingham.

- Mughieda, O., Hazirbaba, K., Bani-Hani, K., & Daoud, W. (2018). Numerical modelling of dynamic stability of RCC dam. In MATEC Web of Conferences, Solo Baru, INDONESIA.

- Nagayama, I., & Jikan, S. (2003). 30 Years’ History of Roller-compacted Concrete Dams in Japan. Fourth Int. Symp. on Roller Compacted Concrete Dams,

- Noorzaei, J., Bayagoob, K. H., Thanoon, W. A., & Jaafar, M. S. (2006). Thermal and stress analysis of Kinta RCC dam. Engineering Structures, 28(13), 1795-1802.

- PCA. (2003). Design Manual for Small RCC Dams. Portland Cement Association.

- Pedro, J. O. E. (2014). Arch dams: Designing and monitoring for safety (Vol. 367). Springer.

- Perumal, L., & Mon, D. T. T. (2011). Finite elements for engineering analysis: a brief review. In Proceedings of the International Conference on Modeling, Simulation and Control, Singapore.

- Punmia, B. C., Lal, P. B. B., Jain, A. K., & Jain, A. K. (2009). Irrigation and water power engineering. Laxmi Publications, Ltd.

- Rao, S. K., Sravana, P., & Rao, T. C. (2016a). Abrasion resistance and mechanical properties of Roller Compacted Concrete with GGBS. Construction and Building Materials, 114, 925-933.

- Rao, S. K., Sravana, P., & Rao, T. C. (2016b). Investigating the effect of M-sand on abrasion resistance of Roller Compacted Concrete containing GGBS. Construction and Building Materials, 122, 191-201.

- Rongmei, J., & Wei, F. (2007). Impact of Interlayer and Size Effect on the Mechanical Performances of Fully Graded RCC. Water Power, 4.

- Rooholamini, H., Hassani, A., & Aliha, M. R. M. (2018). Fracture properties of hybrid fibre-reinforced roller-compacted concrete in mode I with consideration of possible kinked crack. Construction and Building Materials, 187, 248-256.

- Saleh, S. F., Rather, F. F., & Jabbar, M. J. (2017). Roller-compacted concrete (RCC) and its application in modern world of Technology. International Research Journal of Engineering and Technology 4(4).

- Sha, S., Lei, Z., & Zhang, X. (2016). Study on failure mechanism of roller compacted concrete gravity dams by an isotropic damage model. International Conference on Smart City and Systems Engineering (ICSCSE), IEEE.

- Shamsai, A., Ghaemian, M., & Azimfar, S. M. (2009). Thermo-Mechanical Analysis of Roller Compacted Concrete (RCC) Dams (Jahgin Dam). In Symposium on the Application of Geophysics to Engineering and Environmental Problems,

- Su, H., Wen, Z., Yan, X., Liu, H., & Yang, M. (2018). Early-warning model of deformation safety for roller compacted concrete arch dam considering time-varying characteristics. Composite Structures, 203, 373-381.

- Su, P. F., Wang, W. M., & Lu, X. L. (2011). STUDY ON SAFETY EVALUATION METHODS AND FAILURE MECHANISM OF HIGH ROLLER COMPACTED CONCRETE DAM. In Engineering Plasticity And Its Applications, 275-280.

- Tschuchnigg, F., & Schweiger, H. (2014). 3D Finite Element analysis of a RCC dam. In 8th European Conference on Numerical Methods in Geotechnical Engineering, Balkema.

- Tun, Z. P., Kyaw, N. M., & Htwe, K. S. S. (2016). Properties of Roller Compacted Concrete with Pozzolan as Cement Replacement Material. INTERNATIONAL JOURNAL FOR INNOVATIVE RESEARCH IN MULTIDISCIPLINARY FIELD 2(12), 247-255.

- Wang, J., & Chopra, A. K. (2008). EACD-3D-2008: A computer program for three-dimensional earthquake analysis of concrete dams considering spatially-varying ground motion. Earthquake Engineering Research Center.

- Wang, J., Jin, F., & Zhang, C. (2011). Seismic safety of arch dams with aging effects. Science China Technological Sciences, 54(3), 522-530.

- Wang, C., Chen, W., Hao, H., Zhang, S., Song, R., & Wang, X. (2018a). Experimental investigations of dynamic compressive properties of roller compacted concrete (RCC). Construction and building materials, 168, 671-682.

- Wang, L., Zhang, G., Wang, P., & Yu, S. (2018b). Effects of fly ash and crystalline additive on mechanical properties of two-graded roller compacted concrete in a high RCC arch dam. Construction and Building Materials, 182, 682-690.

- Wang, Q., Huang, Z., & Wang, D. (2018c). Influence of high-volume electric furnace nickel slag and phosphorous slag on the properties of massive concrete. Journal of Thermal Analysis and Calorimetry, 131(2), 873-885.

- Warren, T. (2012). Roller Compacted Concrete for Dam Construction. Volume, 22, 87-90.

- Warren, T. (2013). Roller-compacted concrete dams: a brief history and their advantages. Dams and Reservoirs, 22(2), 87-90.

- Willam, K. J., & Warnke, E. D. (1975). Constitutive model for the triaxial behavior of concrete. Proceedings of International Association for Bridge and Structural Engineering, Bergamo, Italy.

- Wilson, E. L., & Habibullah, A. (1989). SAP90: A Series of Computer Programs for the Static and Dynamic Finite Element Analysis of Structures: Users Manual. Computers & Structures, Incorporated.

- Xia, S. F. (2017). Simulation analysis of temperature control on RCC arch dam of hydropower station. In IOP Conference Series: Earth and Environmental Science, Singapore, SINGAPORE.

- Xie, H., & Chen, Y. (2005). Determination of the type and thickness for impervious layer in RCC dam. Advances in Engineering Software, 36(8), 561-566.

- Yahui, D., & Guowei, L. (1995). Study on failure mechanism of roller compacted concrete fravity dam. Journal of Hydraulic Engineering, 5, 55-59.

- Yang, L., & Shi, J. J. (2009). Experimental study on the impact of rainfall on RCC construction. Journal of Construction Engineering and Management, 136(5), 477-483.

- Zarrin, O., Shirazi, M. R., Moniri, H., & Moniri, M. (2016). Roller-compacted concrete dams rehabilitation in terms of different problem. Journal of Civil & Environmental Engineering, 6(2), 1-4.

- Zhang, L., Zhai, Y., Chen, D., & Cui, X. (2019a). Study on influence of dam foundation damage on seismic safety of gravity dam under combined action of main shock and aftershock. In IOP Conference Series: Earth and Environmental Science,

- Zhang, X., Shi, R., Dai, H., Liu, Q., & Zhang, X. (2019b). Simulation and Research on Temperature Field of Taishan Roller Compacted Concrete Gravity Dam. In IOP Conference Series: Earth and Environmental Science, Chengdu, PEOPLES R CHINA.

- Zhang, X., Zhang, X., Yan, T., Huang, Y., Liu, Q., & Wang, X. (2019c). Experimental analysis and numerical calculation on equivalent strength of induced joints of different ages and weakening degrees. Journal of the Ceramic Society of Japan, 127(9), 642-650.

- Zhang, X. F., Li, S. Y., Li, Y. L., Ge, Y., & Li, H. (2011). Effect of superficial insulation on roller-compacted concrete dams in cold regions. Advances in Engineering Software, 42(11), 939-943.

- Zheng, X., Zhou, J., Chen, G., & Chen, S. (2020). Exposure Assessment for Roller Compacted Concrete Dam Construction Integrated Real-Time Location Information. KSCE Journal of Civil Engineering, 24(3), 703-714.

- Zhou, H., Zhou, Y., Zhao, C., & Liang, Z. (2016). Optimization of the temperature control scheme for roller compacted concrete dams based on finite element and sensitivity analysis methods. Civil Engineering Journal-Stavebni Obzor, 3(14), 1-16.

Edited by

Editor:

Publication Dates

-

Publication in this collection

13 May 2021 -

Date of issue

2021

History

-

Received

26 Feb 2021 -

Reviewed

03 Mar 2021 -

Accepted

17 Apr 2021 -

Published

19 Apr 2021