Abstract

Pumpkin is a yellow or orange-colored vegetable with a mild flavor that stands out as a fiber and nutrient source. However, the products with pumpkins are still little explored in Brazil, due to high perishability in natura and to the lack of eating habits of regional baked goods. This study aimed to produce and characterize a pumpkin flour to be used as an ingredient in muffins, evaluate the technological, and sensory characteristics of these cakes, and select the most sensorially accepted muffin for nutritional composition evaluation. Three muffins were produced as following: one control (M0); and two containing 5 (M1) and 10 (M2) g/100 g of partial substitution of wheat flour by pumpkin flour, thus maintaining the other ingredients common to cakes. The technological characteristics of firmness, volume and color were evaluated. Sensory acceptance was assessed using an affective test on an unstructured 9-point hedonic scale. There were no significant differences in the firmness and image analysis (distribution, size, and pore area of the crumb) among the three muffins, however, M1 and M2 presented darker crust color, more orange crumb, and a lower volume compared to M0. The sensory acceptability of the muffins was considered as a criterion for selection for nutritional composition analysis. The muffins’ acceptance of M1 was better than M0, but without differences to M2. The consumers’ opinions were also considered, and M1 was selected for having greater acceptance. Nutritionally, M0 and M1 presented similar levels of proteins, digestible carbohydrates, and lipids, however, M1 showed a higher content of ash and total dietary fibers: 2.01 ± 0.03 and 1.57 g/100 g (dry basis), respectively. Thus, the pumpkin flour could be produced and used as a regional, enriched, and natural-colored ingredient for muffins or other bakery products, and therefore they had a socially positive impact on family farming.

Keywords:

Sustainability; Healthiness; Bakery; Fiber; Cake; Family farming

Resumo

A abóbora é um vegetal de cor amarela ou laranja, de sabor suave, que se destaca como fonte de fibra e nutrientes. Porém, os produtos com abóboras ainda são pouco explorados no Brasil, devido à sua alta perecibilidade in natura e à falta de hábitos alimentares dos produtos de panificação regionais. O objetivo deste estudo foi produzir e caracterizar uma farinha de abóbora para ser utilizada como ingrediente em muffins, além de avaliar as características tecnológicas e sensoriais desses bolos, e selecionar o muffin com maior aceitação sensorial para avaliação de sua composição nutricional. Foram produzidos três muffins: um controle (M0) e dois contendo de 5 (M1) e 10 (M2) g/100 g de substituição parcial da farinha de trigo pela farinha de abóbora, mantendo-se os demais ingredientes comuns aos bolos. Foram avaliadas as características tecnológicas de firmeza, volume e cor. A aceitação sensorial foi avaliada utilizando um teste afetivo em escala hedônica não estruturada de nove pontos. Não houve diferenças significativas na firmeza e na análise de imagem (distribuição, tamanho e área dos poros do miolo) entre os três muffins, porém M1 e M2 apresentaram cor da crosta mais escura, miolo mais laranja e menor volume em relação ao M0. Foi considerada a aceitabilidade sensorial dos muffins como critério de seleção para análise da composição nutricional. A aceitação dos muffins M1 foi melhor do que a aceitação de M0, mas sem diferenças em relação a M2. A opinião dos consumidores também foi considerada e M1 foi selecionado por ter maior aceitação. Nutricionalmente, M0 e M1 apresentaram teores semelhantes de proteínas, carboidratos digestíveis e lipídios, mas M1 apresentou um maior teor de cinzas e fibras totais: 2,01 ± 0,03 e 1,57 g/100 g (base seca), respectivamente. Assim, a farinha de abóbora poderá ser produzida e usada como ingrediente regional, enriquecido e de cor natural para muffins ou outros produtos de panificação e, dessa forma, ter um impacto socialmente positivo para os pequenos agricultores.

Palavras-chave:

Sustentabilidade; Saudabilidade; Panificação; Fibras; Bolo; Agricultura familiar

1 Introduction

In Brazil, pumpkins (Cucurbita sp.) are grown mainly by family farming and locally commercialized due to its high perishability and low-profit margin (Resende et al., 2013Resende, G. M., Borges, R. M. E., & Gonçalves, N. P. (2013). Produtividade da cultura da abóbora em diferentes densidades de plantio no Vale do São Francisco. Horticultura Brasileira, 31(3), 504-508. http://dx.doi.org/10.1590/S0102-05362013000300027

http://dx.doi.org/10.1590/S0102-05362013...

). It is well-known that pumpkins are a high energy food source and possess a considerable amount of total dietary fiber: 1.1 g/100 g in the cooked pulp, without peel and seeds (United States Department of Agriculture, 2019United States Department of Agriculture – USDA. (2019). USDA food data central. Retrieved in 2017, January 20, from https://fdc.nal.usda.gov/

https://fdc.nal.usda.gov/...

). The dietary fibers are very important for health, specifically for the prevention of cardiometabolic diseases due to its roles in satiety, glucose control, maintenance of gastrointestinal regular function and microbiota (Lie et al., 2018Lie, L., Brown, L., Forrester, T., Plange-Rhule, J., Bovet, P., Lambert, E., Layden, B., Luke, A., & Dugas, L. (2018). The association of dietary fiber intake with cardiometabolic risk in four countries across the epidemiologic transition. Nutrients, 10(5), 1-12. PMid:29772682. http://dx.doi.org/10.3390/nu10050628

http://dx.doi.org/10.3390/nu10050628...

).

In addition to the pulp, its peel is also an edible source of fiber, i.e., frequently discarded and considered as a food waste (Staichok et al., 2016Staichok, A. C. B., Mendonça, K. R. B., dos Santos, P. G. A., Garcia, L. G. C., & Damiani, C. (2016). Pumpkin Peel Flour (Cucurbita maxima L.): Characterization and technological applicability. Journal of Food and Nutrition Research, 4(5), 327-333. http://dx.doi.org/10.12691/jfnr-4-5-9

http://dx.doi.org/10.12691/jfnr-4-5-9...

). As vegetable flour, the peel of pumpkins could be largely used, besides the advantage of the extended shelf-life, thus increasing its possibilities of use and the nutritional enhancement of products such as soups, creams, bread, or cakes. Baked goods have been targets for fortification and nutritional improvement due to their daily role in the diets of consumers (Zhou et al., 2014Zhou, W., Hui, Y. H., De Leyn, I., Pagani, M. A., Rosell, C. M., Selman, J. D., & Therdthai, N. (Eds.). (2014). Bakery products science and technology. Chichester: John Wiley & Sons. http://dx.doi.org/10.1002/9781118792001

http://dx.doi.org/10.1002/9781118792001...

).

Notably, there is a demand for healthier formulations of baked goods that traditionally present a high content of sugar and fats – like biscuits and muffins, for instance. The muffins are sweet cakes with a round shape, consisting of a Wheat Flour (WF) base, which are consumed in a meal or snack since they are ready-to-eat products available in small portions (Soong et al., 2015Soong, Y. Y., Quek, R. Y. C., & Henry, J. (2015). Glycemic potency of muffins made with wheat, rice, corn, oat and barley flours: A comparative study between in vivo and in vitro. European Journal of Nutrition, 54(8), 1281-1285. PMid:25637395. http://dx.doi.org/10.1007/s00394-014-0806-9

http://dx.doi.org/10.1007/s00394-014-080...

). In addition to the nutritional purpose, these vegetable flours, such as pumpkin flour, could be beneficial for the partial replacement of WF in bakery products, and appreciation of local agriculture, particularly for countries that have a dependency on wheat import. The use of locally produced food products could also be a nutritious and alternative source of dietary fiber in pandemic times, such as Coronavirus Disease 2019 (COVID-19), where the circulation of products and people is limited (He & Harris, 2020He, H., & Harris, L. (2020). The impact of COVID-19 pandemic on corporate social responsibility and marketing philosophy. Journal of Business Research, 116(0), 176-182. PMid:32457556. http://dx.doi.org/10.1016/j.jbusres.2020.05.030

http://dx.doi.org/10.1016/j.jbusres.2020...

).

Thus, to stimulate a production chain of a new vegetable flour, this research aimed to produce and characterize pumpkin flour (made with the pulp and peel of pumpkins) for chemical and technological characteristics. The addition of pumpkin flour in muffin formulations was also evaluated, through technological and sensory characteristics, in addition to selecting the most sensorially accepted muffin for evaluating nutritional composition.

2 Material and methods

2.1 Material sourcing

Pumpkins (Cucurbita maxima Duch.) were purchased at the Central de Abastecimento SA. (CEASA), located in Campinas, SP, Brazil. The WF used was donated by Moinho Anaconda Industrial e Agrícola de Cereais S.A. (Jaguaré, São Paulo, Brazil). The rheological properties of the WF were: Water Absorption = 58.20%; Dough Development Time (DDT) = 15.33 ± 0.25 min; Mixing Tolerance Index (MTI) = 24.67 ± 2.89 Brabender Units; and Dough Stability (DS) = 23.07 ± 0.76 min, characterizing it as a strong flour (Pyler & Gorton, 2009Pyler, E. J., & Gorton, L. A. (Eds.). (2009). Baking: Science & technology (Vol. II). Kansas City, USA SOSLAND Publishing Company.).

All the other ingredients (eggs, sugar, soybean oil, baking soda, salt, and soybean lecithin) were purchased in retail trade stores of Campinas city (São Paulo, Brazil), making sure that they were from the same lot.

2.2 Production of pumpkin flour

The ripe pumpkins (commercial point of maturation) were received, washed, and sanitized by immersion in chlorine solution at 200 mg/L for 15 min. The pumpkins were cut in half, the seeds removed and each portion of the pumpkin reduced to smaller pieces (cubes, 6 cm3), which were then subjected to the bleaching process (4 min at 95 °C). Then, the pumpkins were dried with forced air circulation at a rate of 2.5 m/s and 50 °C until the moisture content was less than 12 g/100 g (approximately 7 hours).

To obtain the Pumpkin Flour (PF), the dehydrated pumpkin was ground and sieved to 0.5 mm. The PF was packaged hermetically and stored under refrigeration at 8 °C until its use. The yield of flour production was calculated by the difference in the weight of the pumpkins (without the seeds, fibrous pulp, and rotten parts).

2.3 Physicochemical characterization of pumpkin flour

2.3.1 Chemical composition

The chemical composition was evaluated by the following methods from the Association of Official Analytical Chemists (2006)Association of Official Analytical Chemists – AOAC. (2006). Official methods of analysis of the Association of Official Analytical Chemists (18th ed.). Gaithersburg: AOAC International.: n° 926.12, for moisture; n° 945.18, for protein; nº 900.02, for ash; nº 920.39, for lipid in the ethereal extract. The digestible carbohydrate content was calculated by difference: [100 - (moisture + ethereal extract + protein + ash + dietary fiber)].

The total, soluble and insoluble, dietary fiber was evaluated by an enzymatic-gravimetric method, using a Megazyme K-TDFR 05/12 kit (Megazyme, Wicklow, Ireland), based on methods nº 985.29 (Association of Official Analytical Chemists, 2006Association of Official Analytical Chemists – AOAC. (2006). Official methods of analysis of the Association of Official Analytical Chemists (18th ed.). Gaithersburg: AOAC International.) and nº 32-21.01 (American Association of Cereal Chemists, 2010American Association of Cereal Chemists – AACC. (2010). Approved methods of the American Association of Cereal Chemists (11th ed.). St. Paul: AACC International.). The total titratable acidity and reducing sugars were performed according to methodologies of Instituto Adolfo Lutz (2008)Instituto Adolfo Lutz – IAL. (2008). Métodos físico-químicos para análise de alimentos (4. ed.). São Paulo: IAL. nº 310/IV and 176/IV, respectively.

2.3.2 Technological properties

Water Absorption Index (WAI) and Water Solubility Index (WSI) were performed by methodology proposed for Anderson et al. (1970)Anderson, R. A., Conway, H. F., & Peplinski, A. J. (1970). Gelatinization of corn grits by roll cooking, extrusion cooking and steaming. Starch, 22(4), 130. http://dx.doi.org/10.1002/star.19700220408

http://dx.doi.org/10.1002/star.197002204...

, and pH was evaluated according to method n° 02-52.01 (American Association of Cereal Chemists, 2010American Association of Cereal Chemists – AACC. (2010). Approved methods of the American Association of Cereal Chemists (11th ed.). St. Paul: AACC International.) using a potentiometric meter model 300 M (Analyzer, São Paulo, SP, Brazil), in triplicate.

2.3.3 Instrumental color

Color parameters were evaluated by a Mini ScanXE HunterLab colorimeter (Reston MINOLTA, Virginia, USA, 1994), with illuminant D 65 and 10° angle. The CIELab color space method was used, determining the parameters L*, a*, and b*.

2.4 Preparation of muffins

The muffins were made with partial replacement of WF by PF at three levels: M0 (control), M1, and M2, corresponding to 5 g and 10 g of substitution in 100 g of WF, respectively. The formulations and proportions of the other ingredients are described in Table 1.

For the preparation of the muffins, the oil and sugar were mixed for 3 min using a Kitchen Aid (St. Joseph, Michigan, USA), and then the eggs were added and mixed for 3 min. The remaining ingredients were added, and mixed for about 2 min. A fixed amount (55 g) of muffin batter was distributed in paper liners (5 cm diameter, and 4 cm height), and baked in a Technipan oven (Prática Equipamentos, Pouso Alegre, Brazil) at 190 °C for 13 min, cooled at room temperature for 60 min and then stored in polystyrene packages.

2.5 Technological characterization of muffins

2.5.1 Specific volume

The specific volume was determined after 24 hours of storage, by the Rapeseed Displacement method n° 10-05.01 (American Association of Cereal Chemists, 2010American Association of Cereal Chemists – AACC. (2010). Approved methods of the American Association of Cereal Chemists (11th ed.). St. Paul: AACC International.).

2.5.2 Thickness of the crust and instrumental texture of crumb

The muffins were cut in half, and the thickness of the crust was measured using a digital electronic caliper (in mm). Firmness of the crumb was determined using a TA-XT2i Stable Micro Systems Texturometer (Surrey, England), with a 25 kg load cell and cylindrical probe P/36R, according to parameters described in method n° 74-09.01 (American Association of Cereal Chemists, 2010American Association of Cereal Chemists – AACC. (2010). Approved methods of the American Association of Cereal Chemists (11th ed.). St. Paul: AACC International.). The results were obtained in the Texture Expert software for Windows.

2.5.3 Instrumental color parameters

The instrumental color parameters for the crust and the crumb of the muffins were evaluated by the methodology described in item 2.3.3.

2.5.4 Image analysis

For the image analysis, the muffins were cut in half and the images were acquired in triplicate, using the HP Scanjet G2710 scanner equipment (Hewlett-Packard Enterprises, Brazil). Image analysis was performed in ImageJ software (National Institutes of Health, 2017National Institutes of Health – NIH. (2017). ImageJ software. Bethesda, USA. Retrieved in 2017, January 20, from https://imagej.nih.gov/ij/

https://imagej.nih.gov/ij/...

).

For the total number of pores and total area of pores (in mm2) quantification, the Otsu Thresholding algorithm (Otsu, 1979Otsu, N. (1979). A threshold selection method from gray-level histograms. IEEE Transactions on Systems, Man, and Cybernetics, 9(1), 62-66. http://dx.doi.org/10.1109/TSMC.1979.4310076

http://dx.doi.org/10.1109/TSMC.1979.4310...

) was used, combined with the Median filter with a value of 1.5 pixels to allow the contrast between the pores and the continuous part of the images (Turabi et al., 2008Turabi, E., Sumnu, G., & Sahin, S. (2008). Rheological properties and quality of rice cakes formulated with different gums and an emulsifier blend. Food Hydrocolloids, 22(0), 305-312. http://dx.doi.org/10.1016/j.foodhyd.2006.11.016

http://dx.doi.org/10.1016/j.foodhyd.2006...

).

2.5.5 Consumer testing of muffins and selection

The sensory analysis was previously approved by the Research Ethics Committee of Unicamp (CAAE 54667116.9.0000.5404), to apply an acceptance test to 119 consumers, according to the Meilgaard et al. (2000)Meilgaard, M., Civille, G. V., & Carr, B. T. (2000). Sensory evaluation techniques (3rd ed.). Boca Raton: CRC Press. methodology. The consumers were asked to evaluate the samples appearance, aroma, texture and overall liking of the muffins using an unstructured 9-point hedonic scale (9 cm, labelled in the lower extreme as “disliked it extremely” and in the upper extreme, as “liked it extremely”). The best sensory-evaluated muffin containing the PF was selected for the nutritional characterization.

2.5.6 Nutritional characterization of the selected muffin

For the nutritional evaluation, the selected muffin was characterized by its proximate composition with the same methodology described in item 2.3.1. The total dietary fiber was calculated considering only the refined WF and the PF as a source of this food component.

2.6 Statistical analysis

The obtained data from technological and sensory evaluations were analyzed by Analysis of Variance (ANOVA), and the difference between the means evaluated by Tukey’s test, using the software SISVAR, version 5.6 (Ferreira, 2000Ferreira, D. F. (2000). Análises estatísticas por meio do Sisvar para Windows versão 4.0. In Anais da 45ª Reunião Anual da Região Brasileira da Sociedade Internacional de Biometria (pp. 255-258). São Carlos: RBras.). For the nutritional composition of muffins, the data were analyzed by ANOVA followed by F-test using the Excel software Excel software (Microsoft Office Mondo 2016 version, Redmond, Washington, EUA).

3 Results and discussion

3.1 Physicochemical characterization of pumpkin flour

3.1.1 Chemical composition

After the processing of the PF, we observed an acceptable yield of 3.85 g/100 g, considering that pumpkins have only 5 g of dry matter/100 g of fresh pulp (United States Department of Agriculture, 2019United States Department of Agriculture – USDA. (2019). USDA food data central. Retrieved in 2017, January 20, from https://fdc.nal.usda.gov/

https://fdc.nal.usda.gov/...

).

The results of the physicochemical characteristics of the PF are described in Table 2. Regarding moisture content of PF, similar results were observed by Ambrósio et al. (2006)Ambrósio, C. L. B., Campos, F. A. C. S., & Faro, Z. P. (2006). Aceitabilidade de flocos desidratados de abóbora. Revista de Nutrição, 19(1), 39-45. http://dx.doi.org/10.1590/S1415-52732006000100004

http://dx.doi.org/10.1590/S1415-52732006...

, for dehydrated pumpkin flakes. This low content contributes to its microbial stability and nutrient conservation. The protein and lipids content of PF was like those found by Guiné et al. (2011)Guiné, R. P. F., Pinho, S., & Barroca, M. J. (2011). Food and bioproducts processing study of the convective drying of pumpkin (Cucurbita maxima). Food and Bioproducts Processing, 89(4), 422-428. http://dx.doi.org/10.1016/j.fbp.2010.09.001

http://dx.doi.org/10.1016/j.fbp.2010.09....

for its dehydrated pumpkin samples. The ash content of the dehydrated pumpkin of the mentioned study was higher when compared to our PF, which could be due to harvest variations, such as soil type stage of maturation. A higher total dietary fiber content was found for PF when compared to the one reported by Guiné et al. (2011)Guiné, R. P. F., Pinho, S., & Barroca, M. J. (2011). Food and bioproducts processing study of the convective drying of pumpkin (Cucurbita maxima). Food and Bioproducts Processing, 89(4), 422-428. http://dx.doi.org/10.1016/j.fbp.2010.09.001

http://dx.doi.org/10.1016/j.fbp.2010.09....

, probably due to the utilization of the peel of the pumpkin in the production of the flour in our study, and it is also related to a lower total digestible carbohydrate content. During the pumpkin processing, the discard of edible parts is significant and bulky, and the use of pumpkin peel contributes as a source of dietary fiber and reduces food waste (Staichok et al., 2016Staichok, A. C. B., Mendonça, K. R. B., dos Santos, P. G. A., Garcia, L. G. C., & Damiani, C. (2016). Pumpkin Peel Flour (Cucurbita maxima L.): Characterization and technological applicability. Journal of Food and Nutrition Research, 4(5), 327-333. http://dx.doi.org/10.12691/jfnr-4-5-9

http://dx.doi.org/10.12691/jfnr-4-5-9...

).

The reducing sugars content in PF was close to those reported by Guiné et al. (2011)Guiné, R. P. F., Pinho, S., & Barroca, M. J. (2011). Food and bioproducts processing study of the convective drying of pumpkin (Cucurbita maxima). Food and Bioproducts Processing, 89(4), 422-428. http://dx.doi.org/10.1016/j.fbp.2010.09.001

http://dx.doi.org/10.1016/j.fbp.2010.09....

, who also evaluate C. maxima pumpkin dehydrated at two different temperatures (30 °C and 70 °C). While reducing sugars are mostly glucose and fructose, they contribute as a sweetener and for the color of the bakery products toward both caramelization and Maillard reaction, leading to the color and flavor formation (Purlis, 2010Purlis, E. (2010). Browning development in bakery products: A review. Journal of Food Engineering, 99(3), 239-249. http://dx.doi.org/10.1016/j.jfoodeng.2010.03.008

http://dx.doi.org/10.1016/j.jfoodeng.201...

).

3.1.2 Technological properties

The technological properties of the PF were described in Table 2. Regarding the WAI and WSI, the results were probably due to the bleaching process of the pumpkins and their subsequent drying, which could be related to the cold hydration of a pregelatinized starch fraction, which occurs during treatments with heat (Poliszko et al., 2019Poliszko, N., Kowalczewski, P. Ł., Rybicka, I., Kubiak, P., & Poliszko, S. (2019). The effect of pumpkin flour on quality and acoustic properties of extruded corn snacks. Journal of Consumer Protection and Food Safety, 14(2), 121-129. http://dx.doi.org/10.1007/s00003-019-01216-6

http://dx.doi.org/10.1007/s00003-019-012...

). Thus, the PF is a highly recommended ingredient to be used in pre-mix formulations of cakes, and several other baked goods that require a shorter preparation process and a rapid hydration period.

We observed pH value close to 6 in the PF, which was like the one found by Tamer et al. (2010)Tamer, C. E., İncedayi, B., Parseker, S., Yonak, S., & Çopur, Ö. U. (2010). Evaluation of several quality criteria of low-calorie pumpkin dessert. Notulae Botanicae Horti Agrobotanici, 38(1), 76-80. for pulp from C. maxima pumpkin (5.80 ± 0.15). Due to its pH, the pumpkins are classified as a food with low acidity, which associated to its high moisture content - 95 g/100 g of fresh pulp (United States Department of Agriculture, 2019United States Department of Agriculture – USDA. (2019). USDA food data central. Retrieved in 2017, January 20, from https://fdc.nal.usda.gov/

https://fdc.nal.usda.gov/...

) – then favoring the growth of microorganisms that causes deterioration. Thus, the reduction of the water activity by the dehydration process for the production of the PF could contribute to an increase of the shelf life of pumpkins (Staichok et al., 2016Staichok, A. C. B., Mendonça, K. R. B., dos Santos, P. G. A., Garcia, L. G. C., & Damiani, C. (2016). Pumpkin Peel Flour (Cucurbita maxima L.): Characterization and technological applicability. Journal of Food and Nutrition Research, 4(5), 327-333. http://dx.doi.org/10.12691/jfnr-4-5-9

http://dx.doi.org/10.12691/jfnr-4-5-9...

).

The transformation of the pumpkin into a flour also favors its commercialization for a longer period and not only during its production. Regarding the titratable acidity, which is a parameter related to the flavor, it was also reported that the pumpkins have low content, and among the organic acids found in these vegetables, malic acid is highlighted (Nawirska-Olszańska et al., 2014Nawirska-Olszańska, A., Biesiada, A., Sokół-Łętowska, A., & Kucharska, A. Z. (2014). Characteristics of organic acids in the fruit of different pumpkin species. Food Chemistry, 148, 415-419. PMid:24262577. http://dx.doi.org/10.1016/j.foodchem.2013.10.080

http://dx.doi.org/10.1016/j.foodchem.201...

).

3.1.3 Instrumental color

Regarding the parameters of the color of PF (Table 2), the orange color was predominant. In the study of Guiné et al. (2011)Guiné, R. P. F., Pinho, S., & Barroca, M. J. (2011). Food and bioproducts processing study of the convective drying of pumpkin (Cucurbita maxima). Food and Bioproducts Processing, 89(4), 422-428. http://dx.doi.org/10.1016/j.fbp.2010.09.001

http://dx.doi.org/10.1016/j.fbp.2010.09....

with dry pumpkin pulp at 70 °C, the authors observed L*, a*, and b* values of 63.38, 28.01, and 57.26, respectively, i.e., very close to those found in the present study. The orange color of the pumpkins is due to the presence of carotenoids, mainly lutein, lycopene and β-carotene, which is a natural colorant that has effects on human health, associated with anti-inflammatory, antioxidant properties as well as a provitamin A function (Rodriguez-Amaya, 2016Rodriguez-Amaya, D. B. (2016). Food carotenoids: Chemistry, biology and technology (1st ed.). Chichester: John Wiley & Sons.). Processing factors, such as temperature, as well as the characteristics of the food (moisture content, composition and thickness) can affect the rate of loss of these carotenoids, leading to a reduction of the visual orange color intensity. Thus, it is important the control and use of mild heating in the drying process (Sojak et al., 2014Sojak, M. J., Jaros, M., & Głowacki, S. (2014). Analysis of giant pumpkin (Cucurbita maxima) quality parameters in various technologies of convective drying after long-term storage. Drying Technology, 32(1), 106-116. http://dx.doi.org/10.1080/07373937.2013.816854

http://dx.doi.org/10.1080/07373937.2013....

). In studies with carrots, convective drying conditions between 45-55 °C for 8 hours were recommended to obtain greater β-carotene retention (Demiray & Tulek, 2017Demiray, E., & Tulek, Y. (2017). Degradation kinetics of β-carotene in carrot slices during convective drying. International Journal of Food Properties, 20(1), 151-156. http://dx.doi.org/10.1080/10942912.2016.1147460

http://dx.doi.org/10.1080/10942912.2016....

). In study with convective drying methods for pumpkins (C. maxima), temperatures below 60 °C were well suitable for better retention of carotenoids after storage (Sojak et al., 2014Sojak, M. J., Jaros, M., & Głowacki, S. (2014). Analysis of giant pumpkin (Cucurbita maxima) quality parameters in various technologies of convective drying after long-term storage. Drying Technology, 32(1), 106-116. http://dx.doi.org/10.1080/07373937.2013.816854

http://dx.doi.org/10.1080/07373937.2013....

). These conditions were similar to those used in our study.

3.2 Technological characterization of muffins

3.2.1 Specific volume

The results for this parameter are presented in Table 3. The specific volume is mainly related to softness and maintenance of an aerated structure after baking, not only due to the gluten network, but also by the denaturation of egg proteins and starch gelatinization after baking (Zhou et al., 2014Zhou, W., Hui, Y. H., De Leyn, I., Pagani, M. A., Rosell, C. M., Selman, J. D., & Therdthai, N. (Eds.). (2014). Bakery products science and technology. Chichester: John Wiley & Sons. http://dx.doi.org/10.1002/9781118792001

http://dx.doi.org/10.1002/9781118792001...

). The M1 and M2 presented a lower specific volume than M0, probably owing to the fiber content of the PF. According to Aydogdu et al. (2018)Aydogdu, A., Sumnu, G., & Sahin, S. (2018). Effects of addition of different fibers on rheological characteristics of cake batter and quality of cakes. Journal of Food Science and Technology, 55(2), 667-677. PMid:29391631. http://dx.doi.org/10.1007/s13197-017-2976-y

http://dx.doi.org/10.1007/s13197-017-297...

, the vegetal fiber could reduce the volume in cakes due to its physical interference in gas retention capacity of the starch-gluten matrix. However, in cakes, the weakening of the gluten network is desirable, especially with wheat flours that have greater gluten strength (Gutkoski et al., 2011Gutkoski, L. C., Durigon, A., Mazzutti, S., Cezare, K., & Colla, L. M. (2011). Influência do tipo de farinha de trigo na elaboração de bolo tipo inglês. Brazilian Journal of Food Technology, 14(4), 275-282. http://dx.doi.org/10.4260/BJFT2011140400033

http://dx.doi.org/10.4260/BJFT2011140400...

), where the PF can replace the use of commercial starches or gluten-free flours used for this purpose, also promoting the regionalization of the baked goods.

Technological and color parameters of the control muffins (M0) and with pumpkin flour (M1 and M2)(1).

3.2.2 Thickness of the crust and instrumental texture of crumb

The thickness of the crust of muffins were 2.62 ± 0.00, 2.66 ± 0.00 and 2.68 ± 0.00 for M0, M1 and M2, respectively. There were no significative differences for this parameter, which could indicate a homogeneous baking of the surface of the muffins. For the firmness, the M1 (5 g of PF/100 g of WF) showed a softer crumb statistically different from the M0 and M2, as could be observed in Table 3. According to Zhou et al. (2014)Zhou, W., Hui, Y. H., De Leyn, I., Pagani, M. A., Rosell, C. M., Selman, J. D., & Therdthai, N. (Eds.). (2014). Bakery products science and technology. Chichester: John Wiley & Sons. http://dx.doi.org/10.1002/9781118792001

http://dx.doi.org/10.1002/9781118792001...

, a softer crumb in cakes is an important quality parameter for consumers. Thus, the quantity of 5 g of PF could bring a technological benefit for cakes.

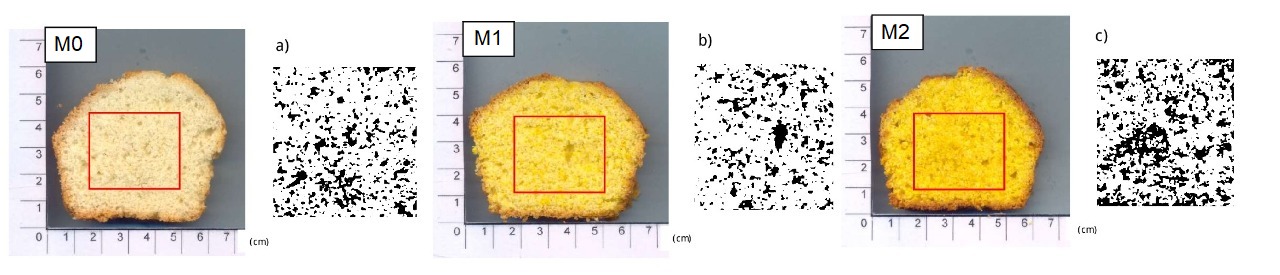

3.2.3 Instrumental color parameters

PF addition affected color parameters L*, a*, and b* of the crumb, and all the muffins with PF differed significantly when compared to M0, as could be observed in Table 3. There was a decrease in the value of luminosity (L*), and an increase in values for parameters a* and b*, visually interpreted as “yellow” and “red”, respectively. That modification was caused due to the intense orange color from the β-carotene present in the pumpkin and that remained in the flour, even after processing (Figure 1).

Images of muffin’s crumb to M0 (flour basis: 100 g Wheat Flour -WF, and 0 g Pumpkin Flour – PF), M1 (95 g WF and 5 g PF), and M2 (90 g WF and 10 g PF) and a, b and c are correspondent binary images with Otsu Threshold algorithm and median filter with a value of 1.5 pixels (the red lines highlight the region of the collected binary image).

Regarding crust color, the muffins containing the PF (M1 and M2) presented a darker (lower L*) and orange (higher a* and b* values) color when compared to M0 (Table 3). The crust color is important for the acceptability of the muffins due to the consumer demand, who want a crust with the characteristic golden color (Zhou et al., 2014Zhou, W., Hui, Y. H., De Leyn, I., Pagani, M. A., Rosell, C. M., Selman, J. D., & Therdthai, N. (Eds.). (2014). Bakery products science and technology. Chichester: John Wiley & Sons. http://dx.doi.org/10.1002/9781118792001

http://dx.doi.org/10.1002/9781118792001...

). So, the use of PF may be beneficial for use as a natural ingredient of color for muffins. Thus, the substitution of the WF by PF, or other natural colored vegetable flour could provide new characteristics and so, can contribute for a new flavor and visual appealing bakery product with enhancement of its nutritional composition.

3.2.4 Image analysis of muffins

The pore evaluations of the muffins are presented in Table 4, and the images of the crumb surface, analyzed area, and binary image are shown in Figure 1. There was no significant difference between the muffins considering the total number of the pores and total area of pores, indicating that PF did not interfere in these parameters. All the muffins presented more than 65% of pores smaller than 0.5 mm2 of area, values like those found by Sozer et al. (2011)Sozer, N., Bruins, R., Dietzel, C., Franke, W., & Kokini, J. L. (2011). Improvement of shelf life stability of cakes. Journal of Food Quality, 34(3), 151-162. http://dx.doi.org/10.1111/j.1745-4557.2011.00379.x

http://dx.doi.org/10.1111/j.1745-4557.20...

for chocolate cakes, which had most of the pores measuring between 0.2 and 0.6 mm2. Small and uniform distributed pores, as observed in the present work, are important for a soft crumb, and appreciated by consumers (Zhou et al., 2014Zhou, W., Hui, Y. H., De Leyn, I., Pagani, M. A., Rosell, C. M., Selman, J. D., & Therdthai, N. (Eds.). (2014). Bakery products science and technology. Chichester: John Wiley & Sons. http://dx.doi.org/10.1002/9781118792001

http://dx.doi.org/10.1002/9781118792001...

).

Results of the image analysis of the control muffins (M0) and with pumpkin flour (M1 and M2)(1).

3.2.5 Consumer testing of muffins

The sensory analysis data is shown in Table 5, and in the radar-chart in Figure S2 (Supplementary material). All the muffin formulations obtained fairly high mean ratings around 6-7 in the 9-point hedonic scale, and according to Meilgaard et al. (2000)Meilgaard, M., Civille, G. V., & Carr, B. T. (2000). Sensory evaluation techniques (3rd ed.). Boca Raton: CRC Press. products with acceptance mean ratings around 7 could be considered sensorially optimized. M1 presented the best scores in comparison to M0 and M2, indicating that the consumer accepted the inclusion of PF in the muffin.

Acceptability in the consumer test of the control muffins (M0) and with pumpkin flour (M1 and M2)(1) (N = 119)(2).

For the selection of the best proportion of pumpkin flour substitution, optional comments were also considered, since they were a source of information on consumer perception. It was observed that 12 out of 119 consumers provided in the comments (optional) information related to negative M2 sensory experience, such as “pumpkin flavor too strong”, “color too yellow”, and “texture too dry”. Thus, we opted for the selection of the M1, and the results for the nutritional characterization. In other studies, with the addition of new ingredients that are a regional source of fibers and natural coloring in cakes, the acceptance mean rates were impaired, as observed by Micheletti et al. (2018)Micheletti, J., Soares, J. M., Franco, B. C., Carvalho, I. R. A., Candido, C. J., Santos, E. F., & Novello, D. (2018). The addition of jaboticaba skin flour to muffins alters the physicochemical composition and their sensory acceptability by children. Brazilian Journal of Food Technology, 21, 1-8. http://dx.doi.org/10.1590/1981-6723.08917

http://dx.doi.org/10.1590/1981-6723.0891...

, for instance, with the addition of jaboticaba peel flour in muffins. Thus, the sensory acceptance of the PF in muffins by the consumers highlighted the possibilities of using this ingredient.

3.2.6 Nutritional characterization of the selected muffin

The results of the chemical composition (Table 6) of M1 were compared to the M0, and it was observed that the composition of protein and lipids did not differ significantly. But, the ash, and total dietary fiber contents were higher for M1, with a proportional reduction of the digestible carbohydrates, what could be especially due to the ash and fiber composition of the PF, even in substitution of 5 g of PF/100 g of WF. According to Brazilian regulation (Brasil, 2012Brasil. Ministério da Saúde. Agência Nacional de Vigilância Sanitária – ANVISA. (2012, novembro 12). Dispõe sobre o Regulamento Técnico sobre Informação Nutricional Complementar (Resolução - RDC nº 54, de 12 de novembro de 2012). Diário Oficial [da] República Federativa do Brasil, Brasília. Retrieved in 2017, January 20, from http://portal.anvisa.gov.br/

http://portal.anvisa.gov.br/...

), the food products should have a minimum of 2.5 g of total fiber by portion to be classified as a “source of fiber”. However, we could consider that the muffins are a part of a daily food intake, and not a usual dietary fiber source.

4 Conclusions

From this study, it was possible to obtain a pumpkin flour using its pulp and peel with the characteristic of attractive coloring and high fiber content, besides reducing sugar content. It is also possible to use the PF as an ingredient in muffins formulations, replacing WF in 5 g/100 g, without prejudice to sensory acceptance. Furthermore, PF contributed mainly as a dietary fiber source in this product. Thus, the PF could be an ingredient for family farming during the off-season, and a way to offer pumpkins for use in bakery products.

Supplementary Material

Supplementary material accompanies this paper.

Figure S2 Radar-chart for the sensory acceptance mean scores of muffins (flour basis: 100 g wheat flour -WF, and 0 g pumpkin flour – PF), M1 (95 g WF and 5 g PF), and M2 (90 g WF and 10 g PF).This material is available as part of the online article from http://www.scielo.br/bjft

Acknowledgements

The authors are grateful to the following funding agencies: Coordenação de Aperfeiçoamento de Pessoal de Nível Superior program (grant number 001), for the maintenance of the Postgraduate Program; Conselho Nacional de Desenvolvimento Científico e Tecnológico - CNPq for scholarship to Michele Scarton (140791/2017-5) and to Maria Teresa Pedrosa Silva Clerici (312786/2020-4); PIBIC/Unicamp for the scientific initiation scholarship to Gustavo Costa do Nascimento; FAEPEX/UNICAMP for research funding. They also thank the Moinho Anaconda Industrial S.A (São Paulo, SP) for donating the wheat flour.

-

Funding: Conselho Nacional de Desenvolvimento Científico e Tecnológico (140791/2017-5, 312786/2020-4)/ Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (001) / Fundo de Apoio ao Ensino, à Pesquisa e Extensão, Universidade Estadual de Campinas - PIBIC/Unicamp.

References

- Ambrósio, C. L. B., Campos, F. A. C. S., & Faro, Z. P. (2006). Aceitabilidade de flocos desidratados de abóbora. Revista de Nutrição, 19(1), 39-45. http://dx.doi.org/10.1590/S1415-52732006000100004

» http://dx.doi.org/10.1590/S1415-52732006000100004 - American Association of Cereal Chemists – AACC. (2010). Approved methods of the American Association of Cereal Chemists (11th ed.). St. Paul: AACC International.

- Anderson, R. A., Conway, H. F., & Peplinski, A. J. (1970). Gelatinization of corn grits by roll cooking, extrusion cooking and steaming. Starch, 22(4), 130. http://dx.doi.org/10.1002/star.19700220408

» http://dx.doi.org/10.1002/star.19700220408 - Association of Official Analytical Chemists – AOAC. (2006). Official methods of analysis of the Association of Official Analytical Chemists (18th ed.). Gaithersburg: AOAC International.

- Aydogdu, A., Sumnu, G., & Sahin, S. (2018). Effects of addition of different fibers on rheological characteristics of cake batter and quality of cakes. Journal of Food Science and Technology, 55(2), 667-677. PMid:29391631. http://dx.doi.org/10.1007/s13197-017-2976-y

» http://dx.doi.org/10.1007/s13197-017-2976-y - Brasil. Ministério da Saúde. Agência Nacional de Vigilância Sanitária – ANVISA. (2012, novembro 12). Dispõe sobre o Regulamento Técnico sobre Informação Nutricional Complementar (Resolução - RDC nº 54, de 12 de novembro de 2012). Diário Oficial [da] República Federativa do Brasil, Brasília. Retrieved in 2017, January 20, from http://portal.anvisa.gov.br/

» http://portal.anvisa.gov.br/ - Demiray, E., & Tulek, Y. (2017). Degradation kinetics of β-carotene in carrot slices during convective drying. International Journal of Food Properties, 20(1), 151-156. http://dx.doi.org/10.1080/10942912.2016.1147460

» http://dx.doi.org/10.1080/10942912.2016.1147460 - Ferreira, D. F. (2000). Análises estatísticas por meio do Sisvar para Windows versão 4.0. In Anais da 45ª Reunião Anual da Região Brasileira da Sociedade Internacional de Biometria (pp. 255-258). São Carlos: RBras.

- Guiné, R. P. F., Pinho, S., & Barroca, M. J. (2011). Food and bioproducts processing study of the convective drying of pumpkin (Cucurbita maxima). Food and Bioproducts Processing, 89(4), 422-428. http://dx.doi.org/10.1016/j.fbp.2010.09.001

» http://dx.doi.org/10.1016/j.fbp.2010.09.001 - Gutkoski, L. C., Durigon, A., Mazzutti, S., Cezare, K., & Colla, L. M. (2011). Influência do tipo de farinha de trigo na elaboração de bolo tipo inglês. Brazilian Journal of Food Technology, 14(4), 275-282. http://dx.doi.org/10.4260/BJFT2011140400033

» http://dx.doi.org/10.4260/BJFT2011140400033 - He, H., & Harris, L. (2020). The impact of COVID-19 pandemic on corporate social responsibility and marketing philosophy. Journal of Business Research, 116(0), 176-182. PMid:32457556. http://dx.doi.org/10.1016/j.jbusres.2020.05.030

» http://dx.doi.org/10.1016/j.jbusres.2020.05.030 - Instituto Adolfo Lutz – IAL. (2008). Métodos físico-químicos para análise de alimentos (4. ed.). São Paulo: IAL.

- Lie, L., Brown, L., Forrester, T., Plange-Rhule, J., Bovet, P., Lambert, E., Layden, B., Luke, A., & Dugas, L. (2018). The association of dietary fiber intake with cardiometabolic risk in four countries across the epidemiologic transition. Nutrients, 10(5), 1-12. PMid:29772682. http://dx.doi.org/10.3390/nu10050628

» http://dx.doi.org/10.3390/nu10050628 - Meilgaard, M., Civille, G. V., & Carr, B. T. (2000). Sensory evaluation techniques (3rd ed.). Boca Raton: CRC Press.

- Micheletti, J., Soares, J. M., Franco, B. C., Carvalho, I. R. A., Candido, C. J., Santos, E. F., & Novello, D. (2018). The addition of jaboticaba skin flour to muffins alters the physicochemical composition and their sensory acceptability by children. Brazilian Journal of Food Technology, 21, 1-8. http://dx.doi.org/10.1590/1981-6723.08917

» http://dx.doi.org/10.1590/1981-6723.08917 - National Institutes of Health – NIH. (2017). ImageJ software Bethesda, USA. Retrieved in 2017, January 20, from https://imagej.nih.gov/ij/

» https://imagej.nih.gov/ij/ - Nawirska-Olszańska, A., Biesiada, A., Sokół-Łętowska, A., & Kucharska, A. Z. (2014). Characteristics of organic acids in the fruit of different pumpkin species. Food Chemistry, 148, 415-419. PMid:24262577. http://dx.doi.org/10.1016/j.foodchem.2013.10.080

» http://dx.doi.org/10.1016/j.foodchem.2013.10.080 - Otsu, N. (1979). A threshold selection method from gray-level histograms. IEEE Transactions on Systems, Man, and Cybernetics, 9(1), 62-66. http://dx.doi.org/10.1109/TSMC.1979.4310076

» http://dx.doi.org/10.1109/TSMC.1979.4310076 - Poliszko, N., Kowalczewski, P. Ł., Rybicka, I., Kubiak, P., & Poliszko, S. (2019). The effect of pumpkin flour on quality and acoustic properties of extruded corn snacks. Journal of Consumer Protection and Food Safety, 14(2), 121-129. http://dx.doi.org/10.1007/s00003-019-01216-6

» http://dx.doi.org/10.1007/s00003-019-01216-6 - Purlis, E. (2010). Browning development in bakery products: A review. Journal of Food Engineering, 99(3), 239-249. http://dx.doi.org/10.1016/j.jfoodeng.2010.03.008

» http://dx.doi.org/10.1016/j.jfoodeng.2010.03.008 - Pyler, E. J., & Gorton, L. A. (Eds.). (2009). Baking: Science & technology (Vol. II). Kansas City, USA SOSLAND Publishing Company.

- Resende, G. M., Borges, R. M. E., & Gonçalves, N. P. (2013). Produtividade da cultura da abóbora em diferentes densidades de plantio no Vale do São Francisco. Horticultura Brasileira, 31(3), 504-508. http://dx.doi.org/10.1590/S0102-05362013000300027

» http://dx.doi.org/10.1590/S0102-05362013000300027 - Rodriguez-Amaya, D. B. (2016). Food carotenoids: Chemistry, biology and technology (1st ed.). Chichester: John Wiley & Sons.

- Sojak, M. J., Jaros, M., & Głowacki, S. (2014). Analysis of giant pumpkin (Cucurbita maxima) quality parameters in various technologies of convective drying after long-term storage. Drying Technology, 32(1), 106-116. http://dx.doi.org/10.1080/07373937.2013.816854

» http://dx.doi.org/10.1080/07373937.2013.816854 - Soong, Y. Y., Quek, R. Y. C., & Henry, J. (2015). Glycemic potency of muffins made with wheat, rice, corn, oat and barley flours: A comparative study between in vivo and in vitro. European Journal of Nutrition, 54(8), 1281-1285. PMid:25637395. http://dx.doi.org/10.1007/s00394-014-0806-9

» http://dx.doi.org/10.1007/s00394-014-0806-9 - Sozer, N., Bruins, R., Dietzel, C., Franke, W., & Kokini, J. L. (2011). Improvement of shelf life stability of cakes. Journal of Food Quality, 34(3), 151-162. http://dx.doi.org/10.1111/j.1745-4557.2011.00379.x

» http://dx.doi.org/10.1111/j.1745-4557.2011.00379.x - Staichok, A. C. B., Mendonça, K. R. B., dos Santos, P. G. A., Garcia, L. G. C., & Damiani, C. (2016). Pumpkin Peel Flour (Cucurbita maxima L.): Characterization and technological applicability. Journal of Food and Nutrition Research, 4(5), 327-333. http://dx.doi.org/10.12691/jfnr-4-5-9

» http://dx.doi.org/10.12691/jfnr-4-5-9 - Tamer, C. E., İncedayi, B., Parseker, S., Yonak, S., & Çopur, Ö. U. (2010). Evaluation of several quality criteria of low-calorie pumpkin dessert. Notulae Botanicae Horti Agrobotanici, 38(1), 76-80.

- Turabi, E., Sumnu, G., & Sahin, S. (2008). Rheological properties and quality of rice cakes formulated with different gums and an emulsifier blend. Food Hydrocolloids, 22(0), 305-312. http://dx.doi.org/10.1016/j.foodhyd.2006.11.016

» http://dx.doi.org/10.1016/j.foodhyd.2006.11.016 - United States Department of Agriculture – USDA. (2019). USDA food data central. Retrieved in 2017, January 20, from https://fdc.nal.usda.gov/

» https://fdc.nal.usda.gov/ - Zhou, W., Hui, Y. H., De Leyn, I., Pagani, M. A., Rosell, C. M., Selman, J. D., & Therdthai, N. (Eds.). (2014). Bakery products science and technology. Chichester: John Wiley & Sons. http://dx.doi.org/10.1002/9781118792001

» http://dx.doi.org/10.1002/9781118792001

Publication Dates

-

Publication in this collection

22 Oct 2021 -

Date of issue

2021

History

-

Received

13 Sept 2020 -

Accepted

22 June 2021