Abstract

Noodles are popular food and fortified noodles with vital nutrients may build a healthy food habit among people. Oat is a cereal with high nutritional value. Therefore, the current research was undertaken to increase the nutrient content of noodles using oat flour and to evaluate the effects of oat flour on the physicochemical properties and sensory attributes of the noodles. The noodles were prepared following five different formulations (oats: wheat flour in the ratio of 0:100, 20:80, 25:75, 30:70 and 35:65). Other ingredients like table salt, carboxymethyl cellulose (CMC), corn starch, and water were equal in each formulation. To evaluate the best formulation, proximate analysis, functional characteristics and sensory assay were conducted on samples. The formulation having 70% of wheat flour and 30% of oat flour showed the best performance in proximate analysis and sensory evaluation. This formulation of noodles has 13.03% of protein, 1.51% of fat, 1.46% of total ash, 0.76% of fibre, 73.87% of carbohydrate, 361.19 kcal of energy and also a good amount of important minerals. The formulation regarding wheat flour 70% and oat flour 30% may be suggested to the large population who are habituated to consume noodles regularly as the main diet.

Keywords:

Oat; Noodles; Physiochemical properties; Wheat; Noodles formulation; Sensory attributes

Resumo

Macarrão tipo noodle é um alimento popular e macarrão fortificado com nutrientes vitais pode criar um hábito alimentar saudável entre as pessoas. A aveia é sabidamente um cereal de alto valor nutritivo, o que motivou esta pesquisa: buscou-se aumentar o teor de nutrientes do macarrão tipo noodle usando farinha de aveia e avaliar os efeitos desse acréscimo nas propriedades físico-químicas e nos atributos sensoriais do macarrão. O macarrão foi preparado seguindo cinco formulações diferentes com a relação aveia:farinha de trigo nas proporções de 0:100, 20:80, 25:75, 30:70 e 35:65. Outros ingredientes, como sal de cozinha, carboximetilcelulose (CMC), amido de milho e água, foram mantidos na mesma proporção em todas formulações. Para avaliar a melhor formulação, análises de composição centesimal, características funcionais e sensoriais foram realizadas nas amostras. A formulação contendo a relação 70% de farinha de trigo e 30% de farinha de aveia apresentou melhor composição centesimal e melhor desempenho na avaliação sensorial. Esta formulação de macarrão possui 13,03% de proteína, 1,51% de gordura, 1,46% de cinzas totais 0,76% de fibra, 73,87% de carboidrato 361,19 kcal e uma expressiva quantidade de minerais importantes. A formulação com 70% de farinha de trigo e 30% de farinha de aveia é recomendada para a população que está habituada a consumir macarrão regularmente como dieta principal.

Palavras-chave:

Aveia; Macarrão tipo noodle; Propriedades físico-químicas; Trigo; Formulação de macarrão; Atributos sensoriais

1 Introduction

Noodles are popular food in almost all over the world due to high palatability and fast cooking properties (Aydin & Gocmen, 2011Aydin, E., & Gocmen, D. (2011). Cooking quality and sensorial properties of noodle supplemented with oat flour. Food Science and Biotechnology, 20(2), 507-511. http://dx.doi.org/10.1007/s10068-011-0070-1

http://dx.doi.org/10.1007/s10068-011-007...

). Based on ingredients used, noodles are categorized into White Salted Noodles (WSN) and Yellow Alkaline Noodles (YAN) (Asenstorfer et al., 2006Asenstorfer, R. E., Wang, Y., & Mares, D. J. (2006). Chemical structure of flavonoid compounds in wheat (Triticum aestivum L.) flour that contribute to the yellow colour of Asian alkaline noodles. Journal of Cereal Science, 43(1), 108-119. http://dx.doi.org/10.1016/j.jcs.2005.09.001.

http://dx.doi.org/10.1016/j.jcs.2005.09....

). Traditional noodles are tasty and enriched in carbohydrate, however, less enriched in protein, minerals, dietary fibers and vitamins (Kudake et al., 2017Kudake, D. C., Pawar, A. V., Muley, A. B., Parate, V. R., & Talib, M. I. (2017). Enrichment of wheat flour noodles with oat flour: Effect on physical, nutritional, antioxidant and sensory properties. International Journal of Current Microbiology and Applied Sciences, 6(12), 204-213. http://dx.doi.org/10.20546/ijcmas.2017.612.026

http://dx.doi.org/10.20546/ijcmas.2017.6...

). Wheat flour is considered as raw ingredient of noodles and in milling process around 18.34% of protein, 38.4% of fat, 72.77% of insoluble dietary fiber, 58.73% of ash and 70% of vitamins was loosed from it (Oghbaei & Prakash, 2013Oghbaei, M., & Prakash, J. (2013). Effect of fractional milling of wheat on nutritional quality of milled fractions. Trends in Carbohydrate Research, 5(1). Retrieved in 2017, August 4, from http://www.trendscarbo.com/shoppingcart.php

http://www.trendscarbo.com/shoppingcart....

, 2016Oghbaei, M., & Prakash, J. (2016). Effect of primary processing of cereals and legumes on its nutritional quality: A comprehensive review. Cogent Food & Agriculture, 2(1), 1136015. http://dx.doi.org/10.1080/23311932.2015.1136015

http://dx.doi.org/10.1080/23311932.2015....

). Supplementing or fortifying noodles by nutrient-enriched ingredients could add extra nutrients to the traditional noodles. Sequentially replacing 10, 20, 30, 40 and 50% of wheat flours by ragi flour improved nutrition in noodles (Kulkarni et al., 2012Kulkarni, S. S., Desai, A. D., Ranveer, R. C., & Sahoo, A. K. (2012). Development of nutrient rich noodles by supplementation with malted ragi flour. International Food Research Journal, 19(1), 309. Retrieved in 2017, August 4, from http://www.ijoart.org/docs/DEVELOPMENT-OF-NUTRIENTRICH-NOODLES-BY-SUPPLEMENTATION-WITH-MALTED-KODO-MILLET-FLOUR.pdf

http://www.ijoart.org/docs/DEVELOPMENT-O...

). Finger millet flour (30%) fortified noodles showed reduction of Glycemic Index (GI) than noodles made from wheat flour (45.13 vs 62.59 in wheat flour) (Shukla & Srivastava, 2014Shukla, K., & Srivastava, S. (2014). Evaluation of finger millet incorporated noodles for nutritive value and glycemic index. Journal of Food Science and Technology, 51(3), 527-534. PMid:24587528. http://dx.doi.org/10.1007/s13197-011-0530-x

http://dx.doi.org/10.1007/s13197-011-053...

). Noodles that characterize the foremost end-use of wheat flour are appropriate for enhancing healthiness while fusing with principle nutrients (Choo & Aziz, 2010Choo, C. L., & Aziz, N. A. A. (2010). Effects of banana flour and β-glucan on the nutritional and sensory evaluation of noodles. Food Chemistry, 119(1), 34-40. http://dx.doi.org/10.1016/j.foodchem.2009.05.004

http://dx.doi.org/10.1016/j.foodchem.200...

). Due to having high nutritional values and fiber content, oats may be added to improve nutritional quality of noodles.

The oat is characterized as starchy grain and easily cultivatable in all over the world. Oats have high percentage of protein (17%), fat (7%), carbohydrate (66%), fiber (11%), ash (1.56% to 0.l0% Ca, 0.23% P), tryptophan (0.17%), threonine (0.36%), lysine (0.41%), cysteine (0.34%), methionine (0.21%) and β-D gluten (Thies et al., 2014Thies, F., Masson, L. F., Boffetta, P., & Kris-Etherton, P. (2014). Oats and CVD risk markers: A systematic literature review. British Journal of Nutrition, 112(Suppl. 2), S19-S30. PMid:25267241. http://dx.doi.org/10.1017/S0007114514002281

http://dx.doi.org/10.1017/S0007114514002...

; Welch, 1995Welch, R. W. (1995). The chemical composition of oats. In R. W. Welch (Ed.), The oat crop (World Crop Series). Springer: Dordrecht. http://dx.doi.org/10.1007/978-94-011-0015-1_10.

http://dx.doi.org/10.1007/978-94-011-001...

). The β-D gluten among oats is not only important for its nutritional and health application but also its water-binding capacity (between 3.14 and 4.52 g g−1) (Thies et al., 2014Thies, F., Masson, L. F., Boffetta, P., & Kris-Etherton, P. (2014). Oats and CVD risk markers: A systematic literature review. British Journal of Nutrition, 112(Suppl. 2), S19-S30. PMid:25267241. http://dx.doi.org/10.1017/S0007114514002281

http://dx.doi.org/10.1017/S0007114514002...

). Whole oats are the only source of a unique group of antioxidants called avenanthramides (137.84 µg/g) (Manzoor et al., 2020Manzoor, M. S., Pasha, I., Shehzad, A., Zia, M. A., & Zhu, M. J. (2020). Antioxidant profiling of indigenous oat cultivars with special reference to avenanthramides. International Food Research Journal, 27(2), 261-269. Retrieved in 2017, August 4, from https://www.cabdirect.org/globalhealth/abstract/20203241436

https://www.cabdirect.org/globalhealth/a...

). Avenanthramides have preventive and treatment capacity of aging-related human diseases associated with oxidative stress and inflammation, including dermatological, cardiovascular, cerebrovascular, neurodegenerative properties, as well as metabolic disease and cancer (Perrelli et al., 2018Perrelli, A., Goitre, L., Salzano, A. M., Moglia, A., Scaloni, A., & Retta, S. F. (2018). Biological activities, health benefits, and therapeutic properties of avenanthramides: From skin protection to prevention and treatment of cerebrovascular diseases. Oxidative Medicine and Cellular Longevity, 2018, 6015351. PMid:30245775. http://dx.doi.org/10.1155/2018/6015351

http://dx.doi.org/10.1155/2018/6015351...

). Oats is associated with reducing the risk of type-II diabetes (having low GI value and high fiber content), hypertension and cardiovascular disease due to significant reduction of total cholesterol level (2% to 23%) (Hou et al., 2015Hou, Q., Li, Y., Li, L., Cheng, G., Sun, X., Li, S., & Tian, H. (2015). The metabolic effects of oats intake in patients with type 2 diabetes: A systematic review and meta-analysis. Nutrients, 7(12), 10369-10387. PMid:26690472. http://dx.doi.org/10.3390/nu7125536

http://dx.doi.org/10.3390/nu7125536...

; Thies et al., 2014Thies, F., Masson, L. F., Boffetta, P., & Kris-Etherton, P. (2014). Oats and CVD risk markers: A systematic literature review. British Journal of Nutrition, 112(Suppl. 2), S19-S30. PMid:25267241. http://dx.doi.org/10.1017/S0007114514002281

http://dx.doi.org/10.1017/S0007114514002...

). Ahmad et al., investigated the market and explained that foods processed with oats have significant demand as a healthy food (Ahmad et al., 2010Ahmad, A., Anjum, F. M., Zahoor, T., Nawaz, H., & Ahmed, Z. (2010). Extraction and characterization of β-d-glucan from oat for industrial utilization. International Journal of Biological Macromolecules, 46(3), 304-309. PMid:20083136. http://dx.doi.org/10.1016/j.ijbiomac.2010.01.002

http://dx.doi.org/10.1016/j.ijbiomac.201...

). The consumption of noodles has become significantly greater during the last 20 years (Mahmoud et al., 2012Mahmoud, E. A., Nassef, S. L., & Basuny, A. M. (2012). Production of high protein quality noodles using wheat flour fortified with different protein products from lupine. Annals of Agricultural Science, 57(2), 105-112. http://dx.doi.org/10.1016/j.aoas.2012.08.003

http://dx.doi.org/10.1016/j.aoas.2012.08...

). It is a great opportunity to provide nutrition among people by fortifying the noodles with protein, fiber, iron, iodine, vitamins etc. On the other hand, noodles have comparative low price and people will easily be afforded it with enjoyment.

Noodles fortified with cereals showed significant qualitative improvement. Oats flour (0, 10, 20, 30 and 40% w/w) fortified noodles improves rheological properties of dough (Majzoobi et al., 2014Majzoobi, M., Layegh, B., & Farahnaky, A. (2014). Inclusion of oat flour in the formulation of regular salted dried noodles and its effects on dough and noodle properties. Journal of Food Processing and Preservation, 38(1), 48-58 http://dx.doi.org/10.1111/j.1745-4549.2012.00742.x

http://dx.doi.org/10.1111/j.1745-4549.20...

). Continuously replacing wheat flour with oats flour improves chemical and sensory properties in noodles (Kudake et al., 2017Kudake, D. C., Pawar, A. V., Muley, A. B., Parate, V. R., & Talib, M. I. (2017). Enrichment of wheat flour noodles with oat flour: Effect on physical, nutritional, antioxidant and sensory properties. International Journal of Current Microbiology and Applied Sciences, 6(12), 204-213. http://dx.doi.org/10.20546/ijcmas.2017.612.026

http://dx.doi.org/10.20546/ijcmas.2017.6...

; Chauhan et al., 2018Chauhan, D., Kumar, K., Kumar, S., & Kumar, H. (2018). Effect of incorporation of oat flour on nutritional and organoleptic characteristics of bread and noodles. Current Research in Nutrition and Food Science Journal, 6(1), 148-156. http://dx.doi.org/10.12944/CRNFSJ.6.1.17.

http://dx.doi.org/10.12944/CRNFSJ.6.1.17...

). Oat and oat products have significant health benefits that increase the consumer awareness to this cereal (Liu et al., 2020Liu, S., Sun, Y., Obadi, M., Jiang, Y., Chen, Z., Jiang, S., & Xu, B. (2020). Effects of vacuum mixing and mixing time on the processing quality of noodle dough with high oat flour content. Journal of Cereal Science, 91, 102885 http://dx.doi.org/10.1016/j.jcs.2019.102885

http://dx.doi.org/10.1016/j.jcs.2019.102...

). However, no research has been published to evaluate how physical, chemical and sensory attributes have been changed in oat fortified noodles. To considering the gap of previous research the current research was undertaken to develop acceptable formulation of noodles supplemented with oats flour and evaluate its physical, chemical, and sensory attributes.

2 Materials and methods

The materials like Wheat Flour (WF) (all-purpose refined wheat flour), Oats Flour (OF) (ACI Nutrilife Atta Oat Plus), cooking salt, carboxymethyl cellulose (CMC) and corn starch were procured from the near market of Bangladesh Council for Scientific and Industrial Research, Dhanmondi, Dhaka, Bangladesh. Food grade stainless steel utensils accessories (SS 304) and Imperia pasta maker machine (Model 150, Italy) were used during noodles preparation. Proximate analysis such as moisture, protein, fat, fiber and ash (sub section 2.2, 2.3.2.4, 2.5 and 2.6 accordingly) content of raw OF, WF and sample noodles were examined using Official methods of analysis AOAC 2005 (Association of Analytical Communities) with little modification (Horwitz & Latimer, 2005Horwitz, W., & Latimer, G. W. (2005). Official methods of analysis of AOAC International. Gaithersburg: AOAC International.).

2.1 Preparation of control and sample noodles

For the preparation of control noodles, 25 g sieved WF was mixed with 0.50% of CMC, 4.65% of cooking salt and 4.50% of corn starch in 110 mL tap water. Dough ball was prepared to make a pasta sheet by following the “two-stage mixing” process. Before preparing pasta sheet, the dough balls were kept 15-30 min covering in a bowl with a wet towel to keep the dough soften and activate sulfur-sulfur bond (Singh et al., 2019Singh, C., Singh, B., Satpal, P. K., Ankush, M., Gora, K., & Kumar, A. (2019). Micronutrient management for enhancing production of major fodder crops: A review. Forage Research, 45(2), 95-102. Retrieved in 2017, August 4, from http://forageresearch.in/micronutrient-management-for-enhancing-production-of-major-fodder-crops-a-review/

http://forageresearch.in/micronutrient-m...

).

Then, the pasta sheet was prepared by folding and passing several times through the plain rollers of the noodle machine. The thickness of the pasta sheet was gradually reduced by minimizing the roller space. In addition, the pasta sheet was cut pouring into 4mm thick mold. After cutting the sheets, noodles were air dried for around 6-7h at room temperature to loss maximum moisture. To make the fortified samples, 20%, 25%, 30% and 35% of OF were replaced with WF, however, the other ingredients were the same as control noodles (Table 1). Other process was the same as like plain noodles preparation (Figure 1). Each of the samples was prepared in triplicate. After drying, the sample noodles were collected and packed in a polypropylene zipper bag (Figure 2).

Dried sample noodles (S0, S1, S2, S3, S4 contain 0:100, 20:80, 25:75, 30:70 and 35:65 percentage of oats and wheat flour, respectively).

2.2 Determination of the moisture content

Approximately 5.0 g of each sample as given into dry oven at 105 °C temperature and after 5 to 6 h the evaporated volume was noted as moisture content.

2.3 Determination of the protein content

Protein contents were determined by the classical Kjeldahl method. Where 0.2 g of sample was taken in a cleaned and dried digestion tube at which digestion mixture (K2SO4 and Cu) and 10.00 mL of concentrated H2SO4 were added. The mixture was digested by continues heating till the fumes could be seen. After digestion, solution was cooled and the volume was made to 100 mL with distilled water. Then 10 mL of diluted sample and 40% of NaOH were transferred into Kjeldahl distillation flask. Then the essence was collected through distillation in conical flask where 10 mL 0.1 N HCl was taken and 1 to 2 drop of methyl red was added. Finally, the sample was titrated against 0.1 N NaOH till the colour changed from pink to yellow. The same procedure was carried out for the blanks (Formula 1).

2.4 Determination of the fat content

Fat was estimated as crude ether extract of dry material. Total 15 g of grained sample was taken in a thimble and extract fat within a fat free dried Soxhlet flask with C6H14 for 48 h. After the period, C6H14 (contained fat) was poured into a conical flask and heated (65 °C) with a hot plate. After evaporation of C6H14 the conical flask was cooled in desiccators and then measured the fat content (Formula 2).

2.5 Determination of the crude fiber content

To determine the crude fiber, 20 g of dried, fat free and crushed noodles were taken into a conical flask contained 200 mL of H2SO4. The solution was boiled for 30 min with bumping chips with occasional rotation. Then, the content into flask was filtered through muslin and washed with boiled water. Wash residue was transferred back to the flask by spatula and again boiled for 30 min with bumping chips in 200 mL of NaOH. Then it was filtered and washed as previous way then the residue was transferred to a crucible and dried at 110 °C for 2 h. After drying and noted the weight, the samples were ignited for 20 min at 600 °C then the weight of burned particle was noted (Formula 3).

2.6 Determination of the ash content

To estimate the ash content, 1.5 g of sample was taken into a dried and weighted crucible. Then, the crucible was placed onto a gas burner for primary combustion (heated order: low-medium-high) and after combustion the crucible was heated for 6 to 7 h at 700 °C. After that period, the crucible was then cooled in desiccator and weighted (Formula 4).

2.7 Estimation of the carbohydrate and calorie content

The percentage of utilizable carbohydrates in the noodles samples was calculated by subtracting the protein, fat, moisture and crude fiber from 100 (Mertens, 2005Mertens, D. (2005). AOAC official method 975.03: Metal in plants and pet foods. In W. Horwitz & G. W. Latimer (Eds.), Official methods of analysis (18th ed., Chap. 3, pp. 3-4). Gaitherburg: AOAC International. Retrieved in 2017, August 4, from https://www.worldcat.org/title/official-methods-of-analysis-of-aoac-international/oclc/62751475

https://www.worldcat.org/title/official-...

). The calorie of samples noodles was calculated with the Atwater’s conversion factor, 9 kcal/g for fat and 4 kcal/g for carbohydrate and protein (Sánchez-Peña et al., 2017Sánchez-Peña, M. J., Márquez-Sandoval, F., Ramirez-Anguiano, A. C., Velasco-Ramirez, S. F., Macedo-Ojeda, G., & Gonzalez-Ortiz, L. J. (2017). Calculating the metabolizable energy of macronutrients: A critical review of Atwater’s results. Nutrition Reviews, 75(1), 37-48. PMid:27974598. http://dx.doi.org/10.1093/nutrit/nuw044

http://dx.doi.org/10.1093/nutrit/nuw044...

).

2.8 Determination of the mineral content

Mineral content such as Calcium (Calcium), Sodium (Na) and Potassium (K) contents were estimated by using a Systronics Type 130 flame photometer and following standard protocol (Eneche, 1999Eneche, E. H. (1999). Biscuit-making potential of millet/pigeon pea flour blends. Plant Foods for Human Nutrition, 54(1), 21-27. PMid:10646626. http://dx.doi.org/10.1023/A:1008031618117

http://dx.doi.org/10.1023/A:100803161811...

; Parvin et al., 2020Parvin, R., Farzana, T., Mohajan, S., Rahman, H., & Rahman, S. S. (2020). Quality improvement of noodles with mushroom fortified and its comparison with local branded noodles. NFS Journal, 20, 37-42. http://dx.doi.org/10.1016/j.nfs.2020.07.002.

http://dx.doi.org/10.1016/j.nfs.2020.07....

). The used reagents and chemicals were analytical grades (Sigma Aldrich). The working solutions were diluted to make them suitable for measuring each mineral (100 ppm Ca, 200 ppm Na and 200 ppm K) from the stock (standard) solutions (1000 μg/mL). Then, 01 g of sample noodles was mixed with 20 mL of a di-acid mixture (4 HNO3:1 HClO4) and poured into a conical flask (100 mL). To digest the sample, around 60-70 °C temperature was applied with a magnetic hot plate to obtain a colorless liquid (Somvanshi et al., 2017Somvanshi, A., Patel, A., & Jalgaonwala, R. (2017). Effect of microbial fermentation and processing on nutritional and antinutritional properties of selected fermented foods. Asian Journal of Research in Chemistry, 10(4), 531-540. http://dx.doi.org/10.5958/0974-4150.2017.00088.8

http://dx.doi.org/10.5958/0974-4150.2017...

).

The amount of Iron was measured by the Flame Atomic Absorption Spectrophotometer (FAAS) at 248.3-327 nm wavelength (Eneche, 1999Eneche, E. H. (1999). Biscuit-making potential of millet/pigeon pea flour blends. Plant Foods for Human Nutrition, 54(1), 21-27. PMid:10646626. http://dx.doi.org/10.1023/A:1008031618117

http://dx.doi.org/10.1023/A:100803161811...

). The sample noodles (5 to 15 g) were dried in a drying oven at 221 °F for 3.0 h following burnt in muffle furnace at 600 °C to collect the residue (ash). The residue was poured into a 100 mL of volumetric flask and 50 mL of concentrated HCL (hydrochloric acid) was added to it. As standard solution, ferric nitrate (FeN3O9) was used and the amount of iron in the noodles was calculated comparing with the standard curve (Siong et al., 1989Siong, T. E., Choo, K. S., & Shahid, S. M. (1989). Determination of iron in foods by the atomic absorption spectrophotometric and colorimetric methods. Pertanika, 12(3), 313-322. Retrieved in 2017, August 4, from http://www.pertanika.upm.edu.my/Pertanika%20PAPERS/PERT%20Vol.%2012%20(3)%20Dec.%201989/05%20Pertanika%20Vol.12%20(3)%20Dec.%201989%20(Pg%20315-322).pdf

http://www.pertanika.upm.edu.my/Pertanik...

; Pearson, 1999Pearson, D. (1999). Pearsons composition and analysis of foods (pp. 117-123). Reading: University of Reading. Retrieved in 2017, August 4, from http://ludibuk.com/pearson_analysis_of_foods.pdf

http://ludibuk.com/pearson_analysis_of_f...

). A calibration curve with five concentrations (0.5, 1.0, 1.5, 2.0, 2.5 mg/L) of iron within the analytical range was prepared. Concentrations of iron in test solutions (of noodles) were calculated from the standard curve prepared.

2.9 Water absorption capacity (WAC)

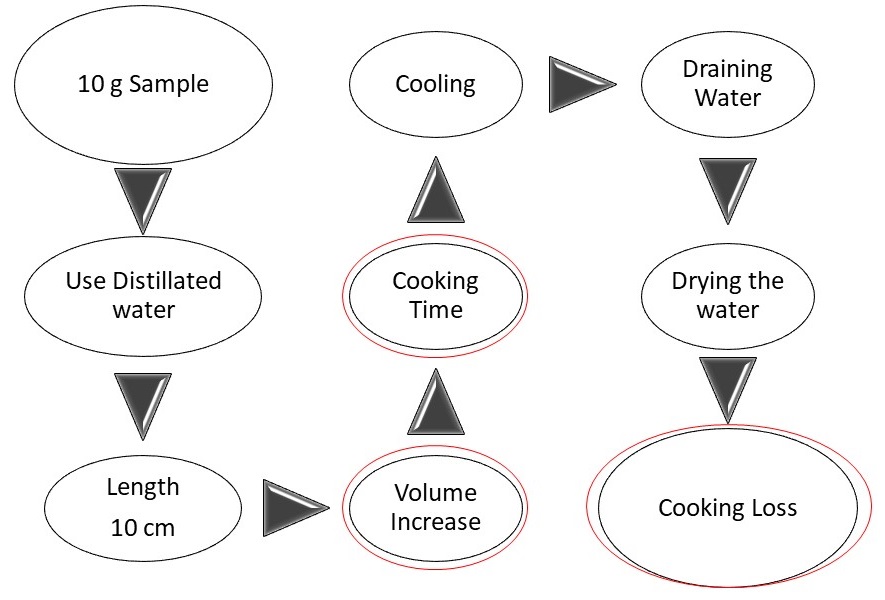

Water Absorption Capacity (WAC), cooling loss, volume increase and cooking time of each sample were processed for analysis following standard procedures (Figure 3).

The WAC was measured by cooking 10 g of fresh noodles in 150 mL of water for optimum cooking period. After cooling for 5 min in a cold-water bath, the excess water was drained for 30s and WAC was calculated according to the following Formula 5 (American Association of Cereal Chemists, 2010American Association of Cereal Chemists – AACC. (2010). Approved methods of the American Association of Cereal Chemists. St. Paul: AACC International. Retrieved in 2017, August 4, from http://methods.aaccnet.org/toc.aspx

http://methods.aaccnet.org/toc.aspx...

).

2.10 Cooking Loss

The cooking losses regarding the formulations of noodles were measured following standard procedures (American Association of Cereal Chemists, 2010American Association of Cereal Chemists – AACC. (2010). Approved methods of the American Association of Cereal Chemists. St. Paul: AACC International. Retrieved in 2017, August 4, from http://methods.aaccnet.org/toc.aspx

http://methods.aaccnet.org/toc.aspx...

). Simply, to identify the cooking loss, 25 g of sample noodles were cooked (boiled) following optimum cooking time in 250 mL of tap water. The cooked water was drained in a beaker then dried at 105 °C in a drying oven until the total water dried and the percentage of cooking loss was calculated following standard Formula 6 (Chakraborty et al., 2003Chakraborty, M., Hareland, G. A., Manthey, F. A., & Berglund, L. R. (2003). Evaluating quality of yellow alkaline noodles made from mechanically abraded sprouted wheat. Journal of the Science of Food and Agriculture, 83(5), 487-495. http://dx.doi.org/10.1002/jsfa.1403

http://dx.doi.org/10.1002/jsfa.1403...

).

2.11 Volume increase and optimum cooking time

The volume increase was identified as the percentage varies between the volume of cooked and uncooked noodles. For this, 25 g of cooked and uncooked noodles were put into 300 mL of water in a 500 mL of measuring cylinder. The volume increase was calculated according to the following Formula 7.

The optimum cooking time was corresponded to the disappearance of the white core of noodles after being squeezed between two glasses (Bhise et al., 2015Bhise, S., Kaur, A., & Aggarwal, P. (2015). Development of protein enriched noodles using texturized defatted meal from sunflower, flaxseed and soybean. Journal of Food Science and Technology, 52(9), 5882-5889. PMid:26345004. http://dx.doi.org/10.1007/s13197-014-1630-1

http://dx.doi.org/10.1007/s13197-014-163...

). After conducting two to three trials, optimum cooking time was identified.

2.12 Sensory analysis

The sensory analyses were assessed by subjecting the cooked sample noodles by seven in-house semi and highly skilled panelist age ranged 25 to 35 years and were worked to assure food quality at Bangladesh Council for Scientific and Industrial Research, Bangladesh. The scores were obtained on a 9-point hedonic scale where scored them from 1 to 9 (low score 1 for dislike extremely and top score 9 for like extremely). The test was done in separate booths and maintained standard taste panel area under daylight illumination.

2.13 Statistical analysis

The data was analyzed using the Analysis of Variance (ANOVA) by the method of Snedecor and Cochran using Completely Randomized Design (CRD) (Snedecor & Cochran, 1994Snedecor, G. W., & Cochran, W. G. (1994). Statistical methods (8th ed.). Ames: Iowa State University Press. Retrieved in 2017, August 4, from https://journals.sagepub.com/doi/abs/10.3102/10769986019003304

https://journals.sagepub.com/doi/abs/10....

). Statistical analysis was carried out by using IBM SPSS® 20.0 for Windows®. The means were separated using Duncan’s test at p < 0.05.

3 Result and discussion

The difference between the proximate composition of OF and WF are given in Table 2. The selected WF for noodles preparation was contained 10.84% of protein, 0.26% of minerals, 0.21% of crude fiber, 1.20% of fat and 78.11% of carbohydrate which was in agreement with the earlier results (10.68% to 10.73%, 1.49% to 1.52%, 0.47% to 0.51%, 1.15% to 1.17% and 76.44% to 76.46%, respectively) and reported by (Kudake et al., 2017Kudake, D. C., Pawar, A. V., Muley, A. B., Parate, V. R., & Talib, M. I. (2017). Enrichment of wheat flour noodles with oat flour: Effect on physical, nutritional, antioxidant and sensory properties. International Journal of Current Microbiology and Applied Sciences, 6(12), 204-213. http://dx.doi.org/10.20546/ijcmas.2017.612.026

http://dx.doi.org/10.20546/ijcmas.2017.6...

; Bhalerao et al., 2018Bhalerao, P. P., Chaudhari, N. S., Muley, A. B., Talib, M. I., Parate, V. R., & Kudake, D. C. (2018). Fortification of wheat flour with ragi flour: Effect on physical, nutritional, antioxidant and sensory profile of noodles. Current Research in Nutrition and Food Science, 6(1), 165-173.http://dx.doi.org/10.12944/CRNFSJ.6.1.19

http://dx.doi.org/10.12944/CRNFSJ.6.1.19...

). The chemical composition obtained from oats flour (7.39% of moisture, 17.06% of protein, 2.62% of fat, 2.55% of fiber and 2.44% of ash) was also similar with the study conducted by Vollmann (Vollmann et al., 2004Vollmann, J., Grausgruber, H., & Ruckenbauer, P. (Eds.). (2004). Genetic variation for plant breeding. In Proceedings of the 17th EUCARPIA General Congress. Vienna: University of Natural Resources and Applied Life Sciences. Retrieved in 2017, August 4, from https://zenodo.org/record/1204819/files/Vollmann_Grausgruber_Ruckenbauer_2004_EUCARPIA_XVII.pdf

https://zenodo.org/record/1204819/files/...

).

3.1 Noodles characteristics

In this study, formulations S0, S1, S2, S3 and S4 were prepared with 0%, 20%, 25%, 30% and 35% of OF, respectively. The fiber content of OF regarding incorporated noodles S1, S2, S3 and S4 were 0.47%, 0.63%, 0.76% and 0.87%, respectively. Other nutrients such as protein, fat, ash, and energy content of noodles incorporated with oats flour were increased as compared to control (S0). The percentage of moisture and carbohydrate were decreased gradually with supplementing OF (Table 3).

In addition, early studies have shown that the incorporation of oats flour supports to decreased moisture contents (7.42% to 6.90%) and carbohydrate contents (from 80.32% to 71.23%) (Aydin & Gocmen, 2011Aydin, E., & Gocmen, D. (2011). Cooking quality and sensorial properties of noodle supplemented with oat flour. Food Science and Biotechnology, 20(2), 507-511. http://dx.doi.org/10.1007/s10068-011-0070-1

http://dx.doi.org/10.1007/s10068-011-007...

; Chauhan et al., 2018Chauhan, D., Kumar, K., Kumar, S., & Kumar, H. (2018). Effect of incorporation of oat flour on nutritional and organoleptic characteristics of bread and noodles. Current Research in Nutrition and Food Science Journal, 6(1), 148-156. http://dx.doi.org/10.12944/CRNFSJ.6.1.17.

http://dx.doi.org/10.12944/CRNFSJ.6.1.17...

). As all other ingredients were the same except oats flour, in which the variation in nutrition content was due to the addition of oats flour. Mineral contents of noodles containing oat flour are shown in Table 3. As the portion of oats flour incorporated in formulations, Calcium (Ca), Iron (Fe), Sodium (Na) and Potassium(K) contents were increased significantly (p < 0.05) in noodles (Aydin & Gocmen, 2011Aydin, E., & Gocmen, D. (2011). Cooking quality and sensorial properties of noodle supplemented with oat flour. Food Science and Biotechnology, 20(2), 507-511. http://dx.doi.org/10.1007/s10068-011-0070-1

http://dx.doi.org/10.1007/s10068-011-007...

). The difference of Ca, Fe, Na and K between the S0 (control) and S4 (35% of oats flour) were 1.44, 1.10, 1.30 and 1.69 times, respectively. For this reason, oats and oats products were considered as a worthy contributor to the mineral needs of consumers (Webster, 2002Webster, F. H. (2002). Whole-grain oats and oat products: Whole-grain foods in health and disease (pp. 83-123). St. Paul: American Association of Cereal Chemists. Retrieved in 2017, August 4, from https://wholegrainscouncil.org/sites/default/files/atoms/files/Slavin Article 0504.pdf

https://wholegrainscouncil.org/sites/def...

).

The results of this study revealed that addition of OF (S0<S1<S2<S3<S4) improved the nutrition value especially increases mineral contents significantly (Table 2). Therefore, the sample S4 (OF 35% and WF 65%) has showed superior formulation according to chemical composition.

3.2 Water absorption quality

Water absorption of sample is the capability to hold water within its interior structure and it is affected by some other factors like protein quality, fiber content, damaged starch, physical properties of the flour etc. (Vollmann et al., 2004Vollmann, J., Grausgruber, H., & Ruckenbauer, P. (Eds.). (2004). Genetic variation for plant breeding. In Proceedings of the 17th EUCARPIA General Congress. Vienna: University of Natural Resources and Applied Life Sciences. Retrieved in 2017, August 4, from https://zenodo.org/record/1204819/files/Vollmann_Grausgruber_Ruckenbauer_2004_EUCARPIA_XVII.pdf

https://zenodo.org/record/1204819/files/...

). The Water absorption percentage of S0, S1, S2, S3 and S4 were 142.48%, 144.90%, 146.35%, 152.32% and 156.15%, respectively. The water absorption rate of S3 and S4 were significantly (p < 0.05) higher than the control noodles (S0) (Table 4). Previous studies showed that higher amount of β-Glucans found at oats flour than wheat flour and also the higher amount of β-glucan in oat flour was responsible for increased water absorption (Tiefenbacher, 2017Tiefenbacher, K. F. (2017). Technology of main ingredients: water and flours. In K. F. Tiefenbacher (Ed.), Wafer and waffle: Processing and manufacturing (pp. 15-121). San Diego: Academic Press. Retrieved in 2017, August 4, from https://www.sciencedirect.com/science/article/pii/B9780128094389000028

https://www.sciencedirect.com/science/ar...

; Niu et al., 2017Niu, Q., Pu, Y., Li, X., Ma, Z., & Hu, X. (2017). Solvent retention capacities of oat flour. International Journal of Molecular Sciences, 18(3), 590. PMid:28335393. http://dx.doi.org/10.3390/ijms18030590

http://dx.doi.org/10.3390/ijms18030590...

).

3.3 Cooking loss and volume increase quality of noodles

Cooking quality is the most important characteristic to final consumers and therefore of great importance to noodle processors. In this study, the cooking loss increased significantly (p < 0.05) from 8.15% to 8.53% with the incorporation of OF in noodles (S1 to S4), whereas S0 lost 7.14% (Table 4). It indicated that addition of oat flour was responsible for higher (p < 0.05) percentage of cooking loss compared to wheat flour (Izydorczyk et al., 2005Izydorczyk, M. S., Lagassé, S. L., Hatcher, D. W., Dexter, J. E., & Rossnagel, B. G. (2005). The enrichment of Asian noodles with fiber‐rich fractions derived from roller milling of hull‐less barley. Journal of the Science of Food and Agriculture, 85(12), 2094-2104. http://dx.doi.org/10.1002/jsfa.2242

http://dx.doi.org/10.1002/jsfa.2242...

). The variation in cooking quality was attributed mainly to gluten fraction and due to the disruption of the protein starch matrix (Bhise et al., 2015Bhise, S., Kaur, A., & Aggarwal, P. (2015). Development of protein enriched noodles using texturized defatted meal from sunflower, flaxseed and soybean. Journal of Food Science and Technology, 52(9), 5882-5889. PMid:26345004. http://dx.doi.org/10.1007/s13197-014-1630-1

http://dx.doi.org/10.1007/s13197-014-163...

).

The percentage of volume increased of S0, S1, S2, S3, and S4 were 189.62%, 179.48%, 139.81%, 131.21% and 120.70%, accordingly. The sample S4 showed maximum volume decreased (p < 0.05) from the control noodles (S0) (Table 4), i.e., being in accordance with previous study (Chauhan et al., 2018Chauhan, D., Kumar, K., Kumar, S., & Kumar, H. (2018). Effect of incorporation of oat flour on nutritional and organoleptic characteristics of bread and noodles. Current Research in Nutrition and Food Science Journal, 6(1), 148-156. http://dx.doi.org/10.12944/CRNFSJ.6.1.17.

http://dx.doi.org/10.12944/CRNFSJ.6.1.17...

). Aydin et al., found that 10% of OF added noodles could increase maximum volume (238.46%), however, replacing 20%, 30% and 40% of OF minimized 206.25%, 188.24% and 181.25% of swelling, respectively (Aydin & Gocmen, 2011Aydin, E., & Gocmen, D. (2011). Cooking quality and sensorial properties of noodle supplemented with oat flour. Food Science and Biotechnology, 20(2), 507-511. http://dx.doi.org/10.1007/s10068-011-0070-1

http://dx.doi.org/10.1007/s10068-011-007...

).

3.4 Cooking time

The ideal or optimum time of cooking food is defined by the required time to fully hydrate the food. Ideal cooking time is an important factor for snacks food (Sui et al., 2006Sui, Z., Lucas, P. W., & Corke, H. (2006). Optimal cooking time of noodles related to their notch sensitivity. Journal of Texture Studies, 37(4), 428-441. http://dx.doi.org/10.1111/j.1745-4603.2006.00061.x

http://dx.doi.org/10.1111/j.1745-4603.20...

). The ideal cooking time of S0, S1, S2, S3 and S4 were 1.56, 2.20, 2.25, 2.53 and 3.51 min, respectively (Table 4). The result showed that noodles with an increasing percentage of protein with low gluten flour involved an extension of optimum cooking time which was consistent with the previous report (Bhise et al., 2015Bhise, S., Kaur, A., & Aggarwal, P. (2015). Development of protein enriched noodles using texturized defatted meal from sunflower, flaxseed and soybean. Journal of Food Science and Technology, 52(9), 5882-5889. PMid:26345004. http://dx.doi.org/10.1007/s13197-014-1630-1

http://dx.doi.org/10.1007/s13197-014-163...

; Xu et al., 2020Xu, M., Hou, G. G., Ma, F., Ding, J., Deng, L., Kahraman, O., Niu, M., Trivettea, K., Lee, B., Wu, L., & Baik, B.-K. (2020). Evaluation of aleurone flour on dough, textural, and nutritional properties of instant fried noodles. LWT, 126, 109294. http://dx.doi.org/10.1016/j.lwt.2020.109294.

http://dx.doi.org/10.1016/j.lwt.2020.109...

; Yao et al., 2020Yao, M., Li, M., Dhital, S., Tian, Y., & Guo, B. (2020). Texture and digestion of noodles with varied gluten contents and cooking time: The view from protein matrix and inner structure. Food Chemistry, 315, 126230. PMid:32014665. http://dx.doi.org/10.1016/j.foodchem.2020.126230

http://dx.doi.org/10.1016/j.foodchem.202...

). Yao et al., reported that 8.0% of protein containing noodles required 2 min10s as optimum cooking time but higher protein containing noodles (14.0%) required more time (3 min 5s) (Yao et al., 2020Yao, M., Li, M., Dhital, S., Tian, Y., & Guo, B. (2020). Texture and digestion of noodles with varied gluten contents and cooking time: The view from protein matrix and inner structure. Food Chemistry, 315, 126230. PMid:32014665. http://dx.doi.org/10.1016/j.foodchem.2020.126230

http://dx.doi.org/10.1016/j.foodchem.202...

).

3.5 Sensory properties

The mean values of the hedonic scores for sensory attributes of cooked noodles samples are shown in Table 5 with statistical analysis. The results showed that the texture, flavor, mouth feel and overall acceptance of formulations S1, S2, were not significantly different from S0. On the other hand, S3 (30%OF: 70%WF) was higher than S0 (100%WF). It was a noticeable factor that lowest score of sensory evaluations found at sample S4 (35% OF: 65% WF) which contained highest amount of oats flour among other samples (Table 1). The picture of cooked noodles could produce dark brown colour and braked down into small pieces instead of forming a long shape (Figure 4).

Dried and cooked noodles fortified with different percentages of oats flour: S0, S1, S2, S3, S4 contains 0:100, 20:80, 25:75, 30:70 and 35:65 percentage of oat and wheat flour, respectively.

It could be noted that more OF containing noodles have shown a tendency to breakdown its structure even during boiling or cooking (Chauhan et al., 2018Chauhan, D., Kumar, K., Kumar, S., & Kumar, H. (2018). Effect of incorporation of oat flour on nutritional and organoleptic characteristics of bread and noodles. Current Research in Nutrition and Food Science Journal, 6(1), 148-156. http://dx.doi.org/10.12944/CRNFSJ.6.1.17.

http://dx.doi.org/10.12944/CRNFSJ.6.1.17...

) and oats affected adversely the color of noodles (become dark brown color) due to high fiber content (Guo et al., 2018Guo, Q., Kang, J., Bai, Y., & Xu, F. (2018). Dietary fiber: Chemistry, structure, and properties. Journal of Chemistry, 2018, 1-2. http://dx.doi.org/10.1155/2018/1328797

http://dx.doi.org/10.1155/2018/1328797...

; Reungmaneepaitoon et al., 2006Reungmaneepaitoon, S., Sikkhamondhol, C., & Tiangpook, C. (2006). Nutritive improvement of instant fried noodles with oat bran. Songklanakarin Journal of Science and Technology, 28(Suppl. 1), 89-97. Retrieved in 2017, August 4, from https://www.semanticscholar.org/paper/Nutritive-improvement-of-instant-fried-noodles-with-Reungmaneepaitoon/d4abc77841e233231f1f18c5ee9cffa27bd72212

https://www.semanticscholar.org/paper/Nu...

). Among the noodles formulations, the sample with 30% of oat flour (S3) exhibited statistically (p < 0.05) higher qualitative attributes than the control (S0) during sensory evaluation (Table 5).

4 Conclusions

According to the present study, noodles manufactured with a combination of 70% of wheat flour and 30% of oat flour with optimized ingredients may keep good organoleptic and cooking quality attributes as well as nutritional properties. This formulation resulted in a higher amount of protein, fiber and minerals (Ca, Fe, Na and K) but lower carbohydrate content than noodle 100% wheat flour. Then, oat supplemented noodles up to 30% may be considered for commercialization considering its nutritional benefits. However, the main constraints for commercialization may be product color and cooking loss that must be improved by further research. More than 30% of oat flour will deform the noodles, therefore, maximum 30:70 (oat flour: wheat flour) ratio should be consider as the best formulation.

Acknowledgements

The authors are thankful to the Department of Nutrition and Food Engineering, Daffodil International University and Institute of Food Science & Technology, Bangladesh Council of Scientific & Industrial Research (BCSIR) for their supports.

-

Funding: None.

References

- Ahmad, A., Anjum, F. M., Zahoor, T., Nawaz, H., & Ahmed, Z. (2010). Extraction and characterization of β-d-glucan from oat for industrial utilization. International Journal of Biological Macromolecules, 46(3), 304-309. PMid:20083136. http://dx.doi.org/10.1016/j.ijbiomac.2010.01.002

» http://dx.doi.org/10.1016/j.ijbiomac.2010.01.002 - American Association of Cereal Chemists – AACC. (2010). Approved methods of the American Association of Cereal Chemists. St. Paul: AACC International. Retrieved in 2017, August 4, from http://methods.aaccnet.org/toc.aspx

» http://methods.aaccnet.org/toc.aspx - Asenstorfer, R. E., Wang, Y., & Mares, D. J. (2006). Chemical structure of flavonoid compounds in wheat (Triticum aestivum L.) flour that contribute to the yellow colour of Asian alkaline noodles. Journal of Cereal Science, 43(1), 108-119. http://dx.doi.org/10.1016/j.jcs.2005.09.001

» http://dx.doi.org/10.1016/j.jcs.2005.09.001 - Aydin, E., & Gocmen, D. (2011). Cooking quality and sensorial properties of noodle supplemented with oat flour. Food Science and Biotechnology, 20(2), 507-511. http://dx.doi.org/10.1007/s10068-011-0070-1

» http://dx.doi.org/10.1007/s10068-011-0070-1 - Bhalerao, P. P., Chaudhari, N. S., Muley, A. B., Talib, M. I., Parate, V. R., & Kudake, D. C. (2018). Fortification of wheat flour with ragi flour: Effect on physical, nutritional, antioxidant and sensory profile of noodles. Current Research in Nutrition and Food Science, 6(1), 165-173.http://dx.doi.org/10.12944/CRNFSJ.6.1.19

» http://dx.doi.org/10.12944/CRNFSJ.6.1.19 - Bhise, S., Kaur, A., & Aggarwal, P. (2015). Development of protein enriched noodles using texturized defatted meal from sunflower, flaxseed and soybean. Journal of Food Science and Technology, 52(9), 5882-5889. PMid:26345004. http://dx.doi.org/10.1007/s13197-014-1630-1

» http://dx.doi.org/10.1007/s13197-014-1630-1 - Chakraborty, M., Hareland, G. A., Manthey, F. A., & Berglund, L. R. (2003). Evaluating quality of yellow alkaline noodles made from mechanically abraded sprouted wheat. Journal of the Science of Food and Agriculture, 83(5), 487-495. http://dx.doi.org/10.1002/jsfa.1403

» http://dx.doi.org/10.1002/jsfa.1403 - Chauhan, D., Kumar, K., Kumar, S., & Kumar, H. (2018). Effect of incorporation of oat flour on nutritional and organoleptic characteristics of bread and noodles. Current Research in Nutrition and Food Science Journal, 6(1), 148-156. http://dx.doi.org/10.12944/CRNFSJ.6.1.17

» http://dx.doi.org/10.12944/CRNFSJ.6.1.17 - Choo, C. L., & Aziz, N. A. A. (2010). Effects of banana flour and β-glucan on the nutritional and sensory evaluation of noodles. Food Chemistry, 119(1), 34-40. http://dx.doi.org/10.1016/j.foodchem.2009.05.004

» http://dx.doi.org/10.1016/j.foodchem.2009.05.004 - Eneche, E. H. (1999). Biscuit-making potential of millet/pigeon pea flour blends. Plant Foods for Human Nutrition, 54(1), 21-27. PMid:10646626. http://dx.doi.org/10.1023/A:1008031618117

» http://dx.doi.org/10.1023/A:1008031618117 - Guo, Q., Kang, J., Bai, Y., & Xu, F. (2018). Dietary fiber: Chemistry, structure, and properties. Journal of Chemistry, 2018, 1-2. http://dx.doi.org/10.1155/2018/1328797

» http://dx.doi.org/10.1155/2018/1328797 - Horwitz, W., & Latimer, G. W. (2005). Official methods of analysis of AOAC International. Gaithersburg: AOAC International.

- Hou, Q., Li, Y., Li, L., Cheng, G., Sun, X., Li, S., & Tian, H. (2015). The metabolic effects of oats intake in patients with type 2 diabetes: A systematic review and meta-analysis. Nutrients, 7(12), 10369-10387. PMid:26690472. http://dx.doi.org/10.3390/nu7125536

» http://dx.doi.org/10.3390/nu7125536 - Izydorczyk, M. S., Lagassé, S. L., Hatcher, D. W., Dexter, J. E., & Rossnagel, B. G. (2005). The enrichment of Asian noodles with fiber‐rich fractions derived from roller milling of hull‐less barley. Journal of the Science of Food and Agriculture, 85(12), 2094-2104. http://dx.doi.org/10.1002/jsfa.2242

» http://dx.doi.org/10.1002/jsfa.2242 - Kudake, D. C., Pawar, A. V., Muley, A. B., Parate, V. R., & Talib, M. I. (2017). Enrichment of wheat flour noodles with oat flour: Effect on physical, nutritional, antioxidant and sensory properties. International Journal of Current Microbiology and Applied Sciences, 6(12), 204-213. http://dx.doi.org/10.20546/ijcmas.2017.612.026

» http://dx.doi.org/10.20546/ijcmas.2017.612.026 - Kulkarni, S. S., Desai, A. D., Ranveer, R. C., & Sahoo, A. K. (2012). Development of nutrient rich noodles by supplementation with malted ragi flour. International Food Research Journal, 19(1), 309. Retrieved in 2017, August 4, from http://www.ijoart.org/docs/DEVELOPMENT-OF-NUTRIENTRICH-NOODLES-BY-SUPPLEMENTATION-WITH-MALTED-KODO-MILLET-FLOUR.pdf

» http://www.ijoart.org/docs/DEVELOPMENT-OF-NUTRIENTRICH-NOODLES-BY-SUPPLEMENTATION-WITH-MALTED-KODO-MILLET-FLOUR.pdf - Liu, S., Sun, Y., Obadi, M., Jiang, Y., Chen, Z., Jiang, S., & Xu, B. (2020). Effects of vacuum mixing and mixing time on the processing quality of noodle dough with high oat flour content. Journal of Cereal Science, 91, 102885 http://dx.doi.org/10.1016/j.jcs.2019.102885

» http://dx.doi.org/10.1016/j.jcs.2019.102885 - Mahmoud, E. A., Nassef, S. L., & Basuny, A. M. (2012). Production of high protein quality noodles using wheat flour fortified with different protein products from lupine. Annals of Agricultural Science, 57(2), 105-112. http://dx.doi.org/10.1016/j.aoas.2012.08.003

» http://dx.doi.org/10.1016/j.aoas.2012.08.003 - Majzoobi, M., Layegh, B., & Farahnaky, A. (2014). Inclusion of oat flour in the formulation of regular salted dried noodles and its effects on dough and noodle properties. Journal of Food Processing and Preservation, 38(1), 48-58 http://dx.doi.org/10.1111/j.1745-4549.2012.00742.x

» http://dx.doi.org/10.1111/j.1745-4549.2012.00742.x - Manzoor, M. S., Pasha, I., Shehzad, A., Zia, M. A., & Zhu, M. J. (2020). Antioxidant profiling of indigenous oat cultivars with special reference to avenanthramides. International Food Research Journal, 27(2), 261-269. Retrieved in 2017, August 4, from https://www.cabdirect.org/globalhealth/abstract/20203241436

» https://www.cabdirect.org/globalhealth/abstract/20203241436 - Mertens, D. (2005). AOAC official method 975.03: Metal in plants and pet foods. In W. Horwitz & G. W. Latimer (Eds.), Official methods of analysis (18th ed., Chap. 3, pp. 3-4). Gaitherburg: AOAC International. Retrieved in 2017, August 4, from https://www.worldcat.org/title/official-methods-of-analysis-of-aoac-international/oclc/62751475

» https://www.worldcat.org/title/official-methods-of-analysis-of-aoac-international/oclc/62751475 - Niu, Q., Pu, Y., Li, X., Ma, Z., & Hu, X. (2017). Solvent retention capacities of oat flour. International Journal of Molecular Sciences, 18(3), 590. PMid:28335393. http://dx.doi.org/10.3390/ijms18030590

» http://dx.doi.org/10.3390/ijms18030590 - Oghbaei, M., & Prakash, J. (2013). Effect of fractional milling of wheat on nutritional quality of milled fractions. Trends in Carbohydrate Research, 5(1). Retrieved in 2017, August 4, from http://www.trendscarbo.com/shoppingcart.php

» http://www.trendscarbo.com/shoppingcart.php - Oghbaei, M., & Prakash, J. (2016). Effect of primary processing of cereals and legumes on its nutritional quality: A comprehensive review. Cogent Food & Agriculture, 2(1), 1136015. http://dx.doi.org/10.1080/23311932.2015.1136015

» http://dx.doi.org/10.1080/23311932.2015.1136015 - Parvin, R., Farzana, T., Mohajan, S., Rahman, H., & Rahman, S. S. (2020). Quality improvement of noodles with mushroom fortified and its comparison with local branded noodles. NFS Journal, 20, 37-42. http://dx.doi.org/10.1016/j.nfs.2020.07.002

» http://dx.doi.org/10.1016/j.nfs.2020.07.002 - Pearson, D. (1999). Pearsons composition and analysis of foods (pp. 117-123). Reading: University of Reading. Retrieved in 2017, August 4, from http://ludibuk.com/pearson_analysis_of_foods.pdf

» http://ludibuk.com/pearson_analysis_of_foods.pdf - Perrelli, A., Goitre, L., Salzano, A. M., Moglia, A., Scaloni, A., & Retta, S. F. (2018). Biological activities, health benefits, and therapeutic properties of avenanthramides: From skin protection to prevention and treatment of cerebrovascular diseases. Oxidative Medicine and Cellular Longevity, 2018, 6015351. PMid:30245775. http://dx.doi.org/10.1155/2018/6015351

» http://dx.doi.org/10.1155/2018/6015351 - Reungmaneepaitoon, S., Sikkhamondhol, C., & Tiangpook, C. (2006). Nutritive improvement of instant fried noodles with oat bran. Songklanakarin Journal of Science and Technology, 28(Suppl. 1), 89-97. Retrieved in 2017, August 4, from https://www.semanticscholar.org/paper/Nutritive-improvement-of-instant-fried-noodles-with-Reungmaneepaitoon/d4abc77841e233231f1f18c5ee9cffa27bd72212

» https://www.semanticscholar.org/paper/Nutritive-improvement-of-instant-fried-noodles-with-Reungmaneepaitoon/d4abc77841e233231f1f18c5ee9cffa27bd72212 - Sánchez-Peña, M. J., Márquez-Sandoval, F., Ramirez-Anguiano, A. C., Velasco-Ramirez, S. F., Macedo-Ojeda, G., & Gonzalez-Ortiz, L. J. (2017). Calculating the metabolizable energy of macronutrients: A critical review of Atwater’s results. Nutrition Reviews, 75(1), 37-48. PMid:27974598. http://dx.doi.org/10.1093/nutrit/nuw044

» http://dx.doi.org/10.1093/nutrit/nuw044 - Shukla, K., & Srivastava, S. (2014). Evaluation of finger millet incorporated noodles for nutritive value and glycemic index. Journal of Food Science and Technology, 51(3), 527-534. PMid:24587528. http://dx.doi.org/10.1007/s13197-011-0530-x

» http://dx.doi.org/10.1007/s13197-011-0530-x - Singh, C., Singh, B., Satpal, P. K., Ankush, M., Gora, K., & Kumar, A. (2019). Micronutrient management for enhancing production of major fodder crops: A review. Forage Research, 45(2), 95-102. Retrieved in 2017, August 4, from http://forageresearch.in/micronutrient-management-for-enhancing-production-of-major-fodder-crops-a-review/

» http://forageresearch.in/micronutrient-management-for-enhancing-production-of-major-fodder-crops-a-review/ - Siong, T. E., Choo, K. S., & Shahid, S. M. (1989). Determination of iron in foods by the atomic absorption spectrophotometric and colorimetric methods. Pertanika, 12(3), 313-322. Retrieved in 2017, August 4, from http://www.pertanika.upm.edu.my/Pertanika%20PAPERS/PERT%20Vol.%2012%20(3)%20Dec.%201989/05%20Pertanika%20Vol.12%20(3)%20Dec.%201989%20(Pg%20315-322).pdf

» http://www.pertanika.upm.edu.my/Pertanika%20PAPERS/PERT%20Vol.%2012%20(3)%20Dec.%201989/05%20Pertanika%20Vol.12%20(3)%20Dec.%201989%20(Pg%20315-322).pdf - Snedecor, G. W., & Cochran, W. G. (1994). Statistical methods (8th ed.). Ames: Iowa State University Press. Retrieved in 2017, August 4, from https://journals.sagepub.com/doi/abs/10.3102/10769986019003304

» https://journals.sagepub.com/doi/abs/10.3102/10769986019003304 - Somvanshi, A., Patel, A., & Jalgaonwala, R. (2017). Effect of microbial fermentation and processing on nutritional and antinutritional properties of selected fermented foods. Asian Journal of Research in Chemistry, 10(4), 531-540. http://dx.doi.org/10.5958/0974-4150.2017.00088.8

» http://dx.doi.org/10.5958/0974-4150.2017.00088.8 - Sui, Z., Lucas, P. W., & Corke, H. (2006). Optimal cooking time of noodles related to their notch sensitivity. Journal of Texture Studies, 37(4), 428-441. http://dx.doi.org/10.1111/j.1745-4603.2006.00061.x

» http://dx.doi.org/10.1111/j.1745-4603.2006.00061.x - Thies, F., Masson, L. F., Boffetta, P., & Kris-Etherton, P. (2014). Oats and CVD risk markers: A systematic literature review. British Journal of Nutrition, 112(Suppl. 2), S19-S30. PMid:25267241. http://dx.doi.org/10.1017/S0007114514002281

» http://dx.doi.org/10.1017/S0007114514002281 - Tiefenbacher, K. F. (2017). Technology of main ingredients: water and flours. In K. F. Tiefenbacher (Ed.), Wafer and waffle: Processing and manufacturing (pp. 15-121). San Diego: Academic Press. Retrieved in 2017, August 4, from https://www.sciencedirect.com/science/article/pii/B9780128094389000028

» https://www.sciencedirect.com/science/article/pii/B9780128094389000028 - Vollmann, J., Grausgruber, H., & Ruckenbauer, P. (Eds.). (2004). Genetic variation for plant breeding. In Proceedings of the 17th EUCARPIA General Congress Vienna: University of Natural Resources and Applied Life Sciences. Retrieved in 2017, August 4, from https://zenodo.org/record/1204819/files/Vollmann_Grausgruber_Ruckenbauer_2004_EUCARPIA_XVII.pdf

» https://zenodo.org/record/1204819/files/Vollmann_Grausgruber_Ruckenbauer_2004_EUCARPIA_XVII.pdf - Webster, F. H. (2002). Whole-grain oats and oat products: Whole-grain foods in health and disease (pp. 83-123). St. Paul: American Association of Cereal Chemists. Retrieved in 2017, August 4, from https://wholegrainscouncil.org/sites/default/files/atoms/files/Slavin Article 0504.pdf

» https://wholegrainscouncil.org/sites/default/files/atoms/files/Slavin - Welch, R. W. (1995). The chemical composition of oats. In R. W. Welch (Ed.), The oat crop (World Crop Series). Springer: Dordrecht. http://dx.doi.org/10.1007/978-94-011-0015-1_10

» http://dx.doi.org/10.1007/978-94-011-0015-1_10 - Xu, M., Hou, G. G., Ma, F., Ding, J., Deng, L., Kahraman, O., Niu, M., Trivettea, K., Lee, B., Wu, L., & Baik, B.-K. (2020). Evaluation of aleurone flour on dough, textural, and nutritional properties of instant fried noodles. LWT, 126, 109294. http://dx.doi.org/10.1016/j.lwt.2020.109294

» http://dx.doi.org/10.1016/j.lwt.2020.109294 - Yao, M., Li, M., Dhital, S., Tian, Y., & Guo, B. (2020). Texture and digestion of noodles with varied gluten contents and cooking time: The view from protein matrix and inner structure. Food Chemistry, 315, 126230. PMid:32014665. http://dx.doi.org/10.1016/j.foodchem.2020.126230

» http://dx.doi.org/10.1016/j.foodchem.2020.126230

Publication Dates

-

Publication in this collection

15 Nov 2021 -

Date of issue

2021

History

-

Received

15 Dec 2020 -

Accepted

03 Aug 2021