Abstract

Cheese whey is the main by-product obtained in the production of cheese. Despite its high nutritional value, approximately half of the whey volume generated is still disposed incorrectly, which causes damage to the ecosystem due to the high cheese whey pollutant load. Therefore, it is important to use this by-product and its components in an increasing number of applications, especially as food ingredient. This review aimed to show the technology of production of butter from whey cream, as well as showing the physico-chemical, sensory, and nutritional characteristics of the product. There were no significant variations in the physico-chemical composition of milk cream butter and whey cream butter in the literature available. As the technology to produce whey butter is quite simple, this by-product has potential to be exploited by the dairy industry. Additionally, further studies on production process, characterization, and sensory analysis are required to enable its large-scale production.

Keywords:

Milk cream; Physico-chemical composition; Whey cream; Fermentation; Lactic acid bacteria; By-products

Resumo

O soro de queijo é o principal coproduto obtido durante o processo de fabricação de queijos. Apesar de possuir um valor nutricional elevado, cerca da metade do volume de soro gerado ainda é descartada de forma incorreta, constituindo-se uma prática prejudicial para o ecossistema devido à enorme carga poluente do soro de queijo. Dessa forma, é importante a utilização desse coproduto e de seus componentes em um número maior de aplicações, especialmente como ingrediente alimentício. O objetivo deste artigo de revisão é apresentar a tecnologia para produção da manteiga a partir do reúso do creme de soro de queijo, demonstrando as características físico-químicas, sensoriais e nutricionais do produto, e apontando as alternativas e possíveis utilizações para os principais componentes do soro. Na comparação entre a manteiga de creme de leite e a manteiga de creme de soro, na literatura disponível, os resultados não apresentam variações significativas em relação à sua composição físico-química. Dada a simplicidade da tecnologia de produção, a manteiga de soro possui potencial para ser explorada pelas indústrias lácteas. Além disso, mais estudos sobre o processo de fabricação, caracterização e análise sensorial são necessários para viabilizar sua produção em maior escala.

Palavras-chave:

Creme de leite; Composição físico-química; Creme de soro; Fermentação; Bactérias ácido-lácticas; Coprodutos

HIGHLIGHTS

Butter obtained from cheese whey had a good nutritional composition

Whey cream butter is characterized by high concentration of unsaturated fatty acids

Shelf-life of whey cream butter is reduced due to oxidation of unsaturated fatty acids

1 Introduction

Cheese whey is the aqueous portion separated from curd during the production of cheese or casein. It comprises approximately 80 to 90% of the milk volume used in cheese making and is thus the main dairy by-product (Tsermoula et al., 2021Tsermoula, P., Khakimov, B., Nielsen, J. H., & Engelsen, S. B. (2021). WHEY-The waste-stream that became more valuable than the food product. Trends in Food Science & Technology, 118, 230-241. http://dx.doi.org/10.1016/j.tifs.2021.08.025

http://dx.doi.org/10.1016/j.tifs.2021.08...

). Its physico-chemical composition derives from several factors, including the type of cheese manufactured, composition of the milk used, as well as animal diet, lactation stage, and management (Trindade et al., 2019Trindade, M. B., Soares, B. C. V., Scudino, H., Guimarães, J. T., Esmerino, E. A., Freitas, M. V., Pimentel, T. C., Silva, M. C., Souza, S. L. Q., Almada, R. B., & Cruz, A. G. (2019). Cheese whey exploitation in Brazil: A questionnaire survey. Food Science and Technology (Campinas), 39(3), 788-791. http://dx.doi.org/10.1590/fst.07419

http://dx.doi.org/10.1590/fst.07419...

).

Considering there is a steady increase in annual cheese production, the volume of whey generated has also increased, which requires new strategies to enhance its use and application (Elleuch et al., 2020Elleuch, L., Salem-Berrabah, O. B., Cherni, Y., Sghaier-Hammami, B., Kasmi, M., Botta, C., Ouerghi, I., Franciosa, I., Cocolin, L., Trabelsi, I., & Chatti, A. (2020). A new practical approach for the biological treatment of a mixture of cheese whey and white wastewaters using Kefir grains. Environmental Science and Pollution Research International, 27(26), 33127-33139. PMid:32529610. http://dx.doi.org/10.1007/s11356-020-09549-8

http://dx.doi.org/10.1007/s11356-020-095...

). The pollutant potential of cheese whey is due to its Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD), and approximately half of its volume generated is processed and used in animal or human diets; the rest is either sent for effluent treatment, which generates additional costs, or resulted from inadequate sewage disposal, i.e., there is water or soil contamination, thus causing environmental issues (Izzo et al., 2020Izzo, L., Luz, C., Ritieni, A., Mañes, J., & Meca, G. (2020). Whey fermented by using Lactobacillus plantarum strains: A promising approach. Journal of Dairy Science, 103(7), 5906-5915. PMid:32389480. http://dx.doi.org/10.3168/jds.2019-17547

http://dx.doi.org/10.3168/jds.2019-17547...

; Macwan et al., 2016Macwan, S. R., Dabhi, B. K., Parmar, S. C., & Aparnathi, K. D. (2016). Whey and its utilization. International Journal of Current Microbiology and Applied Sciences, 5(8), 134-155. http://dx.doi.org/10.20546/ijcmas.2016.508.016

http://dx.doi.org/10.20546/ijcmas.2016.5...

). Therefore, the use of cheese whey is of high interest to the industry due to the amount produced daily and to its nutritional quality, which leads to its potential as ingredient in food production (Rama et al., 2019Rama, G. R., Kuhn, D., Beux, S., Maciel, M. J., & Souza, C. F. V. (2019). Potential applications of dairy whey for the production of lactic acid bacteria. International Dairy Journal, 98, 25-37. http://dx.doi.org/10.1016/j.idairyj.2019.06.012

http://dx.doi.org/10.1016/j.idairyj.2019...

).

One economic and feasible option for dairy products is the production of butter using cheese whey. For that purpose, whey cream is separated from the aqueous fraction of cheese whey and processed to obtain whey cream butter (Aly, 2009Aly, A. H. (2009). Fatty acid composition, textural and organoleptic properties of whey butter. Journal of Food and Dairy Sciences, 34(4), 3081-3094. http://dx.doi.org/10.21608/jfds.2009.113433.

http://dx.doi.org/10.21608/jfds.2009.113...

; Jinjarak et al., 2006Jinjarak, S., Olabi, A., Jiménez-Flores, R., & Walker, J. H. (2006). Sensory, functional, and analytical comparisons of whey butter with other butters. Journal of Dairy Science, 89(7), 2428-2440. PMid:16772559. http://dx.doi.org/10.3168/jds.S0022-0302(06)72316-5

http://dx.doi.org/10.3168/jds.S0022-0302...

; Morin et al., 2006Morin, P., Pouliot, Y., & Jiménez-Flores, R. (2006). A comparative study of the fractionation of regular buttermilk and whey buttermilk by microfiltration. Journal of Food Engineering, 77(3), 521-528. http://dx.doi.org/10.1016/j.jfoodeng.2005.06.065

http://dx.doi.org/10.1016/j.jfoodeng.200...

; Nadeem et al., 2015Nadeem, M., Mahud, A., Imran, M., & Khalique, A. (2015). Enhancement of the oxidative stability of whey butter through almont (Prunus dulcis) peel extract. Journal of Food Processing and Preservation, 39(6), 591-598. http://dx.doi.org/10.1111/jfpp.12265

http://dx.doi.org/10.1111/jfpp.12265...

). Therefore, this review aimed to show the technology of production of butter from whey cream, as well as showing the physico-chemical, sensory, and nutritional characteristics of the product. Firstly, there will be a discussion about cheese whey, emphasizing its composition and pollutant load. Then, different types of butter in the market will be described, along with their compositions and production processes. Finally, the technique to obtain whey cream butter will be described, comparing milk cream butter and whey cream butter through their physico-chemical parameters, obtained from several studies.

2 Cheese whey

Cheese whey can be defined as the yellow-green liquid that is separated from curd during the production of some dairy products (Enteshari & Martínez-Monteagudo, 2020Enteshari, M., & Martínez-Monteagudo, S. I. (2020). One-pot synthesis of lactose derivatives from whey permeate maryam. Foods, 9(6), 784. PMid:32545728. http://dx.doi.org/10.3390/foods9060784

http://dx.doi.org/10.3390/foods9060784...

). It accounts for 80 to 90% of the milk processed, containing approximately 55% of milk nutrients. It is chiefly composed of water (~90%), lactose (4-5%), soluble proteins (0.6-0.8%), lipids (0.4-0.5%), mineral salts (0.5-0.7%), and components such as organic acids and B-complex vitamins (Enteshari & Martínez-Monteagudo, 2020Enteshari, M., & Martínez-Monteagudo, S. I. (2020). One-pot synthesis of lactose derivatives from whey permeate maryam. Foods, 9(6), 784. PMid:32545728. http://dx.doi.org/10.3390/foods9060784

http://dx.doi.org/10.3390/foods9060784...

; Zikmanis et al., 2020Zikmanis, P., Kolesovs, S., & Semjonovs, P. (2020). Production of biodegradable microbial polymers from whey. Bioresources and Bioprocessing, 7(1), 36. http://dx.doi.org/10.1186/s40643-020-00326-6

http://dx.doi.org/10.1186/s40643-020-003...

). Cheese whey has 20% of milk proteins, containing all essential amino acids, and it is a mixture of globular proteins composed of β-lactoglobulin (β-LG; ~50%), α-lactalbumin (α-LA; ~20%), immunoglobulins (IgC; <10%), and serum albumin (BSA; <6%), as well as glycomacropeptides (GMP) and other components, such as peptides, lactoferrin (LF), lactoperoxidase (LPO), and lysozyme (Coltelli et al., 2020Coltelli, M. B., Aliotta, L., Gigante, V., Bellusci, M., Cinelli, P., Bugnicourt, E., Schmid, M., Staebler, A., & Lazzeri, A. (2020). Preparation and compatibilization of pbs/whey protein isolate based blends. Molecules (Basel, Switzerland), 25(14), 3313. PMid:32708298. http://dx.doi.org/10.3390/molecules25143313

http://dx.doi.org/10.3390/molecules25143...

; Maciel et al., 2020Maciel, K. S., Santos, L. S., Bonomo, R. C. F., Verissimo, L. A. A., Minim, V. P. R., & Minim, L. A. (2020). Purification of lactoferrin from sweet whey using ultrafiltration followed by expanded bed chromatography. Separation and Purification Technology, 251, 117324. http://dx.doi.org/10.1016/j.seppur.2020.117324

http://dx.doi.org/10.1016/j.seppur.2020....

; Trindade et al., 2019Trindade, M. B., Soares, B. C. V., Scudino, H., Guimarães, J. T., Esmerino, E. A., Freitas, M. V., Pimentel, T. C., Silva, M. C., Souza, S. L. Q., Almada, R. B., & Cruz, A. G. (2019). Cheese whey exploitation in Brazil: A questionnaire survey. Food Science and Technology (Campinas), 39(3), 788-791. http://dx.doi.org/10.1590/fst.07419

http://dx.doi.org/10.1590/fst.07419...

).

Cheese whey might be classified as either sweet whey or acid whey according to its acidity level. Sweet whey has pH of 5.6 – 6.5 and is obtained via the enzyme coagulation of milk proteins. Acid whey, on the other hand, has a pH below 5 and is obtained by acid coagulation in the production of cheese (Ryan & Walsh, 2016Ryan, M. P., & Walsh, G. (2016). The biotechnological potential of whey. Reviews in Environmental Science and Biotechnology, 15(3), 479-498. http://dx.doi.org/10.1007/s11157-016-9402-1

http://dx.doi.org/10.1007/s11157-016-940...

; Zikmanis et al., 2020Zikmanis, P., Kolesovs, S., & Semjonovs, P. (2020). Production of biodegradable microbial polymers from whey. Bioresources and Bioprocessing, 7(1), 36. http://dx.doi.org/10.1186/s40643-020-00326-6

http://dx.doi.org/10.1186/s40643-020-003...

). Sweet whey is used as ingredient in the production of flour and meat products, beverages, and baby food, due to its nutritional value and sweet taste. Acid whey is used in the production of fruit beverages, fermented milk, and salad seasonings (Faucher et al., 2020Faucher, M., Perreault, V., Gaaloul, S., & Bazinet, L. (2020). Defatting of sweet whey by electrodialysis with bipolar membranes: Effect of protein concentration factor. Separation and Purification Technology, 251, 117248. http://dx.doi.org/10.1016/j.seppur.2020.117248

http://dx.doi.org/10.1016/j.seppur.2020....

; Smithers, 2015Smithers, G. W. (2015). Whey-ing up the options–Yesterday, today and tomorrow. International Dairy Journal, 48, 2-14. http://dx.doi.org/10.1016/j.idairyj.2015.01.011

http://dx.doi.org/10.1016/j.idairyj.2015...

; Panghal et al., 2018Panghal, A., Patidar, R., Jaglan, S., Chhikara, N., Khatkar, S. K., Gat, Y., & Sindhu, N. (2018). Whey valorization: Current options and future scenario–a critical review. Nutrition & Food Science, 48(3), 520-535. http://dx.doi.org/10.1108/NFS-01-2018-0017

http://dx.doi.org/10.1108/NFS-01-2018-00...

).

The dairy industry has had a sharp growth, thus leading to an increase in the volume of cheese whey produced (Elleuch et al., 2020Elleuch, L., Salem-Berrabah, O. B., Cherni, Y., Sghaier-Hammami, B., Kasmi, M., Botta, C., Ouerghi, I., Franciosa, I., Cocolin, L., Trabelsi, I., & Chatti, A. (2020). A new practical approach for the biological treatment of a mixture of cheese whey and white wastewaters using Kefir grains. Environmental Science and Pollution Research International, 27(26), 33127-33139. PMid:32529610. http://dx.doi.org/10.1007/s11356-020-09549-8

http://dx.doi.org/10.1007/s11356-020-095...

). The whey volume produced worldwide has increased over 100% and approximately over the last 45 years and it reached the amount of 160 million tons in 2020. According to the Global Cheese Market, the global production of cheese in 2023 is estimated to be 26 million tons, leading to an estimated cheese whey volume of 230 million tons (Choi et al., 2020Choi, H. S., Yang, X., Kim, D. S., Yang, J. H., Han, S. O., Park, C., & Kim, S. W. (2020). Power generation from cheese whey using enzymatic fuel cell. Journal of Cleaner Production, 254, 120181. http://dx.doi.org/10.1016/j.jclepro.2020.120181

http://dx.doi.org/10.1016/j.jclepro.2020...

; Rama et al., 2019Rama, G. R., Kuhn, D., Beux, S., Maciel, M. J., & Souza, C. F. V. (2019). Potential applications of dairy whey for the production of lactic acid bacteria. International Dairy Journal, 98, 25-37. http://dx.doi.org/10.1016/j.idairyj.2019.06.012

http://dx.doi.org/10.1016/j.idairyj.2019...

).

Considering the high volume of cheese whey produced and its nutritional composition, the use of this by-product is of great interest to the dairy industry. Half of the volume of whey produced is currently used in the industry; approximately 2/3 of this volume is used as either liquid or powder whey and approximately 1/3 is used as protein concentrate and isolate, and whey hydrolysates. Figure 1 shows the main cheese whey components and some uses (Izzo et al., 2020Izzo, L., Luz, C., Ritieni, A., Mañes, J., & Meca, G. (2020). Whey fermented by using Lactobacillus plantarum strains: A promising approach. Journal of Dairy Science, 103(7), 5906-5915. PMid:32389480. http://dx.doi.org/10.3168/jds.2019-17547

http://dx.doi.org/10.3168/jds.2019-17547...

; Mollea et al., 2013Mollea, C., Marmo, L., & Bosco, F. (2013). Valorisation of cheese whey, a by-product from the dairy industry. In I. Muzzalupo (Ed.), Food industry (pp. 549-588). London: IntechOpen. http://dx.doi.org/10.5772/53159). The approximate composition (in dry base) of the whey, after extracting the fat to produce the whey butter, is 77% of lactose, 12% of proteins, and 11% of mineral salts (Zikmanis et al., 2020Zikmanis, P., Kolesovs, S., & Semjonovs, P. (2020). Production of biodegradable microbial polymers from whey. Bioresources and Bioprocessing, 7(1), 36. http://dx.doi.org/10.1186/s40643-020-00326-6

http://dx.doi.org/10.1186/s40643-020-003...

).

Despite its characteristics, approximately 50% of the cheese whey volume generated by the dairy industry is still sent to effluent treatment stations or may be discharged onto the soil or into water bodies (Izzo et al., 2020Izzo, L., Luz, C., Ritieni, A., Mañes, J., & Meca, G. (2020). Whey fermented by using Lactobacillus plantarum strains: A promising approach. Journal of Dairy Science, 103(7), 5906-5915. PMid:32389480. http://dx.doi.org/10.3168/jds.2019-17547

http://dx.doi.org/10.3168/jds.2019-17547...

; Macwan et al., 2016Macwan, S. R., Dabhi, B. K., Parmar, S. C., & Aparnathi, K. D. (2016). Whey and its utilization. International Journal of Current Microbiology and Applied Sciences, 5(8), 134-155. http://dx.doi.org/10.20546/ijcmas.2016.508.016

http://dx.doi.org/10.20546/ijcmas.2016.5...

; Smithers, 2015Smithers, G. W. (2015). Whey-ing up the options–Yesterday, today and tomorrow. International Dairy Journal, 48, 2-14. http://dx.doi.org/10.1016/j.idairyj.2015.01.011

http://dx.doi.org/10.1016/j.idairyj.2015...

; Panghal et al., 2018Panghal, A., Patidar, R., Jaglan, S., Chhikara, N., Khatkar, S. K., Gat, Y., & Sindhu, N. (2018). Whey valorization: Current options and future scenario–a critical review. Nutrition & Food Science, 48(3), 520-535. http://dx.doi.org/10.1108/NFS-01-2018-0017

http://dx.doi.org/10.1108/NFS-01-2018-00...

). Cheese whey is considered a pollutant due to its BOD (30-50 g/L) and COD (60-80 g/L) (Meng et al., 2020Meng, W., Zhang, Y., Cao, M., Zhang, W., Lü, C., Yang, C., Gao, C., Xu, P., & Ma, C. (2020). Efficient 2,3-butanediol production from whey powder using metabolically engineered Klebsiella oxytoca. Microbial Cell Factories, 19(1), 162. PMid:32778112. http://dx.doi.org/10.1186/s12934-020-01420-2

http://dx.doi.org/10.1186/s12934-020-014...

). Lactose, which comprises approximately 75% of total solids in cheese whey, is the major component responsible for these values (Choi et al., 2020Choi, H. S., Yang, X., Kim, D. S., Yang, J. H., Han, S. O., Park, C., & Kim, S. W. (2020). Power generation from cheese whey using enzymatic fuel cell. Journal of Cleaner Production, 254, 120181. http://dx.doi.org/10.1016/j.jclepro.2020.120181

http://dx.doi.org/10.1016/j.jclepro.2020...

). According to Ryan & Walsh (2016)Ryan, M. P., & Walsh, G. (2016). The biotechnological potential of whey. Reviews in Environmental Science and Biotechnology, 15(3), 479-498. http://dx.doi.org/10.1007/s11157-016-9402-1

http://dx.doi.org/10.1007/s11157-016-940...

, the polluting potential of whey is 100-175 times higher than the same volume of domestic wastewater. Therefore, the disposal of untreated cheese whey into the environment is responsible for an increased oxygen demand, thus leading to eutrophication and shifts in the physico-chemical characteristics of the environment into which it is discharged (Li et al., 2020Li, C., Ding, J., Chen, D., Shi, Z., & Wang, L. (2020). Bioconversion of cheese whey into a hetero-exopolysaccharide via a one-step bioprocess and its applications. Biochemical Engineering Journal, 161, 107701. http://dx.doi.org/10.1016/j.bej.2020.107701

http://dx.doi.org/10.1016/j.bej.2020.107...

; Meng et al., 2020Meng, W., Zhang, Y., Cao, M., Zhang, W., Lü, C., Yang, C., Gao, C., Xu, P., & Ma, C. (2020). Efficient 2,3-butanediol production from whey powder using metabolically engineered Klebsiella oxytoca. Microbial Cell Factories, 19(1), 162. PMid:32778112. http://dx.doi.org/10.1186/s12934-020-01420-2

http://dx.doi.org/10.1186/s12934-020-014...

).

3 Milk cream butter

Butter is a greasy product exclusively derived from milk. It consists of a complex mix of Short- and Medium-Chain Fatty Acids (SCFA and MCFA) (4 to 12 carbons), such as caproic, caprylic, and butiric acids (which are the most abundant). Aside from proteins, butter also has water, minerals, vitamin A, and β-carotene in its composition. It has a typical aroma derived from aromatic substances, such as diacetyl and acetaldehyde (Karaca et al., 2018Karaca, Y., Gün, I., Seydim, A. C., & Guzel-Seydim, Z. B. (2018). Production and quality of kefir cultured butter. Mljekarstvo, 68(1), 64-72. http://dx.doi.org/10.15567/mljekarstvo.2018.0108

http://dx.doi.org/10.15567/mljekarstvo.2...

; Obeidat, 2020Obeidat, S. M. (2020). Investigation of butter adulteration with margarine using 1H NMR and PCA. Applied Magnetic Resonance, 51(8), 691-701. http://dx.doi.org/10.1007/s00723-020-01211-3

http://dx.doi.org/10.1007/s00723-020-012...

; Tamura et al., 2021Tamura, H., Ueno, S., Naka, A., Zhao, H., Yonekura, L., Isogai, T., Wakui, R., & Shiota, M. (2021). Characterisation of aroma profile and evaluation of aroma quality in sweet cream butter. International Dairy Journal, 114, 104935. http://dx.doi.org/10.1016/j.idairyj.2020.104935

http://dx.doi.org/10.1016/j.idairyj.2020...

).

Butter contains a minimum milkfat content of 80% and a maximum water content of 16% (Buldo et al., 2013Buldo, P., Kirkensgaard, J. J. K., & Wiking, L. (2013). Crystallization mechanisms in cream during ripening and initial butter churning. Journal of Dairy Science, 96(11), 6782-6791. PMid:24035028. http://dx.doi.org/10.3168/jds.2012-6066

http://dx.doi.org/10.3168/jds.2012-6066...

). However, the physico-chemical and micro-structural properties of butter might differ due to several factors, such as milkfat composition, water content, and processing and storage conditions (Buldo et al., 2013Buldo, P., Kirkensgaard, J. J. K., & Wiking, L. (2013). Crystallization mechanisms in cream during ripening and initial butter churning. Journal of Dairy Science, 96(11), 6782-6791. PMid:24035028. http://dx.doi.org/10.3168/jds.2012-6066

http://dx.doi.org/10.3168/jds.2012-6066...

; Food and Agriculture Organization of the United Nations, 2011Food and Agriculture Organization of the United Nations – FAO. (2011). Codex Alimentarius: milk and milk products. Rome: FAO. http://dx.doi.org/10.1016/B978-0-12-384730-0.00221-4.

http://dx.doi.org/10.1016/B978-0-12-3847...

; Sert & Mercan, 2020Sert, D., & Mercan, E. (2020). Characterisation of physicochemical, microbiological, thermal, oxidation properties and fatty acid composition of butter produced from thermosonicated cream. International Dairy Journal, 109, 104777. http://dx.doi.org/10.1016/j.idairyj.2020.104777

http://dx.doi.org/10.1016/j.idairyj.2020...

). Milk cream is the major raw material in the production of butter, and it directly affects end-product quality. Thus, it is important that the cream is filtered and treated before churning, so that the end product complies with hygiene standards and develops the sensory characteristics required for consumption. Cream is the milk fraction rich in fat, comprised basically of water (60%), lipids (37%), and small concentrations of proteins, carbohydrates, and minerals (3%) (Ewe & Loo, 2016Ewe, J. A., & Loo, S. Y. (2016). Effect of cream fermentation on microbiological, physicochemical and rheological properties of L. helveticus-butter. Food Chemistry, 201, 29-36. PMid:26868544. http://dx.doi.org/10.1016/j.foodchem.2016.01.049

http://dx.doi.org/10.1016/j.foodchem.201...

; Karaca et al., 2018Karaca, Y., Gün, I., Seydim, A. C., & Guzel-Seydim, Z. B. (2018). Production and quality of kefir cultured butter. Mljekarstvo, 68(1), 64-72. http://dx.doi.org/10.15567/mljekarstvo.2018.0108

http://dx.doi.org/10.15567/mljekarstvo.2...

).

Butter is produced by churning of milk cream (whether fermented or not), which forms a stable water/oil emulsion. During this process, a by-product called buttermilk is created, with a good nutritional quality due to its composition, which includes caseins, whey proteins, minerals, and material derived from the Milk Fat Globule Membrane (MFGM) (Qu et al., 2019Qu, X., Hu, H., Wang, Y., Cao, C., Li, H., Liu, X., & Yu, J. (2019). Proteomics analysis of milk fat globule membrane enriched materials derived from by-products during different stages of milk-fat processing. Journal of Food Science and Technology, 116, 108531.; Sakkas et al., 2020Sakkas, L., Spiliopoulos, M., & Moatsou, G. (2020). Partial substitution of sheep and goat milks of various fat contents by the respective sweet buttermilks: Effect of cream heat treatment. LWT, 133, 1-25. http://dx.doi.org/10.1016/j.lwt.2020.109926

http://dx.doi.org/10.1016/j.lwt.2020.109...

).

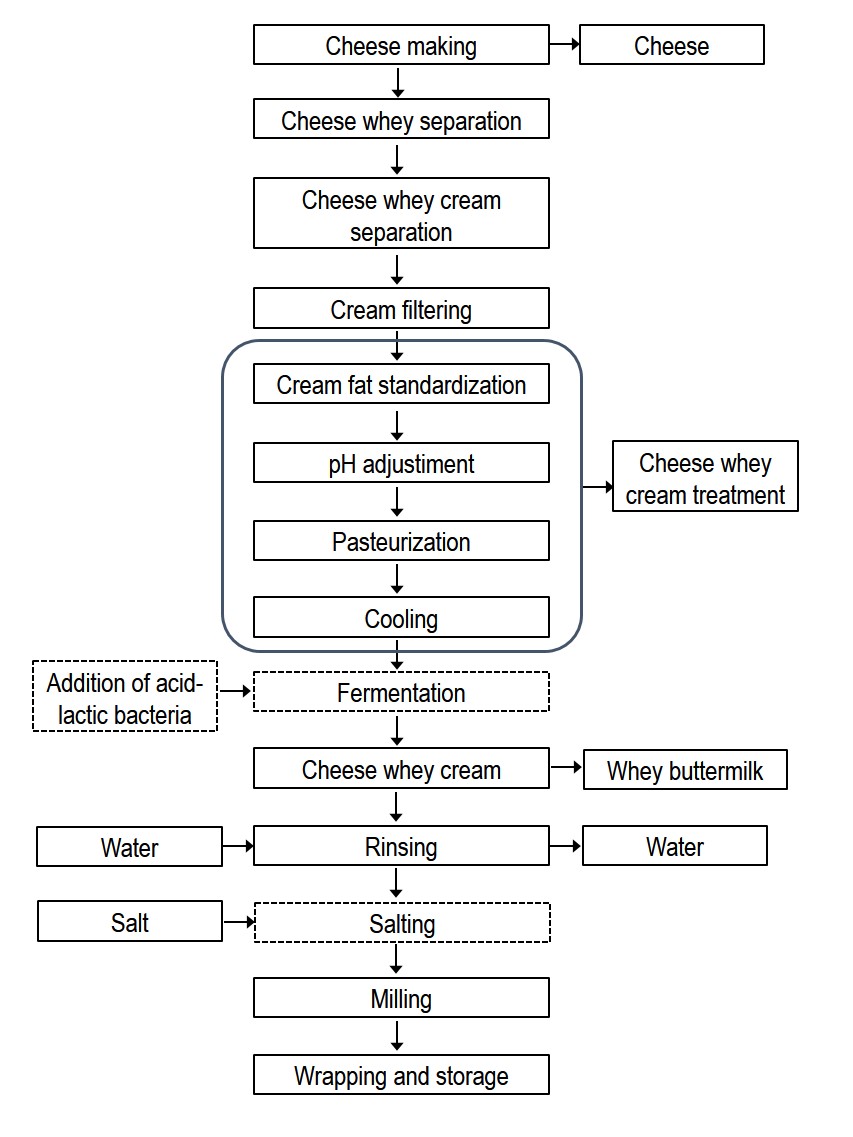

The butter-making process starts with milk centrifugation, through which the cream is obtained; this cream is filtered to remove debris that might affect product quality. After that, fat content is standardized and pH is adjusted, where required, so that the butter has suitable fat and acidity percentages. Among the key stages are cream pasteurization and cooling, for cream microbiological control. In addition, depending on the type of butter produced, microorganisms are used for fermentation, and they are responsible for developing suitable butter sensory characteristics. After fermentation, the cream is churned to form butter and separate buttermilk, followed by rinsing and optional salting. The final stage is milling, i.e., butter grains undergo aggregation until they form a homogeneous and elastic mass. Finally, the product is packaged and stored at refrigerated temperatures (Deosarkar et al., 2016Deosarkar, S. S., Khedkar, C. D., & Kalyankar, S. D. (2016). Butter Manufacture. In B. Caballero, Finglas, P., & Toldrá, F. (Eds.), The Encyclopedia of Food and Health (Vol. 1, pp. 529-534). United Kingdom: Academic Press. http://dx.doi.org/10.1016/B978-0-12-384947-2.00094-5

http://dx.doi.org/10.1016/B978-0-12-3849...

; Dias et al., 2010Dias, H. M. H. M., Berbicz, F., Pedrochi, F., Baesso, M. L., & Matioli, G. (2010). Butter cholesterol removal using different complexation methods with beta-cyclodextrin, and the contribution of photoacoustic spectroscopy to the evaluation of the complex. Food Research International, 43(4), 1104-1110. http://dx.doi.org/10.1016/j.foodres.2010.02.002

http://dx.doi.org/10.1016/j.foodres.2010...

).

Different types of milk butter are available in the market. However, the most popular are sweet cream butter and cultured cream butter (Table 1). Sweet cream butter has a sweeter taste compared to other butters due to its pH. Cultured cream butter has a more acidic pH due to the addition of Lactic Acid Bacteria (LAB) for the fermentation process. During this stage, bacteria are used as raw material factories, developing the taste, aroma, and texture that are typical of butter. These microorganisms are responsible for the development of the typical “butter aroma” of cultured cream butter, owing to the formation of the diacetyl compound. Sour cream butter is another type of butter produced via cream fermentation. However, specific strains of LAB are used here; typically, from the genus Lactococcus, such as L. lactis and L. paracasei. Another type of sour cream butter available in the market is whipped butter, which has a suitable spreadability owing to the addition of nitrogen gas in the cream churning stage (Budhkar, Bankar & Singhal, 2014Budhkar, Y. A., Bankar, S. B., & Singhal, R. S. (2014). Microbiology of cream and butter. In C. Batt & M. L. Tortorello (Eds.), Encyclopedia of food microbiology (Vol. 1, 2nd ed., pp. 728-737). Cambridge: Academic Press. http://dx.doi.org/10.1016/B978-0-12-384730-0.00221-4

http://dx.doi.org/10.1016/B978-0-12-3847...

; Jinjarak et al., 2006Jinjarak, S., Olabi, A., Jiménez-Flores, R., & Walker, J. H. (2006). Sensory, functional, and analytical comparisons of whey butter with other butters. Journal of Dairy Science, 89(7), 2428-2440. PMid:16772559. http://dx.doi.org/10.3168/jds.S0022-0302(06)72316-5

http://dx.doi.org/10.3168/jds.S0022-0302...

; Lorenzen et al., 2013Lorenzen, P. C., Walte, H., & Bosse, B. (2013). Development of a method for butter type differentiation by electronic nose technology. Sensors and Actuators. B, Chemical, 81, 690-693. http://dx.doi.org/10.1016/j.snb.2013.01.034

http://dx.doi.org/10.1016/j.snb.2013.01....

).

According to Market Watch (2020)Market Watch. (2020). Global Butter Market 2020: Industry Trends and Investigation Growth Rate, consumption by Regional data, Product & Application Segmentation, Key Companies a Top Countries Analysis & Top manufacturers, Showing Impressive Growth by 2026. New York: Market Watch., the global butter market had a turnover of approximately 54 billion dollars in 2020, and 2026 is estimated to reach over 60 billion dollars, with a growth rate of 3% per year. In addition to the butters shown in Table 1, other types of butter have drawn the attention of the dairy industry, e.g., whey cream butter, produced from whey cream (Jinjarak et al., 2006Jinjarak, S., Olabi, A., Jiménez-Flores, R., & Walker, J. H. (2006). Sensory, functional, and analytical comparisons of whey butter with other butters. Journal of Dairy Science, 89(7), 2428-2440. PMid:16772559. http://dx.doi.org/10.3168/jds.S0022-0302(06)72316-5

http://dx.doi.org/10.3168/jds.S0022-0302...

).

4 Whey cream butter

Cheese whey is highly pollutant and has a high nutritional value. The high volume produced of this by-product justifies an analysis of its potential applications. One option for the industry is to add value to cheese whey by reusing it in the production of butter (Nadeem et al., 2015Nadeem, M., Mahud, A., Imran, M., & Khalique, A. (2015). Enhancement of the oxidative stability of whey butter through almont (Prunus dulcis) peel extract. Journal of Food Processing and Preservation, 39(6), 591-598. http://dx.doi.org/10.1111/jfpp.12265

http://dx.doi.org/10.1111/jfpp.12265...

).

As shown in Figure 2, whey cream is removed by whey centrifugation. After the separation, whey cream is treated and churned, following the conventional milk cream butter-making process (Aly, 2009Aly, A. H. (2009). Fatty acid composition, textural and organoleptic properties of whey butter. Journal of Food and Dairy Sciences, 34(4), 3081-3094. http://dx.doi.org/10.21608/jfds.2009.113433.

http://dx.doi.org/10.21608/jfds.2009.113...

; Budhkar et al., 2014Budhkar, Y. A., Bankar, S. B., & Singhal, R. S. (2014). Microbiology of cream and butter. In C. Batt & M. L. Tortorello (Eds.), Encyclopedia of food microbiology (Vol. 1, 2nd ed., pp. 728-737). Cambridge: Academic Press. http://dx.doi.org/10.1016/B978-0-12-384730-0.00221-4

http://dx.doi.org/10.1016/B978-0-12-3847...

; Jinjarak et al., 2006Jinjarak, S., Olabi, A., Jiménez-Flores, R., & Walker, J. H. (2006). Sensory, functional, and analytical comparisons of whey butter with other butters. Journal of Dairy Science, 89(7), 2428-2440. PMid:16772559. http://dx.doi.org/10.3168/jds.S0022-0302(06)72316-5

http://dx.doi.org/10.3168/jds.S0022-0302...

).

The physico-chemical composition of whey butter has no significant differences to milk butter (Table 2) (Aly, 2009Aly, A. H. (2009). Fatty acid composition, textural and organoleptic properties of whey butter. Journal of Food and Dairy Sciences, 34(4), 3081-3094. http://dx.doi.org/10.21608/jfds.2009.113433.

http://dx.doi.org/10.21608/jfds.2009.113...

; Jinjarak et al., 2006Jinjarak, S., Olabi, A., Jiménez-Flores, R., & Walker, J. H. (2006). Sensory, functional, and analytical comparisons of whey butter with other butters. Journal of Dairy Science, 89(7), 2428-2440. PMid:16772559. http://dx.doi.org/10.3168/jds.S0022-0302(06)72316-5

http://dx.doi.org/10.3168/jds.S0022-0302...

; Morin et al., 2006Morin, P., Pouliot, Y., & Jiménez-Flores, R. (2006). A comparative study of the fractionation of regular buttermilk and whey buttermilk by microfiltration. Journal of Food Engineering, 77(3), 521-528. http://dx.doi.org/10.1016/j.jfoodeng.2005.06.065

http://dx.doi.org/10.1016/j.jfoodeng.200...

; Nadeem et al., 2015Nadeem, M., Mahud, A., Imran, M., & Khalique, A. (2015). Enhancement of the oxidative stability of whey butter through almont (Prunus dulcis) peel extract. Journal of Food Processing and Preservation, 39(6), 591-598. http://dx.doi.org/10.1111/jfpp.12265

http://dx.doi.org/10.1111/jfpp.12265...

).

Comparison of physico-chemical characteristics of whey cream butter obtained in different studies.

According to Table 2, lipid, solid, protein and ash contents in whey cream butter varied from 80 to 96%, 83 to 87%, 0.50 to 0.75%, and 0.08 to 0.09%, respectively. The studies published did not employ fermentation in the production of whey cream butter and compared it to sweet cream butter. The process that employs LAB resulted in reduced butter pH and in improved aroma, due to diacetyl release (Jinjarak et al., 2006Jinjarak, S., Olabi, A., Jiménez-Flores, R., & Walker, J. H. (2006). Sensory, functional, and analytical comparisons of whey butter with other butters. Journal of Dairy Science, 89(7), 2428-2440. PMid:16772559. http://dx.doi.org/10.3168/jds.S0022-0302(06)72316-5

http://dx.doi.org/10.3168/jds.S0022-0302...

).

Whey cream butter is characterized by high concentration of unsaturated fatty acids (Aly, 2009Aly, A. H. (2009). Fatty acid composition, textural and organoleptic properties of whey butter. Journal of Food and Dairy Sciences, 34(4), 3081-3094. http://dx.doi.org/10.21608/jfds.2009.113433.

http://dx.doi.org/10.21608/jfds.2009.113...

; Nadeem et al., 2015Nadeem, M., Mahud, A., Imran, M., & Khalique, A. (2015). Enhancement of the oxidative stability of whey butter through almont (Prunus dulcis) peel extract. Journal of Food Processing and Preservation, 39(6), 591-598. http://dx.doi.org/10.1111/jfpp.12265

http://dx.doi.org/10.1111/jfpp.12265...

) and by biologically active compounds (such as sphingomyelin and mucins) in the MFGM. According to Aly (2009)Aly, A. H. (2009). Fatty acid composition, textural and organoleptic properties of whey butter. Journal of Food and Dairy Sciences, 34(4), 3081-3094. http://dx.doi.org/10.21608/jfds.2009.113433.

http://dx.doi.org/10.21608/jfds.2009.113...

, the linolenic fatty acid content is approximately 50% higher in whey cream butter than in milk cream butter, which provides whey butter with nutritional quality and higher healthiness than milk cream butter. Furthermore, there are studies (Aly, 2009Aly, A. H. (2009). Fatty acid composition, textural and organoleptic properties of whey butter. Journal of Food and Dairy Sciences, 34(4), 3081-3094. http://dx.doi.org/10.21608/jfds.2009.113433.

http://dx.doi.org/10.21608/jfds.2009.113...

; Morin et al., 2006Morin, P., Pouliot, Y., & Jiménez-Flores, R. (2006). A comparative study of the fractionation of regular buttermilk and whey buttermilk by microfiltration. Journal of Food Engineering, 77(3), 521-528. http://dx.doi.org/10.1016/j.jfoodeng.2005.06.065

http://dx.doi.org/10.1016/j.jfoodeng.200...

; Nadeem et al., 2015Nadeem, M., Mahud, A., Imran, M., & Khalique, A. (2015). Enhancement of the oxidative stability of whey butter through almont (Prunus dulcis) peel extract. Journal of Food Processing and Preservation, 39(6), 591-598. http://dx.doi.org/10.1111/jfpp.12265

http://dx.doi.org/10.1111/jfpp.12265...

) indicating that the physico-chemical composition of whey butter has no significant differences compared to milk butter.

Regarding sensory characteristics, the major difference between whey butter and the others is its softer texture due to the higher concentration of unsaturated fatty acids in whey cream (Aly, 2009Aly, A. H. (2009). Fatty acid composition, textural and organoleptic properties of whey butter. Journal of Food and Dairy Sciences, 34(4), 3081-3094. http://dx.doi.org/10.21608/jfds.2009.113433.

http://dx.doi.org/10.21608/jfds.2009.113...

). According to Jinjarak et al. (2006)Jinjarak, S., Olabi, A., Jiménez-Flores, R., & Walker, J. H. (2006). Sensory, functional, and analytical comparisons of whey butter with other butters. Journal of Dairy Science, 89(7), 2428-2440. PMid:16772559. http://dx.doi.org/10.3168/jds.S0022-0302(06)72316-5

http://dx.doi.org/10.3168/jds.S0022-0302...

, while the texture of milk cream butter was approximately 2752 N, the texture of whey butter was 1792 N. Shelf-life of whey butter is reduced due to oxidation of these unsaturated fatty acids. Therefore, the use of antioxidants in the production of whey butter is an alternative to delay the autoxidation process (Chen et al, 2004Chen, S., Bobe, G., Zimmerman, S., Hammond, E. G., Luhman, C. M., Boylston, T. D., Freeman, A. E., & Beitz, D. C. (2004). Physical and sensory properties of dairy products from cows with various milk fatty acid compositions. Journal of Agricultural and Food Chemistry, 52(11), 3422-3428. PMid:15161209. http://dx.doi.org/10.1021/jf035193z

http://dx.doi.org/10.1021/jf035193z...

; Nadeem et al., 2015Nadeem, M., Mahud, A., Imran, M., & Khalique, A. (2015). Enhancement of the oxidative stability of whey butter through almont (Prunus dulcis) peel extract. Journal of Food Processing and Preservation, 39(6), 591-598. http://dx.doi.org/10.1111/jfpp.12265

http://dx.doi.org/10.1111/jfpp.12265...

; Lee, 2020Lee, J. H. (2020). Changes in flavor compounds and quality parameters of goat cream butter during extended refrigerated storage. International Journal of Food Properties, 23(1), 306-318. http://dx.doi.org/10.1080/10942912.2020.1720716

http://dx.doi.org/10.1080/10942912.2020....

).

Literature available on whey butter (Aly, 2009Aly, A. H. (2009). Fatty acid composition, textural and organoleptic properties of whey butter. Journal of Food and Dairy Sciences, 34(4), 3081-3094. http://dx.doi.org/10.21608/jfds.2009.113433.

http://dx.doi.org/10.21608/jfds.2009.113...

; Jinjarak et al., 2006Jinjarak, S., Olabi, A., Jiménez-Flores, R., & Walker, J. H. (2006). Sensory, functional, and analytical comparisons of whey butter with other butters. Journal of Dairy Science, 89(7), 2428-2440. PMid:16772559. http://dx.doi.org/10.3168/jds.S0022-0302(06)72316-5

http://dx.doi.org/10.3168/jds.S0022-0302...

; Costa et al., 2010Costa, M. R., Elias-Argote, X. E., Jiménez-flores, R., & Gigante, M. L. (2010). Use of ultrafiltration and supercritical fluid extraction to obtain a whey buttermilk powder enriched in milk fat globule membrane phospholipids. International Dairy Journal, 20(9), 598-602. http://dx.doi.org/10.1016/j.idairyj.2010.03.006

http://dx.doi.org/10.1016/j.idairyj.2010...

; Morin et al., 2006Morin, P., Pouliot, Y., & Jiménez-Flores, R. (2006). A comparative study of the fractionation of regular buttermilk and whey buttermilk by microfiltration. Journal of Food Engineering, 77(3), 521-528. http://dx.doi.org/10.1016/j.jfoodeng.2005.06.065

http://dx.doi.org/10.1016/j.jfoodeng.200...

; Nadeem et al., 2015Nadeem, M., Mahud, A., Imran, M., & Khalique, A. (2015). Enhancement of the oxidative stability of whey butter through almont (Prunus dulcis) peel extract. Journal of Food Processing and Preservation, 39(6), 591-598. http://dx.doi.org/10.1111/jfpp.12265

http://dx.doi.org/10.1111/jfpp.12265...

) indicated that this product is an alternative to reuse one component of cheese whey in the dairy industry, thus reducing the organic load of the whey, and consequently the cost of treatment. Moreover, the butter obtained from cheese whey had a good nutritional composition, which along with the significant cheese whey volume generated, could justifies the need to produce this type of product on an industrial scale. The approximated yield was of 5 kg of butter/1000 L of whey, considering the fat content in cheese whey.

5 Conclusion

The development of technological strategies to reuse the main components of cheese whey as a by-product is justified by the increased volume generated, its pollutant load, and its nutritional quality. Therefore, the reuse of dairy-generated cheese whey at a large scale is important, in addition to exploring new and differentiated ways to use whey and its components as dietary ingredients.

Butter-making process is relatively simple, and it might be applied to fat separated from cheese whey, called whey cream. There are few studies on the characterization of butter obtained from whey cream, and the comparison of these types of butter with milk cream butter indicates a potential for developing a product with higher added value, good nutritional characteristics, and suitable sensory attributes.

Acknowledgements

We would like to thank Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) (grant no. 308515/2020-0) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) for the scholarships, and Universidade do Vale do Taquari - Univates for the financial support. The team has conducted a study financed in part by the CAPES - Finance Code 001.

-

Cite as: Costa, M. A., Kuhn, D., Rama, G. R., Lehn, D. N., & Souza, C. F. V. (2022). Whey butter: a promising perspective for the dairy industry. Brazilian Journal of Food Technology, 25, e2021088. https://doi.org/10.1590/1981-6723.08821

-

Funding: Ministério da Ciência, Tecnologia e Inovação /Conselho Nacional de Desenvolvimento Científico e Tecnológico (308515/2020-0); Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (001); Universidade do Vale do Taquari - Univates.

References

- Aly, A. H. (2009). Fatty acid composition, textural and organoleptic properties of whey butter. Journal of Food and Dairy Sciences, 34(4), 3081-3094. http://dx.doi.org/10.21608/jfds.2009.113433

» http://dx.doi.org/10.21608/jfds.2009.113433 - Budhkar, Y. A., Bankar, S. B., & Singhal, R. S. (2014). Microbiology of cream and butter. In C. Batt & M. L. Tortorello (Eds.), Encyclopedia of food microbiology (Vol. 1, 2nd ed., pp. 728-737). Cambridge: Academic Press. http://dx.doi.org/10.1016/B978-0-12-384730-0.00221-4

» http://dx.doi.org/10.1016/B978-0-12-384730-0.00221-4 - Buldo, P., Kirkensgaard, J. J. K., & Wiking, L. (2013). Crystallization mechanisms in cream during ripening and initial butter churning. Journal of Dairy Science, 96(11), 6782-6791. PMid:24035028. http://dx.doi.org/10.3168/jds.2012-6066

» http://dx.doi.org/10.3168/jds.2012-6066 - Chen, S., Bobe, G., Zimmerman, S., Hammond, E. G., Luhman, C. M., Boylston, T. D., Freeman, A. E., & Beitz, D. C. (2004). Physical and sensory properties of dairy products from cows with various milk fatty acid compositions. Journal of Agricultural and Food Chemistry, 52(11), 3422-3428. PMid:15161209. http://dx.doi.org/10.1021/jf035193z

» http://dx.doi.org/10.1021/jf035193z - Choi, H. S., Yang, X., Kim, D. S., Yang, J. H., Han, S. O., Park, C., & Kim, S. W. (2020). Power generation from cheese whey using enzymatic fuel cell. Journal of Cleaner Production, 254, 120181. http://dx.doi.org/10.1016/j.jclepro.2020.120181

» http://dx.doi.org/10.1016/j.jclepro.2020.120181 - Clark, S., Costello, M., Drake, M., & Bodyfelt, F. (2009). The sensory evaluation of dairy products (2nd ed.). New York: Springer.

- Coltelli, M. B., Aliotta, L., Gigante, V., Bellusci, M., Cinelli, P., Bugnicourt, E., Schmid, M., Staebler, A., & Lazzeri, A. (2020). Preparation and compatibilization of pbs/whey protein isolate based blends. Molecules (Basel, Switzerland), 25(14), 3313. PMid:32708298. http://dx.doi.org/10.3390/molecules25143313

» http://dx.doi.org/10.3390/molecules25143313 - Costa, M. R., Elias-Argote, X. E., Jiménez-flores, R., & Gigante, M. L. (2010). Use of ultrafiltration and supercritical fluid extraction to obtain a whey buttermilk powder enriched in milk fat globule membrane phospholipids. International Dairy Journal, 20(9), 598-602. http://dx.doi.org/10.1016/j.idairyj.2010.03.006

» http://dx.doi.org/10.1016/j.idairyj.2010.03.006 - Deosarkar, S. S., Khedkar, C. D., & Kalyankar, S. D. (2016). Butter Manufacture. In B. Caballero, Finglas, P., & Toldrá, F. (Eds.), The Encyclopedia of Food and Health (Vol. 1, pp. 529-534). United Kingdom: Academic Press. http://dx.doi.org/10.1016/B978-0-12-384947-2.00094-5

» http://dx.doi.org/10.1016/B978-0-12-384947-2.00094-5 - Dias, H. M. H. M., Berbicz, F., Pedrochi, F., Baesso, M. L., & Matioli, G. (2010). Butter cholesterol removal using different complexation methods with beta-cyclodextrin, and the contribution of photoacoustic spectroscopy to the evaluation of the complex. Food Research International, 43(4), 1104-1110. http://dx.doi.org/10.1016/j.foodres.2010.02.002

» http://dx.doi.org/10.1016/j.foodres.2010.02.002 - Ekinci, F. Y., Okur, O. D., Ertekin, B., & Guzel-Seydim, Z. (2008). Effects of probiotic bacteria and oils on fatty acid profiles of cultured cream. European Journal of Lipid Science and Technology, 110(3), 216-224. https://doi.org/10.1002/ejlt.200700038.

- Elleuch, L., Salem-Berrabah, O. B., Cherni, Y., Sghaier-Hammami, B., Kasmi, M., Botta, C., Ouerghi, I., Franciosa, I., Cocolin, L., Trabelsi, I., & Chatti, A. (2020). A new practical approach for the biological treatment of a mixture of cheese whey and white wastewaters using Kefir grains. Environmental Science and Pollution Research International, 27(26), 33127-33139. PMid:32529610. http://dx.doi.org/10.1007/s11356-020-09549-8

» http://dx.doi.org/10.1007/s11356-020-09549-8 - Enteshari, M., & Martínez-Monteagudo, S. I. (2020). One-pot synthesis of lactose derivatives from whey permeate maryam. Foods, 9(6), 784. PMid:32545728. http://dx.doi.org/10.3390/foods9060784

» http://dx.doi.org/10.3390/foods9060784 - Ewe, J. A., & Loo, S. Y. (2016). Effect of cream fermentation on microbiological, physicochemical and rheological properties of L. helveticus-butter. Food Chemistry, 201, 29-36. PMid:26868544. http://dx.doi.org/10.1016/j.foodchem.2016.01.049

» http://dx.doi.org/10.1016/j.foodchem.2016.01.049 - Faucher, M., Perreault, V., Gaaloul, S., & Bazinet, L. (2020). Defatting of sweet whey by electrodialysis with bipolar membranes: Effect of protein concentration factor. Separation and Purification Technology, 251, 117248. http://dx.doi.org/10.1016/j.seppur.2020.117248

» http://dx.doi.org/10.1016/j.seppur.2020.117248 - Food and Agriculture Organization of the United Nations – FAO. (2011). Codex Alimentarius: milk and milk products. Rome: FAO. http://dx.doi.org/10.1016/B978-0-12-384730-0.00221-4

» http://dx.doi.org/10.1016/B978-0-12-384730-0.00221-4 - Izzo, L., Luz, C., Ritieni, A., Mañes, J., & Meca, G. (2020). Whey fermented by using Lactobacillus plantarum strains: A promising approach. Journal of Dairy Science, 103(7), 5906-5915. PMid:32389480. http://dx.doi.org/10.3168/jds.2019-17547

» http://dx.doi.org/10.3168/jds.2019-17547 - Jinjarak, S., Olabi, A., Jiménez-Flores, R., & Walker, J. H. (2006). Sensory, functional, and analytical comparisons of whey butter with other butters. Journal of Dairy Science, 89(7), 2428-2440. PMid:16772559. http://dx.doi.org/10.3168/jds.S0022-0302(06)72316-5

» http://dx.doi.org/10.3168/jds.S0022-0302(06)72316-5 - Karaca, Y., Gün, I., Seydim, A. C., & Guzel-Seydim, Z. B. (2018). Production and quality of kefir cultured butter. Mljekarstvo, 68(1), 64-72. http://dx.doi.org/10.15567/mljekarstvo.2018.0108

» http://dx.doi.org/10.15567/mljekarstvo.2018.0108 - Lee, J. H. (2020). Changes in flavor compounds and quality parameters of goat cream butter during extended refrigerated storage. International Journal of Food Properties, 23(1), 306-318. http://dx.doi.org/10.1080/10942912.2020.1720716

» http://dx.doi.org/10.1080/10942912.2020.1720716 - Li, C., Ding, J., Chen, D., Shi, Z., & Wang, L. (2020). Bioconversion of cheese whey into a hetero-exopolysaccharide via a one-step bioprocess and its applications. Biochemical Engineering Journal, 161, 107701. http://dx.doi.org/10.1016/j.bej.2020.107701

» http://dx.doi.org/10.1016/j.bej.2020.107701 - Lorenzen, P. C., Walte, H., & Bosse, B. (2013). Development of a method for butter type differentiation by electronic nose technology. Sensors and Actuators. B, Chemical, 81, 690-693. http://dx.doi.org/10.1016/j.snb.2013.01.034

» http://dx.doi.org/10.1016/j.snb.2013.01.034 - Maciel, K. S., Santos, L. S., Bonomo, R. C. F., Verissimo, L. A. A., Minim, V. P. R., & Minim, L. A. (2020). Purification of lactoferrin from sweet whey using ultrafiltration followed by expanded bed chromatography. Separation and Purification Technology, 251, 117324. http://dx.doi.org/10.1016/j.seppur.2020.117324

» http://dx.doi.org/10.1016/j.seppur.2020.117324 - Macwan, S. R., Dabhi, B. K., Parmar, S. C., & Aparnathi, K. D. (2016). Whey and its utilization. International Journal of Current Microbiology and Applied Sciences, 5(8), 134-155. http://dx.doi.org/10.20546/ijcmas.2016.508.016

» http://dx.doi.org/10.20546/ijcmas.2016.508.016 - Mallia, S., Escher, F., & Schlichterle-Cerny, H. (2008). Aroma-active compounds of butter: A review. European Food Research and Technology, 226(3), 315-325. https://doi.org/10.1007/s00217-006-0555-y

» https://doi.org/10.1007/s00217-006-0555-y - Market Watch. (2020). Global Butter Market 2020: Industry Trends and Investigation Growth Rate, consumption by Regional data, Product & Application Segmentation, Key Companies a Top Countries Analysis & Top manufacturers, Showing Impressive Growth by 2026 New York: Market Watch.

- Meng, W., Zhang, Y., Cao, M., Zhang, W., Lü, C., Yang, C., Gao, C., Xu, P., & Ma, C. (2020). Efficient 2,3-butanediol production from whey powder using metabolically engineered Klebsiella oxytoca. Microbial Cell Factories, 19(1), 162. PMid:32778112. http://dx.doi.org/10.1186/s12934-020-01420-2

» http://dx.doi.org/10.1186/s12934-020-01420-2 - Mollea, C., Marmo, L., & Bosco, F. (2013). Valorisation of cheese whey, a by-product from the dairy industry. In I. Muzzalupo (Ed.), Food industry (pp. 549-588). London: IntechOpen. http://dx.doi.org/10.5772/53159

- Morin, P., Pouliot, Y., & Jiménez-Flores, R. (2006). A comparative study of the fractionation of regular buttermilk and whey buttermilk by microfiltration. Journal of Food Engineering, 77(3), 521-528. http://dx.doi.org/10.1016/j.jfoodeng.2005.06.065

» http://dx.doi.org/10.1016/j.jfoodeng.2005.06.065 - Musiy, L., Tsisaryk, O., Slyvka, I., Mykhaylytska, O., & Gutji, B. (2017). Study of keeping probiotic proporties of cultured butter in storage. EUREKA: Life Sciences, 2(2), 27-33. http://dx.doi.org/10.21303/2504-5695.2017.00318

» http://dx.doi.org/10.21303/2504-5695.2017.00318 - Nadeem, M., Mahud, A., Imran, M., & Khalique, A. (2015). Enhancement of the oxidative stability of whey butter through almont (Prunus dulcis) peel extract. Journal of Food Processing and Preservation, 39(6), 591-598. http://dx.doi.org/10.1111/jfpp.12265

» http://dx.doi.org/10.1111/jfpp.12265 - Obeidat, S. M. (2020). Investigation of butter adulteration with margarine using 1H NMR and PCA. Applied Magnetic Resonance, 51(8), 691-701. http://dx.doi.org/10.1007/s00723-020-01211-3

» http://dx.doi.org/10.1007/s00723-020-01211-3 - Panghal, A., Patidar, R., Jaglan, S., Chhikara, N., Khatkar, S. K., Gat, Y., & Sindhu, N. (2018). Whey valorization: Current options and future scenario–a critical review. Nutrition & Food Science, 48(3), 520-535. http://dx.doi.org/10.1108/NFS-01-2018-0017

» http://dx.doi.org/10.1108/NFS-01-2018-0017 - Peterson, D. G., & Reineccius, G. A. (2003). Characterization of the volatile compounds that constitute fresh sweet cream butter aroma. Flavour and Fragrance Journal, 18(3), 215-220. https://doi.org/10.1002/ffj.1192

» https://doi.org/10.1002/ffj.1192 - Qu, X., Hu, H., Wang, Y., Cao, C., Li, H., Liu, X., & Yu, J. (2019). Proteomics analysis of milk fat globule membrane enriched materials derived from by-products during different stages of milk-fat processing. Journal of Food Science and Technology, 116, 108531.

- Rama, G. R., Kuhn, D., Beux, S., Maciel, M. J., & Souza, C. F. V. (2019). Potential applications of dairy whey for the production of lactic acid bacteria. International Dairy Journal, 98, 25-37. http://dx.doi.org/10.1016/j.idairyj.2019.06.012

» http://dx.doi.org/10.1016/j.idairyj.2019.06.012 - Ryan, M. P., & Walsh, G. (2016). The biotechnological potential of whey. Reviews in Environmental Science and Biotechnology, 15(3), 479-498. http://dx.doi.org/10.1007/s11157-016-9402-1

» http://dx.doi.org/10.1007/s11157-016-9402-1 - Sakkas, L., Spiliopoulos, M., & Moatsou, G. (2020). Partial substitution of sheep and goat milks of various fat contents by the respective sweet buttermilks: Effect of cream heat treatment. LWT, 133, 1-25. http://dx.doi.org/10.1016/j.lwt.2020.109926

» http://dx.doi.org/10.1016/j.lwt.2020.109926 - Sert, D., & Mercan, E. (2020). Characterisation of physicochemical, microbiological, thermal, oxidation properties and fatty acid composition of butter produced from thermosonicated cream. International Dairy Journal, 109, 104777. http://dx.doi.org/10.1016/j.idairyj.2020.104777

» http://dx.doi.org/10.1016/j.idairyj.2020.104777 - Schieberle, P., Gassenmeier, K., Guth, H., Sen, A., & Grosch, W. (1993). Character impact odour compounds of different kinds of butter. LWT - Food Science and Technology, 26(4), 347-356. https://doi.org/10.1006/fstl.1993.1070

» https://doi.org/10.1006/fstl.1993.1070 - Smithers, G. W. (2015). Whey-ing up the options–Yesterday, today and tomorrow. International Dairy Journal, 48, 2-14. http://dx.doi.org/10.1016/j.idairyj.2015.01.011

» http://dx.doi.org/10.1016/j.idairyj.2015.01.011 - Tamura, H., Ueno, S., Naka, A., Zhao, H., Yonekura, L., Isogai, T., Wakui, R., & Shiota, M. (2021). Characterisation of aroma profile and evaluation of aroma quality in sweet cream butter. International Dairy Journal, 114, 104935. http://dx.doi.org/10.1016/j.idairyj.2020.104935

» http://dx.doi.org/10.1016/j.idairyj.2020.104935 - Trindade, M. B., Soares, B. C. V., Scudino, H., Guimarães, J. T., Esmerino, E. A., Freitas, M. V., Pimentel, T. C., Silva, M. C., Souza, S. L. Q., Almada, R. B., & Cruz, A. G. (2019). Cheese whey exploitation in Brazil: A questionnaire survey. Food Science and Technology (Campinas), 39(3), 788-791. http://dx.doi.org/10.1590/fst.07419

» http://dx.doi.org/10.1590/fst.07419 - Tsermoula, P., Khakimov, B., Nielsen, J. H., & Engelsen, S. B. (2021). WHEY-The waste-stream that became more valuable than the food product. Trends in Food Science & Technology, 118, 230-241. http://dx.doi.org/10.1016/j.tifs.2021.08.025

» http://dx.doi.org/10.1016/j.tifs.2021.08.025 - Yu, J., Mo, L., Pan, L., Yao, C., Ren, D., An, X., Tsogtgerel, T., Zhang, H., & Liu, W. (2018). Bacterial microbiota and metabolic character of traditional sour cream and butter in Buryatia, Russia. Frontiers in Microbiology, 9, 2496. PMid:30459729. http://dx.doi.org/10.3389/fmicb.2018.02496

» http://dx.doi.org/10.3389/fmicb.2018.02496 - Zikmanis, P., Kolesovs, S., & Semjonovs, P. (2020). Production of biodegradable microbial polymers from whey. Bioresources and Bioprocessing, 7(1), 36. http://dx.doi.org/10.1186/s40643-020-00326-6

» http://dx.doi.org/10.1186/s40643-020-00326-6

Edited by

Publication Dates

-

Publication in this collection

18 July 2022 -

Date of issue

2022

History

-

Received

10 May 2021 -

Accepted

30 May 2022