Abstract

The increased worldwide demand for chicken meat requires constant automation of operating systems and the proper implementation of self-control programs by slaughterhouses. Thus, this study aimed to evaluate the efficacy of a self-washing system using heated water on reducing the load of public health concern bacteria on a broiler feet-cutter disc. In a three-month period, 84 samples (n = 42 per group) were collected for microbiological analysis from the feet-cutter disc with an operational self-washing process with Non-Heated Water (NHW) and Heated Water (HW). The logarithmic counts of Mesophilic Aerobics, Sulphite-Reducing Clostridia (SRC), Escherichia coli and Staphylococcus aureus in the NHW group were 1.82, 0.56, 0.31 and 0.14 Log10 CFU/cm2, respectively, whereas in the HW group were 1.17, 0.04, 0.15 and 0.08 Log10 CFU/cm2. Salmonella spp. was absent in all evaluated samples in both groups. The heated-water system reduced bacterial count, but statistical differences were solely observed for Mesophilic Aerobics and SRC. Nevertheless, its usage could be an additive in the operational procedure to avoid microbiological violations of food safety, in addition to being easy-to-implement and affordable for the industry.

Keywords:

Cross-contamination; Hock; Poultry; Saw blade; Self-control program; Water jet

Resumo

O aumento mundial da demanda por carne de frango exige constante automação de sistemas de operação e implementação adequada de programas de autocontrole pelos abatedouros. Assim, o objetivo do presente estudo foi avaliar a eficiência de sistema de autolavagem com água aquecida na redução da contagem de bactérias de interesse em saúde pública em disco corta-pés de frangos. Em um período de três meses, 84 amostras (n = 42, por grupo) foram colhidas para análises microbiológicas em disco corta-pés contando com um sistema operacional de autolavagem com água não aquecida (NHW) e água aquecida (HW). As contagens de Aeróbios Mesófilos, Clostridium Sulfito-redutor, Escherichia coli e Staphylococcus aureus, no grupo NHW, foram de 1,82, 0,56, 0,31 e 0,14 Log10 UFC/cm2, respectivamente, enquanto que, no grupo HW, foram de 1,17, 0,04, 0,15 e 0,08 Log10 UFC/cm2. Salmonella spp. foi ausente em todas amostras avaliadas, em ambos os grupos. O sistema com água aquecida reduziu as contagens bacterianas, mas diferenças estatísticas foram observadas somente em Aeróbios Mesófilos e Clostridium Sulfito-redutor. Apesar disso, seu uso pode ser um adicional ao procedimento operacional para evitar a violação dos limites microbiológicos de segurança alimentar, além de ser um sistema de fácil implementação e de baixo custo.

Palavras-chave:

Aves domésticas; Contaminação cruzada; Disco de serra; Jato de água; Jarrete; Programa de autocontrole

Highlights

• Heating Water (HW) for self-washing systems in feet-cutter discs is easy-to-implement for the industry

• Bacterial load can be reduced by heated-water on a feet-cutter disc surface

• A self-washing system could be used in self-control programs, to avoid violation of food safety

1 Introduction

The food industry is constantly improving itself to minimize the occurrence of pathogens and contaminants to guarantee the quality of the final product that reach the consumer (Perez-Arnedo et al., 2020Perez-Arnedo, I., Cantalejo, M. J., Martínez-Laorden, A., & Gonzalez-Fandos, E. (2020). Effect of processing on the microbiological quality and safety of chicken carcasses at slaughterhouse. International Journal of Food Science & Technology, 56(4), 1885-1864. ). The increased worldwide demand for chicken meat requires the automation of operating systems and the proper implementation of self-control programs (Nääs et al., 2015Nääs, I. A., Mollo Neto, M., Canuto, S. A., Waker, R., Oliveira, D. R. M. S., & Vendrametto, O. (2015). Brazilian chicken meat production chain: A 10-year overview. Brazilian Journal of Poultry Science, 17(1), 87-94. http://dx.doi.org/10.1590/1516-635x170187-94

http://dx.doi.org/10.1590/1516-635x17018...

; Althaus et al., 2017Althaus, D., Zweifel, C., & Stephan, R. (2017). Analysis of a poultry slaughter process: Influence of process stages on the microbiological contamination of broiler carcasses. Italian Journal of Food Safety, 6(4), 7097. PMid:29564242. http://dx.doi.org/10.4081/ijfs.2017.7097

http://dx.doi.org/10.4081/ijfs.2017.7097...

; Esper et al., 2021Esper, I. M., From, P. J., & Mason, A. (2021). Robotisation and intelligent systems in abattoirs. Trends in Food Science & Technology, 108, 214-222. http://dx.doi.org/10.1016/j.tifs.2020.11.005

http://dx.doi.org/10.1016/j.tifs.2020.11...

).

In this scenario, the Standard Operating Sanitation Procedures (SOSP) plays a central role in several industrial process steps in order to monitor the hygienic-health conditions and to avoid the occurrence of cross or direct contamination (Brasil, 1996Brasil. Ministry of Agriculture, Livestock and Food Supply. (1996). Diretrizes para preparação de Plano de APPCC (HACCP) para o processo de abate de aves (Official Notice no 36/1996/CGCOA/DIPOA/SDA/MAPA). Diário Oficial da República Federativa do Brasil, Brasília.; Potter et al., 2012Potter, B. D., Marcy, J. A., Owens, C. M., Slavik, M. F., Goodwin, H. L., & Apple, J. K. (2012). Impact of performance-based sanitation systems on microbiological characteristics of poultry processing equipment and carcasses as compared with traditional sanitation systems. Journal of Applied Poultry Research, 21(3), 669-678. http://dx.doi.org/10.3382/japr.2011-00513

http://dx.doi.org/10.3382/japr.2011-0051...

; Dias et al., 2017Dias, M. R., Dianin, K. C. S., Bersot, L. S., & Nero, L. A. (2017). Self-monitoring microbiological criteria for the assessment of hygienic procedures during chicken slaughtering. Brazilian Journal of Poultry Science, 19(2), 317-324. http://dx.doi.org/10.1590/1806-9061-2016-0381

http://dx.doi.org/10.1590/1806-9061-2016...

). As part of these procedures, equipment sanitation protocols often include dry cleaning process equipment disassembly, rinsing with heated water, and the addition of chemical compounds, such as appropriate disinfectants against microorganisms of interest (Marriott & Gravani, 2014Marriott, N. G., & Gravani, R. B. (2014). Principles of food sanitization (5. ed.). New York: Springer.). Thus, it prevents the formation of biofilms that protect the bacteria and favor their multiplication on equipment surfaces (Carpentier & Cerf, 1993Carpentier, B., & Cerf, O. (1993). Biofilms and their consequences, with particular reference to hygiene in the food industry. The Journal of Applied Bacteriology, 75(6), 499-511. PMid:8294303. http://dx.doi.org/10.1111/j.1365-2672.1993.tb01587.x

http://dx.doi.org/10.1111/j.1365-2672.19...

; Potter et al., 2012Potter, B. D., Marcy, J. A., Owens, C. M., Slavik, M. F., Goodwin, H. L., & Apple, J. K. (2012). Impact of performance-based sanitation systems on microbiological characteristics of poultry processing equipment and carcasses as compared with traditional sanitation systems. Journal of Applied Poultry Research, 21(3), 669-678. http://dx.doi.org/10.3382/japr.2011-00513

http://dx.doi.org/10.3382/japr.2011-0051...

).

Among these equipment, the industrial chicken feet-cutter increased the slaughter speed and reduced the carcasses handling thereupon the scalding and defeathering processes, considered a highly contaminated area (Rasschaert et al., 2007Rasschaert, G., Houf, K., & De Zutter, L. (2007). Impact of the slaughter line contamination on the presence of Salmonella on broiler carcasses. Journal of Applied Microbiology, 103(2), 333-341. PMid:17650193. http://dx.doi.org/10.1111/j.1365-2672.2006.03248.x

http://dx.doi.org/10.1111/j.1365-2672.20...

; Lehner et al., 2014Lehner, Y., Reich, F., & Klein, G. (2014). Influence of process parameter on Campylobacter spp. counts on poultry meat in a slaughterhouse environment. Current Microbiology, 69(3), 240-244. PMid:24715049. http://dx.doi.org/10.1007/s00284-014-0575-y

http://dx.doi.org/10.1007/s00284-014-057...

; Althaus et al., 2017Althaus, D., Zweifel, C., & Stephan, R. (2017). Analysis of a poultry slaughter process: Influence of process stages on the microbiological contamination of broiler carcasses. Italian Journal of Food Safety, 6(4), 7097. PMid:29564242. http://dx.doi.org/10.4081/ijfs.2017.7097

http://dx.doi.org/10.4081/ijfs.2017.7097...

). Moreover, it has a self-washing system with a continuous water jet, which removes the residues from the cutting disc and prevents the formation of biofilm (Borges et al., 2018Borges, K. A., Furian, T. Q., Souza, S. N., Menezes, R., Tondo, E. C., Salle, C. T. P., Moraes, H. L. S., & Nascimento, V. P. (2018). Biofilm formation capacity of Salmonella serotypes at different temperature conditions. Pesquisa Veterinária Brasileira, 38(1), 71-76. http://dx.doi.org/10.1590/1678-5150-pvb-4928

http://dx.doi.org/10.1590/1678-5150-pvb-...

). As described in the current Brazilian legislation by means of the Regulation of Industrial and Sanitary Inspection of Products of Animal Origin (RIISPOA), one of the authorized sanitizing methods of utensils and equipment present in environments with immediate risk of contamination is washing with renewable and heated water systems at, at least, 82.2°C (Brasil, 2017Brasil. Ministry of Agriculture, Livestock and Food Supply. (2017). Regulamento da Inspeção Industrial e Sanitária de Produtos de Origem Animal - RIISPOA (Decreto nº 9013, de 29 de março de 2017). Diário Oficial da União, Brasília.). Thus, we hypothesized that heating the jetted water on the surface of a feet-cutter disc could reduce the bacterial count and be used as an addition to the self-control of poultry slaughterhouses. Taking into account the aforementioned issues, this study aimed to evaluate the bacterial load on feet-cutter discs at broiler slaughterhouses that use Heated Water (HW) in the self-washing system.

2 Materials and methods

2.1 Experimental design

The experiment was carried out in a commercial broiler abattoir with a daily slaughter capacity of 65,000 birds in a single working shift located in the eastern region of Santa Catarina state, in Brazil. Furthermore, on harvesting days, birds of Ross® lineage were slaughtered with an average age and weight of 39 days and 2.7 kg, respectively. The sampling was performed on the surface of the cutting disc of a broiler feet-cutting equipment (MAREL S/A, Garoabaer, Iceland), which has a maximum cutting capacity of 30,000 feet per hour. The removal of residues on its surface is carried out with a continuous jet of potable water at room temperature (24°C ± 1) during the entire cutting process.

The study was carried out to evaluate the operational self-washing process of the feet-cutter disc, which cuts the feet of all slaughtered birds. A total of 84 samples were collected and divided into two experimental groups (n = 42). In the Non-Heated Water (NHW) group (NHW; Figure 1A), the disc was washed continuously with a jet of water at room temperature (24°C ± 1). On the other hand, the equipment received a continuous jet of water at 85°C ± 1 in the HW group (HW; Figure 1B). To fit the heated self-washing system, a pump was installed to supply the washing hoses with heated water coming from the steam heat exchanger system.

Schematic designs of the operational self-washing system of the feet-cutter disc with (A) non-heated and (B) heated water.

Samples were collected prior the slaughter (right after the pre-operational sanitation), during operational meal breaks (three breaks), and after the end of the slaughter (before pre-operational sanitation). For this, a sterile swab was scrubbed on the cutter disc’s surface using a 10 cm2 sterile area marker and conditioned within tubes containing 10 mL of 1% buffered peptone water solution (Neogen Corporation, Lansing, USA), which in turn were stored under refrigeration until the microbiological analysis.

2.2 Microbiological analysis

Microbiological analyses were performed by a governmental-accredited laboratory in accordance with current technical regulations. 3M™ Petrifilm™ Plates (3M™, Sumaré, Brazil) were used for Salmonella spp. (ISO-6579-1:2017) isolation and for the quantification at a ten-fold serial dilution of Mesophilic Aerobics (AOAC 990.12), Sulphite-reducing Clostridia (SRC) (ISO 15213:2003), Escherichia coli (AOAC 998.08) and Staphylococcus aureus (AOAC 2003.07) (International Organization for Standardization, 2003; 2017; Association of Official Analytical Chemists, 2019Association of Official Analytical Chemists - AOAC. (2019). Official Methods of Analysis. Gaithersburg: AOAC.).

2.3 Statistical analysis

Statistical analyses and graphs from microbiological assays data were done using GraphPad Prism version 8.0.1 for Windows (GraphPad Software, La Jolla, CA, USA). Firstly, the microbiological counts were transformed into Log10 and normality of residues was assessed by means of D'Agostino-Pearson omnibus (K2) test. Then, data with normal distribution were submitted to the Paired t test, whereas non-Gaussian data were evaluated with Wilcoxon matched-pairs signed rank test. The results were considered statistically significant when the P value was less than 5% (p < 0.05). A Confidence Interval (CI) of 95% (CI95) was used in the graphs.

3 Results and discussion

Pathogens control methods in the food industry undergo constant improvements to ensure that industrial processes are within acceptable thresholds (Dias et al., 2017Dias, M. R., Dianin, K. C. S., Bersot, L. S., & Nero, L. A. (2017). Self-monitoring microbiological criteria for the assessment of hygienic procedures during chicken slaughtering. Brazilian Journal of Poultry Science, 19(2), 317-324. http://dx.doi.org/10.1590/1806-9061-2016-0381

http://dx.doi.org/10.1590/1806-9061-2016...

). For this, the use of chemical compounds or physical action are authorized (Northcutt et al., 2007Northcutt, J., Smith, D., Ingram, K. D., Hinton Junior, A., & Musgrove, M. (2007). Recovery of bacteria from broiler carcasses after spray washing with acidified electrolyzed water or sodium hypochlorite solutions. Poultry Science, 86(10), 2239-2244. PMid:17878456. http://dx.doi.org/10.1093/ps/86.10.2239

http://dx.doi.org/10.1093/ps/86.10.2239...

; Potter et al., 2012Potter, B. D., Marcy, J. A., Owens, C. M., Slavik, M. F., Goodwin, H. L., & Apple, J. K. (2012). Impact of performance-based sanitation systems on microbiological characteristics of poultry processing equipment and carcasses as compared with traditional sanitation systems. Journal of Applied Poultry Research, 21(3), 669-678. http://dx.doi.org/10.3382/japr.2011-00513

http://dx.doi.org/10.3382/japr.2011-0051...

; Micciche et al., 2018Micciche, A. C., Rubinelli, P. M., & Ricke, S. C. (2018). Source of water and potential sanitizers and biological antimicrobials for alternative poultry processing food safety applications. Frontiers in Sustainable Food Systems, 2(82), 1-17. http://dx.doi.org/10.3389/fsufs.2018.00082

http://dx.doi.org/10.3389/fsufs.2018.000...

; Thomas et al., 2020Thomas, C., Schönknecht, A., Püning, C., Alter, T., Martin, A., & Bandick, N. (2020). Effect of peracetic acid solutions and lactic acid on microorganisms in on-line reprocessing systems for chicken slaughter plants. Journal of Food Protection, 83(4), 615-620. PMid:32221565. http://dx.doi.org/10.4315/0362-028X.JFP-19-350

http://dx.doi.org/10.4315/0362-028X.JFP-...

) and the assess of bacterial load on equipment surfaces is essential to monitor the effectiveness of sanitization procedures throughout the whole process (ICMSF, 2011International Commission on Microbiological Specifications for Foods - ICMSF. (2011). Microorganisms in foods. (6. ed.). New York: Kluwer Academy/Plenum Publishers. ). In broiler slaughterhouses, the main microbiological indicators are the presence of Mesophilic bacteria, as an indicator of sanitizing degree; quantification of total coliforms and E. coli for faecal/environmental contamination; and finally, the quantification of S. aureus as an indicator of poor hygiene, handling and temperature control problems (González-Fandos & Dominguez, 2006González-Fandos, E., & Dominguez, J. L. (2006). Efficacy of lactic acid against Listeria monocytogenes attached to poultry skin during refrigerated storage. Journal of Applied Microbiology, 101(6), 1331-1339. PMid:17105564. http://dx.doi.org/10.1111/j.1365-2672.2006.03022.x

http://dx.doi.org/10.1111/j.1365-2672.20...

; González-Miret et al., 2006González-Miret, M. L., Escudero-Gilete, M. L., & Heredia, F. J. (2006). The establishment of critical control points at the washing and air chilling stages in poultry meat production using multivariate statistics. Food Control, 17(12), 935-941. http://dx.doi.org/10.1016/j.foodcont.2005.06.012

http://dx.doi.org/10.1016/j.foodcont.200...

; Rindhe et al., 2008Rindhe, S. N., Zanjad, P. N., Doifode, V. K., Siddique, A., & Mendhe, M. S. (2008). Assessment of microbial contamination of chicken products sold in Parbhani city. Veterinary World, 1(7), 208-210.; Milios et al., 2014Milios, K. T., Drosinos, E. H., & Zoiopoulos, P. E. (2014). Food Safety Management System validation and verification in meat industry: carcass sampling methods for microbiological hygiene criteria - A review. Food Control, 43, 74-81. http://dx.doi.org/10.1016/j.foodcont.2014.02.041

http://dx.doi.org/10.1016/j.foodcont.201...

; Maharjan et al., 2019Maharjan, S., Rayamajhee, B., Chhetri, V. S., Sherchan, S. P., Panta, O. P., & Karki, T. B. (2019). Microbial quality of poultry meat in an ISO 22000:2005 certified poultry processing plant of Kathmandu valley. International Journal of Food Contamination, 6(8), 1-9. http://dx.doi.org/10.1186/s40550-019-0078-5

http://dx.doi.org/10.1186/s40550-019-007...

).

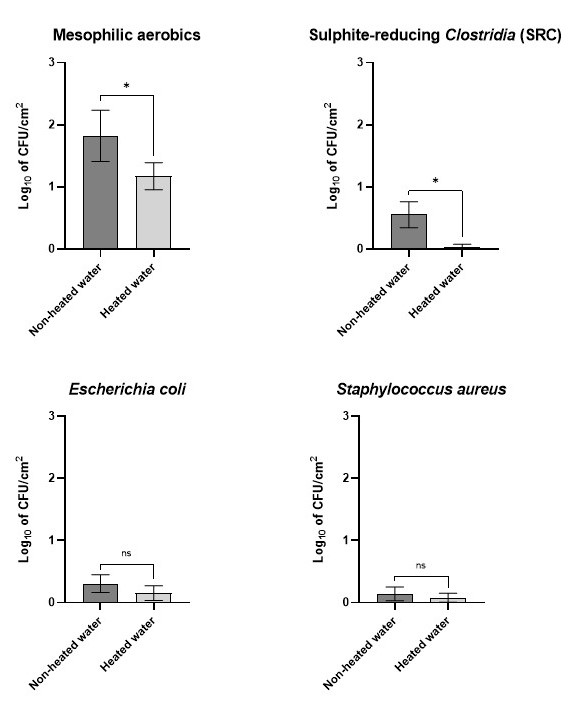

The results of the microbiological quantification of the feet-cutter disc, using ambient (24°C ± 1) and heated (85°C ± 1) water are described in Figure 2. The logarithmic counts of Mesophilic Aerobics, SRC, E. coli and S. aureus in the NHW group were 1.82, 0.56, 0.31 and 0.14 Log10 CFU/cm2, respectively, whereas in the HW group were 1.17, 0.04, 0.15 and 0.08 Log10 CFU/cm2. Salmonella spp. was absent in all evaluated samples in both groups. The use of the heating system (HW) reduced the count of bacteria of public health concern, but statistical differences (p < 0.05) were observed solely for Mesophilic Aerobics and SRC.

Microbiological quantification on the surface of the feet-cutter disc in a broiler slaughterhouse using a self-washing system with non-heated and heated water. *: means with statistically significant differences (p < 0.05); ns: not statistically significant (p > 0.05).

It is noteworthy that either intrinsic factors, such as rapid production rate, proximity of the carcasses and the equipment or processes as scalding, defeathering and evisceration, both favor the spread of microorganisms and hamper their control in slaughterhouses (Mead et al. 1993Mead, G. C., Hudson, W. R., & Hinton, M. H. (1993). Microbiological survey of five poultry processing plants in the UK. British Poultry Science, 34(3), 497-503. PMid:8358637. http://dx.doi.org/10.1080/00071669308417605

http://dx.doi.org/10.1080/00071669308417...

). According to legislation, equipment surfaces must be smooth and imperfection-free to be frequently and easily cleaned without compromising food hygiene (Brasil, 1996Brasil. Ministry of Agriculture, Livestock and Food Supply. (1996). Diretrizes para preparação de Plano de APPCC (HACCP) para o processo de abate de aves (Official Notice no 36/1996/CGCOA/DIPOA/SDA/MAPA). Diário Oficial da República Federativa do Brasil, Brasília.). Thus, the continuous cleaning of the feet-cutter disc is of outstanding importance, since it is located right after the defeathering machine outlet, considered a sector of high bacterial pressure. The use of running water as a physical cleaning mechanism reduces residues on the equipment surfaces (Borges et al., 2018Borges, K. A., Furian, T. Q., Souza, S. N., Menezes, R., Tondo, E. C., Salle, C. T. P., Moraes, H. L. S., & Nascimento, V. P. (2018). Biofilm formation capacity of Salmonella serotypes at different temperature conditions. Pesquisa Veterinária Brasileira, 38(1), 71-76. http://dx.doi.org/10.1590/1678-5150-pvb-4928

http://dx.doi.org/10.1590/1678-5150-pvb-...

). Furthermore, it proved to be an important mechanism to avoid cross-contamination when heated and maintains bacterial loads even lower.

The use of simple control methodologies can maximize the process, reduce the incidence of pathogens and still be affordable for the industry (Micciche et al., 2018Micciche, A. C., Rubinelli, P. M., & Ricke, S. C. (2018). Source of water and potential sanitizers and biological antimicrobials for alternative poultry processing food safety applications. Frontiers in Sustainable Food Systems, 2(82), 1-17. http://dx.doi.org/10.3389/fsufs.2018.00082

http://dx.doi.org/10.3389/fsufs.2018.000...

). Therefore, it was demonstrated in the present study that the use of HW reduced bacteria of public health concern on the surface of equipment of high contact with the carcasses.

In a study conducted by Dillard et al. (2016)Dillard, L., Herrick, R., & Lawrence, T. (2016). Time-temperature relations for sanitizing meat processing equipment. Meat and Muscle Biology, 1(2), 165. http://dx.doi.org/10.22175/rmc2016.159

http://dx.doi.org/10.22175/rmc2016.159...

in slaughterhouses in the United States of America (USA), it could be evaluated the antimicrobial activity of immersing knives, hooks and pneumatic skinning saw in HW. The authors reported that the sanitizing effectiveness of the procedure depends on the time exposure and the size of the surface, which should be more than 10 seconds for larger surfaces. Similarly, Taormina & Dorsa (2007)Taormina, P. J., & Dorsa, W. J. (2007). Evaluation of hot-water and sanitizer dip treatments of knives contaminated with bacteria and meat residue. Journal of Food Protection, 70(3), 648-654. PMid:17388054. http://dx.doi.org/10.4315/0362-028X-70.3.648

http://dx.doi.org/10.4315/0362-028X-70.3...

experimentally inoculated E. coli O157:H7, S. Typhimurium DT104, Clostridium perfringens and Lactobacillus spp. on knife blades and subjected them to different temperatures with or without the use of disinfectants. It was observed that the longer the exposure time to HW, the greater was the reduction of bacterial counts. In the present study, the disk has large dimensions and it was possible to maintain it at high temperature (85°C ± 1) due to the continuous jet of HW, facilitating its constant exposure to high temperatures and therefore reducing the bacterial load on its surface.

Furthermore, there is a correlation between exposure time and temperature regarding the reduction of microorganisms on knives. Higher water temperatures (82°C for 1 s) require less immersion time, whereas lower temperatures require longer immersion periods (Goulter et al., 2008Goulter, R. M., Dykes, G. A., & Small, A. (2008). Decontamination of knives used in the meat industry: Effect of different water temperature and treatment time combinations on the reduction of bacterial numbers on knife surfaces. Journal of Food Protection, 71(7), 1338-1342. PMid:18680930. http://dx.doi.org/10.4315/0362-028X-71.7.1338

http://dx.doi.org/10.4315/0362-028X-71.7...

). Barbosa et al. (2016)Barbosa, J., Cuppini, M., Flach, J., Steffens, C., Cansian, R. L., & Toniazzo, G. (2016). Removal of Escherichia coli in boning knives with different sanitizers. Lebensmittel-Wissenschaft + Technologie, 71, 309-315. http://dx.doi.org/10.1016/j.lwt.2016.04.002

http://dx.doi.org/10.1016/j.lwt.2016.04....

evaluated biofilm formation on deboning knives submitted to several cleaning procedures and also demonstrated that a longer period of immersion in heated water is required against long time-formed biofilm to reduce E. coli contamination levels.

Thus, we observed herein that the constancy of the continuous jet combined with the high temperature of the heated water significantly favored the reduction of the microbiological load (p < 0.05), thus minimizing the possibilities of cross-contamination occurrence between the carcasses. Although the effectiveness of the process has been observed, the use of HW becomes an addition to the operational procedure since the food security thresholds implemented by current national and international marketing regulations were not exceeded in both groups (Agri-Food and Veterinary Authority, 2000Agri-Food and Veterinary Authority - AVA. (2000). Circular/Directive n. 2000/1 - Microbiological specifications for imported meat, Singapore: AVA. ; Brasil, 2017Brasil. Ministry of Agriculture, Livestock and Food Supply. (2017). Regulamento da Inspeção Industrial e Sanitária de Produtos de Origem Animal - RIISPOA (Decreto nº 9013, de 29 de março de 2017). Diário Oficial da União, Brasília.; National Standards of the People's Republic of China, 2014National Standards of the People's Republic of China. (2014). GBT 16869-2005: National food standard fresh and frozen poultry products. Beijing, CN: GB National Standards of the People's Republic of China.; Commision Regulation (EC), 2005Commision Regulation (EC). (2005). Microbiological criteria for foodstuffs (Commision Regulation (EC) No 2073/2005). Brussels: Official Journal of the European Union.; Standardization Organization for G.C.C (GSO), 2014; NB, 2017NB. (2017). NB:310013: Carnes y derivados - Poultry meat - Microbiological requirements. La Paz, Bolivia: NB.).

4 Conclusion

The use of a continuous self-washing system with heated water on the feet-cutter disc in broiler slaughterhouses did not statistically decreased the load of neither E. coli nor S. aureus, but reduced the levels of both Mesophilic Aerobics and Sulphite-Reducing Clostridia. Thus, it can be a tool for self-control programs to maintain the load of public health concern pathogens on the surface of the equipment below the food safety thresholds and by reducing potential cross-contamination.

-

Cite as: Cavani, R., Rubio, M. S., Alves, L. B. R., Alves, K. A. P., & Cardozo, M. V. (2023). Microbiological evaluation of feet-cutter disc for broiler with a self-washing system using heated and non-heated water. Brazilian Journal of Food Technology, 26, e2022046. https://doi.org/10.1590/1981-6723.04622

-

Funding: None.

References

- Agri-Food and Veterinary Authority - AVA. (2000). Circular/Directive n. 2000/1 - Microbiological specifications for imported meat, Singapore: AVA.

- Althaus, D., Zweifel, C., & Stephan, R. (2017). Analysis of a poultry slaughter process: Influence of process stages on the microbiological contamination of broiler carcasses. Italian Journal of Food Safety, 6(4), 7097. PMid:29564242. http://dx.doi.org/10.4081/ijfs.2017.7097

» http://dx.doi.org/10.4081/ijfs.2017.7097 - Association of Official Analytical Chemists - AOAC. (2019). Official Methods of Analysis Gaithersburg: AOAC.

- Barbosa, J., Cuppini, M., Flach, J., Steffens, C., Cansian, R. L., & Toniazzo, G. (2016). Removal of Escherichia coli in boning knives with different sanitizers. Lebensmittel-Wissenschaft + Technologie, 71, 309-315. http://dx.doi.org/10.1016/j.lwt.2016.04.002

» http://dx.doi.org/10.1016/j.lwt.2016.04.002 - Borges, K. A., Furian, T. Q., Souza, S. N., Menezes, R., Tondo, E. C., Salle, C. T. P., Moraes, H. L. S., & Nascimento, V. P. (2018). Biofilm formation capacity of Salmonella serotypes at different temperature conditions. Pesquisa Veterinária Brasileira, 38(1), 71-76. http://dx.doi.org/10.1590/1678-5150-pvb-4928

» http://dx.doi.org/10.1590/1678-5150-pvb-4928 - Brasil. Ministry of Agriculture, Livestock and Food Supply. (1996). Diretrizes para preparação de Plano de APPCC (HACCP) para o processo de abate de aves (Official Notice no 36/1996/CGCOA/DIPOA/SDA/MAPA). Diário Oficial da República Federativa do Brasil, Brasília.

- Brasil. Ministry of Agriculture, Livestock and Food Supply. (2017). Regulamento da Inspeção Industrial e Sanitária de Produtos de Origem Animal - RIISPOA (Decreto nº 9013, de 29 de março de 2017). Diário Oficial da União, Brasília.

- Carpentier, B., & Cerf, O. (1993). Biofilms and their consequences, with particular reference to hygiene in the food industry. The Journal of Applied Bacteriology, 75(6), 499-511. PMid:8294303. http://dx.doi.org/10.1111/j.1365-2672.1993.tb01587.x

» http://dx.doi.org/10.1111/j.1365-2672.1993.tb01587.x - Commision Regulation (EC). (2005). Microbiological criteria for foodstuffs (Commision Regulation (EC) No 2073/2005) Brussels: Official Journal of the European Union.

- Dias, M. R., Dianin, K. C. S., Bersot, L. S., & Nero, L. A. (2017). Self-monitoring microbiological criteria for the assessment of hygienic procedures during chicken slaughtering. Brazilian Journal of Poultry Science, 19(2), 317-324. http://dx.doi.org/10.1590/1806-9061-2016-0381

» http://dx.doi.org/10.1590/1806-9061-2016-0381 - Dillard, L., Herrick, R., & Lawrence, T. (2016). Time-temperature relations for sanitizing meat processing equipment. Meat and Muscle Biology, 1(2), 165. http://dx.doi.org/10.22175/rmc2016.159

» http://dx.doi.org/10.22175/rmc2016.159 - Esper, I. M., From, P. J., & Mason, A. (2021). Robotisation and intelligent systems in abattoirs. Trends in Food Science & Technology, 108, 214-222. http://dx.doi.org/10.1016/j.tifs.2020.11.005

» http://dx.doi.org/10.1016/j.tifs.2020.11.005 - González-Fandos, E., & Dominguez, J. L. (2006). Efficacy of lactic acid against Listeria monocytogenes attached to poultry skin during refrigerated storage. Journal of Applied Microbiology, 101(6), 1331-1339. PMid:17105564. http://dx.doi.org/10.1111/j.1365-2672.2006.03022.x

» http://dx.doi.org/10.1111/j.1365-2672.2006.03022.x - González-Miret, M. L., Escudero-Gilete, M. L., & Heredia, F. J. (2006). The establishment of critical control points at the washing and air chilling stages in poultry meat production using multivariate statistics. Food Control, 17(12), 935-941. http://dx.doi.org/10.1016/j.foodcont.2005.06.012

» http://dx.doi.org/10.1016/j.foodcont.2005.06.012 - Goulter, R. M., Dykes, G. A., & Small, A. (2008). Decontamination of knives used in the meat industry: Effect of different water temperature and treatment time combinations on the reduction of bacterial numbers on knife surfaces. Journal of Food Protection, 71(7), 1338-1342. PMid:18680930. http://dx.doi.org/10.4315/0362-028X-71.7.1338

» http://dx.doi.org/10.4315/0362-028X-71.7.1338 - International Commission on Microbiological Specifications for Foods - ICMSF. (2011). Microorganisms in foods. (6. ed.). New York: Kluwer Academy/Plenum Publishers.

- International Organization for Standardization - ISO. (2003). ISO 15213:2003: Microbiology of food and animal feeding stuffs — Horizontal method for the enumeration of sulfite-reducing bacteria growing under anaerobic conditions. Geneva: ISO.

- International Organization for Standardization - ISO. (2017). ISO/IEC 17025-1: General requirements for the competence of testing and calibration laboratories. Geneva: ISO.

- Lehner, Y., Reich, F., & Klein, G. (2014). Influence of process parameter on Campylobacter spp. counts on poultry meat in a slaughterhouse environment. Current Microbiology, 69(3), 240-244. PMid:24715049. http://dx.doi.org/10.1007/s00284-014-0575-y

» http://dx.doi.org/10.1007/s00284-014-0575-y - Maharjan, S., Rayamajhee, B., Chhetri, V. S., Sherchan, S. P., Panta, O. P., & Karki, T. B. (2019). Microbial quality of poultry meat in an ISO 22000:2005 certified poultry processing plant of Kathmandu valley. International Journal of Food Contamination, 6(8), 1-9. http://dx.doi.org/10.1186/s40550-019-0078-5

» http://dx.doi.org/10.1186/s40550-019-0078-5 - Marriott, N. G., & Gravani, R. B. (2014). Principles of food sanitization (5. ed.). New York: Springer.

- Mead, G. C., Hudson, W. R., & Hinton, M. H. (1993). Microbiological survey of five poultry processing plants in the UK. British Poultry Science, 34(3), 497-503. PMid:8358637. http://dx.doi.org/10.1080/00071669308417605

» http://dx.doi.org/10.1080/00071669308417605 - Micciche, A. C., Rubinelli, P. M., & Ricke, S. C. (2018). Source of water and potential sanitizers and biological antimicrobials for alternative poultry processing food safety applications. Frontiers in Sustainable Food Systems, 2(82), 1-17. http://dx.doi.org/10.3389/fsufs.2018.00082

» http://dx.doi.org/10.3389/fsufs.2018.00082 - Milios, K. T., Drosinos, E. H., & Zoiopoulos, P. E. (2014). Food Safety Management System validation and verification in meat industry: carcass sampling methods for microbiological hygiene criteria - A review. Food Control, 43, 74-81. http://dx.doi.org/10.1016/j.foodcont.2014.02.041

» http://dx.doi.org/10.1016/j.foodcont.2014.02.041 - Nääs, I. A., Mollo Neto, M., Canuto, S. A., Waker, R., Oliveira, D. R. M. S., & Vendrametto, O. (2015). Brazilian chicken meat production chain: A 10-year overview. Brazilian Journal of Poultry Science, 17(1), 87-94. http://dx.doi.org/10.1590/1516-635x170187-94

» http://dx.doi.org/10.1590/1516-635x170187-94 - National Standards of the People's Republic of China. (2014). GBT 16869-2005: National food standard fresh and frozen poultry products Beijing, CN: GB National Standards of the People's Republic of China.

- NB. (2017). NB:310013: Carnes y derivados - Poultry meat - Microbiological requirements La Paz, Bolivia: NB.

- Northcutt, J., Smith, D., Ingram, K. D., Hinton Junior, A., & Musgrove, M. (2007). Recovery of bacteria from broiler carcasses after spray washing with acidified electrolyzed water or sodium hypochlorite solutions. Poultry Science, 86(10), 2239-2244. PMid:17878456. http://dx.doi.org/10.1093/ps/86.10.2239

» http://dx.doi.org/10.1093/ps/86.10.2239 - Perez-Arnedo, I., Cantalejo, M. J., Martínez-Laorden, A., & Gonzalez-Fandos, E. (2020). Effect of processing on the microbiological quality and safety of chicken carcasses at slaughterhouse. International Journal of Food Science & Technology, 56(4), 1885-1864.

- Potter, B. D., Marcy, J. A., Owens, C. M., Slavik, M. F., Goodwin, H. L., & Apple, J. K. (2012). Impact of performance-based sanitation systems on microbiological characteristics of poultry processing equipment and carcasses as compared with traditional sanitation systems. Journal of Applied Poultry Research, 21(3), 669-678. http://dx.doi.org/10.3382/japr.2011-00513

» http://dx.doi.org/10.3382/japr.2011-00513 - Rasschaert, G., Houf, K., & De Zutter, L. (2007). Impact of the slaughter line contamination on the presence of Salmonella on broiler carcasses. Journal of Applied Microbiology, 103(2), 333-341. PMid:17650193. http://dx.doi.org/10.1111/j.1365-2672.2006.03248.x

» http://dx.doi.org/10.1111/j.1365-2672.2006.03248.x - Rindhe, S. N., Zanjad, P. N., Doifode, V. K., Siddique, A., & Mendhe, M. S. (2008). Assessment of microbial contamination of chicken products sold in Parbhani city. Veterinary World, 1(7), 208-210.

- Standardization organization for G.C.C (GSO). (2014). GSO/FDS 1016/2014: Microbiological criteria for foodstuffs. Riyadh, KSA: GSO.

- Taormina, P. J., & Dorsa, W. J. (2007). Evaluation of hot-water and sanitizer dip treatments of knives contaminated with bacteria and meat residue. Journal of Food Protection, 70(3), 648-654. PMid:17388054. http://dx.doi.org/10.4315/0362-028X-70.3.648

» http://dx.doi.org/10.4315/0362-028X-70.3.648 - Thomas, C., Schönknecht, A., Püning, C., Alter, T., Martin, A., & Bandick, N. (2020). Effect of peracetic acid solutions and lactic acid on microorganisms in on-line reprocessing systems for chicken slaughter plants. Journal of Food Protection, 83(4), 615-620. PMid:32221565. http://dx.doi.org/10.4315/0362-028X.JFP-19-350

» http://dx.doi.org/10.4315/0362-028X.JFP-19-350

Edited by

Publication Dates

-

Publication in this collection

23 Jan 2023 -

Date of issue

2023

History

-

Received

26 Apr 2022 -

Accepted

20 Sept 2022