Abstract

The application of Nondestructive Testing methods (NDT) may be an interesting strategy to monitor the condition state of reinforced concrete structures, especially when there are problems related to mixing, conveying or placing the concrete. Among the NDT methods, the Ultrasonic Pulse Velocity (UPV) has been one of the most used in various fields of civil engineering, due to the ease of operation, low cost, test velocity and low level of damage to the surface analyzed. This work aims to study the influence of certain technological variables in the results obtained through UPV tests. With this aim two large blocks were cast at the laboratory, with dimensions close to real concrete elements. One of the elements was reinforcement with steel meshes on both sides while the other was cast without reinforcement. Inside these elements objects were introduced to reproduce internal concrete flaws. To facilitate the analysis the results were represented by means of a surface mapping image technique and were also subjected to statistical analysis. Through the study it was demonstrated that the correct choice of test parameters is crucial to obtain a right interpretation of UPV results from real structures.

Keywords:

Nondestructive Testing; Ultrasonic Pulse Velocity; Reinforced Concrete Structures

Resumo

A aplicação de Ensaios Não Destrutivos (END) é uma estratégia interessante para monitorar o estado de conservação das estruturas de concreto armado, principalmente quando ocorrem erros de dosagem, problemas na mistura, transporte ou lançamento do concreto. Dentre os métodos de END, aplicáveis ao concreto, o método de ensaio da Velocidade de Propagação do Pulso Ultrassônico (VPU) vem sendo utilizado comumente em diversas áreas da Engenharia Civil, devido à facilidade da operação, ao seu baixo custo, à rapidez na execução dos testes e à ausência de danos ao material analisado. Este trabalho visa estudar a influência que determinadas variáveis tecnológicas exercem sobre os resultados obtidos através dos ensaios de VPU. Foram moldados em laboratório dois elementos de concreto, com dimensões próximas a estruturas reais. Um elemento com armadura nas duas faces e outro sem armadura, nos quais foram introduzidos objetos para reproduzir possíveis falhas de concretagem. De modo a facilitar a análise dos dados, os resultados são apresentados por meio de imagens geradas através de programas computacionais e análises estatísticas. Através deste estudo verificou-se que a escolha dos parâmetros de ensaios é fator crucial para que se tenha uma interpretação correta dos resultados.

Palavras - chave:

Ensaios Não Destrutivos; Velocidade de Propagaçao do Pulso Ultrassônico; Estruturas de Concreto Armado

1. Introduction

The use of construction materials is intertwined with the proper history of the civilization, because it was necessary to men to serve themselves to survive and to satisfy their necessities of shelter and comfort [1[1] ISAIA, G.C., O Concreto: da Era Clássica à Contemporânea. In: ISAIA, G. C. (Editor), Concreto: Ensino, Pesquisa e Realizações. São Paulo: IBRACON, 2005. cap.1, vol.1, p.1-44.]. Many of the buildings in reinforced concrete which form the civil infrastructure are approaching the end of its useful life. Consequently, there is a growing concern about its state of decay and security [2[2] LORENZI, A. Aplicação de redes neurais artificiais para estimativa da resistência à compressão do concreto a partir da velocidade de propagação do pulso ultra-sônico, Porto Alegre, 2009, Tese (doutorado) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul. Escola de Engenharia, 196p.]. In the current scenario, in which the effective product quality requirements are reinforcing, is of vital importance to the development of alternatives that allow, effectively, evaluate the quality "in loco" of concrete structures. The application of NDT, in this panorama, ends up being in an attractive and vital strategy to assess and monitor the condition and characteristics of important structures, especially when they fail, or suffer from errors of dosing, mixing, transport and release of concrete.

Amongst NDT methods used worldwide, which involves the measurement of the UPV is one of the most promising, for simplicity, low cost and good performance. In the literature there are many references to it, being common to description of curves of correlation that seek to correlate the UPV with compressive strength, since both these results are affected by the amount and size of existing voids in the material.

Exactly for this potentiality, the UPV has been the most investigated NDT in research in Structural Tests and Materials Laboratory of the Federal University of Rio Grande do Sul (LEME/UFRGS). In various research work conducted, on the field and in the laboratory, a technique of UPV was developed, mapping with indirect readings, and confirmed that the method, when properly employed, can offer ease of implementation, fast and suitable fault detection capability [3[3] LORENZI, A.; CAETANO, Luciane Fonseca ; CAMPAGNOLO, João Luiz ; SILVA FILHO, Luiz Carlos Pinto da . An investigation of the suitability of different NDT test methods to detected voids of concrete elements. E-Journal of Nondestructive Testing and Ultrasonics, v. 14, p. ID 7698, 2009., 4[4] LORENZI, A.; SILVA FILHO, Luiz Carlos Pinto da ; CAMPAGNOLO, João Luiz ; STRIEDER, Adelir Jose ; QUININO, Uziel Cavalcante de Medeiros ; CAETANO, Luciane Fonseca . Estudos de caso sobre avaliação de estruturas de concreto através da utilização de ensaios não destrutivos. Revista ALCONPAT, v. 1, p. 188, 2011., 5[5] LORENZI, A.; SILVA FILHO, Luiz Carlos Pinto da ; CAMPAGNOLO, João Luiz ; CAETANO, Luciane Fonseca . Analyzing two different data processing strategies for monitoring concrete structures using ultrasonic pulse velocity. Revista ALCONPAT , v. 2, p. 192, 2012., 6[6] LORENZI, A.; SILVA FILHO, L. C. P. ; CAETANO, Luciane Fonseca ; CHIES, J. A. . Investigation of the Potential for Evaluation of Concrete Flaws Using Nondestructive Testing Methods. ISRN Civil Engineering, v. 2014, p. 1-8, 2014., 7[7] LORENZI, A.; CAETANO, Luciane Fonseca ; CAMPAGNOLO, João Luiz ; LORENZI, L. S. ; SILVA FILHO, L. C. P. . Application of Ultrasonic Pulse Velocity to Detect Concrete Flaws. E-Journal of Nondestructive Testing and Ultrasonics , v. 11.2015, p. 18430, 2015., 8[8] CHIES, J. A. ; ADAMATTI, D. S. ; LORENZI, A. ; SILVA FILHO, L. C. P. . Detecção de Falhas em Estruturas de Concreto através de Ensaios Ultrassônicos. In: 57° Congresso Brasileiro do Concreto, 2015, Bonito. Anais do 57° Congresso Brasileiro do Concreto. São Paulo: IBRACON , 2015., 9[9] NOGUEIRA, C. L., Ensaios Não Destrutivos: Novas Ferramentas para Inspeção de Obras Públicas. In: VI SINAOP - VI SIMPÓSIO NACIONAL DE AUDITORIA EM OBRAS PÚBLICAS. Anais... ,Florianópolis: 2001.]. Several researches related to UPV and concrete. To evaluate the degradation of mechanical properties of concrete and mortar [10[10] MEDEIROS, A., PADARATZ, I.J., PINTO, R.C.A., Influência da Presença de Armaduras na Estimativa da Profundidade de Fissuras Superficiais em Concreto Armado através do Ultra-som. In: CONGRESSSO BRASILEIRO DO CONCRETO (COBRACON 2009), 51, 2009, Curitiba. Anais..., São Paulo: Instituto Brasileiro do Concreto, 2009. 14p. 1 CD-ROM.], examined the influence of the presence of reinforcement in estimating the depth of surface cracks [11[11] LORENZI, A.., SILVA FILHO, L.C.P., CAETANO, L.F, LORENZI, L.S., Monitoramento de Estruturas de Concreto através de Ensaios de Velocidade de Propagação do Pulso Ultra-sônico. In: CONGRESSSO BRASILEIRO DO CONCRETO (COBRACON 2009), 51, 2009, Curitiba. Anais..., São Paulo: Instituto Brasileiro do Concreto, 2009. 13p. 1 CD-ROM.], tested the ability of monitoring reinforced concrete structures [12[12] BARBOSA, M.T.G., MENDES, L.O., COURA, C.G., Resistência à Compressão do Concreto x Velocidade de Propagação de Pulso Ultrasônico - Estudo de Caso. In: CONGRESSSO BRASILEIRO DO CONCRETO (COBRACON 2009), 51, 2009, Curitiba. Anais.... São Paulo: Instituto Brasileiro do Concreto , 2009. 16p. 1 CD-ROM.], evaluated the relationship with compressive strength [13[13] EVANGELISTA, A. C. J., Avaliação da Resistência do Concreto usando Diferentes Ensaios Não Destrutivos. 2002. 219p. Tese (Doutorado) - Programa de Pós-Graduação em Engenharia da Universidade Federal do Rio de Janeiro. Universidade Federal do Rio de Janeiro, Rio de Janeiro, 2002.] and to generate sophisticated models for the same, with use of Artificial Neural Network techniques [2[2] LORENZI, A. Aplicação de redes neurais artificiais para estimativa da resistência à compressão do concreto a partir da velocidade de propagação do pulso ultra-sônico, Porto Alegre, 2009, Tese (doutorado) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul. Escola de Engenharia, 196p.].

Despite the contribution of information brought by these studies, doubts about the accuracy of the results, especially when they are necessary interpretations of data from field tests, without standardized conditions. This work has been designed aiming to help reduce existing doubts regarding the use and operation of the ultrasound equipment in field situations, despite many researches developed in laboratory, with test specimens, demonstrate a good ability to fault detection of concreting and estimation of compressive strength of concrete. This is because some variables will interfere with results, differently, especially when used in elements with dimensions close to the real.

The objective proposed for the research is to study the influence that some relevant technological variables exert on the results obtained through tests of UPV. The present work focuses on finding out what limitations of the UPV readings and what degree of interference of the same on the results, when in real conditions. For the development of research, two concrete elements called wall 1 and wall 2 were shaped in laboratory, with dimensions close to real structures. One element is without reinforcement (wall 1) and the other is with reinforcement on both sides (wall 2), in which objects were introduced to play possible failures of concrete.

The current standardization and articles do not express clearly and objectively the ability of fault detection and interpretation of the results obtained in the readings with the UPV tests, both 'in situ' as in lab environment. Therefore, it is necessary to carry out experiments that might generate correlation factors to enable and enhance the confidence of the UPV test results. Thus, this study seeks to mitigate issues concerning different technological variables, providing a better understanding of the results obtained through the trials of UPV in concrete structures.

2. Nondestructive testing

NDT methods are those that do not cause damage to the element being tested or leave only small lesions that can be repaired easily after the test, not provoking, thus, significant loss of strength or performance of the element. In the case of new structures, these tests can be used for monitoring the strength evolution and to clarify doubts about the quality of the concrete. In existing structures, they aim to evaluate the integrity of the structure. According to Evangelista [14[14] INTERNATIONAL ATOMIC ENERGY AGENCY. IAEA-TCS-17: Guidebook on Non-Destructive Testing of Concrete Structures. Viena: 2002, 231 p.], there are some properties of concrete that can be evaluated with the use of NDT, among them we can mention: density, modulus of elasticity and compressive strength. The surface hardness, absorption, permeability, moisture conditions, the location of the reinforcement, the existence of gaps and cracking can also be investigated.

The TCS-17 document, from the International Atomic Energy Agency [15[15] KUMAR, S. A., SANTHANAM, M., Detection of Concrete Damage Using Ultrasonic Pulse Velocity Method. In: NATIONAL SEMINAR ON NON-DESTRUCTIVE EVALUATION, 2006, Hyderabad. Proceedings.... Hyderabad: Indian Society for Non-Destrctive Testing. Disponível em: <Disponível em: http://www.ndt.net

> . Acesso em: 18/07/2007.

http://www.ndt.net...

], points out several specific situations associated with the civil construction, in which the use of NDT methods can be considered attractive:

-

quality control in precast or construction in situ;

-

removing uncertainties about the acceptability of the material supplied owing to apparent non-compliance with specification;

-

confirming or negating doubt concerning the workmanship involved in batching, mixing, placing, compacting or curing of concrete;

-

monitoring of strength development in relation to formwork removal, cessation of curing, prestressing, load application or similar purpose;

-

location and determination of the extent of cracks, voids, honeycombing and similar defects within a concrete structure;

-

determining the concrete uniformity, possibly preliminary to core cutting, load testing or other more expensive or disruptive tests;

-

determining the position, quantity or condition of reinforcement increasing the confidence level of a smaller number of destructive tests;

-

determining the extent of concrete variability in order to help in the selection of sample locations representative of the quality to be assessed;

-

confirming or locating suspected deterioration of concrete resulting from such factors as overloading, fatigue, external or internal chemical attack or change, fire, explosion, environmental effects;

-

assessing the potential durability of the concrete;

-

monitoring long term changes in concrete properties;

-

providing information for any proposed change of use of a structure for insurance or for change of ownership.

Kumar and Santhanam [16[16] VALLUZZI, M. R., DA PORTO, F., CASARIN, F., MONTEFORTE, N., MODENA, C., A Contribution to the Characterization of Masonry Typologies by using Sonic Waves Investigations. In: NON-DESTRUCTIVE TESTING IN CIVIL ENGINEERING (NDTCE'09), 2009, Nantes. Procedings.... Paris: Confédération Française por lês Essais Non Desctructifs, 2009. 6p.] claim that, today, the main objective of the use of NDT in construction is associated, in most cases, to the location and the importance of failures and defects in structures of hardened concrete. Valluzzi et al. [17[17] BREYSSE, D., SOUTSOS, M., FELICETTI, R, KRAUSE, M., LATASTE, J., MOCZKO, A., How to improve the quality of concrete assessment by combining several NDT measurements. In: NON-DESTRUCTIVE TESTING IN CIVIL ENGINEERNG (NDTCE 2009), 2009 , Nantes. Proceedings.... Paris: Confédération Française pour les Essais Non Destructifs, 2009. Disponível em: <Disponível em: http://www.ndt.net

>. Acesso em: 18 ago. 2013.

http://www.ndt.net...

], consider the application of these methods very useful for more complex diagnostic programs, as this allows identification of regions where the presence of deficiencies is more likely. Breysse et al. [18[18] ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS - ABNT. NBR 8802: Concreto Endurecido - Determinação da Velocidade de Propagação da Onda Ultra-sônica: Método de Ensaio. Rio de Janeiro: 2013.] also point out that some performance loss or deterioration of the safety level of the material induces significant maintenance costs. According to Lorenzi [12[12] BARBOSA, M.T.G., MENDES, L.O., COURA, C.G., Resistência à Compressão do Concreto x Velocidade de Propagação de Pulso Ultrasônico - Estudo de Caso. In: CONGRESSSO BRASILEIRO DO CONCRETO (COBRACON 2009), 51, 2009, Curitiba. Anais.... São Paulo: Instituto Brasileiro do Concreto , 2009. 16p. 1 CD-ROM.], several of these test methods are efficient and accurate, among which the UPV test combines flexibility, low cost, great capacity for detection and good capability of providing concrete information, being a pretty method used for the analysis of concrete structures.

2.1 Factors involved in the propagation of ultrasonic pulse velocity

The Brazilian standard NBR 8802 [19[19] CHUNG, H. W., LAW, K.S., Diagnosing in situ Concrete by Ultrasonic Pulse Technique. Concrete International. [s.l.], n. 05, p.42-49, 1983.], prescribes that several factors influence on the results of determination of ultrasonic wave propagation velocity, highlighting the main ones:

The size and shape of the element does not affect the velocity of propagation. However, the equation used to calculate the velocity of ultrasound in solid material is valid only for infinite dimensions. This condition, in practice, is satisfied if the side dimension of the element under consideration is, at least, equal to the wavelength of the transmitted pulse. Below this length, the accuracy of the results reduces.

The pulse velocity are usually not affected by the wave path length, as long as it's not too small. In this case, the heterogeneous nature of the concrete becomes important. Physical limitations on the time meter equipment can also introduce errors, in which small path lengths are involved. In previous studies, it was concluded that the measured velocity decreases with the increase in the wave path length.

Several technical standards indicate special care with the surface of the concrete, in order to keep it smooth and clean, and to achieve the perfect coupling of the transducers in the concrete. Following the NBR 8802 [19[19] CHUNG, H. W., LAW, K.S., Diagnosing in situ Concrete by Ultrasonic Pulse Technique. Concrete International. [s.l.], n. 05, p.42-49, 1983.] presents procedures in case of necessity of settlement of the surface by mechanical process or with the use of cement paste, plaster or resin epoxy, in minimum thickness as possible.

According to Lorenzi et al. [12[12] BARBOSA, M.T.G., MENDES, L.O., COURA, C.G., Resistência à Compressão do Concreto x Velocidade de Propagação de Pulso Ultrasônico - Estudo de Caso. In: CONGRESSSO BRASILEIRO DO CONCRETO (COBRACON 2009), 51, 2009, Curitiba. Anais.... São Paulo: Instituto Brasileiro do Concreto , 2009. 16p. 1 CD-ROM.], very rough surfaces or the ones that have received any finish should be avoided, because the properties of concrete in the main layer are not necessarily the same of its interior. For curved surfaces, Chung and Law [20[20] HAMASSAKI, L. T., Utilização do ultra-som em concreto. 1986. 108p. Dissertação (Mestrado em Engenharia Civil) - Escola Politécnica. Universidade de São Paulo, São Paulo, 1986. ], indicate the use of dry-point-of-contact transducers.

Studies by Hamassaki [21[21] CARCAÑO, R. S; PEREYRA, J.B. The influence of the physical properties of aggregates on the ultrasound pulse thecnique in predicting the compressive strength of concrete. Rev. Téc. Ing. Univ. Zulia, Vol. 26, No. 1, 2003.], Carcaño and Pereyra [22[22] RODRIGUES, G. S. S.; FIGUEIREDO, E. I. P. Módulo de deformação do concreto pelo método ultrassônico; Estudo da Correlação. In: 46º Congresso Brasileiro do Concreto, Florianópolis, 2004. Anais..., IBRACON, Florianópolis, 2004, pp. II 1309-1324.], indicate that the aggregate type variation affects the velocity of the pulse to concretes with compressive strength similar. In studies with the use of limestone gravel. Carcaño and Pereyra [22[22] RODRIGUES, G. S. S.; FIGUEIREDO, E. I. P. Módulo de deformação do concreto pelo método ultrassônico; Estudo da Correlação. In: 46º Congresso Brasileiro do Concreto, Florianópolis, 2004. Anais..., IBRACON, Florianópolis, 2004, pp. II 1309-1324.] found that measures of UPV values for a same level of compressive strength of concrete were higher for households who have better physical properties in terms of density, absorption and resistance to wear. In studies conducted about the influence of the maximum size of coarse aggregate on UPV. Evangelista [14[14] INTERNATIONAL ATOMIC ENERGY AGENCY. IAEA-TCS-17: Guidebook on Non-Destructive Testing of Concrete Structures. Viena: 2002, 231 p.] found that, in a series of maximum diameter (Dmax) of 19 mm, the UPV 2.5% were 11% higher than the series with Dmax. = 9.5 mm, in which was kept the proportion of aggregates in the concrete series, in order to avoid any interference from the variation of the amount of aggregate.

Rodrigues e Figueiredo [23[23] ELVERY, R. H.; IBRAHIM, L. A. M. Ultrasonic assessment of concrete strength at early ages. Megazine of Concrete Research, Dec., 1976, pp 181-190.] also noted this effect in studies with concrete cylindrical speciments (15 cm x 30 cm), in which were produced two similar concrete using coarse aggregate with different densities. They concluded that the molded concrete with aggregate of higher density showed higher values of UPV than those framed with coarse aggregate of lower density. Elvery and Ibrahim [24[24] COSTA, M. R., A importância do material acoplante no ensaio de ultrassonografia. 2013. Disponível em: Disponível em: http://techne.pini.com.br/engenharia-civil/191/a-importancia-do-material-acoplante-no-ensaio-de-ultrassonografia--286986-1.aspx

. Acesso em: 15/06/ 2013.

http://techne.pini.com.br/engenharia-civ...

] claim that the correlation between compressive strength and expressive influence by UPV undergoes variations in quantity of aggregates in concrete due to the elastic modulus of the aggregate exceeds the value of the cement paste. With increased volume of aggregate in concrete, keeping the other parameters constant, the velocity of the pulse tends to be greater.

Some studies indicate that, in the first 24 hours, the UPV in concrete is influenced by the cement type. However, in his study with concretes with ordinary portland cement (CP III) and high initial resistance (CP V), there are no difference was observed between the values of the UPV in tests aged three or more days [14[14] INTERNATIONAL ATOMIC ENERGY AGENCY. IAEA-TCS-17: Guidebook on Non-Destructive Testing of Concrete Structures. Viena: 2002, 231 p.].

According to Costa [25[25] COMITÉ MERCOSUL DE NORMALIZACION, NM 58: Hormigón endurecido - Determinación de la velocidad de propagación de pulsos ultrasónicos. São Paulo: 1996.], there are some factors that can interfere with the result of the test, including the nature of couplant material. It should be understood as couplant the materials that apply to areas of transducers before putting them in contact with the concrete. Its function is to promote the homogenization of the concrete surface, which will receive the transducers and prevent the penetration of air during the test.

Because the ultrasound machine does not have automated use, and depends on the human sensitivity, the NM 58:1996 [26[26] NAIK, T. R.; MALHOTRA, V. M.; POPOVICS, J. S., The Ultrasonic Pulse Velocity Method, CRC handbook on nondestructive testing of concrete, Tarun R. Naik and V M Malhotra eds, CRC Press, pp 169-189, 2004.] points out that the test must be carried out by experienced personnel in the application of this technique. The work plan, the analysis and interpretation of results shall be carried out by responsible and qualified professional.

In case of the concrete do not present any reinforcement, cracks or voids, sound waves travel the shortest path. If there are reinforcement located parallel to the path of the waves, depending on the proximity of the transducers, the waves can use part through concrete and part through the steel [14[14] INTERNATIONAL ATOMIC ENERGY AGENCY. IAEA-TCS-17: Guidebook on Non-Destructive Testing of Concrete Structures. Viena: 2002, 231 p.].

According to Naik et al. [27[27] MEDEIROS, A. Aplicação do ultra-som na estimativa da profundidade de fendas superficiais e na avaliação da eficácia de injeções em elementos de concreto armado. Dissertação de Mestrado em Engenharia Civil da Universidade Federal de Santa Catarina. Florianópolis, 2007.], in reinforced concrete the pulse velocity is higher than that of simple concrete of same composition, reaching a value around 40% to 70% higher, approaching the order of 5900 m/s in steel, to a solid medium and infinity. Medeiros [28[28] BRITISH STANDARDS INSTITUTION. BSI 1881 - Part 203: Recommendations for measurement of velocity of ultrasonic pulses in concrete. London: 1986. 20 p.], asserts that steel bars parallel to the direction of the readings with the ultrasound by indirect transmission mode can influence the results of UPV tests. The presence of faults, cracks or voids within concrete cause the obstruction of incident wave propagation path, moving it through the outskirts of the defect, resulting in longer propagation. This effect can be used to locate defects larger than 100 mm in diameter or depth, since minor defects do not usually cause significant effects on the propagation time [29].

According to Evangelista [14[14] INTERNATIONAL ATOMIC ENERGY AGENCY. IAEA-TCS-17: Guidebook on Non-Destructive Testing of Concrete Structures. Viena: 2002, 231 p.], there is a minimum length for waves propagation in order to avoid the transducers stay very close, because, in this last case, the results would be significantly influenced by the concrete heterogeneity. For the analysis of concrete structures, transducers are suitable with frequencies between 20 and 150 kHz, being the most used the 54kHz, available commercially in several countries. The choice of transducer frequency stems from the size of the structural element being investigated. However, the connection between the concrete and the transducer is a critical point of the method, as well as the interpretation of the results, which can become a difficult task.

3. Materials e methods

In order to identify and quantify the influence of certain variables on the results of UPV, the experimental program searched to inquire how these tests on two elements made of concrete behave (called walls 1 and 2), inside of which were introduced voids (concrete failures) artificially (Figure 1). The development of the research took place at the Structural Tests and Materials Laboratory of the Federal University of Rio Grande do Sul (LEME/UFRGS), involving the use of a sample set shaped and evaluated by the technical team of the lab. For the production of these elements, materials were used with specific features, described below.

3.1 Molds

To make the molds, plywood laminated was used, in order to represent a real structure. It was decided to produce the molds horizontally, facilitating the concreting of the elements. On the surface in contact with the compensated, a sufficiently smooth face was gotten, simulating surfaces like curtains, slabs, pillars and beams. On the other side, which was unwarped, a rough surface, which simulates foundation blocks, floors and any surface that does not present an ideal finish for readings with ultrasound. Figures 2 (a) and (b) illustrate, respectively, the molds without reinforcement and with reinforcement, used for making up the walls.

The dimensions were defined in 1.70 m x 1.70 m x 0.60 m, thus enabling different distances between transducers, since small readings until the maximum distance possible for an operator to get work ergonomically correct.

The molds have a depth of 60 cm, in order to simulate robust elements, making it possible to evaluate the ability of ultrasound machine to intercept failure of concrete at different depths.

3.2 Concrete

Concrete was dosed in central batching plant, transported via mixer truck to make walls. The characteristic resistance to compression (fck) was set at 30 MPa, for being a fairly usual resistance in many construction sites.

3.3 Reinforcement

Most concrete structures have reinforcement. So, in order to evaluate the influence of these on UPV readings, two steel meshes were used, with density of relatively high reinforcement, composed of structural steel bars of type CA-50 12.5 mm diameter, and spacing of 15 cm.

3.4 Voids

The presence of voids causes the delay of waves, because of the low velocity of sound in air. The interpretation is based on the fact that the time of propagation of ultrasonic pulses can be correlated with the density of the material.

To represent the existence of voids and failures of concrete, styrofoam balls were used with dimensions varying between 5, 10 and 15 cm, in different positions within the walls. The use of styrofoam is justified because of its density, which is quite lower than the concrete, not allowing the penetration of cement paste inside. All the styrofoam balls were fixed with nylon cord, so that each one remains on its place, avoiding the interference of one over the other.

3.5 Concreting of elements

A vibrator needle type was used to concrete. The launch time of concrete was 2 hours. Due care was taken to avoid the displacement of voids (styrofoam balls). In figures 3 (a) and (b) are presented, respectively, the concreting of the element without reinforcement and the concreting of the element with reinforcement.

At the time of concreting, temperature and moisture conditions were 13 C and 70% humidity. After the release of total concrete, the elements remained stored inside the lab, in a covered place, well ventilated and no exposure to weather direct action.

3.6 Influence of technological variables in the tests

There are several variables that influence the NDT results for concrete in determining the UPV. For this research, technological variables chosen are as follows:

3.6.1 Transducers distance

In the tests to determine the UPV, measurements are performed with the variation of the distance between the transducers (grid). Considering the distances between the various measuring points in the tests, carried out with the use of the method of indirect reading, sought to identify whether there is a correlation between the mesh refinement and the ability of voids detection through the UPV method. For this, we used, distances of 25, 50 and 75 cm.

3.6.2 Reinforcement presence

It was sought to verify the influence reinforcement in these essays and quantify it.

3.6.3 Operators

Due to the fact the NBR 8802 [19[19] CHUNG, H. W., LAW, K.S., Diagnosing in situ Concrete by Ultrasonic Pulse Technique. Concrete International. [s.l.], n. 05, p.42-49, 1983.] indicate that the coupling and the pressure between the surfaces of the transducers must be considered satisfactory, we analyzed the influence of using the ultrasound machine with two operators. These was doing to identify if there is difference between the pressures applied by each operator, whereas UPV tests still depend on the human operation, not being automatized tests. Large structures require several operators running measurements simultaneously, since there is a large number of points needed, what justifies this analysis.

3.6.4 Surface conditions

In the blocks, it was formed a smooth surface and other rough, to analyze what is the influence of this variable in both walls.

3.7 Reading processes

To start the UPV readings, it was expected the minimum time of 28 days since the concreting, so as to minimize the influence of the variation of resistance of concrete in the UPV measures. Indirect readings were made as NBR 8802 guidelines [19[19] CHUNG, H. W., LAW, K.S., Diagnosing in situ Concrete by Ultrasonic Pulse Technique. Concrete International. [s.l.], n. 05, p.42-49, 1983.]. For the coupling of transducers, it was used gel. In Figure 4, are shown the combinations of the readings performed.

According to the process of readings presented, the two walls with horizontal, vertical and diagonal readings around each point have been mapped. These readings were grouped together, creating what's called reading quadrants.

At the time of carrying out the tests, predetermined points were used to locate accurately on a map, how long the wave takes to traverse the path between the transmitter-transducer and the transducer-receiver in accordance with their respective coordinate on the structure analyzed. Figure 5 shows how to obtain a set of reading positioned from a selected grid.

With the UPV values obtained, velocity variations were mapped graphically through computer image generator program. Later, statistical analysis are suitable was performed for the validation of the method.

4. Result analysis

The analysis of results obtained from the tests will be presented. Initially, the results of axial compressive strength tests performed on the control specimens are presented. Then, are highlighted the results regarding questions about technological variables, which are divided into effects of grid size, the presence of reinforcement, the operator and the superficial roughness. In the end, the interference that the presence of faults in the concrete, possibly generated in the results.

4.1 Axial compressive strength of bodies-of-proof control

For the control of the concrete used on the walls, were tested 6 bodies-of-evidence of 10 x 20 cm for each block. The result of compressive strength reached average value of 50 Mpa, with a coefficient of variation of 5%. As can be seen, the concrete obtained superior resistance to fck specified, which was 30 MPa. However, the results obtained, even different specification, did not hamper the search.

4.2 Analysis of the effect of technological variables studied

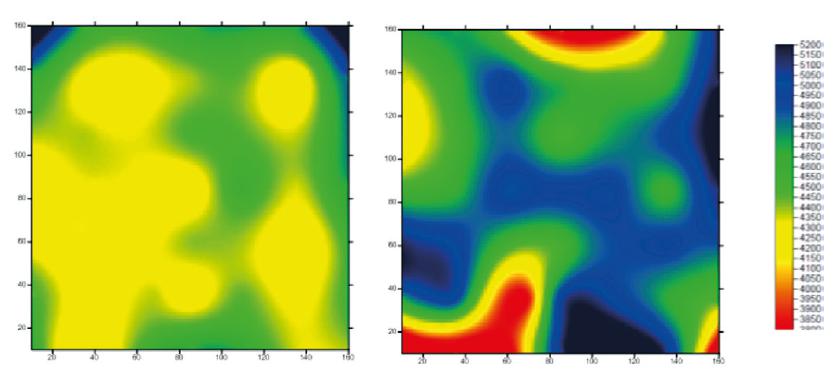

The UPV readings were initiated to 28 days after the concreting and lasted about a week. Initially, many data were taken, so that it could be evaluated the effect of each of the technological variables selected for the study. In Figures 6, 8, 10, 12 and 14 it is possible to see clearly the hottest regions (in red), which indicate lower values of UPV, and colder regions (in blue), which indicate UPV zones with higher values.

(a) images generated on the wall with reinforcement (b) images generated on the wall without reinforcement

(a) images generated from the wall, with experienced operator (B) images generated from the wall with operator training phase.

(a) images generated from the wall with smooth surface (b) images generated from the wall with rough surface

To allow the comparison between two concrete elements used in this research, the variables were analyzed from the results obtained by the experienced operator (presence of reinforcement, roughness and presence of failures). Except in this case the operator variable, which was performed by two different operators, one with experience in testing and another in training phase.

4.2.1 Grid size

As discussed in item 3, three mesh spacing were used to determine changes in the type of response obtained through the mapping of the data in relation to the defect identification. In Figures 6 (a), (b) and (c), can be verified, respectively, the images generated in grid of 75 cm, 50 cm and 25 cm, which were held on the wall without reinforcement and on a smooth face. In the grid of 25 cm is gotten a total of 120 readings, on the grid of 50 cm, 33 readings, and 75 cm grid, 20 readings, all indirect ones.

As it can be seen, the image generated with 25 cm reading grid enabled better representation of different regions, more defined regions when compared to images obtained with readings of 50 cm and 75 cm. In this way, to the analysis of the effects of different variables it was used the grid of 25 cm reading.

The UPV values obtained were between 4300 and 4800 m/s, corresponding to concretes of excellent quality. In general, the choice of the grid significantly influences the interpretation of possible regions committed to a massive concrete. However, this interpretation and the choice of grid are strongly related to the magnitude of the problem to be found. More refined grids have the ability to detect more sensible defects. When the diagnosis of a structure is the most significant extension search, less refined grids are already sufficient and facilitate both the execution of the tests and their analyses. To highlight the differences between grids presented in Figure 6, a statistical analysis was performed through variance (ANOVA), with the aim of comparing the UPV obtained for the different grids. Figure 7 graphically presents the results obtained.

It is possible to observe that the analysis gives us a probability close to zero (with a significance level of 95%), showing that the differences of UPV are significant, when you change the distance between the transducers. With the increase in the grid, it shows a tendency of reduction of the UPV, independent of the presence or absence of reinforcement. This result highlights the importance of maintaining the same distance between transducers, when carried out a survey of the homogeneity of a concrete structure. The mixing of distances within the same structure is not indicated, since it can put at risk the analyses, and may generate wrong interpretations, from velocity reduction with increasing distance, and not a region necessarily suspect.

4.2.2 Presence of reinforcement

Although several authors have studied the influence of the presence of reinforcement in the UPV, the differential of this study is to present elements in size and very close to those used daily in construction sites.

Figures 8 (a) and (b) are, respectively, the images generated from reinforcement walls and walls without presence of reinforcement.

Analyzing visually the images, it is possible to see some differences in coloration. These differences, although represent only a sharp reduction, are significant in the average of the velocity obtained with presence of reinforcement.

This behavior is not only contrary to what some authors claim, but is also contrary to the initial hypothesis of this research. About the homogeneity of the walls, the presence of reinforcement does not harm the interpretation of images, since the mapping of regions with different velocity was similar in both settings. Figure 9 presents the statistical analysis that evaluates the significance of the presence of reinforcement in the analysis of UPV.

It can be observed in the chart above, a slight tendency for the velocity on the wall without reinforcement being larger than on the wall with the presence of reinforcement. When all data were subjected to statistical analysis, the presence of reinforcement used led to significant changes in UPV, reduced UPV with 95% significance level.

4.2.3 Operator

A comparisons concerning the use of the ultrasound machine for different operators was also held. This factor is relevant, because the field analyses demand often several operators working simultaneously. Figure 10 shows two images generated from velocity of two operators, one with experience in previous works and another on training phase, Figure 9 (a) and (b). Both readings were performed on the wall without presence of reinforcement.

Analyzing Figure 9, it can observed that when the readings are made by experienced operator, the image shows more regular, both in colors as the average of the velocity. In the case of the inexperienced operator, were generated lower velocity and regions that could be interpreted as having problems inside the concrete. To prove this fact, Figure 10 presents the statistical analysis made from all velocity obtained by each of the operators in analysis of the same wall.

The analysis of Figure 11 proves exactly what had already been checked in the interpretations of the images generated by the computer program, in which the inexperienced operator obtained velocity significantly below those of experienced operator, generating differences in average of 300 m/s. From this, it is possible to conclude that it is of the utmost importance, for future work in the field, the training team that will perform these jobs. This training should not be limited only to the team that will run the test, but must contemplate, as well, the team that will interpretate the results. As it can be seen, the lack of training of a professional can compromise the analysis of a structure, or part of it, by condemning it, even if this, in fact, is in perfect condition.

4.2.4 Superficial roughness

Another test parameter studied was the roughness of the surface available for UPV readings. Two different roughness were studied, one favourable for tests for been smooth, and the other with enough roughness, however, more found in situations of in situ inspections. Figures 12 (a) and (b) show the influence of smooth and rough surfaces, respectively.

It can be observed that the readings performed by a single operator, in the same structure, but with different surface roughness, are significantly different. With the image generated from the velocity obtained in rough surface, it can be concluded that this setting nullifies any interpretation, due to any noise caused by these irregularities in the propagation of UPV. Figure 13 presents graphically the proof of this effect.

It can be concluded, from the chart, that the roughness on the surface of the concrete influences significantly the UPV values, decreasing them. It is concluded that, in situations where readings are made under these conditions, it is imperative that the regularization of the parsed structure, by means of mechanical wear, especially at the points where the transducers come into contact with the surface.

4.3 Identification of possible failures

Regarding the location of voids inside the concrete, one of the several variables studied, Figure 14 presents the image obtained by combination of parameters that showed greater ability to detect voids. The image presented is the result of the analysis of a wall without reinforcement, tested by a skilled operator, in a grid of 25 cm and smooth face.

It is evidenced that there is a region with velocity below the overall average, exactly in the center of the wall, where it was introduced a considerable void, compared to the size of the analyzed element, represented in Figure 14 for void 1. Due to the size of the void (15 cm), regions above and below it had affected UPV readings, as can be seen.

The advantage of using a finer grid is exactly the location closely to the defects. Minor defects can also be located through this setting, but not with the same accuracy that occurs with the void 1, located in the center. This is the case of the voids 3 and 4, in which the image shows areas with lower average velocity, even though the styrofoam balls have been displaced from its original position during concreting. The void 5 was identified with precision, although the image shows not clearly this difference in velocity. The void 2 was the only defect that the method failed to detect, probably through a combination of reduced size and depth it was in. Despite some uncertainties, the analysis by generating images indicates some trends similar to those that would have been produced during the investigation of a real structure.

In that way, there is the guarantee that, with the support of the appropriate tool to perform the analysis, it is possible to see the concrete areas in which there are differences in uniformity. However, it must be taken into account the size of the concrete surface that will be analyzed, to determine the size of the meshed test to the size of the surface and the magnitude of the heterogeneities to be located. With this investigation, it becomes feasible to infer the detection capability of heterogeneities in the concrete of actual structures, through the use of UPV, combined with the generation of a suitable software, confirming thus the potential use of UPV in the case of inspection of structures.

5 Conclusions

This work aimed to analyze the influences that various parameters produced in the test results of UPV. In these trials, were verified as operational variables: differences of grids, operators with different experience levels, different surfaces, and the presence or absence of reinforcement.

Analyzing and comparing the results obtained from tests, it can be concluded that:

-

the choice of a reading grid will depend on the size of the element and the significance of the size of the defect in its interior. In the situation under consideration, the size of the grid had significant influence on the readings, and the more refined grid (25 cm) presented the best results regarding average velocity and the interpretation of images.

-

it was found that the presence of reinforcement changed significantly the average velocity obtained by reducing velocity, being in disagreement with what has been published by many authors.

-

the operator's experience proved to be the most important and significant variable in the analysis, since the lack of training can lead to erroneous interpretations, in order that the operator is essential to the carrying out of the trials.

A careful choice of parameters enables complete interpretation of the quality of concrete structures. For the localization of voids, the composition of the wall parameters without reinforcement, smooth face, grid 25 cm and experienced operator was that one that presented in more clear and objective regions, in fact, contained defects inside.

The UPV test presents several advantages for the assessment of structures. However, the choice of test parameters is the key factor for a correct interpretation and without mistakes. It is important to note that all the conclusions reached at this work relate exclusively to the studied element.

Physically, there must be a relation between compactness and resistance to compression. The complex and heterogeneous nature of the concrete makes the modeling of the relation an arduous task. A large number of variables, potentially, affect the compactness results correlation, obtained via ultrasonic pulse, and compressive strength of concrete. The analysis of the data obtained by UPV allows to obtain parameters for assessing the characteristics of concrete structures. The crucial point to use the UPV for analysis of concrete structures is the interpretation of the results obtained.

The lack of knowledge about the real situation in which a structure is, is a complicating factor when interventing damaged structures or under suspicion. The lack of information in a situation of emergency character, can make conservative decisions, increasing the scope and complexity of the interventions envisaged, increasing costs or generating additional disorders to its users. The use of the UPV may assist in decision making and establishing intervention strategies.

In general, the case studies reinforce the idea that the use of UPV are useful tools for the analysis of structures. It is confirmed the idea that they have great potential for use in the case of inspection of structures. Its usage allows to get important information to the characterization of the concrete, as well as data on the uniformity and quality of the structure.

This study indicates that UPV tests are sensitive tools to variations of uniformity and density, and can therefore provide important data for decision making regarding the concrete structures. Upon the execution of UPV tests it is possible to contribute to the control of the quality of concrete structures. In this way, it can be inferred that the UPV application is very useful for mapping studies of variations of homogeneity of a structure.

References

-

[1]ISAIA, G.C., O Concreto: da Era Clássica à Contemporânea. In: ISAIA, G. C. (Editor), Concreto: Ensino, Pesquisa e Realizações. São Paulo: IBRACON, 2005. cap.1, vol.1, p.1-44.

-

[2]LORENZI, A. Aplicação de redes neurais artificiais para estimativa da resistência à compressão do concreto a partir da velocidade de propagação do pulso ultra-sônico, Porto Alegre, 2009, Tese (doutorado) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul. Escola de Engenharia, 196p.

-

[3]LORENZI, A.; CAETANO, Luciane Fonseca ; CAMPAGNOLO, João Luiz ; SILVA FILHO, Luiz Carlos Pinto da . An investigation of the suitability of different NDT test methods to detected voids of concrete elements. E-Journal of Nondestructive Testing and Ultrasonics, v. 14, p. ID 7698, 2009.

-

[4]LORENZI, A.; SILVA FILHO, Luiz Carlos Pinto da ; CAMPAGNOLO, João Luiz ; STRIEDER, Adelir Jose ; QUININO, Uziel Cavalcante de Medeiros ; CAETANO, Luciane Fonseca . Estudos de caso sobre avaliação de estruturas de concreto através da utilização de ensaios não destrutivos. Revista ALCONPAT, v. 1, p. 188, 2011.

-

[5]LORENZI, A.; SILVA FILHO, Luiz Carlos Pinto da ; CAMPAGNOLO, João Luiz ; CAETANO, Luciane Fonseca . Analyzing two different data processing strategies for monitoring concrete structures using ultrasonic pulse velocity. Revista ALCONPAT , v. 2, p. 192, 2012.

-

[6]LORENZI, A.; SILVA FILHO, L. C. P. ; CAETANO, Luciane Fonseca ; CHIES, J. A. . Investigation of the Potential for Evaluation of Concrete Flaws Using Nondestructive Testing Methods. ISRN Civil Engineering, v. 2014, p. 1-8, 2014.

-

[7]LORENZI, A.; CAETANO, Luciane Fonseca ; CAMPAGNOLO, João Luiz ; LORENZI, L. S. ; SILVA FILHO, L. C. P. . Application of Ultrasonic Pulse Velocity to Detect Concrete Flaws. E-Journal of Nondestructive Testing and Ultrasonics , v. 11.2015, p. 18430, 2015.

-

[8]CHIES, J. A. ; ADAMATTI, D. S. ; LORENZI, A. ; SILVA FILHO, L. C. P. . Detecção de Falhas em Estruturas de Concreto através de Ensaios Ultrassônicos. In: 57° Congresso Brasileiro do Concreto, 2015, Bonito. Anais do 57° Congresso Brasileiro do Concreto. São Paulo: IBRACON , 2015.

-

[9]NOGUEIRA, C. L., Ensaios Não Destrutivos: Novas Ferramentas para Inspeção de Obras Públicas. In: VI SINAOP - VI SIMPÓSIO NACIONAL DE AUDITORIA EM OBRAS PÚBLICAS. Anais... ,Florianópolis: 2001.

-

[10]MEDEIROS, A., PADARATZ, I.J., PINTO, R.C.A., Influência da Presença de Armaduras na Estimativa da Profundidade de Fissuras Superficiais em Concreto Armado através do Ultra-som. In: CONGRESSSO BRASILEIRO DO CONCRETO (COBRACON 2009), 51, 2009, Curitiba. Anais..., São Paulo: Instituto Brasileiro do Concreto, 2009. 14p. 1 CD-ROM.

-

[11]LORENZI, A.., SILVA FILHO, L.C.P., CAETANO, L.F, LORENZI, L.S., Monitoramento de Estruturas de Concreto através de Ensaios de Velocidade de Propagação do Pulso Ultra-sônico. In: CONGRESSSO BRASILEIRO DO CONCRETO (COBRACON 2009), 51, 2009, Curitiba. Anais..., São Paulo: Instituto Brasileiro do Concreto, 2009. 13p. 1 CD-ROM.

-

[12]BARBOSA, M.T.G., MENDES, L.O., COURA, C.G., Resistência à Compressão do Concreto x Velocidade de Propagação de Pulso Ultrasônico - Estudo de Caso. In: CONGRESSSO BRASILEIRO DO CONCRETO (COBRACON 2009), 51, 2009, Curitiba. Anais.... São Paulo: Instituto Brasileiro do Concreto , 2009. 16p. 1 CD-ROM.

-

[13]EVANGELISTA, A. C. J., Avaliação da Resistência do Concreto usando Diferentes Ensaios Não Destrutivos. 2002. 219p. Tese (Doutorado) - Programa de Pós-Graduação em Engenharia da Universidade Federal do Rio de Janeiro. Universidade Federal do Rio de Janeiro, Rio de Janeiro, 2002.

-

[14]INTERNATIONAL ATOMIC ENERGY AGENCY. IAEA-TCS-17: Guidebook on Non-Destructive Testing of Concrete Structures. Viena: 2002, 231 p.

-

[15]KUMAR, S. A., SANTHANAM, M., Detection of Concrete Damage Using Ultrasonic Pulse Velocity Method. In: NATIONAL SEMINAR ON NON-DESTRUCTIVE EVALUATION, 2006, Hyderabad. Proceedings.... Hyderabad: Indian Society for Non-Destrctive Testing. Disponível em: <Disponível em: http://www.ndt.net > . Acesso em: 18/07/2007.

» http://www.ndt.net -

[16]VALLUZZI, M. R., DA PORTO, F., CASARIN, F., MONTEFORTE, N., MODENA, C., A Contribution to the Characterization of Masonry Typologies by using Sonic Waves Investigations. In: NON-DESTRUCTIVE TESTING IN CIVIL ENGINEERING (NDTCE'09), 2009, Nantes. Procedings.... Paris: Confédération Française por lês Essais Non Desctructifs, 2009. 6p.

-

[17]BREYSSE, D., SOUTSOS, M., FELICETTI, R, KRAUSE, M., LATASTE, J., MOCZKO, A., How to improve the quality of concrete assessment by combining several NDT measurements. In: NON-DESTRUCTIVE TESTING IN CIVIL ENGINEERNG (NDTCE 2009), 2009 , Nantes. Proceedings.... Paris: Confédération Française pour les Essais Non Destructifs, 2009. Disponível em: <Disponível em: http://www.ndt.net >. Acesso em: 18 ago. 2013.

» http://www.ndt.net -

[18]ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS - ABNT. NBR 8802: Concreto Endurecido - Determinação da Velocidade de Propagação da Onda Ultra-sônica: Método de Ensaio. Rio de Janeiro: 2013.

-

[19]CHUNG, H. W., LAW, K.S., Diagnosing in situ Concrete by Ultrasonic Pulse Technique. Concrete International. [s.l.], n. 05, p.42-49, 1983.

-

[20]HAMASSAKI, L. T., Utilização do ultra-som em concreto. 1986. 108p. Dissertação (Mestrado em Engenharia Civil) - Escola Politécnica. Universidade de São Paulo, São Paulo, 1986.

-

[21]CARCAÑO, R. S; PEREYRA, J.B. The influence of the physical properties of aggregates on the ultrasound pulse thecnique in predicting the compressive strength of concrete. Rev. Téc. Ing. Univ. Zulia, Vol. 26, No. 1, 2003.

-

[22]RODRIGUES, G. S. S.; FIGUEIREDO, E. I. P. Módulo de deformação do concreto pelo método ultrassônico; Estudo da Correlação. In: 46º Congresso Brasileiro do Concreto, Florianópolis, 2004. Anais..., IBRACON, Florianópolis, 2004, pp. II 1309-1324.

-

[23]ELVERY, R. H.; IBRAHIM, L. A. M. Ultrasonic assessment of concrete strength at early ages. Megazine of Concrete Research, Dec., 1976, pp 181-190.

-

[24]COSTA, M. R., A importância do material acoplante no ensaio de ultrassonografia. 2013. Disponível em: Disponível em: http://techne.pini.com.br/engenharia-civil/191/a-importancia-do-material-acoplante-no-ensaio-de-ultrassonografia--286986-1.aspx Acesso em: 15/06/ 2013.

» http://techne.pini.com.br/engenharia-civil/191/a-importancia-do-material-acoplante-no-ensaio-de-ultrassonografia--286986-1.aspx -

[25]COMITÉ MERCOSUL DE NORMALIZACION, NM 58: Hormigón endurecido - Determinación de la velocidad de propagación de pulsos ultrasónicos. São Paulo: 1996.

-

[26]NAIK, T. R.; MALHOTRA, V. M.; POPOVICS, J. S., The Ultrasonic Pulse Velocity Method, CRC handbook on nondestructive testing of concrete, Tarun R. Naik and V M Malhotra eds, CRC Press, pp 169-189, 2004.

-

[27]MEDEIROS, A. Aplicação do ultra-som na estimativa da profundidade de fendas superficiais e na avaliação da eficácia de injeções em elementos de concreto armado. Dissertação de Mestrado em Engenharia Civil da Universidade Federal de Santa Catarina. Florianópolis, 2007.

-

[28]BRITISH STANDARDS INSTITUTION. BSI 1881 - Part 203: Recommendations for measurement of velocity of ultrasonic pulses in concrete. London: 1986. 20 p.

Publication Dates

-

Publication in this collection

Apr 2017

History

-

Received

09 May 2015 -

Accepted

04 Aug 2016