ABSTRACT

Stingless bee Trigona spinipes (Hymenoptera: Apidae) is an important pest of calla lily, Zantedeschia aethiopica (L.), damaging flowers, especially the spadix. The aim was to identify the most efficient packaging for bagging calla lily inflorescences, aiming to protect against the attack of stingless bee and to maintain postharvest quality. The experiment was carried out in a calla lily plantation cultivated in soil under 50% shading screen. Treatments consisted in bagging calla lily flowers with: 1) brown kraft paper bag, 2) non-woven fabric (NWF) bag; 3) transparent plastic bag, 4) transparent micro-perforated plastic bag and 5) control (without bagging). The experimental design was completely randomized with 25 replicates and one inflorescence per plot. Inflorescences received treatments when they presented definitive color, but still with completely closed spathe. Seven days after bagging, inflorescences were collected and evaluated for damages caused by insects in the field and the postharvest characteristics. Postharvest quality evaluations of inflorescences were performed for 12 days, observing expansion of the spathe in length and width, stem weight and visual quality expressed by the number of days that remained in each class. The bagging of calla lily inflorescences was efficient in the control of stingless bee, regardless of packaging used, because under these conditions, no inflorescence presented damage. In control, 84% of damaged inflorescences were observed. Differences in postharvest characteristics were observed and inflorescences remained for longer periods in the process of spathe opening, which is characterized by the measurement of their length and width, when packed. Among packages, NWF allowed longer spathe length at the 6th day of evaluation, larger width at 7th day of evaluation and less fresh mass loss at the end of the experiment (8%). In control, reduction of spathe measurements from the first day of evaluation and loss of 11% of fresh mass were observed. It was concluded that NWF is an efficient packaging to protect calla lily against the attack of stingless bee without compromising the postharvest quality of inflorescences.

Keywords:

Zantedeschia aethiopica; alternative control of pests; floriculture; pest management

RESUMO

A abelha irapuá Trigona spinipes (Hymenoptera: Apidae) é uma importante praga do cultivo do copo-de-leite, Zantedeschia aethiopica (L.), pois causa danos nas inflorescências, principalmente na espádice. O objetivo foi identificar a embalagem mais eficiente para o ensacamento de inflorescências de copo-de-leite, visando a proteção contra o ataque da abelha irapuá e a manutenção da qualidade pós-colheita. O experimento foi conduzido em cultivo de copo-de-leite plantado em solo sob 50% de sombreamento. Os tratamentos consistiram do ensacamento das inflorescências com: 1) papel kraft; 2) TNT branco (comercialmente denominado tecido não tecido); 3) plástico transparente; 4) plástico transparente microperfurado; 5) testemunha (sem ensacamento). O delineamento experimental foi inteiramente casualizado contendo 25 repetições e uma inflorescência de copo-de-leite por parcela. As inflorescências receberam os tratamentos quando as mesmas apresentavam-se com a cor definitiva, mas ainda com a espata totalmente fechada. Sete dias após o ensacamento, as inflorescências foram colhidas e avaliadas quanto aos danos ocasionados pelos insetos no campo e quanto às características pós-colheita. As avaliações da qualidade pós-colheita das inflorescências foram realizadas por 12 dias, observando a expansão da espata em comprimento e largura, peso da haste e a qualidade visual expressa pelo número de dias que permaneceram em cada classe. O ensacamento das inflorescências de copo-de-leite foi eficiente no controle da abelha irapuá, independentemente do tipo de embalagem utilizada, pois nessas condições nenhuma inflorescência apresentou danos. Já na testemunha foram observadas 84% das inflorescências danificadas. Observaram-se diferenças nas características pós-colheita, sendo que as inflorescências permaneceram por maior período em fase de abertura da espata, que é caracterizada pelas medidas de comprimento e largura das mesmas, quando embaladas. Dentre as embalagens, destacou-se o TNT que possibilitou maior comprimento da espata ao 6° dia de avaliação, maior largura da mesma ao 7° dia de avaliação e menor perda de massa fresca ao final do experimento (8%). Já a testemunha teve murcha precoce caracterizada pela redução das medidas da espata à partir do primeiro dia de avaliação e perda de 11% da massa fresca. Conclui-se que o TNT mostrou-se como uma embalagem eficiente para proteção contra o ataque da abelha irapuá sem comprometer a qualidade das inflorescências na pós-colheita.

Palavras-chave:

Zantedeschia aethiopica; controle alternativo de pragas; floricultura; manejo de pragas

1. INTRODUCTION

Calla lily, Zantedeschia aethiopica (L.) (Araceae), is a species widely appreciated for the composition of floral arrangements and also of gardens due to the exoticism and beauty of its flowers. Minas Gerais State, Brazil, stands out in the production of calla lily, and the southern region of the state accounts for 44% of calla lily production (LANDGRAF and PAIVA, 2008LANDGRAF, P.R.; PAIVA, P.D.O. Floricultura Produção e comercialização no estado de Minas Gerais. Lavras: Editora da UFLA. 2008. 96p.). Calla lily is a rustic plant and its cultivation is an excellent alternative for family farming due to the low investment for culture implementation and maintenance and high yield per planted area (ALMEIDA and PAIVA, 2012ALMEIDA, E.F.A.; PAIVA, P.D.O. Cultivo de copo-de-leite. p. 148-177. In: ALMEIDA, E.F. A.; PAIVA, P.D.O. (Org.). Produção de Flores de Corte. Lavras: Editora UFLA, 2012. 678p. Vol1.). However, the lack of technologies for pest control in this species is a concern due to the increased use of insecticides. In addition, there are no insecticides and acaricides registered in the Ministério de Agricultura, Pecuária e Abastecimento (MAPA) for pest control in this crop (BRASIL, 2018BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. AGROFIT: Sistemas de Agrotóxicos Fitossanitários. Brasília. 2018. Available in: <http://www.agricultura.gov.br/agrofit> Acessed on: June 3th, 2018.

http://www.agricultura.gov.br/agrofit...

).

Stingless bee, Trigona spinipes (Hymenoptera: Apidae), is a species that causes cuts in flowers, leaves and fruits to build their nests or to penetrate the nectar of some flowers, damaging flowering (NOGUEIRA-NETO, 1962NOGUEIRA-NETO, P. The scutelum nest structure of Trigona spinipes (Fabr., 1793) (Hymenoptera: Apidae). Journal of New York Entomological Society, v.70, p.239-264, 1962.; GALLO et al., 2002GALLO, D.; NAKANO, O.; SILVEIRA NETO, S.; CARVALHO, R.P.L.; BAPTISTA, G.C.; BERTI FILHO, E.; PARRA, J.R.P.; ZUCCHI, R.A.; ALVES, S.B.; VENDRAMIN, J.D.; MARCHINI, L.C.; LOPES, J. R.S.; OMOTO, C. Entomologia agrícola. Piracicaba: FEALQ, 2002. 920p. vol10.). Stingless bee is considered a pest of various crops, mainly fruit trees (BOIÇA J.R. et al., 2004BOICA, J.R., A.L.; SANTOS, T.M.; PASSILONGO, J. Trigona spinipes (Fabr.) (Hymenoptera: Apidae) em espécies de maracujazeiro: flutuação populacional, horário de visitação e danos às flores. Neotropical Entomology, v.33, n.2, p.135-139, 2004. DOI: http://dx.doi.org/10.1590/S1519-566X2004000200002

http://dx.doi.org/10.1590/S1519-566X2004...

; COELHO et al., 2008COELHO, L.R.; LEONEL, S.; CROCOMO, W.B.; LABINAS, A.M. Controle de pragas do pessegueiro através do ensacamento dos frutos. Ciência Agrotecnologia, v.32, n.6, p.1743-1747, 2008. DOI: http://dx.doi.org/10.1590/S1413-70542008000600010

http://dx.doi.org/10.1590/S1413-70542008...

; VENZON et al., 2016VENZON, M.; DIEZ-RODRÍGUEZ, G.I.; FERRAZ, C.S.; LEMOS, F.; NAVA, D.E.; PALLINI, A. Manejo agroecológico das pragas das fruteiras. Informe Agropecuário, v.37, n.293, p.94-103, 2016.) and also ornamental plants such as roses, chrysanthemums, camellias and tropical flowers, causing petals to open and damaging floral buds (IMENES and IDE, 2001IMENES, S.D.L.; IDE, S. Insetos mastigadores e seu controle. In: IMENES, S.D.L.; ALEXANDRE. M.A.V. (Org.). Pragas e Doenças em Plantas Ornamentais. [CD-Rom]. São Paulo: Instituto Biológico, 2001.; WARUMBY et al., 2004WARUMBY, J.F.; COELHO, R.S.B.; LINS, S.R.O. Principais doenças e pragas em flores tropicais no Estado de Pernambuco. Recife: Sebrae, 2004. 98p.; CARVALHO et al., 2009CARVALHO, L.M.; BUENO, V.H.P.; SANTA-CECÍLIA, L.V.C.; SILVA, R.A.; REIS, P.R. Pragas na floricultura: identificação e controle. Informe Agropecuário, v.30, p.36-46, 2009.; 2011CARVALHO, L.M.; BUENO, V.H.P; ALMEIDA, E.F.A. Pragas do copo-de-leite: identificação e danos. Revista Plasticultura, v.17, p. 26-28, 2011.; ALMEIDA et al., 2014ALMEIDA, E.F.A.; PIVETTA, K.F.L.; PAIVA, P.D.O.; ICHINOSE, J.G.S.; GIMENES, R.; LESSA, M.A.; REIS, S.N.; CARVALHO, L.M.; RIBEIRO, M.N.O. Rosa. In: PAIVA, P.D.O.; ALMEIDA, E.F.A. (Org.). Produção de Flores de Corte, Lavras: Editora UFLA, 2014. p.606-708. Vol2.). In calla lily cultivation, this insect cuts floral parts with its mandibles, especially the spadix, in search of resinous substances for the construction of its nest, also collecting pollen and nectar. These injuries can damage the postharvest quality of this ornamental plant and make inflorescences unsuitable for commercialization.

Few strategies are recommended for the control of stingless bees, and the destruction of nests has been basically reported (GALLO et al., 2002GALLO, D.; NAKANO, O.; SILVEIRA NETO, S.; CARVALHO, R.P.L.; BAPTISTA, G.C.; BERTI FILHO, E.; PARRA, J.R.P.; ZUCCHI, R.A.; ALVES, S.B.; VENDRAMIN, J.D.; MARCHINI, L.C.; LOPES, J. R.S.; OMOTO, C. Entomologia agrícola. Piracicaba: FEALQ, 2002. 920p. vol10.; CHIARADIA et al., 2003CHIARADIA, L.A.; CROCE, D.M.; MILANEZ, J.M.; MORGAN, C. Dano e controle da abelha-'irapuá' em eucalipto. Agropecuária Catarinense, v.16, n.1, p.60-62, 2003.; ALMEIDA and PAIVA, 2012ALMEIDA, E.F.A.; PAIVA, P.D.O. Cultivo de copo-de-leite. p. 148-177. In: ALMEIDA, E.F. A.; PAIVA, P.D.O. (Org.). Produção de Flores de Corte. Lavras: Editora UFLA, 2012. 678p. Vol1.). However, this practice, although popularly known, is not permitted in accordance with standards set forth in Resolution 346, of August 16, 2004, of the Conselho Nacional do Meio Ambiente (CONAMA), which recognizes the importance of conservation and utilization of the wildlife of native bees. It is also not recommended to combat this bee with the use of insecticides because it is a species that helps pollination of native plants such as umbu (Spondias tuberosa L.), pomegranate (Punica granatum L.), gritadeira (Palicourea rigida Kunth), virola (Virola surinamensis Rol. ex Rottb.), caroá (Neoglaziovia variegata Arruda) and cultivated plants, including brassicaceae (Brassica oleraceae L.), onion (Allium cepa L.), pumpkin (Cucurbita maxima L.), passion fruit (Passiflora spp.), blueberry (Vaccinium ashei Reade), among others (BARRETO et al., 2006BARRETO, L.S.; LEAL, S.M.; ANJOS, J.C.DOS; CASTRO, M.S. Tipos polínicos dos visitantes florais do umbuzeiro (Spondias tuberosa, Anacardiaceae) no Território Indígena Pankararé, Raso da Catarina, Bahia, Brasil, Candombá Revista Virtual, v.2, n.2, p.80-85, 2006.; MARTINS et al., 2015MARTINS, G.; FERRAZ, R.L.S.; BATISTA, J.L.; BARBOSA, M.A. Incentivo para o plantio de árvores nativas em áreas urbanas para proliferação de abelhas sem ferrão. Acta Apícola Brasílica, v.3, n.2, p.1-9, 2015. DOI: http://dx.doi.org/10.18378/aab.v3i2.3449

http://dx.doi.org/10.18378/aab.v3i2.3449...

). Thus, in recent years, with changes in consumer requirements for certified products with reduced levels or even free of chemical pesticides, there is need for more sustainable strategies for pest management in calla lily cultivation.

Fruit bagging to protect them from pest attack is one of the oldest and most effective phytosanitary practices used by fruit growers (LIPP and SECCHI, 2002LIPP, J.P.; SECCHI, V.A. Ensacamento de frutos: uma antiga prática ecológica para controle da mosca-das-frutas. Agroecologia e Desenvolvimento Rural Sustentável, v.3, n.4, p.53-58, 2002.; HERNANDES et al., 2013HERNANDES, J.L.; BLAIN, G.C.; PEDRO JUNIOR, M.J. Controle de moscas-das-frutas (Diptera: Tephritidae) em cultivo orgânico de ameixa pelo ensacamento dos frutos com diferentes materiais. Revista Brasileira Fruticultura, v.35, n.4, p.1209-1213, 2013. DOI: http://dx.doi.org/10.1590/S0100-29452013000400032

http://dx.doi.org/10.1590/S0100-29452013...

; GRASSWITZ and FIMBRES, 2013GRASSWITZ, T.R.; FIMBRES, O. Efficacy of a physical method for control of direct pests of apples and peaches. Journal of Applied Entomology, v.137, p.790-800, 2013. DOI: https://doi.org/10.1111/jen.12064

https://doi.org/10.1111/jen.12064...

; AZEVEDO et al., 2016AZEVEDO, F.R.; NERE, D.R.; SANTOS, C.A.M.; MOURA, E.S.; AZEVEDO, R. Efeito do ensacamento sobre a incidência de moscas-das-frutas e na qualidade das goiabas. Arquivo do Instituto Biológico, v.83, e0122014, 2016. DOI: http://dx.doi.org/10.1590/1808-1657000122014

http://dx.doi.org/10.1590/1808-165700012...

; VENZON et al., 2016VENZON, M.; DIEZ-RODRÍGUEZ, G.I.; FERRAZ, C.S.; LEMOS, F.; NAVA, D.E.; PALLINI, A. Manejo agroecológico das pragas das fruteiras. Informe Agropecuário, v.37, n.293, p.94-103, 2016.). Bagging fruit to avoid pest attack is a recommended practice, for example, in the production of plums (HERNANDES et al., 2013HERNANDES, J.L.; BLAIN, G.C.; PEDRO JUNIOR, M.J. Controle de moscas-das-frutas (Diptera: Tephritidae) em cultivo orgânico de ameixa pelo ensacamento dos frutos com diferentes materiais. Revista Brasileira Fruticultura, v.35, n.4, p.1209-1213, 2013. DOI: http://dx.doi.org/10.1590/S0100-29452013000400032

http://dx.doi.org/10.1590/S0100-29452013...

), fig (MAZARO et al., 2005MAZARO, S.M.; GOUVÊA, A.; CITADIN, I.; DANNER, M.A. Ensacamento de figos cv. roxo de Valinhos. Scientia Agraria, v.6, n.1/2, p.59-63, 2005. DOI: http://dx.doi.org/10.5380/rsa.v6i1.4595

http://dx.doi.org/10.5380/rsa.v6i1.4595...

), guava (AZEVEDO et al., 2016AZEVEDO, F.R.; NERE, D.R.; SANTOS, C.A.M.; MOURA, E.S.; AZEVEDO, R. Efeito do ensacamento sobre a incidência de moscas-das-frutas e na qualidade das goiabas. Arquivo do Instituto Biológico, v.83, e0122014, 2016. DOI: http://dx.doi.org/10.1590/1808-1657000122014

http://dx.doi.org/10.1590/1808-165700012...

), apple (TEIXEIRA et al., 2011TEIXEIRA, R.; BOFF, M.I.C.; AMARANTE, C.V.T.; STEFFENS, C.A.; BOFF, P. Efeito do ensacamento dos frutos no controle de pragas e doenças e na qualidade e maturação de maçãs ‘Fuji Suprema’. Bragantia, v.70, n.3, p.688-695, 2011. DOI: http://dx.doi.org/10.1590/S0006-87052011000300027

http://dx.doi.org/10.1590/S0006-87052011...

), pitaia (COSTA et al., 2017COSTA, A.C.; RAMOS, J.D.; MENEZES, T.P.; LAREDO, R.R.; DUARTE, M.H. Quality of pitaia fruits submitted to field bagging. Revista Brasileira de Fruticultura, v.39, 2017. DOI: https://dx.doi.org/10.1590/0100-29452017377

https://dx.doi.org/10.1590/0100-29452017...

), peach (COELHO et al., 2008COELHO, L.R.; LEONEL, S.; CROCOMO, W.B.; LABINAS, A.M. Controle de pragas do pessegueiro através do ensacamento dos frutos. Ciência Agrotecnologia, v.32, n.6, p.1743-1747, 2008. DOI: http://dx.doi.org/10.1590/S1413-70542008000600010

http://dx.doi.org/10.1590/S1413-70542008...

), myrtle, blackberry, araçá and pitanga (VENZON et al., 2016VENZON, M.; DIEZ-RODRÍGUEZ, G.I.; FERRAZ, C.S.; LEMOS, F.; NAVA, D.E.; PALLINI, A. Manejo agroecológico das pragas das fruteiras. Informe Agropecuário, v.37, n.293, p.94-103, 2016.). In artichoke culture, Isechi et al. (1998)ISECHI, K., PAIVA, L.C., MALUF, W.R. Como plantar alcachofra. Lavras: UFLA. 1998. (Boletim Técnico de Hortaliças, 11). recommend the bagging of buds or inflorescences with paper bags, aiming at the quality of flowers to ensure a better price in the market. In the floriculture sector, flower bagging is not a common practice and its use can be an effective alternative for the management of stingless bee in the calla lily culture. Therefore, the aim of this study was to identify the most efficient packaging for the bagging of calla lily inflorescences in order to protect them against the attack of stingless bee and to maintain postharvest quality.

2. MATERIAL AND METHODS

The experiment was carried out in the state of Minas Gerais State, Brazil (889 m altitude and geographical coordinates of 21°06'S and 44°15'W). The local climate is temperate (Cwa, according to the Köppen classification), characterized by wet summer and dry winter. Calla lily planting was carried out on January 2013, using seedlings with 50 cm in height, coming from the division of rhizomes. A total of 300 calla lily seedlings were used, which were planted in three beds of double rows with spacing of 1.00 m between rows and 0.50 m between plants, containing 50 plants per row, under cover with 50% shading screen. In planting fertilization, 20 L of cattle manure per m2 and 20 g of magnesium thermophosphate per plant were used. Coverage fertilization consisted of supplying 25 g NPK (10:10:10) per plant every three months. The beginning of calla lily flowering occurred on July 2013 and inflorescences were bagged on August 2013, when higher production occurred.

A total of 125 calla lily inflorescences were selected at the closed opening point (inflorescences with definitive color, but still with completely closed spathe), which were submitted to complete bagging of the upper inflorescence to protect the spathe and spadix, using four types of packages: 1) kraft paper bag; 2) white NWF (commercially termed non-woven fabric bag, with weight of 40 g m-2); 3) transparent plastic bag; 4) micro-perforated transparent plastic bag; 5) Control (without bagging). All packages were standardized in the size of 21 cm x 30 cm.

For the closure of packages, a clamp was fixed at the base of the inflorescence. Bagging was carried out in the morning, randomly distributing the different types of packages in calla lily inflorescences in beds. During the experimental period, the temperature was on average 17.1 °C (variation of 14.5-20.1 °C), and average relative humidity of 68.9% (variation of 56.3%-82%) with occurrence of 0.6 mm of rain on August 18, 2013.

After seven days of bagging inflorescences, when they showed ideal pattern for harvesting (erected spathe tip and absence of pollen on the spadix), stems were harvested in the morning and transported to the laboratory for treatment evaluation.

The damage caused by stingless bee in the spadix of calla lily inflorescence was visually evaluated with the presence or absence of injuries. Spadix that presented dark spots of small or large dimensions (characteristics of the attack of stingless bee) were considered damaged, since these made inflorescences unsuitable for commercialization. These damages were counted to obtain the overall damage percentage.

In order to evaluate the effect of bagging on postharvest quality, calla lily stems were cut to a length of 35 cm, weighed on a precision scale and held individually with the stem base in potable water at depth of 10 cm, placed in a plastic beaker (100 mL). Subsequently, calla lily stems were taken to laboratory with natural light, ambient temperature of 25 ± 5 °C and relative humidity of 75% ± 10%, where they remained for a period of 12 days. During this period, postharvest quality assessments were performed, such as spathe length and width measurements to follow the opening, stem weight and number of days that remained in each quality class, according to Almeida et al. (2007)ALMEIDA, E.F.A.; PAIVA, P.D.O.; LIMA, L.C.O.; RESENDE, M.L.; TAVARES, T.S.; MORAES, D.N.; FONSECA, J.; PAIVA, R. Soluções de condicionamento para conservação pós-colheita de inflorescências de copo-de-leite armazenadas em câmara fria. Ciência Rural, v.37, p.1442-1445, 2007. DOI: http://dx.doi.org/10.1590/S0103-84782007000500035

http://dx.doi.org/10.1590/S0103-84782007...

: Class A1: turgid inflorescences, erected spathe tip, absence of wrinkles or necrosis; Class A2: turgid inflorescences, spathe tip slightly curled down, absence of wrinkles or necrosis; Class B: turgid inflorescences, spathe tip curled down, presence of wrinkles, absence of necrosis; Class C: wilted inflorescences, spathe tip curled down, presence of necrosis. The total number of days in which inflorescences remained in the A1 and A1 + A2 classes was considered the ideal standard for commercialization. For the market pattern (inflorescences that present some quality restrictions, but that can still be marketed), the number of days that inflorescences remained in the A1 + A2 + B classes was considered. Inflorescences that received classification C did not present adequate characteristics for commercialization.

A completely randomized experimental design was used, with five treatments (types of packages and control), 25 replicates and one inflorescence per plot. Data were submitted to analysis of variance and means were compared by the Scott and Knott test at 5% probability. Data on the relationship between parameters of spathe length, spathe width and average weight in relation to the types of packages were tested by means of the polynomial regression analysis to determine the most adjusted curves and respective determination coefficients (R2). SISVAR statistical software (FERREIRA, 2011FERREIRA, D.F. Sisvar: a computer statistical analysis system. Ciência e Agrotecnologia, v.35, n.6, p.1039-1042, 2011. DOI: http://dx.doi.org/10.1590/S1413-70542011000600001

http://dx.doi.org/10.1590/S1413-70542011...

) was used for analyses.

3. RESULTS AND DISCUSSION

Bagging performed with the different types of packages protected calla lily inflorescences from the attack of stingless bee, regardless of type of packaging used, because under these conditions, no inflorescence was damaged. However, in control (without bagging), it was observed that 84% (n=25) of inflorescences were damaged, that is, they presented the spadix with dark spots, with small or large dimensions, making them unsuitable for commercialization. Stingless bee is related to several damages in agricultural crops, due to its behavior and diversified feeding habit. Damage to unpacked calla lily is likely to have been caused when bees collect pollen and nectar or use floral tissue and resins to construct their nests. According to Inouye (1980)INOUYE, D.W. The terminology of floral larceny. Ecology, v.61, p.1251-1253. 1980., when T. spinipes collects nectar, it cuts an opening in the external wall of the nectary, which is called the primary nectar theft, damaging flower's tissues.

It was observed that the use of packages to protect calla lily inflorescences from the attack of stingless bee did not impair coloring and other quality attributes of calla lily inflorescences. This showed that packages did not interfere in the development and opening of inflorescences in the period in which they remained bagged.

However, in relation to the postharvest quality of calla lily inflorescences, differences among treatments were observed. Calla lily spathe remained in the opening phase until reaching a maximum point (curve rise), between 5 and 7 days in all treatments. In control, spathe opening occurred already on the first day of evaluation. After this period, a reduction in spathe length and width (curve decline) was observed, indicating that it started the wilt phase (Figures 1 and 2). According to Tjia and Funnell (1986)TJIA, B.O.; FUNNELL, K.A. Postharvest studies of Zantedeschia inflorescences. Acta Horticulturae, v.181, p.451-458, 1986. DOI: 10.17660/ActaHortic.1986.181.64

https://doi.org/10.17660/ActaHortic.1986...

, it is desirable that the process of spathe opening occurs more slowly so that it remains the largest number of days in the expansion phase, which indicates greater durability of calla lily flower stems.

Spathe length (cm) of Zantedeschia aethiopica inflorescence as a function of the packages used to protect against the attack of Trigona spinipes kept for up to 12 days at 25 ± 5 °C and 75 ± 10% RH.

Spathe width (cm) of Zantedeschia aethiopica inflorescence as a function of the packages used to protect against the attack of Trigona spinipes kept for up to 12 days at 25 ± 5°C and 75% ± 10% RH.

For spathe length, there was a significant difference (p <0.05) among calla lily inflorescences kept under the different packages (Figure 1). Calla lily inflorescences packed with kraft paper bag presented longer length at day 6 (14.9 cm), as well as those packed with NWF bag (13.7 cm). Inflorescences bagged with plastic (micro-perforated or not) started the wilting process earlier, as they presented longer spathe length at day 5, that is, they began to wilt one day before the other inflorescences submitted to the other treatments. Control calla lily that received no packing had the largest spathe length already on the first day of evaluation (13.3 cm) (Figure 1). After this period, the spathe of inflorescences began to wilt, which caused a decrease in their length.

As for spathe width, it was verified that calla lily inflorescences packed with NWF bag presented greater spathe width (12.5 cm) at the 7th day of opening, followed by inflorescences packed with plastic (11.9 cm) and micro-perforated plastic (11.6 cm), at the 6th day of evaluation (Figure 2). Inflorescences packed with kraft paper bag presented the largest widths (13.7 cm) on the 5th day, i.e., two days earlier than those packed with NWF bag. Control had the largest width on the 1st day of evaluation (12.4 cm), which accelerated the senescence process (Figure 2).

A progressive weight loss of calla lily stems submitted to the different treatments during the postharvest quality assessment period was observed (Figure 3).

Average weight (g) of Zantedeschia aethiopica inflorescence as a function of the packages used to protect against the attack of Trigona spinipes kept for up to 12 days at 25 ± 5 °C and 75% ± 10% RH.

The percentage of fresh mass loss of calla lily stems varied significantly (p < 0.05) according to treatments. Calla lily inflorescences packed with kraft paper bag presented higher fresh mass loss (14%), followed by stems packed with micro-perforated plastic (12%) and control (11%). The lowest fresh mass losses were observed in stems packed with NWF bag (8%) and plastic (8%). The weight loss of floral stems can be considered a natural process during the days after harvest, since the senescence process begins and reserves deplete until stem wilting occurs. According to Nowak and Rudnicki (1990)NOWAK, J.; RUDNICKI, R.M. Postharvest handling and storage of cut flowers, florist greens, and potted plants. Portland: Timber, 1990. 210p., fresh mass loss of 10% to 15% already compromises the quality and durability of flowers.

In this study, it was observed that bagging may have contributed to keep postharvest quality, since in control (without bagging), the decrease in spathe length and width was quite pronounced since the first day of assessment (Figures 1 and 2), allied to loss of turgidity (wilted edges), which led to wilting, necrosis and accelerated senescence of inflorescences. According to Tjia and Funnell (1986)TJIA, B.O.; FUNNELL, K.A. Postharvest studies of Zantedeschia inflorescences. Acta Horticulturae, v.181, p.451-458, 1986. DOI: 10.17660/ActaHortic.1986.181.64

https://doi.org/10.17660/ActaHortic.1986...

, the reduction of spathe length and width indicates that its borders are wilted and necrotic, characterizing inflorescence senescence.

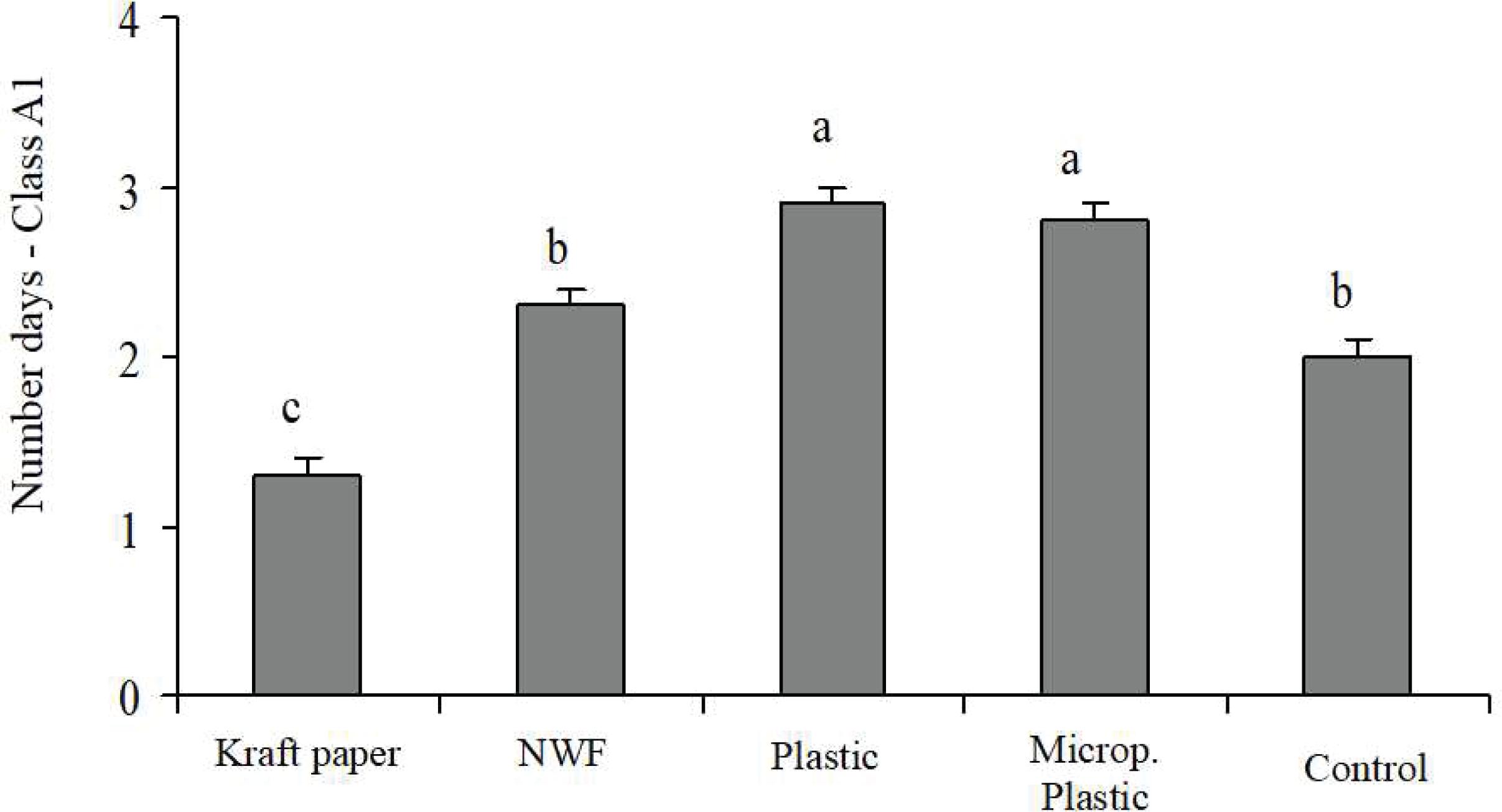

In relation to the quality classification of calla lily inflorescences analyzed during the postharvest evaluation period, it was possible to observe that for A1 class, calla lily inflorescences packed with plastics, micro-perforated or not, presented higher durability (p < 0.05), that is, they remained on average for 2.9 and 2.8 days, respectively, in this class (Figure 4). Inflorescences packed with kraft paper bag remained fewer number of days, with mean of 1.3 days in class A1 (Figure 4).

Number of days that Zantedeschia aethiopica inflorescences remained in A1 class (A1: turgid inflorescences, erected spathe tip, absence of wrinkles or necrosis), as a function of the packages used to protect against the attack of Trigona spinipes. *Means of followed by the same letter not differ by Scott and Knott test at 5% level probability.

For the A1 + A2 and A1 + A2 + B classes, it was observed that calla lily inflorescences varied (p <0.05) according to the type of packaging used (Table 1). Packaged stems presented marketing standard for 8 to 9 days, that is, they remained for this period in A1 + A2 + B class (Table 1). The durability of bagged inflorescences was superior to the standard durability for the species, since according to data from Tjia and Funnell (1986)TJIA, B.O.; FUNNELL, K.A. Postharvest studies of Zantedeschia inflorescences. Acta Horticulturae, v.181, p.451-458, 1986. DOI: 10.17660/ActaHortic.1986.181.64

https://doi.org/10.17660/ActaHortic.1986...

the vase life of Z. aethiopica lasts from 6 to 7 days after cut. Almeida and Paiva (2012)ALMEIDA, E.F.A.; PAIVA, P.D.O. Cultivo de copo-de-leite. p. 148-177. In: ALMEIDA, E.F. A.; PAIVA, P.D.O. (Org.). Produção de Flores de Corte. Lavras: Editora UFLA, 2012. 678p. Vol1. reported that calla lily inflorescences remain for a maximum of 5 days in marketing standard.

Number of days that Zantedeschia aethiopica inflorescences remained in classes A1+A2 and A1+A2+B (±SE) (Class A1: turgid inflorescences, erected spathe tip, absence of wrinkles or necrosis; Class A2: turgid inflorescences, spathe tip slightly curled down, absence of wrinkles or necrosis; Class B: turgid inflorescences, spathe tip curled down, presence of wrinkles, absence of necrosis; Class C: wilted inflorescences, spathe tip curled down, presence of necrosis), as a function of the packaging used to protect against the attack of Trigona spinipes, kept in conditioned room at 25 ± 5 °C and 75% ± 10% RH

Unpacked inflorescences (control) presented lower durability in A1 + A2 + B class (7.3 days), and some of these inflorescences lost their commercial quality as soon as the quality evaluation began (two days), receiving C classification, that is, they did not present adequate characteristics for commercialization.

According to results, kraft paper bag used to protect calla lily inflorescences allowed favorable qualitative characteristics as well as durability in commercial standards, equivalent to the other treatments that received packages. However, there was a greater difficulty in visualizing calla lily inflorescences with the use of kraft paper bag packaging, which made it difficult to identify the right moment of harvest, which is a very important stage in the process of calla lily production.

Packages made with micro-perforated plastics or not, although allowing inflorescences to remain for a greater number of days in the classes with the ideal commercial standards (A1 and A1 + A2), induced precocious wilt when compared to the other treatments. It is believed that the lower postharvest quality of calla lily inflorescences in these packages may be related to the fact that the waterproofing feature of plastic, even when perforated, has affected transpiration and evaporation, impairing gas exchanges, which were not efficient in such a process. According to Rabiza-Świder et al. (2004)Rabiza-Świder, J.; Skutnik, E.; Wachowicz, M.; Łukaszewska, A. Senescence of cut leaves of Zantedeschia aethiopica and Z. elliottiana. Part II. Free amino acids accumulation in relation to soluble protein content. Acta Scientiarum Polonorum Hortorum Cultus, v.3, n.2, p.67-74. 2004. DOI: https://pdfs.semanticscholar.org/8664/9f589574ec2b3dfbca8c8609040d25896a1d.pdf

https://pdfs.semanticscholar.org/8664/9f...

, a very high turgidity level is required for the continuation of normal metabolic activities of calla lily flowers. Paulin (1983)PAULIN, A. Improvement in the preservation of cut flower. Acta Horticulturae, v.138, p.299-304, 1986. DOI: https://doi.org/10.17660/ActaHortic.1983.138.35

https://doi.org/10.17660/ActaHortic.1983...

reported that wilt on flowers is the result of reduced water conduction through the stem, which replaces losses during transpiration. This decrease in water circulation partially or totally inhibits the conduction of liquids. Tjia and Funnell (1986)TJIA, B.O.; FUNNELL, K.A. Postharvest studies of Zantedeschia inflorescences. Acta Horticulturae, v.181, p.451-458, 1986. DOI: 10.17660/ActaHortic.1986.181.64

https://doi.org/10.17660/ActaHortic.1986...

reported that the calla lily spathe during the senescence process loses water and turgidity and, consequently, develops necrosis at tip and borders, followed by tissue dissection due to water stress.

NWF packaging positively influenced the characteristics of calla lily inflorescences regarding spathe opening and provided lower fresh mass loss in the postharvest period and better durability results according to pre-established commercialization standards. This fact possibly occurred due to its permeability, which favored gas exchanges with the environment, compared to the other packages evaluated. The durability of calla lily inflorescences bagged with NWF bag was superior to the standard durability for the species, according to Tjia and Funnell (1986)TJIA, B.O.; FUNNELL, K.A. Postharvest studies of Zantedeschia inflorescences. Acta Horticulturae, v.181, p.451-458, 1986. DOI: 10.17660/ActaHortic.1986.181.64

https://doi.org/10.17660/ActaHortic.1986...

. As a result, it could be inferred that NWF packages have great efficiency in preventing the attack of stingless bee without compromising postharvest quality.

The practice of bagging requires investment in material, time and labor; however, it is a technique that allows the harvesting of quality inflorescences without the use of chemical pesticides for the control of stingless bee. It has been found that NWF packages are easily handled, which decreases the time spent with this operation and consequently the final cost of the process. NWF packaging also has the advantage of being reused on subsequent calla lily inflorescences. In addition calla lily is an inflorescence of high added value, which may justify the investment in the packaging and guarantee better quality of the final product.

Therefore, through the results obtained, it was found that the use of NWF packaging was an adequate way of protecting calla lily inflorescences from the attack of stingless bee without adversely affecting their postharvest quality. This practice has great efficiency to avoid damage caused by stingless bee and can completely eliminate the use of insecticides and maintain postharvest quality without residues of chemicals.

4. CONCLUSIONS

The use of kraft paper bag, transparent plastic, micro-perforated plastic and NWF bag in calla lily cultivation is efficient to avoid injuries in inflorescences caused by stingless bee.

NWF (non-woven fabric) is the most suitable packaging for the protection of calla lily inflorescences against the attack of stingless bee without compromising the postharvest quality of inflorescences.

ACKNOWLEDGMENTS

The authors are grateful to the Fundação de Amparo à Pesquisa de Minas Gerais (FAPEMIG) for financial support and research scholarships to carry out this work.

REFERENCES

- ALMEIDA, E.F.A.; PAIVA, P.D.O.; LIMA, L.C.O.; RESENDE, M.L.; TAVARES, T.S.; MORAES, D.N.; FONSECA, J.; PAIVA, R. Soluções de condicionamento para conservação pós-colheita de inflorescências de copo-de-leite armazenadas em câmara fria. Ciência Rural, v.37, p.1442-1445, 2007. DOI: http://dx.doi.org/10.1590/S0103-84782007000500035

» http://dx.doi.org/10.1590/S0103-84782007000500035 - ALMEIDA, E.F.A.; PAIVA, P.D.O. Cultivo de copo-de-leite. p. 148-177. In: ALMEIDA, E.F. A.; PAIVA, P.D.O. (Org.). Produção de Flores de Corte. Lavras: Editora UFLA, 2012. 678p. Vol1.

- ALMEIDA, E.F.A.; PIVETTA, K.F.L.; PAIVA, P.D.O.; ICHINOSE, J.G.S.; GIMENES, R.; LESSA, M.A.; REIS, S.N.; CARVALHO, L.M.; RIBEIRO, M.N.O. Rosa. In: PAIVA, P.D.O.; ALMEIDA, E.F.A. (Org.). Produção de Flores de Corte, Lavras: Editora UFLA, 2014. p.606-708. Vol2.

- AZEVEDO, F.R.; NERE, D.R.; SANTOS, C.A.M.; MOURA, E.S.; AZEVEDO, R. Efeito do ensacamento sobre a incidência de moscas-das-frutas e na qualidade das goiabas. Arquivo do Instituto Biológico, v.83, e0122014, 2016. DOI: http://dx.doi.org/10.1590/1808-1657000122014

» http://dx.doi.org/10.1590/1808-1657000122014 - BARRETO, L.S.; LEAL, S.M.; ANJOS, J.C.DOS; CASTRO, M.S. Tipos polínicos dos visitantes florais do umbuzeiro (Spondias tuberosa, Anacardiaceae) no Território Indígena Pankararé, Raso da Catarina, Bahia, Brasil, Candombá Revista Virtual, v.2, n.2, p.80-85, 2006.

- BOICA, J.R., A.L.; SANTOS, T.M.; PASSILONGO, J. Trigona spinipes (Fabr.) (Hymenoptera: Apidae) em espécies de maracujazeiro: flutuação populacional, horário de visitação e danos às flores. Neotropical Entomology, v.33, n.2, p.135-139, 2004. DOI: http://dx.doi.org/10.1590/S1519-566X2004000200002

» http://dx.doi.org/10.1590/S1519-566X2004000200002 - BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. AGROFIT: Sistemas de Agrotóxicos Fitossanitários. Brasília. 2018. Available in: <http://www.agricultura.gov.br/agrofit> Acessed on: June 3th, 2018.

» http://www.agricultura.gov.br/agrofit - CARVALHO, L.M.; BUENO, V.H.P.; SANTA-CECÍLIA, L.V.C.; SILVA, R.A.; REIS, P.R. Pragas na floricultura: identificação e controle. Informe Agropecuário, v.30, p.36-46, 2009.

- CARVALHO, L.M.; BUENO, V.H.P; ALMEIDA, E.F.A. Pragas do copo-de-leite: identificação e danos. Revista Plasticultura, v.17, p. 26-28, 2011.

- CHIARADIA, L.A.; CROCE, D.M.; MILANEZ, J.M.; MORGAN, C. Dano e controle da abelha-'irapuá' em eucalipto. Agropecuária Catarinense, v.16, n.1, p.60-62, 2003.

- COELHO, L.R.; LEONEL, S.; CROCOMO, W.B.; LABINAS, A.M. Controle de pragas do pessegueiro através do ensacamento dos frutos. Ciência Agrotecnologia, v.32, n.6, p.1743-1747, 2008. DOI: http://dx.doi.org/10.1590/S1413-70542008000600010

» http://dx.doi.org/10.1590/S1413-70542008000600010 - COSTA, A.C.; RAMOS, J.D.; MENEZES, T.P.; LAREDO, R.R.; DUARTE, M.H. Quality of pitaia fruits submitted to field bagging. Revista Brasileira de Fruticultura, v.39, 2017. DOI: https://dx.doi.org/10.1590/0100-29452017377

» https://dx.doi.org/10.1590/0100-29452017377 - FERREIRA, D.F. Sisvar: a computer statistical analysis system. Ciência e Agrotecnologia, v.35, n.6, p.1039-1042, 2011. DOI: http://dx.doi.org/10.1590/S1413-70542011000600001

» http://dx.doi.org/10.1590/S1413-70542011000600001 - IMENES, S.D.L.; IDE, S. Insetos mastigadores e seu controle. In: IMENES, S.D.L.; ALEXANDRE. M.A.V. (Org.). Pragas e Doenças em Plantas Ornamentais. [CD-Rom]. São Paulo: Instituto Biológico, 2001.

- INOUYE, D.W. The terminology of floral larceny. Ecology, v.61, p.1251-1253. 1980.

- ISECHI, K., PAIVA, L.C., MALUF, W.R. Como plantar alcachofra. Lavras: UFLA. 1998. (Boletim Técnico de Hortaliças, 11).

- GALLO, D.; NAKANO, O.; SILVEIRA NETO, S.; CARVALHO, R.P.L.; BAPTISTA, G.C.; BERTI FILHO, E.; PARRA, J.R.P.; ZUCCHI, R.A.; ALVES, S.B.; VENDRAMIN, J.D.; MARCHINI, L.C.; LOPES, J. R.S.; OMOTO, C. Entomologia agrícola Piracicaba: FEALQ, 2002. 920p. vol10.

- GRASSWITZ, T.R.; FIMBRES, O. Efficacy of a physical method for control of direct pests of apples and peaches. Journal of Applied Entomology, v.137, p.790-800, 2013. DOI: https://doi.org/10.1111/jen.12064

» https://doi.org/10.1111/jen.12064 - HERNANDES, J.L.; BLAIN, G.C.; PEDRO JUNIOR, M.J. Controle de moscas-das-frutas (Diptera: Tephritidae) em cultivo orgânico de ameixa pelo ensacamento dos frutos com diferentes materiais. Revista Brasileira Fruticultura, v.35, n.4, p.1209-1213, 2013. DOI: http://dx.doi.org/10.1590/S0100-29452013000400032

» http://dx.doi.org/10.1590/S0100-29452013000400032 - LANDGRAF, P.R.; PAIVA, P.D.O. Floricultura Produção e comercialização no estado de Minas Gerais. Lavras: Editora da UFLA. 2008. 96p.

- LIPP, J.P.; SECCHI, V.A. Ensacamento de frutos: uma antiga prática ecológica para controle da mosca-das-frutas. Agroecologia e Desenvolvimento Rural Sustentável, v.3, n.4, p.53-58, 2002.

- MARTINS, G.; FERRAZ, R.L.S.; BATISTA, J.L.; BARBOSA, M.A. Incentivo para o plantio de árvores nativas em áreas urbanas para proliferação de abelhas sem ferrão. Acta Apícola Brasílica, v.3, n.2, p.1-9, 2015. DOI: http://dx.doi.org/10.18378/aab.v3i2.3449

» http://dx.doi.org/10.18378/aab.v3i2.3449 - MAZARO, S.M.; GOUVÊA, A.; CITADIN, I.; DANNER, M.A. Ensacamento de figos cv. roxo de Valinhos. Scientia Agraria, v.6, n.1/2, p.59-63, 2005. DOI: http://dx.doi.org/10.5380/rsa.v6i1.4595

» http://dx.doi.org/10.5380/rsa.v6i1.4595 - NOGUEIRA-NETO, P. The scutelum nest structure of Trigona spinipes (Fabr., 1793) (Hymenoptera: Apidae). Journal of New York Entomological Society, v.70, p.239-264, 1962.

- NOWAK, J.; RUDNICKI, R.M. Postharvest handling and storage of cut flowers, florist greens, and potted plants Portland: Timber, 1990. 210p.

- PAULIN, A. Improvement in the preservation of cut flower. Acta Horticulturae, v.138, p.299-304, 1986. DOI: https://doi.org/10.17660/ActaHortic.1983.138.35

» https://doi.org/10.17660/ActaHortic.1983.138.35 - TEIXEIRA, R.; BOFF, M.I.C.; AMARANTE, C.V.T.; STEFFENS, C.A.; BOFF, P. Efeito do ensacamento dos frutos no controle de pragas e doenças e na qualidade e maturação de maçãs ‘Fuji Suprema’. Bragantia, v.70, n.3, p.688-695, 2011. DOI: http://dx.doi.org/10.1590/S0006-87052011000300027

» http://dx.doi.org/10.1590/S0006-87052011000300027 - TJIA, B.O.; FUNNELL, K.A. Postharvest studies of Zantedeschia inflorescences. Acta Horticulturae, v.181, p.451-458, 1986. DOI: 10.17660/ActaHortic.1986.181.64

- Rabiza-Świder, J.; Skutnik, E.; Wachowicz, M.; Łukaszewska, A. Senescence of cut leaves of Zantedeschia aethiopica and Z. elliottiana Part II. Free amino acids accumulation in relation to soluble protein content. Acta Scientiarum Polonorum Hortorum Cultus, v.3, n.2, p.67-74. 2004. DOI: https://pdfs.semanticscholar.org/8664/9f589574ec2b3dfbca8c8609040d25896a1d.pdf

» https://pdfs.semanticscholar.org/8664/9f589574ec2b3dfbca8c8609040d25896a1d.pdf - VENZON, M.; DIEZ-RODRÍGUEZ, G.I.; FERRAZ, C.S.; LEMOS, F.; NAVA, D.E.; PALLINI, A. Manejo agroecológico das pragas das fruteiras. Informe Agropecuário, v.37, n.293, p.94-103, 2016.

- WARUMBY, J.F.; COELHO, R.S.B.; LINS, S.R.O. Principais doenças e pragas em flores tropicais no Estado de Pernambuco. Recife: Sebrae, 2004. 98p.

Publication Dates

-

Publication in this collection

Oct-Dec 2018

History

-

Received

04 May 2018 -

Accepted

23 Aug 2018