Abstract

Lab experiments were carried out to check the effect of some process parameters of nitriding, performed simultaneously with decarburization, on magnetic properties of 3%Si Grain-oriented silicon steel produced by a low slab reheating technology. The samples of (GO) 3% Si steel collected as 0.27mm cold-rolled were submitted to a continuous annealing process at two temperatures, 860 and 900ºC; three annealing times, 63.6, 95.4, and 119.25s; and three ammonia flows 0.1, 0.2, and 0.4Nm3/h. The nitrogen content obtained after the treatments was much higher than those obtained by the currently used process, and it increased as the ammonia flow rates and soaking times were increased, hindering the primary grain growth that adversely affected the magnetic properties. The increase of annealing temperature improved the decarburization and the magnetic properties. The best magnetic properties were found in the sample with the highest primary grain size and the lowest amount of absorbed nitrogen. The success of this practice, in terms of magnetic properties, was pointed out to be based on a drastic reduction on strip nitrogen increase.

Keywords:

electrical steels; grain-oriented; simultaneous decarburization and nitriding

1. Introduction

Grain oriented electrical steel can be manufactured using low slab reheating temperature technology with (Al,Si)N as the main grain growth inhibitor to promote secondary recrystallization during box annealing treatment. In this acquired inhibitor technology, the precipitates can be formed by the strip nitriding with NH3 after decarburization annealing. Decarburization and nitriding are performed into two different chambers separated by sealing devices. In this case, nitriding occurs after decarburization and primary recrystallization, allowing a better control of the primary grain size, an important microstructural parameter that affects the secondary recrystallization process and the final magnetic properties (Kumano et al., 2005KUMANO, T., HARATANI, T., FUJII, N. Effect of nitriding on grain oriented silicon steel bearing aluminum. ISIJ International, v. 45, p. 95-100, 2005.; Xia et al., 2008XIA, Z., KANG, Y., WANG, Q. Developments in the production of grain-oriented electrical steel. Journal of Magnetism and Magnetic Materials, v. 320, n. 23, p. 3229-3233, 2008.; Liao and Hou, 2010LIAO, C. C., C. K. Effect of nitriding time on secondary recrystallization behaviours and magnetic properties of grain-oriented electrical steel. Journal of Magnetism and Magnetic Materials, v. 322, n. 4, p. 434-442, 2010.).

In this study, decarburization and nitriding were carried out simultaneously in the same section, to check the feasibility of this process in order to simplify the equipment and operation practices. The parameters of temperature, ammonia flow and time were varied in order to show their effects on microstructure and nitrogen content in the strip, their consequences on the final structure and magnetic properties of the steel, and verification if good magnetic properties could be achieved by acting on these parameters. A summary of the results of this research and the suggestions to achieve better magnetic results are presented.

2. Material and method

Industrial cold-rolled 0.27mm grain-oriented 3.2% Si samples was obtained by a low slab reheating temperature-1150ºC and Steckel reversible finishing mill. They were subject to hot band annealing at 1000ºC/90s; cooled down in two stages at 7ºC/s to 900ºC; quenched with 40ºC/s to room temperature; and warm rolled at 200ºC in the 2nd and 3rd passes, whose chemical composition is shown in Table 1. They were also processed in the Lab to simulate simultaneous decarburization and nitriding processes by performing a continuous annealing with an atmosphere of 0.5 Nm3/h N2 - 0.5 Nm3/h H2 with the dew point 60ºC, at two temperatures 860 and 900 ºC, three annealing soaking times 63.6, 95.4, and 119.3s and three ammonia flows 0.1, 0.2, and 0.4Nm3/h. Afterwards, the samples were coated with MgO and treated in a box annealing furnace, where they were heated at 100ºC/h from room temperature up to 400ºC, and at 10ºC/h from 400ºC up to 1200ºC in 75%H2 + 25%N2 dry atmosphere. They were kept at 1200ºC for 15h in an atmosphere of 100% H2 and cooled down to the room temperature.

Characterization of the microstructure after decarburization and nitriding was made using optical (OM) and scanning electron microscopy (SEM). Chemical analyses of carbon were made using the Leco-CS600 apparatus, and oxygen and nitrogen using Leco TC436 device. The primary grain size was measured by the free intercept method using Electron Back-Scattering Diffraction (EBSD) with 1um step and 15º tolerance angle, and the secondary grain size was measured manually by the equivalent diameter method. The average Goss orientation deviation texture was obtained by EBSD using a stacking of samples, in order to get a reasonable number of grains being analyzed. Magnetic tests in the longitudinal direction were performed in a MPG10D device (Brockhaus manufacturer) with strips of 100 mm x 30mm measuring core loss at 1.7T/60 Hz and magnetic induction at 800 mA/60 Hz.

3. Results and discussions

Chemical Composition

Nitrogen content in the strip increased when ammonia flow and annealing time increased. Temperature effect on nitrogen content is more expressive for the longer time, as can be seen in the Fig.1. Furthermore, Nitrogen content obtained in all the samples was extremely high in comparison with the standard process whose value varies from 150 to 300ppm (Lee et al., 2002LEE, C. S. et al. Method for manufacturing high magnetic flux density grain oriented electrical steel sheet based on low temperature Slab Heating Method. U.S. Patent 6,451,128 B1, September, 17, 2002.; Joo et al., 2008JOO, H. D. et al. Method of manufacturing grain-oriented electrical steel sheets. Wo Patent 078941. July, 3, 2008.). The nitrogen content in the sample nitrated for 63.6s with ammonia flow of 0.1N/m3 was approximately 533ppm at annealing temperature of 860ºC. However, nitrogen content in the sample that was nitrated for 119.3s at 900ºC with ammonia flow of 0.4N/m3 reached 2885ppm. The higher soaking time and the higher ammonia flow inside the treatment chamber contributed for such achieved high level of nitrogen, in comparison to the standard processes. The presence of higher humidity that forms a more permeable oxide layer also contributed for the nitrogen content increasing.

Influence of the ammonia flow on strip nitrogen content at 860 and 900ºC in different treatment times.

The nitriding atmosphere used in this study was a mixture of hydrogen, nitrogen and ammonia gas and humidity. At temperature in the range of 500-550ºC, the ammonia gas underwent the cracking process and dissociated into nitrogen and hydrogen atoms on the surface of the strips. Thus, the nitrogen freshly generated in this process was subsequently absorbed into the strips by the diffusing through the surface. It can be observed that the nitrogen amounts in the strips increased with increasing nitriding time and ammonia flow (Liao and Hou, 2010LIAO, C. C., C. K. Effect of nitriding time on secondary recrystallization behaviours and magnetic properties of grain-oriented electrical steel. Journal of Magnetism and Magnetic Materials, v. 322, n. 4, p. 434-442, 2010.).

The ammonia flow did not influence the carbon content obtained. An acceptable carbon content level in the strip is C≤ 30ppm (Bernier et al., 2013BERNIER, N., XHOFFER, C., PUTTE, T. V., GALCERAN, M., GODET, S. Structure analysis of aluminium silicon manganese nitride precipitates formed in grain-oriented electrical steels. Materials Characterization, v. 86, p. 116-126, 2013.), a value that was only reached for 119.3s and 95.4s times (Fig. 2). The effectiveness of the decarburization was achieved for all the treatment times at 900ºC, but not for the shortest time at 860ºC, as can be seen in the Fig. 3.

Influence of the treatment time on carbon content at 860 and 900ºC in different ammonia flows.

Structure

The increase on strip nitrogen content decreased the primary grain size, while the treatment at 900ºC produced the larger primary grain size, mainly for a lower nitrogen content (Kumano et al., 2005KUMANO, T., HARATANI, T., FUJII, N. Effect of nitriding on grain oriented silicon steel bearing aluminum. ISIJ International, v. 45, p. 95-100, 2005.; Xiang et al. 2017XIANG, L. et al. Characterizing microstructure and texture after recrystallization annealing of Hi-B steel with simultaneous decarburization and nitriding. Journal of Iron and Steel Research, International, v. 24, p.1215-1222, 2017.), as shown in the Fig. 3. The mean primary grain size varied from 8 to 10µm. This small grain size was a consequence of the nitration occurring simultaneously with the recrystallization and grain growth, that was more intense, forming a big amount of precipitates and causing the nitrogen content obtained in all the samples to be extremely high in comparison with the standard process (from 150 to 300ppm) (Lee et al., 2002LEE, C. S. et al. Method for manufacturing high magnetic flux density grain oriented electrical steel sheet based on low temperature Slab Heating Method. U.S. Patent 6,451,128 B1, September, 17, 2002.; Joo et al., 2008JOO, H. D. et al. Method of manufacturing grain-oriented electrical steel sheets. Wo Patent 078941. July, 3, 2008.). These phenomena happening together inhibit the grain growth in an earlier stage, when the proper primary grain size is not yet achieved.

Fig. 4 shows the microstructure of samples recrystallized under different annealing conditions and there can be observed a slight difference in size between the grains close to the surface and close to the centre of the samples. The grains close to the surface are smaller than those close to the centre due to more intense precipitation that occurred on the steel surface (Fig. 5).

Micrographs of samples after decarburization and nitriding (temperature, time, ammonia flow): a) 860ºC, 63.6s, 0.1Nm3/h; b) 860ºC, 95.4s, 0.4Nm3/h; and c) 900ºC, 63.6s, 0.1Nm3/h; d) 900ºC, 95.4s, 0.4Nm3/h. OM.

Samples after decarburization and nitriding: a) 63.6s, 0.2Nm3/h; b) 119.3s, 0.2Nm3/h; c) 63.6s, 0.4Nm3/h; and d) 119.25s, 0.4Nm3/h. Temperature annealing 860ºC. SEM.

Fig. 5 shows a region of approximately 25µm from the surface with a high concentration of precipitates, and there can be observed an increase of precipitate volume fraction with the increase of annealing time and ammonia flow (increase of nitrogen content).

Vigorous secondary recrystallization occurred on all the samples with an average final grain size around 5.5mm, very close to the typical value for GO produced by low slab reheating temperature (Fig. 6). In spite this, crystalline orientation obtained has around 20º average deviation from Goss orientation. (Fig. 7 and Table 2).

Average Goss orientation deviation for a three sample analysed by EBSD: a) 900ºC, 63.6s, 0.1Nm3/h; b) 860ºC, 119.3s,0.2Nm3/h; c) 860ºC,19.3s,0.4Nm3/h.

Characteristics of pole figures: B=magnetic induction; W=core loss; Dp=primary grain size; β=average deviation of ideal Goss direction.

Magnetic properties

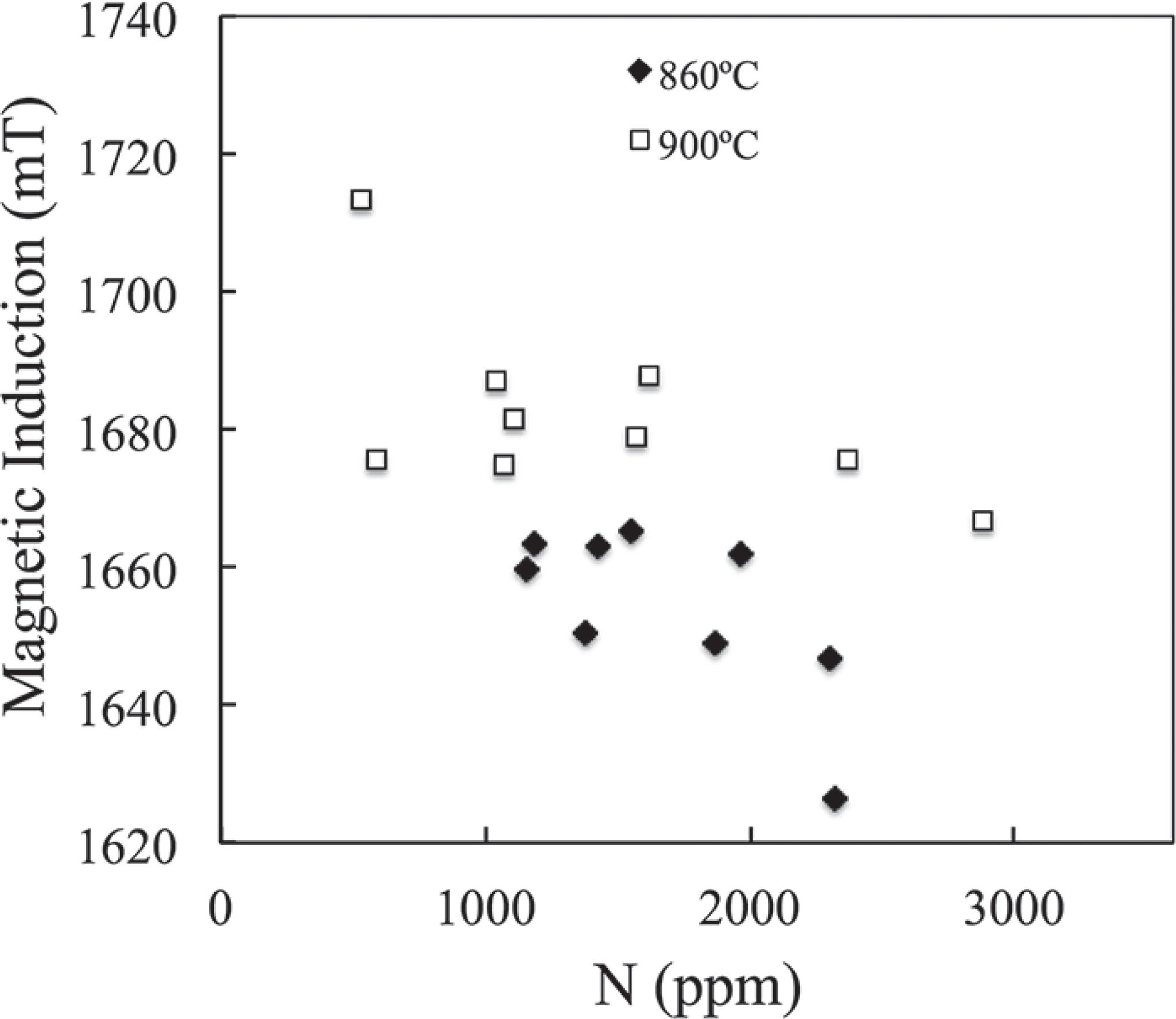

Fig. 8 and 9 show the magnetic induction at 800 A/m as a function of the nitrogen content and primary grain size, respectively, at annealing temperatures 860 and 900ºC. The magnetic induction of the strip steel decreased with the increase of nitrogen content. There was a decrease in the average primary grain size with the increase of nitrogen content, which resulted in a decrease of the magnetic induction. Similar behaviour has been observed for magnetic core loss (Fig. 10).

The crystalline orientation (Fig. 7) observed in all the samples, with about 20º average deviation from ideal Goss orientation, resulted in values of magnetic induction (B8) varying from 1.63 to 1.72T, and the magnetic core loss varying from 1.53 to 1.91W/kg, while with standard process, 1.90T and 1.40W/kg can be obtained. This crystallographic texture can be explained by the small primary grain size and the large nitrogen content of the strips after the simultaneous decarburization and nitriding processes. These processes decreased the onset of a secondary recrystallization temperature, allowing the nucleation and growth of grains with others crystalline orientations. Table 2 presents the characteristics of the three samples tested with small primary grain size and high nitrogen content, resulting in a high average deviation of ideal Goss orientation (Joo et al., 2008JOO, H. D. et al. Method of manufacturing grain-oriented electrical steel sheets. Wo Patent 078941. July, 3, 2008.).

The possibility of success of this process could be increased, if measures such as increasing primary grain size and reduction of strip nitrogen content are taken. In this sense, the incoming strip nitrogen content and ammonia flow could be reduced. In addition, primary grain growth inhibition could be reduced by acting in a chemical composition, slab reheating temperature and hot band annealing thermal cycle parameters. These actions could accelerate the grain growth during the simultaneous decarburization and nitriding processes.

4. Conclusions

The increase of ammonia flow increased the nitrogen amount in the samples hindering the primary grain growth and adversely affected the magnetic properties. The increase of annealing temperature improved the decarburization and the magnetic properties. The best magnetic properties, induction of 1713mT and core loss of 1.54W/kg, were found in the sample with the highest primary grain size and the lowest amount of absorbed nitrogen. The chance of success of this process could increase if a higher primary grain size and lower nitrogen content added in the strip were achieved.

Acknowledgment

The authors would like to thank Aperam South America by using of its facilities and CAPES for supporting this study.

References

- BERNIER, N., XHOFFER, C., PUTTE, T. V., GALCERAN, M., GODET, S. Structure analysis of aluminium silicon manganese nitride precipitates formed in grain-oriented electrical steels. Materials Characterization, v. 86, p. 116-126, 2013.

- JOO, H. D. et al. Method of manufacturing grain-oriented electrical steel sheets. Wo Patent 078941 July, 3, 2008.

- KUMANO, T., HARATANI, T., FUJII, N. Effect of nitriding on grain oriented silicon steel bearing aluminum. ISIJ International, v. 45, p. 95-100, 2005.

- LEE, C. S. et al. Method for manufacturing high magnetic flux density grain oriented electrical steel sheet based on low temperature Slab Heating Method. U.S. Patent 6,451,128 B1, September, 17, 2002.

- LIAO, C. C., C. K. Effect of nitriding time on secondary recrystallization behaviours and magnetic properties of grain-oriented electrical steel. Journal of Magnetism and Magnetic Materials, v. 322, n. 4, p. 434-442, 2010.

- XIA, Z., KANG, Y., WANG, Q. Developments in the production of grain-oriented electrical steel. Journal of Magnetism and Magnetic Materials, v. 320, n. 23, p. 3229-3233, 2008.

- XIANG, L. et al. Characterizing microstructure and texture after recrystallization annealing of Hi-B steel with simultaneous decarburization and nitriding. Journal of Iron and Steel Research, International, v. 24, p.1215-1222, 2017.

Publication Dates

-

Publication in this collection

Oct-Dec 2018

History

-

Received

15 May 2017 -

Accepted

05 June 2018