Abstract

Soilwaste has become an economically viable and sustainable solution in geotechnical engineering, whereas many industrial tailings, when associated with other materials are able to satisfy the properties required in projects. This study aimed to form incorporated soil mixtures with two types of waste aiming to use them in landfill liners. Six soil-waste mixtures were developed, where the waste quantity and the compaction energy were varied. They were normal (NOR) and modified (MOD). The formulated mixtures were: 0R-NOR, 10LM-NOR, 10AG-NOR, 0R-MOD, 10LM-MOD and 10AG-MOD, where 10LM means an addition of 10% lime-mud and 10AG means an addition of 10% agricultural-gypsum, both in relation to dry soil mass. The mixtures were subjected to the variable load permeability test to verify them in terms of the required liner parameters. It is worth mentioning that both compaction energy and waste addition were able to reduce soil permeability, however, the percentage of material added to the mixture was not sufficient to reach values lower than E-07 cm/s.

Keywords:

Soil waste; Permeability; Sanitary landfill; Sustainability

Resumo

A incorporação de resíduos ao solo tornou-se uma solução economicamente viável e sustentável na engenharia geotécnica, uma vez que muitos rejeitos industriais quando associados a outros materiais, se demonstram capazes de sanar propriedades requeridas em projetos. Esta pesquisa objetivou formar misturas de solo incorporadas com dois tipos diferentes de resíduos com a finalidade de empregá-las em camadas impermeáveis (liners) de aterros sanitários. Desenvolveram-se 6 misturas de solo-resíduo, onde foi variado o teor de resíduo e a energia de compactação, sendo elas normal (NOR) e modificada (MOD). As misturas formuladas foram: 0R-NOR, 10LC-NOR, 10GA-NOR, 0R-MOD, 10LC-MOD e 10GA, onde 10LC significa adição de 10% de lama de cal e 10GA significa adição de 10% de gesso agrícola, ambas as adições em relação à massa seca de solo. As misturas foram submetidas ao ensaio de permeabilidade de carga variável para verificá-las quanto aos padrões requeridos para liners. Tanto a energia de compactação quanto a adição do resíduo foram capazes de reduzir a permeabilidade do solo, entretanto, a porcentagem de material adicionada à mistura não foi suficiente para atingir valores menores que E-07 cm/s.

Palavras-chave:

Solo-resíduo; Permeabilidade; Aterro Sanitário; Sustentabilidade

Introduction

Technology and materials science are in constant dynamics in engineering, as well as in society and in the job market. As new products are developed, new needs arise, and a new cycle encourages science to search for answers. In the current scenario, sustainable solutions have become a key parameter in developing new technologies, where many industrial waste and by-products become inputs for geotechnical works.

According to the Panorama of Solid Waste in Brazil (ASSOCIAÇÃO…, 2018ASSOCIAÇÃO BRASILEIRA DE EMPRESAS DE LIMPEZA PÚBLICA E RESÍDUOS ESPECIAIS. Panorama dos resíduos sólidos no Brasil 2017. São Paulo, 2018.), final urban solid waste disposal is increasingly focused on sanitary landfills, representing 59.1% of the final amount collected, while 18% are destined for open pits (dumps) and 22.9% in controlled landfills (without treating leached material).

In a sanitary landfill protection system, the layer of compacted natural clay is one of the essential artifices for maintaining the protection system as they prevent the contaminant from percolating. However, depending on the formation and mineralogical composition of the soils, the material is often unable to meet the permeability, resistance and plasticity parameters that are required. To this end, stabilisation or improvement techniques can be used for the material, to adapt them to impermeable barriers.

This study aimed to incorporate two types of waste from industrial activities into natural residual soil: Lime Mud (Calcium Carbonate) and Agricultural Gypsum (Calcium Sulfate). Through the formulation of soil-waste mixtures, varying the waste content and the compaction energy, the objective was to use this new geotechnical material for an impermeable barrier of a sanitary landfill, as well as to obtain a better understanding of the behaviour of the material regarding its permeability properties.

Theoretical framework

Sanitary landfills are considered one of the most efficient and safe engineering techniques for solid waste disposal as this system can control and monitor pollutants efficiently and safely (ELK, 2007ELK, A. G. H. P. Mecanismo de desenvolvimento limpo aplicado a resíduos sólidos: reduções de emissões na disposição final. Rio de Janeiro: IBAM, 2007. ). Landfill protection elements are defined as structures that allow urban solid waste disposal in smaller areas, ensuring public health and environmental safety (LOCASTRO; DE ANGELIS, 2016LOCASTRO, J. K.; ANGELIS, B. L. D. D. Barreiras de impermeabilização: configurações aplicadas em aterros sanitários. Revista Eletrônica em Gestão, Educação e Tecnologia Ambiental, Santa Maria, v. 20, n. 1, p. 200-210, jan./apr. 2016.).

Waste containment in sanitary landfills works through the bottom lining and the cover. The base coat essentially comprises drainage and waterproofing systems, crucial points for the safety of the structure. It aims to reduce the pollutant transport to the unsaturated zone and the underlying aquifer to concentrations that are not harmful to human health and the environment (BOSCOV, 2008BOSCOV, M. E. G. Geotecnia ambiental. São Paulo: Oficina de Textos, 2008.).

The waterproofing system is formed by a layer of impermeable clay and through the geomembrane. The protective layer (geotextile) is applied to prevent damage caused by the drainage installation and to absorb stress caused by the waste load, such as punctures and tears. The drainage system relieves the hydraulic load on the barrier, in addition to allowing the percolated fluid to be treated and on top of it, the separation and filtration layer prevents direct contact with the waste on the drainage layer (BOSCOV, 2008BOSCOV, M. E. G. Geotecnia ambiental. São Paulo: Oficina de Textos, 2008.).

Most landfills are designed with a set of composite bottom lining, that is, formed by a geomembrane and a layer of compacted clay. According to Manassero, Benson and Bouazza (2000)MANASSERO, M.; BENSON, C. H; BOUAZZA, A. Solid waste containment systems. In: INTERNATIONAL CONFERENCE ON GEOLOGICAL & GEOTECHNICAL, Melbourne, 2000. Proceedings [...] Melbourne, 2000. , composite systems tend to minimise the infiltration of fluids in the soil in relation to those constituted exclusively by geomembranes or purely composed of compacted clays.

Simultaneous use of the clay layer and the geomembrane assumes that the probability of a defect in the geomembrane that coincides with a crack in the clay layer is very low. Therefore, any leaks from the geomembrane will be minimised by the compacted soil, where percolation occurs slowly. It is essential that there is full contact between the two interfaces, otherwise the fluid can pass from the first layer and be directed until it finds the fault in the lower layer (SOARES, 2012SOARES V. Utilização de mistura de solo saprolítico com bentonita na construção de revestimento de fundo de aterros sanitários. São Paulo, 2012. 118 f. Dissertação (Mestrado em Engenharia Civil) - Departamento de Engenharia de Estruturas e Geotécnica, Escola Politécnica, Universidade de São Paulo, São Paulo, 2012. ).

Waterproof barrier

Waterproof barriers, also called liners, are protective layers used both on the cover, to reduce infiltration into the waste cells, and for waterproofing the bottom, to reduce liquid percolation as much as possible so that it does not reach the water and natural soil (KNOP, 2007KNOP, A. Estudo do comportamento de liners atacados por ácido sulfúrico. Porto Alegre, 2007. 256 f. Tese (Doutorado em Engenharia Civil) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2007.; LODI; ZORNBERG; BUENO, 2009LODI, P. C.; ZORNBERG, J. G.; BUENO B. S. Uma breve visão sobre geossintéticos aplicados a aterros sanitários. Revista Tecnologia, Fortaleza, v. 30, n. 2, p. 188-197, dez. 2009.).

Carvalho (1999)CARVALHO, M. F. Comportamento mecânico de resíduos sólidos urbanos. São Carlos, 1999. 330 f. Tese (Doutorado em Geotecnia) - Escola de Engenharia de São Carlos, Universidade de São Paulo, São Carlos, 1999. states that liners must have watertightness, durability, mechanical resistance, and weather resistance properties, and be compatible with the waste that will be disposed of in the landfill.

According to Araujo and Peron (2018)ARAUJO, I. B.; PEJON, O. J. Avaliação da condutividade hidráulica e da capacidade de troca catiônica de misturas de solo arenoso, cimento e argila e seu potencial de uso como barreiras ambientais de fundo em aterros sanitários. In: CONGRESSO BRASILEIRO DE GEOLOGIA DE ENGENHARIA E AMBIENTAL, 16., São Paulo, 2018. Anais [...] São Paulo, 2018. there is no standardisation regarding the capacity to retain contaminants and the necessary resistance to the layer as such characteristics vary according to the project design. Some standards for the design and execution of waterproofing barriers indicate values for the permeability coefficient (k) and minimum thickness, which vary from country to country.

For bottom waterproofing, compacted soil layers (compacted clay liner - CCL), geosynthetics (geomembrane - GM or geocomposite clay liner - GCL) or a system comprising these two materials are commonly used (BOSCOV, 2008BOSCOV, M. E. G. Geotecnia ambiental. São Paulo: Oficina de Textos, 2008.).

According to Boscov (2008)BOSCOV, M. E. G. Geotecnia ambiental. São Paulo: Oficina de Textos, 2008., soils used in impermeable layers have low permeability and must be chemically compatible with the pollutant to be treated over time. The materials to be used in these components are based on the percentage of clay or fines, the liquidity limit and plasticity index, as well as hydraulic conductivity.

The clay layer is the material responsible for maintaining the integrity of the barrier. In order for the hydraulic conductivity to be low, highly plastic clay soils are used with contraction and expansion characteristics with changes in moisture (HEINECK, 2002HEINECK, K. S. Estudo do comportamento hidráulico e mecânico de materiais geotécnicos para barreiras horizontais impermeáveis. Porto Alegre, 2002. 275 f. Tese (Doutorado em Engenharia) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2002. ).

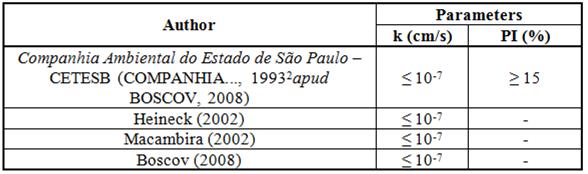

Table 1 shows the permeability coefficient (k) and plasticity index (PI) parameters required for the liners.

Soil permeability

Soils are permeable materials where water is free to flow between pores interconnected by solid particles. As the specific weight of the soil increases, that is, it becomes denser, the void ratio decreases, therefore, the compression of this material will result in a change in its permeability (KNAPPETT; CRAIG, 2014KNAPPETT, J. A.; CRAIG, R. F. Craig mecânica dos solos. 8 ed. Rio de Janeiro: LTC, 2014. ).

As explained by Massad (2016)MASSAD, F. Mecânica dos solos experimental. São Paulo: Oficina de Textos , 2016., the factors that most affect the permeability coefficient are: particle size, void ratio, type of fluid, mineralogical composition and soil structure.

According to the Brazilian Standard 6502 (ABNT, 1995ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 6502: rochas e solos: terminologia. Rio de Janeiro, 1995.), a clayey soil has a fine granulation consisting of fractions with sizes smaller than 0.002 millimeters, presenting cohesion and plasticity. Concerning this position, Lancellota (2009)LANCELLOTA, R. Geotechnical engineering. 2nd. ed. New York: Taylor & Francis, 2009. explains that the term clay is used to refer to particles smaller than 0.002 mm, however, the author points out that this denomination can also be used to refer to specific minerals, which is the case of clay minerals. Clay minerals are hydrated aluminum silicates plus other metal ions, where they can form other primary or secondary minerals.

The hydraulic conductivity of a compacted soil barrier can be verified by combining laboratory and field tests. Laboratory tests, in most cases, are performed using rigid or flexible wall equipment, while field tests are carried out through drilling holes and/or constant or variable load permeameters (MACAMBIRA, 2002MACAMBIRA, I. Q. Comportamento hidráulico de alguns solos lateríticos para uso como barreira impermeável. São Carlos, 2002. 140 f. Dissertação (Mestrado em Geotecnia) - Escola de Engenharia, Universidade de São Paulo, São Carlos, 2002. ).

Behaviour regarding the hydraulic conductivity of compacted soils is related to factors such as: moisture content, compaction method, degree of saturation, hydraulic gradient, granulometric composition, void index, mineralogical composition and mineral activity (MARTINS, 2017MARTINS, L. A. Influência da adição de bentonita em misturas alternativas para a utilização em barreiras impermeabilizantes de aterros sanitários. Vitória, 2017. 108 f. Dissertação (Mestrado em Engenharia Civil) - Universidade Federal do Espírito Santo, Vitória, 2017. ).

Mitchell and Soag (1930)MITCHELL, J. K.; SOAG, K. Fundamentals ofs oil behaviour. 3t h.ed. New York: John Wiley&Sons, 1930. state that concerning fine soils, for compaction dry of optimum, clay particles are flocculated, the resistance to rearrangement between the particles is high, and therefore, a structure with large pores is formed. For higher water content, these new particles are weaker, thus smaller pores are formed.

Concerning the compaction process, Lambe (19581 1 LAMBE, T.W. The engineering behavior of compacted clay. Journal of the Soil Mechanics and Foundations Division, v. 84, n. 8, p. 1-35, 1958. apudMASSAD, 2016MASSAD, F. Mecânica dos solos experimental. São Paulo: Oficina de Textos , 2016.) explains that in the dry optimum, that is, in low moisture contents, the electrolyte concentration is high, which favors the predominance of attractive forces, therefore, the soil flocculate. By adding water, the electrolyte concentration decreases, which allows the expansion of the layer increasing repulsive forces and a decrease in attractive forces.

Impermeable barriers of composite materials

Boscov (2008)BOSCOV, M. E. G. Geotecnia ambiental. São Paulo: Oficina de Textos, 2008. states that other materials can be used as flooring or coverings, where the current trend is to look for recycled waste to replace soils, thus aiming to preserve natural resources and reduce waste disposal in the environment.

Using residual soil from the Botucatu formation and CP II-Z-32 cement (composite cement), Araujo and Peron (2018)ARAUJO, I. B.; PEJON, O. J. Avaliação da condutividade hidráulica e da capacidade de troca catiônica de misturas de solo arenoso, cimento e argila e seu potencial de uso como barreiras ambientais de fundo em aterros sanitários. In: CONGRESSO BRASILEIRO DE GEOLOGIA DE ENGENHARIA E AMBIENTAL, 16., São Paulo, 2018. Anais [...] São Paulo, 2018. prepared soil-cement-bentonite (SCB) and soil-cement-kaolin (SCK) mixtures, aiming to incorporate them into waterproof barriers. The traces were produced by adding 6% of Bentonite/Kaolin and with 11% of moisture in relation to the dry mass. The compaction degree corresponded to 100% of the normal proctor. The specimens underwent a saturation process for 28 days before being tested and the permeability test, at 80 days, resulted in average values of 6.67x10-8 cm/s for the SCB mixtures and 1.97x10- 6 cm/s for the SCK traces, while the permeability of the natural soil was established at 1,067x10-4 cm/s for a moisture content of 7.6%.

Elias, Soares and Souza (2017)ELIAS, D.; SOARES, A. B.; SOUZA, H. B. Aproveitamento de resíduos sólidos: estudo experimental de misturas de solo e cinza volante de carvão mineral. In: CONGRESSO BRASILEIRO DE CARVÃO MINERAL, 5., Criciúma, 2017. Anais [...] Criciúma, 2017. developed mixtures with mineral coal and bentonite fly ash to incorporate them into waterproofing layers in order to mitigate the environmental impact generated by waste disposal into the environment. The research was based on traces with 100% ash, 100% bentonite, 95% ash + 5% bentonite, 90% ash + 10% bentonite, 80% ash + 20% bentonite. The results of the permeability tests at a variable load of these components were in the range of 5.9x10-5 cm/s to 1x10-5 cm/s where the lowest coefficient occurred in the mixture with the highest amount of bentonite in the mixture.

Lime Mud

Lime mud is one of the wastes generated by the paper industry following processes used to extract the cellulose fibers contained in the lignin matrix (SILVA JÚNIOR, 2010SILVA JÚNIOR, W. S. Estudo para a utilização de resíduo da fabricação de papel na construção rodoviária. São Carlos, 2010. 210 f. Dissertação (Mestrado em Ciências) - Escola de Engenharia, Universidade de São Paulo, São Carlos, 2010.).

For the process of separating cellulose fibers adopting the Kraft method, a chemical solution called white bleach is used, consisting of sodium hydroxide (caustic soda), sodium sulfide and small concentrations of sodium carbonate. Thus, by warming these products, unbleached cellulose pulp and black lye are obtained, which is formed by the white lye and dissolved wood components. While the cellulose pulp continues in its manufacturing process, the black liquor undergoes a recycling procedure, where its chemical products are recovered (SILVA JÚNIOR, 2010SILVA JÚNIOR, W. S. Estudo para a utilização de resíduo da fabricação de papel na construção rodoviária. São Carlos, 2010. 210 f. Dissertação (Mestrado em Ciências) - Escola de Engenharia, Universidade de São Paulo, São Carlos, 2010.).

After being evaporated to its solids content (65%), black liquor is burned in the recovery boiler resulting in molten smelt, which when dissolved forms green liquor. From the causticization of the green liquor, that is, after adding lime (CaO), the lime mud is extracted, formed predominantly by calcium carbonate (CaCO3) (ALMEIDA et al., 2007ALMEIDA, H. et al. Composição química de um resíduo alcalino da indústria de papel e celulose (dregs). Química Nova, São Paulo, v. 30, n. 7, 1669-1672, 2007. ).

Agricultural gypsum

Agricultural Gypsum contains approximately 14% of sulfur and 17% of calcium, considered as secondary macronutrients. This compost provides the soil with an efficient source of calcium and sulfur and also reduces aluminum saturation in deeper soil layers (ROSSETE et al., 2002ROSSETE, A. et al. Obtenção do gesso agrícola marcado no 34S (Ca34SO4.2H2O), por reação química entre o H2 34SO4 e o Ca (OH)2. Piracicaba, 2002. Available: <Available: https://www.ipen.br/biblioteca/cd/inac/2002/ENAN/E02/E02_280.PDF >. Access: 15 nov. 2019.

https://www.ipen.br/biblioteca/cd/inac/2...

).

The material used in this study comes from the cleaning process of water contaminated with sulfuric acid. Wastewater from industrial processes is drained through pipes to a settling tank, where it is later sent to treatment ponds.

The material arrives at the treatment with an acidic pH and receives a solution composed of water and approximately 10% of quicklime (CaO) in a tank. The materials are mixed by mechanical equipment and then taken to another tank, where the pH of the effluent is basic. The aqueous solution is fed into a trough where it a polymer is added to separate the solid phase of the material from the liquid phase. While the liquid part of the solution, free of contaminants, returns to another pond, where it will be used again in the factory, the solid part, that is, the generated waste (calcium sulfate), goes to a pressing and drying process, where it is stored and taken to the industrial landfill.

Materials and methods

Materials

The research used a basaltic soil from the municipality of Joaçaba - Santa Catarina (latitude: 27º 9’ 25.11” S; longitude: 51º 31’ 32.17” W) located within the Tigre River Basin. The natural soil was collected through deformed samples which were dried in an oven at a temperature of 100ºC until mass consistency.

In order to characterise and classify the soil by the Transportation Research Board (TRB) system, by the Unified Soil Classification System (USCS) and by the textural method, the material received characterisation procedures such as: determination of natural moisture - NBR 6457 (ABNT, 2016aASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 6457: amostras de solo: preparação para ensaios de compactação e ensaios de caracterização. Rio de Janeiro, 2016a.), granulometric analysis - NBR 7181 (ABNT, 2016bASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7181: solo: análise granulométrica. Rio de Janeiro, 2016b.), liquidity limit - NBR 6459 (ABNT, 2016cASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 6459: solo: determinação do limite de liquidez. Rio de Janeiro, 2016c.), plasticity limit - NBR 7180 (ABNT, 2016dASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7180: solo: determinação do limite de plasticidade. Rio de Janeiro, 2016d.) and the actual specific weight of the particles - DNER-ME 093 (DEPARTAMENTO…, 1994DEPARTAMENTO NACIONAL DE ESTRADAS DE RODAGEM. ME 093/94: solos: determinação da densidade real. Brasília, 1994.).

To develop the research, two types of waste from different industrial processes were used, namely lime mud (calcium carbonate) and agricultural gypsum (calcium sulfate). The waste was collected at the respective supplier companies (Figure 1) and transported in plastic buckets to the Soils, Materials and Asphalt laboratory at the Universidade do Oeste de Santa Catarina (Unoesc).

As informed by technical reports from both companies, the products are classified by NBR 10004 (ABNT, 2004ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 10004: resíduos sólidos: classificação. Rio de Janeiro, 2004.) as Class II A - non-inert, that is, they do not have flammability, corrosivity, reactivity, toxicity or pathogenicity characteristics.

The products were dried in an oven, where the color of the lime mud changed from gray (natural state) to a yellowish white. Afterwards the by-products went through a sieving process as only material passing through mesh #200, with an opening of 0.075 mm, was used in this work.

The waste underwent the following characterisation tests: determination of natural moisture using the oven method, specific mass determination, according to NBR 16605 (ABNT, 2017ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 16605: cimento Portland e outros materiais em pó: determinação da massa específica. Rio de Janeiro, 2017.) and sediment granulometry determination, according to NBR 7181 (ABNT, 2016bASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7181: solo: análise granulométrica. Rio de Janeiro, 2016b.).

Experimental program

Six soil-waste mixtures were defined, in which the addition of waste occurred from the dry soil mass. The compaction energy was also varied in normal and modified mixtures. The identification and formulation of the mixtures can be seen in Table 2.

The mixtures were subjected to the compaction test (normal and modified Proctor, as shown in Table 2 according to the NBR 7182 recommendations (ABNT, 2016eASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7182: solo: ensaio de compactação. Rio de Janeiro, 2016e.). Based on the values arranged in the compaction curve, the indices were obtained: maximum dry apparent specific weight (γd) and optimum moisture (Wot), which were used for the specimen compaction submitted to the permeability test.

Laboratory variable load permeability test

The variable load permeability tests followed the NBR 14545 requirements (ABNT, 2000ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 14545: solo: determinação do coeficiente de permeabilidade de solos argilosos a carAG variável. Rio de Janeiro, 2000.), as indicated in method B.

After compacting their respective specimens, the mixtures were subjected to a saturated hydraulic load carried out in an ascending flow. Specimen saturation occurred from 7 to 10 days for samples with normal energy and reaching up to 21 days for samples with modified energy. The saturation condition was observed by the water output in the upper orifice, without any air bubbles.

Soil permeability coefficient was calculated according to the method proposed by NBR 14545 (ABNT, 2000ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 14545: solo: determinação do coeficiente de permeabilidade de solos argilosos a carAG variável. Rio de Janeiro, 2000.), according to Equation 1.

Where:

a is the internal area of the glass burette;

H is the initial height of the specimen;

A is the initial area of the sample to be tested;

Δt is the difference between time intervals t1 and t2;

h1 is the hydraulic head at time t1; and

h2 is the hydraulic head at time t2.

Results and discussion

Soil and waste characteristics

The soil characteristics can be seen in Table 3.

The soil granulometric curve can be seen in Figure 2.

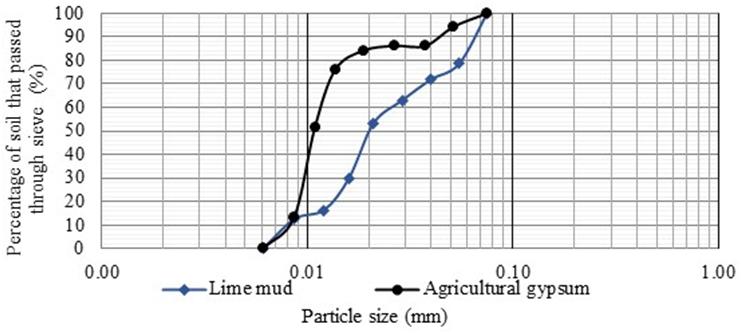

In the granulometric curve, it can be observed that the soil has a predominantly fine fraction, comprising 43.14% of clay and 51.32% of silt, complemented with 5.17% of sand and 0.37% of gravel. The granulometry showed desirable characteristics for use in impermeable barriers as a high content of fines provides lower permeability coefficients when compared to granular soils. The higher percentage of silt (0.002-0.06 mm) compared to clay (<0.06 mm) justifies the addition of waste to seek lower permeabilities. The characteristics of the waste can be found in Table 4. The granulometric curves of the waste used are shown in Figure 3.

Having the granulometric curves of the waste, at first, the predominance of the fine fraction in both curves can be observed. The lime mud (LM) presented 78.60% of its particles smaller than 0.06 mm, with values for D10 at 0.008 mm, D30 at 0.0159 and D60 at 0.026 mm. These values result in a uniformity coefficient (Cu) of 3.25 and a curvature coefficient (CC) of 1.22. Regarding agricultural gypsum (AG), 94.36% of its particles have a diameter of less than 0.06 mm. Moreover, values of D10 at 0.0084 mm, D30 at 0.0097 and D60 at 0.0133 mm were obtained, which characterise a uniformity coefficient (Cu) of 1.35 and a curvature coefficient (CC) of 0.99. For both materials, based on their coefficients, they are classified as uniform particles and that the symmetry of the granulometric curve has well distributed diameters, as explained by Caputo (1988)CAPUTO, H. P. Mecânica dos solos e suas aplicações. 6. ed., rev e ampl. Rio de Janeiro: LTC, 1988..

The granulometric curves for the formulated mixtures are shown in Figure 4.

Analysing the curves formed by adding waste to the soil, it can be observed that there was an improvement, although only slight, in the percentage of fine material resulting from the two mixtures. As expected, while the natural soil presented 94.46% of its particles smaller than 0.06 mm, the mixture with the addition of 10% lime mud (10LM) provided 95.61% of particles within this range. Considering the mixture with 10% addition of agricultural gypsum, the content of fine material less than 0.06 mm was established at 95.01%, thus, 0.55% more than the natural soil.

Table 5 shows the consistency indexes and the plasticity index of the tested mixtures.

Regarding pure soil, without adding waste (0R mixture), according to its plasticity index, it can be classified according to Jenkins as moderately plastic (CAPUTO, 1988CAPUTO, H. P. Mecânica dos solos e suas aplicações. 6. ed., rev e ampl. Rio de Janeiro: LTC, 1988.).

It can be observed that with the inclusion of lime mud waste, there is a decrease in the LL of the 10LM mixture, while for the 10AG mixture, a higher moisture content was necessary for the sample to reach its liquidity limit.

As for the plasticity limit of the mixtures, it can be observed that the addition of the waste in both mixtures caused a reduction in the moisture content necessary for the samples to reach this limit.

The mixtures resulted in plasticity indices of 13% for 0R (soil without waste), 19% for 10LM and 17% for AG. It is evaluated that the addition of waste, in both cases, caused a change in the normal soil plasticity index (0R mixture). It can be observed that the value of the plasticity index of the natural soil does not meet the PI parameter ≥ 15% established by CETESB (COMPANHIA…, 19932 2 COMPANHIA AMBIENTAL DO ESTADO DE SÃO PAULO. Resíduos sólidos industriais. 2. ed. São Paulo: CETESB, 1993. apudBOSCOV, 2008BOSCOV, M. E. G. Geotecnia ambiental. São Paulo: Oficina de Textos, 2008.), which is corrected by the 10LM and 10AG mixtures.

Compaction test

Figure 5 shows the compaction curves of the mixtures.

When analysing the results obtained in the compaction test, there is a clear behaviour of the mixtures when the compaction energy is changed as the mixes compacted with modified energy, in relation to the mixes compacted with normal energy, obtained higher dry apparent specific weight maximum (γd max) while the optimum moisture (Wot) of each mixture decreases.

When verifying the addition of waste to the traces, it can be observed that in the normal energy and in the modified energy, the addition of 10% of lime mud (10LM) in relation to the mixture without waste (0R) caused an increase, although slight, in the γd max of the mixture. In terms of optimum moisture, it was analysed that there were no significant changes, both in the normal and modified energy.

However, adding 10% of agricultural gypsum waste (10AG), it was noticed that in both compaction energies there was a reduction in the γd max of the mixture in relation to the 0R and 10LM traces. This behavior can be understood as a function of the specific weight of the waste (2.60 g/cm³), which is smaller than the specific weight of the soil (2.91 g/cm³) and lime mud (2.77 g/cm³). Regarding the optimal moisture content of this trace, it is estimated that the value increased in relation to the 0R and 10LM mixtures, in both energies. This fact can be interpreted in relation to the granulometry of agricultural gypsum, which has smaller particles in relation to lime mud, thus providing a greater specific surface for the mixture.

Permeability test

Figure 6 shows the characteristics of the samples that were submitted to the permeability test.

The parameters obtained for each trace can be seen in Table 6.

Comparing the maximum dry apparent specific weight (γd max) obtained in the Proctor test with the same parameter for the samples tested, it appears that there were no large variations as this parameter can also be confirmed by the degree of compaction, which was in the range of 100% for all samples. The same analysis can be done for the optimal moisture (Wot), considering that only two mixtures had this variable below the result obtained by the compaction test.

Concerning the porosity, it appears that this index decreased for all mixtures when analysing the change in compaction energy from normal to modified. Regarding the addition of the waste, both in normal and modified energy, when 10% of lime mud (LM) was added, it was observed that there was a decrease in the porosity of the material in relation to the mixture without waste (0R). When 10% of agricultural gypsum (10AG) was added, the porosity of the specimen increased, both in relation to the 0R and 10LM mixtures.

Figure 7 shows the development of permeability tests performed with the formulated mixtures. Having the variables obtained in the test, the values of the permeability coefficient (k) were calculated according to the calculation model proposed by NBR 14545 (ABNT, 2000ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 14545: solo: determinação do coeficiente de permeabilidade de solos argilosos a carAG variável. Rio de Janeiro, 2000.). The values were adjusted through a coefficient Rt, which relates the viscosity of the test water with the viscosity of the water at a temperature of 20ºC, therefore, the values used in this work refer to the permeability coefficient at a temperature of 20ºC (k20).

The mixtures were evaluated by the median value of the data found in the test. We chose to use this feature due to the large variation of values for each sample as this tool provides a more representative value as it is not affected by the maximum and minimum values.

The 0R-NOR mixture, which was compacted with normal energy and has no waste addition, that is, composed only of natural soil, presented a permeability coefficient (k20) of 3.222E-06 cm/s, with a constant value of 85 minutes. In relation to this data, according to Terzaghi, Peck and Mesri (1995)TERZAGHI, K.; PECK, R. B.; MESRI, G. Soilmechanics in engineeringpractice. 3th . ed. New York: Wiley International, 1995. the soil can be considered with poor or low permeability, characteristic of organic and inorganic silts, mixtures of sand, silt and clay or stratified clays.

When analysing the 0R-MOD mixture, compacted with modified energy and without adding waste, the permeability coefficient (k20) changed to the value of 2.779E-07 cm/s, obtaining consistency in the test from 93 minutes of test, with a reduction at 166 minutes and later stabilising again. Note that the change from normal to modified energy resulted in a permeability reduction of 91.37%.

Considering the mixtures in which waste was added, it appears that the 10LM-NOR mixture presented a permeability coefficient (k20) of 9.915E-07 cm/s. This mixture had an oscillating behaviour throughout the test, showing a constant value from 188 minutes onwards. It can be observed that the incorporation of the waste in relation to the white mixture with the same compaction energy (0R-NOR), led to a reduction of k20 in 69.23%.

The 10LM-MOD mixture presented a permeability coefficient value (k20) of 1.116E-07 cm/s, in which the test showed the greatest constancy over time. This mixture, when compared to 10LM-NOR, showed a reduction of 88.74% in its permeability when changing the energy from normal to modified.

When dealing with the mixtures with AG waste, it can be observed that the 10AG-NOR mixture showed a permeability coefficient (k20) of 8.503E-07 cm/s and tended to remain constant at 197 minutes. This mixture, when compared to the mixture without waste and compacted with the same energy (0R-NOR), showed a reduction of 73.61% in the value of the permeability coefficient.

Regarding the 10AG-MOD mixture, its permeability coefficient was in the range of 6.469E-07 cm/s, with a tendency to stabilise its value at 103 minutes of testing. In this mixture, it can be seen that the compaction energy had little effect in terms of reducing permeability as the energy exchange caused a reduction of only 23.92% in value.

Figure 8 shows the range of values obtained for each test performed with the normal energy mixtures, as well as the median of the values.

The 0R-NOR trace, consisting exclusively of normal soil, presented k20 values throughout the test that varied from 3.967E-06 to 3.040E-06 cm/s, marking the median value at 3.222E-06 cm/s. For the 10LM-NOR mixture, the test was the most representative, where the mixture varied from 1.187E-06 to 8.118E-07 cm/s, with a median value of 9.915E-07 cm/s. The 10AG-NOR trace sample had results ranging from 1.306E-06 to 7.225E-07 cm/s, setting the median value at 8.503E-07 cm/s.

In this graph, it can be observed that the lowest permeability values achieved are marked for the 10AG-NOR mixture, where the waste used is agricultural gypsum. From this result, it is assumed that the plastic behaviour of the material (IP=17 and fines content of 95.01%) had a greater influence on the reduction of permeability as the porosity and the maximum dry apparent specific weight (γd max) of the sample showed higher values in relation to the other two mixtures.

After this data interpretation, it can be seen that comparing the compacted mixtures with normal energy, the insertion of the waste was beneficial as it had the ability to reduce the permeability coefficient of the 0R-NOR mixture (natural soil without addition) of E-06 to E-07. However, none of the permeability coefficients achieved for the compacted mixtures with normal energy reached values lower than E-07, as requested by Boscov (2008BOSCOV, M. E. G. Geotecnia ambiental. São Paulo: Oficina de Textos, 2008.), CETESB (COMPANHIA…, 19932 2 COMPANHIA AMBIENTAL DO ESTADO DE SÃO PAULO. Resíduos sólidos industriais. 2. ed. São Paulo: CETESB, 1993. apudBOSCOV, 2008BOSCOV, M. E. G. Geotecnia ambiental. São Paulo: Oficina de Textos, 2008.), Heineck (2002HEINECK, K. S. Estudo do comportamento hidráulico e mecânico de materiais geotécnicos para barreiras horizontais impermeáveis. Porto Alegre, 2002. 275 f. Tese (Doutorado em Engenharia) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2002. ) andMacambira (2002)MACAMBIRA, I. Q. Comportamento hidráulico de alguns solos lateríticos para uso como barreira impermeável. São Carlos, 2002. 140 f. Dissertação (Mestrado em Geotecnia) - Escola de Engenharia, Universidade de São Paulo, São Carlos, 2002. .

Figure 9 shows the range of values obtained for each test performed with the modified energy mixtures, as well as the median of the values.

The 0R-MOD trace, which has no waste addition, throughout the test obtained k20 values that ranged from 4.082E-07 to 2.406E-07 cm/s, indicating the median value at 2.779E-07 cm /s. Concerning the 10LM-MOD mixture, responsible for the lower permeability, the range of values was established in the range of 1.512E-07 to 8.911E-08 cm/s, marking its median permeability at 1.116E-07 cm/s. The 10AG-MOD trace sample showed results that were in the range of 7.040E-07 to 5.523E-07 cm/s, with a median value of 6.469E-07 cm/s.

Among the mixtures compacted with modified energy, it appears that the lowest permeability values are found in the 10LM-MOD trace, where the waste used is lime mud. Thus, it is noticeable that the good performance of this mixture regarding the reduction of permeability is justified by the decrease in the porosity of the material, through the increase of the maximum dry apparent specific weight (γd max) of the compacted sample.

Conclusion

It can be concluded that although the mixtures did not reach permeability values equal to or less than 1.00 E-07 cm/s, as required by the bibliography, they presented reduced permeability values in relation to the trace without adding waste and compressed with normal energy (0R-NOR).

Regarding the granulometric compositions, the insertion of both types of waste provided optimisation in the fines of the natural soil (0R mixture) for formulated materials (10LM and 10AG). This can also be seen in the plasticity index (PI) of the mixtures which were increased adding by-products and began to meet the required conditions.

It was observed that the compaction energy had a significant influence when its variation within the same content was analysed, as well as permeability reduction values of up to 91.37%. It was also analysed that the addition of the waste also reduced the permeability of the materials as the addition of 10% of agricultural gypsum to the soil reduced the permeability by 73.61%.

Research has shown that both types of waste have a good potential for reducing permeability when incorporated into natural soil. However, some adjustments still need to be made in the proportion of the added material or another stabilisation technique should be used, such as substitution.

References

- ALMEIDA, H. et al Composição química de um resíduo alcalino da indústria de papel e celulose (dregs). Química Nova, São Paulo, v. 30, n. 7, 1669-1672, 2007.

- ARAUJO, I. B.; PEJON, O. J. Avaliação da condutividade hidráulica e da capacidade de troca catiônica de misturas de solo arenoso, cimento e argila e seu potencial de uso como barreiras ambientais de fundo em aterros sanitários. In: CONGRESSO BRASILEIRO DE GEOLOGIA DE ENGENHARIA E AMBIENTAL, 16., São Paulo, 2018. Anais [...] São Paulo, 2018.

- ASSOCIAÇÃO BRASILEIRA DE EMPRESAS DE LIMPEZA PÚBLICA E RESÍDUOS ESPECIAIS. Panorama dos resíduos sólidos no Brasil 2017. São Paulo, 2018.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 10004: resíduos sólidos: classificação. Rio de Janeiro, 2004.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 14545: solo: determinação do coeficiente de permeabilidade de solos argilosos a carAG variável. Rio de Janeiro, 2000.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 16605: cimento Portland e outros materiais em pó: determinação da massa específica. Rio de Janeiro, 2017.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 6457: amostras de solo: preparação para ensaios de compactação e ensaios de caracterização. Rio de Janeiro, 2016a.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 6459: solo: determinação do limite de liquidez. Rio de Janeiro, 2016c.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 6502: rochas e solos: terminologia. Rio de Janeiro, 1995.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7180: solo: determinação do limite de plasticidade. Rio de Janeiro, 2016d.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7181: solo: análise granulométrica. Rio de Janeiro, 2016b.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7182: solo: ensaio de compactação. Rio de Janeiro, 2016e.

- BOSCOV, M. E. G. Geotecnia ambiental. São Paulo: Oficina de Textos, 2008.

- CAPUTO, H. P. Mecânica dos solos e suas aplicações. 6. ed., rev e ampl. Rio de Janeiro: LTC, 1988.

- CARVALHO, M. F. Comportamento mecânico de resíduos sólidos urbanos. São Carlos, 1999. 330 f. Tese (Doutorado em Geotecnia) - Escola de Engenharia de São Carlos, Universidade de São Paulo, São Carlos, 1999.

- DEPARTAMENTO NACIONAL DE ESTRADAS DE RODAGEM. ME 093/94: solos: determinação da densidade real. Brasília, 1994.

- ELIAS, D.; SOARES, A. B.; SOUZA, H. B. Aproveitamento de resíduos sólidos: estudo experimental de misturas de solo e cinza volante de carvão mineral. In: CONGRESSO BRASILEIRO DE CARVÃO MINERAL, 5., Criciúma, 2017. Anais [...] Criciúma, 2017.

- ELK, A. G. H. P. Mecanismo de desenvolvimento limpo aplicado a resíduos sólidos: reduções de emissões na disposição final. Rio de Janeiro: IBAM, 2007.

- HEINECK, K. S. Estudo do comportamento hidráulico e mecânico de materiais geotécnicos para barreiras horizontais impermeáveis. Porto Alegre, 2002. 275 f. Tese (Doutorado em Engenharia) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2002.

- KNAPPETT, J. A.; CRAIG, R. F. Craig mecânica dos solos. 8 ed. Rio de Janeiro: LTC, 2014.

- KNOP, A. Estudo do comportamento de liners atacados por ácido sulfúrico. Porto Alegre, 2007. 256 f. Tese (Doutorado em Engenharia Civil) - Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2007.

- LANCELLOTA, R. Geotechnical engineering. 2nd ed. New York: Taylor & Francis, 2009.

- LOCASTRO, J. K.; ANGELIS, B. L. D. D. Barreiras de impermeabilização: configurações aplicadas em aterros sanitários. Revista Eletrônica em Gestão, Educação e Tecnologia Ambiental, Santa Maria, v. 20, n. 1, p. 200-210, jan./apr. 2016.

- LODI, P. C.; ZORNBERG, J. G.; BUENO B. S. Uma breve visão sobre geossintéticos aplicados a aterros sanitários. Revista Tecnologia, Fortaleza, v. 30, n. 2, p. 188-197, dez. 2009.

- MACAMBIRA, I. Q. Comportamento hidráulico de alguns solos lateríticos para uso como barreira impermeável. São Carlos, 2002. 140 f. Dissertação (Mestrado em Geotecnia) - Escola de Engenharia, Universidade de São Paulo, São Carlos, 2002.

- MANASSERO, M.; BENSON, C. H; BOUAZZA, A. Solid waste containment systems. In: INTERNATIONAL CONFERENCE ON GEOLOGICAL & GEOTECHNICAL, Melbourne, 2000. Proceedings [...] Melbourne, 2000.

- MARTINS, L. A. Influência da adição de bentonita em misturas alternativas para a utilização em barreiras impermeabilizantes de aterros sanitários. Vitória, 2017. 108 f. Dissertação (Mestrado em Engenharia Civil) - Universidade Federal do Espírito Santo, Vitória, 2017.

- MASSAD, F. Mecânica dos solos experimental. São Paulo: Oficina de Textos , 2016.

- MITCHELL, J. K.; SOAG, K. Fundamentals ofs oil behaviour. 3t h.ed. New York: John Wiley&Sons, 1930.

- ROSSETE, A. et al Obtenção do gesso agrícola marcado no 34S (Ca34SO42H2O), por reação química entre o H2 34SO4 e o Ca (OH)2 Piracicaba, 2002. Available: <Available: https://www.ipen.br/biblioteca/cd/inac/2002/ENAN/E02/E02_280.PDF >. Access: 15 nov. 2019.

» https://www.ipen.br/biblioteca/cd/inac/2002/ENAN/E02/E02_280.PDF - SILVA JÚNIOR, W. S. Estudo para a utilização de resíduo da fabricação de papel na construção rodoviária. São Carlos, 2010. 210 f. Dissertação (Mestrado em Ciências) - Escola de Engenharia, Universidade de São Paulo, São Carlos, 2010.

- SOARES V. Utilização de mistura de solo saprolítico com bentonita na construção de revestimento de fundo de aterros sanitários. São Paulo, 2012. 118 f. Dissertação (Mestrado em Engenharia Civil) - Departamento de Engenharia de Estruturas e Geotécnica, Escola Politécnica, Universidade de São Paulo, São Paulo, 2012.

- TERZAGHI, K.; PECK, R. B.; MESRI, G. Soilmechanics in engineeringpractice. 3th . ed. New York: Wiley International, 1995.

-

1

LAMBE, T.W. The engineering behavior of compacted clay. Journal of the Soil Mechanics and Foundations Division, v. 84, n. 8, p. 1-35, 1958.

-

2

COMPANHIA AMBIENTAL DO ESTADO DE SÃO PAULO. Resíduos sólidos industriais. 2. ed. São Paulo: CETESB, 1993.

-

3

COMPANHIA AMBIENTAL DO ESTADO DE SÃO PAULO. Resíduos sólidos industriais. 2. ed. São Paulo: CETESB, 1993.

Publication Dates

-

Publication in this collection

09 Sept 2022 -

Date of issue

Oct-Dec 2022

History

-

Received

15 Nov 2021 -

Accepted

18 Apr 2022