Abstract

Broken kernels are among the by-products of processing cashew nuts which have less commercial value. The present work aimed to obtain a cashew kernel protein concentrate from broken kernels, and then characterize it as well as using it in a vegetable burger formulation. The concentrate was obtained by isoelectric precipitation at four different pHs and subsequent drying. Higher yield was 58.6% of proteins (pH 4.0 and 4.5). The concentrate showed Water Absorption Capacity (WAC) of 1.85 mL/g and Oil Absorption Capacity (OAC) of 1.06 mL/g, as well as low solubility in aqueous medium and low foaming capacity. The concentrate was used in vegetable burger production as a substitute for soybean protein. The burgers were submitted to sensory evaluation and obtained an average of 6.6 on a nine-point scale, thus being within the acceptance zone. Regarding the purchase intent, 60% of the judges would probably or would certainly buy the product. Therefore, the cashew kernel protein concentrate can be used as a protein ingredient for food formulation. Producing cashew kernel protein concentrate allows the use of broken kernels generated in the cashew nut industrial process.

Keywords:

Anacardium occidentale L.; Acid precipitation; Functional properties; Nut; Protein ingredient; Proximate composition

Resumo

Amêndoas quebradas estão entre os subprodutos do processamento da castanha de caju e possuem menor valor comercial. O objetivo deste trabalho foi obter um concentrado proteico de amêndoas quebradas de castanha de caju, caracterizá-lo e utilizá-lo em uma formulação de hambúrguer vegetal. O concentrado foi obtido por precipitação isoelétrica em quatro valores de pH diferentes com subsequente secagem. O maior rendimento foi de 58,6% de proteínas nos pHs de 4,0 e 4,5. Quanto à capacidade de absorção de água e de óleo, o concentrado apresentou os seguintes resultados, respectivamente, 1,85 mL/a e 1,06 mL/g, assim como baixa solubilidade em meio aquoso e baixa capacidade de formação de espuma. Como uma alternativa ao uso da proteína de soja, o concentrado foi utilizado na fabricação de hambúrgueres vegetais. Esses hambúrgueres foram submetidos à avaliação sensorial e obtiveram média de 6,6 em uma escala de 9 pontos, estando assim dentro da zona de aceitação. Em relação à intenção de compra, 60% dos provadores declararam que provavelmente ou certamente comprariam o produto. Portanto, o concentrado de amêndoa de castanha de caju pode ser utilizado como um ingrediente proteico para uso na formulação de alimentos. A produção de concentrado proteico de amêndoa de caju permite o uso das amêndoas quebradas geradas no processo industrial da castanha de caju.

Palavras-chave:

Anacardium occidentale L.; Precipitação ácida; Propriedades funcionais; Castanha; Ingrediente proteico; Composição centesimal

1 Introduction

The cashew kernel is an especially important product in the international nut market. However, obtaining this product generates up to 40% of broken kernels (Lima et al., 2017Lima, J. R., Garruti, D. S., Bruno, L. M., Araújo, I. M. S., Nobre, A. C. O., & Garcia, L. G. S. (2017). Replacement of peanut by residue from the cashew nut kernel oil extraction to produce a type paçoca candy. Journal of Food Processing and Preservation, 41(2), e12775. http://dx.doi.org/10.1111/jfpp.12775

http://dx.doi.org/10.1111/jfpp.12775...

). The process of extracting oil from the broken kernels is being used to enhance its economic value and leads to a flour which is rich in proteins (Aroyeun, 2009Aroyeun, S. O. (2009). Utilization of cashew kernel meals in the nutritional enrichment of biscuit. African Journal of Food Science, 10, 316-319. Retrieved in 2020, September 22, from http://www.academicjournals.org/ajfs

http://www.academicjournals.org/ajfs...

). The flour that is obtained from the kernel oil extraction can be used in protein concentrate production, thereby giving a new use to this by-product derived from the cashew nut processing industry.

Vegetable protein extraction can be commercially done by precipitation in acid solutions to obtain concentrates (48% to 70% protein) or by solubilization in alkaline solutions previous to the acid precipitation to obtain an isolate as the final product (85% to 90% of protein) (Moure et al., 2006Moure, A., Sineiro, J., Domínguez, H., & Parajó, J. C. (2006). Functionality of oilseed protein products. A review. Food Research International, 39(9), 945-963. http://dx.doi.org/10.1016/j.foodres.2006.07.002

http://dx.doi.org/10.1016/j.foodres.2006...

).

The use of cashew kernels to obtain concentrate and isolate proteins has been reported by some authors. Ogunwolu et al. (2009)Ogunwolu, S. O., Henshaw, F. O., Mock, H. P., Santros, A., & Awonorin, S. O. (2009). Functional properties of protein concentrates and isolates produced from cashew (Anacardium occidentale L.) nut. Food Chemistry, 115(3), 852-858. http://dx.doi.org/10.1016/j.foodchem.2009.01.011

http://dx.doi.org/10.1016/j.foodchem.200...

reported obtaining protein concentrate and isolate by alkaline extraction and isoelectric precipitation, as well as by alkaline extraction and methanol precipitation. Queiroga Neto et al. (2001)Queiroga Neto, V., Narain, N., Silva, J. B., & Bora, P. S. (2001). Functional properties of raw and heat processed cashew nut (Anacardium occidentale, L.) kernel protein isolates. Die Nahrung, 45(4), 258-262. PMid:11534465. http://dx.doi.org/10.1002/1521-3803(20010801)45:4<258::AID-FOOD258>3.0.CO;2-3

http://dx.doi.org/10.1002/1521-3803(2001...

reported the functional properties of the protein isolates prepared from raw and heat-processed cashew nut kernels. Bora & Queiroga Neto (2004)Bora, P. S., & Queiroga Neto, V. (2004). Functionality of native and denatured cashew nut kernel protein isolates at isoelectric pH as a function of salt concentration. Journal of the Science of Food and Agriculture, 84(15), 2022-2027. http://dx.doi.org/10.1002/jsfa.1905

http://dx.doi.org/10.1002/jsfa.1905...

evaluated the effect of salt on the functionality of native and denatured Cashew Nut Protein Isolates (CNPI). Sharma et al. (2010)Sharma, G. M., Su, M., Joshi, A. U., Roux, K. H., & Sathe, S. K. (2010). Functional properties of selected edible oilseeds proteins. Journal of Agricultural and Food Chemistry, 58(9), 5457-5464. PMid:20201552. http://dx.doi.org/10.1021/jf1002446

http://dx.doi.org/10.1021/jf1002446...

evaluated the characteristics of proteins obtained by saline extraction from the defatted flour of cashews and other nuts. However, none of these authors reported the process and characteristics of the protein concentrate obtained by only acid precipitation, which is a simpler method for obtaining protein.

Proteins obtained from vegetables can be incorporated into foods to increase their nutritional value and functional properties such as solubility, water and oil absorption capacity, foaming capacity and foam stability (Moure et al., 2006Moure, A., Sineiro, J., Domínguez, H., & Parajó, J. C. (2006). Functionality of oilseed protein products. A review. Food Research International, 39(9), 945-963. http://dx.doi.org/10.1016/j.foodres.2006.07.002

http://dx.doi.org/10.1016/j.foodres.2006...

).

The Empresa Brasileira de Pesquisa Agropecuária (Embrapa) developed a vegetable cashew burger formulated with the fiber resulting from juice extraction (Lima et al., 2016Lima, J. R., Garruti, D. S., Pinto, G. A. S., Magalhães, H. C. R., & Machado, T. F. (2016). Vegetal burgers of cashew fiber and texturized soy protein. Revista Brasileira de Fruticultura, 39(3), e-76. http://dx.doi.org/10.1590/0100-29452017376

http://dx.doi.org/10.1590/0100-294520173...

). In this formulation the soybean protein was used to increase the amount of protein in the burger, but other sources of proteins can be tested. Therefore, the objective of this work aimed to obtain a protein concentrate from defatted cashew kernel flour and to evaluate its composition, functional properties and its use in formulating vegetal burgers.

2 Material and methods

2.1 Preparation of the protein concentrate

Broken cashew kernels were obtained from a local industry (Fortaleza, Brazil) and ground (Robot Coupe R502V.V, Vincennes, France). To obtain a flour without oil it was used a Soxhlet apparatus and hexane extraction for 10 h. The extraction was followed by heating at 60 °C for 1h for solvent removal, milling and screening through 60 mesh size (Fritsch Pulverisette 19, Idar-Oberstein, German).

Concentrate protein was obtained by isoelectric precipitation. Four pH levels were tested and the protein content was used to select the best pH. The dried defatted flour was suspended in distilled water at a 1:15 ratio, the pH was adjusted to the test value (3.0, 3.5, 4.0 or 4.5) using 0.5 M HCl and stirred for 15 min. The precipitate was separated by centrifuging at 1600 xG for 30 min, dried at 60 °C for 14 h and milled again as described earlier. The experiment was performed three times, the proteins (N x 6.25) were determined (Association of Official Analytical Chemists, 1997Association of Official Analytical Chemists – AOAC. (1997). Official methods of analysis (16th ed., 3rd rev). Gaithersburg: AOAC.) and the results were submitted to Analysis of Variance (ANOVA) and Tukey’s test (α=0.05) to compare the mean values (SAS Institute, 2009SAS Institute. (2009). Statistical analysis system user’s guide. Cary, NC: SAS Institute.).

2.2 Physicochemical analysis

Defatted cashew kernel flour and cashew kernel protein concentrate obtained in the selected pH in the previous experiment were analyzed for moisture, ash, lipid, carbohydrate and protein contents (N x 6.25) (Association of Official Analytical Chemists, 1997Association of Official Analytical Chemists – AOAC. (1997). Official methods of analysis (16th ed., 3rd rev). Gaithersburg: AOAC.). Analyses were performed three times and the results were submitted to ANOVA and the F-test (α=0.05) was used to compare the mean values (SAS Institute, 2009SAS Institute. (2009). Statistical analysis system user’s guide. Cary, NC: SAS Institute.).

2.3 Functional properties

Cashew kernel protein concentrate obtained in the pH selected in the previous experiment was analyzed for Water Absorption Capacity (WAC) and Oil Absorption Capacity (OAC) (Lin et al., 1974Lin, M. J. Y., Humbert, E. S., & Sosulski, F. W. (1974). Certain functional properties of sunflower meal product. Journal of Food Science, 39(2), 368-370. http://dx.doi.org/10.1111/j.1365-2621.1974.tb02896.x

http://dx.doi.org/10.1111/j.1365-2621.19...

). Medium-sized light textured soybean protein purchased in the local market that was used to formulate the burgers (item 2.4) was also analyzed and used as a reference. Analyses were performed three times and the results were submitted to ANOVA and the F-test (α=0.05) was used to compare the mean values (SAS Institute, 2009SAS Institute. (2009). Statistical analysis system user’s guide. Cary, NC: SAS Institute.).

Water solubility, foaming capacity and foam stability (Glória & Regitano-d’Arce, 2000Glória, M. M., & Regitano-d’Arce, M. A. B. (2000). Concentrado e isolado proteico de torta de castanha do pará: Obtenção e caracterização química e funcional. Food Science and Technology, 20(2), 240-245. http://dx.doi.org/10.1590/S0101-20612000000200019

http://dx.doi.org/10.1590/S0101-20612000...

) were analyzed and the results were presented in graphs.

2.4 Using the cashew kernel protein concentrate in vegetal burger formulation

Two formulations of vegetal burgers were elaborated. The first formulation was prepared according to Lima et al. (2016)Lima, J. R., Garruti, D. S., Pinto, G. A. S., Magalhães, H. C. R., & Machado, T. F. (2016). Vegetal burgers of cashew fiber and texturized soy protein. Revista Brasileira de Fruticultura, 39(3), e-76. http://dx.doi.org/10.1590/0100-29452017376

http://dx.doi.org/10.1590/0100-294520173...

with the use of treated cashew fiber (27.0%), medium-sized light textured soybean protein (27.0%), tomato (16.3%), onion (5.5%), bell pepper (3.1%), garlic (0.9%), powder pepper (0.1%), dehydrated parsley (0.2%), salt (1.2%), corn oil (1.0%), wheat flour (8.0%) and water (9.7%). The burgers were prepared in 80 g units. The second formulation was prepared replacing the 27% of soybean protein by cashew nut concentrate obtained with the pH selected in the previous experiment. Burgers from both formulations were stored in a freezer at -18 °C after being packed in polyethylene plastic materials.

The burgers were analyzed for moisture, ash, lipid, carbohydrate and protein contents (Association of Official Analytical Chemists, 1997Association of Official Analytical Chemists – AOAC. (1997). Official methods of analysis (16th ed., 3rd rev). Gaithersburg: AOAC.). It was also calculated their energy value by the use of the factors of 4 kcal/g for carbohydrates and proteins and 9 kcal/g for lipids (Brasil, 2003Brasil. Agência Nacional de Vigilância Sanitária – Anvisa. (2003, dezembro 26). Regulamento técnico sobre rotulagem nutricional de alimentos embalados (Resolução da Diretoria Colegiada – RDC nº 360, de 23 de dezembro de 2003). Diário Oficial [da] República Federativa do Brasil, Brasília. Retrieved in 2020, September 22, from http://portal.anvisa.gov.br/documents/33880/2568070/res0360_23_12_2003.pdf/5d4fc713-9c66-4512-b3c1-afee57e7d9bc

http://portal.anvisa.gov.br/documents/33...

). They were also submitted to a sensory acceptance test (Meilgaard et al., 2006Meilgaard, M. C., Carr, B. T., & Carr, B. T. (2006). Sensory evaluation techniques. New York: CRC. http://dx.doi.org/10.1201/b16452

http://dx.doi.org/10.1201/b16452...

) performed with 50 judges to access their reasonable level of liking for the burgers. It was used a 9-point structured hedonic scale, ranging from 1 (I disliked it very much) to 9 (I liked it very much). The judges were also questioned about their intent to purchase the burgers using a 5-point structured scale ranging from 1 (I certainly would not buy it) to 5 (I certainly would buy it). The burgers were prepared for the sensory tests on a non-stick frying pan with corn oil added (10 mL) and heated for 5 min. The burgers were served to the judges in white plates coded with random three-digit numbers. The results were presented as histograms of frequency. Sensorial tests protocols were previously approved by the Research Ethics Committee of the Ceará State University (number 147.279).

3 Results and discussion

3.1 Physicochemical and functional properties

Cashew kernels concentrate with higher protein content was obtained by precipitation in pH 4.0 and 4.5 (Table 1). This pH range was also used to obtain protein concentrates from black beans (Ribeiro et al., 2009Ribeiro, H. J. S. S., Prudencio, S. H., Miyagui, D. T., & Ribeiro, E. L. A. (2009). Caracterização de concentrado proteico de feijão comum preto, cultivar Iapar 44, novo e envelhecido. Food Science and Technology, 29(3), 571-580. http://dx.doi.org/10.1590/S0101-20612009000300019

http://dx.doi.org/10.1590/S0101-20612009...

), baru almonds (Guimarães et al., 2012Guimarães, R. C. A., Favaro, S. P., Viana, A. C. A., Braga Neto, J. A., Neves, V. A., & Honer, M. R. (2012). Study of the proteins in the defatted flour and protein concentrate of baru nuts (Dipteryx alata Vog). Revista Ciência e Tecnologia de Alimentos, 32(3), 464-670. http://dx.doi.org/10.1590/S0101-20612012005000065

http://dx.doi.org/10.1590/S0101-20612012...

), Brazil nuts (Glória & Regitano-d’Arce, 2000Glória, M. M., & Regitano-d’Arce, M. A. B. (2000). Concentrado e isolado proteico de torta de castanha do pará: Obtenção e caracterização química e funcional. Food Science and Technology, 20(2), 240-245. http://dx.doi.org/10.1590/S0101-20612000000200019

http://dx.doi.org/10.1590/S0101-20612000...

) and cashew nuts (Ogunwolu et al., 2009Ogunwolu, S. O., Henshaw, F. O., Mock, H. P., Santros, A., & Awonorin, S. O. (2009). Functional properties of protein concentrates and isolates produced from cashew (Anacardium occidentale L.) nut. Food Chemistry, 115(3), 852-858. http://dx.doi.org/10.1016/j.foodchem.2009.01.011

http://dx.doi.org/10.1016/j.foodchem.200...

).

The concentration process by isoelectric precipitation led to a concentrate with 58.6% of total proteins (Table 2). This value corresponds to a 29.9% increase in the originally protein content in the defatted flour. Although there are no specific limits for kernels protein concentrates in Brazilian legislation, there is a limit for protein products in general, which is at least 40% (Brasil, 2005Brasil. (2005, setembro 23). Regulamento técnico para produtos proteicos de origem vegetal (Resolução de Diretoria Colegiada – RDC Nº 268, de 22 de setembro de 2005). Diário Oficial [da] República Federativa do Brasil, Brasília. Retrieved in 2020, September 22, from http://portal.anvisa.gov.br/documents/33880/2568070/RDC_268_2005.pdf/60145a2f-eb4c-4911-b1e0-46d776357a25

http://portal.anvisa.gov.br/documents/33...

). The concentration process did not affect the lipid content of the defatted flour but led to a concentrate with less carbohydrates and ashes than the flour, probably due to the solubilization of these components in water during the precipitation process. The protein content obtained was similar to a Brazil nut concentrate with 59.3% of proteins described by Glória & Regitano-d’Arce (2000)Glória, M. M., & Regitano-d’Arce, M. A. B. (2000). Concentrado e isolado proteico de torta de castanha do pará: Obtenção e caracterização química e funcional. Food Science and Technology, 20(2), 240-245. http://dx.doi.org/10.1590/S0101-20612000000200019

http://dx.doi.org/10.1590/S0101-20612000...

, and higher than cupuaçu (Theobroma grandiflorum (Willd. ex Spreng.) K. Schum.) concentrate with 31.1% of proteins described by Carvalho et al. (2009)Carvalho, A. V., García, N. H. P., Farfán, J. A., & Wada, J. K. A. (2009). Caracterização de concentrado e isolado proteico extraído de sementes de cupuaçu (Theobroma grandiflorum, Schum). Brazilian Journal of Food Technology, 12(1), 1-8. http://dx.doi.org/10.4260/BJFT2009346

https://doi.org/10.4260/BJFT2009346...

, both obtained by isoelectric precipitation.

Proximate composition of defatted cashew kernel flour and cashew kernel protein concentrate (mean ± sd, n=3).

The WAC of the cashew kernel concentrate was 1.85 mL/g (Table 3). The WAC of proteins is influenced by different parameters such as shape, steric factors, conformational characteristics, hydrophilic-hydrophobic balance of amino acids in the protein molecules as well as the components of the food matrix like lipids, carbohydrates and tannins (Adiamo et al., 2015Adiamo, O. Q., Gbadamosi, O. S., & Abiose, S. H. (2015). Functional properties and protein digestibility of protein concentrates and isolates produced from kariya (Hildergadia bateri) seed. Journal of Food Processing and Preservation, 40(5), 979-989. http://dx.doi.org/10.1111/jfpp.12678

http://dx.doi.org/10.1111/jfpp.12678...

). The high water absorption capacity presented by the cashew kernel concentrate may be related to its carbohydrates content since these compounds contain starch which can gelatinize and enhance the water holding capacity (Elleuch et al., 2011Elleuch, M., Bedigian, D., Roiseux, O., Besbes, S., Blecker, C., & Attia, H. (2011). Dietary fibre and fibre-rich by-products of food processing: Characterization, technological functionality and commercial applications: A review. Food Chemistry, 24(2), 411-421. http://dx.doi.org/10.1016/j.foodchem.2010.06.077

http://dx.doi.org/10.1016/j.foodchem.201...

, Wang et al., 2006Wang, S. H., Rocha, G. O., Nascimento, T. P., & Ascheri, J. L. R. (2006). Absorção de água e propriedades espumantes de farinhas extrusadas de trigo. Food Science and Technology (Campinas), 26(2), 457-481. http://dx.doi.org/10.1590/S0101-20612006000200035

http://dx.doi.org/10.1590/S0101-20612006...

). The WAC of cashew kernel concentrate was lower than the results observed for soy protein used as a reference but similar to those observed for cashew kernel concentrate (1.74 mL/g) (Ogunwolu et al., 2009Ogunwolu, S. O., Henshaw, F. O., Mock, H. P., Santros, A., & Awonorin, S. O. (2009). Functional properties of protein concentrates and isolates produced from cashew (Anacardium occidentale L.) nut. Food Chemistry, 115(3), 852-858. http://dx.doi.org/10.1016/j.foodchem.2009.01.011

http://dx.doi.org/10.1016/j.foodchem.200...

), baru nut concentrate (1.93 mL/g) (Guimarães et al., 2012Guimarães, R. C. A., Favaro, S. P., Viana, A. C. A., Braga Neto, J. A., Neves, V. A., & Honer, M. R. (2012). Study of the proteins in the defatted flour and protein concentrate of baru nuts (Dipteryx alata Vog). Revista Ciência e Tecnologia de Alimentos, 32(3), 464-670. http://dx.doi.org/10.1590/S0101-20612012005000065

http://dx.doi.org/10.1590/S0101-20612012...

) and Kariya seed concentrate (2.06 mL/g) (Adiamo et al., 2015Adiamo, O. Q., Gbadamosi, O. S., & Abiose, S. H. (2015). Functional properties and protein digestibility of protein concentrates and isolates produced from kariya (Hildergadia bateri) seed. Journal of Food Processing and Preservation, 40(5), 979-989. http://dx.doi.org/10.1111/jfpp.12678

http://dx.doi.org/10.1111/jfpp.12678...

). The WAC is important in protein concentrates, especially for manufacturing foods like soups and baked products.

Water Absorption Capacity (WAC) and Oil Absorption Capacity (OAC) of cashew kernel protein concentrate (mean ± sd, n=3).

The result of OAC (1.06 mL/g) (Table 3) was lower than the value observed for soy protein used as a reference and the reported for Brazil nut concentrate (1.45 mL/g) (Glória & Regitano-d’Arce, 2000Glória, M. M., & Regitano-d’Arce, M. A. B. (2000). Concentrado e isolado proteico de torta de castanha do pará: Obtenção e caracterização química e funcional. Food Science and Technology, 20(2), 240-245. http://dx.doi.org/10.1590/S0101-20612000000200019

http://dx.doi.org/10.1590/S0101-20612000...

). However, the concentrate can practically absorb its own weight in oil, which is an important characteristic because oil can retain flavors and increase the mouthfeel of foods (Aremu et al., 2007Aremu, M. O., Olaofe, O., & Akintayo, E. T. (2007). Functional properties of some Nigerian varieties of legume seed flours and flour concentration effect on foaming and gelling properties. Journal of Food Technology, 5, 109-115. Retrieved in 2020, September 22, from http://medwelljournals.com/abstract/?doi=jftech.2007.109.115

http://medwelljournals.com/abstract/?doi...

), and is useful in manufacturing sausages, for example (Ogunwolu et al., 2009Ogunwolu, S. O., Henshaw, F. O., Mock, H. P., Santros, A., & Awonorin, S. O. (2009). Functional properties of protein concentrates and isolates produced from cashew (Anacardium occidentale L.) nut. Food Chemistry, 115(3), 852-858. http://dx.doi.org/10.1016/j.foodchem.2009.01.011

http://dx.doi.org/10.1016/j.foodchem.200...

).

The minimum solubility of the cashew kernel concentrate was almost 0% at pH 4, while the maximum solubility was 50% at pH 12.0 (Figure 1). The minimum solubility close to the isoelectric point could be a result of net charge of peptides, and the surface hydrophobicity which leads to the aggregation and precipitation via hydrophobic interactions (Adiamo et al., 2015Adiamo, O. Q., Gbadamosi, O. S., & Abiose, S. H. (2015). Functional properties and protein digestibility of protein concentrates and isolates produced from kariya (Hildergadia bateri) seed. Journal of Food Processing and Preservation, 40(5), 979-989. http://dx.doi.org/10.1111/jfpp.12678

http://dx.doi.org/10.1111/jfpp.12678...

, Sorgentini & Wagner, 2002Sorgentini, D. A., & Wagner, J. R. (2002). Comparative study of foaming properties of whey and isolate soy bean proteins. Food Research International, 35(8), 721-729. http://dx.doi.org/10.1016/S0963-9969(02)00067-4

http://dx.doi.org/10.1016/S0963-9969(02)...

). The obtained maximum solubility values were similar to the values reported for walnut protein concentrate (47.54%) at pH 12.0 (Mao & Hua, 2012Mao, X., & Hua, Y. (2012). Composition, structure and functional properties of protein concentrates and isolates produced from walnut (Juglans regia L.). International Journal of Molecular Sciences, 13(2), 1561-1581. PMid:22408408. http://dx.doi.org/10.3390/ijms13021561

http://dx.doi.org/10.3390/ijms13021561...

), but smaller than that reported for Brazil nut concentrate (86.8%) at pH 12.0 (Glória & Regitano-d’Arce, 2000Glória, M. M., & Regitano-d’Arce, M. A. B. (2000). Concentrado e isolado proteico de torta de castanha do pará: Obtenção e caracterização química e funcional. Food Science and Technology, 20(2), 240-245. http://dx.doi.org/10.1590/S0101-20612000000200019

http://dx.doi.org/10.1590/S0101-20612000...

). Low solubility in the acid pH range of the cashew kernel concentrate indicates its use for producing semi-solid foods such as yogurt, or solid foods such as pasta and other baked products.

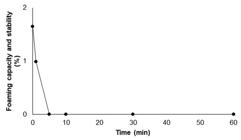

The foaming capacity at the initial time was less than 2% (Figure 2) and moved to zero in five minutes. Protein foaming property refers to the formation of a film between gas and liquid. The presence of sugars, salts and lipids can impair the formation of foam, as it increases the stability of the protein structure, decreasing their ability of adsorption in the air-water interface (Damodaran et al., 2010Damodaran, S., Parkin, K. L., & Fennema, O. R. (2010). Química de los alimentos de Fennema (3. ed.). Zaragoza: Acribia.). The presence of lipids in the cashew kernel protein concentrate was 2.8% which can reduce the foaming of proteins, as they have few cohesive and viscoelastic properties that are necessary for forming bubbles (Damodaran et al., 2010Damodaran, S., Parkin, K. L., & Fennema, O. R. (2010). Química de los alimentos de Fennema (3. ed.). Zaragoza: Acribia.). Therefore, the low foaming formation capacity and stability exhibited by the cashew kernel protein concentrate limit its use as a foaming agent in aerated produts like mousses and ice creams.

Foaming capacity and stability (%) of cashew kernel protein concentrate as a function of time.

3.2 Vegetal burger formulation

The two burgers showed high moisture and carbohydrate contents and low lipid content (Table 4). Burgers elaborated with cashew kernel concentrate presented higher moisture and protein content than the burger with soybean protein, as well as lower carbohydrates, ashes and energy value than the other formulation.

Proximate composition of vegetal burgers made with cashew kernel protein concentrate and soybean protein (mean ± sd, n=3).

The two burgers formulations tested showed low energy values. The burger portion with the added cashew kernel concentrate (80 g) showed 92.3 kcal, which corresponds to only 4.6% of the recommended daily calories (2000 kcal) (Brasil, 2003Brasil. Agência Nacional de Vigilância Sanitária – Anvisa. (2003, dezembro 26). Regulamento técnico sobre rotulagem nutricional de alimentos embalados (Resolução da Diretoria Colegiada – RDC nº 360, de 23 de dezembro de 2003). Diário Oficial [da] República Federativa do Brasil, Brasília. Retrieved in 2020, September 22, from http://portal.anvisa.gov.br/documents/33880/2568070/res0360_23_12_2003.pdf/5d4fc713-9c66-4512-b3c1-afee57e7d9bc

http://portal.anvisa.gov.br/documents/33...

). Furthermore, traditional burgers made with beef have around 170 kcal in a portion of 80 g (Universidade Estadual de Campinas, 2011Universidade Estadual de Campinas – UNICAMP. (2011). TACO: Tabela Brasileira de Composição de Alimentos. Campinas. Retrieved in 2020, September 22, from http://www.unicamp.br/nepa/taco/contar/taco_4_edicao_ampliada_e_revisada.pdf?arquivo=taco_4_versao_ampliada_e_revisada.pdf

http://www.unicamp.br/nepa/taco/contar/t...

) which is 84% more calories than the vegetal burger made with added cashew kernel concentrate. Thus, the physicochemical composition and total energy values showed by the burger elaborated with cashew kernel concentrate indicate its consumption by persons with calorie restriction.

Regarding sensory acceptance, 72% of the hedonic scores (Figure 3) for the soybean protein burger and 80% for the cashew kernel concentrate burger were within the acceptance zone of the scale, between the evaluation of “like slightly” to “extremely like”. Moreover, 55% of the judges said that they would buy or certainly would buy the burgers made with soybean protein and 60% for the cashew kernel concentrate burger when asked about their purchase intent (Figure 4).

Histograms of frequency for the sensory acceptance of burgers made with soybean proteins and with cashew kernel concentrate proteins. (1) Dislike extremely, (2) dislike very much, (3) dislike moderately, (4) dislike slightly, (5) neither like nor dislike, (6) like slightly, (7) like moderately, (8) like very much, (9) like extremely.

Histograms of frequency for the purchase intent of burgers made with soybean proteins and with cashew kernel concentrate proteins. (1) I certainly would not buy it, (2) I probably would not buy it, (3) I’m not sure if I would or would not buy it, (4) I would probably buy it, (5) I certainly would buy it).

The sensory acceptance mean values for the two burgers formulations were 6.6 on a nine-point scale, so it can be concluded that the cashew kernel concentrate protein can replace the soybean protein in the burger formulations.

4 Conclusions

Cashew kernels concentrate with 58.6% protein can be obtained by isoeletric precipitation at the pH range of 4.0 to 4.5. The obtained concentrate had both high Water Absorption Capacity, Oil Absorption Capacity and low water solubility in the acid pH range, low foaming formation capacity and low foaming stability. The sensory hedonic values for burgers formulated with the cashew kernels protein concentrate were high. The functional properties exhibited by cashew kernels protein concentrate and the sensory acceptance of the burgers made with its incorporation showed that the concentrate may be a good source of protein ingredient regarding food formulations. Therefore, the cashew kernel protein concentrate is another way to use the broken kernels generated in the cashew nut industrial process.

-

Cite as: Lima, J. R., Araújo, I. M. S., Pinto, C. O., Goiana, M. L., Rodrigues, M. C. P., & Lima, L. V. (2021). Obtaining cashew kernel protein concentrate from nut processing by-product and its use to formulate vegetal burger. Brazilian Journal of Food Technology, 24, e2020232. https://doi.org/10.1590/1981-6723.23220

-

Funding: None.

References

- Adiamo, O. Q., Gbadamosi, O. S., & Abiose, S. H. (2015). Functional properties and protein digestibility of protein concentrates and isolates produced from kariya (Hildergadia bateri) seed. Journal of Food Processing and Preservation, 40(5), 979-989. http://dx.doi.org/10.1111/jfpp.12678

» http://dx.doi.org/10.1111/jfpp.12678 - Aremu, M. O., Olaofe, O., & Akintayo, E. T. (2007). Functional properties of some Nigerian varieties of legume seed flours and flour concentration effect on foaming and gelling properties. Journal of Food Technology, 5, 109-115. Retrieved in 2020, September 22, from http://medwelljournals.com/abstract/?doi=jftech.2007.109.115

» http://medwelljournals.com/abstract/?doi=jftech.2007.109.115 - Aroyeun, S. O. (2009). Utilization of cashew kernel meals in the nutritional enrichment of biscuit. African Journal of Food Science, 10, 316-319. Retrieved in 2020, September 22, from http://www.academicjournals.org/ajfs

» http://www.academicjournals.org/ajfs - Association of Official Analytical Chemists – AOAC. (1997). Official methods of analysis (16th ed., 3rd rev). Gaithersburg: AOAC.

- Bora, P. S., & Queiroga Neto, V. (2004). Functionality of native and denatured cashew nut kernel protein isolates at isoelectric pH as a function of salt concentration. Journal of the Science of Food and Agriculture, 84(15), 2022-2027. http://dx.doi.org/10.1002/jsfa.1905

» http://dx.doi.org/10.1002/jsfa.1905 - Brasil. Agência Nacional de Vigilância Sanitária – Anvisa. (2003, dezembro 26). Regulamento técnico sobre rotulagem nutricional de alimentos embalados (Resolução da Diretoria Colegiada – RDC nº 360, de 23 de dezembro de 2003). Diário Oficial [da] República Federativa do Brasil, Brasília. Retrieved in 2020, September 22, from http://portal.anvisa.gov.br/documents/33880/2568070/res0360_23_12_2003.pdf/5d4fc713-9c66-4512-b3c1-afee57e7d9bc

» http://portal.anvisa.gov.br/documents/33880/2568070/res0360_23_12_2003.pdf/5d4fc713-9c66-4512-b3c1-afee57e7d9bc - Brasil. (2005, setembro 23). Regulamento técnico para produtos proteicos de origem vegetal (Resolução de Diretoria Colegiada – RDC Nº 268, de 22 de setembro de 2005). Diário Oficial [da] República Federativa do Brasil, Brasília. Retrieved in 2020, September 22, from http://portal.anvisa.gov.br/documents/33880/2568070/RDC_268_2005.pdf/60145a2f-eb4c-4911-b1e0-46d776357a25

» http://portal.anvisa.gov.br/documents/33880/2568070/RDC_268_2005.pdf/60145a2f-eb4c-4911-b1e0-46d776357a25 - Carvalho, A. V., García, N. H. P., Farfán, J. A., & Wada, J. K. A. (2009). Caracterização de concentrado e isolado proteico extraído de sementes de cupuaçu (Theobroma grandiflorum, Schum). Brazilian Journal of Food Technology, 12(1), 1-8. http://dx.doi.org/10.4260/BJFT2009346

» https://doi.org/10.4260/BJFT2009346 - Damodaran, S., Parkin, K. L., & Fennema, O. R. (2010). Química de los alimentos de Fennema (3. ed.). Zaragoza: Acribia.

- Elleuch, M., Bedigian, D., Roiseux, O., Besbes, S., Blecker, C., & Attia, H. (2011). Dietary fibre and fibre-rich by-products of food processing: Characterization, technological functionality and commercial applications: A review. Food Chemistry, 24(2), 411-421. http://dx.doi.org/10.1016/j.foodchem.2010.06.077

» http://dx.doi.org/10.1016/j.foodchem.2010.06.077 - Glória, M. M., & Regitano-d’Arce, M. A. B. (2000). Concentrado e isolado proteico de torta de castanha do pará: Obtenção e caracterização química e funcional. Food Science and Technology, 20(2), 240-245. http://dx.doi.org/10.1590/S0101-20612000000200019

» http://dx.doi.org/10.1590/S0101-20612000000200019 - Guimarães, R. C. A., Favaro, S. P., Viana, A. C. A., Braga Neto, J. A., Neves, V. A., & Honer, M. R. (2012). Study of the proteins in the defatted flour and protein concentrate of baru nuts (Dipteryx alata Vog). Revista Ciência e Tecnologia de Alimentos, 32(3), 464-670. http://dx.doi.org/10.1590/S0101-20612012005000065

» http://dx.doi.org/10.1590/S0101-20612012005000065 - Lima, J. R., Garruti, D. S., Bruno, L. M., Araújo, I. M. S., Nobre, A. C. O., & Garcia, L. G. S. (2017). Replacement of peanut by residue from the cashew nut kernel oil extraction to produce a type paçoca candy. Journal of Food Processing and Preservation, 41(2), e12775. http://dx.doi.org/10.1111/jfpp.12775

» http://dx.doi.org/10.1111/jfpp.12775 - Lima, J. R., Garruti, D. S., Pinto, G. A. S., Magalhães, H. C. R., & Machado, T. F. (2016). Vegetal burgers of cashew fiber and texturized soy protein. Revista Brasileira de Fruticultura, 39(3), e-76. http://dx.doi.org/10.1590/0100-29452017376

» http://dx.doi.org/10.1590/0100-29452017376 - Lin, M. J. Y., Humbert, E. S., & Sosulski, F. W. (1974). Certain functional properties of sunflower meal product. Journal of Food Science, 39(2), 368-370. http://dx.doi.org/10.1111/j.1365-2621.1974.tb02896.x

» http://dx.doi.org/10.1111/j.1365-2621.1974.tb02896.x - Mao, X., & Hua, Y. (2012). Composition, structure and functional properties of protein concentrates and isolates produced from walnut (Juglans regia L.). International Journal of Molecular Sciences, 13(2), 1561-1581. PMid:22408408. http://dx.doi.org/10.3390/ijms13021561

» http://dx.doi.org/10.3390/ijms13021561 - Meilgaard, M. C., Carr, B. T., & Carr, B. T. (2006). Sensory evaluation techniques New York: CRC. http://dx.doi.org/10.1201/b16452

» http://dx.doi.org/10.1201/b16452 - Moure, A., Sineiro, J., Domínguez, H., & Parajó, J. C. (2006). Functionality of oilseed protein products. A review. Food Research International, 39(9), 945-963. http://dx.doi.org/10.1016/j.foodres.2006.07.002

» http://dx.doi.org/10.1016/j.foodres.2006.07.002 - Ogunwolu, S. O., Henshaw, F. O., Mock, H. P., Santros, A., & Awonorin, S. O. (2009). Functional properties of protein concentrates and isolates produced from cashew (Anacardium occidentale L.) nut. Food Chemistry, 115(3), 852-858. http://dx.doi.org/10.1016/j.foodchem.2009.01.011

» http://dx.doi.org/10.1016/j.foodchem.2009.01.011 - Queiroga Neto, V., Narain, N., Silva, J. B., & Bora, P. S. (2001). Functional properties of raw and heat processed cashew nut (Anacardium occidentale, L.) kernel protein isolates. Die Nahrung, 45(4), 258-262. PMid:11534465. http://dx.doi.org/10.1002/1521-3803(20010801)45:4<258::AID-FOOD258>3.0.CO;2-3

» http://dx.doi.org/10.1002/1521-3803(20010801)45:4<258::AID-FOOD258>3.0.CO;2-3 - Ribeiro, H. J. S. S., Prudencio, S. H., Miyagui, D. T., & Ribeiro, E. L. A. (2009). Caracterização de concentrado proteico de feijão comum preto, cultivar Iapar 44, novo e envelhecido. Food Science and Technology, 29(3), 571-580. http://dx.doi.org/10.1590/S0101-20612009000300019

» http://dx.doi.org/10.1590/S0101-20612009000300019 - SAS Institute. (2009). Statistical analysis system user’s guide. Cary, NC: SAS Institute.

- Sharma, G. M., Su, M., Joshi, A. U., Roux, K. H., & Sathe, S. K. (2010). Functional properties of selected edible oilseeds proteins. Journal of Agricultural and Food Chemistry, 58(9), 5457-5464. PMid:20201552. http://dx.doi.org/10.1021/jf1002446

» http://dx.doi.org/10.1021/jf1002446 - Sorgentini, D. A., & Wagner, J. R. (2002). Comparative study of foaming properties of whey and isolate soy bean proteins. Food Research International, 35(8), 721-729. http://dx.doi.org/10.1016/S0963-9969(02)00067-4

» http://dx.doi.org/10.1016/S0963-9969(02)00067-4 - Universidade Estadual de Campinas – UNICAMP. (2011). TACO: Tabela Brasileira de Composição de Alimentos. Campinas. Retrieved in 2020, September 22, from http://www.unicamp.br/nepa/taco/contar/taco_4_edicao_ampliada_e_revisada.pdf?arquivo=taco_4_versao_ampliada_e_revisada.pdf

» http://www.unicamp.br/nepa/taco/contar/taco_4_edicao_ampliada_e_revisada.pdf?arquivo=taco_4_versao_ampliada_e_revisada.pdf - Wang, S. H., Rocha, G. O., Nascimento, T. P., & Ascheri, J. L. R. (2006). Absorção de água e propriedades espumantes de farinhas extrusadas de trigo. Food Science and Technology (Campinas), 26(2), 457-481. http://dx.doi.org/10.1590/S0101-20612006000200035

» http://dx.doi.org/10.1590/S0101-20612006000200035

Publication Dates

-

Publication in this collection

11 June 2021 -

Date of issue

2021

History

-

Received

22 Sept 2020 -

Accepted

01 Mar 2021