Abstract

Carbon nanotubes were employed as adhesive reinforcement/nano-stitches to aluminum bonded joints. The CNT addition to an epoxy adhesive not only lead to an increase on load capacity but it is also the most probable cause of the mixed failure mode (adhesive/cohesive). The damage evolution was described as the stiffness decrease and the failure mixed modes were related to the load capacity. Although the presence of CNT cluster were observed, in small concentrations (< 1.0 wt. %), these clusters acted as crack stoppers and lead to an increase on lap joint shear strength. The addition of 2.0 wt. % carbon nanotubes lead to an increase on load capacity of approximately 116.2 % when the results were compared against the single lap joints without carbon nanotubes.

Keywords:

Carbon nanotubes; bonded joints; hybrid joints; experimental mechanics; failure modes

1 INTRODUCTION

As discussed by Chaves et al (2014Chaves, F.J.P., da Silva, L.F.M., de Moura, M.F.S.F., Dillard, D.A., Esteves, V.H.C. (2014). Fracture mechanics tests in adhesively bonded joints: A literature review. The Journal of Adhesion 90:955-992.), adhesive joints are among the most used techniques in modern structural components nowadays. The reasons are based on cost-effectiveness and load capacity increasing without creating local stress concentrations. Liu et al (2014Liu, Z., Huang, YA., Yin, Z., Bennati, S., Valvo, P.S. (2014) A general solution for the two-dimensional stress analysis of balanced and unbalanced adhesively bonded joints. International Journal of Adhesion and Adhesives. 54:112-123.) pointed out that, bonded joints are expanding their range of applications from traditional civil and mechanical engineering areas to microelectronics and aerospace applications, e.g. satellites and unmanned air vehicles. For these new areas of applications, in addition to load capacity requirement, weight is another important issue. To be able to optimize, or at least decrease the bonded joint weight considerably, modeling and experimental approaches are the most common tools employed. The failure analysis performed by da Costa Mattos et al (2012da Costa Mattos, H.S., Monteiro, A. H., Palazzetti, R. (2012). Failure analysis of adhesively bonded joint in composite materials. Materials and Design 33:242-247.), the experimental analysis on different types of joints done by Li et al (2015Li, J., Ying, Y., Zhang, T., Liang, Z. (2015). Experimental study of adhesively bonded CFRP joints subjected to tensile loads. International Journal of Adhesion and Adhesives 57:95-104.) and da Silva and Campilho (2012da Silva, L.F.M., Campilho, R.D.S.G. (2012). Advances in Numerical Modeling of Adhesive Joints. Springer-Verlag.) where a comprehensive review on numerical modeling of adhesive joints was considered are among the most effective research papers on bonded joints. A different approach considering weight/load capacity was proposed by Avila and Bueno (2004Ávila, A.F., Bueno, P.O. (2004) Stress analysis on a wavy-lap bonded joint for composites. International Journal of Adhesion and Adhesives 24:407-414.), Turaga and Sun (2008Turaga, U.V.R., Sun. C.T. (2008). Impreved design for metallic and composite single-lap joints. Journal of Aircraft 45:440-447.) and Kumar et al (2010Kumar, B., Sun, C.T., Wang, P.H., Sterkenburg, R. (2010) Adding additional load paths in bonded/bolted hybrid joints. Journal of Aircraft 47:1593-1598.). In their case, the bonded joint design was changed, Avila and Bueno (2004Ávila, A.F., Bueno, P.O. (2004) Stress analysis on a wavy-lap bonded joint for composites. International Journal of Adhesion and Adhesives 24:407-414.) used wavy-lap joints, Turaga and Sun (2008Turaga, U.V.R., Sun. C.T. (2008). Impreved design for metallic and composite single-lap joints. Journal of Aircraft 45:440-447.) used single-lap joints with attachments and Kumar et al (2010Kumar, B., Sun, C.T., Wang, P.H., Sterkenburg, R. (2010) Adding additional load paths in bonded/bolted hybrid joints. Journal of Aircraft 47:1593-1598.) added bolts in addition to using attachments, which lead to increase on load capacity close to 41%, 60% and 80%, respectively. In all cases, the load path was changed, in the case of Avila and Bueno, by creating the wavy bonded shape, while Turaga and Sun (2008Turaga, U.V.R., Sun. C.T. (2008). Impreved design for metallic and composite single-lap joints. Journal of Aircraft 45:440-447.) and Kumar et al (2010Kumar, B., Sun, C.T., Wang, P.H., Sterkenburg, R. (2010) Adding additional load paths in bonded/bolted hybrid joints. Journal of Aircraft 47:1593-1598.) focused on additional elements to create new load paths. Unfortunately, the issue of weight was not solved, even though the load capacity was greatly improved. To be able to address the issue of weight optimization with improvement on load capacity, new paradigm must be introduced. This new paradigm is the usage of nanostructures. As shown by Wu et al (2015Wu, S., Ladani, R.B., Zhang, J., Bafekrpour, E., Ghorbani, K., Mouritz, A.P., Kinloch, A.J., Wang, C.H. (2015). Aligning multilayer graphene flakes with an external electric field to improve multifunctional properties of epoxy nanocomposites. Carbon 94:607-618.), carbon based nanostructures, i.e. graphene and carbon nanotubes, are the most promising nanostructures for epoxy mechanical and/or electrical properties improvement. Notice that epoxy systems are among the most used adhesives employed for engineering applications. The usage of functionalized carbon nanotubes (CNT) for improving bonded joints were investigated by Sydlik et al (2013Sydlik, S.A., Lee, J-H., Walish, J.J., Thomas, E.L., Swager, T.M. (2013) Epoxy functionalized multi-walled carbon nanotubes for improved adhesives. Carbon 59:109-120.). They were able to improve the load capacity (lap shear strength) by 50% by adding 1 wt. % of carbon nanotubes over the unmodified adhesive. Korayem et al (2016Korayem, A. H., Chen, S. J., Zhang, Q. H., Li, C. Y., Zhao, X. L., & Duan, W. H. (2016). Failure of CFRP-to-steel double strap joint bonded using carbon nanotubes modified epoxy adhesive at moderately elevated temperatures. Composites Part B: Engineering, 94, 95-101.) proved that CNT-epoxy compared to neat epoxy could provide significant increase of bond strength at moderately elevated temperatures and they have tested it for carbon fibre reinforced polymer laminates and steel. The authors found an improvement of the glass transition temperature of 30% for the addition of 3 wt.% CNTs to the epoxy. The CNT functionalization, however, is a very aggressive procedure due to usage of strong acids, i.e. sulfuric and nitric acids, which introduces a large number of defects into the CNTs and lead to environmental problems. Therefore, this research focuses on dispersion of non-functionalized/as grown CNT into epoxy/adhesive systems for bonded joint shear lap strength improvement.

2 MATERIALS AND EXPERIMENTAL PROCEDURES

As this research is focused on aeronautical structures, the adherents employed are made of aluminum 6063 T5. As discussed by Oliva (2016Oliva, H. N.P. (2016) Estudo de Adesivo Epoxi Reforcado com Nanotubo de Carbono e Comparação com Juntas Coladas, Rebitadas e Híbridas. Dissertação de Mestrado PPGMEC.), this aluminum alloy has an ultimate strength around 140 MPa. The adherent thickness (2.35 mm) was established by using the methodology proposed by Hart-Smith (1983Hart-Smith. (1983) Designing to Minimize Peel Stresses in Adhesive-Bonded Joints. ASTM -STP 876.), which predicts a mainly adhesive failure. The adhesive employed is an epoxy based adhesive provided by Barracuda Advanced Composites (2015Barracuda Advanced Composites. (2015) AR300/AH30-150 Epoxy Systems Data sheet.). This system was selected due to its low viscosity, around 900 centipoise and gel time close to 60 minutes. The adhesive was cured on air for 24 hours and a post-cure at 80 C for six hours at one atmosphere pressure was also performed. The carbon nanotube used in this research was grown by chemical vapor deposition (CVD) and it is a multi-walled CNT. More information about the CNT properties is given in Avila et al (2014Ávila, A.F., Munhoz, V.C., Oliveira, A.M., Monteiro, E.C. (2014). Carbon based nanostructures hybrids for composite materials: The graphene - carbon nanotube interaction investigation. Journal of Multifunctional Materials, 2:195-206.). Considering the design of experiment proposed by Montgomery (2005Montgomery, D.C. (2005). Design of Experiments. Wiley.), three different concentrations of CNT were employed, i.e. low (0.5 wt. %), medium (1.0 wt. %) and high (2.0 wt. %). The CNT dispersion process employed followed the procedure described by Avila et al. (2016Ávila, A.F., da Cruz, D.T.L., Nascimento Jr., H. Vidal, F.A.C. (2016). Graphene Based Hybrid Composites. In: Graphene Science Handbook. CRC Press, Taylor & Francis Group. Chapter 32, 510-524.). In summary, an ultra-sonication at 42 KHz for 30 minutes followed by mixing in a high shear mixer at 17400 RPM for 30 minutes, in both cases the temperature was controlled below 36 C by an iced water bath.

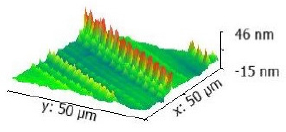

The bonded joint used in this research is a single lap joint and follows the ASTM standard D 1002-10 (2010ASTM D 1002. (2010) Standard test method for apparent shear strength of single-lap-joint adhesively bonded metal specimens by tension loading (metal-to-metal). ASTM International 15-6:1-6.), see Figure 1 for more details. To be able to have a near optimum adhesive thickness, the methodology proposed by da Silva et al (2006da Silva, L.F.M., Rodrigues, T.N.S.S., Figueiredo, M.A.V., de Moura, M.F.S.F., Chousal, J.A. (2006) Effect of adhesive type and thickness on lap shear strength. Journal of Adhesion 82:1019-1115.) was employed. According to them, the 0.15 mm adhesive thickness is the most effective thickness for aluminum adherents and epoxy systems. To be able to investigate the nanostructures formed during the CNT dispersion an atomic force microscopy analysis was performed using an Asylum Research - MFP-3D microscope.

3 RESULTS

3.1 Bonded Joints without Carbon Nanotubes

Although the theory proposed by Hart-Smith (1983Hart-Smith. (1983) Designing to Minimize Peel Stresses in Adhesive-Bonded Joints. ASTM -STP 876.) had predicted the adhesive failure (ADH) as the main failure mode, a mixed mode was observed for the single lap joint group without carbon nanotubes. The ratio between the two failure modes, adhesive (ADH) and cohesive (COH), ranged by 90/10 to 65/35, see Table 1. The load capacity seems to be related to these ratios, as the COH’s area increases there is a growth on load capacity. Furthermore, an increase on elongation was also observed. This phenomenon can be related to the adhesive yielding and damage growth. The damage growth was modeled by Masmanidis and Philippidis (2015Masmanidis, I.T., Philippidis, T.P. (2015) Progressive damage modeling of adhesively bonded lap joints. International Journal of Adhesion and Adhesives 59:53-61.) and related to the stiffness decrease. According to them, as damage evolves, the stiffness decreases at same ratio. As it can be observed in Figure 2, sample #3 has a significant decrease on stiffness, which is an indication on damage evolution. This damage evolution, however, is gradual which allows the energy dissipation and consequently a much higher peak load. When sample #4 is analyzed, the behavior is the opposite. The sharp increase on stiffness lead to small elongation at failure. This phenomenon can be explained by the adhesive thickness at the joint end. According to Kim (2003Kim, H. (2003). The influence of adhesive bondline thickness imperfections on stresses in composite joints. The Journal of Adhesion 79:621-649.), the adhesive shear strength, also referred as load capacity, is affected by the adhesive bond line thickness at the joint end. A small thickness at the joint end lead to a harsh increase on peel and shear stresses at this region and consequently damage initiation and propagation at high speed. By observing sample #4 thickness at upper right end (see Figure 3 D), it can be noticed a thickness around 0.10 mm.

3.2 Bonded joints with 0.5 wt. % of carbon nanotubes

Table 2 summaries the main data obtained during the tensile test of this group of single lap joints. The average load capacity with 0.5 wt. % CNT is 17.87% higher than the ones without CNT. The ratio between ADH/COH shows a correlation between the increase on COH failure mode and the peak force at failure. Moreover, as discussed by Sydlik et al (2013Sydlik, S.A., Lee, J-H., Walish, J.J., Thomas, E.L., Swager, T.M. (2013) Epoxy functionalized multi-walled carbon nanotubes for improved adhesives. Carbon 59:109-120.), the addition of CNT to the adhesive lead to an increase on bonded joint overall stiffness. The damage propagation, however, seems to be less noticeable, as the decrease on stiffness is much smaller (see Figure 4). A possible hypothesis for such behavior is CNT presence, which acts as barrier against the crack propagation inside the adhesive (see Figure 5 - AFM observation). By performing an AFM analysis, it was possible to identify CNT clusters. The dark points shown in Figure 6A-F seem to be the macroscopy representation of such cluster, which can make the crack propagation even harder. Notice that according to Avila et al (2014Ávila, A.F., Munhoz, V.C., Oliveira, A.M., Monteiro, E.C. (2014). Carbon based nanostructures hybrids for composite materials: The graphene - carbon nanotube interaction investigation. Journal of Multifunctional Materials, 2:195-206.), CNTs have a stiffness close to 1.0 TPa and ultimate strength around 60 GPa. The increase on cohesive failure mode (COH) can be also explained by the increase on interface adherent/adhesive strength provided by the CNTs.

3.3 Bonded Joints with 1.0 wt. % of Carbon Nanotubes

It was expected that with the increase on carbon nanotubes quantities the load capacity will also increase. However, this predicted behavior based on rule of mixtures (Jones, 1999Jones, R.M. (1999) Mechanics of Composite Materials, Taylor and Francis.), was not established. As it can be observed in Table 3, the load capacity was reduced when compared against the previous group. One hypothesis for such behavior is the formation of large CNT clusters, which create stress concentration regions. The damage propagation was also affected by these large clusters. As it can be noticed in Figure 7, a stiffness decrease with the elongation was observed. According to Masmanidis and Philippidis (2015Masmanidis, I.T., Philippidis, T.P. (2015) Progressive damage modeling of adhesively bonded lap joints. International Journal of Adhesion and Adhesives 59:53-61.), the damage propagation has direct influence on stiffness changes during the tensile test of single lap joints. As noticed in Figure 8, the cluster formation seems to be aligned and with much larger agglomeration, which can be translated as stress concentration spots. Finally, by observing Figures 9A-F, it is possible to spot “dark dots” inside the failure area. These “dark dots” are the macroscopic representation of those CNT clusters observed at AFM analysis. The reason for such cluster formation can be attributed to the CNT dispersion process. Unfortunately, as the dispersion process is not homogeneous, the stress concentration generated could be the reason for such decrease on load capacity, as the number of crack formation is much higher.

3.4 Bonded Joints with 2.0 wt. % of Carbon Nanotubes

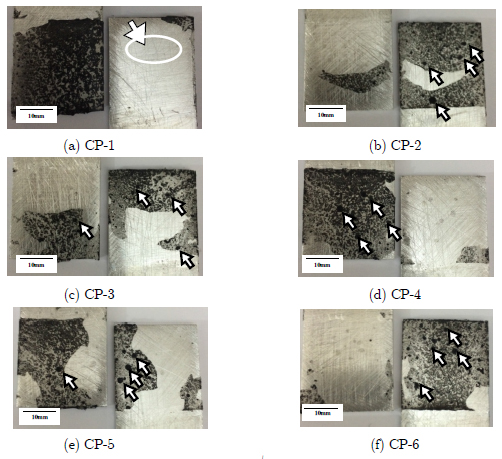

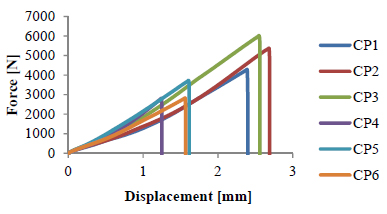

This group represents the highest increase on load capacity (see Table 4). However, as shown in Figure 10, two different sub-groups can be identified. As the load capacity for each sub-group is different, i.e. for sub-group #1 the average peak force at failure is 3118 N while for sub-group #2 the average value is 5223 N, it is possible to suppose that another mechanism for increasing load capacity is acting in addition to the increase on stiffness provided by the CNT dispersion. Figure 11 shows the AFM observation of the CNT cluster formed, which is much more homogeneous and uniformly distributed. The same pattern can be observed at macroscopic level when Figures 12A-F were analyzed. By analyzing the specimen’s photos before each test, it was possible to identify some additional material around the end joint edges. This additional material is defined by da Silva and Campilho (2012da Silva, L.F.M., Campilho, R.D.S.G. (2012). Advances in Numerical Modeling of Adhesive Joints. Springer-Verlag.) as tapering. Moreover, according to them, the tapering effect is to improve the bonded joint load capacity. By measuring the additional area provided by the tapering, it is possible to establish a correlation between the increase on load capacity due to the CNT addition and the additional increase due to tapering. The average increase on load capacity when the 2.0 wt. % CNT samples were compared against the blank (no CNT) samples is around 116.2%. The tapering provided an additional 67.5 % increase on load capacity, which is equivalent to an increase on load capacity with respect to the blank specimens around 262.2 %. According to da Silva and Ochsiner (2008), the tapering, also referred to as spew filet, lead to a load transfer through this additional materials, which makes the peel and shear stresses at joint end decrease. This decrease on peel and shear stresses allow the load capacity to grow before the failure.

4 CONCLUSIONS

Carbon nanotubes were employed as adhesive reinforcement/nano-stitches to aluminum bonded joints. The CNT addition to an epoxy adhesive not only lead to an increase on load capacity but it is also the most probable cause of the mix failure mode (adhesive/cohesive). The experimental work was conducted as recommended in the literature and the microscopic observations allowed a better understanding of the phenomena observed macroscopically in relation to the homogeneity and characteristics of the adhesive area. According to the results obtained, it was noticed that the addition of carbon nanotubes improved the resistance in the adhesive-adherent interface. The observed improvement was more evident for the sets with better dispersion and distribution of the CNT in their failure modes (as an example, group #4 of the bonded joints in Figure 11). On the other hand, the addition of CNT in large quantities, with a poor dispersion, caused stress concentration, due to the presence of clusters. The damage evolution was described as the stiffness decrease and the failure mixed modes were related to the load capacity. The addition of 2.0 wt. % carbon nanotubes lead to an increase on load capacity of approximately 116.2 % when the results were compared against the single lap joints without carbon nanotubes.

Acknowledgments

The authors would like to acknowledge the financial support provided by the Brazilian Research Council, grant 304646/2014-8 and the Air Force Office of Scientific Research grant FA9550-14-1-0377. The first author would like to acknowledge the financial support provided by the Graduate Studies Program in Mechanical Engineering (PPGMEC) from Universidade Federal de Minas Gerais through a fellowship via CAPES foundation. The authors are grateful to the UFMG’s Centre of Microscopy and Microanalysis for the technical support.

References

- ASTM D 1002. (2010) Standard test method for apparent shear strength of single-lap-joint adhesively bonded metal specimens by tension loading (metal-to-metal). ASTM International 15-6:1-6.

- Ávila, A.F., Bueno, P.O. (2004) Stress analysis on a wavy-lap bonded joint for composites. International Journal of Adhesion and Adhesives 24:407-414.

- Ávila, A.F., da Cruz, D.T.L., Nascimento Jr., H. Vidal, F.A.C. (2016). Graphene Based Hybrid Composites. In: Graphene Science Handbook. CRC Press, Taylor & Francis Group. Chapter 32, 510-524.

- Ávila, A.F., Munhoz, V.C., Oliveira, A.M., Monteiro, E.C. (2014). Carbon based nanostructures hybrids for composite materials: The graphene - carbon nanotube interaction investigation. Journal of Multifunctional Materials, 2:195-206.

- Barracuda Advanced Composites. (2015) AR300/AH30-150 Epoxy Systems Data sheet.

- Chaves, F.J.P., da Silva, L.F.M., de Moura, M.F.S.F., Dillard, D.A., Esteves, V.H.C. (2014). Fracture mechanics tests in adhesively bonded joints: A literature review. The Journal of Adhesion 90:955-992.

- da Costa Mattos, H.S., Monteiro, A. H., Palazzetti, R. (2012). Failure analysis of adhesively bonded joint in composite materials. Materials and Design 33:242-247.

- da Silva, L.F.M. Ochsner, A. (2008) Modeling of Adhesively Bonded Joints. Springer-Verlag.

- da Silva, L.F.M., Rodrigues, T.N.S.S., Figueiredo, M.A.V., de Moura, M.F.S.F., Chousal, J.A. (2006) Effect of adhesive type and thickness on lap shear strength. Journal of Adhesion 82:1019-1115.

- da Silva, L.F.M., Campilho, R.D.S.G. (2012). Advances in Numerical Modeling of Adhesive Joints. Springer-Verlag.

- Hart-Smith. (1983) Designing to Minimize Peel Stresses in Adhesive-Bonded Joints. ASTM -STP 876.

- Jones, R.M. (1999) Mechanics of Composite Materials, Taylor and Francis.

- Kim, H. (2003). The influence of adhesive bondline thickness imperfections on stresses in composite joints. The Journal of Adhesion 79:621-649.

- Korayem, A. H., Chen, S. J., Zhang, Q. H., Li, C. Y., Zhao, X. L., & Duan, W. H. (2016). Failure of CFRP-to-steel double strap joint bonded using carbon nanotubes modified epoxy adhesive at moderately elevated temperatures. Composites Part B: Engineering, 94, 95-101.

- Kumar, B., Sun, C.T., Wang, P.H., Sterkenburg, R. (2010) Adding additional load paths in bonded/bolted hybrid joints. Journal of Aircraft 47:1593-1598.

- Li, J., Ying, Y., Zhang, T., Liang, Z. (2015). Experimental study of adhesively bonded CFRP joints subjected to tensile loads. International Journal of Adhesion and Adhesives 57:95-104.

- Liu, Z., Huang, YA., Yin, Z., Bennati, S., Valvo, P.S. (2014) A general solution for the two-dimensional stress analysis of balanced and unbalanced adhesively bonded joints. International Journal of Adhesion and Adhesives. 54:112-123.

- Masmanidis, I.T., Philippidis, T.P. (2015) Progressive damage modeling of adhesively bonded lap joints. International Journal of Adhesion and Adhesives 59:53-61.

- Montgomery, D.C. (2005). Design of Experiments. Wiley.

- Oliva, H. N.P. (2016) Estudo de Adesivo Epoxi Reforcado com Nanotubo de Carbono e Comparação com Juntas Coladas, Rebitadas e Híbridas. Dissertação de Mestrado PPGMEC.

- Sydlik, S.A., Lee, J-H., Walish, J.J., Thomas, E.L., Swager, T.M. (2013) Epoxy functionalized multi-walled carbon nanotubes for improved adhesives. Carbon 59:109-120.

- Turaga, U.V.R., Sun. C.T. (2008). Impreved design for metallic and composite single-lap joints. Journal of Aircraft 45:440-447.

- Wu, S., Ladani, R.B., Zhang, J., Bafekrpour, E., Ghorbani, K., Mouritz, A.P., Kinloch, A.J., Wang, C.H. (2015). Aligning multilayer graphene flakes with an external electric field to improve multifunctional properties of epoxy nanocomposites. Carbon 94:607-618.

Publication Dates

-

Publication in this collection

Mar 2017

History

-

Received

04 Sept 2016 -

Reviewed

14 Feb 2017 -

Accepted

21 Feb 2017