ABSTRACT

The aim of this work was characterize four wood waste samples from lumber industry in order to obtain previous information about structure and properties of wood before use it as a biofuel or as reinforcement in composite formulations. The influence of wood components on the thermal degradation stability of different wood species has been investigated using thermogravimetry, differential scanning calorimetry and scanning electron microscopy. Four wood species, Eucalyptus grandis (EUG), Pinus elliottii (PIE), Dipteryx odorata (DIP) and Mezilaurus itauba (ITA), were used in this study. The results showed that higher extractives contents may form a thin film on the wood fiber surface which can accelerate the degradation process and reduce the wood thermal stability

Keywords:

Wood thermal stability; Wood chemical composition; Wood waste

RESUMO

O objetivo deste trabalho foi caracterizar quatro amostras de resíduos de madeira oriundas da indústria madeireira a fim de obter informações prévias sobre a estrutura e as propriedades da madeira antes do seu uso como biocombustível ou como reforço em compósitos. A influência dos componentes da madeira na estabilidade térmica de diferentes espécies de madeira foi investigada utilizando termogravimetria, calorimetria exploratória diferencial e microscopia eletrônica de varredura. Quatro espécies de madeira, Eucalyptus grandis (EUG), Pinus elliottii (PIE), Dipteryx odorata (DIP) e Mezilaurus itauba (ITA), foram utilizadas neste estudo. Os resultados mostraram que elevadas quantidades de extrativos podem formar uma fina película na superfície da fibra de madeira, o que pode acelerar o processo de degradação e reduzir a estabilidade térmica da madeira.

Palavras-chave:

Estabilidade térmica da madeira; Composição química da madeira; Resíduos de madeira

1. INTRODUCTION

Wood flour is a common waste generated at different stages of the wood processing in lumber industries of Brazil (SIMIONI et al., 2010SIMIONI, F.J.; HOEFLICH, V.A. Productive chain of biomass energy in the south plateau area located in Santa Catarina: a prospective approach. Revista Árvore, v.34, n.6, p.1091-1099, 2010.; DE MENDOZA et al., 2010DE MENDOZA, Z.M.S.H.; EVANGELISTA, W.V.; ARAÚJO, S.O.; DE SOUZA, C.C.; RIBEIRO, F.D.L.; SILVA, J.C. An analysis of the wood residues generated by carpentry shops in Viçosa, state of Minas Gerais. Revista Árvore, v.34, n.4, p.755-760, 2010.). A portion of this waste is generally used for power generation in these industries (SIMIONI et al., 2010SIMIONI, F.J.; HOEFLICH, V.A. Productive chain of biomass energy in the south plateau area located in Santa Catarina: a prospective approach. Revista Árvore, v.34, n.6, p.1091-1099, 2010.; DE MENDOZA et al., 2010DE MENDOZA, Z.M.S.H.; EVANGELISTA, W.V.; ARAÚJO, S.O.; DE SOUZA, C.C.; RIBEIRO, F.D.L.; SILVA, J.C. An analysis of the wood residues generated by carpentry shops in Viçosa, state of Minas Gerais. Revista Árvore, v.34, n.4, p.755-760, 2010.; BRAND et al., 2014BRAND, M.A.; STÄHELIN, T.S.F.; FERREIRA, J.C.; NEVES, M.D. Production of biomass for energy generation in plantations of Pinus taeda L. with different ages. Revista Árvore, v.38, n.2, p.353-360, 2014.), and in some cases is donated or sold. However, a considerable part of the generated waste can be destined to landfill or burning causing serious environmental problems (SIMIONI et al., 2010SIMIONI, F.J.; HOEFLICH, V.A. Productive chain of biomass energy in the south plateau area located in Santa Catarina: a prospective approach. Revista Árvore, v.34, n.6, p.1091-1099, 2010.).

The usage of wood flour as a reinforcement agent in polymer composite is increasing is the last years. Thermoplastic composites filled with wood flour are materials that offer an alternative for using this waste viewing the production of light materials with some specific properties (OKSMAN et al., 2009OKSMAN, K.; MATHEW, A.P.; LÅNGSTRÖM, R.; NYSTRÖM, B.; JOSEPH, K. The influence of fibre microstructure on fibre breakage and mechanical properties of natural fibre reinforced polypropylene. Composites Science and Technology, v.69, n.11-12, p.1847-1853, 2009.; POLETTO et al., 2012aPOLETTO, M.; ZENI, M.; ZATTERA, A.J. Effects of wood flour addition and coupling agent content on mechanical properties of recycled polystyrene/wood flour composites. Journal of Thermoplastic Composite Materials, v.25, n.7, p.821-833, 2012a.) The utilization of wood for development thermoplastic composites has attracted growing interest because of its abundance, biodegradability and renewable nature (OKSMAN et al., 2009). Moreover, the wood composites exhibit low density, low requirements on processing equipment and no abrasion during processing (POLETTO et al., 2012aPOLETTO, M.; ZENI, M.; ZATTERA, A.J. Effects of wood flour addition and coupling agent content on mechanical properties of recycled polystyrene/wood flour composites. Journal of Thermoplastic Composite Materials, v.25, n.7, p.821-833, 2012a.). However, the low degradation temperature of wood is a limitation found when considering their use as filler for thermoplastic composites. The wood degradation occurs at around 200 ºC. The degradation of wood due to high temperatures can lead to undesirable properties, such as odor and discoloration which promotes the loss of wood mechanical strength and also produces composites with low mechanical properties (SHEBANI et al., 2008SHEBANI, A.N.; van REENEN, A.J.; MEINCKEN, M. The effect of wood extractives on the thermal stability of different wood species. Thermochimica Acta, v.471, n.1, p.43-50, 2008.).

The wood thermal degradation is a complex process and can be described by several thermal degradation reactions associated with the degradation of its individual components, such as cellulose, hemicelluloses and lignin (CARNEIRO et al., 2013CARNEIRO, A.C.O.; SANTOS, R.C.; CASTRO, R.V.O.; CASTRO, A.F.N.M.; PIMENTA, A.S.; PINTO, E.M.; ALVES, I.C.N. Study of the thermal decomposition of eight wood species from Seridó region, Rio Grande do Norte. Revista Árvore, v.37, n.6, p.1153-1163, 2013.; PEREIRA et al., 2013PEREIRA, B.L.C.; CARNEIRO, A.C.O.; CARVALHO, A.M.M.L.; TRUGILHO, P.F.; MELO, I.C.N.A.; OLIVEIRA, A.C. Study of thermal degradation of Eucalyptus wood by thermogravimetry and calorimetry. Revista Árvore, v.37, n.3, p.567-576, 2013.). The thermogravimetric analysis (TGA) is normally used to evaluate the variation of the sample proprieties as a function of time or temperature. Based in this method is possible determine when the degradation process initiate and in which temperature the degradation of each wood component occurs (CARNEIRO et al., 2013CARNEIRO, A.C.O.; SANTOS, R.C.; CASTRO, R.V.O.; CASTRO, A.F.N.M.; PIMENTA, A.S.; PINTO, E.M.; ALVES, I.C.N. Study of the thermal decomposition of eight wood species from Seridó region, Rio Grande do Norte. Revista Árvore, v.37, n.6, p.1153-1163, 2013.). On the other hand, using the differential scanning calorimetry (DSC) is possible determine the quantity of heat is absorbed or released by the sample after physical or chemical processes (CARNEIRO et al., 2013CARNEIRO, A.C.O.; SANTOS, R.C.; CASTRO, R.V.O.; CASTRO, A.F.N.M.; PIMENTA, A.S.; PINTO, E.M.; ALVES, I.C.N. Study of the thermal decomposition of eight wood species from Seridó region, Rio Grande do Norte. Revista Árvore, v.37, n.6, p.1153-1163, 2013.). So, is important evaluate the wood composition and thermal stability before it used as fuel or as reinforcement in polymer composites.

However, there are few studies on the relationship between wood composition and thermal stability. In this context, the aim of this study was investigate the chemical composition, thermal degradation and morphologic aspects of four wood species used in the Brazilian lumber industry. Wood flour wastes from Pinus elliottii and Eucalyptus grandis from South Region of Brazil and Mezilaurus itauba and Dipteryx odorata from Central-West Region of Brazil were evaluated.

2. MATERIAL AND METHODS

The wood flour samples used in this study were obtained in form of sawdust wastes of the lumber industry from Brazil. The Pinus elliottii (PIE) and Eucalyptus grandis (EUG) samples were collected in a lumber industry located in Caxias do Sul, Rio Grande do Sul/Brazil. The Mezilaurus itauba (ITA) and Dipteryx odorata were obtained from a lumber industry situated in Sinop, Mato Grosso/Brazil. Samples with a particle size between 200-300 mm were dried in a vacuum oven at 105 ºC for 24 h before the thermal and morphological analysis.

Studies on the wood flour morphology were carried out using a SHIMADZU Superscan SS-550 scanning electron microscope (SEM) with acceleration tension equal to 15 kV. The wood flour surface was sputter-coated with gold before the analysis in order to eliminate electron charging.

The thermogravimetric analysis was carried out in a SHIMADZU TGA-50 analyzer in a N2 atmosphere with 50 cm3/min flow, from 25 up to 600 °C. The heating rate was 10 °C/min and the mass used in each experiment was around 10 mg. DSC analysis was carried out in a SHIMADZU DSC-50 analyzer in a N2 atmosphere with 50 cm3/min flow, from 0 °C until 550 °C. The heating rate was 10 °C/min and the mass used in each experiment was around 5 mg.

3. RESULTS

3.1. Chemical composition

Table 1 shows the chemical composition of the fibers used in this study based on a previous work (POLETTO et al., 2012bPOLETTO, M.; ZATTERA, A.J.; SANTANA, R.M.C. Structural differences between wood species: evidence from chemical composition, FTIR spectroscopy, and thermogravimetric analysis. Journal of Applied Polymer Science, v.126, p.E336-E343, 2012b.). PIE and EUG woods present higher quantities of holocellulose than DIP and ITA. The lignin content is also higher for PIE and EUG than DIP and ITA. However, tropical woods, such as DIP and ITA, showed extractive contents three-times higher than temperate woods, such as PIE and EUG. The ash content is quite similar for all wood species studied.

Chemical composition of the wood species studied.

Tabela 1

Composição química das espécies de madeira estudadas.

3.2. Morphological aspects

The external wood fiber surface morphology, such as contours, defects and surface layer can be seen in Figure 1. EUG and PIE woods showed a more fibrillated and rough structure than ITA and DIP, as can be seen in Figure 1 (a) and Figure 1 (b), respectively. On the other hand, DIP and ITA woods present a smooth fiber surface, as observed in Figure 1 (c) and Figure 1 (d) for DIP and ITA woods, respectively.

Surface morphology of (a) EUG, (b) PIE, (c) DIP and (d) ITA.

Figura 1

Morfologia da superfície de (a) EUG, (b) PIE, (c) DIP e (d) ITA.

3.3. Thermal properties

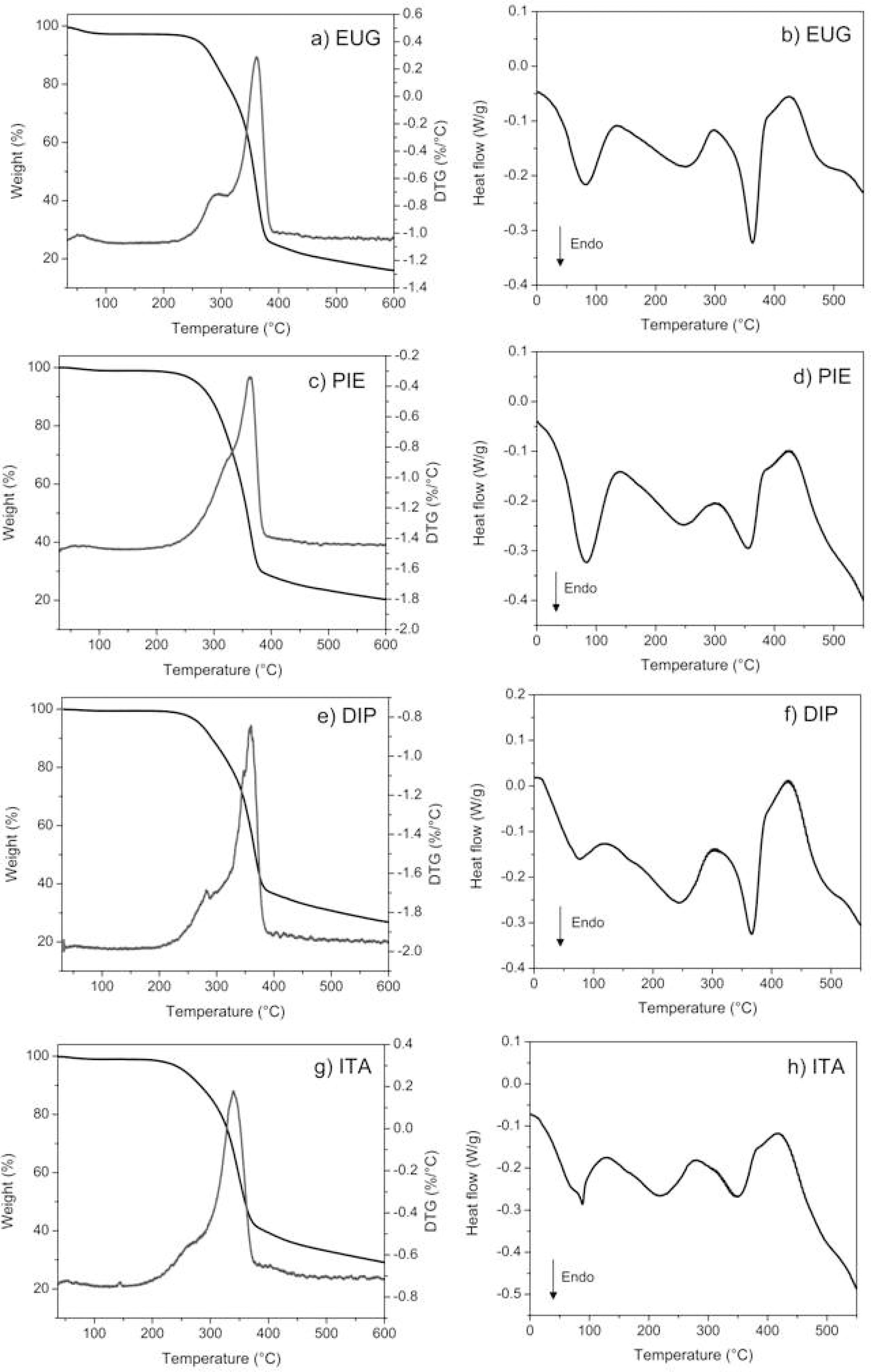

The thermogravimetric curves and DSC curves of the four wood species studied are shown in Figure 2. The TGA and DSC curves of all wood fibers indicated four degradation processes related to moisture evolution, hemicelluloses, cellulose and lignin degradation.

TGA, DTG and DSC curves for the wood species studied.

Figura 2

Curvas de TGA, DTG and DSC para as amostras de madeira estudadas.

After an initial weight loss at 50-100 °C attributed to water loss in the form of absorbed moisture at the wood surface, three other processes occurs: the first one from 250-320 °C is attributed to the decomposition of hemicelluloses, and can be identified by a shoulder in DTG curve. The second process occurs from 300 °C until 400 °C and is associated with the cellulose degradation. Comparing these three components, lignin was the most difficult to decompose, its decomposition occurred slowly at temperatures higher than 400 °C.

The initial weight loss temperature, Ti, of all samples, is considered as the temperature at which the sample loses 3 % of its weight, as showed in Table 2. The higher Ti values were observed for the EUG, PIE and DIP wood species. The lowest Ti value was observed for ITA. On the other hand, ITA and DIP had a significant amount of residue at 600 °C, probably due to higher inorganic contents in these two wood species. The Ti shoulder associated with hemicelluloses decomposition was similar for DIP and EUG. PIE showed the highest hemicelluloses thermal stability. The temperature for maximum decomposition rate of cellulose, the DTG peak, in DIP are the highest, as presented in Table 2. ITA presented the lowest temperature for maximum decomposition of cellulose, while EUG and PIE showed intermediate values.

Thermal degradation temperatures and residue at 600 ºC for the wood species studied.

Tabela 2

Temperaturas de decomposição térmica e resíduo a 600 ºC para as espécies de madeira estudadas.

Besides the TGA and DTG curves, Figure 2 also shown the DSC curves for the wood species studied. All wood species presented four degradation peaks in DSC analysis. The first one, an endothermic peak at around 80 °C, is attributed to the removal of moisture when the sample was heated. A second endothermic peak related to hemicelluloses degradation can be observed between 180-300 °C. A large endothermic peak at about 350-365 °C is related to the cellulose fraction. Finally, an exothermic peak at 415-425 °C is assigned to lignin decomposition. The values of each degradation peak and enthalpy related to degradation of the crystalline part of cellulose for the wood species studied are presented in Table 3. ITA showed the lowest temperature peak values while DIP presented the highest temperature for the peak related to cellulose decomposition, in agreement with the thermogravimetric results. DIP also showed the highest value for the enthalpy related to cellulose degradation.

Peak temperatures and enthalpy of cellulose obtained from DSC curves.

Tabela 3

Temperaturas de pico e entalpia da celulose obtidas das curvas de DSC.

4. DISCUSSION

4.1 Wood chemical composition

The mechanical and thermal properties of the lignocellulosic fibers are mainly influenced by their composition, based on cellulose, hemicelluloses and lignin content (ORNAGHI JR et al., 2014ORNAGHI JR., H.L.; POLETTO, M.; ZATTERA, A.J.; AMICO, S.C. Correlation of the thermal stability and the decomposition kinetics of six different vegetal fibers. Cellulose, v.21, p.177-188, 2014.; POLETTO et al., 2012bPOLETTO, M.; ZATTERA, A.J.; SANTANA, R.M.C. Structural differences between wood species: evidence from chemical composition, FTIR spectroscopy, and thermogravimetric analysis. Journal of Applied Polymer Science, v.126, p.E336-E343, 2012b.) As an example, higher tensile strength and higher thermal stability are obtained for wood fibers that contain more crystalline cellulose (GÜMÜSKAYA et al., 2003GÜMÜSKAYA, E.; USTA, M.; KIREI, H. The effects of various pulping conditions on crystalline structure of cellulose in cotton linters. Polymer Degradation and Stability, v.81, p.559-564, 2003.). Hemicelluloses are one of the fiber components responsible to initial thermal degradation behavior and are also associated with the moisture content (ORNAGHI JR et al., 2014ORNAGHI JR., H.L.; POLETTO, M.; ZATTERA, A.J.; AMICO, S.C. Correlation of the thermal stability and the decomposition kinetics of six different vegetal fibers. Cellulose, v.21, p.177-188, 2014.). So, fibers containing high hemicelluloses content should absorb more moisture and degrade at lower temperature. In addition, higher quantities of extractives may promote fiber degradation at low temperatures (POLETTO et al., 2012bPOLETTO, M.; ZATTERA, A.J.; SANTANA, R.M.C. Structural differences between wood species: evidence from chemical composition, FTIR spectroscopy, and thermogravimetric analysis. Journal of Applied Polymer Science, v.126, p.E336-E343, 2012b.). Thus, the degradation characteristics of lignocellulosic fibers may be estimated based on their chemical composition. So, is expected that differences in the thermal stability of wood samples from different species can be attributed to variations in the chemical composition of wood components (POLETTO et al., 2012bPOLETTO, M.; ZATTERA, A.J.; SANTANA, R.M.C. Structural differences between wood species: evidence from chemical composition, FTIR spectroscopy, and thermogravimetric analysis. Journal of Applied Polymer Science, v.126, p.E336-E343, 2012b.) and can also influence in the mechanical and thermal performance of wood plastic composites.

4.2 Wood morphological aspects

The fiber surface morphology plays a vital role when natural fibers are used in composite materials (BLEDZKI et al., 2010BLEDZKI, A.K.; MAMUN, A.A.; VOLK, J. Physical, chemical and surface properties of wheat husk, rye husk and soft wood and their polypropylene composites. Composites Part A, v.41, p.480-488, 2010.; POLETTO et al., 2012aPOLETTO, M.; ZENI, M.; ZATTERA, A.J. Effects of wood flour addition and coupling agent content on mechanical properties of recycled polystyrene/wood flour composites. Journal of Thermoplastic Composite Materials, v.25, n.7, p.821-833, 2012a.). Every natural fiber has unique surface properties (BLEDZKI et al., 2010BLEDZKI, A.K.; MAMUN, A.A.; VOLK, J. Physical, chemical and surface properties of wheat husk, rye husk and soft wood and their polypropylene composites. Composites Part A, v.41, p.480-488, 2010.), which can influence in the interactions between polymer matrix and reinforcement fibers. The natural fiber surface layer is a minor portion of fiber, but it plays an important role in wettability and surface tension (BLEDZKI et al., 2010BLEDZKI, A.K.; MAMUN, A.A.; VOLK, J. Physical, chemical and surface properties of wheat husk, rye husk and soft wood and their polypropylene composites. Composites Part A, v.41, p.480-488, 2010.), two decisive parameters when natural fibers are used as reinforcements in polymer composites.

The fibers in EUG and PIE woods are more available to do interactions with polymer matrix. In addition, part of the wood lumen may be filled with polymer matrix which could increase the strength of the composites because the mechanical interlocking. DIP and ITA present a smooth surface, as can be seen in Figure 1 (c) and Figure 1 (d) for DIP and ITA woods, respectively. It is possible that some extractives compounds like lipids, fatty acids, resin acids, waxes, among others could be deposited in these wood surfaces since these tropical wood species presented higher quantities of extractives, as presented in Table 1. The amount of extractives on the fiber surface could influence on hydrophobicity and surface tension. It is also possible that higher quantities of extractives could create a more hydrophobic fiber, which can lead to a higher fiber surface tension resulting in a smooth fiber and thus forming a thin film on the fiber surface. As a result, the interaction between polymer matrix and wood fibers may be reduced when ITA and DIP woods will be used for development composite formulations, which will possibly reduce the mechanical properties of the composites. In addition, extractives are compounds with lower molecular mass and can degrade at relatively lower temperatures (POLETTO et al., 2012aPOLETTO, M.; ZENI, M.; ZATTERA, A.J. Effects of wood flour addition and coupling agent content on mechanical properties of recycled polystyrene/wood flour composites. Journal of Thermoplastic Composite Materials, v.25, n.7, p.821-833, 2012a.), which may promote the degradation of other wood components, like hemicelluloses and cellulose at lower temperatures reducing the wood thermal stability.

4.3 Wood thermal properties

The thermal degradation of polysaccharides, like cellulose and hemicelluloses, may occur by cleavage of glycosidic, C-H, C-O and C-C bonds, dehydration, decarboxylation and decarbonylation reactions, with formation of C-C, C=C, C-O bonds as well as carbonyl and carboxyl groups (GARCÌA-PÉREZ et al., 2001GARCÌA-PÉREZ, M.; CHAALA, A.; YANG, J.; ROY, C. Co-pyrolysis of sugarcane bagasse with petroleum residue. Part I: thermogravimetric analysis. Fuel, v.80, p.1245-1258, 2001.; SPINACÉ et al., 2009SPINACÉ, M.A.S.; LAMBERT, C.S.; FERMOSELLI, K.K.G.; DE PAOLI, M-A. Characterization of lignocellulosic curaua fibers. Carbohydrate Polymers, v.77, n.1, p.47-53, 2009.). The weight loss of lignin occurs at higher temperatures and its degradation is associated to dehydration, yielding derivatives with lateral unsaturated chains and the release of water, CO2, CO and methane (SPINACÉ et al., 2009SPINACÉ, M.A.S.; LAMBERT, C.S.; FERMOSELLI, K.K.G.; DE PAOLI, M-A. Characterization of lignocellulosic curaua fibers. Carbohydrate Polymers, v.77, n.1, p.47-53, 2009.). However, wood thermal degradation is a complex process and involves several consecutive and/or competitive reactions.

EUG, PIE and DIP showed similar Ti values, while ITA presented the lowest Ti value. This might be associated to higher volatility of extractives and hemicelluloses in this wood, with can probably reduce the T shoulder in ITA, since the degradation of one wood component may accelerate the degradation of the others. The low degradation temperature of ITA can lead to undesirable composite properties, such as browning and decreasing of the mechanical strength when processed at temperatures above 200 °C. The DSC results confirm that ITA presented lower thermal stability than the others wood species, and starts to degrade at relatively lower temperatures. This behaviour is probably associated whit the degradation of the extractives. According to Table 1, ITA presents the highest extractives content. Extractives are compounds with lower molecular mass and may degrade at relatively lower temperatures reducing the thermal stability of ITA.

DIP wood presents lower holocellulose content than EUG and PIE. In addition, the extractives content in DIP is approximately three times higher than those observed in PIE and EUG. However, this wood presented the highest peak associated to cellulose degradation. This behavior may be associated with the highest crystalline cellulose index in this wood. In a recent study, Kim et al. (2010)KIM, U-J.; EOM, S.H.; WADA, M. Thermal decomposition of native cellulose: influence on crystallite size. Polymer Degradation and Stability, v.95, p.778-781, 2010. showed that the thermal decomposition of cellulose shifted to higher temperatures with increasing crystallinity cellulose index.

The DIP wood presents the highest temperature for cellulose degradation (Tpeak3), in agreement with the results observed in TGA analysis. The enthalpy of cellulose is also higher for DIP when compared with the other woods. The organized cellulose chains in DIP may increase the thermal stability of this wood even with a high content of extractives, since is necessary more energy for melting the cellulose crystallites increasing the enthalpy value.

Carneiro et al. (2013)CARNEIRO, A.C.O.; SANTOS, R.C.; CASTRO, R.V.O.; CASTRO, A.F.N.M.; PIMENTA, A.S.; PINTO, E.M.; ALVES, I.C.N. Study of the thermal decomposition of eight wood species from Seridó region, Rio Grande do Norte. Revista Árvore, v.37, n.6, p.1153-1163, 2013. studied the thermal decomposition of eight wood species from Seridó, a region located in Rio Grande do Norte/Brazil. The authors observed that an endotermic peak associated with the removal of moisture from wood species occurred between 77-84 °C, which is in agreement with the values obtained in this study. In addition, the authors verified that the degradation peak assigned to cellulose occurs in general between 360-370 °C, also in agreement with the values obtained for the wood species evaluated in this study. Pereira et al. (2013)PEREIRA, B.L.C.; CARNEIRO, A.C.O.; CARVALHO, A.M.M.L.; TRUGILHO, P.F.; MELO, I.C.N.A.; OLIVEIRA, A.C. Study of thermal degradation of Eucalyptus wood by thermogravimetry and calorimetry. Revista Árvore, v.37, n.3, p.567-576, 2013. studied six clones of Eucalyptus spp. and also verified that the main degradation peak associated to cellulose occurred between 357-370 °C.

According to Tsujiyama et al. (2000)TSUJIYAMA, S.; MIYAMORI, A. Assignment of DSC thermograms of wood and its components. Thermochimica Acta, v.351, p.177-181, 2000. an exothermal peak related to hemicelluloses can be observed at around 340 °C, while a second exothermal peak assigned to lignin can be observed at 475 °C. According to Yang et al. (2007)YANG, H.; YAN, R.; CHEN, H.; LEE, D.H.; ZHENG, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel, v.86, p.1781-1788, 2007. hemicelluloses presents an exothermal peak at 275 °C. Leroy et al. (2006)LEROY, V.; CANCELLIERI, D.; LEONI, E. Thermal degradation of lingo-cellulosic fuels: DSC and TGA studies. Thermochimica Acta, v.451, n.1, p.131-138, 2006. observed an exothermal peak at 505 °C assigned to lignin degradation of four wood species from Mediterranean. In a recent study, Werner et al. (2014)WERNER, K.; POMMER, L.; BROSTRÖM, M. Thermal decomposition of hemicelluloses. Journal of Analytical and Applied Pyrolysis, v.110, n.1, p.130-137, 2014. reported that hemicelluloses presented an endothermic peak at around 300-330 °C. The endothermic peaks related to hemicelluloses and the exothermic peaks associated with lignin degradation of the wood species studied occur at lower temperatures than those verified in the literature. This behavior might be associated with the differences in wood composition which may cause differences in wood thermal stability.

5. CONCLUSION

The methods used to characterize the wood species studied revels that are differences in the wood components that affect wood thermal stability. Woods with higher extractives content tend to present a smooth fiber surface, which may reduce the interfacial adhesion between polymer matrix and wood flour. In general, higher extractives content also reduce wood thermal stability and might cause browning along with a reduction of composite mechanical properties when wood is used as reinforcement. The TGA and DSC analyses confirm that higher quantities of extractives reduce the wood thermal stability.

The thermogravimetric analysis and calorimetric investigations are useful tools in order to obtain information on the thermal stability, ignitability and combustibility of wood wastes and could help to understand the behavior of wood flour as fuel or when wood is used in composite formulations.

6. REFERENCES

- BLEDZKI, A.K.; MAMUN, A.A.; VOLK, J. Physical, chemical and surface properties of wheat husk, rye husk and soft wood and their polypropylene composites. Composites Part A, v.41, p.480-488, 2010.

- BRAND, M.A.; STÄHELIN, T.S.F.; FERREIRA, J.C.; NEVES, M.D. Production of biomass for energy generation in plantations of Pinus taeda L. with different ages. Revista Árvore, v.38, n.2, p.353-360, 2014.

- CARNEIRO, A.C.O.; SANTOS, R.C.; CASTRO, R.V.O.; CASTRO, A.F.N.M.; PIMENTA, A.S.; PINTO, E.M.; ALVES, I.C.N. Study of the thermal decomposition of eight wood species from Seridó region, Rio Grande do Norte. Revista Árvore, v.37, n.6, p.1153-1163, 2013.

- DE MENDOZA, Z.M.S.H.; EVANGELISTA, W.V.; ARAÚJO, S.O.; DE SOUZA, C.C.; RIBEIRO, F.D.L.; SILVA, J.C. An analysis of the wood residues generated by carpentry shops in Viçosa, state of Minas Gerais. Revista Árvore, v.34, n.4, p.755-760, 2010.

- GARCÌA-PÉREZ, M.; CHAALA, A.; YANG, J.; ROY, C. Co-pyrolysis of sugarcane bagasse with petroleum residue. Part I: thermogravimetric analysis. Fuel, v.80, p.1245-1258, 2001.

- GÜMÜSKAYA, E.; USTA, M.; KIREI, H. The effects of various pulping conditions on crystalline structure of cellulose in cotton linters. Polymer Degradation and Stability, v.81, p.559-564, 2003.

- KIM, U-J.; EOM, S.H.; WADA, M. Thermal decomposition of native cellulose: influence on crystallite size. Polymer Degradation and Stability, v.95, p.778-781, 2010.

- LEROY, V.; CANCELLIERI, D.; LEONI, E. Thermal degradation of lingo-cellulosic fuels: DSC and TGA studies. Thermochimica Acta, v.451, n.1, p.131-138, 2006.

- OKSMAN, K.; MATHEW, A.P.; LÅNGSTRÖM, R.; NYSTRÖM, B.; JOSEPH, K. The influence of fibre microstructure on fibre breakage and mechanical properties of natural fibre reinforced polypropylene. Composites Science and Technology, v.69, n.11-12, p.1847-1853, 2009.

- ORNAGHI JR., H.L.; POLETTO, M.; ZATTERA, A.J.; AMICO, S.C. Correlation of the thermal stability and the decomposition kinetics of six different vegetal fibers. Cellulose, v.21, p.177-188, 2014.

- PEREIRA, B.L.C.; CARNEIRO, A.C.O.; CARVALHO, A.M.M.L.; TRUGILHO, P.F.; MELO, I.C.N.A.; OLIVEIRA, A.C. Study of thermal degradation of Eucalyptus wood by thermogravimetry and calorimetry. Revista Árvore, v.37, n.3, p.567-576, 2013.

- POLETTO, M.; ZENI, M.; ZATTERA, A.J. Effects of wood flour addition and coupling agent content on mechanical properties of recycled polystyrene/wood flour composites. Journal of Thermoplastic Composite Materials, v.25, n.7, p.821-833, 2012a.

- POLETTO, M.; ZATTERA, A.J.; SANTANA, R.M.C. Structural differences between wood species: evidence from chemical composition, FTIR spectroscopy, and thermogravimetric analysis. Journal of Applied Polymer Science, v.126, p.E336-E343, 2012b.

- SHEBANI, A.N.; van REENEN, A.J.; MEINCKEN, M. The effect of wood extractives on the thermal stability of different wood species. Thermochimica Acta, v.471, n.1, p.43-50, 2008.

- SIMIONI, F.J.; HOEFLICH, V.A. Productive chain of biomass energy in the south plateau area located in Santa Catarina: a prospective approach. Revista Árvore, v.34, n.6, p.1091-1099, 2010.

- SPINACÉ, M.A.S.; LAMBERT, C.S.; FERMOSELLI, K.K.G.; DE PAOLI, M-A. Characterization of lignocellulosic curaua fibers. Carbohydrate Polymers, v.77, n.1, p.47-53, 2009.

- TSUJIYAMA, S.; MIYAMORI, A. Assignment of DSC thermograms of wood and its components. Thermochimica Acta, v.351, p.177-181, 2000.

- WERNER, K.; POMMER, L.; BROSTRÖM, M. Thermal decomposition of hemicelluloses. Journal of Analytical and Applied Pyrolysis, v.110, n.1, p.130-137, 2014.

- YANG, H.; YAN, R.; CHEN, H.; LEE, D.H.; ZHENG, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel, v.86, p.1781-1788, 2007.

Publication Dates

-

Publication in this collection

Sep-Oct 2016

History

-

Received

06 May 2015 -

Accepted

02 Sept 2016