ABSTRACT

Massai grass is an important tropical forage grass. The harvested seeds upon being received by the company, are found to be contaminated with impurities which are removable by processing machines. This procedure is necessary to produce seeds of a quality level within standards established for commercialization and sowing purposes. The objective of this project was to evaluate the effects of processing phases on the physical and physiological quality of massai grass (Panicum maximum x P. infestum, cv. Massai) seeds for commercialization purposes. Seeds were sampled before processing and after leaving the air and screen machine (upper and intermediary screens and bottom); first gravity table (drift, upper and intermediate spouts); treating machine; and second gravity table (upper, intermediate, and lower spouts). Seeds were evaluated as to water content, physical (purity and 1,000 seeds weight) and physiological quality (germination, first count of germination, seedling vigor classification, accelerated aging, seedling emergence in the field, speed of emergence index, and primary root length, shoot length). Massai grass seeds had their physical and physiological qualities improved when they were processed by an air and screen machine and a gravity table. Seeds from the intermediate discharge spout of the first gravity table, after going through the air and screen machine, are those of with highest physiological potential. The seeds of this species do not need to be processed to fit the germination and purity standards when the national market is the goal.

Key words:

Panicum maximum; Germination; Vigor; Purity

RESUMO

O capim-massai é uma importante gramínea forrageira tropical e suas sementes ao serem recebidas pelas empresas, após a colheita realizada por varredura no chão, contém impurezas cuja remoção é realizada por máquinas de beneficiamento. Este procedimento é necessário para a obtenção de sementes dentro dos padrões de qualidade para a comercialização e a semeadura. O objetivo deste trabalho foi avaliar o efeito das etapas de beneficiamento na qualidade física e fisiológica de sementes de capim-massai (Panicum maximum x P. infestum, cv. Massai) visando à comercialização. As sementes foram amostradas antes do processamento e após a saída da máquina de ventilador e peneiras (descarga das peneiras superior, intermediária e fundo), primeira mesa gravitacional (deriva, descarga superior e intermediária), máquina tratadora e segunda mesa gravitacional (descarga superior, intermediária e inferior). Sendo avaliadas quanto ao teor de água, qualidade física (pureza e peso de mil sementes) e fisiológica (germinação, primeira contagem, classificação do vigor de plântulas, envelhecimento acelerado, emergência de plântulas em campo, índice de velocidade de emergência e comprimento da raiz primária e da parte aérea de plântulas). O beneficiamento de sementes na máquina de ar e peneiras e mesa gravitacional aprimorou a qualidade física e fisiológica do lote de sementes de capim-massai. A semente de maior potencial fisiológico é obtida na descarga intermediária da primeira mesa gravitacional procedida pelo processamento na máquina de ventilador e peneiras. Para esta espécie o beneficiamento não é necessário para atender os requisitos de pureza e germinação estabelecidos pelos padrões para a comercialização nacional de sementes.

Palavras-chave:

Panicum maximum; Germinação; Vigor; Pureza

INTRODUCTION

Brazil is one of the largest producer, exporter and consumer of forage seeds in the world (TOMAZ et al., 2015TOMAZ, C. A. et al. Time reduction for surinam Grass seed germination test. Ciência e Agrotecnologia, v. 39, n. 5, p. 488-497, 2015.). Part of those seeds are of the Massai cultivar, a hybrid between Panicum maximum and Panicum indestum, which was originally bred in Africa followed by a selection process in Brazil. Its distribution in the country was accomplished by the Brazilian Enterprise for Research in Agriculture and Animal Husbandry (VARGAS JUNIOR et al., 2013VARGAS JUNIOR, F. M. de et al. Disponibilidade e valor nutritivo de gramíneas tropicais sob pastejo com ovinos. Archivos de Zootecnia, v. 62, n. 238, p. 295-298, 2013.).

Tropical forage grass seeds are usually of low quality, both physical and physiologically, in comparison with cereal seeds (TOMAZ et al., 2010TOMAZ, C. A. et al. Duração do teste de germinação do capim-Tanzânia. Revista Brasileira de Sementes, v. 32, n. 4, p. 80-87, 2010.). These problems are basically due to the irregular seed maturation process and the harvesting procedure, by which the seeds are swept with a broom from the soil surface (HESSEL et al., 2012HESSEL, C. L. E. et al. Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012.; MASCHIETTO; NOVEMBRE; SILVA, 2003MASCHIETTO, R. W.; NOVEMBRE, A. D. L. C.; SILVA, W. R. Métodos de colheita e qualidade das sementes de capim colonião cultivar Mombaça. Bragantia, v. 62, n. 2, p. 291-296, 2003.; NERY et al., 2009NERY, M. C. et al. Beneficiamento de sementes de nabo forrageiro. Revista Brasileira de Sementes, v. 31, n. 4, p. 36-42, 2009.).

So, the grass seeds, when received at the processing unit, contain variable amounts of empty spikelets, soil particles, sand, straw and stones, which have to be removed so to conform to commercialization standards and also for sowing (HESSEL et al., 2012HESSEL, C. L. E. et al. Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012.; MASCHIETTO; NOVEMBRE; SILVA, 2003MASCHIETTO, R. W.; NOVEMBRE, A. D. L. C.; SILVA, W. R. Métodos de colheita e qualidade das sementes de capim colonião cultivar Mombaça. Bragantia, v. 62, n. 2, p. 291-296, 2003.; QUADROS et al., 2012QUADROS, D. G. et al. Componentes da produção e qualidade de sementes dos cultivares marandu e xaraés de Brachiaria brizantha (Hochst. ex A. Rich.) Stapf colhidas por varredura manual ou mecanizada. Semina: Ciências Agrárias, v. 33, n. 5, p. 2019-2028, 2012.). Seed processing is understood as the procedure by which sequential operations in specially designed equipment are carried by which the seeds are cleaned, classified and treated having in mind to improve their general quality (FERREIRA; SÁ, 2010FERREIRA, R. L.; SÁ, M. E. Contribuição de etapas do beneficiamento na qualidade fisiológica de sementes de dois híbridos de milho. Revista Brasileira de Sementes, v. 32, n. 4, p. 099-110, 2010.; HESSEL et al., 2012HESSEL, C. L. E. et al. Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012.; PEREIRA; ALBURQUERQUE; OLIVEIRA, 2012PEREIRA, C. E.; ALBURQUERQUE, K. S.; OLIVEIRA, J. A. Qualidade física e fisiológica de sementes de arroz ao longo da linha de beneficiamento. Semina: Ciências Agrárias, v. 33, n. 1, p. 2995-3002, 2012.).

Physical quality refers essentially to seed purity, understood as the percentage of pure seeds found in a seed sample (BRASIL, 2009BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. Secretaria de Defesa Agropecuária. Regras para análise de sementes. Brasília, 2009. 395 p.). Physiological quality refers to seed germination and vigor, which are indicators of the seed capability originate a perfect and vigorous plant in the field (CARVALHO; NAKAGAWA, 2012CARVALHO, N. M.; NAKAGAWA, J. Sementes: ciência, tecnologia e produção. 5. ed. Jaboticabal: FUNEP, 2012. 590 p.).

Grass seeds have been reported to have their physic and physiological quality improved by seed processing procedures such as was the case of rice seeds submitted to the air and screen machine (PEREIRA; ALBURQUERQUE; OLIVEIRA, 2012PEREIRA, C. E.; ALBURQUERQUE, K. S.; OLIVEIRA, J. A. Qualidade física e fisiológica de sementes de arroz ao longo da linha de beneficiamento. Semina: Ciências Agrárias, v. 33, n. 1, p. 2995-3002, 2012.) and that of brachiaria, submitted to the gravity table (HESSEL et al., 2012HESSEL, C. L. E. et al. Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012.). On the other hand, depending on the species, just the physiological quality can be improved by processing procedure. This result was reported by Ferreira and Sá (2010)FERREIRA, R. L.; SÁ, M. E. Contribuição de etapas do beneficiamento na qualidade fisiológica de sementes de dois híbridos de milho. Revista Brasileira de Sementes, v. 32, n. 4, p. 099-110, 2010. with corn seeds, probably as a consequence of the high physical purity of the seeds.

The processing of forage seeds usually employs an air and screen machine, which works based on physical differences between the particles composing the lot, such as size and specific weight. Differences in specific weight are used for the separation of particles in the gravity table (HESSEL et al., 2012HESSEL, C. L. E. et al. Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012.; NERY et al., 2009NERY, M. C. et al. Beneficiamento de sementes de nabo forrageiro. Revista Brasileira de Sementes, v. 31, n. 4, p. 36-42, 2009.). Seed treating machines are of optional use such as those used to add coloring pigments to the seed surface so as to increase their commercial appeal (MELO et al., 2016MELO, L. F. et al. Beneficiamento na qualidade física e fisiológica de sementes de capim-mombaça. Revista Ciência Agronômica, v. 47, n. 4, p. 667-674, 2016.; OLIVEIRA et al., 2014aOLIVEIRA, E. P. et al. Efeito do sombreamento e do incrustamento de sementes sobre o desenvolvimento de cultivares de Panicum maximum Jacq. Bioscience Journal, v. 30, n. 6, p. 1682-1691, 2014a.; PEREIRA et al., 2011PEREIRA, C. E. et al. Armazenamento de sementes de braquiária peletizadas e tratadas com fungicida e inseticida. Ciencia Rural, v. 41, n. 12, p. 2060-2065, 2011.).

The objective of this project was to evaluate the effects of processing phases on the physical and physiological quality of Massai grass (Panicum maximum x P. infestum, cv. Massai) seeds for commercialization purposes.

MATERIAL AND METHODS

Massai grass seeds, produced in the crop year of 2013/14, were mechanically harvested by sweeping the soil surface with the help of a broom in Auriflama, a county of the state of São Paulo, Brazil. These seeds were then passed through screen of the air and screen machine (ASM) and screen machine and two 2.40 m long and 1.25 m wide gravity tables. The speed of vibration of the two gravity tables was of 1.750 rpm and the transversal and longitudinal inclinations were of 17º and 12 º, respectively and a seed treater in a treating equipment of Seed Mix VHM - 4/10 T.

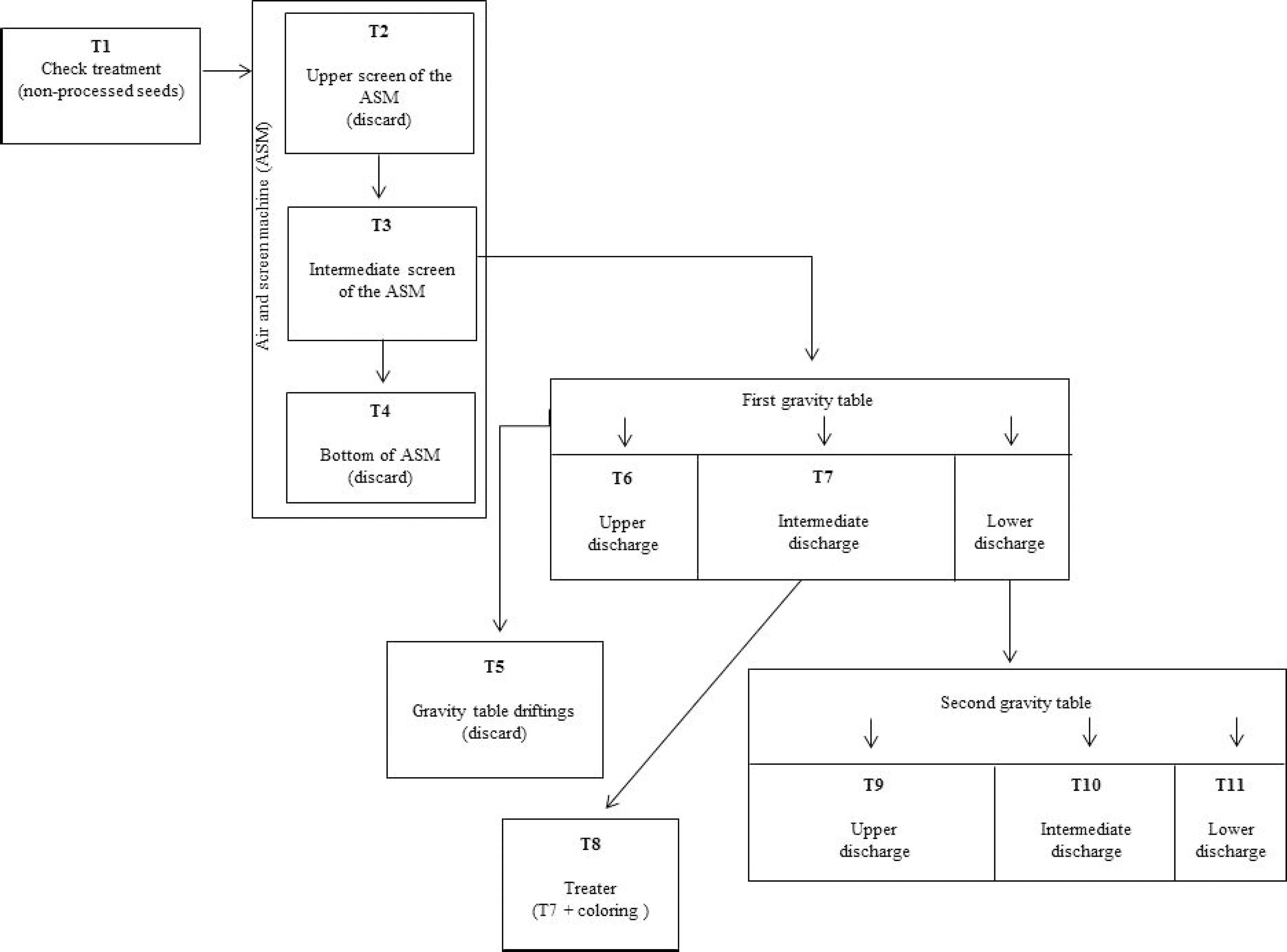

After the operation of the machines was stabilized, approximately six hours after the beginning of the process, the seeds from each phase of the processing procedure were sampled each five minutes, resulting in 20 simple samples with 100 g of each discharge spout, according to Figure 1.

Seed processing flow and the indication of discharge spouts where samples were collected to form treatments T1, T2, T3, T4, T5, T6, T7, T8, T9, T10, and T11

The simple samples were grouped and homogenized to form a composite sample and then reduced to get the mean samples of each treatment. This mean samples were submitted to analysis in the seed laboratory (BRASIL, 2009BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. Secretaria de Defesa Agropecuária. Regras para análise de sementes. Brasília, 2009. 395 p.).

Eleven treatments resulted from the various processing phases, according to the following description: T1 - check treatment, composed by the non processed seeds; T2 - lower screen of the ASM, 7/32 inches (5.5600 mm); T3 - intermediate screen of the air and screen machine 20 AWG (diameter of 0.818 mm) mesh screen (square openings of 30 x 30 mm),; T4 - bottom of the ASM, that is the material which was retained by the screens; T5 - the light material from the first gravity table, removed by an aspirator at the entrance of this machine; T6 - upper discharge spout of the first gravity table, collected at a distance of 35 cm starting from the higher extremity of the table exit when the lateral inclination is considered; T7 - intermediate discharge spout of the first gravity table in the intermediate segment of 60 cm from the table exit; T8 - the seeds taken from the intermediate position of the first gravity table were submitted to coloring with a green pigment made by Laborsan Brasil® and to dry for 24 hours, T9 - upper discharge spout of the second gravity table in the 60 cm long segment starting from the higher table spout; T10 - intermediate discharge spout of the second gravity table, in the 45 cm long intermediate segment; T11 - lower discharge spout of the second gravity table, in the 20 cm long segment of the lowest extremity (Figures 2 A and B).

The discharge divisions of both gravity tables were adjusted so as to allow a higher concentration of undesirable materials at the lowest discharge point, so that they were of different sizes.

Upon arriving at the laboratory, the seeds were halved in a soil divider in order to get a working sample (BRASIL, 2009BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. Secretaria de Defesa Agropecuária. Regras para análise de sementes. Brasília, 2009. 395 p.). Seed quality was evaluated by means of the following tests:

Seed water content - it was evaluated by the oven method: two 2 g samples were submitted to a temperature of 105 ± 3 ºC in a ventilated oven for 24 hours before and after accelerated aging. The results were expressed in percentage (BRASIL, 2009BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. Secretaria de Defesa Agropecuária. Regras para análise de sementes. Brasília, 2009. 395 p.).

Physical purity was determined with two 8 g samples. The physical components of the samples were separated with the help of screens and a seed blower. To get the pure seed fraction, the seeds passed through a pneumatic blower and after was made manual selecting (BRASIL, 2009BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. Secretaria de Defesa Agropecuária. Regras para análise de sementes. Brasília, 2009. 395 p.). Results were expressed in percentage. The used sample weight was larger than that indicated by the Rules for Testing Seeds having in mind a greater representativity and also to guarantee the needed number of seeds for the proposed tests and determinations.

One thousand seed weight - eight 100 pure seed samples were weighed in a 0.001 g precision scale and the mean multiplied by ten to get the one thousand seed weight (BRASIL, 2009BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. Secretaria de Defesa Agropecuária. Regras para análise de sementes. Brasília, 2009. 395 p.).

Germination test - four 100 seed samples were taken and spread over two filter paper sheets and wet with an amount of KNO3 (0.2%) solution weighing two times as much as the substratum. The sheets were placed inside plastic boxes measuring 11.0 x 11.0 x 3.5 cm. These plastic boxes were put inside plastic bags to preserve the substratum moisture (GASPAR et al., 2007GASPAR, C. M. et al. Manutenção da umidade do substrato durante o teste de germinação de Brachiaria brizantha. Revista Brasileira de Sementes, v. 29, n. 3, p. 52-60, 2007.). Seeds were submitted to the alternating temperatures of 15 - 35 ºC and a photoperiod of 8 hours. The normal seedlings were counted 28 days after the beginning of the test (BRASIL, 2009BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. Secretaria de Defesa Agropecuária. Regras para análise de sementes. Brasília, 2009. 395 p.; TOMAZ et al., 2010TOMAZ, C. A. et al. Duração do teste de germinação do capim-Tanzânia. Revista Brasileira de Sementes, v. 32, n. 4, p. 80-87, 2010.; TOMAZ et al., 2016TOMAZ, C. de A., et al. Period of time taken by Brachiaria humidicola (Rendle) Scheweick seed to complete germination. Semina: Ciências Agrárias, v. 37, n. 2, p. 693-700, 2016.).

The occurrence of seed dormancy was verified at the end of the test when the firm, non-germinated seeds were submitted to the tetrazolium test. The seeds were longitudinally sectioned and one of the halves was immersed in a 0.1% tetrazolium solution and kept for three hours in a dark chamber at the temperature of 37 ºC. Following that period, the seeds were washed in running water and evaluated either as viable (dormant) or non-viable (dead) (TOMAZ et al., 2010TOMAZ, C. A. et al. Duração do teste de germinação do capim-Tanzânia. Revista Brasileira de Sementes, v. 32, n. 4, p. 80-87, 2010.).

First count of germination - the percentage of normal seedlings determined at the first count (seven days after the beginning of the test) as established by the Rules for Testing Seeds was considered the result of this test (BRASIL, 2009BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. Secretaria de Defesa Agropecuária. Regras para análise de sementes. Brasília, 2009. 395 p.).

Seedling vigor classification - this test also used the germination test. The normal seedlings present at the first count of germination were classified as “strong” (vigorous). At the final count, the remaining seedlings were classified either as “strong” or “weak” and the normal “strong” were added to those of the first count (OLIVEIRA et al., 2014bOLIVEIRA, S. S. C. et al. Seleção de progênies de nabo-forrageiro para germinação sob altas temperaturas. Ciência Rural, v. 44, n. 2, p. 217-222, 2014b.). The results were expressed as percentage of normal strong seedlings (vigorous).

Accelerated aging test - four 50 seed samples were spread over the metallic surface of a screen inserted in transparent plastic boxes (11.0 x 11.0 x 3.5 cm) containing 40 mL of distilled water (100% of relative humidity) kept at a temperature of 42 ºC for 36 hours (USBERTI, 1982USBERTI, R. Teste de envelhecimento acelerado em sementes de capim colonião. Revista Brasileira de Sementes, v. 4, n. 1, p. 31-44, 1982.). Ensuing that, the seeds were submitted to a standard germination test and the normal seedlings counted seven days after the beginning of the test.

Seedling emergence in the field - four 100 seed samples of each treatment were sown in the field at a depth of 2 cm in lines separated by a distance of 20 cm. Emerged seedlings were daily counted up to 28 days after sowing. The results were expressed in percentage (OLIVEIRA et al., 2014bOLIVEIRA, S. S. C. et al. Seleção de progênies de nabo-forrageiro para germinação sob altas temperaturas. Ciência Rural, v. 44, n. 2, p. 217-222, 2014b.).

Speed of emergence index - concomitantly evaluated with the field test. Normal seedlings were daily counted always at the same time up to 28 days after sowing and the results applied to Maguire’s (1962)MAGUIRE, J. D. Speed of germination-aid selection and evaluation for seedling emergence and vigor. Crop Science, v. 2, n. 1, p. 176-177, 1962. formula to calculate the speed of emergence index.

Seedling primary root and shoot length - four 20 seed samples were sown on a line drawn on the upper part of a paper towel which was previously moistened with distilled water in an amount two times heavier than the paper substratum and submitted to a temperature of 25 ºC for 14 days. At the end of that period, the normal seedlings were pulled out of the substratum and their root and shoot lengths measured with the help of a common rule. The results were expressed in cm/seedling (OLIVEIRA et al., 2014bOLIVEIRA, S. S. C. et al. Seleção de progênies de nabo-forrageiro para germinação sob altas temperaturas. Ciência Rural, v. 44, n. 2, p. 217-222, 2014b.).

The experiment was conducted according to a completely random design with 11 treatments and four repetitions. The data were submitted to the analysis of variance and the treatment means, when significant by F test, were compared by Tukey’s test, at the 5% level of probability.

RESULTS AND DISCUSSION

Seed initial water content as evaluated during the processing operation was found to be between 9.7 and 10.7%. After accelerated aging, these values were between 23.6 and 26.2% (Table 1). The similarity between results is important for the validity of the seed quality tests conducted a posteriori (MARCOS FILHO; NOVEMBRE, 2009MARCOS FILHO, J.; NOVEMBRE, A. D. L. C. Avaliação do potencial fisiológico de sementes de hortaliças. In: NASCIMENTO, W. M. (Ed.). Tecnologia de sementes de hortaliças. Brasília: Embrapa Hortaliças, 2009. p. 185-246.; STEINER et al., 2011STEINER, F. et al. Comparação entre métodos para a avaliação do vigor de lotes de sementes de triticale. Ciência Rural, v. 41, n. 2, p. 200-204, 2011.).

Initial (IW) and after accelerated aging (WAA) seed water content, physical purity (P), one thousand seed weight (TSW), and germination (G) of Massai grass seeds after phases of seed processing

At the different phases of seed processing, it was observed that physical purity varied from zero to 78.8% (Table 1). Samples taken from the upper screen and the bottom of the air and screen machine (T2 and T4) had no seeds and this did not permit to analyze the other quality characteristics of those samples (Tables 1 and 2).

First count of germination (FC), seedling vigor classification (SVC), accelerated aging (AA), seedling emergence in the field (EF), speed of emergence index (SEI) and primary root length (RL) of Massai grass seeds following processing phases

According to Norm Instruction Nº 30 of the Ministry of Agriculture and Animal Husbandry, the minimum purity for the commercialization of certified seeds of Panicum maximum is 50% (BRASIL, 2008). So, in addition to the samples resulting from the upper screen and the bottom of the air and screen machine (T2 and T4), the seeds resulting from the drifting and the upper discharge of the first gravity table (T5 and T6), from the intermediate and lower discharge spouts of the second gravity table (T10 and T11), due to their low quality standards (Table 1), would not be in proper conditions for commercialization.

The treatments which resulted in purity levels lower than 17% are usually discharged by the seed companies. The impurities found in the samples were identified as straw, stones, soil particles and other seeds, mainly Brachiaria brizanta L. These impurities were also observed in other works, with forage turnip (NERY et al., 2009NERY, M. C. et al. Beneficiamento de sementes de nabo forrageiro. Revista Brasileira de Sementes, v. 31, n. 4, p. 36-42, 2009.), corn (FERREIRA; SÁ, 2010FERREIRA, R. L.; SÁ, M. E. Contribuição de etapas do beneficiamento na qualidade fisiológica de sementes de dois híbridos de milho. Revista Brasileira de Sementes, v. 32, n. 4, p. 099-110, 2010.), soybean (SILVA et al., 2011SILVA, R. P. et al. Qualidade fisiológica de sementes de soja (Glycine max. L.) durante o beneficiamento. Semina: Ciências Agrárias, v. 32, n. 4, p. 1219-1230, 2011.), brachiaria (HESSEL et al., 2012HESSEL, C. L. E. et al. Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012.) and rice (PEREIRA; ALBURQUERQUE; OLIVEIRA, 2012PEREIRA, C. E.; ALBURQUERQUE, K. S.; OLIVEIRA, J. A. Qualidade física e fisiológica de sementes de arroz ao longo da linha de beneficiamento. Semina: Ciências Agrárias, v. 33, n. 1, p. 2995-3002, 2012.).

Based only on percentage of purity, the original lot, non-processed (T1), would be in conditions for commercialization in the national market since its purity was 58.3%, as well as the seeds from the upper discharge spout of the second gravity table (T9) with an even lower purity level (52%), due to their high content of straw and soil particles. On the other hand, seed processing permitted increments in the purity level of the seeds from the intermediate screen of the air and screen machine (T3), from the intermediate discharge spout of the first gravity table (T7) and after passing through the treater (T8).

These results allow to evaluate the importance of the use of the air and screen machine and the gravity table to improve the quality of massai grass seeds as has been shown to be the case of rice (PEREIRA; ALBURQUERQUE; OLIVEIRA, 2012PEREIRA, C. E.; ALBURQUERQUE, K. S.; OLIVEIRA, J. A. Qualidade física e fisiológica de sementes de arroz ao longo da linha de beneficiamento. Semina: Ciências Agrárias, v. 33, n. 1, p. 2995-3002, 2012.) and brachiaria seeds (HESSEL et al., 2012HESSEL, C. L. E. et al. Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012.). In a way similar to what has been found for Massai grass seeds, Hessel et al. (2012)HESSEL, C. L. E. et al. Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012. highlighted the importance of the processing of brachiaria seed due to their high content of impurities resulting from the harvesting method applied to them.

As to the one-thousand seed weight, it was verified that, in comparison with the seeds of the check treatment (T1), the heaviest seeds were those from the intermediate screen of the air and screen machine (T3), upper and intermediate discharge spouts of the first gravity table and from the treater (T6, T7, and T8). The seeds from the first discharge spout of the first gravity table (T7) and those of the treater (T8) showed similar weight, and this was expected, since only the seeds of the preceding treatment were colored by the treater (Table 1).

These results corroborate the efficiency of seed processing on the physical quality of seed lots when seed density is used as basis for seed separation. Similar results were reported for guinea grass seeds (MELO et al., 2016MELO, L. F. et al. Beneficiamento na qualidade física e fisiológica de sementes de capim-mombaça. Revista Ciência Agronômica, v. 47, n. 4, p. 667-674, 2016.), tobacco (GADOTTI; BAUDET; VILELLA, 2012GADOTTI, G. I.; BAUDET, L.; VILELLA, F. A. Several regulations in gravity table in quality of tobacco seeds. Engenharia agrícola, v. 32, n. 2, p. 361-368, 2012.), brachiaria (HESSEL et al., 2012HESSEL, C. L. E. et al. Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012.) and rice seeds (PEREIRA; ALBURQUERQUE; OLIVEIRA, 2012PEREIRA, C. E.; ALBURQUERQUE, K. S.; OLIVEIRA, J. A. Qualidade física e fisiológica de sementes de arroz ao longo da linha de beneficiamento. Semina: Ciências Agrárias, v. 33, n. 1, p. 2995-3002, 2012.).

Seeds from the intermediate discharge spout from the first gravity table (T7) showed the highest germination. On the other hand, they did not differ significantly from those of the intermediate screen of the air and screen machine (T3) and those from the upper discharge spout of the first gravity table (T6) and those of the treater (T8). These last three treatments resulted in germination values not statistically different from the check treatment (T1).

Concomitantly with the seeds of the aforementioned treatments, the seeds from the upper discharge spout of the second gravity table (T9) showed germination values higher than the minimum established for P. maximum seeds by the Norm Instruction Nº 30, that is, 40% for certified seeds (BRASIL, 2008BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. Gabinete do Ministro. Instrução Normativa nº 30, de 21 de maio de 2008. Diário Oficial da União, Poder Executivo, Brasília, DF, 23 maio 2008. Seção 1, p. 45.). So, with basis on the results of germination and purity, the non-processed lot (T1) would be in proper conditions for commercialization in the national market thus reducing costs of production (BRASIL, 2008BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. Gabinete do Ministro. Instrução Normativa nº 30, de 21 de maio de 2008. Diário Oficial da União, Poder Executivo, Brasília, DF, 23 maio 2008. Seção 1, p. 45.).

On the other hand, seed processing caused an increment in purity and germination of 20 and 12 %, respectively, in comparison with the non-processed seeds. These seeds were those from the intermediate discharge spout of the first gravity table (T7). Tobacco (GADOTTI; VILELLA; BAUDET, 2011GADOTTI, G. I.; VILELLA, F. A.; BAUDET, L. Influência da mesa densimétrica na qualidade de sementes de cultivares de tabaco. Revista Brasileira de Sementes, v. 33, n. 2, p. 372-378, 2011.), brachiaria (HESSEL et al., 2012HESSEL, C. L. E. et al. Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012.), and rice seeds (PEREIRA; ALBURQUERQUE; OLIVEIRA, 2012PEREIRA, C. E.; ALBURQUERQUE, K. S.; OLIVEIRA, J. A. Qualidade física e fisiológica de sementes de arroz ao longo da linha de beneficiamento. Semina: Ciências Agrárias, v. 33, n. 1, p. 2995-3002, 2012.) were also reported to have their germination results increased after being submitted to the air and screen machine and the gravity table.

The seeds used in this experiment were not dormant, since the tetrazolium test run on the non-germinated seeds showed them to be dead. Dormancy is not totally unlikely in massai grass seeds in Brazil but this has seldom been verified due to the harvest procedure adopted in Brazil - the mature seeds are let to fall off the plant and, once on the ground, are gathered by means of a broom and, although this causes them to be mixed with variable amounts and types of impurities, the occurrence of dormancy is less probable since, under natural conditions, only the real mature seeds drop onto the ground. Another important reason for the rarity of dormancy in P. maximum seeds in Brazil is the period of time between the harvesting of the seeds and their arrival at the processing unit - dormancy is naturally overcome during that period (MASCHIETTO; NOVEMBRE; SILVA, 2003MASCHIETTO, R. W.; NOVEMBRE, A. D. L. C.; SILVA, W. R. Métodos de colheita e qualidade das sementes de capim colonião cultivar Mombaça. Bragantia, v. 62, n. 2, p. 291-296, 2003.; TOMAZ et al., 2010TOMAZ, C. A. et al. Duração do teste de germinação do capim-Tanzânia. Revista Brasileira de Sementes, v. 32, n. 4, p. 80-87, 2010.; TOMAZ et al., 2016TOMAZ, C. de A., et al. Period of time taken by Brachiaria humidicola (Rendle) Scheweick seed to complete germination. Semina: Ciências Agrárias, v. 37, n. 2, p. 693-700, 2016.).

The results of the vigor tests (first count of germination, seedling vigor classification, accelerated aging, seedling emergence in the field, speed of emergence index, and primary root length) are shown in Table 2. Length of the seedling shoot was not influenced by the processing procedures and thus the results are not shown.

Detailed discussions concerning sample vigor were presented only for those classifiable as seeds, that is, those with germination and purity values within the established standards for the commercialization of forage species (BRASIL, 2008), i.e., the check treatment (T1), the intermediate screen of the air and screen machine (T3), intermediate discharge spout of the first gravity table (T7), treater (T8), and upper discharge spout of the second gravity table (T9).

Among those phases, the seeds resulting from the intermediate discharge spout of the first gravity (T7) table were those showing the maximum physiological potential (all vigor tests considered); their performance was better than those of the check treatment (T1). Similar results were reported for forage turnip (NERY et al., 2009NERY, M. C. et al. Beneficiamento de sementes de nabo forrageiro. Revista Brasileira de Sementes, v. 31, n. 4, p. 36-42, 2009.) and brachiaria (HESSEL et al., 2012HESSEL, C. L. E. et al. Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012.).when the seeds of these species were submitted to the gravity table.

The seeds from the upper discharge spout of the second gravity table (T9) displayed the worst vigor performance among the samples considered as seeds (T1, T3, T7, T8, and T9). Root length was the only exception to those results, probably as a consequence of the low seed reserves, as shown by the weight of one thousand seeds, (Table 1). Similar results were reported to seeds of forage turnip (NERY et al., 2009NERY, M. C. et al. Beneficiamento de sementes de nabo forrageiro. Revista Brasileira de Sementes, v. 31, n. 4, p. 36-42, 2009.), brachiaria (HESSEL et al., 2012HESSEL, C. L. E. et al. Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012.), corn (FERREIRA; SÁ, 2010FERREIRA, R. L.; SÁ, M. E. Contribuição de etapas do beneficiamento na qualidade fisiológica de sementes de dois híbridos de milho. Revista Brasileira de Sementes, v. 32, n. 4, p. 099-110, 2010.), rice (PEREIRA; ALBURQUEQUE; OLIVEIRA, 2012PEREIRA, C. E.; ALBURQUERQUE, K. S.; OLIVEIRA, J. A. Qualidade física e fisiológica de sementes de arroz ao longo da linha de beneficiamento. Semina: Ciências Agrárias, v. 33, n. 1, p. 2995-3002, 2012.) and soybean (SILVA et al., 2011SILVA, R. P. et al. Qualidade fisiológica de sementes de soja (Glycine max. L.) durante o beneficiamento. Semina: Ciências Agrárias, v. 32, n. 4, p. 1219-1230, 2011.).

CONCLUSIONS

-

Massai grass seeds had their physical and physiological qualities improved when they were processed by an air and screen machine and a gravity table;

-

Seeds from the intermediate discharge spout of the first gravity table, after being through the air and screen machine, are those of the highest physiological potential;

-

The seeds of this species do not need to be processed to fit the germination and purity standards when the national market is the goal.

-

1

Parte da Tese de Doutorado da primeira autora apresentada ao programa de Pós-graduação em Agronomia, Universidade Estadual Paulista/UNESP; financiamento de bolsa da Capes da primeira autora e CNPq do terceiro e últimos autores

REFERENCES

- BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. Secretaria de Defesa Agropecuária. Regras para análise de sementes Brasília, 2009. 395 p.

- BRASIL. Ministério da Agricultura, Pecuária e Abastecimento. Gabinete do Ministro. Instrução Normativa nº 30, de 21 de maio de 2008. Diário Oficial da União, Poder Executivo, Brasília, DF, 23 maio 2008. Seção 1, p. 45.

- CARVALHO, N. M.; NAKAGAWA, J. Sementes: ciência, tecnologia e produção. 5. ed. Jaboticabal: FUNEP, 2012. 590 p.

- FERREIRA, R. L.; SÁ, M. E. Contribuição de etapas do beneficiamento na qualidade fisiológica de sementes de dois híbridos de milho. Revista Brasileira de Sementes, v. 32, n. 4, p. 099-110, 2010.

- GADOTTI, G. I.; BAUDET, L.; VILELLA, F. A. Several regulations in gravity table in quality of tobacco seeds. Engenharia agrícola, v. 32, n. 2, p. 361-368, 2012.

- GADOTTI, G. I.; VILELLA, F. A.; BAUDET, L. Influência da mesa densimétrica na qualidade de sementes de cultivares de tabaco. Revista Brasileira de Sementes, v. 33, n. 2, p. 372-378, 2011.

- GASPAR, C. M. et al Manutenção da umidade do substrato durante o teste de germinação de Brachiaria brizantha. Revista Brasileira de Sementes, v. 29, n. 3, p. 52-60, 2007.

- HESSEL, C. L. E. et al Mesa densimétrica e qualidade fisiológica de sementes de brachiária. Informativo ABRATES, v. 22, n. 3, p. 73-76, 2012.

- MAGUIRE, J. D. Speed of germination-aid selection and evaluation for seedling emergence and vigor. Crop Science, v. 2, n. 1, p. 176-177, 1962.

- MARCOS FILHO, J.; NOVEMBRE, A. D. L. C. Avaliação do potencial fisiológico de sementes de hortaliças. In: NASCIMENTO, W. M. (Ed.). Tecnologia de sementes de hortaliças. Brasília: Embrapa Hortaliças, 2009. p. 185-246.

- MASCHIETTO, R. W.; NOVEMBRE, A. D. L. C.; SILVA, W. R. Métodos de colheita e qualidade das sementes de capim colonião cultivar Mombaça. Bragantia, v. 62, n. 2, p. 291-296, 2003.

- MELO, L. F. et al Beneficiamento na qualidade física e fisiológica de sementes de capim-mombaça. Revista Ciência Agronômica, v. 47, n. 4, p. 667-674, 2016.

- NERY, M. C. et al Beneficiamento de sementes de nabo forrageiro. Revista Brasileira de Sementes, v. 31, n. 4, p. 36-42, 2009.

- OLIVEIRA, E. P. et al Efeito do sombreamento e do incrustamento de sementes sobre o desenvolvimento de cultivares de Panicum maximum Jacq. Bioscience Journal, v. 30, n. 6, p. 1682-1691, 2014a.

- OLIVEIRA, S. S. C. et al Seleção de progênies de nabo-forrageiro para germinação sob altas temperaturas. Ciência Rural, v. 44, n. 2, p. 217-222, 2014b.

- PEREIRA, C. E. et al Armazenamento de sementes de braquiária peletizadas e tratadas com fungicida e inseticida. Ciencia Rural, v. 41, n. 12, p. 2060-2065, 2011.

- PEREIRA, C. E.; ALBURQUERQUE, K. S.; OLIVEIRA, J. A. Qualidade física e fisiológica de sementes de arroz ao longo da linha de beneficiamento. Semina: Ciências Agrárias, v. 33, n. 1, p. 2995-3002, 2012.

- QUADROS, D. G. et al Componentes da produção e qualidade de sementes dos cultivares marandu e xaraés de Brachiaria brizantha (Hochst. ex A. Rich.) Stapf colhidas por varredura manual ou mecanizada. Semina: Ciências Agrárias, v. 33, n. 5, p. 2019-2028, 2012.

- SILVA, R. P. et al Qualidade fisiológica de sementes de soja (Glycine max. L.) durante o beneficiamento. Semina: Ciências Agrárias, v. 32, n. 4, p. 1219-1230, 2011.

- STEINER, F. et al Comparação entre métodos para a avaliação do vigor de lotes de sementes de triticale. Ciência Rural, v. 41, n. 2, p. 200-204, 2011.

- TOMAZ, C. A. et al Duração do teste de germinação do capim-Tanzânia. Revista Brasileira de Sementes, v. 32, n. 4, p. 80-87, 2010.

- TOMAZ, C. A. et al Time reduction for surinam Grass seed germination test. Ciência e Agrotecnologia, v. 39, n. 5, p. 488-497, 2015.

- TOMAZ, C. de A., et al Period of time taken by Brachiaria humidicola (Rendle) Scheweick seed to complete germination. Semina: Ciências Agrárias, v. 37, n. 2, p. 693-700, 2016.

- USBERTI, R. Teste de envelhecimento acelerado em sementes de capim colonião. Revista Brasileira de Sementes, v. 4, n. 1, p. 31-44, 1982.

- VARGAS JUNIOR, F. M. de et al Disponibilidade e valor nutritivo de gramíneas tropicais sob pastejo com ovinos. Archivos de Zootecnia, v. 62, n. 238, p. 295-298, 2013.

Publication Dates

-

Publication in this collection

Apr-Jun 2018

History

-

Received

16 Jan 2017 -

Accepted

19 Apr 2017