Abstract

The aim of the study was to analyze the impact on the strip ratio (SR) through varying haul road geometric parameters in two types of deposits, namely one with a steeper dip and a second one with a more equidimensional horizontal behavior. The SRs and the overall slope angle were compared with a base scenario, where the results show an increase in the SR when: (a) the width of the haul roads was increased; (b) the longitudinal grade of the road was decreased; and (c) switchbacks were added. The increase in the longitudinal grade of 2% was considered the best-case scenario, resulting in 1.08% decrease in the SR for the horizontal deposit and in a 4.15% decrease for the vertical one. It was also noticed that the SR variations are inversely proportional to the overall slope angle variations, illustrating the important role that the geometric design of the haul roads has in the return on capital.

Keywords:

haul road design; strip ratio; overall slope angle; pit design

1. Introduction

One of the main tasks within strategic mine planning is the operational pit design, aiming to maximize the return on investment. The haul road design is an essential element of the final pit, typically composed of geometric, structural and functional aspects (Thompson and Visser, 1997THOMPSON, R. J., VISSER, A. T. An introduction to the integrated design of surface mine haul roads. International Journal of Surface Mining, Reclamation and Environment, v. 11, n. 3, p. 115-120, 1997.). In open pit excavations, the geometric design is directly related to the mass of ore and waste being hauled, and thus it is important to critically analyze the relationship between all the variables involved in the process of haul road design and the effects that it may have on the economic outcome of the final pit.

According to Hustrulid et al. (2013)HUSTRULID, W. A., KUCHTA, M., MARTIN, R. K. Open pit mine planning and design, two volume set & CD-ROM pack. CRC Press, 2013., the strip ratio (SR) is defined as the mass of waste that needs to be removed to release a unit mass of ore. The variation of SR values is due to the alteration of certain design parameters of the pit, among them the overall slope angle, which can release or block the ore located to the final pit, as well as increase or reduce the waste mass (Wyllie and Mah, 2014WYLLIE, D. C., MAH, C. Rock slope engineering. CRC Press, 2014.). It is intuitive that the flatter the overall slope angle, the greater the mass of waste being removed to access the ore. Thus, when measuring this value as a function of the geometry of the deposit and the final pit design with the incorporation of roads, it is necessary to understand the consequences of decisions taken in the planning stage. For example, an increase in SR and mining costs may invariably penalize the cash flow and the net present value (NPV) of the project (Frith and Colwell, 2011FRITH, R., COLWELL, M. Introduction to ground mechanics. In: DARLING, P. (Ed.). SME mining engineering handbook, 2011. p. 463-470.).

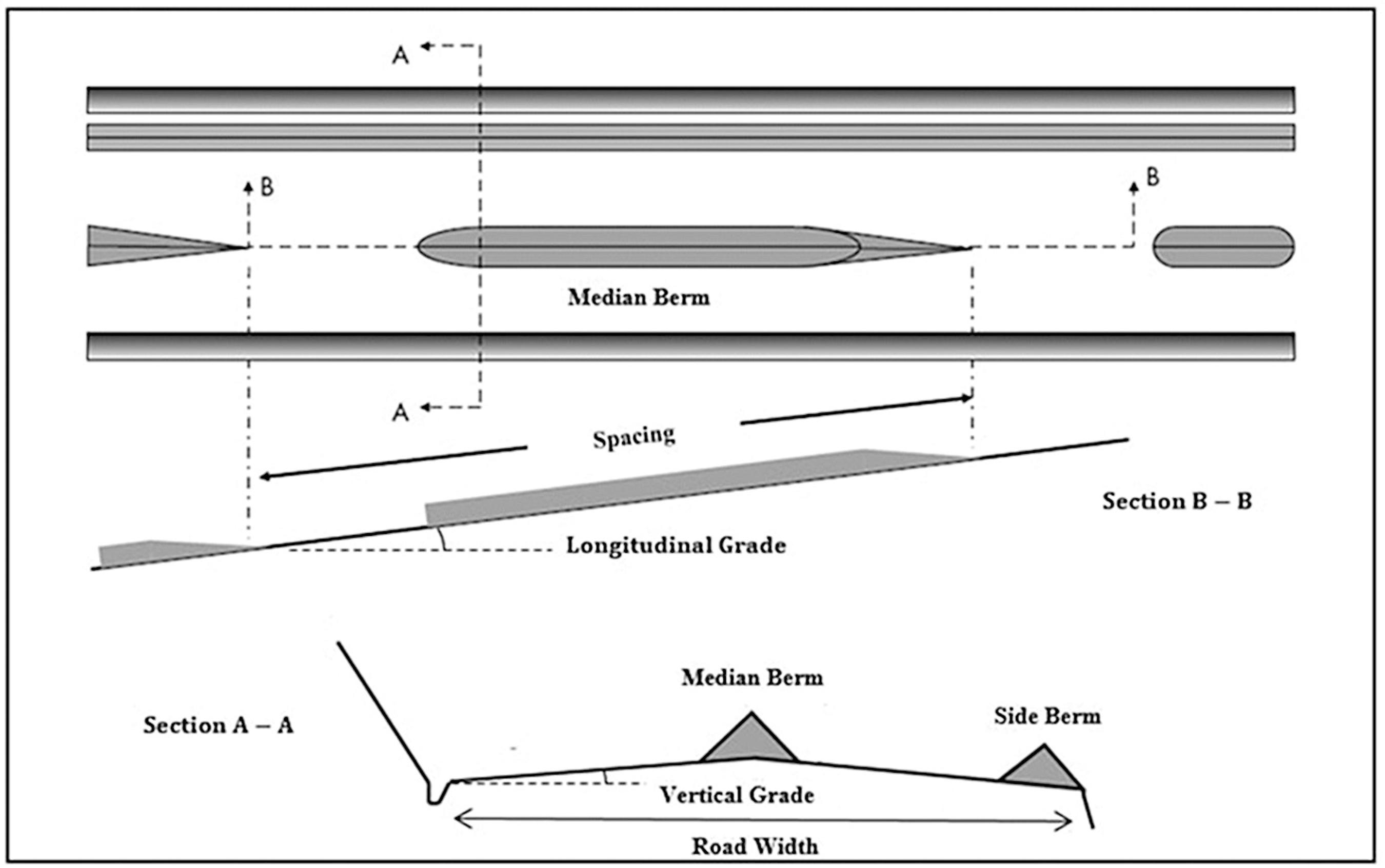

Typically, production is hauled by trucks and to reach the bottom of the pit, it is necessary to use access ramps. Thompson (2011)THOMPSON, R. J. Design, construction, and maintenance of haul roads. In: DARLING, P. (Ed.). SME mining engineering handbook, 2011. p. 957-975. stated that the main objective of haul road geometric design is to ensure that the trucks can travel the shortest possible distance with the maximum speed, leading to shortest time and guaranteeing the safety of the operation. The main geometric elements of open pit haul roads can be seen in Figure 1.

Geometric elements of haul roads in mining operations (Thompson, 2011THOMPSON, R. J. Design, construction, and maintenance of haul roads. In: DARLING, P. (Ed.). SME mining engineering handbook, 2011. p. 957-975.).

During the planning or production phases, there may be a need for changes in the geometry of haul roads because of operational adaptations, such as fleet replacement, addition of safety elements (e.g. central berms), elevation of lateral berms, etc. Among the various geometric parameters that are affected by these changes are width, longitudinal grade and the need to add switchbacks. As the variation of these elements affect the overall slope angle - and consequently the SR, it becomes important that these changes are planned and analyzed with special attention to evaluate the impacts in the project (Hustrulid et al., 2013HUSTRULID, W. A., KUCHTA, M., MARTIN, R. K. Open pit mine planning and design, two volume set & CD-ROM pack. CRC Press, 2013.).

Therefore, the dependence relationship between the SR, the overall slope angle and the haul road geometry is evident. The magnitude of economic implications when varying these parameters differs according to the deposit and the operational pit generated. For example, Sullivan (2006)SULLIVAN, T. D. Pit slope design and risk- A view of the current state of the art. In: Proceeding of the Int. Symposium on Stability of Rock Slopes in Open Pit Mining and Civil Engineering Situations. 2006. showed that a decrease in the overall slope angle by 5° for a medium-size open pit operation using haul roads can result in a 20% reduction in the costs associated with mining. However, no studies have been found that compare these variations for different deposits and scenarios with different road geometries.

Consequently, the objective of this paper is to evaluate the impact on the SR when varying the geometric parameters of the final pit haul roads for two different types of deposits. The article first presents the operational and geometrical parameter and the variables being studied. Thereafter the analysis is performed for a range of parameters and discussed. Finally, the conclusions are presented and show the significant effect of haul road properties on the economic feasibility for different mine pit configurations, and is thus an issue that must be considered during the initial mine planning stage.

2. Material and methods

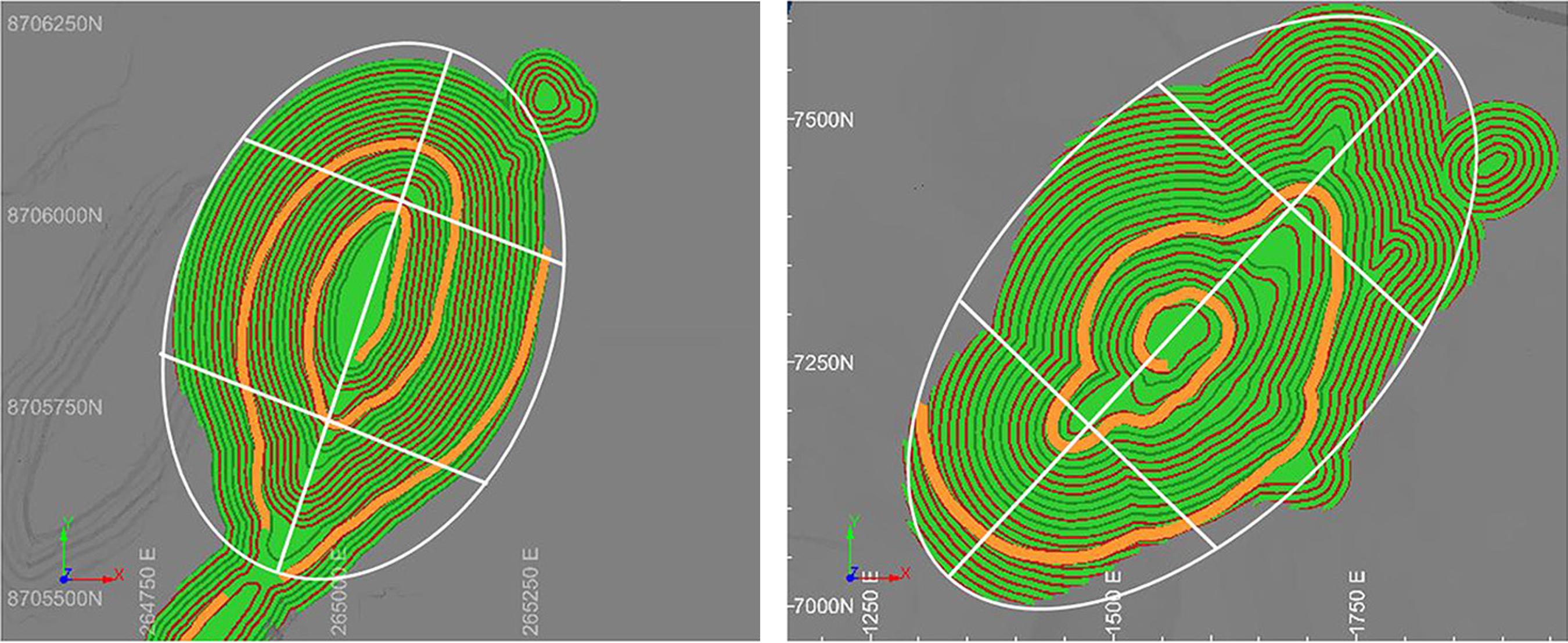

In order to evaluate the consequences of the variation of haul road geometric parameters, two types of deposits with different dimensions were selected, one more vertical and the other more horizontal, as shown in the cross sections presented in Figure 2.

Table 1 presents the information about the dimensions of the blocks used for each type of deposit, as well as the total number of blocks.

The optimum pits were generated using the NPV Scheduler® software, which resulted from the maximization of NPV through the Lerchs-Grossmann optimization algorithm (Lerchs and Grossmann, 1965LERCHS, H., GROSSMANN, I. F. Optimum design of open pit mines. CIM Bulletin. p. 47-54, 1965.; Tolwinski and Underwood, 1996TOLWTNSKI, B., UNDERWOOD, R. A scheduling algorithm for open pit mines. IMA Journal of Management Mathematics, v. 7, n. 3, p. 247-270, 1996.). Several alternative pit designs were generated using the Studio OP® software. The geometric parameters used in the analysis for each deposit are presented in Table 2.

For each type of deposit, different scenarios were generated by varying the geometric parameters of the haul roads of a base pit, as well as the addition of switchbacks with different radius of curvature. The variation of the parameters was not additive, as can be observed in Table 3 where the alternative layouts are designated A to E, which shows the values used for each distinct scenario. Since no operational information was provided (e.g. type of haul truck, production, etc.), usual values were used for the parameters.

The overall slope angles of all scenarios were measured using 6 distinct sectors of the pit. The overall slope angle of each pit was then calculated by the average value of the 6 cross-sections.

Finally, the comparative analysis was carried out by evaluating the percentage differences in SR, in the ore and waste masses (increased or reduced) and in the overall slope angle of A, B, C, D and E alternatives in relation to the base pit.

3. Results and discussion

Figure 3 presents the ultimate pits generated and used for the development of each scenario where the different haul roads geometries were included in the pit design.

The automatic generation of operational pits resulted in more than one pit in both situations. In order to standardize the comparison between scenarios, it was decided to work only with the largest pit observed and the geometric parameters of the smaller pit roads were not modified during the analysis. Figures 4 and 5 show the pits generated in each scenario for the deposits I and II, respectively. The road designs developed are highlighted in orange for each scenario.

Figure 6 shows the sections used to calculate the overall slope angle in the scenarios. In each sector, the overall slope angle was measured and the average value of the 6 sections was used to calculate an average overall slope angle of the entire pit.

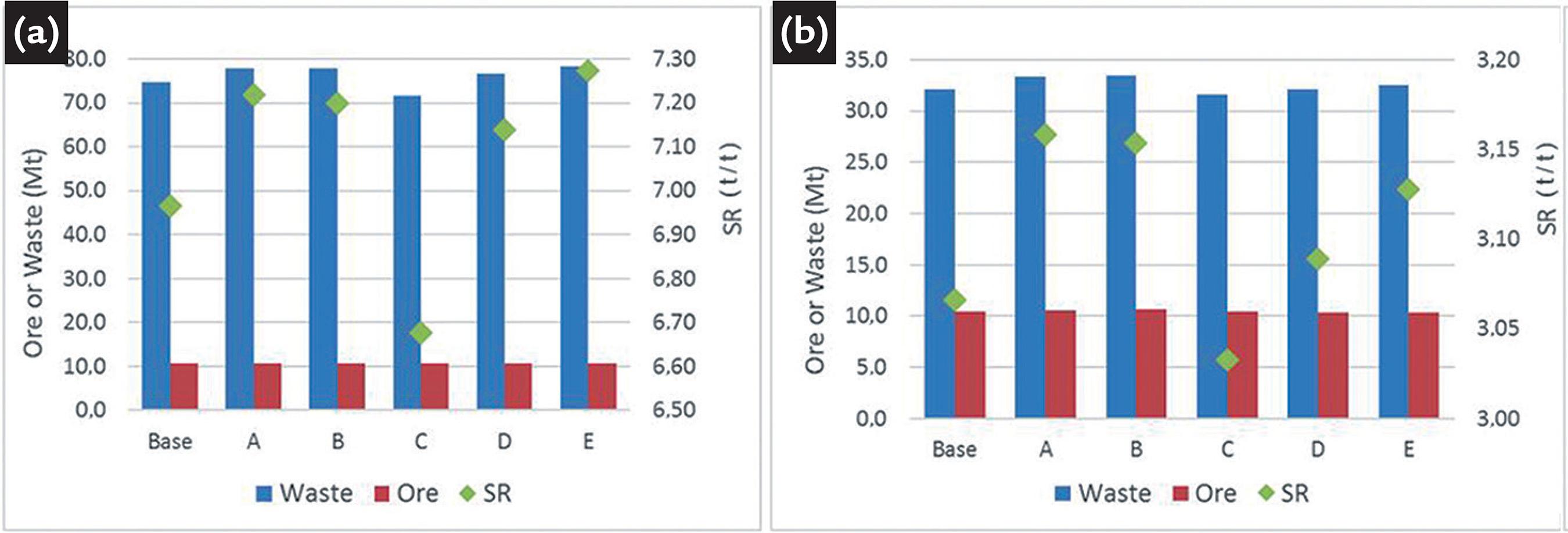

The results showed that in both types of deposits changes in the geometric parameters of the roads impacted on the masses of waste and ore in the final operational pit. Figure 7 shows the quantitative results obtained from the generation of the pits and inclusion of the different geometric road designs for deposits I and II.

Quantitative results of ore, waste, SR for each scenario of (a) deposit I and (b) deposit II.

The results also showed that the variations in the amount of waste and ore in the final operational pits presented similar trends in both deposits. Since the amount of ore remained practically steady, it can be stated that the SR is dictated by the amount of waste material.

While there were slight changes in ore masses, there was observed an increase in the waste mass in practically all cases when compared to the base case design, which consequently increased the SR values as well. Scenario C, which corresponds to a 2% increase in the longitudinal grade of the road, was the exception. In this scenario, there was a decrease in the waste mass incorporated into the final pit due to a lower average haulage distance. This geometrical design reduced the number of road passes in a certain highwall, with a consequent increase in the overall slope angle and reduction of SR, as can be seen in Figure 8, which shows the overall slope angle for the same section in the base pit design and in the alternative scenario C.

Overall slope angle for a same section in (a) base pit and (b) scenario C – vertical deposit.

In order to better understand the relationship between the SR and the overall slope angle when varying the haul road geometric design, linear regression curves were created using all scenarios. Figure 9 shows the behavior of SR as a function of the overall slope angle for each scenario in the deposits I and II.

The analysis of Figure 9 indicates that these variations in SR are directly associated with the overall slope angles resulting from the operational pits with an inversely proportional relationship between them, a behavior already observed in other similar studies (Oliveira, 2016OLIVEIRA, B. J. A. L. Avaliação geométrica do ângulo de talude na delineação da cava final - estudo de caso: Mina F4, Vale Fertilizantes. Centro Federal de Educação Tecnológica de Minas Gerais, 2016. (Trabalho de conclusão de curso).). In addition, the figure also shows that this relationship can be extended to similar deposits, allowing the possibility of creating average SR estimates for hypothetical final pit designs. In this analysis, the overall slope angle was obtained by varying geometric elements in a cross section of the pit using basic trigonometry, as shown in Figure 10.

The variations are better understood when calculating the percentage differences of waste, ore, SR and overall slope angle in relation to the base pits, as shown in Tables 4 and 5 for deposits I and II, respectively. The negative values stand for decrease, and positive values for increase.

It is observed that the variations of the SR were more accentuated for the vertical pit, which is explained by the more significant changes in the overall slope angles because of the deposit geometry and consequently the confinement and depth of the pit.

The increase of road width (scenario A) and the decrease of longitudinal grade by 2% (scenario B) contributed to a slight increase of ore in both cases. However, there is a higher increase in the waste mass, which negatively affected the SR. Hustrulid et al. (2013)HUSTRULID, W. A., KUCHTA, M., MARTIN, R. K. Open pit mine planning and design, two volume set & CD-ROM pack. CRC Press, 2013. stated that wider roads tend to decrease the overall slope angle, which was evident and quantified in the results of scenario A. In scenario B, the reduction of this angle can be explained by the increase in the number of road passes in a cross section, which increases the length of the haul roads to the same depth.

The addition of switchbacks with different radius of curvature (scenarios D and E) did not favor the reduction of SR. The vertical deposit had more expressive additions of waste to the final pit design, which can be explained by its greater depth and the need for a greater number of passes in the same section for the ramp to reach the surface topography. However, the scenario E - horizontalized deposit, seems to be a promising option, since it increased SR at a smaller rate than the other scenarios. In this case, a strategic allocation of switchbacks in an attempt to increase the recovery of ore blocks could prove to be effective. Nevertheless, a better analysis of the economic drawbacks is necessary, since switchbacks increase the haulage costs due to the additional number of curves with a resultant decrease in the speed of the trucks, penalizing the production and safety (Tannant and Regensburg, 2001TANNANT, D., REGENSBURG, B. Guidelines for mine haul road design. 2001.).

In both deposits, the increase of the longitudinal grade by 2% (scenario C) produced a negative impact on the masses of ore and waste. In this scenario, the increase in the overall slope angle was due to the decrease in the number of road passes in the same cross section of the pit. However, there were fewer blocks of waste added to the final pit, reducing the SR and providing a best-case scenario in the context of mine planning. It is still important to consider an economic analysis to better understand the consequences that this change can cause in the trucks' cycle times, which is already described in literature and in haul road guidelines for mining (Kaufman and Ault, 1997KAUFMAN, W. W., AULT, J. C. Design of surface mine haulage roads. 1977. (Manual).; Tannant and Regensburg, 2001TANNANT, D., REGENSBURG, B. Guidelines for mine haul road design. 2001.; Thompson, 2010THOMPSON, Roger. Mine haul road design and management best practices for safe and cost-efficient truck haulage. In: SOCIETY FOR MINING, METALLURGY AND EXPLORATION 2010 CONFERENCE PROCEEDINGS PRE-PRINT. Society for Mining, Metallurgy and Exploration, 2010. p. 1-10.; Visser, 2015VISSER, A. T. Haul roads can make money. Journal of the Southern African Institute of Mining and Metallurgy, v. 115, n. 11, p. 993-999, 2015.).

4. Conclusions

This study concluded that strategic changes in geometric parameters of the haul roads can affect the overall slope angle of the final pit and the mass of waste and ore - and consequently the SR. The results showed that a 2% increase in the longitudinal grade of the road contributed to a reduction in SR of 1.08% for a more horizontalized pit, and up to 4.15% in a deeper and more vertical one. However, the increase in road width, decrease in longitudinal grade and inclusion of switchbacks increased the SR for both deposits, which resulted from the decrease of the overall slope angle and consequent addition of waste blocks to the final pit.

These variations are important in the mining sector, which aims to generate profit through strategic mine planning. That is because the decrease in SR may have a positive impact on the annual cash flow of the project, possibly contributing to the maximization of NPV. Considering that many mining companies are constantly optimizing their mine plan, the study provides important insights to the industry in terms of financial assessment of mining projects. Further research is planned to continue with the investigation of scenarios, where it is possible to compare the financial gains resulting from the reduction of SR with possible increases in the cycle time of trucks and/or in operational costs.

The results can be extended to other deposits that have equivalent geometries through the regression curves obtained as a first approximation of the impact in SR for different alternatives of haul road design. However, it is considered that for a higher level of detail, similar studies must be carried out to determine the size of equipment in the early stages of design or in fleet replacement analysis. It is also recommended to carry out a more detailed study to evaluate an optimum scenario as a function of NPV.

Acknowledgments

The authors would like to thank the Brazilian National Council for Scientific and Technological Development (CNPq) for sponsoring this research through a master's degree scholarship. We are also grateful to our colleagues and professors from the Mineral Research and Mine Planning Laboratory (LPM - UFRGS) who provided insight and expertise that greatly assisted this work.

References

- FRITH, R., COLWELL, M. Introduction to ground mechanics. In: DARLING, P. (Ed.). SME mining engineering handbook, 2011. p. 463-470.

- HUSTRULID, W. A., KUCHTA, M., MARTIN, R. K. Open pit mine planning and design, two volume set & CD-ROM pack CRC Press, 2013.

- KAUFMAN, W. W., AULT, J. C. Design of surface mine haulage roads 1977. (Manual).

- LERCHS, H., GROSSMANN, I. F. Optimum design of open pit mines. CIM Bulletin p. 47-54, 1965.

- OLIVEIRA, B. J. A. L. Avaliação geométrica do ângulo de talude na delineação da cava final - estudo de caso: Mina F4, Vale Fertilizantes Centro Federal de Educação Tecnológica de Minas Gerais, 2016. (Trabalho de conclusão de curso).

- SULLIVAN, T. D. Pit slope design and risk- A view of the current state of the art. In: Proceeding of the Int. Symposium on Stability of Rock Slopes in Open Pit Mining and Civil Engineering Situations 2006.

- TANNANT, D., REGENSBURG, B. Guidelines for mine haul road design 2001.

- THOMPSON, R. J. Design, construction, and maintenance of haul roads. In: DARLING, P. (Ed.). SME mining engineering handbook, 2011. p. 957-975.

- THOMPSON, R. J., VISSER, A. T. An introduction to the integrated design of surface mine haul roads. International Journal of Surface Mining, Reclamation and Environment, v. 11, n. 3, p. 115-120, 1997.

- THOMPSON, Roger. Mine haul road design and management best practices for safe and cost-efficient truck haulage. In: SOCIETY FOR MINING, METALLURGY AND EXPLORATION 2010 CONFERENCE PROCEEDINGS PRE-PRINT. Society for Mining, Metallurgy and Exploration, 2010. p. 1-10.

- TOLWTNSKI, B., UNDERWOOD, R. A scheduling algorithm for open pit mines. IMA Journal of Management Mathematics, v. 7, n. 3, p. 247-270, 1996.

- VISSER, A. T. Haul roads can make money. Journal of the Southern African Institute of Mining and Metallurgy, v. 115, n. 11, p. 993-999, 2015.

- WYLLIE, D. C., MAH, C. Rock slope engineering CRC Press, 2014.

Publication Dates

-

Publication in this collection

Jan-Mar 2019

History

-

Received

30 Aug 2018 -

Accepted

6 Nov 2018