Abstract

One of the main purposes of the addition of fibers to the concrete is the control of the plastic shrinkage cracking in the fresh state and the increase of the post-crack resistance in the hardened state. The cementitious matrix is one of the factors that influences the performance of fiber reinforced concrete, interfering in the fluidity of the mixture and in the adhesion between fiber and matrix. In this context, the present paper evaluates the behavior of two concrete, one of conventional strength and another of high-strength, without fiber and with a content of 1%, by volume, of fiber, being used steel fiber and macro-polymeric fiber. For this, the mechanical properties of the concrete were evaluated in the hardened state by the tests of compressive strength, Barcelona, flexure of prisms and punching of plates. From the experimental results, statistically analyzed, there were significant changes in toughness and residual strength due to change in the cementitious matrix. Finally, an equivalence of performance between the fibers as to the toughness was observed, with the change of the cementitious matrix.

Keywords:

fiber reinforced concrete; cementitious matrix; steel fiber; macro-polimeric fiber; properties

Resumo

Uma das principais finalidades da adição de fibras ao concreto é o controle da fissuração por retração plástica no estado fresco, e o aumento da capacidade resistente pós-fissuração no estado endurecido. A matriz cimentícia é um dos fatores que influencia no desempenho do concreto reforçado com fibras, interferindo na fluidez da mistura e na aderência entre as fibras e a matriz. Neste contexto, o presente trabalho avalia o comportamento de dois concretos, um de resistência convencional e outro de alta resistência, sem fibras e com teor de 1%, em volume, de fibras, sendo utilizadas fibras de aço e macrofibras polimérica. Para isso, foram avaliadas as propriedades mecânicas dos concretos no estado endurecido, a partir dos ensaios de resistência à compressão, Barcelona, flexão em prismas e punção em placas. A partir dos resultados experimentais, analisados estatisticamente, verificou-se alterações significativas da tenacidade e da resistência residual com a mudança da matriz cimentícia. Por fim, observou-se uma equivalência de desempenho entre as fibras quanto à tenacidade, com a alteração da matriz cimentícia.

Palavras-chave:

concreto reforçado com fibras; matriz cimentícia; fibras de aço; macrofibras polimérica; propriedades

1. Introduction

Fiber reinforced concrete is a composite material that has been used for several applications, such as tunnel lining, radier, industrial floors, precast elements, among others. The fibers improve the crack distribution and limit the crack openings in the Service Limit State, reducing the concrete exposure to the environment. Fiber reinforcement is suitable for structures with high stress distribution capacity. In the case of structures with localized stresses and dispersed stresses, local reinforcements with steel bars and fibers randomly arranged on concrete can be used simultaneously [1[1] DI PRISCO, M.; PLIZZARI, G.; VANDEWALLE, L. Fibre reincorced concrete: new desing perspectives. Materials and Structures, v.42, n.9, 2009, p.1261-1281.].

The addition of fibers to the concrete causes changes in the properties of the material, both in fresh and hardened states. In the fresh state, to improve the workability of the mixture, which is affected by the incorporation of fibers, superplasticizer admixture is generally used. However, in the case of concrete with higher fibers content, the addition of superplasticizer admixture may be impracticable, being necessary to change the cementitious matrix to improve the flowability of the concrete.

The main contribution of the fibers occurs in the hardened state of the concrete after the cement matrix failure, providing residual strength to the composite. The fibers act as a stress transfer bridge, reducing the stress concentration at the crack tip. Thus, the concrete becomes a pseudo-ductile material, presenting some ductility [2[2] FIGUEIREDO, A. D. Concreto reforçado com fibras, São Paulo, 2011, Tese (Livre-Docência) - Escola Politécnica, Universidade de São Paulo, 248 p.].

The cementitious matrix is one of the factors that interfere with the behavior of fiber reinforced concrete in the hardened state. The properties of the matrix affect the adherence between fibers and matrix, reflecting on the post-cracking performance of the concrete [2[2] FIGUEIREDO, A. D. Concreto reforçado com fibras, São Paulo, 2011, Tese (Livre-Docência) - Escola Politécnica, Universidade de São Paulo, 248 p.]. Thus, depending on the type and content of fibers added, and the properties of the cementitious matrix, fiber reinforced concrete may exhibit softening or hardening behavior after cracking. The softening behavior is characterized by deformations located in a single crack and by a reduction of the post-cracking resistant strength, while in the hardening behavior occurs the formation of multiple cracks and increased resistant capacity after concrete failure [3[3] INTERNATIONAL FEDERATION FOR STRUCTURAL CONCRETE - FIB. Model Code 2010: First complete draft - Bulletin 55. Germany: Document Competence Center Siegmar Kästl e.K., 2010, 292 p.].

Nowadays there are fibers of different materials available in the construction market: steel, polymer, glass etc. The properties of the fibers material, such as modulus of elasticity and tensile strength, will define their function in concrete. Fibers with high modulus of elasticity and higher tensile strength than the matrix should act as primary reinforcement of the concrete, providing resistant capacity after matrix cracking. On the other hand, fibers that have low modulus of elasticity and tensile strength are more used in the control of cracking by plastic shrinkage of the concrete.

1.1 Justification and objective

The two main types of fibers used as primary reinforcement of the concrete are steel fibers and polymeric macrofibers. While the former is historically more used for this purpose, since it began to be marketed in the 1970s, and has more advantageous properties (higher modulus of elasticity modulus and higher tensile strength), the latter has a more recent commercialization and application, started in the 2000s [4[4] THE CONCRETE SOCIETY. Guidance on the use of Macro-synthetic-fibre-reinforced Concrete. Trowbridge: Cromwell Press, 2007. 76 p.], being object of several studies that seek to better understand its performance in concrete, especially in high strength concrete.

In addition, studies involving the influence of cementitious matrix on fiber reinforced concrete performance are still limited. It is known that a more resistant matrix has greater adherence to the fibers [2[2] FIGUEIREDO, A. D. Concreto reforçado com fibras, São Paulo, 2011, Tese (Livre-Docência) - Escola Politécnica, Universidade de São Paulo, 248 p.]. However, little is known about the impact of this greater adherence on the mechanical properties of fiber reinforced concrete. Thus, the present study aims to evaluate the influence of cementitious matrix on the behavior of fiber reinforced concrete, considering the use of steel fibers and polymeric macrofibers as reinforcement for ordinary and high strength concrete.

2. Materials and experimental program

2.1 Materials

For the production of the concrete, a pozzolan-modified Portland cement, with compressive strength class of 32 MPa (CPII Z 32) was used. In the high strength concrete it was also used silica fume derived from the production process of metallic silicon or iron-silicon alloys.

As fine aggregate two natural sands of quartzous origin, classified as fine sand and medium sand, were used. The coarse aggregate used was a crushed stone of basaltic origin, with a maximum characteristic particle size of 19 mm.

In all mixtures, water from the local water supply was used. To achieve the desired consistency, a polycarboxylate-based superplasticizer admixture was employed.

For the mixtures with fibers, two types of fibers were used as reinforcement for the concrete: steel fibers and polymeric macrofibers. The steel fibers had circular cross-section and anchor at the ends; the polymeric macrofibers were made of polypropylene, had a rectangular cross-section, straight shape, and grooved surface, so that the anchorage occurred along their length. Table 1 shows the main properties of the fibers used, according to the data provided by the manufacturers.

2.2 Mix design and production of the concrete

In the present study two concrete mixes design were produced: one mix design for an ordinary concrete, with mean compressive strength at 28 days of age (fcm,28) of 40 MPa; and another for a high strength concrete with fcm,28 of 70 MPa. As the water/cement ratio was kept constant, the desired consistency for all mixtures was achieved by adjusting the superplasticizer admixture. The slump value was set at (120 ± 20) mm for both concrete.

The mix design, by mass, for the reference ordinary concrete (without fibers) was 1: 2.30: 2.70: 0.47. In the reference high strength concrete (without fibers),it was used the mix design, by mass, 1: 1.70: 1.80: 0.35, with silica fume incorporated in the content of 10% in substitution to cement (by volume). The materials consumption for the reference concrete mixes design is presented in Table 2. In both mixes design, fine aggregate was composed of 40% of fine sand and 60% of medium sand.

Consumption of materials (in kg/m³ of concrete) for the reference concrete (without fibers) used in the study

For the production of ordinary and high strength fiber reinforced concrete mixtures, both steel fibers and polymeric macrofibers were added at the content of 1.0% by volume, which corresponds to the consumptions of 78.5 kg/m³ for steel fibers and 9.5 kg/m³ for polymeric macrofibers. Thus, in total six concrete mixtures were produced, varying the cementitious matrix and the type of fiber.

For the production of concrete, the same mixing procedure was considered for all concrete. At the end of the mixing, the concrete consistency was verified by the slump test, prescribed by NBR NM 67:1998 [5[5] ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS - ABNT. Concreto - Determinação da consistência pelo abatimento do tronco de cone. - NBR NM 67, Rio de Janeiro, 1998.]. If the slump value was within the established range, the specimens were molded. Otherwise, the slump was adjusted by the superplasticizer. After 24 hours of molding, the specimens were demolded, transferred to a humid chamber and subjected to continuous cure until 28 days of age, when the mechanical tests were performed.

2.3 Test methods

The compressive strength was determined according to the specifications of NBR 5739:2007 [6[6] ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS - ABNT. Concreto - Ensaios de compressão de corpos-de-prova cilíndricos. - NBR 5739, Rio de Janeiro, 2007.] using a hydraulic testing machine. To analyze the toughness of the concrete it was performed the flexural test in prisms and the punching test in plates, besides the Barcelona test.

The Barcelona test, also known as double punching test, was performed according to the recommendations of the Spanish standard UNE 83515:2010 [7[7] ASOCIACIÓN ESPAÑOLA DE NORMALIZACIÓN Y CERTIFICACIÓN - AENOR. Hormigones con fibras - Determinación de la resistencia a fisuración, tenacidad y resistencia residual a tracción - Método Barcelona. - UNE 83515, Barcelona, 2010.], considering a machine piston displacement speed of 0.5 mm/min. For the flexural test in prisms, the procedure prescribed by the Japanese standard JSCE-SF4 [8[8] THE JAPAN SOCIETY OF CIVIL ENGINEERS - JSCE. Method of tests for flexural strength and flexural toughness of steel fiber reinforced concrete. - JSCE-SF4, Tokyo, 1984.] was employed, with machine piston displacement speed equal to 0.15 mm/min. For the punching test in plates, the European recommendation EFNARC [9[9] EUROPEAN FEDERATION OF PRODUCERS AND APPLICATORS OF SPECIALIST PRODUCTS FOR STRUCTURES - EFNARC. European Specification for Sprayed Concrete. Farnham, 1996.] was used, with machine piston displacement speed equal to 1.5 mm/min.

For the result of each test, the average corresponding to the individual results obtained in the specimens was considered, as well as the standard deviation and the coefficient of variation.

To verify the influence of the factors that affect the various properties of the concrete, analysis of variance (ANOVA) and Student’s t-tests were performed. All statistical tests were performed considering a 95% confidence level, being ANOVA used to evaluate the relevance of adding different fiber types and contents to the concrete properties and the Student’s t-test performed to investigate which factors were responsible for changes in such properties. Details of the statistical analysis performed can be found in Leite [10[10] LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.].

3. Results and discussions

3.1 Compressive strength

The value of the mean compressive strength at 28 days of age (fcm,28), for each concrete mixture produced, is presented in Table 3. The values correspond to the average of five individual results obtained in cylindrical specimens, with 100 mm in diameter and 200 mm in height.

Both ordinary and high strength concrete increased the compressive strength with the addition of fibers. Although some studies are contradictory regarding the effect of fiber addition on the compressive strength of the concrete, some researchers state that high strength fiber reinforced concrete generally has higher compressive strength than fiber-free concrete [11[11] MENDOZA, C. J.; AIRE, C.; DAVILA, P. Influencia de las fibras de polipropileno en las propriedades del concreto en estados plástico y endurecido. Concreto y cemento. Investigación y desarrollo, v.2, n.2, 2011, p.5-47.; 12[12] AFROUGHSABET, V.; BIOLZI, L.; OZBAKKALOGLU, T. High-performance fiber-reinforced concrete: a review. Journal of Materials Science, v. 51, n. 14, 2016, p. 6517-6551.]. According to the fib Model Code 2010 [3[3] INTERNATIONAL FEDERATION FOR STRUCTURAL CONCRETE - FIB. Model Code 2010: First complete draft - Bulletin 55. Germany: Document Competence Center Siegmar Kästl e.K., 2010, 292 p.], the elastic properties and compressive strength of the concrete do not change significantly with the addition of fibers, since low fiber contents are used. Song and Hawang [13[13] SONG, P.S; HAWANG, S. Mechanical properties of high-strength steel fibre-reinforced concrete. Construction and Building Materials, v.18, n.9, 2004, p. 669-673.] found an increasing compressive strength for a high strength concrete by adding steel fibers to the content of 1.5% by volume. For higher fibers contents, the value of compressive strength began to decrease.

In ordinary concrete, the mixture with polymeric macrofibers presented the highest compressive strength, while in the high strength concrete the mixture with steel fiber showed the highest value of such strength. This situation is different from that observed by Monte [14[14] MONTE, R. Caracterização e controle do comportamento mecânico do concreto reforçado com fibras para tubos. São Paulo, Tese (Doutorado em Ciências) - Escola Politécnica, Universidade de São Paulo, 159 p.], whose ordinary concrete with polymeric macrofibers presented a significantly lower compressive strength value than the mixture with steel fibers.

According to the statistical analysis [10[10] LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.], there was a significant variation of the compressive strength with the addition of fibers only in the high strength concrete, which may be due to the greater adherence between fibers and matrix in this type of concrete. Furthermore, it was found that the addition of steel fibers was the factor responsible for the significant variation of compressive strength in these concrete. According to Mehta and Monteiro [15[15] MEHTA, K.; MONTEIRO P. J. M. Concreto. Microestrutura, Propriedades e Materiais, São Paulo: Ibracon, 4ed, 2014. 751 p.], the use of low and moderate fibers contents should have little influence on the value of compressive strength of the concrete, with its main contribution occurring in the toughness of the composite.

The mixtures with fibers and with higher compressive strength values than those of reference concrete may have exhibited hardening behavior after the matrix failure, with increased resistant capacity of the composite. To confirm this hypothesis, the load versus displacement curve of the concrete under compression would be necessary; however, the test machine used did not provide such data for analysis.

3.2 Barcelona test

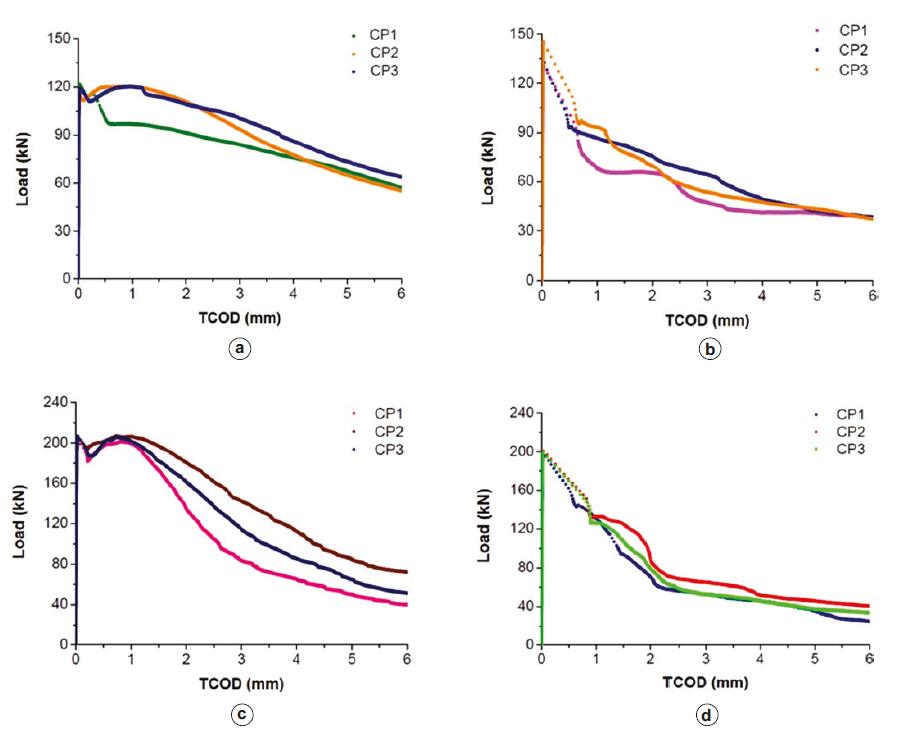

The Barcelona test was performed considering three cylindrical specimens (150 mm in diameter and 150 mm in height) for each concrete mixture produced. The curves of load versus total circumferential opening displacement (TCOD) obtained by testing the ordinary and high strength concrete, with steel fibers and polymeric macrofibers, are shown in Figure 1.

Barcelona test − load versus TCOD curves for samples of ordinary concrete with (a) steel fibers and (b) polymeric macrofibers, and high strength concrete with (c) steel fibers and (d) polymeric macrofibers, with a fiber content of 1% by volume

In the mixtures of concrete with steel fibers, both ordinary (Figure 1a) and high strength (Figure 1c), the resistant load remained constant until certain TCOD, from which they began to reduce this load, characterizing softening behavior. Polymeric macrofibers reinforced concrete showed softening behavior immediately after the matrix failure (Figures 1b and 1d). The post-peak instability phenomenon was practically nonexistent in mixtures with steel fibers; in concrete with polymeric macrofibers, such instability was observed up to TCOD values between 0.5 mm and 1.0 mm.

The Barcelona test results for all concrete mixtures are shown in Table 4. In addition to tensile strength (f ct ) and toughness up to a TCOD of 6 mm, it is presented the residual strength for the TCOD of 1.5 mm (f ct,TCOD = 1.5 ) and 6 mm (f ct,TCOD = 6 ), corresponding to the Service Limit State (SLS) and the Ultimate Limit State (ULS), respectively, as observed by Monte, Toaldo and Figueiredo [16[16] MONTE, R.; TOALDO, G. S.; FIGUEIREDO, A. D. Avaliação da tenacidade de concretos reforçados com fibras através de ensaios com sistema aberto. Revista Matéria, v.19, n.2, 2014, p. 132-149.].

Concrete mixtures with fibers had higher tensile strength values than the fiber-free concrete (reference). Such variation occurred due to the performance of the cementitious matrix, having little influence of the fibers in this aspect, since no mixture showed hardening behavior. However, from the statistical analysis [10[10] LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.], it was found that the addition of fibers significantly modified the tensile strength of ordinary and high strength concrete. In addition, the fiber type and the addition of polymeric macrofibers had a significant influence on the tensile strength of both ordinary and high strength concrete. On the other hand, in ordinary concrete the addition of steel fibers did not cause a significant change in such strength.

Regarding the toughness and the residual strength in the SLS and ULS, it was found that both ordinary and high strength steel fibers reinforced concrete showed higher values of these properties than those reinforced with polymeric macrofibers (Table 4). According to the statistical analysis [10[10] LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.], there was a significant variation of these properties with the fiber type in ordinary concrete, while in the high strength concrete there was a significant difference only in toughness and residual strength in the SLS.

Both steel fibers and polymeric macrofibers reinforced concrete showed an increase in the value of toughness and residual strength in the SLS with the change of the cementitious matrix. This increase was due to the better adherence between fibers and cementitious matrix that occurs in concrete with higher strength values, as highlighted by Figueiredo [2[2] FIGUEIREDO, A. D. Concreto reforçado com fibras, São Paulo, 2011, Tese (Livre-Docência) - Escola Politécnica, Universidade de São Paulo, 248 p.]. Due to the lower porosity, the contact area between the fibers and the matrix in the high strength concrete is larger, contributing to the formation of a stronger bond, which reflects in the mechanical behavior of the material [17[17] BUTTIGNOL, T. E. T; SOUSA, J. L. A. O.; BITTENCOURT, T. N. Ultra High-Performance Fiber-Reinforced Concrete (UHPFRC): a review of material properties and design procedures. Ibracon Structures and Materials Journal, v. 10, n. 4, 2017, p. 957-971.].

According to the statistical analysis [10[10] LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.], the cementitious matrix had a significant contribution to the toughness of both steel fibers and polymeric macrofibers reinforced concrete. Further increase in the strength of concrete by using an ultra-high strength concrete, Abu-Lebdeh et al. [18[18] ABU-LEBDEH, T.; HAMOUSH, S.; HEARD, W.; ZORNIG, B. Effect of matrix strength on pullout behavior of steel fiber reinforced very-high strength concrete composites. Construction and Building Materials, v.25, n.1, 2011, p. 39-46.] verified an increase of energy absorption in pullout tests, indicating an even better adherence between fibers and matrix.

It is interesting to highlight that the ordinary steel fiber reinforced concrete had a higher toughness and a residual strength in the SLS equal to the high strength concrete with polymeric macrofibers, which indicates the lower efficiency of these fibers compared to steel fibers even improving the characteristics of the cementitious matrix and, consequently, the fiber-matrix interaction. According to Student’s t-test (Table 5), the difference between the toughness values is not significant, suggesting a possible performance equivalence between the fibers by changing the cementitious matrix in which they are immersed.

Student's t-test to verify performance equivalence between fibers considering different cementitious matrices

With the change from ordinary concrete to high strength concrete, a reduction in the residual strength in the ULS was observed for both steel fibers and polymeric macrofibers reinforced mixtures. As there is a greater adherence between fibers and cementitious matrix in the high strength concrete, the fibers may have failure. Statistical analysis indicates that the change of the cementitious matrix is not significant for this parameter.

3.3 Flexural test in prisms

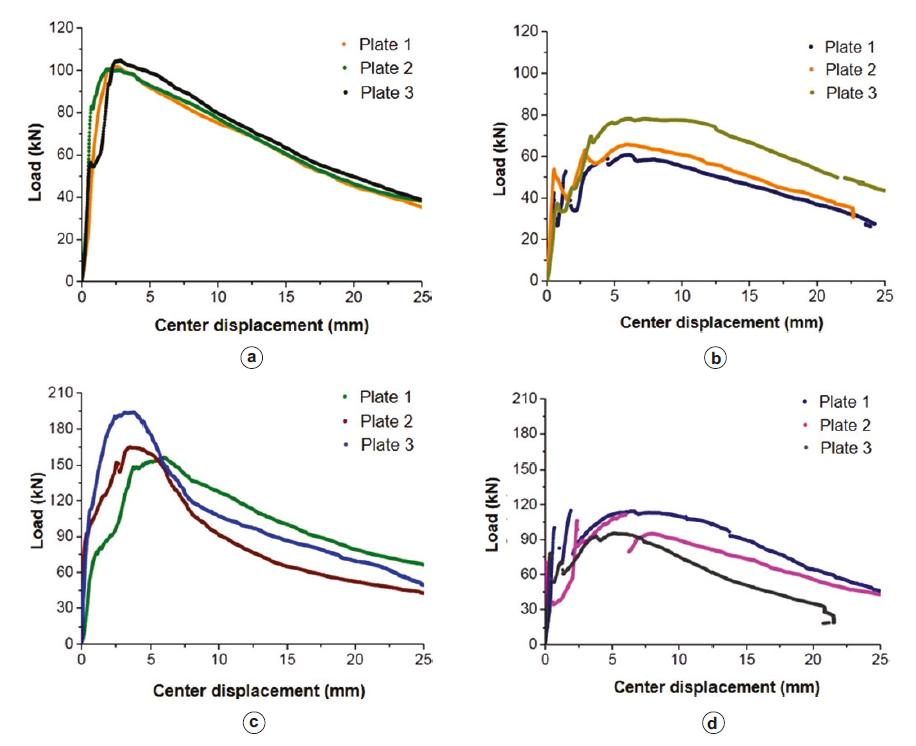

The flexural test in prisms was performed considering three prismatic specimens, with dimensions of 150 mm x 150 mm x 500 mm, for each concrete mixture produced. Figure 2 shows the load versus vertical displacement curves resulting from the flexural test on ordinary and high strength concrete prisms with steel fibers and polymeric macrofibers.

Flexural test in prisms − load versus vertical displacement curves for samples of ordinary concrete with (a) steel fibers and (b) polymeric macrofibers, and high strength concrete with (c) steel fibers and (d) polymeric macrofibers, with a fiber content of 1% by volume

For ordinary concrete, in the CC10FA (Figure 2a) the hardening behavior predominated up to the vertical displacement of 0.25 mm, when it began to show resistant load drop. In the CC10PP (Figure 2b), an initial softening behavior was verified and, after the reduction of the resistant capacity due to the matrix failure, such concrete began to show a gain on the resistant capacity with increasing displacement (slip-hardening behavior). This result was also obtained in ordinary concrete (with compressive strength below 50 MPa) evaluated by Monte, Toaldo and Figueiredo [16[16] MONTE, R.; TOALDO, G. S.; FIGUEIREDO, A. D. Avaliação da tenacidade de concretos reforçados com fibras através de ensaios com sistema aberto. Revista Matéria, v.19, n.2, 2014, p. 132-149.] and Salvador and Figueiredo [19[19] SALVADOR, R. P.; FIGUEIREDO, A. D. Análise comparativa de comportamento mecânico de concreto reforçado com macrofibra polimérica e com fibras de aço. Revista Matéria, v.18, n.2, 2013, p. 1273-1285.], who attributed this behavior to fibers defibrillation. Analyzing the ordinary concrete, only the sample with polymeric macrofibers presented post-peak instability.

For the high strength concrete, the CAR10FA curves (Figure 2c) showed a small instability after the matrix failure. In this case, the post-cracking resistant load was approximately constant and equal to the matrix load failure up to the vertical displacement of 0.75 mm. For higher displacement values, the resistant load was reduced, indicating a softening behavior. CAR10PP samples (Figure 2d) showed the highest post-peak instability, which extended to a vertical displacement of 1.0 mm in one of the prisms. It is interesting to highlight that, after the end of the instability, there was an increase of the resistant load with the increase of the displacement (slip-hardening behavior) in the mixture containing polymeric macrofibers.

The results of the flexural test in prisms for each concrete mixture are shown in Table 6. These results include flexural tensile strength (f ct,f ), toughness factor , and residual strength in the displacements of 0.75 mm and 3.00 mm .

In most concrete, an increase in flexural tensile strength was observed with the addition of fibers. However, only the CC10FA mixture showed a hardening behavior, with increased resistant capacity after matrix failure. According to the statistical analysis [10[10] LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.], the addition of fibers caused significant changes in the tensile strength of both ordinary and high strength concrete. Furthermore, it was found that both type and presence of fibers had a significant influence on the value of such strength. The CC10FA concrete, which showed hardening behavior, had a flexural tensile strength value 35.9% higher than the reference concrete (CCR). This was due to the fact of having used a volume of fibers greater than the critical volume.

High strength steel fibers reinforced concrete had a flexural tensile strength value 22.8% higher than high strength concrete without fibers (CARR). End-anchored steel fibers have a more relevant contribution to flexural tensile strength compared to other types of fibers, as the use of mineral additions promotes greater adherence between matrix and steel fibers, reflecting the increased of such strength. The addition of synthetic fibers has a greater effect on the energy absorption and cracking control than on the maximum concrete load bearing [12[12] AFROUGHSABET, V.; BIOLZI, L.; OZBAKKALOGLU, T. High-performance fiber-reinforced concrete: a review. Journal of Materials Science, v. 51, n. 14, 2016, p. 6517-6551.].

Regarding the toughness factor and the residual strength in the SLS and ULS, it was found that in both ordinary and high strength concrete, the mixtures with steel fibers presented values of these properties superior to the mixtures with polymeric macrofibers. The statistical analysis of the results [10[10] LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.] confirmed the significant influence of the fiber type on the toughness factor and on the residual strength in the SLS of ordinary and high strength concrete, while the change in the residual strength in the ULS was considered non-significant.

By changing the cementitious matrix from ordinary to high strength concrete, the values of toughness and residual strength (SLS and ULS) had higher percentage increases in the concrete with polymeric macrofibers than in the concrete with steel fibers. According to the statistical analysis [10[10] LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.], the variation in the values of such properties due to the change of the cementitious matrix is considered significant for both steel fibers and polymeric macrofibers reinforced concrete. The increased strength of the matrix-fibers bond causes considerable changes in the flexural tensile strength and absorbed energy of fiberreinforced concrete [20[20] GRAY, R. J.; Johnston, C. D. The influence of fibre-matrix interfacial bond strength on the mechanical properties of steel fibre reinforced mortars. The International Journal of Cement Composites and Lightweight Concrete, v.9, n.1, 1987, p. 43-55.; 21[21] ABBAS, Y. M.; KHAN, M. I. Fiber-Matrix Interactions in Fiber-Reinforced Concrete: A Review. Arabian Journal for Science and Engineering, v.41, n.4, p. 1183-1198.].

The values of toughness factor and residual strength in the SLS of ordinary steel fiber reinforced concrete were higher than those of high strength polymeric macrofibersreinforced concrete. Student’s t-test (Table 5) indicates that the toughness factor results are statistically equivalent, while the difference between the results of residual strengthin the ULS is considered significant.

3.4 Punching test in plates

The punching test in plates was performed considering three plates, with plant dimensions of 600 mm x 600 mm and 100 mm in thickness, for each mixture produced. Figure 3 shows the load versus center displacement curves obtained in the test of ordinary and high strength concreteplates reinforced with steel fibers and with polymeric macrofibers.

Punching test in plates − load versus center displacement curves for samples of ordinary concrete with (a) steel fibers and (b) polymeric macrofibers, and high strength concrete with (c) steel fibers and (d) polymeric macrofibers, with a fiber content of 1% by volume

In ordinary steel fibers reinforced concrete (Figure 3a) an increase in the resistant capacity (hardening behavior) was observed after the matrix failure. The increase of the resistant load was observed up to the center displacement of 2.5 mm, from which the load reduction was observed. The instability phenomenon was barely noticeable in this concrete. In ordinarypolymeric macrofibers reinforced concrete (Figure 3b) the predominant behavior was slip-hardening, being possible to verify successive losses and increments of the resistant capacity up to the center displacement of 7.5 mm, from which the load reduction began. Only one sample of the CC10PP concrete (Figure 3b) showed post-peak instability.

For the high strength concrete, for the steel fibers reinforced mixture (Figure 3c), the hardening behavior was verified, with increasing of the resistant load up to the center displacement of approximately 5 mm. After reaching the maximum load, the resistant capacity was reduced until the final displacement. Post-peak instability was nonexistent in this concrete. The high strength polymeric macrofibers reinforced concrete (Figure 3d) presented oscillations in the value of the resistant load after the cementitious matrix failure, being predominant the slip-hardening behavior. Figueiredo [2[2] FIGUEIREDO, A. D. Concreto reforçado com fibras, São Paulo, 2011, Tese (Livre-Docência) - Escola Politécnica, Universidade de São Paulo, 248 p.] attributes these oscillations to the formation of multiple cracks that occur in small displacements, and whose amount stabilizes at a given time. In this concrete, the maximum load was reached with a center displacement of approximately 7.5 mm and there was the occurrence of post-peak instability.

Regarding the maximum load values, the results obtained in the punching test in plates are presented in Table 7. It is verified that the addition of fibers caused an increase in the maximum load value of the concrete, with predominance of hardening and slip-hardening behavior. According to the statistical analysis [10[10] LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.], the addition of fibers caused significant changes in the maximum load value of ordinary and high strength concrete. The samples with steel fibers and polymeric macrofibers showed hardening and slip-hardening behavior, respectively, which contributed to present a higher maximum load than the reference concrete (CCR and CARR). In addition, the variation of the maximum load of concrete with the addition of steel fibers is considered significant for both ordinary and high strength concrete. The addition of polymeric macrofibers had a significant influence on the maximum load only of the high strength concrete.

The steel fibers reinforced concrete presented a higher maximum load than the polymeric macrofibers reinforced concrete in both cementitious matrices analyzed. Statistical analysis of the data indicates a significant influence of fiber type on the concrete maximum load value [10[10] LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.].

Regarding the toughness, as well as the maximum load, the values of this property obtained in the mixture with steel fibers were higher than those of the mixture with polymeric macrofibers in both ordinary and high strength concrete (Table 7). However, according to statistical analysis [10[10] LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.], there was a significant difference between the performance of the two fibers only in the ordinary concrete.

The percentage increase in toughness due to the change of the cementitious matrix was more relevant for steel fibers reinforced concrete than for polymeric macrofibers reinforced concrete. According to the statistical analysis [10[10] LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.], the change of the cementitious matrix had a significant influence on the toughness value only for steel fibers reinforced concrete.

Due to the hardening effect, both the maximum load and toughness of the ordinary steel fibers reinforced concrete were close to the values of these properties obtained in the high strength polymeric macrofibers reinforced concrete. Student’s t-test (Table 5) confirms that these results are statistically equivalent, suggesting a performance equivalence between the fibers with the change of the cementitious matrix.

4. Conclusions

This paper evaluated the influence of cementitious matrix on the mechanical properties of concrete reinforced with different types of fibers. Thus, mixtures of ordinary and high strength concrete, without fibers and containing steel fibers or polymeric macrofibers, were analyzed.

The desired workability was not achieved in most ordinary fiber reinforced concrete mixtures, even with the increase in superplasticizer admixture content. By changing the cementitious matrix to a high strength concrete with a higher mortar content in the mixture, it was possible to achieve the required consistency, indicating that in some cases it is necessary to modify the cementitious matrix, and not just add superplasticizer to improve the workability of the mixture.

As for compressive strength, only the high strength concrete showed significant variation of this mechanical property with the addition of fibers, and the addition of steel fibers was the factor responsible for such variation. In high strength concrete there is a greater adherence between fibers and matrix, which may have caused this result.

In both Barcelona test and punching test in plates, there was no change in the behavior pattern of the mixtures with the change of the cementitious matrix. Only in the flexural test in prisms,the steel fiber reinforced concrete no longer exhibits hardening behavior, presenting a softening behavior with the change of the cementitious matrix. In addition, the mixtures showed different behaviors according to the test performed. While in the Barcelona test the predominant behavior was softening, in the toughness tests (flexural in prisms and punching in plates) the hardening and slip-hardening behaviors predominated.

Tensile strength and maximum load values showed significant variations with the addition of fibers, even in the case of mixtures that showed softening behavior. This may have been caused by the loss in homogeneity due to the addition of fibers.

The toughness in both Barcelona test and flexural test in prisms had a significant change with the change of the cementitious matrix of fiber reinforced concrete. In the punching test in plates, only the mixture with steel fibers showed a significant increase in toughness when using a high strength concrete.

Residual strength in the SLS of the Barcelona test and flexural test in prisms showed significant influence of the cementitious matrix. Regarding the residual strength in the ULS, only in the flexural test it was verified a significant variation of this property, indicating that the change of the cementitious matrix in the fiber reinforced concrete may not be effective in increasing the residual strength in larger displacements depending on the test performed.

It is important to highlight that statistically equivalent toughness values were obtained for ordinary steel fibersreinforced concrete and high strength polymeric macrofibers reinforced concrete. These results suggest a performance equivalence between the fibers, and indicate a lower efficiency of the polymeric macrofibers compared to steel fibers in this respect.

5. Acknowledgements

The authors thank the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) for funding the research scholarship, and the companies Votorantim Cimentos, Grace Construction Products, Tecnosil and Belgo Bekaert Arames for donating the materials used in the study.

6. References

-

[1]DI PRISCO, M.; PLIZZARI, G.; VANDEWALLE, L. Fibre reincorced concrete: new desing perspectives. Materials and Structures, v.42, n.9, 2009, p.1261-1281.

-

[2]FIGUEIREDO, A. D. Concreto reforçado com fibras, São Paulo, 2011, Tese (Livre-Docência) - Escola Politécnica, Universidade de São Paulo, 248 p.

-

[3]INTERNATIONAL FEDERATION FOR STRUCTURAL CONCRETE - FIB. Model Code 2010: First complete draft - Bulletin 55. Germany: Document Competence Center Siegmar Kästl e.K., 2010, 292 p.

-

[4]THE CONCRETE SOCIETY. Guidance on the use of Macro-synthetic-fibre-reinforced Concrete. Trowbridge: Cromwell Press, 2007. 76 p.

-

[5]ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS - ABNT. Concreto - Determinação da consistência pelo abatimento do tronco de cone. - NBR NM 67, Rio de Janeiro, 1998.

-

[6]ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS - ABNT. Concreto - Ensaios de compressão de corpos-de-prova cilíndricos. - NBR 5739, Rio de Janeiro, 2007.

-

[7]ASOCIACIÓN ESPAÑOLA DE NORMALIZACIÓN Y CERTIFICACIÓN - AENOR. Hormigones con fibras - Determinación de la resistencia a fisuración, tenacidad y resistencia residual a tracción - Método Barcelona. - UNE 83515, Barcelona, 2010.

-

[8]THE JAPAN SOCIETY OF CIVIL ENGINEERS - JSCE. Method of tests for flexural strength and flexural toughness of steel fiber reinforced concrete. - JSCE-SF4, Tokyo, 1984.

-

[9]EUROPEAN FEDERATION OF PRODUCERS AND APPLICATORS OF SPECIALIST PRODUCTS FOR STRUCTURES - EFNARC. European Specification for Sprayed Concrete. Farnham, 1996.

-

[10]LEITE, A. M. Avaliação do uso da macrofibra polimérica na composição de concreto para fins estruturais. São Carlos, Dissertação (Mestrado em Engenharia de Estruturas) - Escola de Engenharia de São Carlos, Universidade de São Paulo, 257 p.

-

[11]MENDOZA, C. J.; AIRE, C.; DAVILA, P. Influencia de las fibras de polipropileno en las propriedades del concreto en estados plástico y endurecido. Concreto y cemento. Investigación y desarrollo, v.2, n.2, 2011, p.5-47.

-

[12]AFROUGHSABET, V.; BIOLZI, L.; OZBAKKALOGLU, T. High-performance fiber-reinforced concrete: a review. Journal of Materials Science, v. 51, n. 14, 2016, p. 6517-6551.

-

[13]SONG, P.S; HAWANG, S. Mechanical properties of high-strength steel fibre-reinforced concrete. Construction and Building Materials, v.18, n.9, 2004, p. 669-673.

-

[14]MONTE, R. Caracterização e controle do comportamento mecânico do concreto reforçado com fibras para tubos. São Paulo, Tese (Doutorado em Ciências) - Escola Politécnica, Universidade de São Paulo, 159 p.

-

[15]MEHTA, K.; MONTEIRO P. J. M. Concreto. Microestrutura, Propriedades e Materiais, São Paulo: Ibracon, 4ed, 2014. 751 p.

-

[16]MONTE, R.; TOALDO, G. S.; FIGUEIREDO, A. D. Avaliação da tenacidade de concretos reforçados com fibras através de ensaios com sistema aberto. Revista Matéria, v.19, n.2, 2014, p. 132-149.

-

[17]BUTTIGNOL, T. E. T; SOUSA, J. L. A. O.; BITTENCOURT, T. N. Ultra High-Performance Fiber-Reinforced Concrete (UHPFRC): a review of material properties and design procedures. Ibracon Structures and Materials Journal, v. 10, n. 4, 2017, p. 957-971.

-

[18]ABU-LEBDEH, T.; HAMOUSH, S.; HEARD, W.; ZORNIG, B. Effect of matrix strength on pullout behavior of steel fiber reinforced very-high strength concrete composites. Construction and Building Materials, v.25, n.1, 2011, p. 39-46.

-

[19]SALVADOR, R. P.; FIGUEIREDO, A. D. Análise comparativa de comportamento mecânico de concreto reforçado com macrofibra polimérica e com fibras de aço. Revista Matéria, v.18, n.2, 2013, p. 1273-1285.

-

[20]GRAY, R. J.; Johnston, C. D. The influence of fibre-matrix interfacial bond strength on the mechanical properties of steel fibre reinforced mortars. The International Journal of Cement Composites and Lightweight Concrete, v.9, n.1, 1987, p. 43-55.

-

[21]ABBAS, Y. M.; KHAN, M. I. Fiber-Matrix Interactions in Fiber-Reinforced Concrete: A Review. Arabian Journal for Science and Engineering, v.41, n.4, p. 1183-1198.

Publication Dates

-

Publication in this collection

13 July 2020 -

Date of issue

May-Jun 2020

History

-

Received

15 Oct 2018 -

Accepted

07 Apr 2019 -

Published

26 May 2020